Page 1

SYSTEM OVERVIEW

Description:

Home

The Power Distribution Center…

• List 20, 25 (One Row Distribution Cabinet) is rated…

• List 27 (One Row Distribution Cabinet) is rated…

• List 21 (Two Row Distribution Cabinet) is rated…

• List 26 (Two Row Distribution Cabinet) is rated…

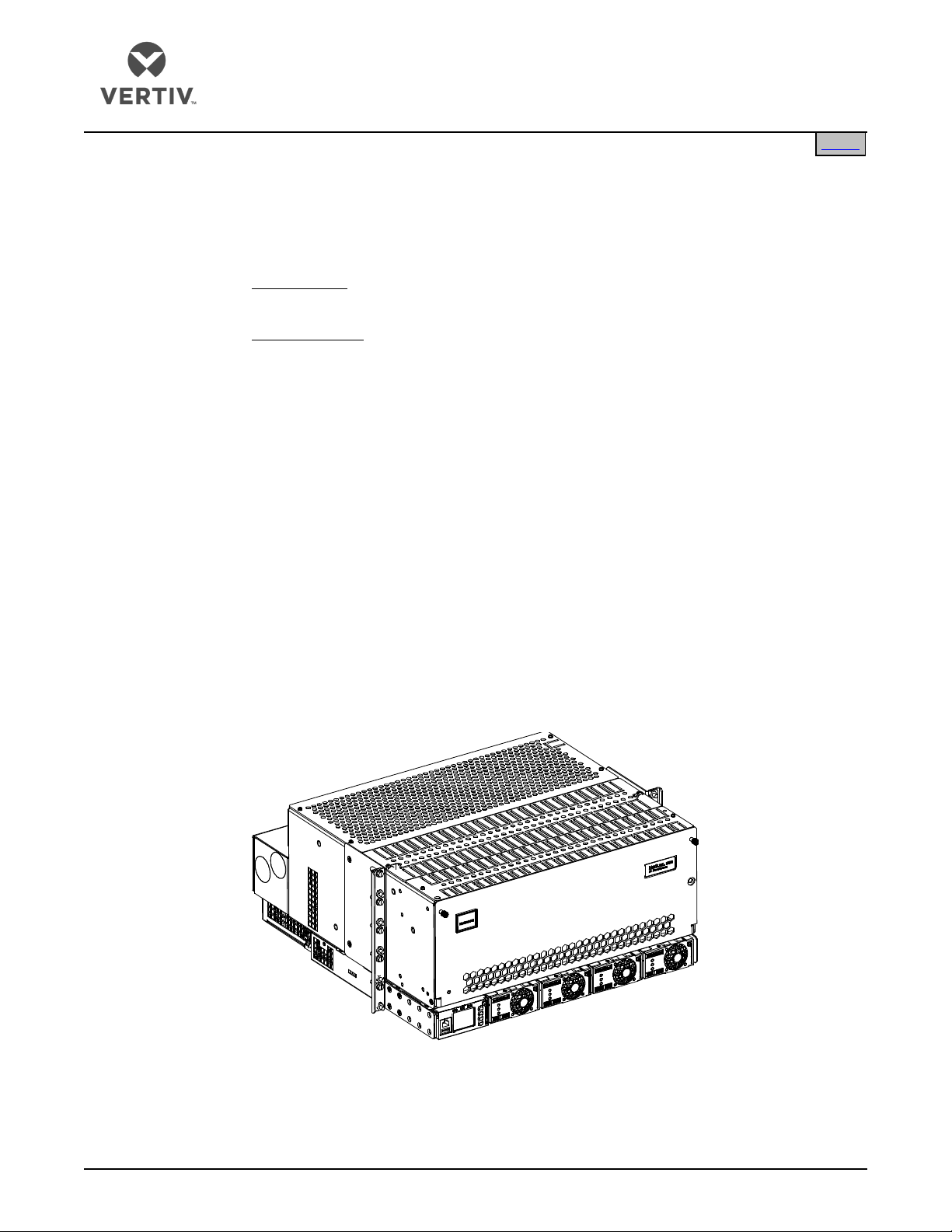

The NetSure™ 5100 DC Power System is an integrated power system containing rectifiers (-48 VDC

output), optional solar converters (-48 VDC output), optional converters (+24 VDC output), intelligent

control, metering, monitoring, and distribution. This power system is available in configurations for 19” and

23” rack mounting.

This power system is designed to power a load while charging a positive grounded battery. This power

system is capable of operating in a batteryless installation or off battery for maintenance purposes. The

power system is designed for operation with the positive output grounded.

Spec. No. 582137100 (Model NetSure™ 5100)

-48 VDC; 400 A at 40 °C.

-48 VDC; 300 A at 65 °C.

Charge Ratings:

-48 VDC; 600 A and +24 VDC; 63 A at 40 °C.

-48 VDC; 525 A and +24 VDC; 50 A at 65 °C.

Discharge Ratings:

-48 VDC; 771 A at 40 °C.

-48 VDC; 600 A at 65 °C.

-48 VDC; 600 A (400 A maximum per row) at 40 °C.

-48 VDC; 400 A (300 A maximum per row) at 65 °C.

-48 VDC; 600 A (400 A maximum per row) and +24 VDC; 400 A at 40 °C.

-48 VDC; 400 A (300 A maximum per row) and +24 VDC; 300 A at 65°C.

SAG582137100

System Application Guide

Revision S, September 12, 2018

Page 1 of 146

Page 2

SAG582137100 System Application Guide

Distribution Cabinet

Controller

Module Mounting Assembly

Rectifier Modules

Optional Solar Converter Modules

Optional -48 VDC to +24 VDC Converter Modules

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

This system consists of the following components.

•

The system always includes a distribution cabinet, which provides DC distribution through fuses

and/or circuit breakers. The distribution cabinet is factory mounted in the relay rack specified when

ordered. Different sizes of distribution cabinets are available to accept from one (1) to two (2)

distribution panels. A variety of distribution panels are available that provide load distribution, battery

distribution, and dual voltage load distribution for use with -48 VDC to +24 VDC converters. These

distribution panels are configured to accept bullet nose type circuit breakers and TPS/TLS

fuseholders. The distribution cabinet may be equipped with low voltage load disconnect (LVLD)

and/or low voltage battery disconnect (LVBD) (depending on available configuration options).

•

NCU (NetSure Control Unit) Controller: The NCU controller provides power system control (including

optional low voltage battery disconnect (LVBD) and low voltage load disconnect (LVLD) control),

rectifier module control (including a charge control function), solar converter module control, -48 VDC

to +24 VDC converter module control, metering functions, monitoring functions, local/remote alarm

functions, and connections for binary inputs and programmable relay outputs. The controller also

supports rectifier temperature compensation if the system is equipped with a temperature probe(s).

Temperature probe(s) may also be designated to monitor ambient temperature and/or battery

temperature. The controller also provides data acquisition, system alarm management, and advanced

battery and energy management. The controller contains a color TFT display and keypad for local

access. The controller provides an Ethernet port and comes with comprehensive webpages for

remote access. The controller has SNMP V3 capability for remote system management. The

controller supports software upgrade via its USB port. Refer to the NCU Controller Instructions

(UM1M830BNA) for more information.

•

The system contains one (1) to five (5) module mounting assemblies (depending on system

configuration, see “List Descriptions” starting on page 14), which may house rectifier modules, optional

solar converter modules, optional -48 VDC to +24 VDC converter modules, and a controller

(depending on configuration, see “List Descriptions” in Power Data Sheet PD588705300). Refer to

PD588705300 for additional information.

•

The system contains rectifier modules, which provide load power, battery float current, and battery

recharge current during normal operating conditions. Refer to the Rectifier Instructions

(UM1R482000E3) for more information.

•

The system may contain solar converter modules (depending on configuration, see “List Descriptions”

starting on page 14), which provide load power, battery float current, and battery recharge current

during solar conditions. Refer to the Solar Converter Instructions (UM1S482000E3) for more

information.

•

Where +24 VDC load power is also required, converter modules are available (depending on

configuration, see “List Descriptions” starting on page 14). These converters operate from the

main -48 VDC system bus to provide +24 VDC load power. Refer to the Converter Instructions

(UM1C48241500) for more information.

Page 2 of 146

Page 3

System Application Guide SAG582137100

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

General Specifications

See detailed specifications starting on page 127.

Family: NetSure™

System Spec. No.: 582137100

System Model: NetSure™ 5100

System Rectifier AC Input Voltage: Nominal 120 VAC / 208 VAC / 240 VAC, single phase, 3-wire, 50 Hz /

60 Hz, with an operating range of 100 VAC to 250 VAC. Acceptable

input frequency range is 45 Hz to 65 Hz.

Permitted Variation: 85 VAC to 300 VAC.

System Solar Converter DC Input Voltage: 140 VDC to 200 VDC / 200 VDC to 400 VDC

System DC Output Capacity:

System: 600 A @ -48 VDC and 400 A @ +24 VDC, maximum

Distribution Panel: 400 A, maximum [for all cabinet distribution List options - except

when distribution panel List DF is used in a List 27 distribution

cabinet. A List DF distribution panel used in a List 27 distribution

cabinet allows a maximum of 600 A (charge) and 771 A (discharge).]

588705300 Assembly Ratings: See PD588705300.

1R482000E3 Rectifier Rating: See UM1R482000E3.

1S482000E3 Solar Converter Rating: See UM1S482000E3.

1C48241500 Converter Rating: See UM1C48241500.

System Agency Approval: UL 1801 Listed (“c UL”), NEBS

Framework Type: Rack Mounted in a Relay Rack or Cabinet

Mounting Width: See “Mechanical Specifications” starting on page 129.

Mounting Depth: See “Mechanical Specifications” starting on page 129.

Access: Front for Operation

Front and Rear for Installation and Maintenance

Supplemental Bay(s) Available: None

Control: Microprocessor

Color: Bay and Module Faceplates: Textured Gray

Module Mounting Assembly and Module Bodies: Bright Zinc Plating

Environment: -40 °C to +65 °C (-40 °F to +149 °F)

Page 3 of 146

Page 4

SAG582137100 System Application Guide

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

TABLE OF CONTENTS

SYSTEM OVERVIEW ............................................................................................................................................................................................................. 1

MAIN COMPONENTS ILLUSTRATIONS .......................................................................................................................................................................... 8

Typical System with a 19” 1-Row Distribution Cabinet (List 20) ........................................................................................................................ 8

Typical System with a 19” 2-Row Distribution Cabinet (List 21) ........................................................................................................................9

Typical System with a 23” 1-Row Distribution Cabinet (List 25) ...................................................................................................................... 10

Typical System with a 23” 2-Row Distribution Cabinet (List 26) ...................................................................................................................... 11

Typical System with a 23” 1-Row Distribution Cabinet (List 27) ...................................................................................................................... 12

Typical Configured System with a 23” 1-Row or 2-Row Distribution Cabinet and Equipped with Solar Converter and

Hybrid Connection Cabinets ..................................................................................................................................................................................... 13

LIST DESCRIPTIONS .......................................................................................................................................................................................................... 14

List Numbers .................................................................................................................................................................................................................. 14

List 20: 1-Row Distribution Cabinet for 19-Inch Relay Rack Mounting......................................................................................................................... 14

List 21: 2-Row Distribution Cabinet for 19-Inch Relay Rack Mounting ......................................................................................................................... 15

List 25: 1-Row Distribution Cabinet for 23-Inch Relay Rack Mounting ........................................................................................................................ 16

List 26: 2-Row Distribution Cabinet for 23-Inch Relay Rack Mounting........................................................................................................................ 17

List 27: 1-Row Distribution Cabinet for 23-Inch Relay Rack Mounting ......................................................................................................................... 18

List 30: Shelf Rail Mounting Kits, Insulation Sheets, Output Busbar Kits, and Rear Cover Kits ................................................................. 20

List 33: Field Expansion Module Mounting Assembly (23”) Configured with Rectifier and -48 VDC to +24 VDC

Converter Module Mounting Positions and Molex Input Connectors ............................................................................................................................ 21

List 34: Field Expansion Module Mounting Assembly (23”) Configured with Rectifier and/or Solar Converter

Module Mounting Positions and Molex Input Connectors ................................................................................................................................................... 22

List 36: Field Expansion Module Mounting Assembly (19”) Configured with Rectifier and/or Solar Converter

Module Mounting Positions and Molex Input Connectors ................................................................................................................................................... 23

List 40: 19” Rectifier AC Input / Solar Converter DC Input Panel, Each Input Feeds One Module ........................................................... 24

List 45: 23” Rectifier AC Input / Solar Converter DC Input Panel, Each Input Feeds One Module ........................................................... 25

List 46: Rectifier AC Input Panel for 23” System, Each Input Feeds Two Rectifier Modules ........................................................................ 26

List 60: 23” Hybrid Connection Cabinet ......................................................................................................................................................................................... 27

List 61: 23” Solar Connection Cabinet .............................................................................................................................................................................................. 29

List 70: Optional EIB (Controller Extended Interface Board), P/N MA455U41....................................................................................................... 30

List 93: Pre-Cabled Battery Tray for 23” Relay Rack .............................................................................................................................................................. 30

List 94: Pre-Cabled Battery Tray for 19” Relay Rack .............................................................................................................................................................. 36

Single Voltage Load Distribution Panel ................................................................................................................................................................. 40

List AA: -48 VDC Load Distribution Panel (24) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions .......................... 40

List AB: -48 VDC Load Distribution Panel (26) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ............................ 41

List AN: -48 VDC Load Distribution Panel (19) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ............................ 42

List AO: -48 VDC Load Distribution Panel (21) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ............................ 43

List KG: Distribution Panel with (20) GMT Load Fuses ........................................................................................................................................................ 44

Single Voltage Plus Battery Disconnect Distribution Panel ............................................................................................................................. 45

List BA: -48 VDC Load Distribution Plus -48 VDC Battery Disconnect Panel (18) -48 VDC Bullet/TPS/TLS Circuit

Breaker/Fuse Load Positions (6) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Battery Positions ...................................................... 45

List BB: -48 VDC Load Distribution Plus -48 VDC Battery Disconnect Panel (6) -48 VDC Bullet/TPS/TLS Circuit

Breaker/Fuse Load Positions (20) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Battery Positions ................................................... 46

List BC: -48 VDC Load Distribution Plus -48 VDC Battery Disconnect Panel (16) -48 VDC Bullet/TPS/TLS Circuit

Breaker/Fuse Load Positions (8) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Battery Positions ...................................................... 47

List BD: -48 VDC Load Distribution Plus -48 VDC Battery Disconnect Panel (16) -48 VDC Bullet/TPS/TLS Circuit

Breaker/Fuse Load Positions (10) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Battery Positions .................................................... 48

List BN: -48 VDC Load Distribution Plus -48 VDC Battery Disconnect Panel (14) -48 VDC Bullet/TPS/TLS Circuit

Breaker/Fuse Load Positions (5) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Battery Positions ...................................................... 49

List BO: -48 VDC Load Distribution Plus -48 VDC Battery Disconnect Panel (12) -48 VDC Bullet/TPS/TLS Circuit

Breaker/Fuse Load Positions (9) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Battery Positions ...................................................... 50

Dual Voltage Load Distribution Panel ..................................................................................................................................................................... 51

List DA: -48 VDC / +24 VDC Load Distribution Panel (21) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load

Positions (4) +24 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ........................................................................................................ 51

List DB: -48 VDC / +24 VDC Load Distribution Panel (17) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load

Positions (8) +24 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ....................................................................................................... 52

List DC: -48 VDC / +24 VDC Load Distribution Panel (13) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load

Positions (12) +24 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ...................................................................................................... 53

Page 4 of 146

Page 5

System Application Guide SAG582137100

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

List DD: -48 VDC / +24 VDC Load Distribution Panel (9) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load

Positions (16) +24 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions ..................................................................................................... 54

List DE: -48 VDC / +24 VDC Load Distribution Panel (5) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load

Positions (20) +24 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load Positions .................................................................................................... 55

List DF: -48 VDC / +24 VDC Load Distribution Panel (26) -48 VDC Bullet/TPS/TLS Circuit Breaker/Fuse Load

Positions (4) Positions Can Be Converted from -48 VDC to +24 VDC Positions in the Field ....................................................................... 56

Low Voltage Disconnect Options ............................................................................................................................................................................ 57

List LB: Low Voltage Battery Disconnect (LVBD) .................................................................................................................................................................... 57

List LL: Low Voltage Load Disconnect (LVLD) .......................................................................................................................................................................... 57

ACCESSORY DESCRIPTIONS ......................................................................................................................................................................................... 58

Relay Racks ................................................................................................................................................................................................................... 58

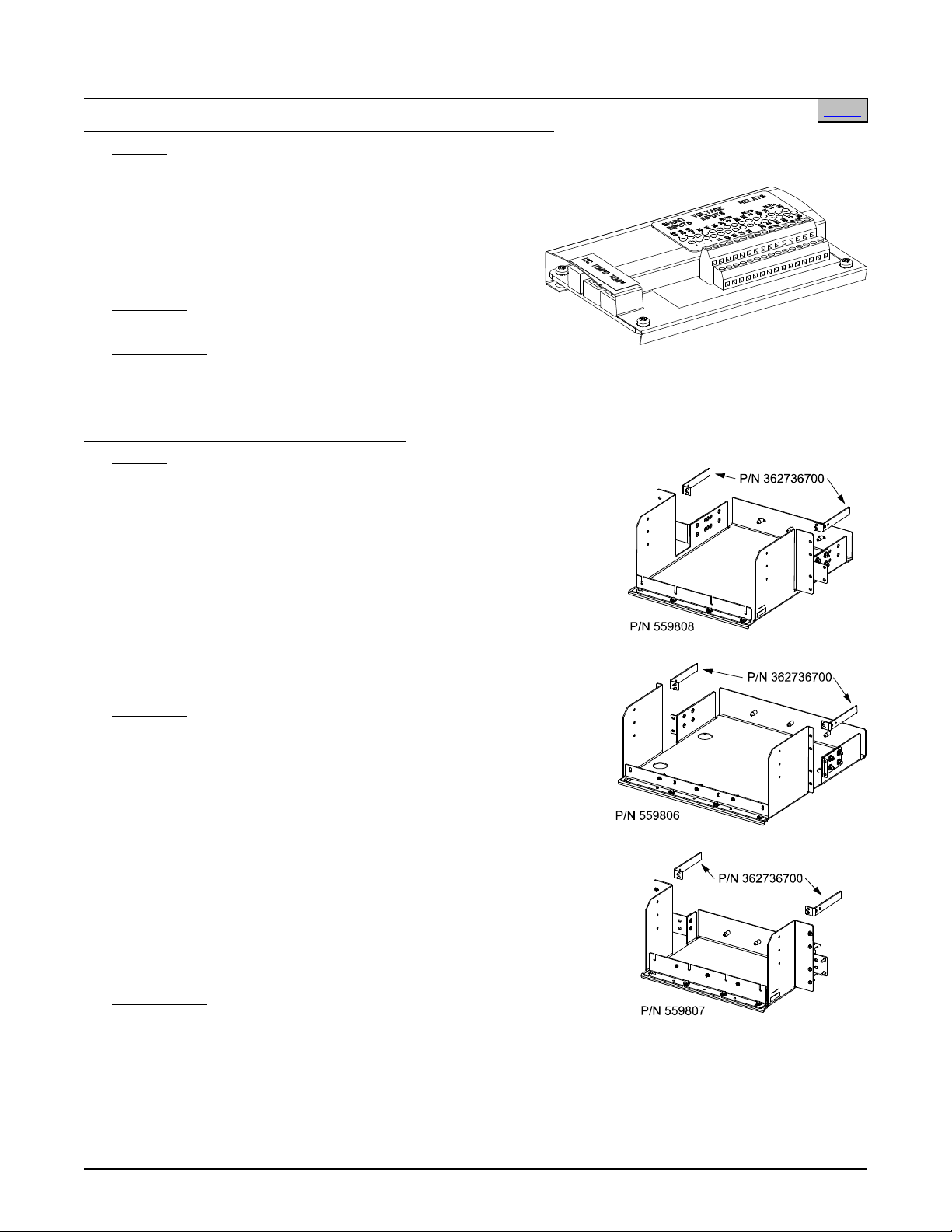

Flush Mounting Kit ...................................................................................................................................................................................................... 59

Data Cabinet 4-Post Kit, P/N 559801................................................................................................................................................................................................. 59

Special Mounting Bracket Kit ................................................................................................................................................................................... 59

P/N 564300 ........................................................................................................................................................................................................................................................ 59

19” to 23” Wide Relay Rack Mounting Bracket Kit .............................................................................................................................................. 59

P/N 553630 ......................................................................................................................................................................................................................................................... 59

Controller ....................................................................................................................................................................................................................... 60

NCU (NetSure Control Unit) Controller, P/N 1M830BNA..................................................................................................................................................... 60

Optional NCU Controller 2nd Ethernet Port Kit, P/N 559741 ............................................................................................................................ 61

Optional RS485 Modbus Interface Cable, P/N 564643 ...................................................................................................................................... 61

Optional Temperature Probes .................................................................................................................................................................................. 62

Optional SM-Temp Temperature Concentrator, P/N 547490 ......................................................................................................................... 63

Alarm and Digital Input Cables ................................................................................................................................................................................ 63

Critical Alarm Indicator Kit, P/N 555877 ................................................................................................................................................................ 64

Rectifier Module ........................................................................................................................................................................................................... 64

Rectifier Module, P/N 1R482000E3 ..................................................................................................................................................................................................... 64

Solar Converter Module ............................................................................................................................................................................................. 64

Solar Converter Module, P/N 1S482000E3 .................................................................................................................................................................................... 64

Converter Module ........................................................................................................................................................................................................ 64

-48 VDC to +24 VDC Converter Module, P/N 1C48241500 ................................................................................................................................................. 64

Module Mounting Position Blank Cover Panel ..................................................................................................................................................... 65

Module Mounting Position Blank Cover Panel, P/N SXA 110 0035/1............................................................................................................................. 65

Optional Transient Voltage Surge Suppressor (TVSS) Device, P/N 565281 ............................................................................................... 65

Distribution Devices .................................................................................................................................................................................................... 66

Bullet Nose Type Circuit Breakers and Bullet Nose Type Fuseholders equipped with TPS/TLS Fuses ................................................ 66

Bullet Nose Bypass Busbar, P/N 535015 .......................................................................................................................................................................................... 68

Optional Bullet Nose Type 6-Position GMT Distribution Fuse Block, P/N 559737 ............................................................................................... 69

Optional Bullet Nose Type 6-Position GMT Distribution Fuse Block, P/N 549017 ............................................................................................... 70

GMT Type Load Distribution Fuses ..................................................................................................................................................................................................... 71

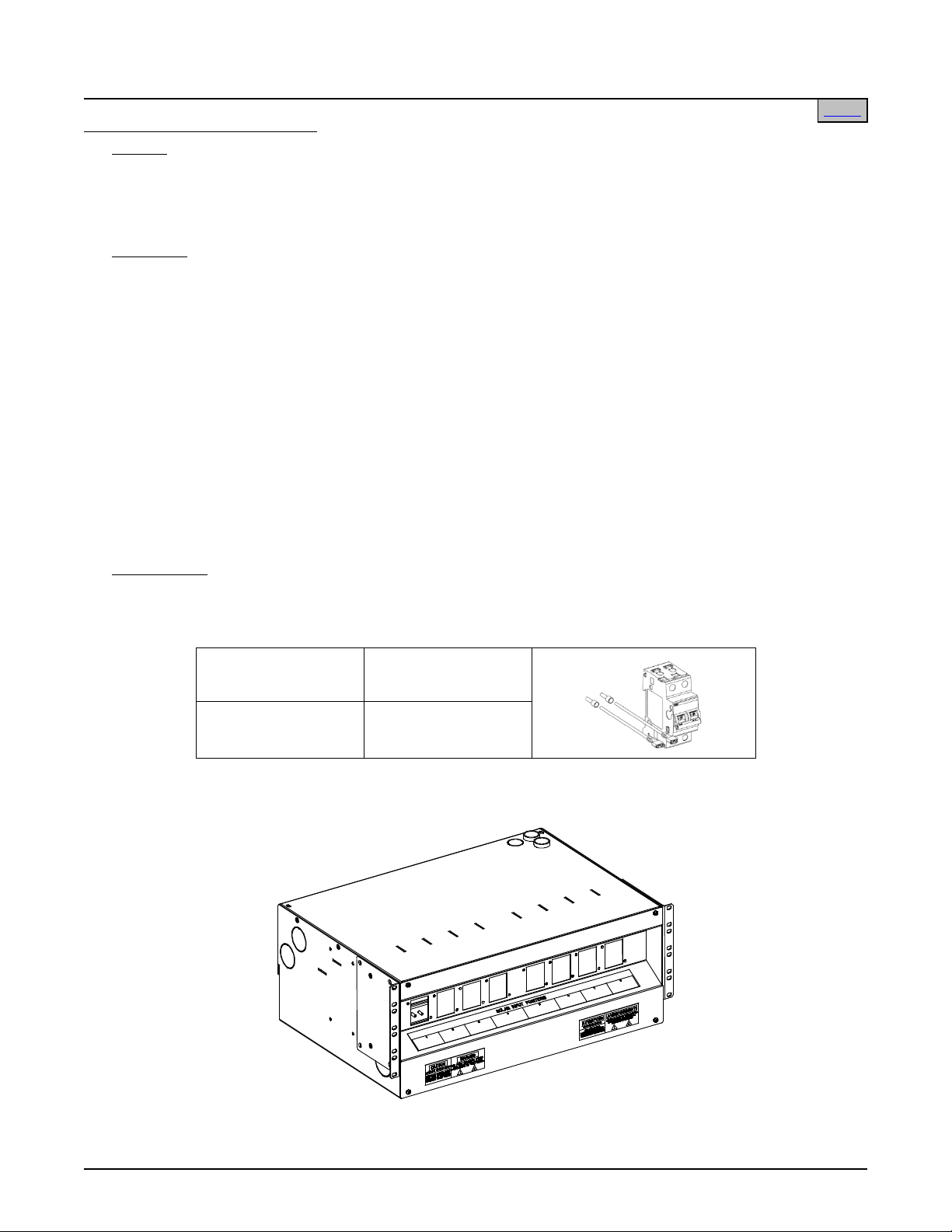

GJ/218 Type Circuit Breakers for List 60 ......................................................................................................................................................................................... 71

MCB Circuit Breakers for List 61 ............................................................................................................................................................................................................ 71

Standard Crimp Lugs, Special Application Crimp Lugs, and Busbar Adapter Kits and Hardware Kits ................................................ 72

Standard Crimp Lugs ................................................................................................................................................................................................................................... 72

Special Application Crimp Lug / Strap Combination, Busbar Lug Adapters, and Hardware Kits ............................................................... 73

Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords .................................................. 76

Rectifier AC Input / Solar Converter DC Input Cable Assembly, P/N 535232.......................................................................................................... 76

Rectifier AC Input / Solar Converter DC Input Cable Assembly, P/N 547898 ......................................................................................................... 76

Rectifier AC Input / Solar Converter DC Input Cable Assembly, P/N 553202 ......................................................................................................... 76

Rectifier AC Input Line Cord, P/N 540946 ..................................................................................................................................................................................... 77

Rectifier AC Input Line Cord, P/N 545252 ...................................................................................................................................................................................... 77

Rectifier AC Input Line Cord, P/N 545616 ...................................................................................................................................................................................... 77

Input Cord Bracket Kit (P/N 562050) .................................................................................................................................................................... 78

Input Cord Bracket Kit (P/N 563456) ..................................................................................................................................................................... 78

User Replaceable Alarm, Reference, and Control Fuses ................................................................................................................................... 79

User Replaceable Components ................................................................................................................................................................................ 79

RECOMMENDED WIRE SIZES, BRANCH CIRCUIT PROTECTION, CRIMP LUGS, AND WIRING ILLUSTRATIONS.................................. 80

Relay Rack / Cabinet Frame Grounding Requirements ..................................................................................................................................... 80

Central Office Grounding Connection .................................................................................................................................................................... 80

Page 5 of 146

Page 6

SAG582137100 System Application Guide

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

Rectifier AC Input Connections ................................................................................................................................................................................ 81

To 19” Rectifier AC Input / Solar Converter DC Input Panel (List 40) ........................................................................................................................... 81

To 23” Rectifier AC Input / Solar Converter DC Input Panel (List 45).......................................................................................................................... 83

To 23” Rectifier AC Input Panel (List 46) ........................................................................................................................................................................................ 85

To Individual Module Mounting Assemblies Equipped with Molex Connectors and Provided with Rectifier AC

Input Cable Assemblies or Rectifier AC Input Line Cords .................................................................................................................................................... 87

Solar Converter DC Input Connections ................................................................................................................................................................. 88

To 19” Rectifier AC Input / Solar Converter DC Input Panel (List 40) .......................................................................................................................... 88

To 23” Rectifier AC Input / Solar Converter DC Input Panel (List 45)......................................................................................................................... 90

To Solar Connection Cabinet (List 61) .............................................................................................................................................................................................. 92

External Alarm, Reference, Monitoring, and Control Connections ................................................................................................................. 94

General .................................................................................................................................................................................................................................................................. 94

582137100 List 20, List 25 Distribution Cabinet .......................................................................................................................................................................... 94

582137100 List 21, List 26 Distribution Cabinet ........................................................................................................................................................................... 94

582137100 List 27 Distribution Cabinet ............................................................................................................................................................................................ 94

IB2 (Controller Interface Board) ............................................................................................................................................................................................................ 94

Optional EIB (Controller Extended Interface Board)................................................................................................................................................................ 94

System Interface Board .............................................................................................................................................................................................................................. 94

NCU Controller Ethernet Connection (if required) ............................................................................................................................................ 101

To NCU Front Panel .....................................................................................................................................................................................................................................101

To IB4 Board (if furnished) ......................................................................................................................................................................................................................101

Load Distribution Connections .............................................................................................................................................................................. 102

General ................................................................................................................................................................................................................................................................ 102

582137100 List 20, List 25 Distribution Cabinet ........................................................................................................................................................................ 102

582137100 List 21, List 26 Distribution Cabinet ......................................................................................................................................................................... 102

582137100 List 27 Distribution Cabinet .......................................................................................................................................................................................... 102

GMT Fuse Block............................................................................................................................................................................................................................................. 102

Load Distribution Wiring (List KG) ........................................................................................................................................................................ 102

Optional Transient Voltage Surge Suppressor (TVSS) Device Ground Connection ................................................................................ 113

DC Breaker Wiring to Hybrid Connection Cabinet (List 60) ........................................................................................................................... 117

Input Battery Connections ....................................................................................................................................................................................... 119

582137100 List 20, List 25 Distribution Cabinet ......................................................................................................................................................................... 119

582137100 List 21, List 26 Distribution Cabinet ......................................................................................................................................................................... 122

582137100 List 27 Distribution Cabinet .......................................................................................................................................................................................... 125

Remote Distribution Unit (DU) Connections ....................................................................................................................................................... 125

582137100 List 27 Distribution Cabinet .......................................................................................................................................................................................... 125

SPECIFICATIONS ............................................................................................................................................................................................................... 127

1. System ..................................................................................................................................................................................................................... 127

1.1 DC Output Ratings ............................................................................................................................................................................................................................. 127

1.2 Rectifier AC Input Ratings ............................................................................................................................................................................................................. 127

1.3 Solar Converter DC Input Ratings ............................................................................................................................................................................................ 127

1.4 Environmental Ratings..................................................................................................................................................................................................................... 127

1.5 Compliance Information .................................................................................................................................................................................................................. 127

1.6 IB2 and EIB (Controller Interface Board) Ratings ........................................................................................................................................................... 128

2. Module Mounting Assembly .............................................................................................................................................................................. 128

3. Rectifier ................................................................................................................................................................................................................... 128

4. Solar Converter ..................................................................................................................................................................................................... 128

5. -48 VDC to +24 VDC Converter ....................................................................................................................................................................... 128

6. Controller ................................................................................................................................................................................................................ 128

MECHANICAL SPECIFICATIONS ..................................................................................................................................................................................129

Overall Dimensions .....................................................................................................................................................................................................129

List 20 Distribution Cabinet ................................................................................................................................................................................................................... 129

List 21 Distribution Cabinet .................................................................................................................................................................................................................... 130

List 25 Distribution Cabinet .................................................................................................................................................................................................................... 131

List 26 Distribution Cabinet ................................................................................................................................................................................................................... 132

List 27 Distribution Cabinet ................................................................................................................................................................................................................... 133

List 40 Rectifier AC Input / Solar Converter DC Input Panel ........................................................................................................................................... 134

List 45 Rectifier AC Input / Solar Converter DC Input Panel............................................................................................................................................ 135

List 46 Rectifier AC Input Panel .......................................................................................................................................................................................................... 136

Page 6 of 146

Page 7

System Application Guide SAG582137100

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

List 60 Hybrid Connection Cabinet .................................................................................................................................................................................................. 137

List 61 Solar Connection Cabinet ....................................................................................................................................................................................................... 138

List KG GMT Fuse Distribution Panel .............................................................................................................................................................................................. 139

List 93 (23” Battery Tray) ....................................................................................................................................................................................................................... 140

List 94 (19” Battery Tray) ......................................................................................................................................................................................................................... 141

Weights......................................................................................................................................................................................................................... 142

BATTERY MANUFACTURER INFORMATION........................................................................................................................................................... 144

RELATED DOCUMENTATION ...................................................................................................................................................................................... 145

Page 7 of 146

Page 8

SAG582137100 System Application Guide

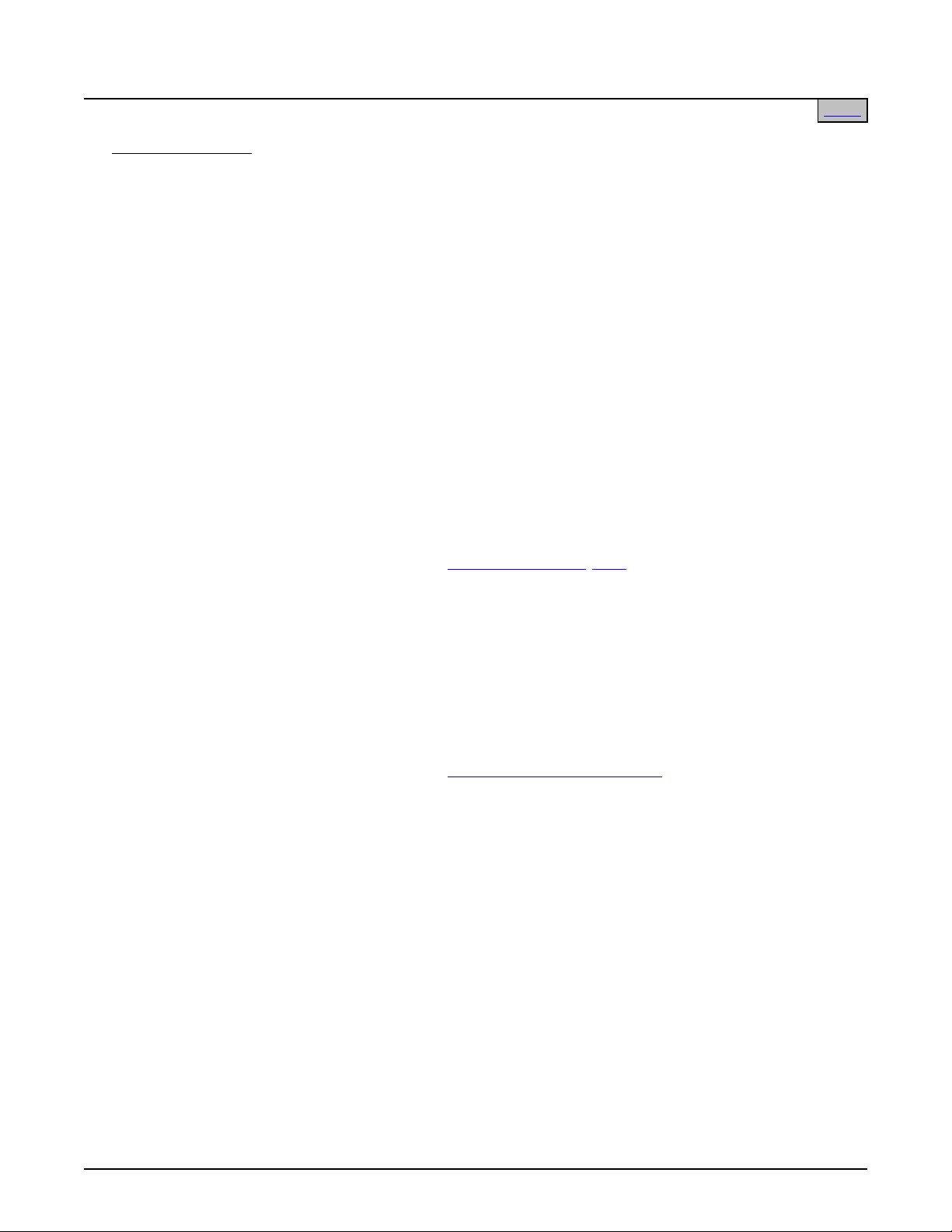

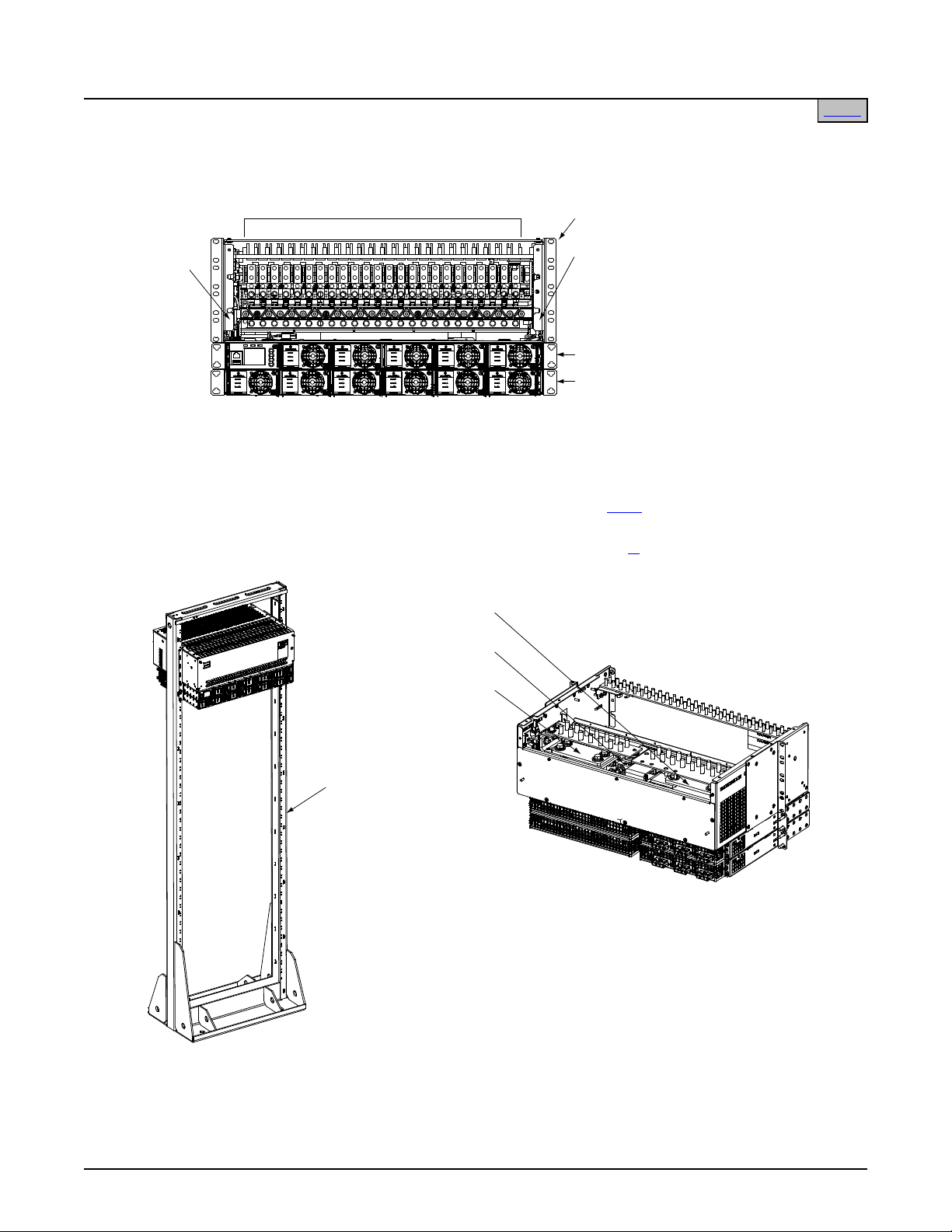

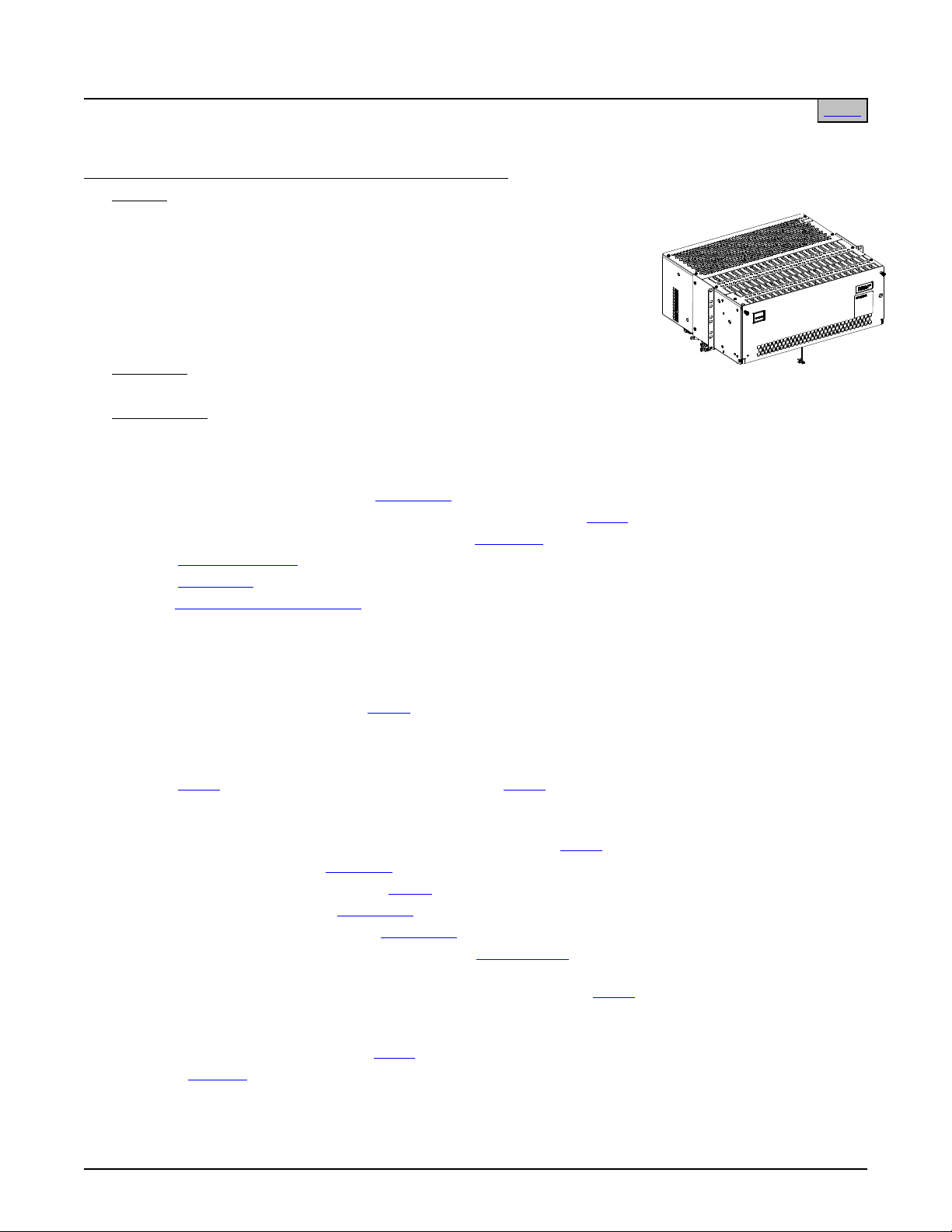

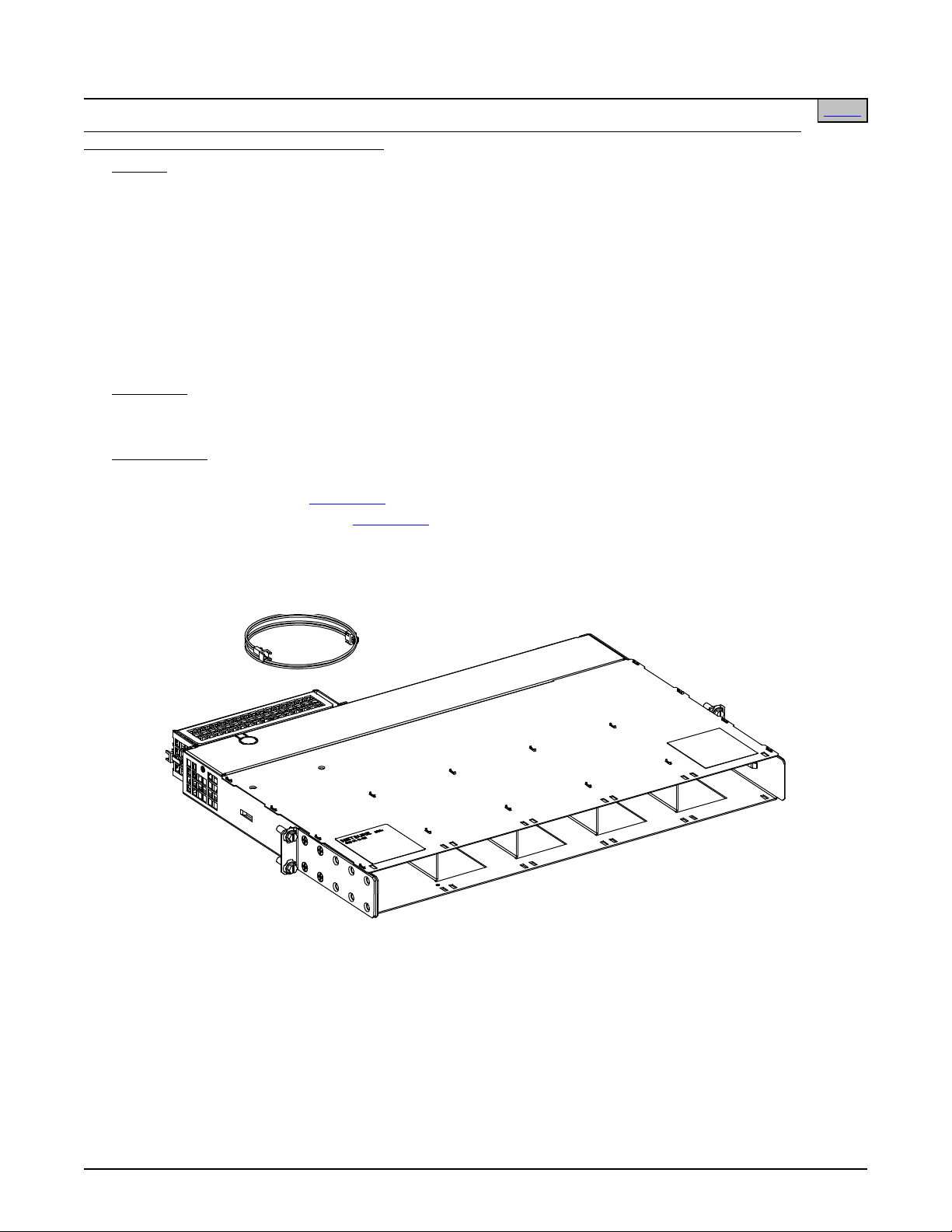

Rear (components removed

in illustration for clarity only)

Optional LVLD

Contactor Location

Optional LVBD

Contactor Location

800 A / 25 mV Battery

Shunt Location

Various relay racks are available.

Load return busbar can

be rotated 90 degrees.

Front

IB2 Controller

Interface Board

(mounted on

side panel)

Optional EIB Controller

Extended Interface

Board (mounted on

side panel)

19-inch, 1-Row

Distribution Cabinet

See distribution panel List descriptions. Distribution panel may be

equipped with one or more of the following distribution positions.

-48 VDC Primary Voltage Load Positions

-48 VDC Battery Disconnect Positions

Optional IB4 Board

(second Ethernet port)

Mounted on Floor of

Distribution Cabinet

Up to Four (4) Additional

Module Mounting Assemblies

588705300 List 41, 44, 45:

Rectifier, Solar Converter Mounting Positions

(See PD588705300)

One (1) Module Mounting Assembly w/ Controller

588705300 List 31, 34, 35: Controller, Rectifier,

Solar Converter Mounting Positions

(See PD588705300)

List 20

Rectifier Module:

1R482000E3

Solar Converter Module

1S482000E3

List 30: Module Mounting Assembly

Interface

List 36

Field Expansion

List LL

(LVLD)

List LB

(LVBD)

Single Voltage Distribution Panels

Single Voltage Plus

Distribution Panels

NCU: 1M830BNA

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

MAIN COMPONENTS ILLUSTRATIONS

Typical System with a 19” 1-Row Distribution Cabinet (List 20)

Battery Disconnect

(factory)

: Module Mounting Assembly

List 70

Page 8 of 146

Page 9

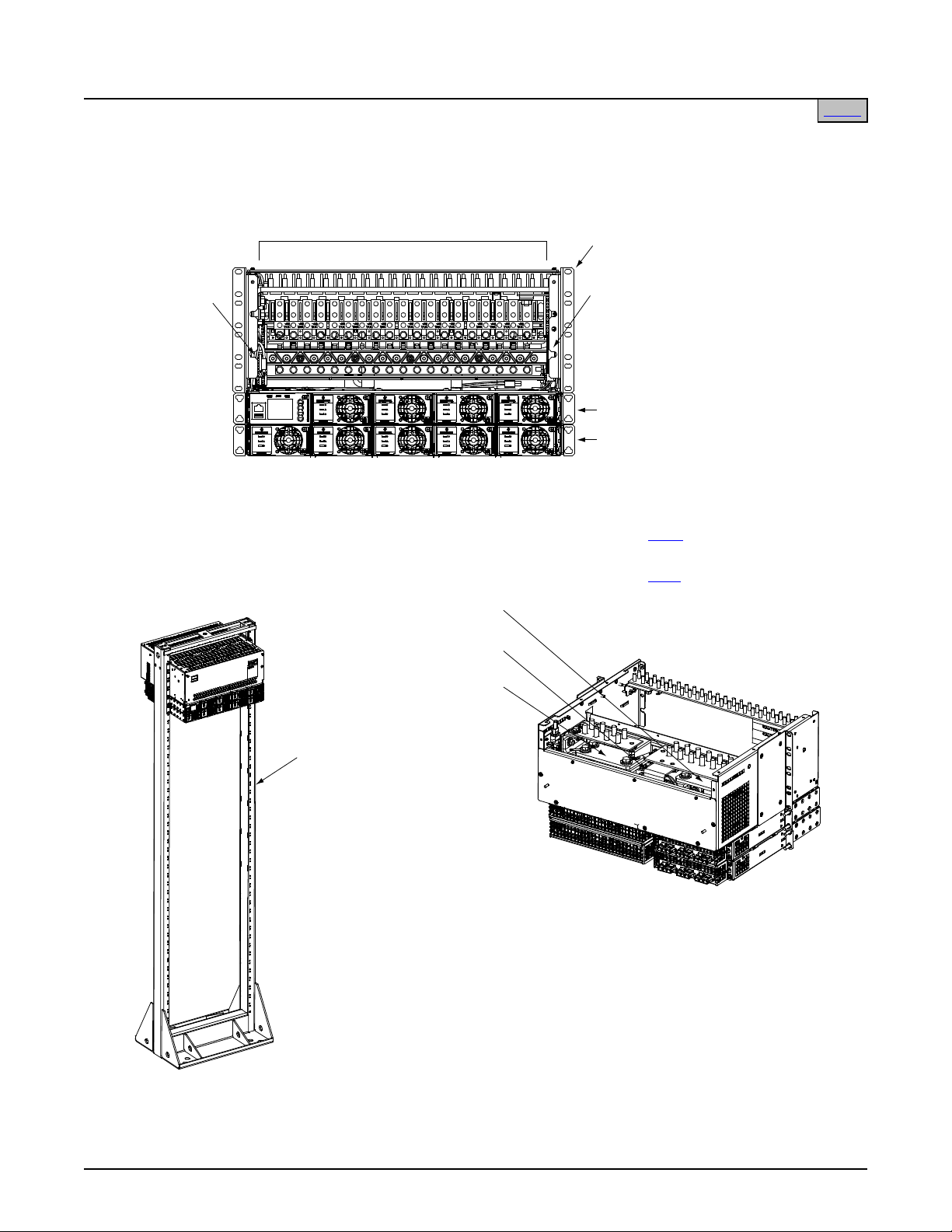

System Application Guide SAG582137100

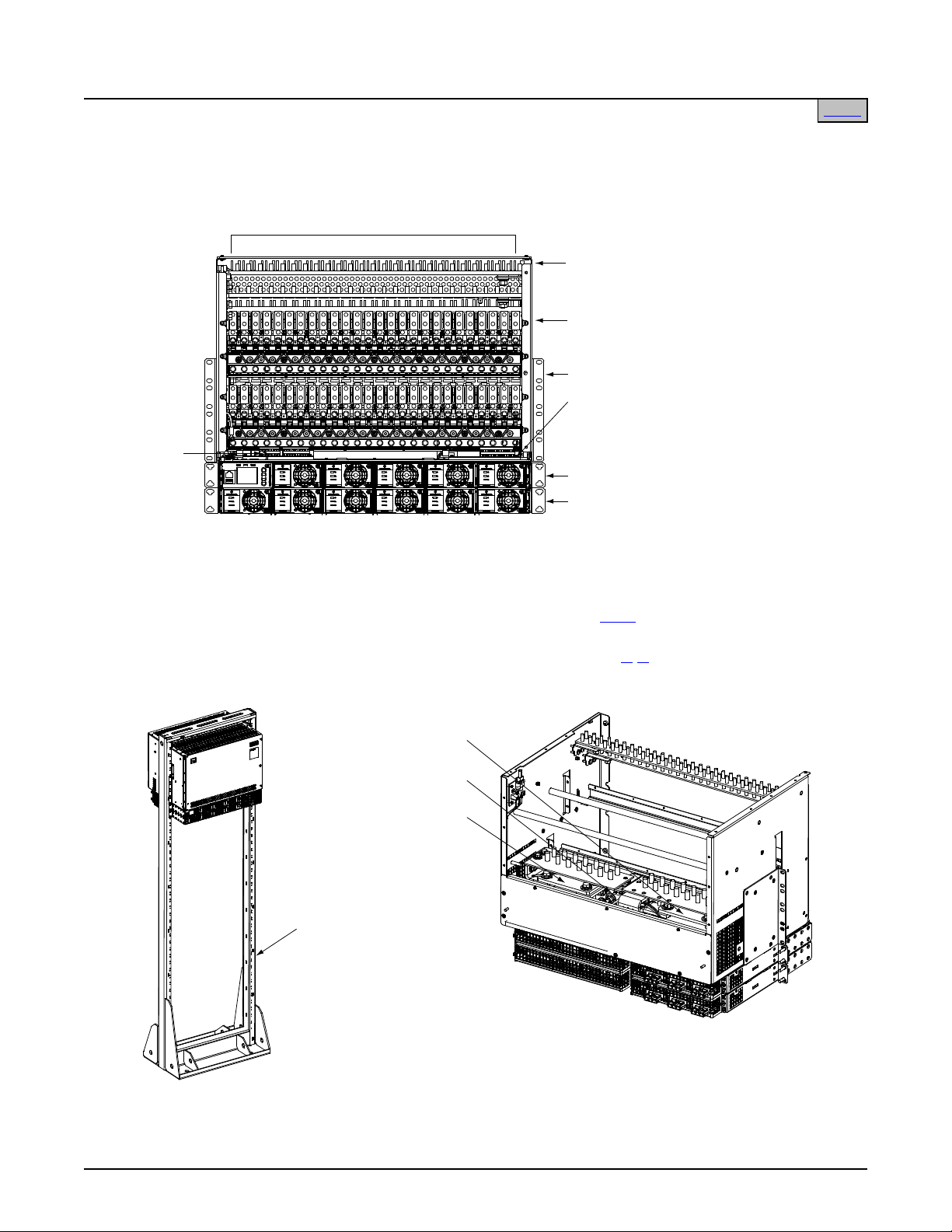

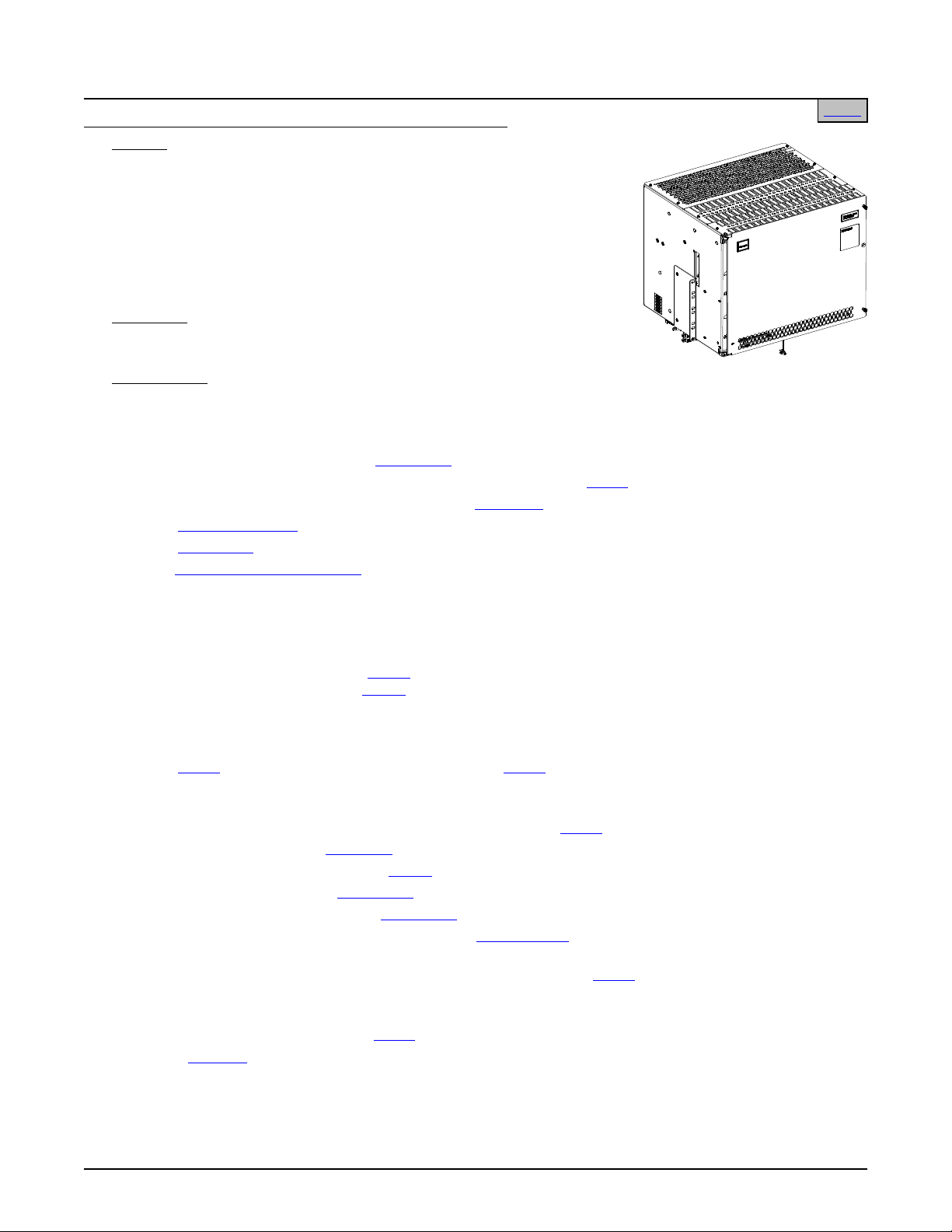

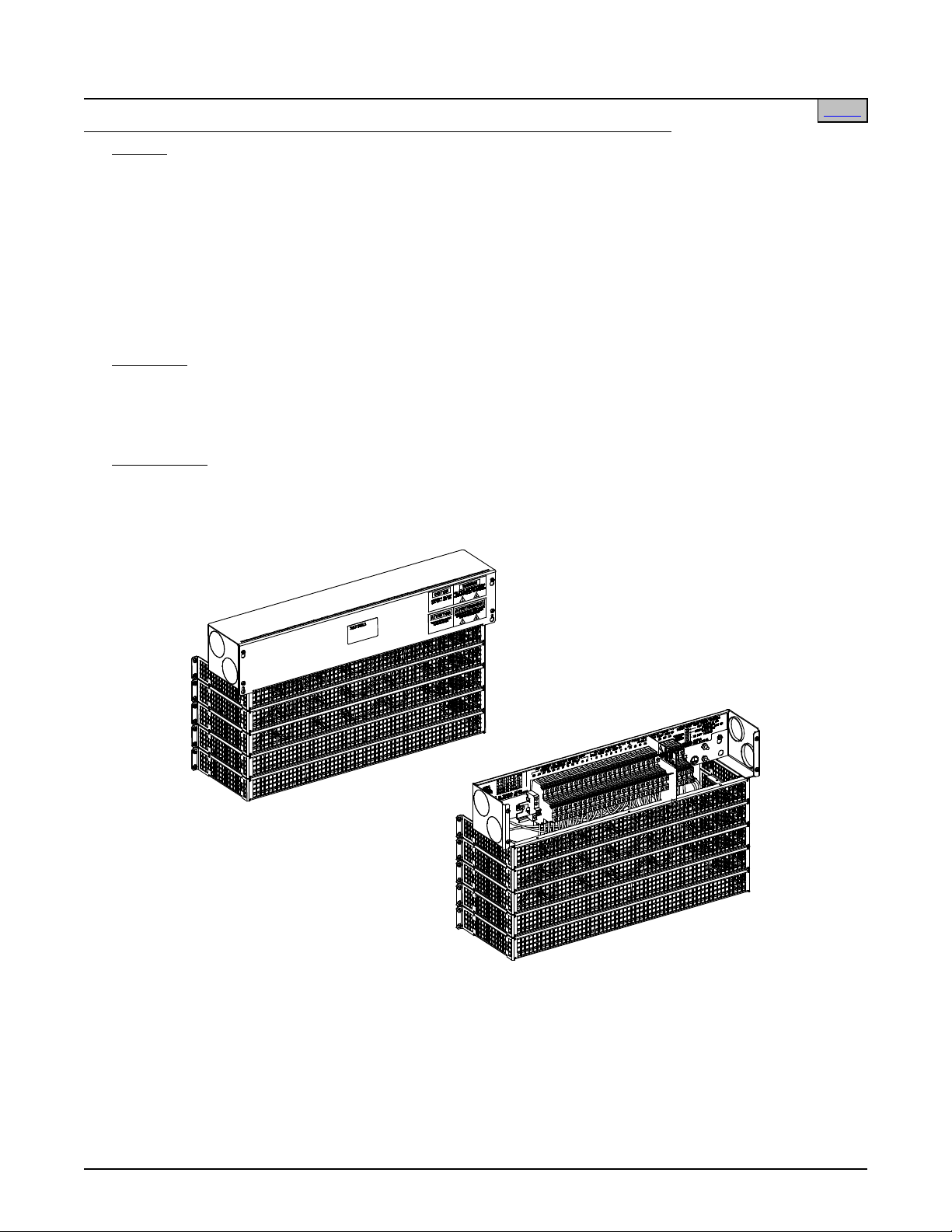

Various relay racks are available.

Load return busbars can

be rotated 90 degrees.

Rear (components removed

in illustration for clarity only)

Top Distribution Row

Bottom Distribution Row

19-inch, 2-Row

Distribution Cabinet

Front

See distribution panel List descriptions. Distribution panels may be

equipped with one or more of the following distribution positions.

-48 VDC Primary Voltage Load Positions

-48 VDC Battery Disconnect Positions

IB2 Controller

Interface Board

Optional IB4 Board

(second Ethernet port)

Mounted on Floor of

Distribution Cabinet

Optional EIB Controller

Extended Interface Board

Up to Four (4) Additional

Module Mounting Assemblies

588705300 List 41, 44, 45:

Rectifier, Solar Converter Mounting Positions

(See PD588705300)

One (1) Module Mounting Assembly w/ Controller

588705300 List 31, 34, 35: Controller, Rectifier,

Solar Converter Mounting Positions

(See PD588705300)

Optional LVLD

Contactor Location

Optional LVBD

Contactor Location

800 A / 25 mV Battery

Shunt Location

List 21

Single Voltage Distribution Panels

Single Voltage Plus Battery Disconnect

Distribution Panels

List 70

List 30: Module Mounting Assembly

Interface (factory)

List 36

Field Expansion

List LL

(LVLD)

List LB

(LVBD)

NCU: 1M830BNA

Rectifier Module:

1R482000E3

Solar Converter Module

1S482000E3

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

Typical System with a 19” 2-Row Distribution Cabinet (List 21)

: Module Mounting Assembly

Page 9 of 146

Page 10

SAG582137100 System Application Guide

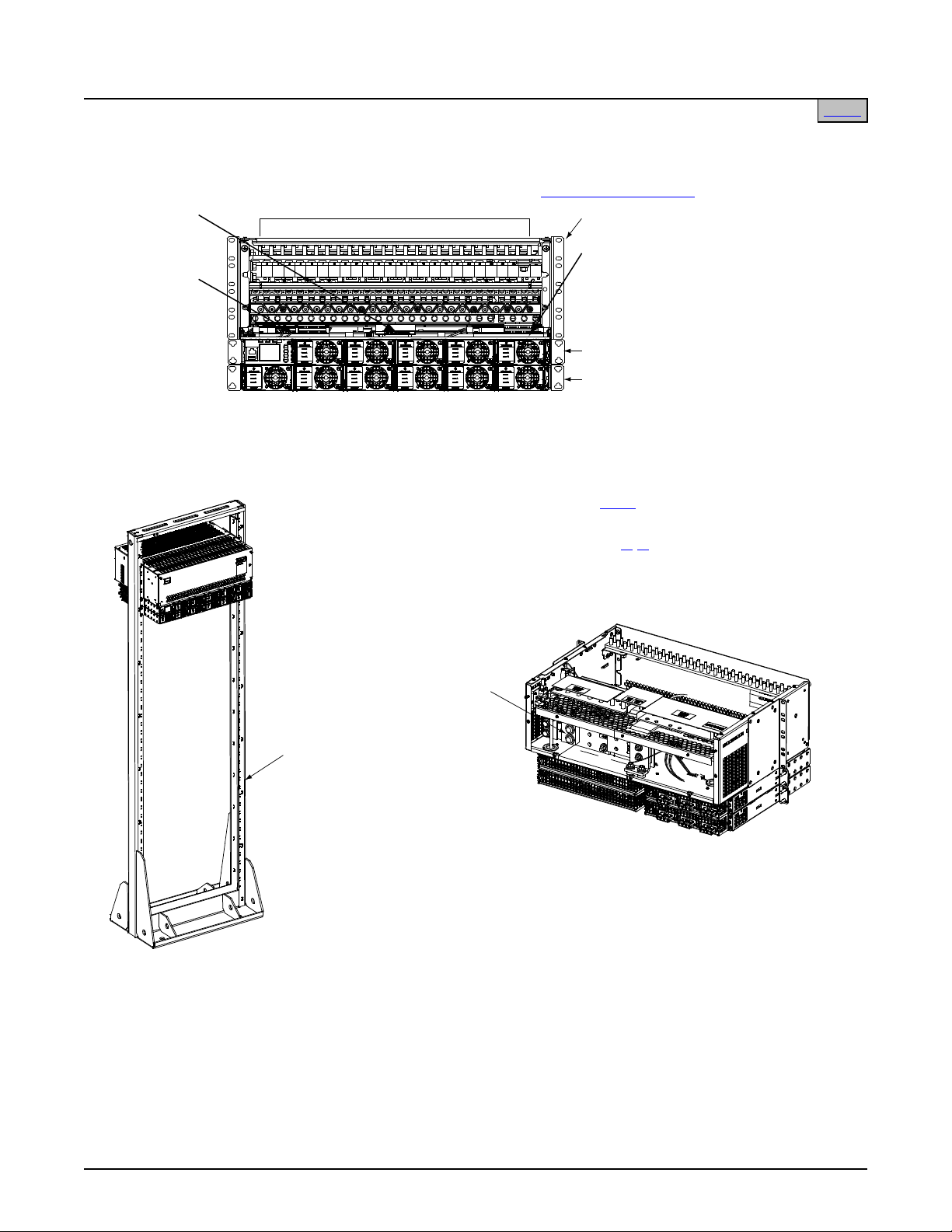

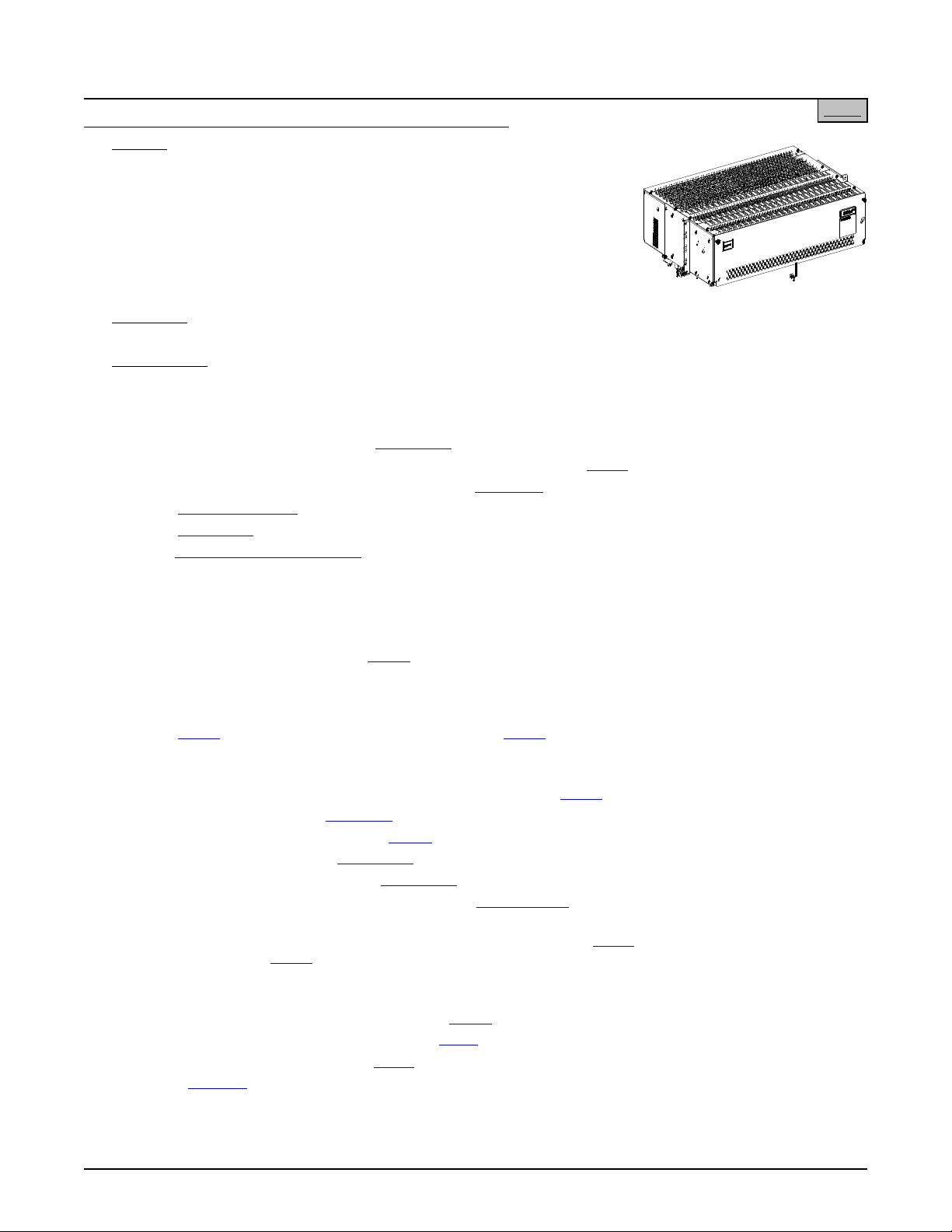

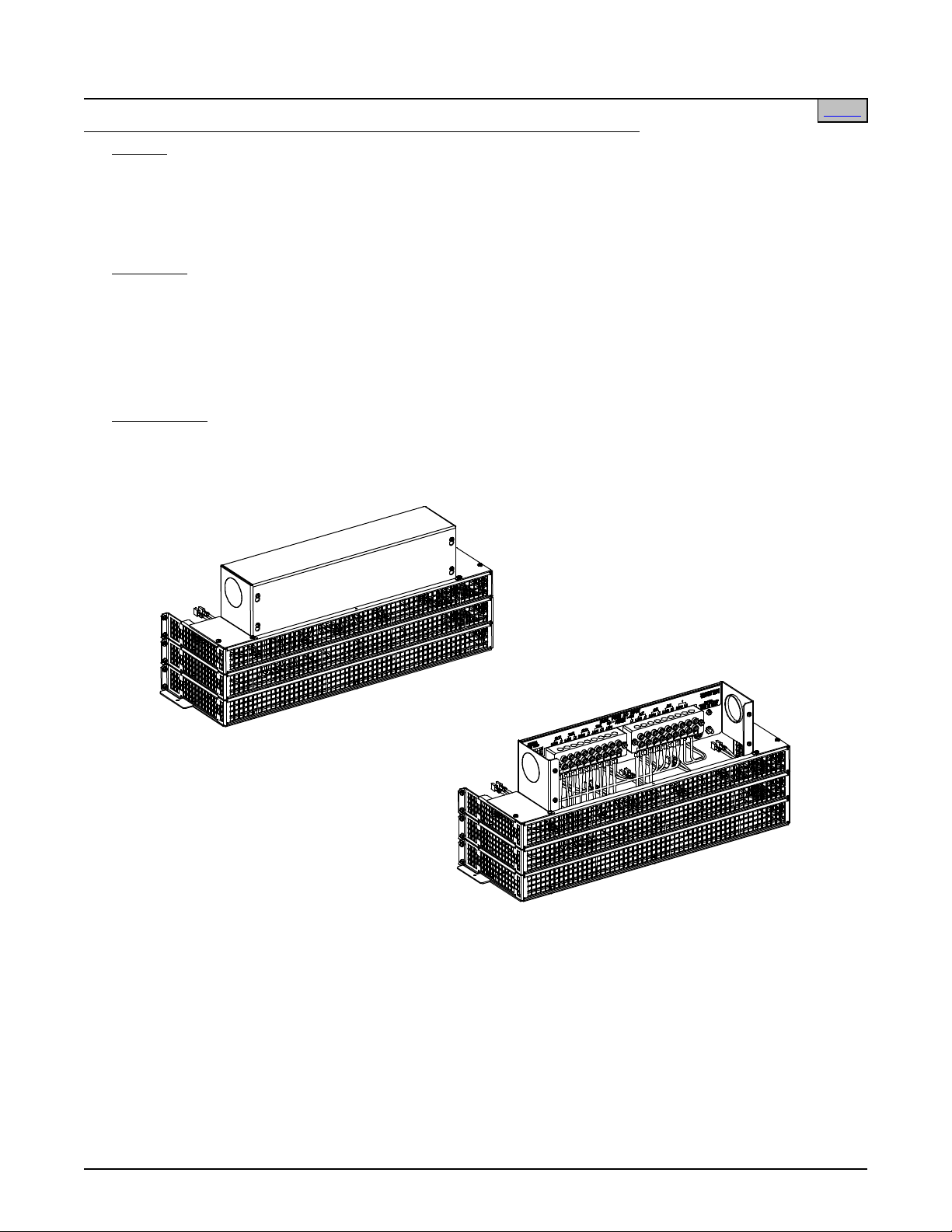

Various relay racks are available.

Rear (components removed

in illustration for clarity only)

Load return busbar can

be rotated 90 degrees.

Front

23-inch, 1-Row

Distribution Cabinet

See distribution panel List descriptions. Distribution panel may be

equipped with one or more of the following distribution positions.

-48 VDC Primary Voltage Load Positions

-48 VDC Battery Disconnect Positions

Optional IB4 Board

Mounted on Floor of

Distribution Cabinet

Optional LVLD

Contactor Location

Optional LVBD

Contactor Location

800 A / 25 mV Battery

Shunt Location

IB2 Controller

Interface Board

(mounted on

side panel)

Optional EIB Controller

Extended Interface

Board (mounted on

side panel)

Up to Four (4) Additional Module Mounting Assemblies

588705300 List 21, 24, 25: Rectifier, Solar Converter

Mounting Positions

(See PD588705300)

One (1) Module Mounting Assembly w/ Controller

588705300 List 11, 14, 15: Controller, Rectifier,

Solar Converter Mounting Positions

(See PD588705300)

List 25

List 70

List 30: Module Mounting Assembly

Interface (factory)

List

Field Expansion

List LL

(LVLD)

List LB

(LVBD)

NCU: 1M830BNA

Home

Rectifier Module:

1R482000E3

Solar Converter Module

1S482000E3

Single Voltage Distribution Panels

Single Voltage Plus Battery Disconnect

Distribution Panels

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

Typical System with a 23” 1-Row Distribution Cabinet (List 25)

34: Module Mounting Assembly

Page 10 of 146

Page 11

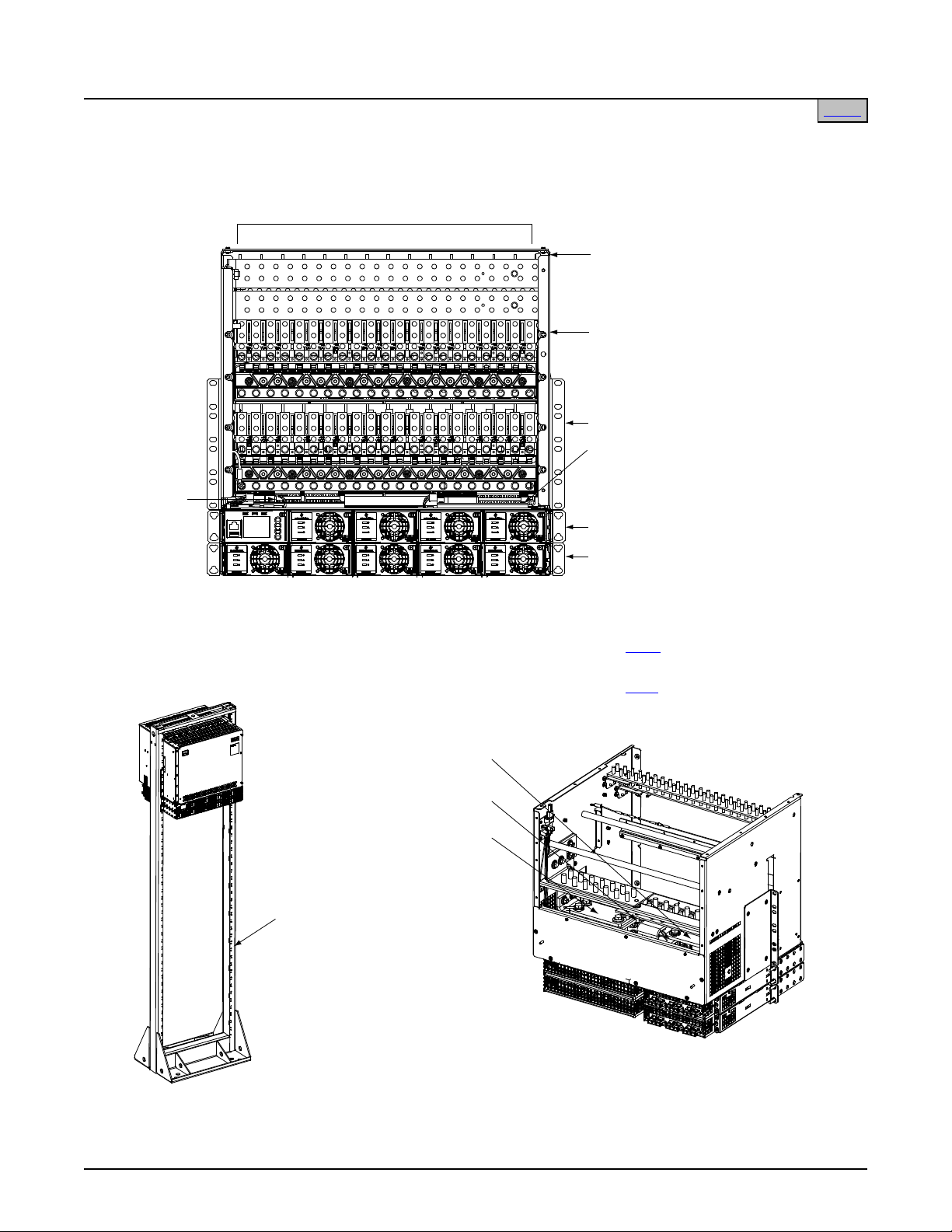

System Application Guide SAG582137100

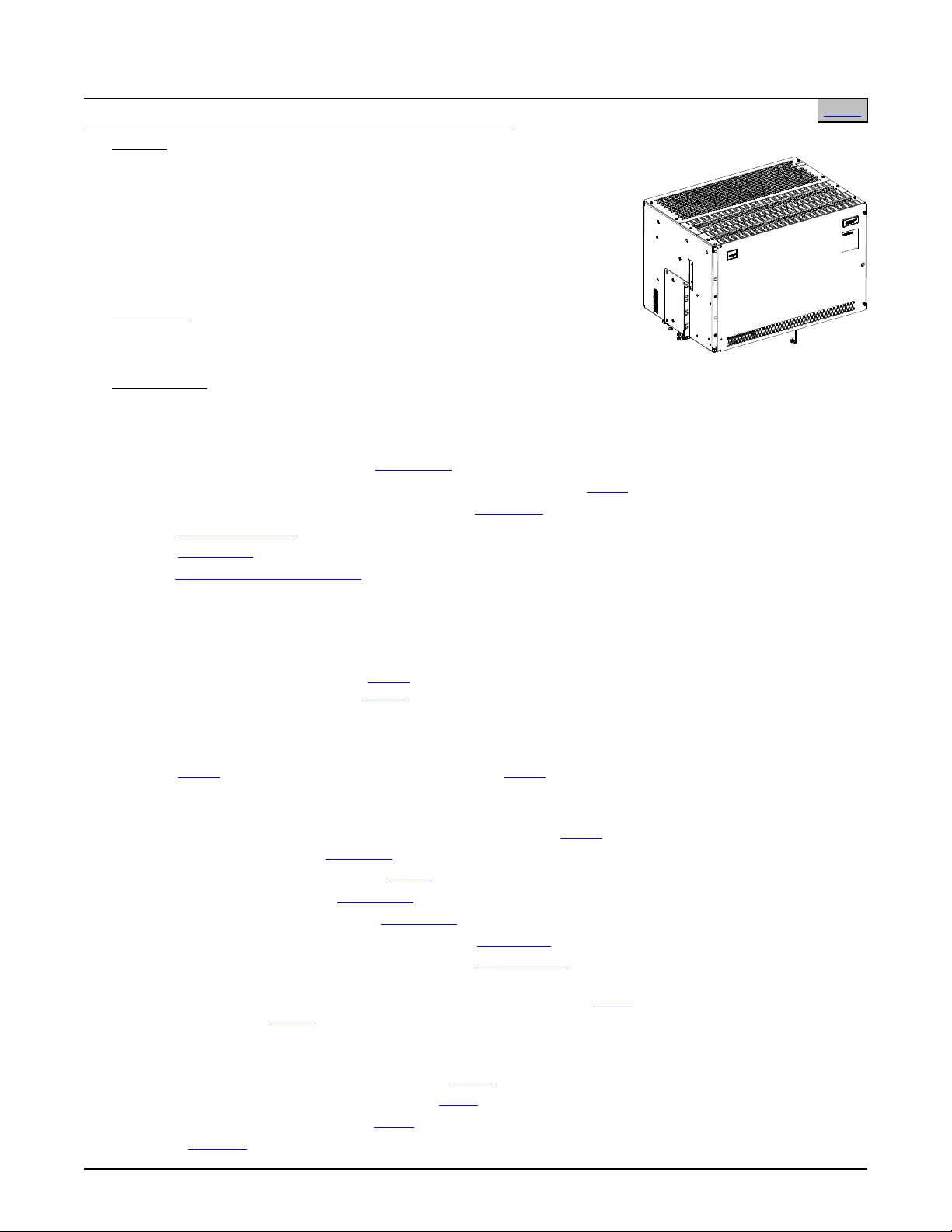

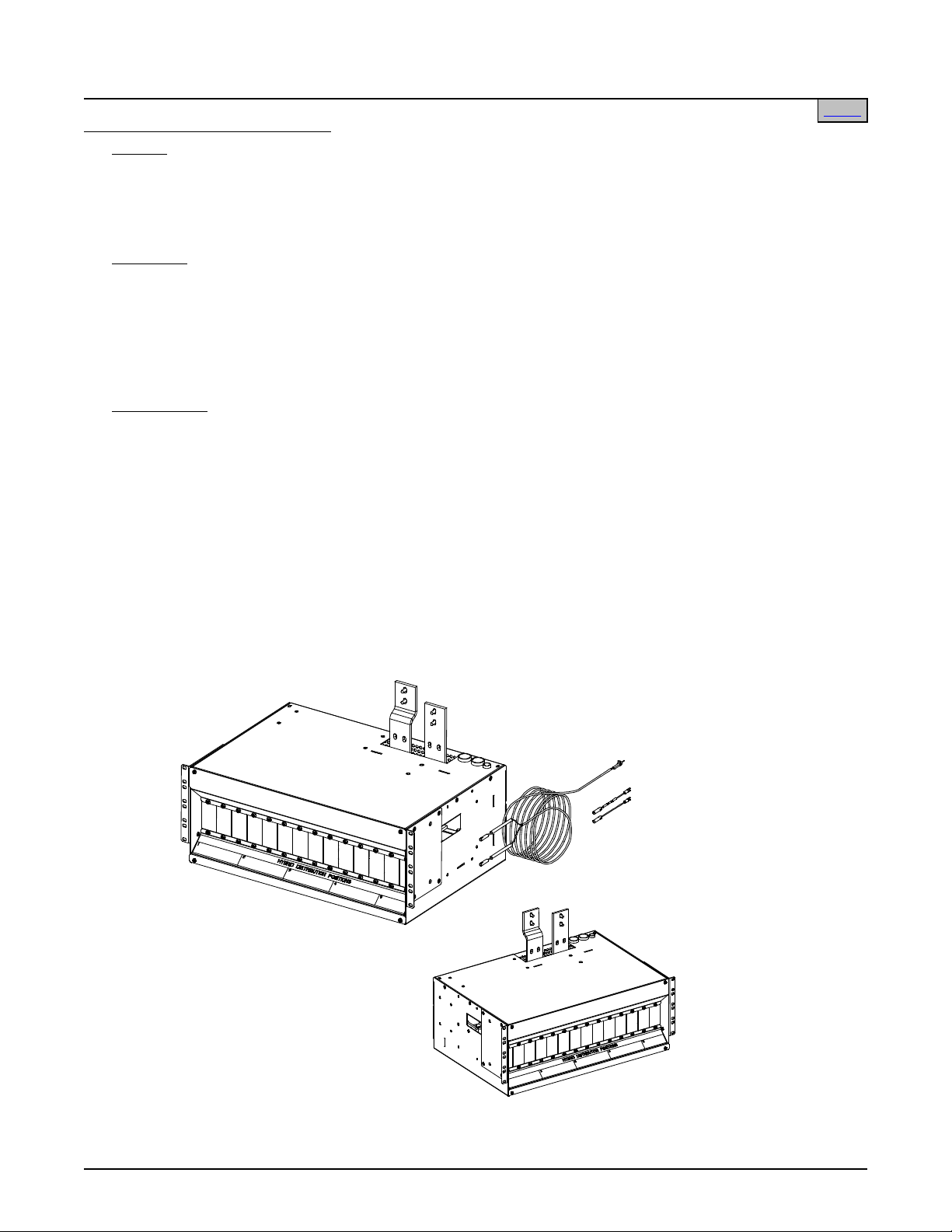

Various relay racks are available.

Rear (components removed

in illustration for clarity only)

Load return busbars can

be rotated 90 degrees.

23-inch, 2-Row

Distribution Cabinet

Front

See distribution panel List descriptions. Distribution panels may be

equipped with one or more of the following distribution positions.

-48 VDC Primary Voltage Load Positions

+24 VDC Secondary Voltage Load Positions

-48 VDC Battery Disconnect Positions

IB2 Controller

Interface Board

Optional IB4 Board

(second Ethernet port)

Mounted on Floor of

Distribution Cabinet

Optional LVLD

Contactor Location

Optional LVBD

Contactor Location

800 A / 25 mV Battery

Shunt Location

Top Distribution Row

Bottom Distribution Row

Optional EIB Controller

Extended Interface Board

Up to Four (4) Additional Module Mounting Assemblies

588705300

List 01, 04, 05: Rectifier, Solar Converter,

Converter Mounting Positions

List 21, 24, 25: Rectifier, Solar Converter

Mounting Positions

(See PD588705300)

One (1) Module Mounting Assembly w/ Controller

588705300 List 11, 14, 15: Controller, Rectifier,

Solar Converter Mounting Positions

(See PD588705300)

List 26

NCU: 1M830BNA

Single Voltage Distribution Panels

Dual Volage Distribution Panels

Single Voltage Plus

Distribution Panels

List LL

)

List LB

(LVBD)

List 70

List 30: Module Mounting Assembly

Interface (factory)

List

Assembly

Field Expansion

Rectifier Module:

1R482000E3

Solar Converter Module

1S482000E3

Converter Module

1C48241500

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

Typical System with a 23” 2-Row Distribution Cabinet (List 26)

Battery Disconnect

33, 34: Module Mounting

(LVLD

Page 11 of 146

Page 12

SAG582137100 System Application Guide

Various relay racks are available.

Rear (components removed

in illustration for clarity only)

Front

23-inch, 1-Row

Distribution Cabinet

800 A / 25 mV Battery

Shunt Location

See List DF distribution panel List description.

-48 VDC Primary Voltage Load Positions

+24 VDC Secondary Voltage Load Positions

IB2 Controller

Interface Board

Mounted on Floor of

Distribution Cabinet

Optional IB4 Board

Mounted on Floor of

Distribution Cabinet

Optional EIB Controller

Extended Interface Board

Mounted on Floor of

Distribution Cabinet

Up to Four (4) Additional Module Mounting Assemblies

588705300

List 01, 04, 05: Rectifier, Solar Converter,

Converter Mounting Positions

List 21, 24, 25: Rectifier, Solar Converter

Mounting Positions

(See PD588705300)

One (1) Module Mounting Assembly w/ Controller

588705300 List 11, 14, 15: Controller, Rectifier,

Solar Converter Mounting Positions

(See PD588705300)

List 27

NCU: 1M830BNA

List DF

List 70

List 30: Module Mounting Assembly

Interface (factory)

List

Assembly

Field Expansion

Rectifier Module:

1R482000E3

Solar Converter Module

1S482000E3

Converter Module

1C48241500

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

Typical System with a 23” 1-Row Distribution Cabinet (List 27)

Distribution Panel

33, 34: Module Mounting

Page 12 of 146

Page 13

System Application Guide SAG582137100

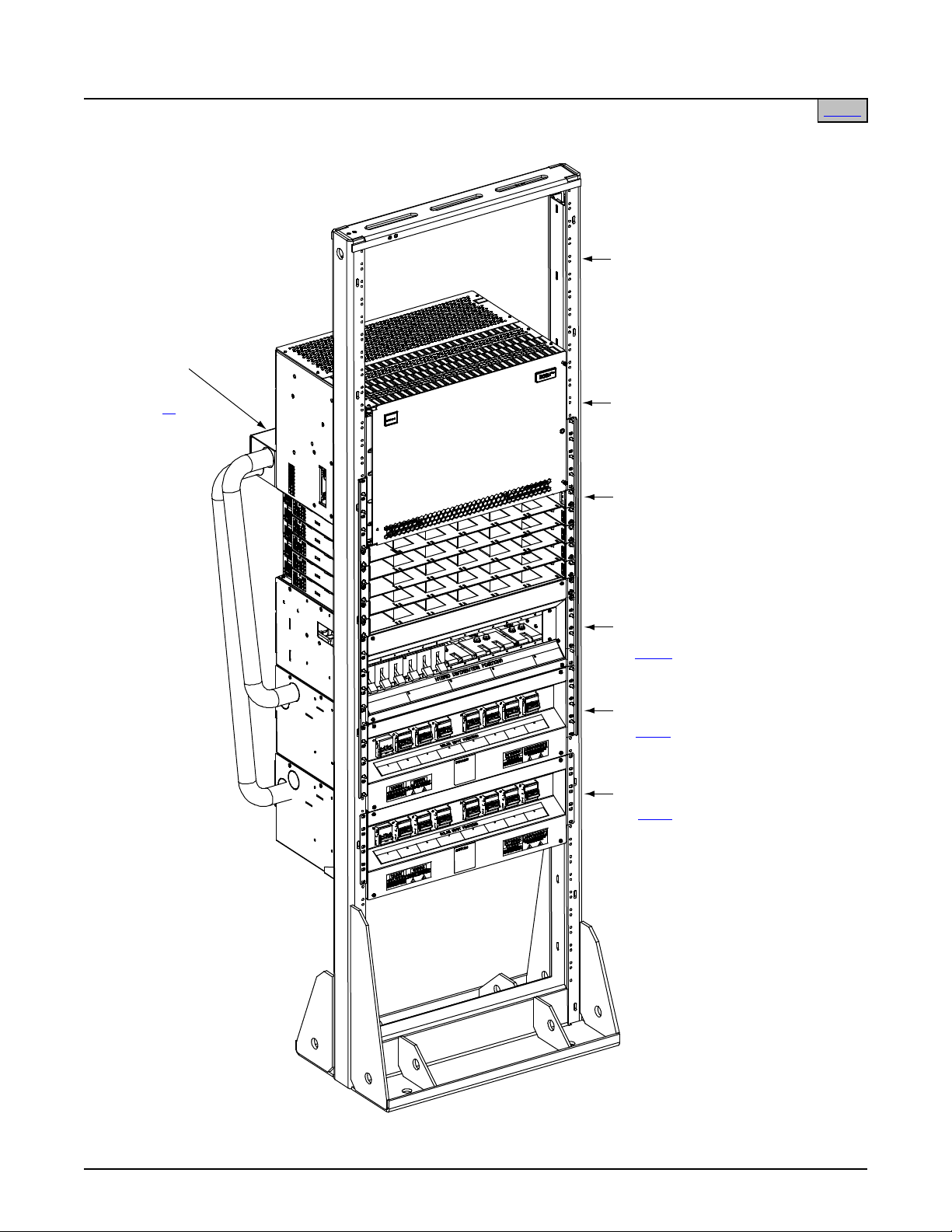

List

List 60

List 61

List 61

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

Typical Configured System with a 23” 1-Row or 2-Row Distribution Cabinet and Equipped with Solar Converter and Hybrid Connection Cabinets

23-inch

Relay Rack

45

1-Row or 2-Row

Distribution Cabinet

Up to Five (5)

Module Mounting Assemblies

(588705300)

(See PD588705300)

Hybrid Connection Cabinet *

Solar Connection Cabinet *

Solar Connection Cabinet *

* Hybrid Connection Cabinet

and Solar Connection Cabinet

are 23” Mounting Only

Page 13 of 146

Page 14

SAG582137100 System Application Guide

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

LIST DESCRIPTIONS

List Numbers

List 20: 1-Row Distribution Cabinet for 19-Inch Relay Rack Mounting

Features

♦ 4RU high by 19” wide distribution cabinet.

♦ Accepts one (1) distribution panel.

♦ Includes the IB2 controller interface board.

The IB2 provides eight (8) programmable form C- relay outputs, eight (8)

programmable binary inputs, and two (2) temperature inputs.

♦ Accepts the EIB controller extended interface board.

♦ Accepts the IB4 (second Ethernet port) board.

Restrictions

Rated -48 VDC; 400 A @ 40 °C, 300 A @ 65 °C.

Ordering Notes

1) Order List 20 and the following for a configured system.

2) Order one (1) distribution panel to be mounted in the cabinet (see the distribution panel List descriptions starting on

page 40).

3) For mounting in a data cabinet, order a mounting kit as required (see page 59).

4) Order the optional EIB controller extended interface board as required per List 70 (see page 30).

5) Order the optional IB4 (second Ethernet port) board kit P/N 559741 as required (see page 61).

6) Order temperature probes as required (see page 62).

7) Order alarm cables as required (see page 63).

8) Order RS485 Modbus interface cable as required (see page 61).

9) Order optional Transient Voltage Surge Suppressor (TVSS) Device(s) as required (see page 65).

10) Order fuses and/or circuit breakers as required per “Distribution Devices” starting on page 66.

11) Order one (1) List KG GMT distribution fuse panel per system as required (see page 44).

Order GMT fuses as required per Table 17.

12) Order 6-position GMT fuse block P/N 559737 (see page 69) as required.

Order GMT fuses as required per Table 17.

13) Order battery and load distribution lugs, lug adapters, and lug hardware kits as required per “Standard Crimp Lugs,

Special Application Crimp Lugs, and Busbar Adapter Kits and Hardware Kits” starting on page 72.

14) Order List LB low voltage battery disconnect (LVBD) and/or List LL low voltage load disconnect (LVLD) as required per

“Low Voltage Disconnect Options” on page 57.

15) Order one (1) to five (5) module mounting assembly(s) P/N 588705300 per PD588705300.

a) Order the appropriate rail mounting kit and output busbar kit per List 30 (see page 20).

b) Order NCU controller P/N 1M830BNA (see page 60).

c) Order critical alarm indicator kit P/N 555877 as required (see page 64).

d) Order rectifier modules P/N 1R482000E3 as required (see page 64).

e) Order solar converter modules P/N 1S482000E3 as required (see page 64).

f) Order a blank module mounting position cover P/N SXA 110 0035/1 for each unused mounting position in the system

as required (see page 65).

16) Order a Rectifier AC Input / Solar Converter DC Input Panel as required per List 40 (see page 24).

17) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76). Order “Input Cord Bracket Kit (P/N 562050)” as required (see page 78).

18) Order a battery tray(s) as required per List 94 (see page 36).

19) Order a relay rack (see page 58).

Page 14 of 146

Page 15

System Application Guide SAG582137100

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

List 21: 2-Row Distribution Cabinet for 19-Inch Relay Rack Mounting

Features

♦ 8RU high by 19” wide distribution cabinet.

♦ Accepts two (2) distribution panels.

♦ Includes the IB2 controller interface board.

The IB2 provides eight (8) programmable form C- relay outputs, eight (8)

programmable binary inputs, and two (2) temperature inputs.

♦ Accepts the EIB controller extended interface board.

♦ Accepts the IB4 (second Ethernet port) board.

Restrictions

Rated -48 VDC; 600 A (400 A maximum per row) @ 40 °C, 400 A (300 A maximum

per row) @ 65 °C.

Ordering Notes

1) Order List 21 and the following for a configured system.

2) Order two (2) distribution panels to be mounted in the cabinet (see the distribution panel List descriptions starting on

page 40).

3) For mounting in a data cabinet, order a mounting kit as required (see page 59).

4) Order the optional EIB controller extended interface board as required per List 70 (see page 30).

5) Order the optional IB4 (second Ethernet port) board kit P/N 559741 as required (see page 61).

6) Order temperature probes as required (see page 62).

7) Order alarm cables as required (see page 63).

8) Order RS485 Modbus interface cable as required (see page 61).

9) Order optional Transient Voltage Surge Suppressor (TVSS) Device(s) as required (see page 65).

10) Order fuses and/or circuit breakers as required per “Distribution Devices” starting on page 66.

11) Order one (1) List KG GMT distribution fuse panel per system as required (see page 44).

Order GMT fuses as required per Table 17.

12) Order 6-position GMT fuse block P/N 559737 for the top row (see page 69) as required.

Order 6-position GMT fuse block PN 549017 for the bottom row (see page 70) as required.

Order GMT fuses as required per Table 17.

13) Order battery and load distribution lugs, lug adapters, and lug hardware kits as required per “Standard Crimp Lugs,

Special Application Crimp Lugs, and Busbar Adapter Kits and Hardware Kits” starting on page 72.

14) Order List LB low voltage battery disconnect (LVBD) and/or List LL low voltage load disconnect (LVLD) as required per

“Low Voltage Disconnect Options” on page 57.

15) Order one (1) to five (5) module mounting assembly(s) P/N 588705300 per PD588705300.

a) Order the appropriate rail mounting kit and output busbar kit per List 30 (see page 20).

b) Order NCU controller P/N 1M830BNA (see page 60).

c) Order critical alarm indicator kit P/N 555877 as required (see page 64).

d) Order rectifier modules P/N 1R482000E3 as required (see page 64).

e) Order solar converter modules P/N 1S482000E3 as required (see page 64).

f) Order a blank module mounting position cover P/N SXA 110 0035/1 for each unused mounting position in the system

as required (see page 65).

16) Order a Rectifier AC Input / Solar Converter DC Input Panel as required per List 40 (see page 24).

17) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76). Order “Input Cord Bracket Kit (P/N 562050)” as required (see page 78).

18) Order a battery tray(s) as required per List 94 (see page 36).

19) Order a relay rack (see page 58).

Page 15 of 146

Page 16

SAG582137100 System Application Guide

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

List 25: 1-Row Distribution Cabinet for 23-Inch Relay Rack Mounting

Features

♦ 4RU high by 23” wide distribution cabinet.

♦ Accepts one (1) distribution panel.

♦ Includes the IB2 controller interface board.

The IB2 provides eight (8) programmable form C- relay outputs, eight (8)

programmable binary inputs, and two (2) temperature inputs.

♦ Accepts the EIB controller extended interface board.

♦ Accepts the IB4 (second Ethernet port) board.

Restrictions

Rated -48 VDC; 400 A @ 40 °C, 300 A @ 65 °C.

Ordering Notes

1) Order List 25 and the following for a configured system.

2) Order one (1) distribution panel to be mounted in the cabinet (see the distribution panel List descriptions starting on

page 40).

3) For mounting in a data cabinet, order a mounting kit as required (see page 59).

4) Order the optional EIB controller extended interface board as required per List 70 (see page 30).

5) Order the optional IB4 (second Ethernet port) board kit P/N 559741 as required (see page 61).

6) Order temperature probes as required (see page 62).

7) Order alarm cables as required (see page 63).

8) Order RS485 Modbus interface cable as required (see page 61).

9) Order optional Transient Voltage Surge Suppressor (TVSS) Device(s) as required (see page 65).

10) Order fuses and/or circuit breakers as required per “Distribution Devices” starting on page 66.

11) Order one (1) List KG GMT distribution fuse panel per system as required (see page 44).

Order GMT fuses as required per Table 17.

12) Order 6-position GMT fuse block P/N 559737 (see page 69) as required.

Order GMT fuses as required per Table 17.

13) Order battery and load distribution lugs, lug adapters, and lug hardware kits as required per “Standard Crimp Lugs,

Special Application Crimp Lugs, and Busbar Adapter Kits and Hardware Kits” starting on page 72.

14) Order List LB low voltage battery disconnect (LVBD) and/or List LL low voltage load disconnect (LVLD) as required per

“Low Voltage Disconnect Options” on page 57.

15) Order one (1) to five (5) module mounting assembly(s) P/N 588705300 per PD588705300.

a) Order the appropriate rail mounting kit and output busbar kit per List 30 (see page 20).

b) Order NCU controller P/N 1M830BNA (see page 60).

c) Order critical alarm indicator kit P/N 555877 as required (see page 64).

d) Order rectifier modules P/N 1R482000E3 as required (see page 64).

e) Order solar converter modules P/N 1S482000E3 as required (see page 64).

f) Order a blank module mounting position cover P/N SXA 110 0035/1 for each unused mounting position in the system

as required (see page 65).

16) Order a Rectifier AC Input / Solar Converter DC Input Panel as required per List 45 (see page 25) or Rectifier AC Input

Panel as required per List 46 (see page 26). See restrictions under List 46 on page 26.

17) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76). Order “Input Cord Bracket Kit (P/N 563456) as required (see page 78).

18) Order a Hybrid Connection Cabinet as required per List 60 (see page 27).

19) Order a Solar Connection Cabinet as required per List 61 (see page 29).

20) Order a battery tray(s) as required per List 93 (see page 30).

21) Order a relay rack (see page 58).

Page 16 of 146

Page 17

System Application Guide SAG582137100

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

List 26: 2-Row Distribution Cabinet for 23-Inch Relay Rack Mounting

Features

♦ 8RU high by 23” wide distribution cabinet.

♦ Accepts two (2) distribution panels.

♦ Includes the IB2 controller interface board.

The IB2 provides eight (8) programmable form C- relay outputs, eight (8)

programmable binary inputs, and two (2) temperature inputs.

♦ Accepts the EIB controller extended interface board.

♦ Accepts the IB4 (second Ethernet port) board.

Restrictions

Rated -48 VDC; 600 A (400 A maximum per row) and +24 VDC; 400 A @ 40 °C.

Rated -48 VDC; 400 A (300 A maximum per row) and +24 VDC; 300 A @ 65 °C.

Ordering Notes

1) Order List 26 and the following for a configured system.

2) Order two (2) distribution panels to be mounted in the cabinet (see the distribution panel List descriptions starting on

page 40).

3) For mounting in a data cabinet, order a mounting kit as required (see page 59).

4) Order the optional EIB controller extended interface board as required per List 70 (see page 30).

5) Order the optional IB4 (second Ethernet port) board kit P/N 559741 as required (see page 61).

6) Order temperature probes as required (see page 62).

7) Order alarm cables as required (see page 63).

8) Order RS485 Modbus interface cable as required (see page 61).

9) Order optional Transient Voltage Surge Suppressor (TVSS) Device(s) as required (see page 65).

10) Order fuses and/or circuit breakers as required per “Distribution Devices” starting on page 66.

11) Order one (1) List KG GMT distribution fuse panel per system as required (see page 44).

Order GMT fuses as required per Table 17.

12) Order 6-position GMT fuse block P/N 559737 for the top row (see page 69) as required.

Order 6-position GMT fuse block PN 549017 for the bottom row (see page 70) as required.

Order GMT fuses as required per Table 17.

13) Order battery and load distribution lugs, lug adapters, and lug hardware kits as required per “Standard Crimp Lugs,

Special Application Crimp Lugs, and Busbar Adapter Kits and Hardware Kits” starting on page 72.

14) Order List LB low voltage battery disconnect (LVBD) and/or List LL low voltage load disconnect (LVLD) as required per

“Low Voltage Disconnect Options” on page 57.

15) Order one (1) to five (5) module mounting assembly(s) P/N 588705300 per PD588705300.

a) Order the appropriate rail mounting kit and output busbar kit per List 30 (see page 20).

b) Order NCU controller P/N 1M830BNA (see page 60).

c) Order critical alarm indicator kit P/N 555877 as required (see page 64).

d) Order rectifier modules P/N 1R482000E3 as required (see page 64).

e) Order solar converter modules P/N 1S482000E3 as required (see page 64).

f) Order -48 VDC to +24 VDC converter modules P/N 1C48241500 as required (see page 64).

g) Order a blank module mounting position cover P/N SXA 110 0035/1 for each unused mounting position in the system

as required (see page 65).

16) Order a Rectifier AC Input / Solar Converter DC Input Panel as required per List 45 (see page 25) or Rectifier AC Input

Panel as required per List 46 (see page 26). See restrictions under List 46 on page 26.

17) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76). Order “Input Cord Bracket Kit (P/N 563456) as required (see page 78).

18) Order a Hybrid Connection Cabinet as required per List 60 (see page 27).

19) Order a Solar Connection Cabinet as required per List 61 (see page 29).

20) Order a battery tray(s) as required per List 93 (see page 30).

21) Order a relay rack (see page 58).

Page 17 of 146

Page 18

SAG582137100 System Application Guide

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

List 27: 1-Row Distribution Cabinet for 23-Inch Relay Rack Mounting

Features

♦ 4RU high by 23” wide distribution cabinet.

♦ Accepts one (1) List DF distribution panel.

♦ Includes the IB2 controller interface board.

The IB2 provides eight (8) programmable form C- relay outputs, eight (8)

programmable binary inputs, and two (2) temperature inputs.

♦ Accepts the EIB controller extended interface board.

♦ Accepts the IB4 (second Ethernet port) board.

Restrictions

Charge Ratings:

-48 VDC; 600 A and +24 VDC; 63 A; -48 VDC Battery Re-Charge; 195 A at 40 °C.

-48 VDC; 525 A and +24 VDC; 50 A; -48 VDC Battery Re-Charge; 120 A at 65 °C.

Discharge Ratings:

-48 VDC; 771 A at 40 °C.

-48 VDC; 600 A at 65 °C.

Bulk Output Rating:

-48 VDC; 300 A @ 40 °C and 65 °C. The Bulk Output current value used in the end use application is to be subtracted from

the available current of the -48 VDC charge ratings.

List 27 cannot be ordered with Lists LL or List LB.

List 27 is only for use with List DF.

No LVD.

Ordering Notes

1) Order List 27 and the following for a configured system.

2) Order one (1) List DF distribution panel to be mounted in the cabinet (see the distribution panel List description on page

56).

3) For mounting in a data cabinet, order a mounting kit as required (see page 59).

4) Order the optional EIB controller extended interface board as required per List 70 (see page 30).

5) Order the optional IB4 (second Ethernet port) board kit P/N 559741 as required (see page 61).

6) Order temperature probes as required (see page 62).

7) Order alarm cables as required (see page 63).

8) Order RS485 Modbus interface cable as required (see page 61).

9) Order optional Transient Voltage Surge Suppressor (TVSS) Device(s) as required (see page 65).

10) Order fuses and/or circuit breakers as required per “Distribution Devices” starting on page 66.

11) Order one (1) List KG GMT distribution fuse panel per system as required (see page 44).

Order GMT fuses as required per Table 17.

12) Order 6-position GMT fuse block P/N 559737 (see page 69) as required.

Order GMT fuses as required per Table 17.

13) Order battery and load distribution lugs, lug adapters, and lug hardware kits as required per “Standard Crimp Lugs,

Special Application Crimp Lugs, and Busbar Adapter Kits and Hardware Kits” starting on page 72.

14) Order one (1) to five (5) module mounting assembly(s) P/N 588705300 per PD588705300.

a) Order the appropriate rail mounting kit and output busbar kit per List 30 (see page 20).

b) Order NCU controller P/N 1M830BNA (see page 60).

c) Order critical alarm indicator kit P/N 555877 as required (see page 64).

d) Order rectifier modules P/N 1R482000E3 as required (see page 64).

e) Order solar converter modules P/N 1S482000E3 as required (see page 64).

f) Order -48 VDC to +24 VDC converter modules P/N 1C48241500 as required (see page 64).

g) Order a blank module mounting position cover P/N SXA 110 0035/1 for each unused mounting position in the system

as required (see page 65).

Page 18 of 146

Page 19

System Application Guide SAG582137100

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

15) Order a Rectifier AC Input / Solar Converter DC Input Panel as required per List 45 (see page 25) or Rectifier

AC Input Panel as required per List 46 (see page 26). See restrictions under List 46 on page 26.

16) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76). Order “Input Cord Bracket Kit (P/N 563456) as required (see page 78).

17) Order a Hybrid Connection Cabinet as required per List 60 (see page 27).

18) Order a Solar Connection Cabinet as required per List 61 (see page 29).

19) Order a battery tray(s) as required per List 93 (see page 30).

20) Order a relay rack (see page 58).

Page 19 of 146

Page 20

SAG582137100 System Application Guide

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

List 30: Shelf Rail Mounting Kits, Insulation Sheets, Output Busbar Kits, and Rear Cover Kits

Features

♦ Provides components to add one (1) to five (5) module mounting assembly(s) (Spec. No. 588705300) below a List 20, List

21, List 25, List 26, or List 27 distribution cabinet.

Restrictions

Factory installed only.

Includes ‘module mounting assembly-to-power system/distribution cabinet' interconnect components only. The module

mounting assembly(s) must be ordered separately.

Ordering Notes

1) Order one (1) List 30 per quantity of module mounting assemblies comprising the system. Specify how many module

mounting assembly(s) are to be installed in the system with these interconnect components and if the system consists of

a List 20, List 21, List 25, List 26, or List 27 distribution cabinet so correct kits can be provided and factory installed.

Page 20 of 146

Page 21

System Application Guide SAG582137100

Note:

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

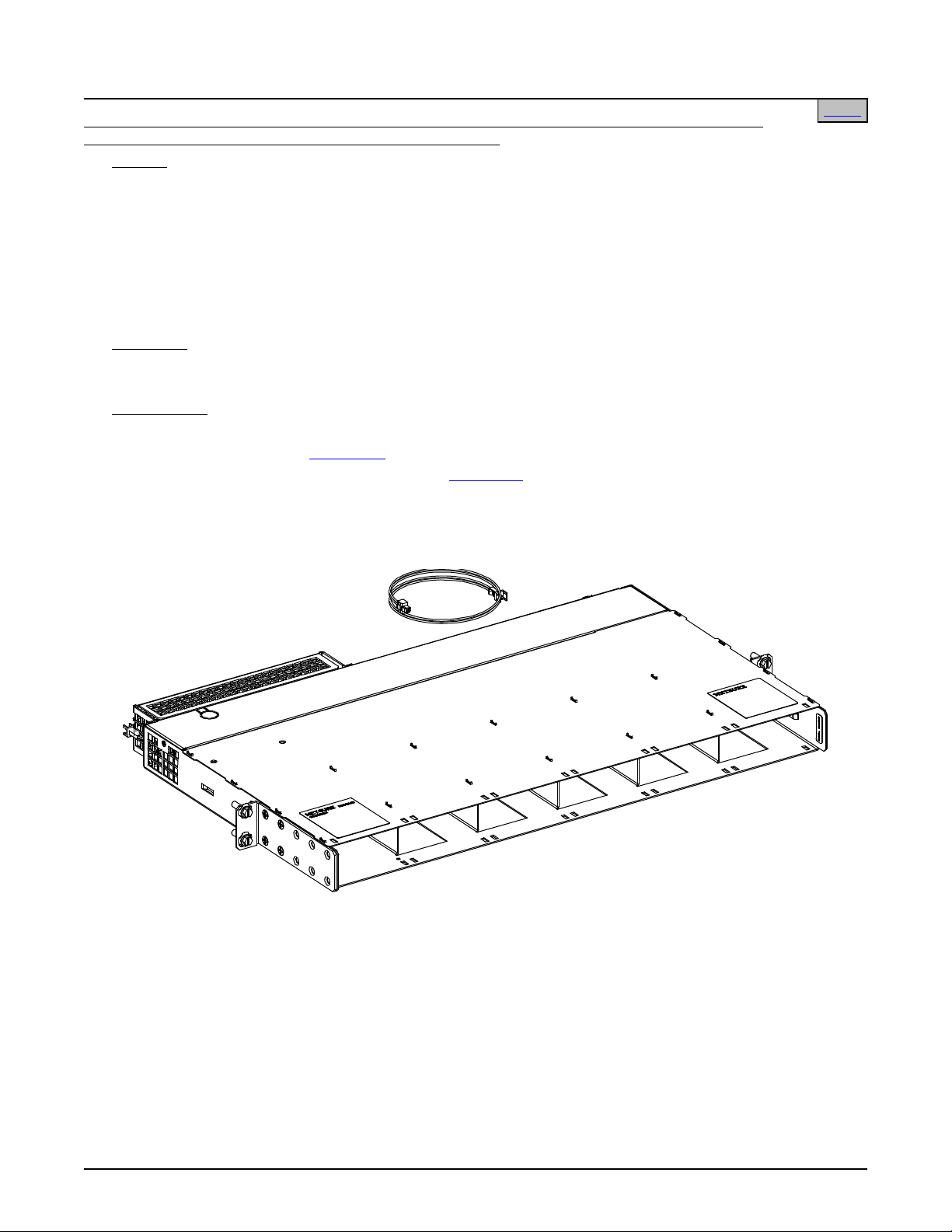

List 33: Field Expansion Module Mounting Assembly (23”) Configured with Rectifier and -48 VDC to +24 VDC Converter Module Mounting Positions and Molex Input Connectors

Features

♦ Provides a field expansion module mounting assembly (P/N 58870530005) plus mounting hardware.

♦ The module mounting assembly holds up to six (6) rectifier and/or -48 VDC to +24 VDC converter modules. Rectifier

modules can be installed in any mounting position. Converter modules can be installed in any of the three far right

mounting positions (as viewed from the front).

♦ Input cover assembly is provided with rear input Molex connectors factory wired to the rectifier mounting positions.

Three (3) AC input Molex connectors furnished and factory wired to provide three (3) AC input feeds to the

assembly. First AC input feeds rectifier mounting positions #1 and #2. Second AC input feeds rectifier

mounting positions #3 and #4. Third AC input feeds rectifier mounting positions #5 and #6.

Restrictions

Maximum of one (1) List 33, List 34, or List 36 per system.

Cannot expand system beyond five (5) module mounting assemblies.

Ordering Notes

1) Order List 33 for a module mounting assembly to be added in the field.

2) Order rectifier modules P/N 1R482000E3 as required (see page 64).

3) Order -48 VDC to +24 VDC converter modules P/N 1C48241500 as required (see page 64).

4) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76).

Page 21 of 146

Page 22

SAG582137100 System Application Guide

Note:

Home

Revision S, September 12, 2018 Spec. No. 582137100 (Model NetSure™ 5100)

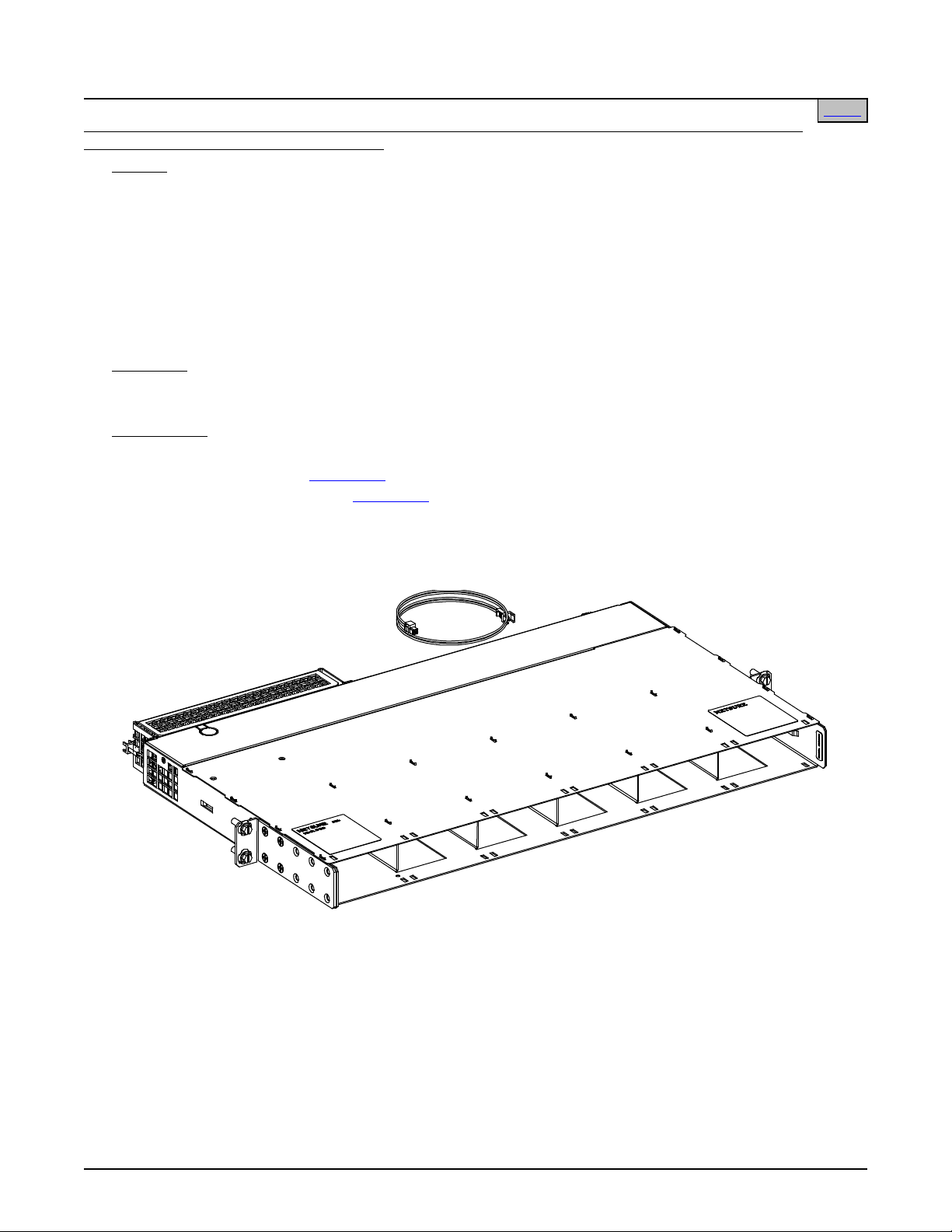

List 34: Field Expansion Module Mounting Assembly (23”) Configured with Rectifier and/or Solar Converter Module Mounting Positions and Molex Input Connectors

Features

♦ Provides a field expansion module mounting assembly (P/N 58870530025) plus mounting hardware.

♦ The module mounting assembly holds up to six (6) rectifier and/or solar converter modules.

♦ Input cover assembly is provided with rear input Molex connectors factory wired to the rectifier / solar converter

mounting positions.

Three (3) rectifier / solar converter input Molex connectors furnished and factory wired to provide three (3)

rectifier / solar converter input feeds to the assembly. First rectifier / solar converter input feeds rectifier / solar

converter mounting positions #1 and #2. Second rectifier / solar converter input feeds rectifier / solar converter

mounting positions #3 and #4. Third rectifier / solar converter input feeds rectifier / solar converter mounting

positions #5 and #6.

Restrictions

Maximum of one (1) List 33, List 34, or List 36 per system.

Cannot expand system beyond five (5) module mounting assemblies.

Ordering Notes

1) Order List 34 for a module mounting assembly to be added in the field.

2) Order rectifier modules P/N 1R482000E3 as required (see page 64).

3) Order solar converter modules P/N 1S482000E3 as required (see page 64).

4) Order “Rectifier AC Input / Solar Converter DC Input Cable Assemblies and Rectifier AC Input Line Cords” as required

(see page 76).

Page 22 of 146

Page 23

System Application Guide SAG582137100

Note:

Home

Spec. No. 582137100 (Model NetSure™ 5100) Revision S, September 12, 2018

List 36: Field Expansion Module Mounting Assembly (19”) Configured with Rectifier and/or Solar Converter Module Mounting Positions and Molex Input Connectors

Features

♦ Provides a field expansion module mounting assembly (P/N 58870530045) plus mounting hardware.

♦ The module mounting assembly holds up to five (5) rectifier and/or solar converter modules.

♦ Input cover assembly is provided with rear input Molex connectors factory wired to the rectifier / solar converter

mounting positions.