Page 1

Liebert®

Air-cooled, Direct-drive Drycooler

Installer/User Guide

50 Hz and 60 Hz

Page 2

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.Vertiv.com/en-us/support/ for additional assistance.

Vertiv | Liebert® Drycooler Installer/User Guide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 1

2 Nomenclature and Components 7

2.1 Liebert Drycooler Model Number Nomenclature 7

2.2 Product Description and Features 8

2.2.1 Control Options 8

2.2.2 Typical System Configurations 9

3 Preinstallation andSitePreparationGuidelines 11

3.1 Shipping Dimensions and Weights 11

3.2 Planning Dimensions and Anchor Plans 13

3.3 Pump Packages 14

3.3.1 Expansion Tank 15

3.3.2 Compression Tank 15

4 Equipment Inspection and Handling 17

4.1 Packaging Material 17

4.2 Unit Storage 18

4.3 Handling Unit on the Skid 18

4.4 Unpacking the Unit—All Unit Sizes 19

4.5 Preparing 1 to 4 Fan Drycooler forMovingandInstallation 21

4.6 Preparing 6 and 8 Fan Drycoolers for Moving and Installation 25

4.7 Mounting the Drycooler 29

5 Piping 31

5.1 Guidelines for Expansion Tanks, Fluid-reliefValves,AirManagementandOtherDevices 36

5.2 Preparing to Fill the System 36

5.3 Filling the Drycooler System 38

6 Electrical Connections 39

6.1 Line Voltage Wiring 40

6.2 Low Voltage Control Wiring 46

7 Checklist for Completed Installation 49

7.1 Moving and Placing Equipment 49

7.2 Electrical Installation Checks 49

7.3 Piping Installation Checks 49

7.4 Other Installation Checks 49

8 Troubleshooting 51

9 Operation 53

9.1 Start-up Checklist 53

9.2 Startup: Drycooler Aquastat Settings 53

10 Maintenance 55

10.1 General Maintenance 56

10.2 Drycooler Cleaning 56

10.2.1 When to Clean the Drycooler Coil 56

Vertiv | Liebert® Drycooler Installer/User Guide | i

Page 4

10.2.2 What to Use to Clean the Drycooler Coil 56

10.2.3 Cleaning the Drycooler Coil 56

11 Preventive Maintenance Checklist 59

Appendices 63

Appendix A: Technical Support and Contacts 63

Appendix B: Submittal Drawings 65

Vertiv | Liebert® Drycooler Installer/User Guide | ii

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and maintenance of the

Liebert®Drycooler. Read this manual thoroughly before attempting to install or operate this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit and in this manual.

Follow all installation, operation and maintenance instructions and all applicable national and local building, electrical and

plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory-supplied disconnect switch is inside the

unit. The line side of this switch contains live high-voltage. The only way to ensure that there is NO voltage

inside the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all

local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

WARNING! Risk of electric shock. Can cause serious injury or death. The Liebert® iCOM microprocessor does

not isolate power from the unit, even in the "Unit Off" mode. Some internal components require and receive

power even during the "unit off" mode of the Liebert® iCOM control. Open all local and remote electric power

disconnect switches and verify with a voltmeter that power is Off before working on any component of the

system.

WARNING! Risk of electrical fire and short circuit. Can cause property damage, injury or death. Select and

install the line side electrical supply wire and overcurrent protection device(s) according to the specifications

on the unit nameplate(s), per the instructions in this manual and according to the applicable national, state

and local code requirements. Use copper conductors only. Verify that all electrical connections are tight.

Unit-specific wiring diagrams are provided on each unit.

1 Importan t Safety In structions

1

Page 6

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment damage,

serious injury or death. Installation and service of this equipment should be done only by qualified personnel

who have been specially-trained in the installation of air-conditioning equipment and who are wearing

appropriate, OSHA-approved PPE. See Table 3.1 on page11, and Table 3.2 on page13, for weights.

WARNING! Risk of improper moving, lifting, or handling of the unit. Can cause equipment damage, injury or

death. Read all of the following instructions and verify that all lifting and moving equipment is rated for the

weight of the unit before attempting to move, lift, remove packaging from or prepare the unit for installation.

Table 3.1 on page11, and Table 3.2 on page13, for weights.

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or death. Open all

local and remote electric power-supply disconnect switches, verify with a voltmeter that power is off, and

verify that all fan blades have stopped rotating before working in the unit cabinet or on the fan assembly. If

control voltage is applied, the fan motor can restart without warning after a power failure. Do not operate the

unit with any or all cabinet panels removed.

CAUTION: Risk of unsecured strap ends with sharp edges flying uncontrollably in any direction when cut.

Can cause serious injury. Secure both ends of strap when cutting and wear OSHA-approved protective

headgear, gloves, and eye protection when working with the securing straps.

CAUTION: Risk of contact with hot surfaces. Can cause injury. Personal burn injury can be the result of

touching some electrical components that are extremely hot during unit operation. Allow sufficient time for

them to cool to a touch-safe temperature before working within the unit cabinet. Use extreme caution and

wear appropriate, OSHA-approved PPE when working on or near hot components.

2

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 7

NOTICE

NOTICE

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up generator

systems) for start-up, commissioning, testing, or normal operation, ensure that these sources are correctly

adjusted to the nameplate voltage and frequency of all equipment to be connected. In general, power-source

voltages should be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure

that no three-phase sources are single-phased at any time.

Risk of piping-system corrosion and freezing fluids. Can cause leaks resulting in equipment and expensive

building damage. Cooling coils and piping systems are at high risk of freezing and premature corrosion. Fluids

in these systems must contain an inhibitor to prevent premature corrosion.

The system coolant fluid must be analyzed by a competent fluid-treatment specialist before start up to

establish the inhibitor level and evaluated at regularly scheduled intervals throughout the life of the system to

determine the pattern of inhibitor depletion. The fluid complexity and variations of required treatment

programs make it extremely important to obtain the advice of a competent and experienced fluid-treatment

specialist and follow a regularly scheduled coolant-fluid system-maintenance program.

Fluid chemistry varies greatly as do the required additives, called inhibitors, that reduce the corrosive effect of

the fluids on the piping systems and components.

The chemistry of the coolant fluid used must be considered, because some sources may contain corrosive

elements that reduce the effectiveness of the inhibited formulation. Sediment deposits prevent the formation of

a protective oxide layer on the inside of the coolant system components and piping. The coolant fluid must be

treated and circulating through the system continuously to prevent the buildup of deposits and/or growth of

bacteria. Proper inhibitor maintenance must be performed to prevent corrosion of the system.

NOTICE

Consult fluid manufacturer for testing and maintenance of inhibitors.

Commercial-grade coolant fluid is generally less corrosive to the common metals of construction than water

itself. It will, however, assume the corrosivity of the coolant fluid from which it is prepared and may become

increasingly corrosive with use if not properly inhibited.

Vertiv recommends installing a monitored fluid-detection system that is wired to activate the automaticclosure of field-installed coolant-fluid supply and return shut-off valves to reduce the amount of coolant-fluid

leakage and consequential equipment and building damage. The shut-off valves must be sized to close-off

against the maximum coolant-fluid system pressure in case of a catastrophic fluid leak.

Risk of frozen pipes and corrosion from improper coolant mixture. Can cause water leaks resulting in

equipment and building damage.

When the drycooler, the cooling unit or piping may be exposed to freezing temperatures, charge the system

with the proper percentage of glycol and water for the coldest design ambient temperature. Automotive

antifreeze is unacceptable and must NOT be used in any glycol fluid system. Use only HVAC glycol solution

that meets the requirements of recommended industry practices. Do not use galvanized pipe.

1 Importan t Safety In structions

3

Page 8

NOTICE

NOTICE

NOTICE

NOTICE

Risk of excessive coolant fluid pressure, improper piping material, and unsupported piping. Can cause piping

rupture, coolant fluid leaks and building and/or equipment damage.

To avoid the possibility of burst pipes, the system installer must supply and install a relief valve in the system.

Galvanized pipe must not be used in glycol systems. To help prevent piping failures, supply and return lines

must be supported such that their weight does not bear on the piping of the unit or pumps.

Risk of overheated pump seals. Can cause piping system damage, coolant fluid leaks, and substantial building

damage.

Do not run pumps without fluid in the system. Pump seals require fluid to keep them cool; running them without

fluid for any amount of time will damage the seals, which may cause a failure.

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

Risk of a catastrophic water circuit rupture. Can cause expensive building and equipment damage.

Install shutoff valves in the supply and return water lines that automatically close if water is detected by the

leak detection system. The shutoff valves should be spring return and must be rated for a close-off pressure

that is the same as or higher than the supply water pressure. A monitored leak detection system should be

installed in the base of the unit or under the unit to actuate the shutoff valves immediately on a leak detection

signal.

NOTICE

Risk of no-flow condition. Can cause equipment damage.

Do not leave the water/coolant fluid-supply circuit in a no-flow condition. Idle fluid allows the collection of

sediment that prevents the formation of a protective oxide layer on the inside of tubes. Keep unit switched On

and water/coolant fluid-supply circuit system operating continuously.

4

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 9

NOTICE

Risk of using the wrong type of glycol. Can cause piping damage, coolant fluid leaks, and catastrophic and

expensive building and equipment damage.

Do not use automotive antifreeze as it contains chemicals that can damage the piping system.

Typical inhibited formula ethylene glycol and propylene glycol are supplied with corrosion inhibitors and do

not contain a silicone anti-leak formula. Commercial ethylene glycol and propylene glycol, when pure, are

generally less corrosive to the common metals of construction than water itself. Aqueous solutions of these

glycols, however, assume the corrosivity of the water from which they are prepared and may become

increasingly corrosive with use when not properly inhibited.

1 Importan t Safety In structions

5

Page 10

This page intentionally left blank

6

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 11

2 NOMENCLATURE AND COMPONENTS

This section describes the model number for Liebert® Drycooler units and components.

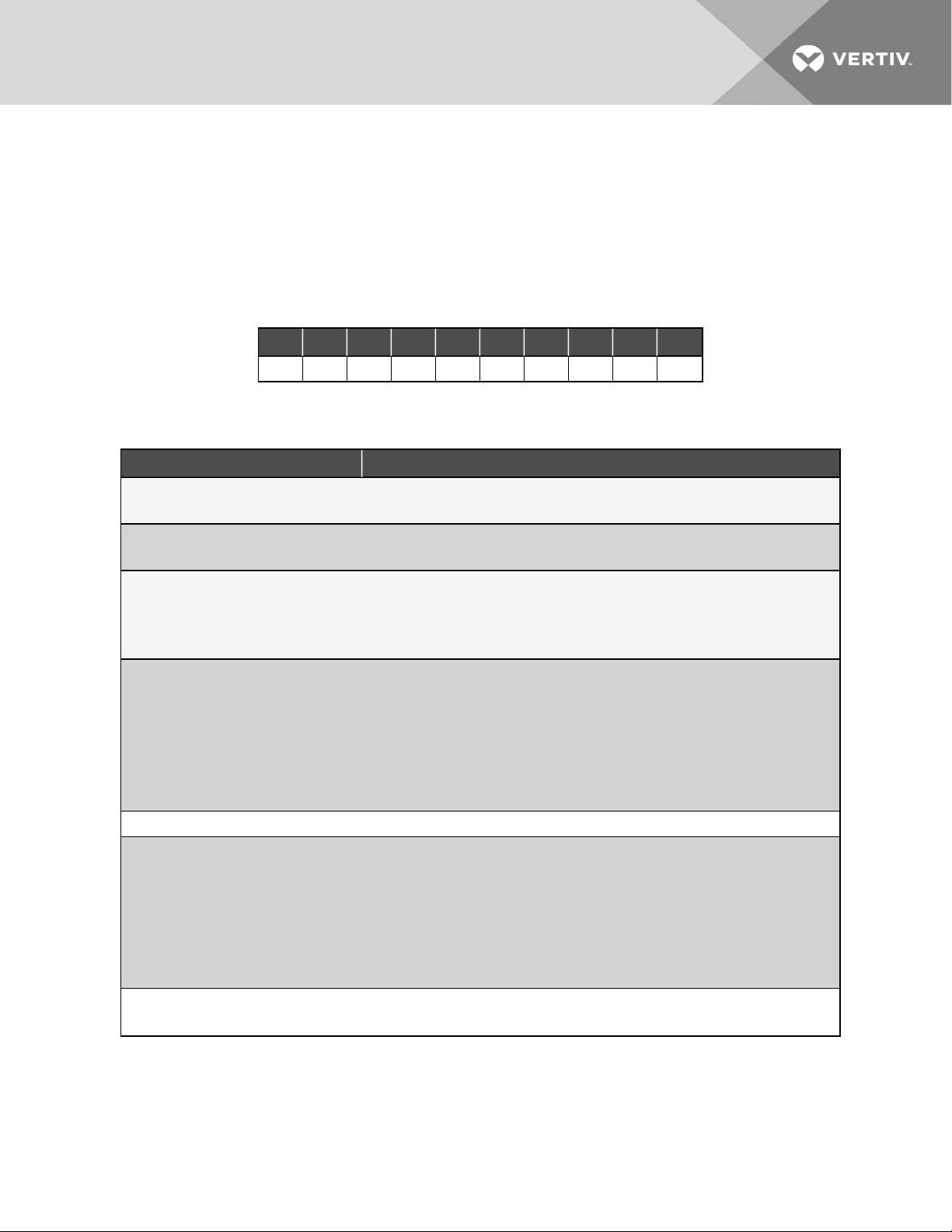

2.1 Liebert Drycooler Model Number Nomenclature

Table 2.2 below, describes each digit of the model number.

Table 2.1 Liebert Drycooler Model Number Example

1 2 3 4 5 6 7 8 9 10

D D N T 3 5 0 A 4 8

Table 2.2 Drycooler Model-number Digit Definitions

Digit Description

Digit 1 - Disconnect Switc h

D = Disconnect switch designat or on unit s wi thout pump cont rols, see Digit 3., otherwi se blank.

Digit2 = Uni t Fami ly

D = Dry cooler

Digit 3 - P ump Cont rol

N = No pump c ontrol

S = Single pump contr ol

D = Dual pump cont rol

Digits 4 - Fan C ontrol

C = No fan cont rol

L = Main fan c ontrol

T = Fa n cycl ing

O = Fan cy cli ng and pump cont rol

S = Specia l-or der fan/pump cont rol

F = Fan speed contr ol

Digits 5, 6, 7 - Model Size

Digit 8 - Power Supply

P = 208/ 230V / 1ph / 60Hz

W = 200 /2 20V / 1ph / 50 Hz

Y = 208/ 230V / 3ph / 60 Hz

A = 460V / 3ph / 60H z

B = 575V / 3ph / 60Hz

M = 380/415V / 3ph / 50 Hz

Digits, 9 and 10 - Cir cuit ing

Blank for standar d cir cuit ing. See Table 5.3 on page34 and Table 5.4 on pag e35 for sta ndard and optiona l ci rcui ti ng.

2 Nomenclature and Components

7

Page 12

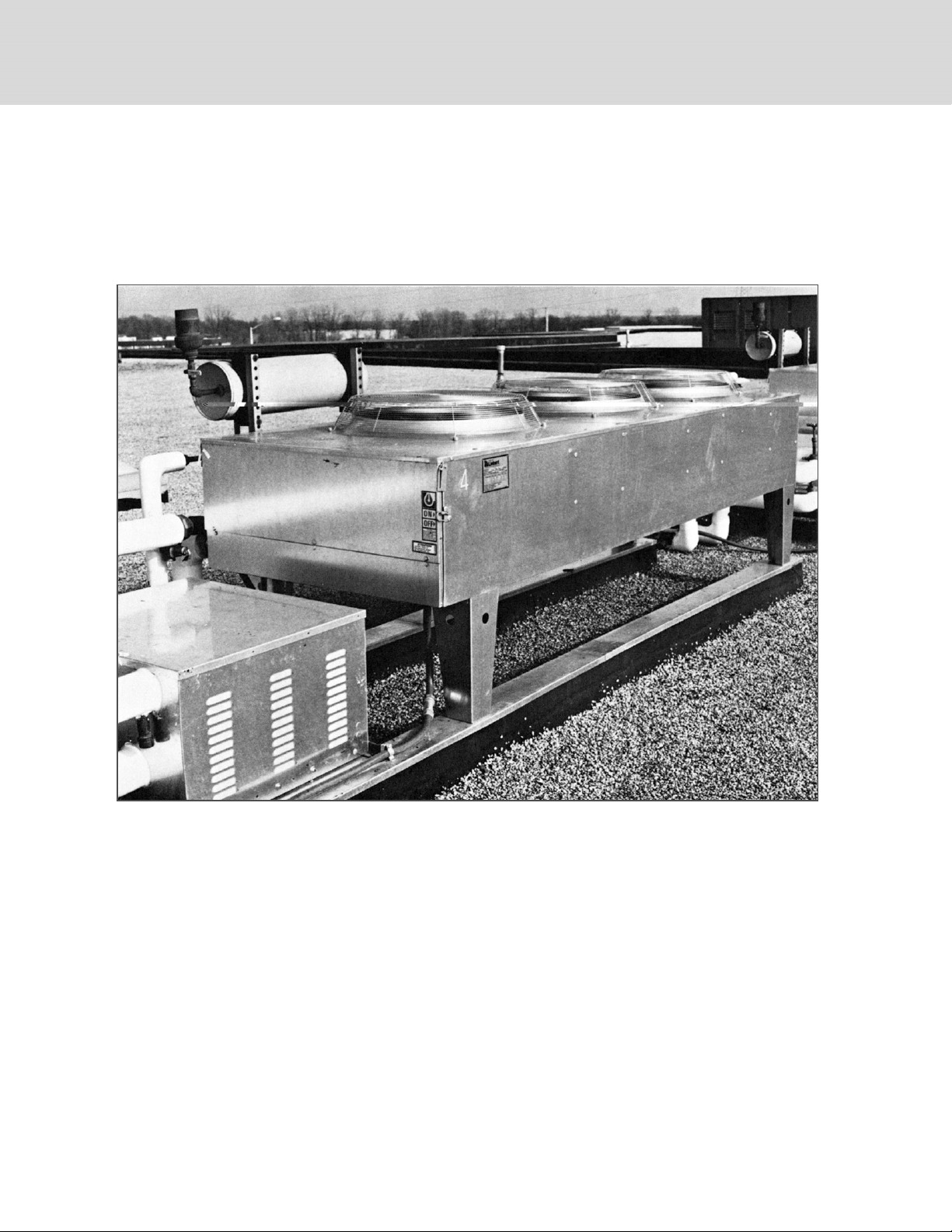

2.2 Product Description and Features

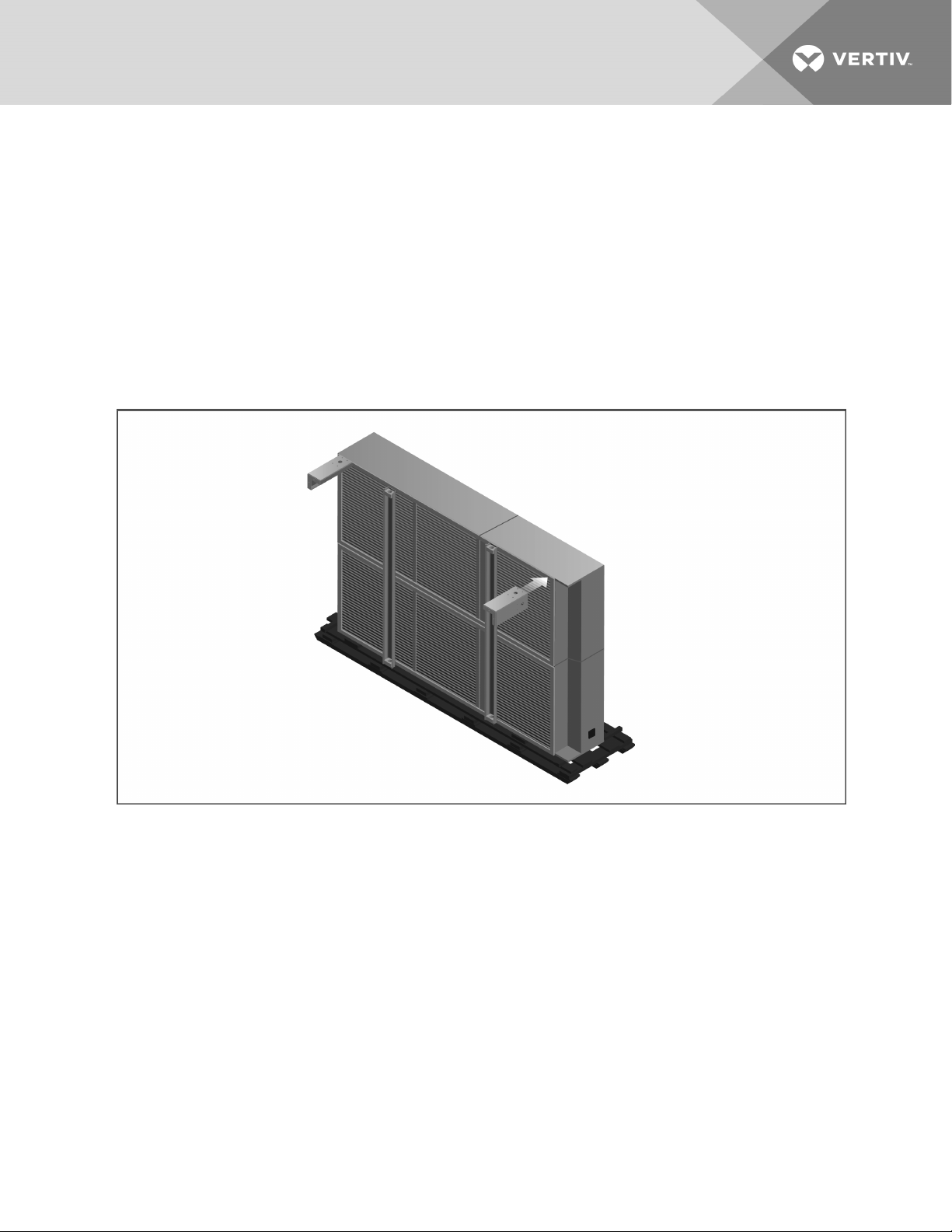

The Liebert® Air-cooled, Direct-drive Drycooler is a low-profile, direct-drive propeller fan-type air-cooled unit. Constructed

with an aluminum cabinet and a copper-tube aluminum fin coil, the unit is quiet and corrosion resistant. All electrical

connections and controls are enclosed in an integral NEMA 3R rated electrical panel section of the drycooler.

Figure 2.1 Liebert® Three Fan Drycooler

2.2.1 Control Options

Fan Speed—DSF, DDF

Available only on single-fan standard drycoolers with integral pump controls. Fan speed control provides an infinite number

of speed variations on specially designed, single-phase, permanent split capacitor motor, by monitoring leaving fluid

temperature.

Fan speed control provides air delivery in direct proportion to heat rejection requirements of the system. The control is

adjustable to maintain the temperature of the fluid leaving the drycooler. Either of two temperature ranges can be fieldselected: 30 to 60°F (-1 to 16°C) for GLYCOOL™applications or 70 to 100°F (21 to 38°C) for glycol applications.

8

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 13

Fan Cycling Control—DDNT, DSO, DDO

Available on all sizes of standard sound and Quiet-Line drycoolers. A thermostatic control cycles the fan on a single-fan

drycooler in response to leaving fluid temperatures. Two or more thermostats are employed on drycoolers with two or more

fans to cycle fans or groups of fans in response to leaving fluid temperatures. The thermostat setpoints are listed on the

factory-supplied schematic. They typically range from 35 to 45°F (2 to 7°C) for GLYCOOL applications and 65 to 75°F (18 to

24°C) for glycol applications.

Main Fan Control—DDNL

Available on all sizes of standard-sound and Quiet-Line drycoolers without pump controls. All fans run when an external

contact closure completes internal 24VAC circuit.

No Controls - DDNC

Available on all sizes of standard-sound and Quiet-Line drycoolers without pump controls. All fans are activated at full

speed when power is applied to the drycooler.

Pump Controls

Available on all Fan Speed and Fan Cycling Control drycoolers. Controls for pump(s) up to 7.5hp are built into the same

integral electric panel as the drycooler fan controls. Pump fuses, overload heaters and flow switch (dual pump control

models) are included with the Liebert® pump packages or must be field-supplied for field-supplied pumps.

Dual pump option—Provides controls for primary and standby pump. The flow switch senses loss of flow and switches to the

standby pump for continuous system operation in the event of a pump failure. An internal switch allows manual selection of

the lead/lag pump.

2.2.2 Typical System Configurations

The standard glycol-cooled precision air conditioning system includes these major components:

• indoor air conditioning unit with heat exchangers (refrigerant/glycol)

• glycol regulating valve

• outdoor air-cooled drycooler

• glycol pump(s)

• expansion/compression tank

• pump controls

• interconnection piping

• unit interlock control wiring

The piping general-arrangement drawings, listed in Table 2.3 on the next page, show single unit to drycooler loop

arrangement, multiple indoor units and multiple outdoor drycoolers using a dual pump package and on a common piping

loop. The drawings are included in the Submittal Drawings Contents on page65.

Additional field-supplied components, such as valves, expansion tank, strainers and flow or pressure switches are also shown

in the piping general-arrangement drawings. These components are necessary and should be included when designing a

system with one indoor and one outdoor unit on a piping loop or a system using multiple indoor and outdoor units on a

common piping loop. Larger systems may also benefit from an air separator (not shown).

2 Nomenclature and Components

9

Page 14

Table 2.3 Piping General-arrangment Drawings

Document Number Title

DPN000895 Piping diagram, Liebert® DS, glycol, semi-hermetic compressor models

DPN000896 Piping diagram, Liebert®DS, water/glycol, scroll compressor models

DPN001430 Piping diagram, Liebert® DS, water/glycol, digital-scroll com pressor models

DPN001432 Piping diagram, Liebert® DS, GLYCOOL, digital-scroll com pressor models

DPN000897 Piping diagram, Liebert®DS, GLYCOOL, semi-hermetic compressormodels

DPN000898 Piping diagram, Liebert®DS, GLYCOOL, scroll compressor m odels

DPN002931 Piping diagram, Liebert® PDX with water/glycol

DPN002932 Piping diagram, Liebert® PDX with GLYCOOL

DPN003822 Typical piping arrangement with multiple drycoolers and multiple indoor units

10

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 15

3 PREINSTALLATION ANDSITEPREPARATIONGUIDELINES

The unit dimensions, pipe-connection locations, and piping schematics are described in the submittal documents included

in the Submittal Drawings Contents on page65.

• Install the drycooler in a location offering maximum security and access for maintenance.

• Avoid ground-level sites with public access and areas prone to heavy snow or ice accumulations.

• Whenever interior building locations must be used, utilize a Piggyback drycooler. Contact your Vertiv sales

representative for more information.

• To ensure adequate air supply, we recommend that drycoolers be installed in an area with clean air, away from

loose dirt and foreign matter that might clog the coil, and away from steam, hot-air, or fume exhaust.

• Drycoolers must not be installed in a pit because discharge air is likely to be recirculated through the unit.

• Drycoolers should be located no closer than 3 ft (1m) from a wall, obstruction, or adjacent unit and avoid

locations where objects restrict the air-inlet free area.

• For roof installation, mount the drycooler on suitable curbs or other supports in accordance with local codes.

• The drycooler must be installed on a level surface to ensure proper glycol flow, venting and drainage.

• Allow adequate space for pump packages, expansion/compression tanks, piping and additional field-supplied

devices.

• When mounting pump packages, mount on level surface or suitable curbs that will allow cooling ventilation air

to enter from underneath the pump package frame and exit through the louvers.

• The drycooler must be installed in a vertical air-flow orientation to maintain NEMA 3R rating of electrical box.

The unit is CSA c-us Certified for vertical air flow only and has not been tested for any other orientation.

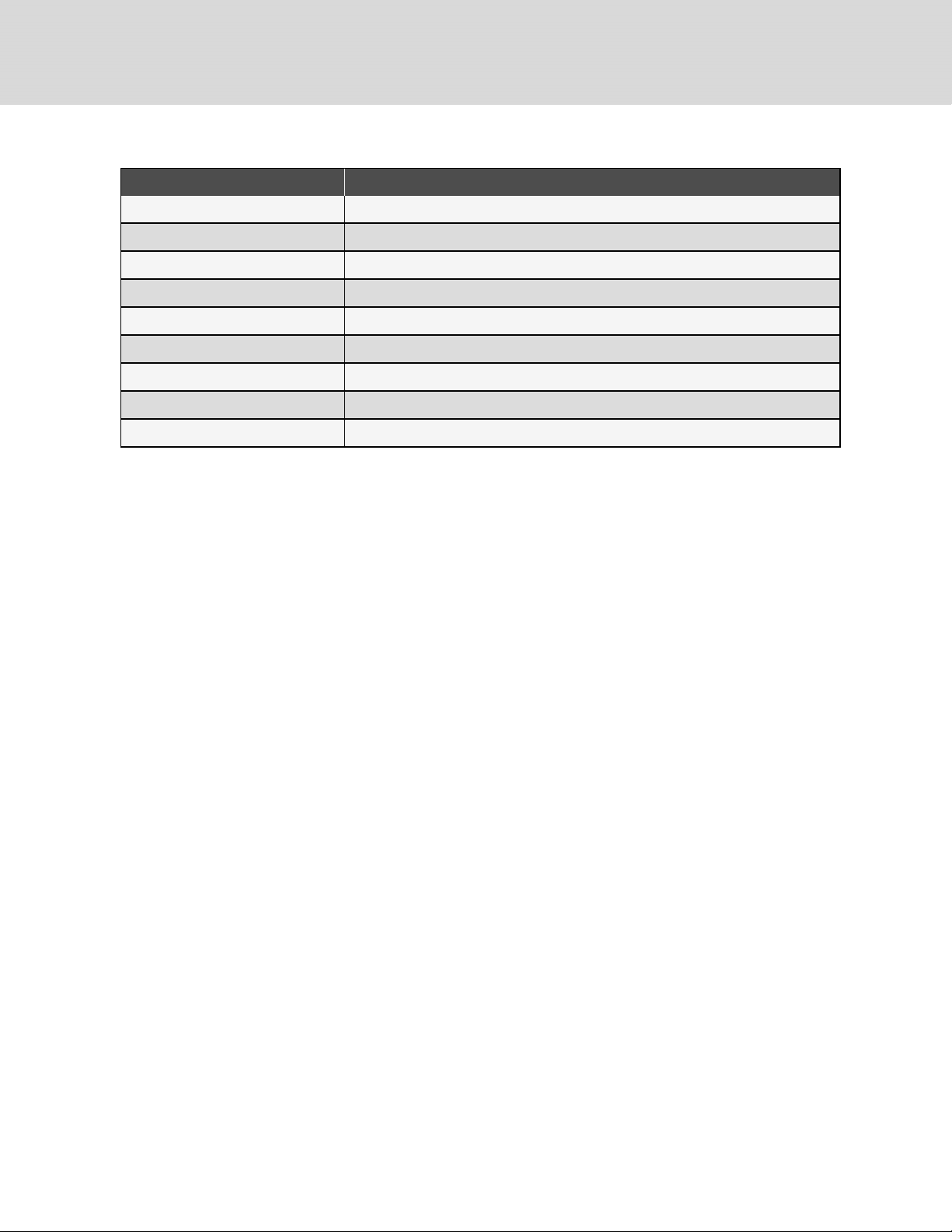

3.1 Shipping Dimensions and Weights

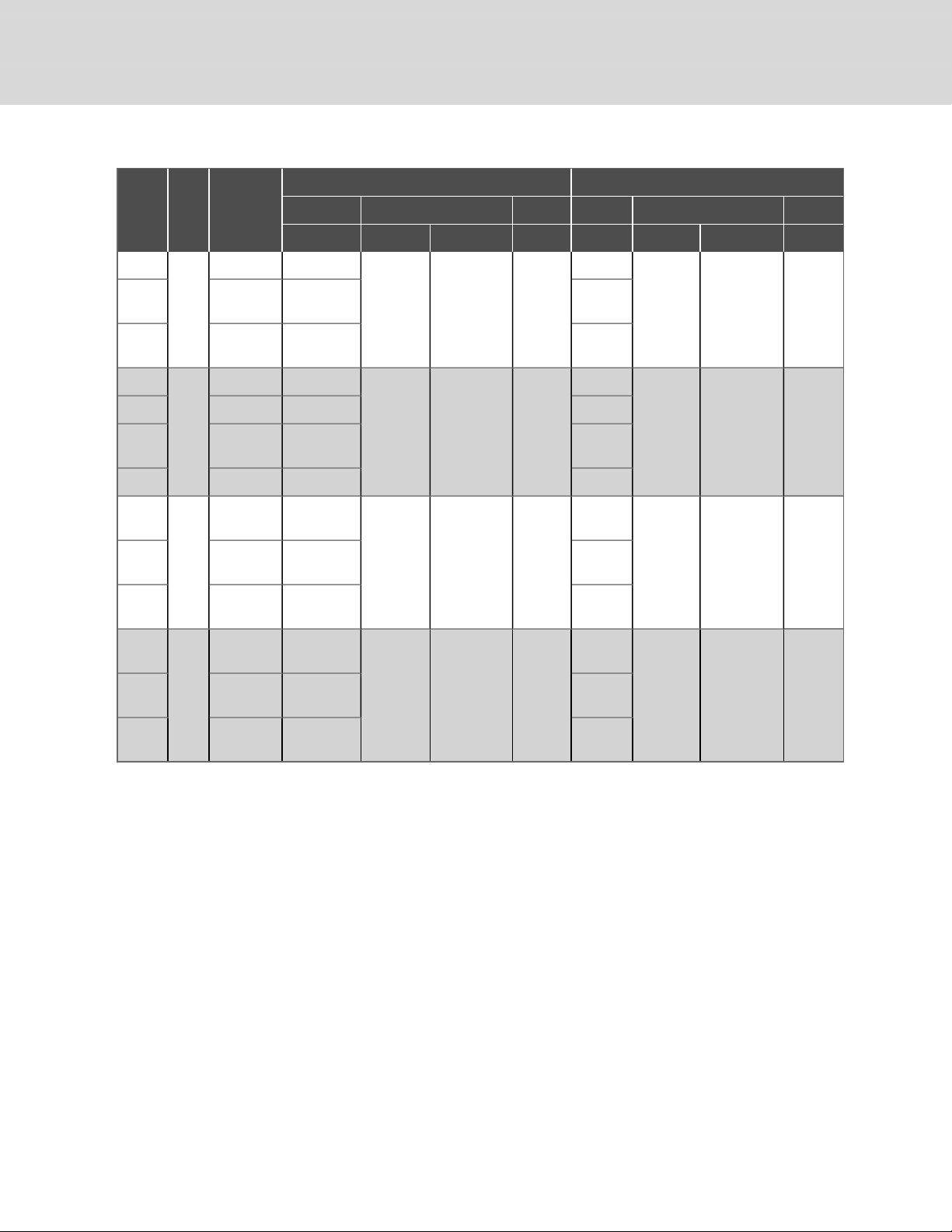

Table 3.1 Standard Drycooler Net Weights, Shipping Weights, Dimensions and Volume, Approximate

Domestic Packed Export Packed

No. of

Model

*D**033

*D**069 375 (17 0) 530 (240) 637 (289)

*D**092 395 (179) 550 (249) 657 (298)

*D**109 415 (188) 570 (259) 677 (307 )

*D**112 435 (197) 590 (268) 697 (316)

*D**139

*D**174 540 (245) 797 (362) 954 (433)

*D**197 580 (263) 837 (380) 994 (451)

*D**225 620 (281) 877 (398)

Dry Weight

Fans

lb (kg)

355 (161) 510 (231)

1

500 (227 ) 757 (343)

2

Weight Dimension (LxWxH) Volume Weight Dimension (LxWxH) Volume

lb. (kg) in. (cm) ft3(m3) lb. (kg.) in. (cm) ft3(m3)

617 (280)

62x36x63 (157x91x160) 81 (2.3)

914 (415)

102x36x63 (259x91x160) 134 (3.8)

1034

(469)

63x37x 64 (160x94x163) 86 (2.5)

103x37x64 (262x94x163) 141 (4.0)

3 Pr einst allation andS itePreparationGuideli nes

11

Page 16

Table 3.1 Standard Drycooler Net Weights, Shipping Weights, Dimensions and Volume, Approximate (continued)

Domestic Packed Export Packed

No. of

Model

Fans

Dry Weight

lb (kg)

Weight Dimension (LxWxH) Volume Weight Dimension (LxWxH) Volume

lb. (kg) in. (cm) ft3(m3) lb. (kg.) in. (cm) ft3(m3)

*D**260

*D**310 795 (361) 1164 (528)

*D**350 855 (388) 1224 (555)

*D**352

735 (333) 1104 (501)

3

940 (426) 1401 (635)

142x36x63 (361x91x 160) 186 (5.3)

1282 (582)

1342

(609)

1402

(636)

1658 (752)

*D**419 1 020 (463) 1481 (672) 1738 (788)

*D**466 1050 (476) 151 1 (685)

4

182x36x63 (462x91x 160) 239 (6.7)

1768

(802)

*D**491 1100 (499) 1561 (708) 1818 (825)

*D**620

1780 (808) 2223 (1008)

6

*D**700 1 880 (854) 2323 (1054)

*D**790

*D**880 2330 (1058) 2895 (131 3)

2250 (1022) 2815 (1277 )

8

142x36x94 (361x91x239) 2 78 (7.9)

182x36x94 (462x91x2 39)

356

(10.0)

2948

(1337)

2998

(1360)

3048

(1383)

3769

(1710)

3849

(1746)

143x37 x64 (363x94x163) 1 96 (5.6)

183x37x64 (465x94x163) 251 (7.0)

143x37 x95 (363x94x241) 291 (8.2)*D**650 1830 (831) 2273 (1031)

183x37x95 (465x94x241) 372 (10.5)

*D**940 2430 (1103) 2995 (1359)

12

3949

(1791)

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 17

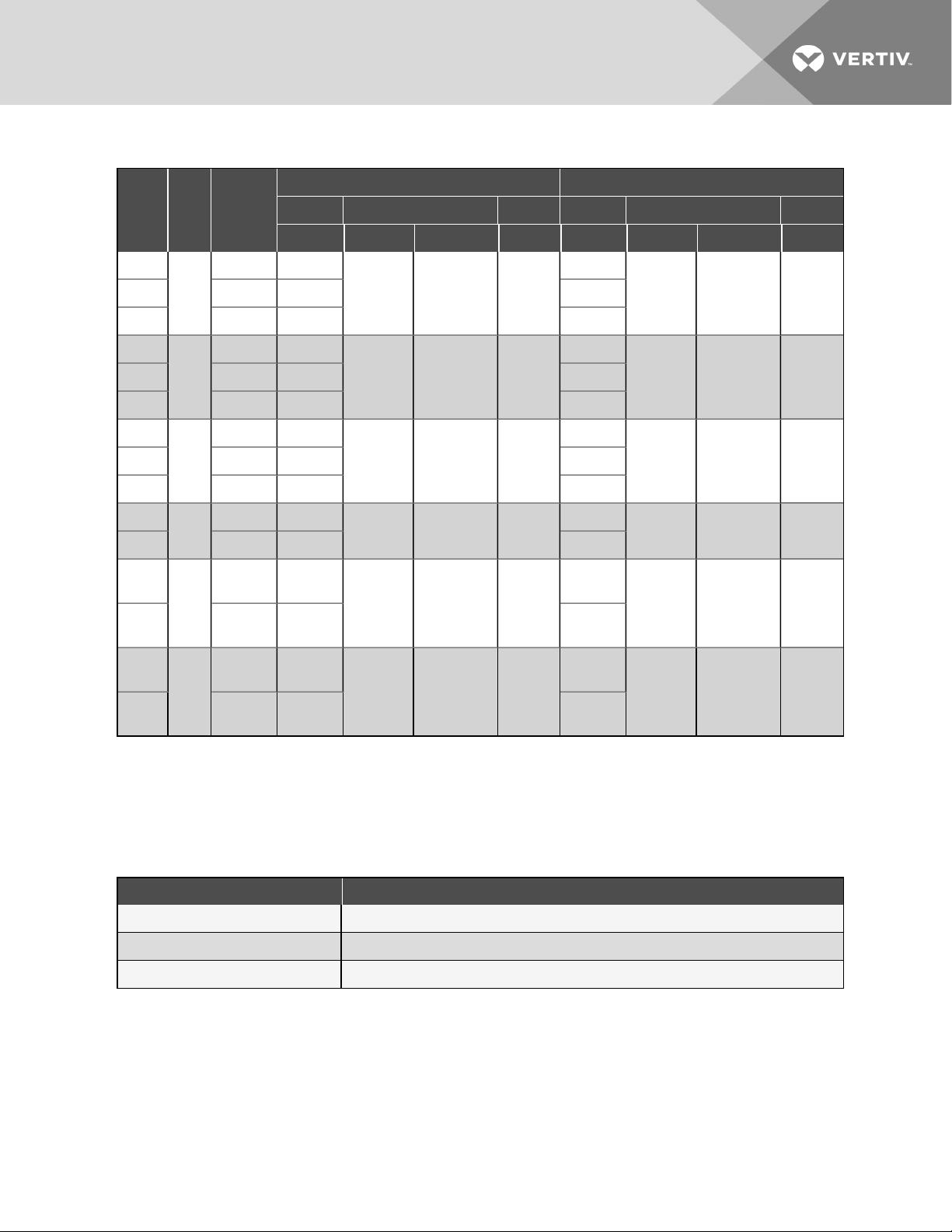

Table 3.2 Quiet-Line Drycooler Net weights, Shipping Weights, DimensionsandVolume,Approximate

Domestic Packed Export Packed

No. of

Model

Fans

Dry Weight

lb (kg)

Weight Dimension (LxWxH) Volume Weight Dimension (LxWxH) Volume

lb. (kg) in. (cm) ft3(m3) lb. (kg.) in. (cm) ft3(m3)

*D**040

*D**060 415 (188) 570 (259) 677 (307)

*D**080

*D**121 580 (263) 837 (380) 994(451)

*D**158

*D**178 855 (388) 1224 (555) 1402 (636)

*D**205

*D**248 1020 (463) 1481 (672) 1 738 (788)

*D**347

*D**356 1880 (854)

*D**453

*D**498

375 (17 0) 530 (240)

1

500 (227 ) 757 (343)

2

735 (333) 110 4 (501)

3

940 (426) 1 401 (635)

4

1780 (808)

6

2250

(1022)

8

2430

(1103)

2223

(1008)

2323

(1054)

2815 (1277)

2995

(1359)

637 (289)

62x36x63 (157x91x160) 81 (2.3)

914 (415)

102x36x63 (259x91x1 60) 134 (3.8)

1282 (582)

142x36x63 (361x91x160) 186 (5.3)

1658 (752)

182x36x63 (462x91x160) 239 (6.7)

2948

(1337)

142x36x94 (361x91x239) 278 (7. 9)

3048

(1383)

3769

(1710)

182x36x94 (462x91x239) 356 (10.0)

3949 (1791)

63x37x 64 (160x94x163) 86 (2.5)*D**057 395 (179) 550 (249) 657 (298)

103x37x64 (262x94x163) 141 (4.0)*D**111 540 (245) 797 (362) 954 (433)

143x37 x64 (363x94x163) 196 (5.6)*D**173 795 (361) 1 164 (528) 1342 (609)

183x37x64 (465x94x163) 251 (7. 0)

143x37 x95 (363x94x241) 291 (8.2)

183x37x95 (465x94x241) 372 (10.5)

3.2 Planning Dimensions and Anchor Plans

The unit dimensions are described in the submittal documents included in the Submittal Drawings Contents on page65.

The following table lists the relevant documents by number and title.

Table 3.3 Dimension Planning Drawings

Document Number Title

DPN000274 Cabinet and Anchor dimensions for 1to4f an drycoolers

DPN000280 Cabinet and Anchor dimensions for 1 to4 fan Quiet-Line drycoolers

DPN000721 Cabinet and Anchor dimensions for 6to8 fa n standard and Quiet-Line drycoolers

3 Pr einst allation andS itePreparationGuideli nes

13

Page 18

3.3 Pump Packages

The planning dimensions, electrical power-supply requirements, piping connections, and electrical connections are

described in the submittal documents included in the Submittal Drawings Contents on page65.

The following table lists the relevant documents by number and title.

Table 3.4 Drycooler Pump Drawings

Document Number Title

DPN000329 Pump Electrical Power Data and Piping-connection sizes.

DPN000278 Single-pump Piping connection locations and dimensional data

DPN000328 Dual-pump Piping connection locations and dimensional data

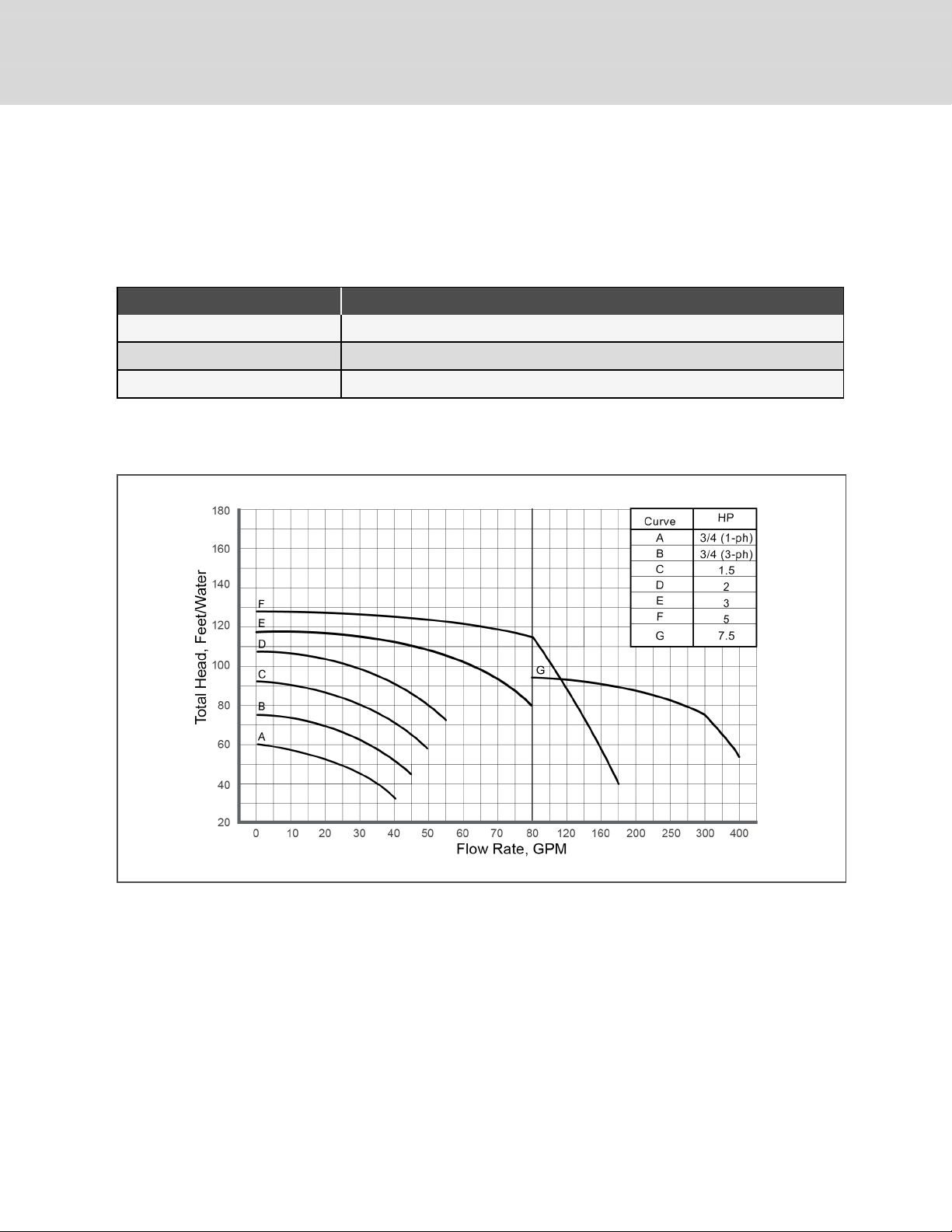

Figure 3.1 Pump curve, 60 Hz

NOTE: Higher-capacity pumps are available. Please contact your local sales rep for more information.

14

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 19

3.3.1 Expansion Tank

The expansion tank, included in a standard pump package, has an internal volume of 8.8gal.(33l) and a maximum pressure

of 100psi(690kPa).

The tank is sized for a typical “open” system with a fluid volume of less than 75gal.(280l). When used in a “closed” system,

volumes of up to 140gal.(530l) can be accommodated. We recommend use of a field-supplied safety-relief valve for

systems “closed” to atmospheric venting. Other piping accessories for filling, venting, or adjusting the fluid in the system,

are recommended, but not included.

The planning dimensions and general arrangement are described in the submittal documents included in the Submittal

Drawings Contents on page65.

The following table lists the relevant documents by number and title.

Table 3.5 Drycooler Pump and Tank Drawings

Document Number Title

DPN004183 Expansion Tank General Arrangement and Dimensional Data

3.3.2 Compression Tank

The compression tank for glycol/GLYCOOL™ systems includes:

• Tank

• Airtrol fitting

• Sight glass with shut-off valves

• 50-psi relief valve

• Drain valve

Mounting brackets are not included. Maximum design pressure 125psig.

The planning dimensions and general arrangement are described in the submittal documents included in the Submittal

Drawings Contents on page65.

The following table lists the relevant documents by number and title.

Table 3.6 Drycooler Pump and Tank Drawings

Document Number Title

DPN003898 Compression Tank General Arrangement and Dimensional Data

3 Pr einst allation andS itePreparationGuideli nes

15

Page 20

This page intentionally left blank

16

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 21

4 EQUIPMENT INSPECTION AND HANDLING

WARNING! Risk of improper moving, lifting, or handling of the unit. Can cause equipment damage, injury or

death. Read all of the following instructions and verify that all lifting and moving equipment is rated for the

weight of the unit before attempting to move, lift, remove packaging from or prepare the unit for installation.

SeeTable 3.1 on page11, and Table 3.2 on page13

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of improper lifting. Can cause equipment damage. Make sure that the spreader bars are wider than the

unit. If the spreader bars are too short, the slings may crush the unit.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Keep the unit upright, indoors and protected from dampness, freezing temperatures

and contact damage.

Upon arrival of the unit and before unpacking:

• Verify that the labeled equipment matches the bill of lading.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv or to your sales

representative.

Equipment Recommended for Handling the Unit:

• Forklift

• Lift beam

• Slings

• Spreader bars

• Crane

4.1 Packaging Material

All material used to package this unit is recyclable. Please save for future use or dispose of the material

appropriately.

4 Eq uipment Ins pection an d Handlin g

17

Page 22

4.2 Unit Storage

Store the drycooler in the original packaging in an area protected from excessive dirt, debris and contact damage until final

installation

4.3 Handling Unit on the Skid

Transport unit using a fork lift or a crane with sling and spreader bars.

Using a forklift

NOTICE

Risk of improper forklift handling. Can cause unit damage.

Keep the forklift tines level and at a height that will fit under the skid.

• Make sure the forks (if adjustable) are spread to the widest allowable distance to still fit under the skid.

• Type of forklift used will depend on the terrain the unit is to be moved across during handling.

• Minimum forklift fork length:

• for 1 fan and two fan units—48in (1219mm)

• for 3 fan and 4 fan units—72in. (1829mm)

• for 6 fan units—72 in. (1829 mm)

• for 8 fan units—96 in. (2438 mm)

• When moving the packaged unit, do not lift it any higher than 6in. (152mm). If the unit must be lifted higher

than 6-in. (152mm), you must exercise great care, and no one may be closer than 20ft(6m) to the lift point.

• We recommend lifting one end off the ground no more than 6in.(152mm)and using the forklift to push or pull

the unit.

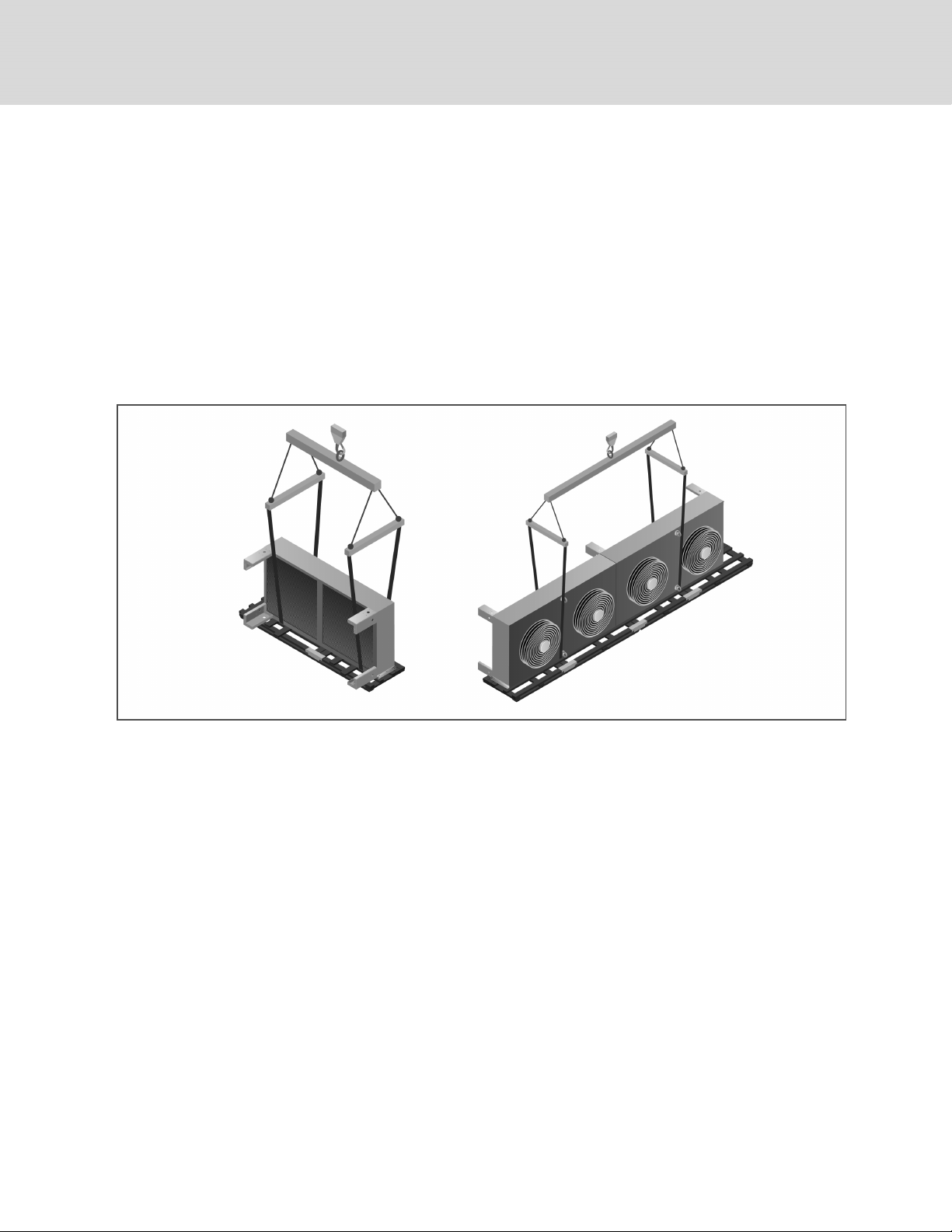

Figure 4.1 Forklift position with 1 to 8fan units

Using a Crane

• We recommend using slings rated for the unit weight.

• Spreader bars must be used for sling stability and to keep the slings from pressing against the unit. Make sure

spreader bars are wider than the unit.

• Place the slings near the ends of the unit, under the top deck boards of the skid.

18

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 23

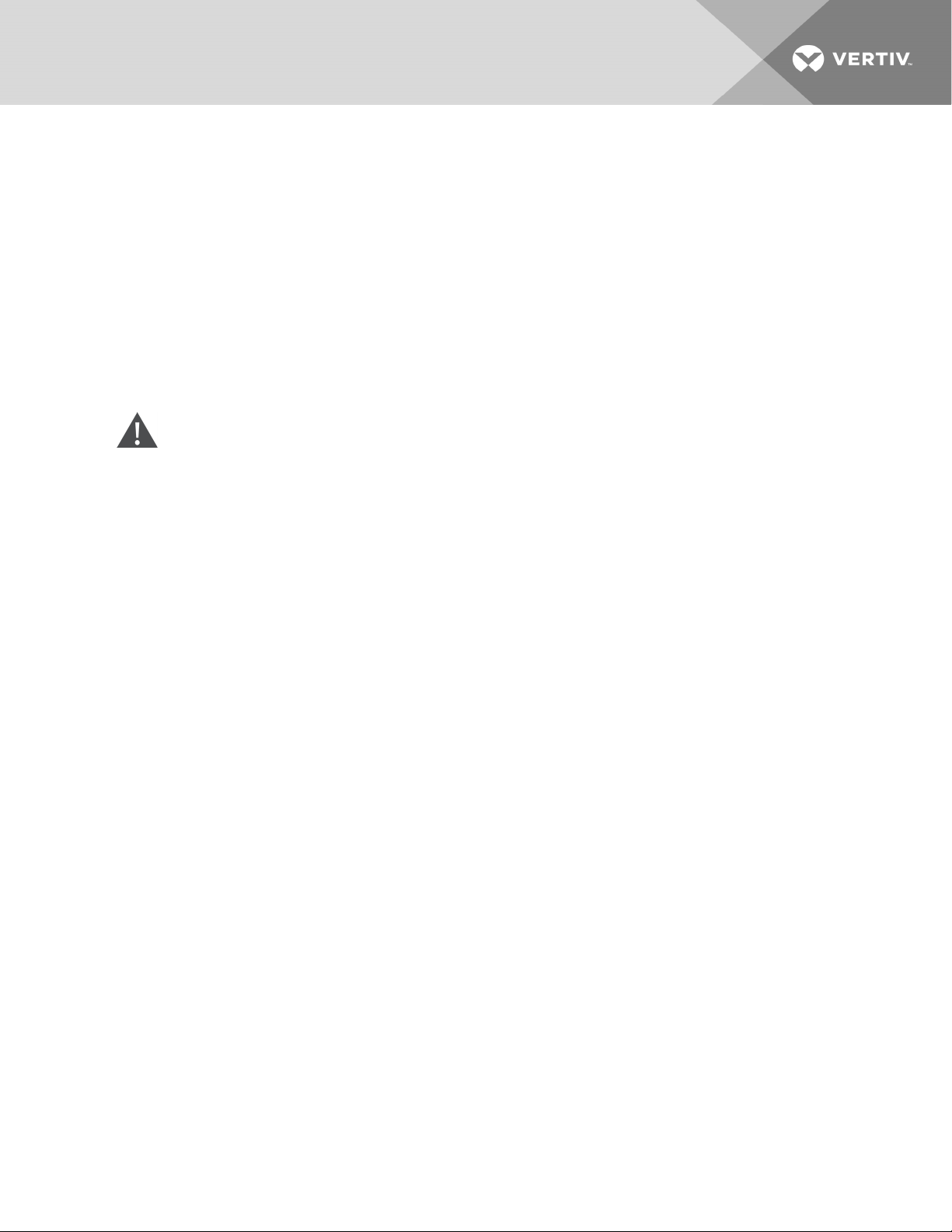

4.4 Unpacking the Unit—All Unit Sizes

Refer to Figure 4.2 on the next page, for the following steps:

1. For domestic packaging:

• Remove the fastener clamps from the top and sides of the unit.

• Remove all screws and washer from the wooden fencing.

• Remove the fence

–or–

For export packaging, remove the crate.

2. Carefully remove the steel straps securing the unit to the skid.

CAUTION: Risk of unsecured strap ends with sharp edges flying uncontrollably in any direction when cut.

Can cause serious injury. Secure both ends of each strap when cutting and wear OSHA approved protective

headgear, gloves and eye protection when working with the securing straps.

3. Set the legs aside, but keep accessible.

• Depending on the number of fans, more or less steel straps may be removed at this step.

4 Eq uipment Ins pection an d Handlin g

19

Page 24

Figure 4.2 Removing Protective Material

20

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 25

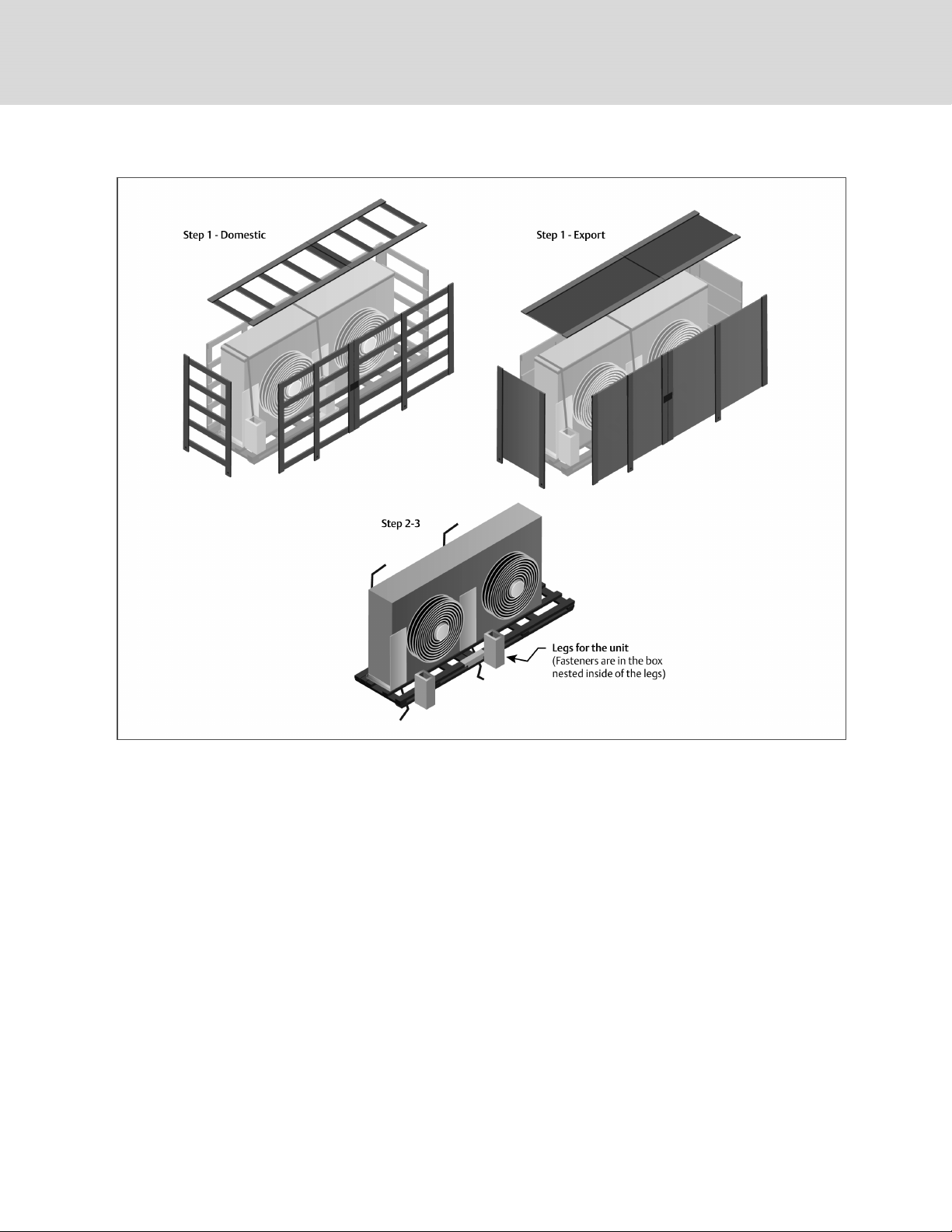

4.5 Preparing 1 to 4 Fan Drycooler forMovingandInstallation

The following procedure is one recommended method for removing a unit from the shipping skid. Other methods may be

used, provided that they are safe for personnel, the unit and equipment.

1. Attach legs to the unit at indicated locations, using the fasteners provided with the legs, Figure 4.3 below.

• Recommended tools for attachment is a 5/8” socket and ratchet.

• More legs may be available for installation than are shown. This will depend on the unit type and number

of fans. Refer to the appropriate planning-dimensions drawing in Submittal Drawings Contents on

page65, for the number of legs on your unit.

Figure 4.3 Attaching Legs to 1 to 4 Fan Drycoolers

4 Eq uipment Ins pection an d Handlin g

21

Page 26

2. Place slings around the unit between the unit and the top deck boards of the skid as shown in Figure 4.4

below:

• 1 fan, 2 fan and 3 fan units: against the inside of the attached legs.

• 4 fan units: against the outside of the attached eye bolts.

3. Use spreader bars, a lift beam and a crane to lift the unit off the skid. Make sure spreader bars are wider than

the unit to prevent crushing force.

NOTICE

Risk of improper lifting. Can cause equipment damage. Make sure that the spreader bars are wider than the

unit. If the spreader bars are too short, the slings may crush the unit.

Figure 4.4 Securing Slings to 1 to 4 Fan Drycoolers for Lifting off Skid

22

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 27

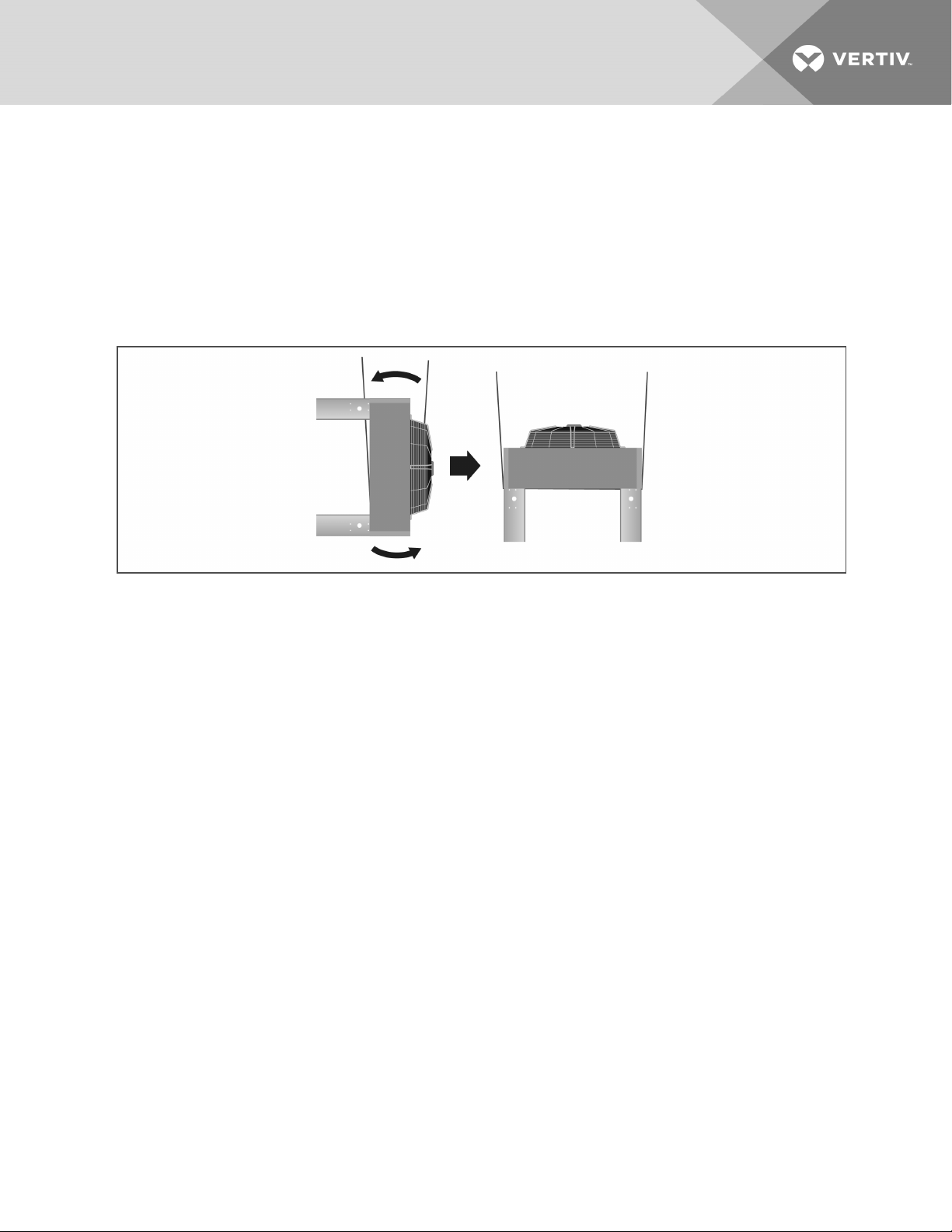

4. Lift the unit 24" (610mm) off the top deck of the skid.

5. Remove the skid from under the unit.

6. To rotate the unit, a mechanized method is recommended, but if one is not available, use a minimum of four

properly-protected individuals to rotate the elevated unit 90 degrees so the unit legs are pointing toward the

ground, Figure 4.5 below.

7. Set the upright unit on the ground so the legs support unit weight.

8. Remove the straps from around unit.

Figure 4.5 Rotate and Set Drycooler on Ground or Level Surface

4 Eq uipment Ins pection an d Handlin g

23

Page 28

9. Refer to Figure 4.6 below, to attach rigging for lifting.

Spreader bars are still required. Make sure that the spreader bars are wider than the unit.

• 1 fan, 2 fan and 3 fan units: Route the straps through the large holes in the side of the legs.

• 4-fan units: Secure straps or chains to the eye bolts on top of the unit.

NOTICE

Risk of improper lifting. Can cause equipment damage. Make sure that the spreader bars are wider than the

unit. If the spreader bars are too short, the slings may crush the unit.

The unit is ready to be lifted and moved to its installation location.

Figure 4.6 Rigging to Lift 1 to 4 Fan Drycoolers

24

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 29

4.6 Preparing 6 and 8 Fan Drycoolers for Moving and Installation

The following procedure is one recommended process for removing a unit from the shipping skid. Other methods may be

used, provided that the methods are safe for personnel, the drycooler and equipment.

1. Refer to Figure 4.7 below, to attach the legs to the higher side of the unit:

• Use four (4) fasteners per leg. Fasteners are provided with the legs.

• Recommended tools for attachment is a 5/8” socket and ratchet.

• More legs may be required for installation than are shown. This will depend on the unit type and number

of fans. Refer to the appropriate planning-dimensions drawing in Submittal Drawings Contents on

page65, for the number of legs on your unit.

Figure 4.7 Attach Legs to Higher side of 6 or 8 Fan Drycooler

4 Eq uipment Ins pection an d Handlin g

25

Page 30

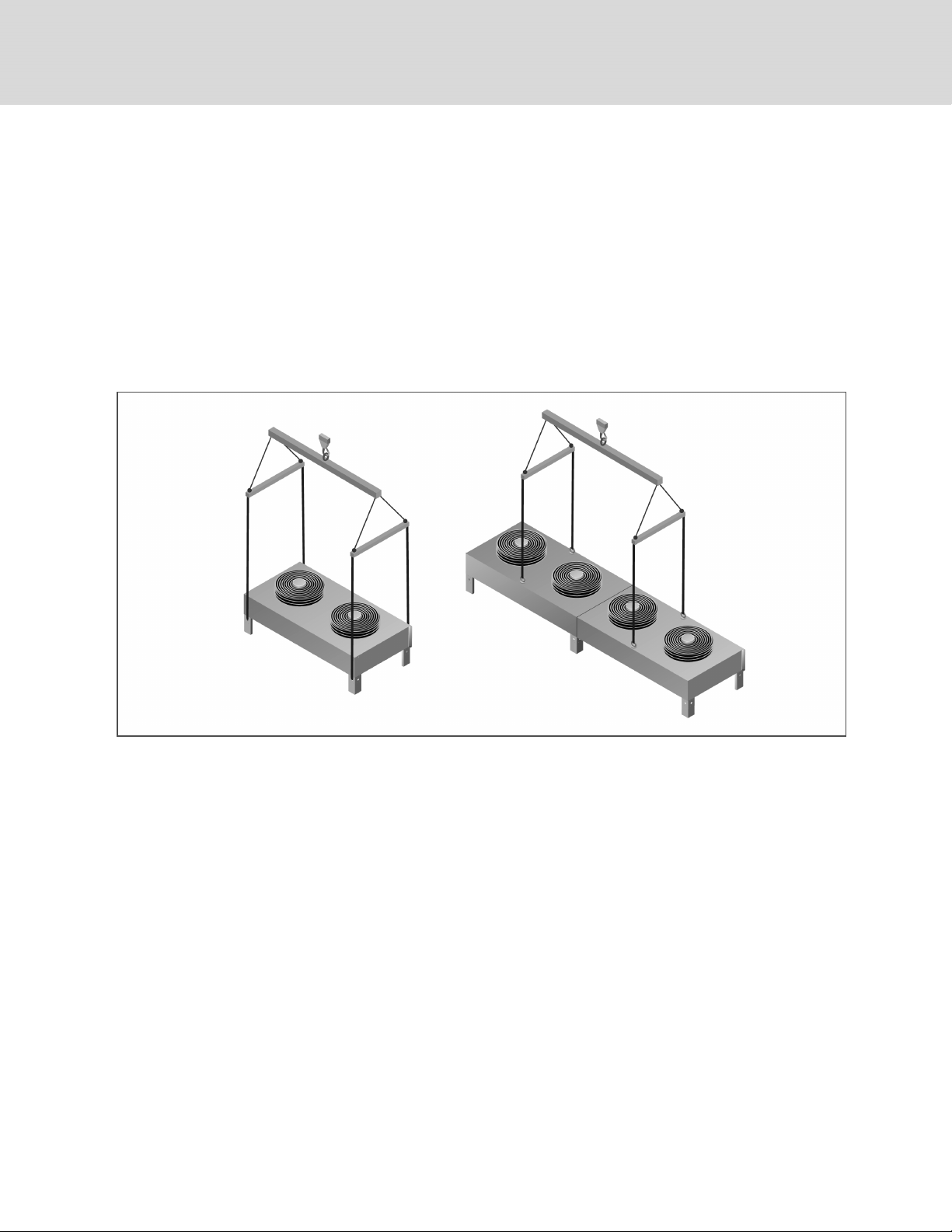

2. Attach slings or chains to the unit lift rails as shown in Figure 4.8 below

• Mechanically lower the unit in order to rest on the attached legs.

• Make sure not to damage the opposite side of the unit.

Figure 4.8 Use Sling to Lower Side with Legs Attached

26

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 31

3. Move the slings or chains to the lift rail side that is resting on the skid, Figure 4.9 below.

• Mechanically lift the unit to a point where the side being lifted is just high enough to allow for safe

attachment of the remaining unit legs.

• Move the skid out the way and attach remaining legs.

Figure 4.9 Move Sling to Side Resting on Skid and Lift to Remove Skid and Install Legs

4 Eq uipment Ins pection an d Handlin g

27

Page 32

4. Set the upright unit on the ground so that the legs support the unit’s weight.

5. Reposition and add straps and spreader bars to prepare the unit for lifting to installation location, Figure 4.10

below.

• Use the support channels located under the unit to attach straps or chains.

• Spreader bars are still required. Make sure spreader bars are wider than the unit to keep the straps from

pressing on the sides of the unit.

NOTICE

Risk of improper lifting. Can cause equipment damage. Make sure that the spreader bars are wider than the

unit. If the spreader bars are too short, the slings may crush the unit.

The unit is ready to be lifted and moved to its installation location.

Figure 4.10 Rigging 6 and 8 Fan Drycooler for Lifting

28

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 33

4.7 Mounting the Drycooler

The drycooler must be installed so that it is level within 1/2in.(13mm) to ensure proper glycol flow, venting, and drainage.

For roof installation, mount the drycooler on suitable curbs or other supports. Follow all local and national codes. Secure the

legs to the mounting surface using a field-supplied 1/2-in.(13-mm) diameter bolt in each of the two 9/16-in. (14-mm) holes in

each leg. For anchor dimensions, refer to the appropriate drawing for your unit model included in the Submittal Drawings

Contents on page65.

4 Eq uipment Ins pection an d Handlin g

29

Page 34

This page intentionally left blank

30

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 35

5 PIPING

NOTICE

Risk of piping-system corrosion and freezing fluids. Can cause leaks resulting in equipment and expensive

building damage. Cooling coils and piping systems are at high risk of freezing and premature corrosion. Fluids

in these systems must contain an inhibitor to prevent premature corrosion.

The system coolant fluid must be analyzed by a competent fluid-treatment specialist before start up to

establish the inhibitor level and evaluated at regularly scheduled intervals throughout the life of the system to

determine the pattern of inhibitor depletion. The fluid complexity and variations of required treatment

programs make it extremely important to obtain the advice of a competent and experienced fluid-treatment

specialist and follow a regularly scheduled coolant-fluid system-maintenance program.

Fluid chemistry varies greatly as do the required additives, called inhibitors, that reduce the corrosive effect of

the fluids on the piping systems and components.

The chemistry of the coolant fluid used must be considered, because some sources may contain corrosive

elements that reduce the effectiveness of the inhibited formulation. Sediment deposits prevent the formation of

a protective oxide layer on the inside of the coolant system components and piping. The coolant fluid must be

treated and circulating through the system continuously to prevent the buildup of deposits and/or growth of

bacteria. Proper inhibitor maintenance must be performed to prevent corrosion of the system.

Consult fluid manufacturer for testing and maintenance of inhibitors.

Commercial-grade coolant fluid is generally less corrosive to the common metals of construction than water

itself. It will, however, assume the corrosivity of the coolant fluid from which it is prepared and may become

increasingly corrosive with use if not properly inhibited.

NOTICE

NOTICE

Vertiv recommends installing a monitored fluid-detection system that is wired to activate the automaticclosure of field-installed coolant-fluid supply and return shut-off valves to reduce the amount of coolant-fluid

leakage and consequential equipment and building damage. The shut-off valves must be sized to close-off

against the maximum coolant-fluid system pressure in case of a catastrophic fluid leak.

Risk of a catastrophic water circuit rupture. Can cause expensive building and equipment damage.

Install shutoff valves in the supply and return water lines that automatically close if water is detected by the

leak detection system. The shutoff valves should be spring return and must be rated for a close-off pressure

that is the same as or higher than the supply water pressure. monitored leak detection system should be

installed in the base of the unit or under the unit to actuate the shutoff valves immediately on a leak detection

signal.

Risk of no-flow condition. Can cause equipment damage.

Do not leave the water/coolant fluid-supply circuit in a no-flow condition. Idle fluid allows the collection of

sediment that prevents the formation of a protective oxide layer on the inside of tubes. Keep unit switched On

and water/coolant fluid-supply circuit system operating continuously.

5 Pi pin g

31

Page 36

Piping between the drycooler, any external pump and the cooling unit is required to complete the system.

Properly-sized pipes will help reduce pumping power and operating costs. Pipe material choices are typically copper,

plastic or steel/black iron. Consult glycol and pipe manufacturing literature for compatibility and sizing assistance.

Galvanized piping should not be used. Any copper piping installed should be “L” or “K” refrigerant-grade copper.

Drycooler supply and return connections vary in size and number. See Table 5.3 on page34, and Table 5.4 on page35.

Consider the following guidelines when planning and performing the piping installation:

• Follow local piping codes, safety codes.

• Qualified personnel must install and inspect system piping.

• Do not hang or suspend piping from the drycooler-tube sheets protruding below the finned sections of the coil.

• On multiple-pump packages install a check valve at the discharge of each pump to prevent back-flow through

the standby pump(s).

• To extend the service life of the drycooler and pumps, install 16-20 mesh-screen filters/strainers in the supply

line to the pumps. The filter/strainer(s) should be easily replaced or cleaned.

• Consider Installing hose bibs at the lowest point of the system to facilitate filling.

• Keep piping runs as straight as possible, avoid unnecessary bends, and minimize additional fittings.

• Isolate piping from the building with vibration-isolating supports. Use soft, flexible material to seal between

pipes and wall openings to prevent pipe damage.

• Use welded or high-temperature soldered joints where possible. Threaded pipe joints, if needed, can be made

with tightly drawn Teflon™ tape.

• Clean and prepare all pipe connections before joining. Be careful not to allow solder/joining debris to get inside

the lines during the connection process.

32

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 37

The piping general arrangement and schematics are described in the submittal documents included in the Submittal

Drawings on page65.

The following tables list the relevant documents by number and title.

Table 5.1 Piping General-arrangment Drawings

Document Number Title

DPN000895 Piping diagram, Liebert® DS, glycol, semi-hermetic compressor models

DPN000896 Piping diagram, Liebert®DS, water/glycol, scroll compressor models

DPN001430 Piping diagram, Liebert® DS, water/glycol, digital-scroll com pressor models

DPN001432 Piping diagram, Liebert® DS, GLYCOOL, digital-scroll com pressor models

DPN000897 Piping diagram, Liebert®DS, GLYCOOL, semi-hermetic compressormodels

DPN000898 Piping diagram, Liebert®DS, GLYCOOL, scroll compressor m odels

DPN002931 Piping diagram, Liebert® PDX with water/glycol

DPN002932 Piping diagram, Liebert® PDX with GLYCOOL

DPN003822 Typical piping arrangement with multiple drycoolers and multiple indoor units

Table 5.2 Piping Connection Drawings

Document Number Title

DPN000275 Connection locations for standard 1 fan, 2 fan, 3 fan, and 4 fan units

DPN000281 Connection locations for Quiet-Line 1 fan, 2 fan, 3 fa n, and 4 fan units

DPN002429 Connection locations f or standard 6 fan and 8 fa n units

DPN002430 Connection locations for Quiet-Line 6 fan and 8 fan units

5 Pi pin g

33

Page 38

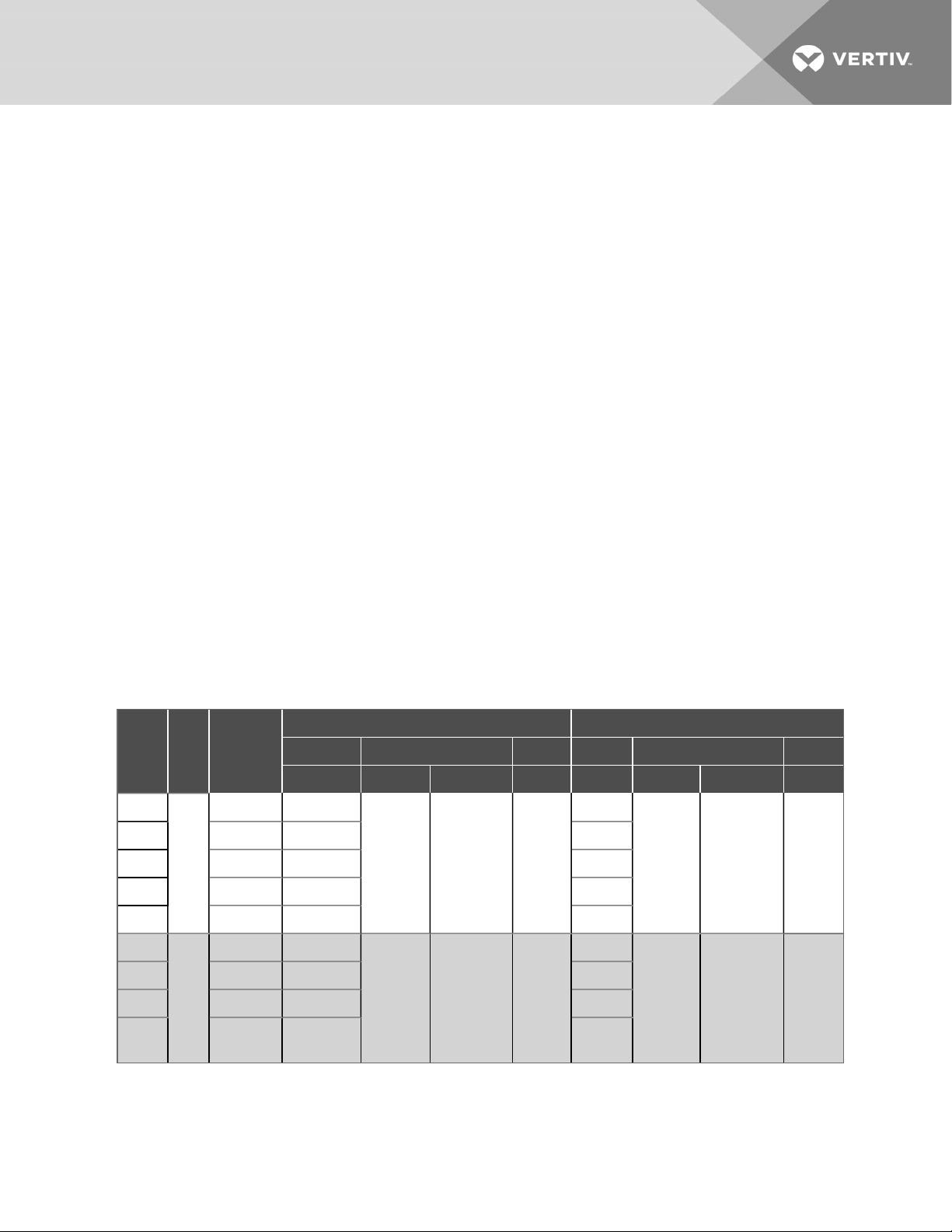

Table 5.3 Standard Drycooler Piping Connection Sizes and Internal Volume

Model #

No. of Internal Coil Circuits No. of Fans

Internal Volume,

gal. (L)

No. of Inlets/Outlets

Inlet & Outlet Connection Size

ODS Copper, in. IDS Copper, in.

033 4*

069 4, 8* 2.4 (9.2) 1/1 1-3/8 —

092 6, 12*, 16 3.7 (13.9) 1/1 1-5/8 —

109

8

16* 1/1 2-1/8 —

8

112

16*, 26 1/1 2-1/8 —

139 8, 16*

174 8, 16*, 24 6.9 (26.2) 1/1 2-1/8 —

8 9.0 (34.0) 1/1 1-3/8 —

197

16*, 32 9.0 (34.0) 1/1 2-1/8 —

225 16, 26* 11.1 (42.1) 1/1 2-1/8 —

260 16, 24*

310 16, 32* 13.1 (49.6) 1/1 2-1/8 —

16, 32*

350

48 1/1 2-5/8 —

352 16, 24*

1

2

3

1.2 (4.6) 1/1 1-3/8 —

1/1 1-3/8 —

4.9 (18.6)

1/1 1-3/8 —

5.8 (22.0)

4.8 (18.2) 1/1 2-1/8 —

10. 0 (37. 9) 1/1 2-1/8 —

1/1 2-1/8 —

19.4 (73.3)

13.1 (49.6) 1/1 2-1/8 —

419 16, 32* 17.4 (65.9) 1/1 2-1/8 —

466 26

466 40* 1/1 2-5/8 —

16, 32

491

48* 1/1 2-5/8 —

620 32, 64*

40, 52*

650

80 4/4 — 2-1/8

32, 64*

700

96 4/4 — 2-1/8

790 32, 64*

52

880

80* 4/4 — 2-1/8

32, 64

940

96* 4/4 — 2-1/8

* = Standard Circuiting

4

6

8

22.0 (83.3)

26.3 (99.6)

27. 0 (102 .2) 2/2 — 2-1/8

33.0 (124.9)

40.0 (151 .4)

35.0 (132.5) 2/2 — 2-1/8

44.0 (166.5)

52.0 (196.8)

1/1 2-1/8 —

1/1 2-1/8 —

2/2 — 2-1/8

2/2 — 2-1/8

2/2 — 2-1/8

2/2 — 2-1/8

34

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 39

Table 5.4 Liebert Quiet-Line™ Drycooler Piping Connection Sizes and Internal Volume

Model # No. of Internal Coil Circuits No. of Fans

Internal Volume,

gal. (L)

No. of Inlets/Outlets

Inlet & Outlet Connection Size

ODS Copper, in. IDSCopper, in.

040 4, 8*

12*

057

16 1/1 2-1/8 —

8

060

1

2.4 (9.2) 1/1 1-3/8 —

1/1 1 -5/8 —

3.7 (13.9)

1/1 1 -3/8 —

4.9 (18.6)

16* 1/1 2-1/8 —

080 8, 16*

111 16*, 24 6.9 (26.2) 1 /1 2-1/8 —

2

4.8 (18.2) 1/1 2-1/8 —

121 1 6*, 32 9.0 (34.0) 1/1 2-1/8 —

158 1 6, 24*

10. 0 (37. 9) 1 /1 2-1/8 —

173 16, 32* 13.1 (49.6) 1/1 2-1/8 —

3

178

16, 32*

19.4 (73.3)

1/1 2-1/8 —

48 1/1 2-5/8 —

205 16, 24*

13.1 (49.6) 1/1 2-1/8 —

4

248 16, 32* 17.4 (65.9) 1/1 2-1/8 —

347 32, 64*

32, 64*

356

6

27. 0 (102 .2) 2/2 — 2-1/8

2/2 — 2-1/8

39.3 (148.8)

96 4/4 — 2-1/8

5 Pi pin g

453 32, 64*

498

* = Standard circuiting

35.0 (132.5) 2/2 — 2-1/8

32, 64

8

2/2 — 2-1/8

52.0 (196.8)

96* 4/4 — 2-1/8

35

Page 40

5.1 Guidelines for Expansion Tanks, Fluid-reliefValves,AirManagementandOtherDevices

An expansion tank must be provided for expansion and contraction of the fluid due to temperature change in this closed

system. Vents are required at system high points to vent trapped air when filling the system. A fluid pressure relief valve is

also a necessary piping component.

All systems must have an air management system to ensure proper component operation and system performance. There

are several methods that can be used to manage the air within a closed loop hydronic system. Depending on the method

chosen, the system may include one or more of the following ancillary components: tank-steel (expansion, compression,

diaphragm or bladder), air separator and air vent.

Consult your local engineer to determine which method will be used and where these components must be installed.

Depending on the complexity of the system, various other devices may be specified—refer to site-specific drawings. Some

of the devices that may be required are: pressure gauges, flow switches, automatic air separator, tempering valves, standby

pumps and sensors for electrical controls.

5.2 Preparing to Fill the System

NOTICE

Risk of improper handling of glycol products. Can cause environmental damage.

Before using any glycol products, review the latest manufacturer's Material Safety Data Sheets and ensure that

you can use the product safely. The installer must read, understand and comply with the information on the

product packaging and in the current Material Safety Data Sheets. Make this information available to anyone

responsible for operation, maintenance and repair of the drycooler and related equipment.

Because government regulations and use conditions are subject to change, it is the user's responsibility to

determine that this information is appropriate and suitable under current, applicable laws and regulations.

NOTICE

Risk of using the wrong type of glycol. Can cause piping damage, coolant fluid leaks, and catastrophic and

expensive building and equipment damage.

Do not use automotive antifreeze as it contains chemicals that can damage the piping system.

Typical inhibited formula ethylene glycol and propylene glycol are supplied with corrosion inhibitors and do

not contain a silicone anti-leak formula. Commercial ethylene glycol and propylene glycol, when pure, are

generally less corrosive to the common metals of construction than water itself. Aqueous solutions of these

glycols, however, assume the corrosivity of the water from which they are prepared and may become

increasingly corrosive with use when not properly inhibited.

Remove any dirt, oil, or metal filings that may contaminate the cooling system piping to prevent contamination of the fresh

glycol solution and fouling of the drycooler piping. Flush the system thoroughly using a mild cleaning solution or highquality water and then completely drain before charging with glycol.

Cleaning a new system is just as important as cleaning an old one. New systems can be coated with oil or a protective film.

Dirt and scale are also common. Any residual contaminants could adversely affect the heat-transfer stability and

performance of your system. In most cases, special cleaners are needed to remove scale, rust, and hydrocarbon foulants

from pipes, manifolds, and passages. For more information on cleaners and degreasers, contact your Vertiv representative.

Follow the manufacturer’s instructions when using these products.

36

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 41

Calculate the internal volume of the system as closely as possible. The drycooler volumes are shown in 5.2 on the previous

page, and 5.2 on the previous page. Use Table 5.5 below, for field-installed piping volumes. Indoor unit volumes are found

in their respective user manuals.

Table 5.5 Glycol volume in standard type "L" copper piping

Diameter, in. Volume

Outside Inside gal/ft l/m

1-3/8 1.265 0.065 0. 81

1-5/8 1.505 0.092 1.1 5

2-1/8 1 .985 0.161 2.00

2-5/8 2.465 0. 248 3.08

3-1/8 2.945 0.354 4.40

3-5/8 3.425 0. 479 5.95

4-1/8 3.905 0.622 7. 73

When considering the use of any glycol products in a particular application, review the latest Material Safety Data Sheets

and ensure that the intended use can be accomplished safely. For Material Safety Data Sheets and other product safety

information, contact the supplier nearest you. Before handling any other products mentioned in the text, you should obtain

available product safety information and take necessary steps to ensure safety of use.

Table 5.6 Glycol Concentrations for Freeze Protection by Ambient Temperature

Minimum Outdoor Ambient Tem perature, °F(°C)

Coolant 20 (–7) 10 (–12) 0 (–18) –10 (–23) –20 (–29) –30 (–34) –40 (–40) –50 (–46)

Propylene Glycol, % by volume 18* 29* 36 42 46 50 54 57

Ethylene Glycol, % by volume 17* 26* 35 41 46 50 55 59

Based on Dowfrost™ (PG) and Dowtherm™ (EG) product lit erature.

*Inhibitor levels should be adjusted to properly protect the syst em if solution concentrates are les s than 30% .

There are two basic types of additives:

• Corrosion inhibitors

• Environmental stabilizers

The corrosion inhibitors function by forming a surface barrier that protects the metals from attack. Environmental stabilizers,

while not corrosion inhibitors in the strictest sense, decrease corrosion by stabilizing or favorably altering the overall

environment. An alkaline buffer, such as borax, is a simple example of an environmental stabilizer, because its prime

purpose is to maintain an alkaline condition (pH above 7).

The percentage of glycol to water must be determined by using the lowest design outdoor temperature in which the system

is operating. Table 5.6 above, indicates the solution volume of inhibited glycol required to provide freeze protection at

various ambient temperatures.

5 Pi pin g

37

Page 42

5.3 Filling the Drycooler System

We recommend installing hose bibs at the lowest point of the system.

When filling a glycol system, keep air to a minimum. Air in glycol turns to foam and is difficult and time consuming to

remove. (Consider anti-foam additives.)

To fill the system:

1. Open all operating systems to the loop.

2. With the top vent(s) open, fill the system from the bottom of the loop.

The glycol will push the air out of the top of the system, minimizing trapped air.

3. Fill to approximately 80% of calculated capacity, then continue to fill slowly from this point, checking fluid

levels until full.

NOTE: For glycol solution preparation and periodic testing, follow manufacturer's recommendations. Do not mix

products of different manufacturers.

38

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 43

6 ELECTRICAL CONNECTIONS

Line-voltage electrical service is required for all models. Electrical service must conform to national and local electrical

codes. Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer to electrical schematic

when making connections. Refer the appropriate submittal drawing, listed in Table 6.1 on the next page, for electrical

service entrances into unit.

A manual electrical disconnect switch should be installed in accordance with local codes and distribution system. Consult

local codes for external disconnect requirements.

All internal wiring is completed at the factory.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory-supplied disconnect switch is inside the

unit. The line side of this switch contains live high-voltage. The only way to ensure that there is NO voltage

inside the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all

local codes.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment damage,

serious injury or death. Installation and service of this equipment should be done only by qualified personnel

who have been specially-trained in the installation of air-conditioning equipment and who are wearing

appropriate, OSHA-approved PPE.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

NOTICE

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up generator

systems) for start-up, commissioning, testing, or normal operation, ensure that these sources are correctly

adjusted to the nameplate voltage and frequency of all equipment to be connected. In general, power-source

voltages should be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure

that no three-phase sources are single-phased at any time.

NOTE: Use copper wiring only. Make sure that all connections are tightened to the proper torque mentioned on the

component.

6 Electrical Connections

39

Page 44

NOTE: Installation and service of this equipment should be done only by properly-trained and qualified personnel who

are specially-trained in the installation of air-conditioning equipment.

The electrical connections are described in the submittal documents included in the Submittal Drawings Contents on

page65.

The following table lists the relevant documents by number and title.

Table 6.1 Electrical Field Connection Drawings

Document Number Title

DPN000277 Electrical field connections, 1 fan DSF/DDF drycooler with pump control

DPN000276 Electrical field connections, 1, 2, 3 and 4 fan DSO/DDO drycooler with pump control

DPN000703 Electrical field connections, 6 a nd 8 fan DSO/DDO drycooler with pump control

DPN000702 Electrical field connections, 6 and 8 fan DDNC drycooler without pump control

DPN000704 Electrical field connections, 6 and 8 fan DDNL/DDNT drycooler without pump control

DPN000282 Electrical field connections, Fluid-temperature control drycooler, Q uiet-Line

DPN000722 Electrical field connections, 6- and 8-fan Quiet-Line drycooler with no control

DPN000723 Electrical field connections, 6- and 8-fan Quiet-Line drycooler with DSO/DDO pump control

DPN000724 Electrical field connections, 6- and 8-fan Quiet-Line drycooler with DDNL and DDNT pump control

6.1 Line Voltage Wiring

WARNING! Risk of electrical fire and short circuit. Can cause property damage, injury or death. Select and

install the line side electrical supply wire and overcurrent protection device(s) according to the specifications

on the unit nameplate(s), per the instructions in this manual and according to the applicable national, state

and local code requirements. Use copper conductors only. Verify that all electrical connections are tight.

Unit-specific wiring diagrams are provided on each unit.

NOTICE

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty coverage.Prior to

connecting any equipment to a main or alternate power source (for example: back-up generator systems) for start-up,

commissioning, testing, or normal operation, ensure that these sources are correctly adjusted to the nameplate

voltage and frequency of all equipment to be connected. In general, power-source voltages should be stabilized and

regulated to within ±10% of the load nameplate nominal voltage. Also, ensure that no three-phase sources are singlephased at any time.

Drycooler-rated voltage should be verified with available power supply before installation. Refer to the unit’s electrical

schematic and serial tag for specific electrical requirements.

Line voltage electrical service is required for all drycoolers at the location of the drycooler. If the drycooler contains pump

controls, the pump package voltage must match the drycooler voltage. See the unit's serial tag for specific electrical

requirements of the drycooler and any pump package. A unit disconnect is standard on all drycoolers. Site disconnect (s)

may also be required per local code to isolate the drycooler/pumps for maintenance. Route the supply power to the site

disconnect switch and then to the drycooler. Route the conduit through the hole provided in the cabinet. Connect earth

ground to lug provided near the terminal board. Refer to the appropriate drawing in the Submittal Drawings Contents on

page65.

40

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 45

NOTE: A separate neutral wire does not need to be run to the Liebert® Drycooler.

Table 6.2 60Hz Electrical Values—Drycoolers without Pump Controls

No. of Fans Model N o. Voltage Phase FLA WSA OPD

Standard Models

1 33, 69, 092, 109, 112

2 139, 174, 1 97, 225

3 260, 310, 350

4 352, 419, 466, 491

6 620, 650, 700

208/230

1 4.8 6 1 5

3 3.5 4.4 1 5

460 3 1. 7 2.1 15

575 3 1 .4 1.8 15

208/230 3 7 .0 7.9 15

460 3 3. 4 3. 8 1 5

575 3 2.8 3. 2 15

208/230 3 10.5 11.4 1 5

460 3 5.1 5.5 15

575 3 4.2 4.6 15

208/230 3 14.0 14.9 20

460 3 6.8 7. 2 15

575 3 5.6 6.0 15

208/230 3 21.0 21.9 25

460 3 10.2 10.6 15

575 3 8.4 8.8 15

208/230 3 28.0 28.9 35

6 Electrical Connections

8 790, 880, 940

Liebert® Quiet-Line Models

1 40, 57, 60

2 80, 1 11 , 1 21

3 158, 1 73, 178

4 205, 248

460 3 1 3.6 14.0 20

575 3 1 1. 2 11. 6 15

208/230 3 1 .8 2. 3 15

460 3 0.9 1 .1 1 5

575 3 0.7 0. 9 15

208/230 3 3.6 4.1 15

460 3 1. 8 2.0 1 5

575 3 1 .4 1.6 1 5

208/230 3 5.4 5.9 1 5

460 3 2.7 2.9 15

575 3 2.1 2.3 15

208/230 3 7.2 7.7 1 5

460 3 3. 6 3. 8 1 5

575 3 2.8 3.0 15

41

Page 46

Table 6.2 60Hz Electrical Values—Drycoolers without Pump Controls (continued)

No. of Fans Model N o. Voltage Phase FLA WSA OPD

208/230 3 10.8 11 .3 1 5

6 347, 356

8 453, 498

Values are calculated per UL 1995. OPD values may be adjusted higher than calculations to compensate for maximum

anticipated application temperatures.

460 3 5. 4 5. 6 15

575 3 4.2 4.4 15

208/230 3 14.4 14.9 20

460 3 7.2 7. 4 15

575 3 5.6 5.8 15

Table 6.3 50Hz Electrical Values—Drycoolerswithout

Pump Controls

No. of Fans Model # Voltage Phase FLA

Standard Models

1

2

3

33, 69, 92,

109, 112

139, 174, 197,

225

260, 310,

350

200/230 1 4.0

380/415 3 1 .7

380/415 3 3.4

380/415 3 5.1

4

6

8

Quiet-Line Models

1 40, 57, 60 380/415 3 0.9

2 80, 1 11, 121 380/415 3 1.8

3 158, 173, 17 8 380/415 3 2. 7

4 205, 248 380/415 3 3.6

6 347, 356 380/415 3 5. 4

8 453, 498 380/415 3 7 .2

352, 419,

466, 491

620, 650,

700

790, 880,

940

380/415 3 6.8

380/415 3 10. 2

380/415 3 13.6

42

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 47

Table 6.4 60Hz Electrical Values—Standard Drycoolers with Integral Pump Controls, 1to4 Fans

No. of Fans: 1 2 3 4

Model #: 33, 69, 092, 109, 112 139, 174, 197, 225 260, 310, 350 352, 419, 466, 491

Pump

hp

Ph

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

208/230/60

0.7 5 1 1 2.4 14.3 20 — — — — — — — — —

0.7 5 3 7 7.9 15 10.5 11. 4 15 14.0 14.9 20 17.5 18.4 25

1.5 3 10.1 1 1. 8 15 1 3.6 15.3 20 17 .1 18.8 25 20.6 22.3 25

2.0 3 11.0 12. 9 2 0 14.5 16.4 20 18.0 19.9 25 21. 5 23.4 30

3.0 3 14.1 16.8 25 1 7. 6 20.3 30 21 .1 23.8 30 24.6 27.3 35

5.0 3 20.2 24.4 40 23.7 27.9 40 27.2 31 .4 45 30.7 34.9 50

7.5 * 3 27 .7 33.8 50 31.2 37.3 60 34.7 40.8 60

38.2

44.3 60

460/60

0.7 5 3 3.3 3. 7 15 5.0 5.4 15 6.7 7.1 15 8. 4 8.8 1 5

1.5 3 4.7 5. 5 15 6.4 7.2 15 8.1 8.9 15 9.8 10.6 15

2.0 3 5.1 6.0 15 6.8 7. 7 1 5 8.5 9.4 15 1 0.2 11.1 15

3.0 3 6.5 7.7 15 8.2 9.4 15 9.9 11 .1 15 11 .6 12.8 15

5.0 3 9.3 11.2 1 5 11.0 12. 9 20 12.7 14.6 20 14.4 1 6.3 20

O

P

D

7.5 3 12.7 15.5 25 14.4 1 7. 2 25 16.1 1 8.9 25 17 .8 20.6 30

575/60

0.7 5 3 2. 7 3.1 15 4.1 4.5 15 5.5 5.9 15 6.9 7. 3 15

1.5 3 3.8 4.4 15 5. 2 5.8 15 6.6 7.2 15 8.0 8.6 15

2.0 3 4.1 4.8 15 5.5 6.2 15 6.9 7. 6 1 5 8.3 9.0 15

3.0 3 5.3 6.3 1 5 6.7 7. 7 1 5 8.1 9.1 15 9.5 1 0.5 15

5.0 3 7.5 9.0 15 8.9 10.4 1 5 1 0.3 11.8 15 11.7 1 3.2 15

7.5 3 10. 4 12.7 20 11.8 14.1 20 13. 2 15.5 20 14.6 16.9 25

Values are calc ulated per UL 1995. Pump FLA values used are based on NEC tables f or motor horsepower. OPD values may be adjusted higher t han calculations to compensate for

* May r equire el ectrical component(s) with higher capacity in the drycooler. Consult factory representatives for as sis tance before ordering.

maximum anticipated application temperatures.

6 Electrical Connections

43

Page 48

Table 6.5 60Hz Electrical Values—Standard Drycoolers with Integral Pump Controls, 6–8Fans

No. of Fans: 6 8

Model #: 620, 650, 700 7 90, 880, 940

Pump hp Ph

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

208/230/60

0.7 5 1 — — — — — —

0.7 5 3 24.5 25. 4 30 31.5 32.4 40

1.5 3 27.6 29.3 35 34.6 36.3 40

2.0 3 28.5 30.4 35 35.5 37.4 45

3.0 3 31. 6 34.3 40 38.6 41.3 50

5.0 3 37.7 41.9 50 44.7 48.9 60

7.5 * 3 45.2 51 .3 70 52. 2 58.3 80

460/60

0.7 5 3 11.8 12. 2 15 15.2 15.6 20

1.5 3 13. 2 14.0 20 16.6 17. 4 20

2.0 3 13. 6 14.5 20 17.0 17.9 20

3.0 3 1 5.0 16.2 20 1 8.4 19.6 25

5.0 3 17.8 19.7 25 21.2 23. 1 30

O

P

D

7.5 3 21.2 24.0 30 24.6 27. 4 35

575/60

0.7 5 3 9.7 1 0.1 15 12. 5 12. 9 15

1.5 3 1 0. 8 11. 4 15 13.6 14.2 20

2.0 3 11. 1 11 .8 15 1 3.9 14.6 20

3.0 3 12. 3 13. 3 15 15. 1 16.1 20

5.0 3 14.5 16.0 20 17.3 18.8 20

7.5 3 1 7. 4 19.7 25 20. 2 22.5 30

Values are calc ulated per UL 1995. Pump FLA values used are based on NEC tables f or motor horsepower. OPD values may be adjusted higher t han calculations to compensate for

* May r equire el ectrical component(s) with higher capacity in the drycooler. Consult factory representatives for as sis tance before ordering.

maximum anticipated application temperatures.

44

Vertiv | Liebert ® Drycooler Installer/U ser Guide

Page 49

Table 6.6 Hz Electrical Values--Quiet-line Drycoolers with Integral Pump Controls

No. of Fans: 1 2 3 4 6 8

Model #: 40, 57, 60 80, 111, 121 158, 173, 178 205, 248 347, 356 453, 498

W

O

F

W

O

F

W

O

F

W

O

F

W

O

F

Pump

hp

PhFL

S

P

L

S

P

L

S

P

L

S

P

L

S

P

A

A

S

A

A

D

A

A

D

A

A

D

A

A

D

208/230/3/60

0.7 5 3 5.3 6.2 15 7. 1 8.0 15 8.9 9.8 15 10. 7 11 .6 15 14.3 15.2 20 1 7. 9 1 8.8 25

1.5 3 8.4 10.1 15 1 0.2 11.9 15 12.0 13.7 20 13.8 15.5 20 17.4 1 9.1 25 21 .0 22.7 25

2.0 3 9.3 1 1. 2 15 11 .1 13.0 20 12.9 14.8 20 14.7 16.6 20 18. 3 20.2 25 21.9 23. 8 30

3.0 3 12 .4 15.1 25 14.2 16.9 25 16.0 18.7 25 17.8 20.5 30 21.4 24.1 30 25.0 27.7 35

5.0 3 18. 5 22.7 35 20.3 24.5 40 22.1 26.3 40 23.9 28.1 40 27.5 31.7 45 31.1 35.3 50

7.5 * 3 26.0 32.1 50 27.8 33.9 50 29.6 35. 7 50 31.4 37.5 60 35.0 41. 1 60 38.6 44.7 60

10. 0* 3 32. 6 40. 3 70 34.4 42.1 70 36.2 43.9 7 0 38.0 45.7 70 41.6 49.3 80 45.2 52. 9 80

15* 3 48.0 59.6 100 49.8 61.4 100 51.6 63.2 100 53.4 65.0 110 57.0 68.6 110 60.6 72.2 110

460/3/60

0.7 5 3 2. 5 2.9 1 5 3.4 3.8 15 4.3 4.7 15 5.2 5.6 15 7 .0 7.4 15 8.8 9.2 15

W

L

S

A

A

O

P

D

1.5 3 3. 9 4.7 15 4.8 5. 6 1 5 5.7 6.5 15 6.6 7. 4 15 8.4 9.2 15 1 0. 2 11.0 15

2.0 3 4.3 5. 2 15 5.2 6.1 15 6.1 7.0 15 7.0 7.9 15 8.8 9.7 15 10.6 11.5 1 5

3.0 3 5.7 6.9 15 6.6 7. 8 15 7.5 8.7 15 8.4 9.6 15 10.2 11.4 1 5 12.0 13. 2 15

5.0 3 8.5 1 0.4 15 9.4 1 1. 3 15 1 0.3 12. 2 15 11.2 13.1 20 13.0 14.9 20 14.8 16.7 20

7.5 3 11.9 14.7 25 12. 8 1 5.6 25 13.7 1 6.5 25 14.6 1 7. 4 25 16.4 19.2 30 18.2 21. 0 30

10. 0 3 1 4.9 1 8.4 30 15.8 19.3 30 16.7 20.2 30 1 7. 6 21.1 35 19.4 22.9 35 21. 2 24.7 35

15* 3 21.9 27.2 45 22. 8 28.1 45 23.7 29.0 45 24.6 29.9 50 26.4 31.7 50 28.2 33. 5 50

575/3/60

0.7 5 3 2. 0 2.3 15 2.7 3.0 15 3.4 3.7 15 4.1 4.4 15 5. 5 5. 8 15 6.9 7. 2 1 5

1.5 3 3. 1 3.7 15 3. 8 4.4 15 4.5 5.1 1 5 5.2 5. 8 15 6.6 7.2 15 8.0 8.6 15

2.0 3 3. 4 4.1 1 5 4.1 4.8 15 4.8 5.5 15 5.5 6.2 1 5 6.9 7.6 15 8.3 9.0 15

3.0 3 4.6 5.6 15 5.3 6.3 1 5 6.0 7.0 15 6.7 7. 7 15 8.1 9.1 15 9.5 1 0. 5 15

5.0 3 6.8 8.3 15 7.5 9.0 15 8.2 9.7 1 5 8.9 10. 4 15 10.3 11.8 15 1 1. 7 13. 2 15

7.5 3 9.7 12.0 20 1 0.4 12.7 2 0 11.1 13. 4 20 1 1. 8 1 4.1 20 13. 2 15.5 20 1 4.6 1 6.9 25

10. 0 3 1 1. 7 14.5 25 12.4 15.2 25 13.1 15.9 25 13.8 16.6 2 5 15.2 18.0 25 16.6 19.4 30

15 3 17 .7 22.0 35 18.4 22.7 35 19.1 23.4 40 19.8 24.1 40 21.2 25. 5 40 22. 6 26.9 40

Values are calculated per UL 1995. Pump FLA values used are based on N EC tables for motor horsepower. OPD values may be adjusted higher than

calculations to compensate f or maximum a nticipated application temperatures.

* May require electrical component(s)with higher capacity in the drycooler. Consult fa ctory representatives for assistance before ordering.

6 Electrical Connections

45

Page 50

Table 6.7 60-Hz Pump FLA Values

Pump hp Phase

3/4 3 3.5 1.6 1.3

1.5 3 6.6 3. 0 2.4

2 3 7 .5 3.4 2.7

3 3 10.6 4.8 3.9

5 3 16.7 7. 6 6.1

7.5 3 24.2 11.0 9.0

10 3 30.8 14.0 11.0

15 3 46.2 21 .0 17. 0

Values based on NEC handbook values for three-phase motors.

For larger pumphors epower, please c onsult you local sales representative.

Input Power, Volts

208/230 460 575

6.2 Low Voltage Control Wiring

A control interlock between the drycooler and the indoor cooling units is required. Field-supplied copper wire is required for

connection between like-numbered terminals 70 and 71 on both units for remote On/Off control of the drycooler,

synchronized with the indoor unit. Wiring must be sized and selected for insulation class per NEC and other local codes. See

Table 6.8 below, Table 6.10 on the facing page, Table 6.10 on the facing page, and Table 6.11 on page48 for

recommended wire sizing for control wiring (24 VAC), runs up to 150 ft. (45.7m).

Contact the factory for assistance with longer wiring runs.

Refer to the drawings contained in Table 6.1 on page40 as well as the indoor unit manual for location of terminals on

drycoolers and indoor units. Refer to the electrical schematics supplied with the drycooler and indoor units for proper wiring

of terminals 70 and 71.