Page 1

Liebert® XDC™

50 & 60 Hz, 130 & 160kW Nominal Cooling Capacity;

ModelRevision5orHigher

User Manual

Page 2

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of

this manual to see if the issue can be resolved by following outlined procedures. Visit

https://www.VertivCo.com/en-us/support/ for additional assistance.

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 5

2 Product Description 9

2.1 General Product Information 9

2.1.1 Product/System Description 9

2.2 Equipment Inspection 10

2.3 Equipment Handling 10

2.3.1 Handling the Liebert XDC While it is on Skid and Packaged 10

2.3.2 Unpacking the Liebert XDC 11

2.3.3 Removing the Unit from the Skid Using a Forklift 11

2.3.4 Removing the Unit from the Skid using Rigging 12

2.3.5 Moving the Liebert XDC Using Piano Jacks 13

2.3.6 Removing the Unit from the Piano Jacks 14

3 Installation 15

3.1 Mechanical Considerations 15

3.1.1 Positioning the Liebert XDC 15

3.1.2 Placing the Liebert XDC on a Floor Stand 17

3.1.3 Positioning the Liebert XDC with Floor Stand 20

3.2 Electrical Considerations 22

3.2.1 High Voltage Connections 22

3.2.2 Connecting High-Voltage Cables 23

3.3 External Pump Overloads 27

3.4 Extra Low Voltage Connections 28

3.5 Remote Sensor Installation—Proper Placement 34

4 Piping and Filling with Refrigerant: R-134a and R-407C Circuits 37

4.1 European Union Fluorinated Greenhouse Gas Requirements 37

4.2 Recommended Pipe Size 37

4.3 Liebert XDC Interconnection With Liebert XD Cooling Module 38

4.4 Piping Installation Method 38

4.4.1 Piping Installation—R-134a Pumped Circuit 39

4.4.2 Bypass Flow Controllers 39

4.5 Piping Details—Shutoff/Isolation Valves 41

4.6 Filling the Pumped Circuit—R-134a 41

4.6.1 Calculating Refrigerant Charge—Example 44

4.6.2 Piping for Direct Expansion (DX) Circuit—R-407C Air-Cooled Units 45

4.7 Install Double Discharge Risers 45

4.7.1 Air-Cooled Condenser with Liebert Lee-Temp “Flooded Condenser” Head Pressure

Control System—R-407C (DX) Circuit 54

4.8 Filling the Direct Expansion (DX) Circuit—R-407C 55

4.9 System Refrigerant Charges Over 55lb. (24.9kg) Require Additional Oil 57

4.9.1 Liebert XDC DX R-407C Circuit Volume 57

5 Installation Checklist 59

Vertiv | Liebert® XDC™ User Manual | 3

Page 4

6 Liebert iCOM Control—Firmware Version XP1.00.009.STD 61

6.1 Liebert iCOM Components and Functions 61

6.2 Display Lamp Indicators 63

6.3 Navigating Through the Liebert iCOM Display 63

6.3.1 Accessing Menus and Settings 64

6.3.2 Cooling Module Overview 64

6.3.3 Entering the Password 65

6.4 Changing Liebert iCOM’s Display Settings 66

6.5 Changing Operational Settings 67

6.6 Graphical Data Record 67

6.7 Liebert iCOM User Menu Icons and Legend 68

6.8 Liebert iCOM User Menu Screens 69

6.9 Liebert iCOM Service Menu Icons and Legend 79

6.10 Liebert iCOM Service Menu Screens 80

7 Start the Liebert XDC with Liebert iCOM 111

7.1 Checklist for Liebert XDC Startup 111

8 Alarm Descriptions and Solutions 115

8.1 Alarm Descriptions 115

8.2 Warning Descriptions 118

8.3 System Shutdown Causes 118

9 Troubleshooting 121

10 Maintenance 123

10.1 Fluorinated Greenhouse Gas Requirements 123

10.2 Air-Cooled Condenser 123

10.3 Water/Glycol Floor Stand Condenser 124

10.3.1 Shell and Tube Condensers 124

10.3.2 Regulating Valves 124

10.3.3 Glycol Solution Maintenance 124

11 Specifications 127

Vertiv | Liebert® XDC™ User Manual | 4

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

Save These Instructions

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert XDC. Read this manual thoroughly before attempting to install or operate this

unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit

and in this manual. Follow all operating and user instructions.

Follow all local codes.

WARNING! Risk of arc flash and electric shock. Can cause equipment damage or death.

Disconnect all local and remote electric power supplies and wear protective equipment per

NFPA 70E before working within electric control enclosure. Failure to comply can cause serious

injury or death.

Customer must provide earth ground to unit, per NEC, CEC and local codes, as applicable.

Before proceeding with installation, read all instructions, verify that all the parts are included

and check the nameplate to be sure the voltage matches available utility power.

The Liebert iCOM microprocessor does not isolate power from the unit, even in the Unit Off

mode. Some internal components require and receive power even during the Unit Off mode of

Liebert iCOM control.

The line side of the disconnect switch on the front of the unit contains live high-voltage.

The only way to ensure that there is NO voltage inside the unit is to install and open a remote

disconnect switch. Refer to unit electrical schematic.

Follow all local codes.

WARNING! Risk of unit falling over. Can cause equipment damage, injury and death.

The Liebert XDC is top-heavy. Use extreme caution and care when moving and installing this

unit.

WARNING! Risk of refrigerant system explosion or rupture from overpressurization. Can cause

equipment damage, injury and death.

Installer must install a 400 psig pressure relief valve in each of the two R-407C refrigerant

circuits of the Liebert XDC system. Do not install shutoff valves between the compressors and

the pressure relief valves.

For systems requiring EU CE compliance, the pressure relief valves must be CE-certified by a

notified body to the EU Pressure Equipment Directive.

CAUTION: Risk of piping and component rupture. Can cause equipment damage and injury.

Closing service valves may isolate liquid refrigerant, causing high pressure and rupture of

piping. Do not close valves without following recommended procedures for repair, maintenance

and replacement of components. Install pressure relief valves in field piping that may become

isolated by service valves.

Vertiv | Liebert® XDC™ User Manual | 5

Page 6

NOTICE

CAUTION: Risk of contact with hot surfaces. Can cause burn injury.

The compressors, pump motors and refrigerant discharge lines are extremely hot during unit

operation. Allow sufficient time for the compressors, pump motors and refrigerant discharge

lines to cool before working within the unit cabinet. Use extreme caution and wear protective

gloves and arm protection when working on or near hot compressor, pump motors or

discharge lines.

CAUTION: Risk of improper installation and startup. Can cause warranty cancellation,

equipment damage and injury.

Read and follow completely the installation and start up instructions that are factory supplied

with the unit.

CAUTION: Risk of sharp edges, splinters and exposed fasteners. Can cause personal injury.

Only properly trained personnel wearing appropriate safety headgear, gloves, shoes and

glasses should attempt to move, lift, remove packaging from or prepare the unit for installation.

Risk of a leaking coil due to freezing and/or corrosion. Can cause equipment and serious

building damage.

NOTICE

Cooling and heat rejection coils, heat exchangers and piping systems that are connected to

open cooling towers or other open water/glycol systems are at high risk for freezing and

premature corrosion. Fluids in these systems must contain the proper antifreeze and inhibitors

to prevent freezing and premature coil corrosion. The water or water/glycol solution must be

analyzed by a competent water treatment specialist before startup to establish the inhibitor

requirement. The water or water/glycol solution must be analyzed every six months to

determine the pattern of inhibitor depletion. The complexity of water-caused problems and

their correction makes it important to obtain the advice of a water treatment specialist and

follow a regularly scheduled maintenance program.

Risk of leaking chilled water lines. Can cause equipment and building damage.

Lines and joints must be inspected regularly. Improper installation, application and service

practices can result in water leakage from the unit. Water leakage can result in severe property

damage and loss of critical data center equipment. Do not locate unit directly above any

equipment that could sustain water damage. Vertiv recommends installing monitored leak

detection equipment for the unit and supply and return lines.

Vertiv | Liebert® XDC™ User Manual | 6

Page 7

NOTICE

Risk of clogged or leaking drain lines. Can cause equipment and building damage.

This unit requires a water drain connection. Drain lines must be inspected regularly and

maintenance must be performed to ensure that drain water runs freely through the drain

system and that lines are clear and free of obstructions and in good condition with no visible

sign of damage or leaks. This unit may also require an external water supply to operate.

Improper installation, application and service practices can result in water leakage from the

unit. Water leakage can result in severe property damage and loss of critical data center

equipment.

Do not locate unit directly above any equipment that could sustain water damage.

Vertiv recommends installing monitored leak detection equipment for the unit and the supply

and return lines.

NOTE: This document must be used with site specific documentation and documentation for other

parts of the system (heat rejection devices and cooling modules).

NOTE: Before any action that could cause a disturbance in the Liebert XD system’s cooling function is

begun, the facility manager MUST be informed. In addition, after the action is taken and the work is

finished, the facility manager MUST be informed.

Figure 1.1 Model number nomenclature

Vertiv | Liebert® XDC™ User Manual | 7

Page 8

This page intentionally left blank.

Vertiv | Liebert® XDC™ User Manual | 8

Page 9

2 PRODUCT DESCRIPTION

2.1 General Product Information

2.1.1 Product/System Description

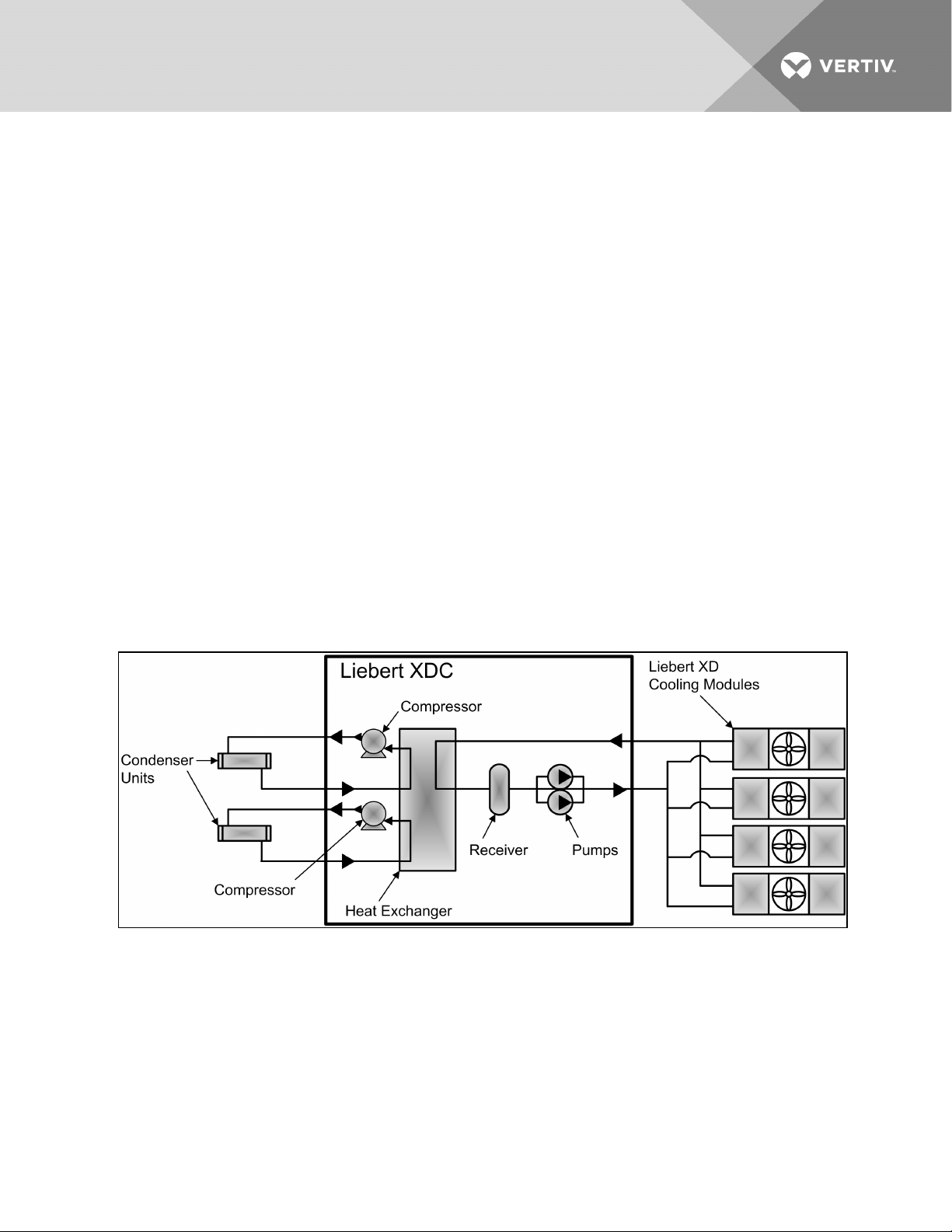

The Liebert XDC™(X-treme Density Chiller) is a self-contained refrigeration distribution unit designed to

cool rooms with high heat producing equipment. There are two distinct circuits, each utilizing different

refrigerants and mechanical parts. The R-134a circuit is the “pumped” circuit containing redundant

circulating pumps, a brazed plate heat exchanger along with valves and piping. The R-407C circuit is the

dual direct expansion circuit containing scroll compressors, expansion valves, brazed plate heat

exchanger, and piping. Heat removal is accomplished by using condensers connected to the dual direct

expansion circuit. Heat rejection is available in two options: an outdoor air-cooled condenser and a

water/glycol condenser. See Figure 2.1 below below.

The Liebert XDC monitors room conditions and prevents coil condensation by maintaining the refrigerant

being pumped to the cooling modules at a temperature above the room dew point. All functions, such as

temperature control, switching pumps (if necessary), etc., are automatic.

The Liebert XDC’s minimum recommended operating load is 40% of system nominal capacity. For

example, a Liebert XDC160 60Hz system’s minimum load would be 64kW. Loading below this value can

unfavorably affect system operation.

See Table 11.1 on page127 for the Liebert XDC160 rated cooling capacity.

Figure 2.1 Liebert XDC components

Vertiv | Liebert® XDC™ User Manual | 9

Page 10

2.2 Equipment Inspection

When the unit is delivered, inspect all items for visible and concealed damage. Damage should be

immediately reported to the carrier and a damage claim filed with a copy sent to Liebert or to your sales

representative.

NOTICE

Risk of improper storage. Can cause equipment damage.

Keep the Liebert XDC upright, indoors and protected from dampness, freezing temperatures

and contact damage.

2.3 Equipment Handling

WARNING! Risk of unit falling over. Can cause injury or death.

The Liebert XDC is top-heavy. Use extreme caution when moving and installing this unit. Use

lifting equipment that is rated for the weight of the unit by an OSHA-certified rating

organization. See Table 11.1 on page127 for unit weights. Personnel should be properly trained

and certified to move and rig equipment

CAUTION: Risk of sharp edges, splinters and exposed fasteners. Can cause personal injury.

Only properly trained personnel wearing appropriate safety headgear, gloves, shoes and

glasses should attempt to move, lift, remove packaging from or prepare the unit for installation.

2.3.1 Handling the Liebert XDC While it is on Skid and Packaged

• Always keep the unit upright, indoors and protected from damage.

• If possible, transport the unit using a forklift truck. Otherwise use a crane with slings and

spreader cables. In either case, do NOT press on the top edges of the packaging.

• If using a forklift or pallet jack, make sure the forks (if adjustable) are spread to the widest

allowable distance to still fit under the skid.

• When moving the skidded unit with a forklift, do not lift the unit any higher than 3"(76mm). If

circumstances require the unit to be lifted higher than 3"(76mm), great care must be

exercised and all by-standing personnel are to be no closer than 20 feet (6m) from the lift point

of the unit.

NOTICE

Risk of structural interference. Can cause equipment or building damage.

While on the skid, the unit is too tall (83" [2108mm] overall height) to fit through a standard

doorway. Any attempt to move the unit, while skidded, through a standard doorway will cause

damage to the unit and to the building.

NOTICE

Risk of damage from forklift. Can cause unit damage.

Keep the forklift tines level and at a height suitable to fit below the skid and/or unit to prevent

exterior and/or underside damage.

Vertiv | Liebert® XDC™ User Manual | 10

Page 11

NOTICE

Risk of improper storage. Can cause unit damage.

Keep the Liebert XDC upright, indoors and protected from dampness, freezing temperatures

and contact damage.

NOTICE

Risk of overtightening securing straps. Can cause damage to panels.

Place a protective material between the straps of the piano jacks and the unit. Ensure that the

straps are not tightened to a point of damaging panels.

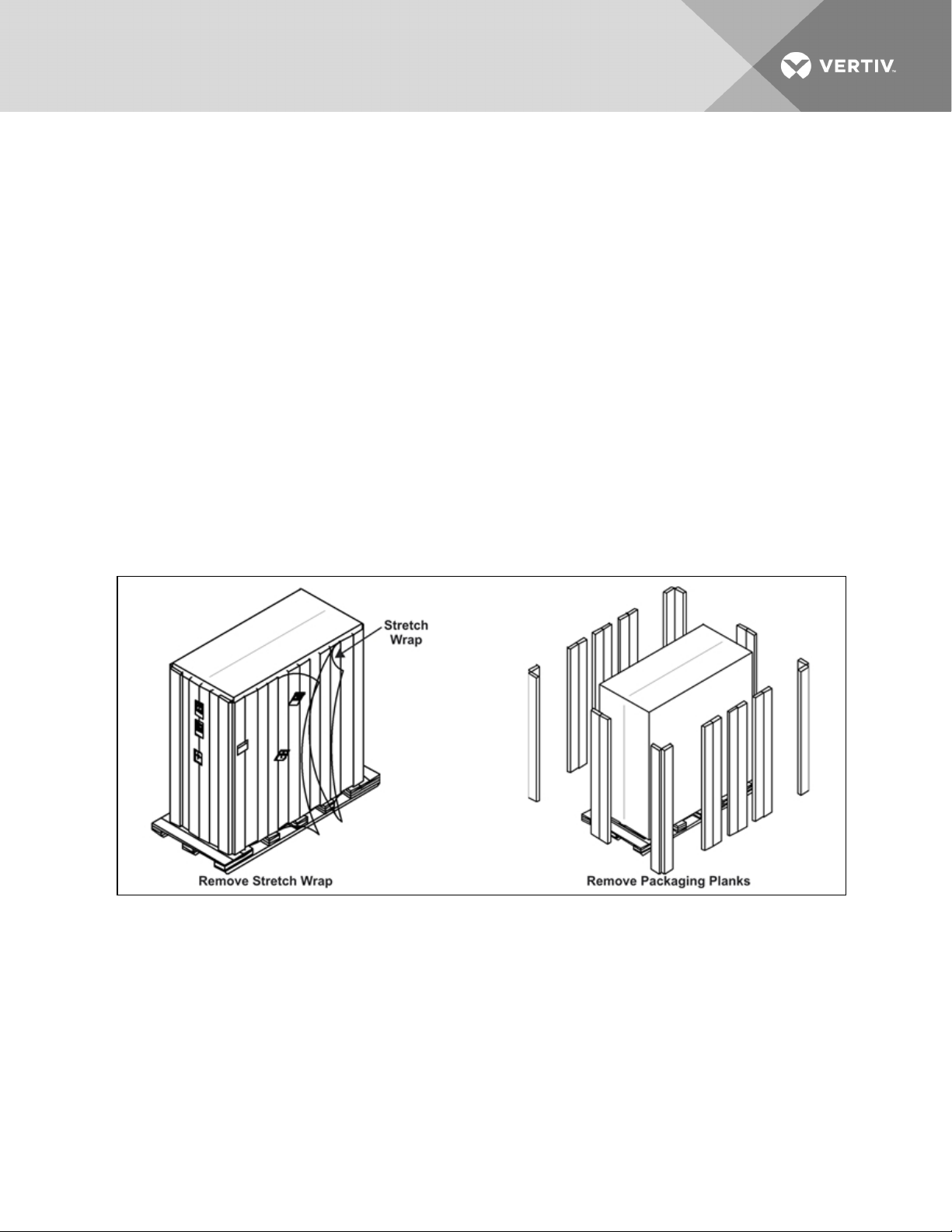

2.3.2 Unpacking the Liebert XDC

1. Remove the exterior stretch wrap packaging from the unit, exposing the protective corner and

side packaging planks.

2. Remove the corner and side packaging planks from the unit, exposing the bag over the unit.

The bag may remain in place for dust and panel protection or removed for immediate unit

installation.

3. Remove the bag from the unit when ready to remove the skid for installation.

Figure 2.2 Unpacking the Liebert XDC

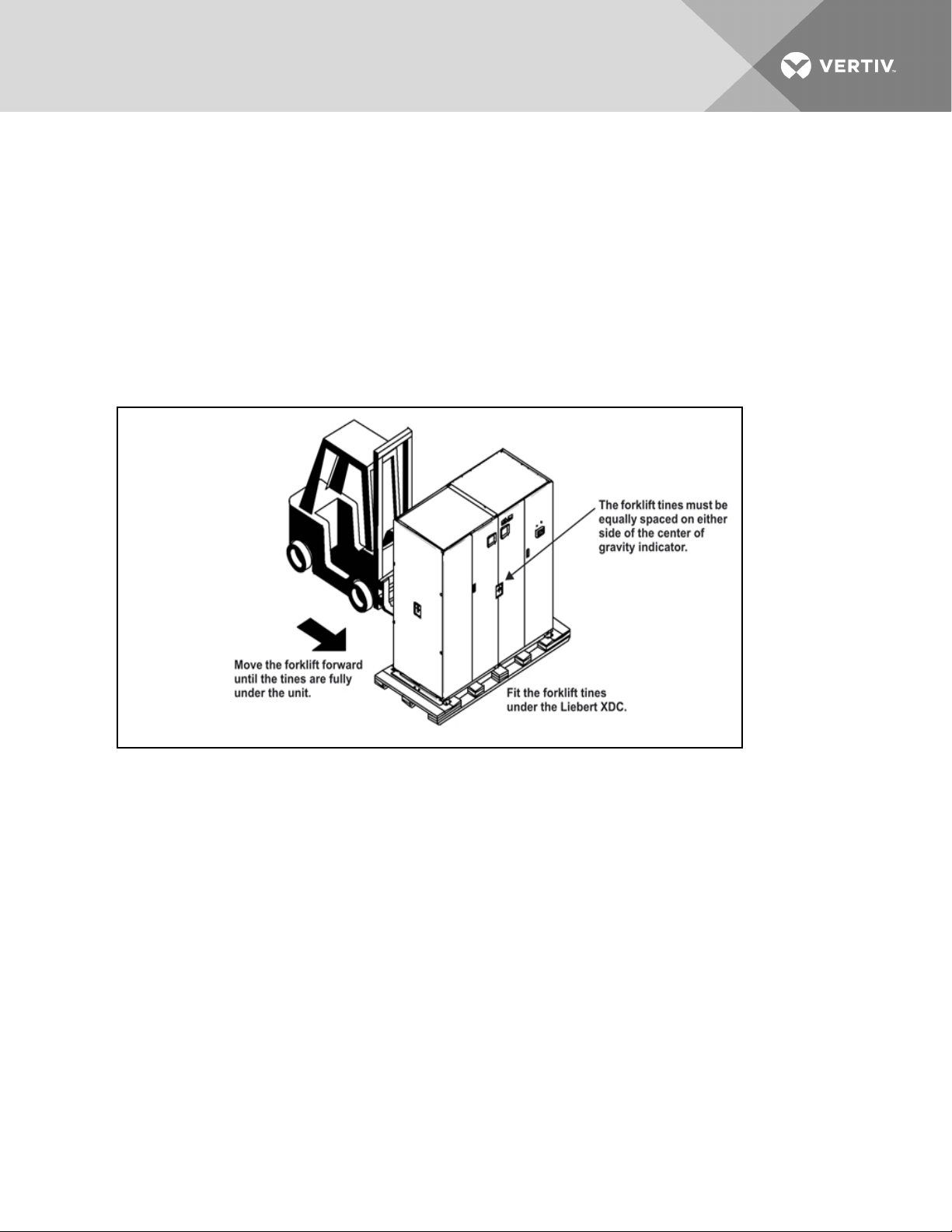

2.3.3 Removing the Unit from the Skid Using a Forklift

1. Align the forklift with either the front or rear side of the unit.

Make sure the tines of the forklift are locked at their widest position.

Use the center of gravity indicators to determine the entry points for the tines. The tines must

be equally spaced on either side of the center of gravity indicator (see Figure 2.3 on the next

page).

Vertiv | Liebert® XDC™ User Manual | 11

Page 12

2. Insert the tines of the forklift under the unit.

Make sure the tines are level. The tines must be low enough to fit under the unit without

damaging it.

Make sure the tines extend beyond the opposite side of the unit.

3. Remove the 12 lag bolts and two brackets that secure the unit to the skid.

NOTE: Each lag bolt is 1-1/2" (38mm) long. They can be removed with a 9/16" socket or wrench.

4. Lift the unit to a height that it is not being support by the skid.

5. Move the skid from under the unit.

Figure 2.3 Use a forklift to remove the Liebert XDC from the skid

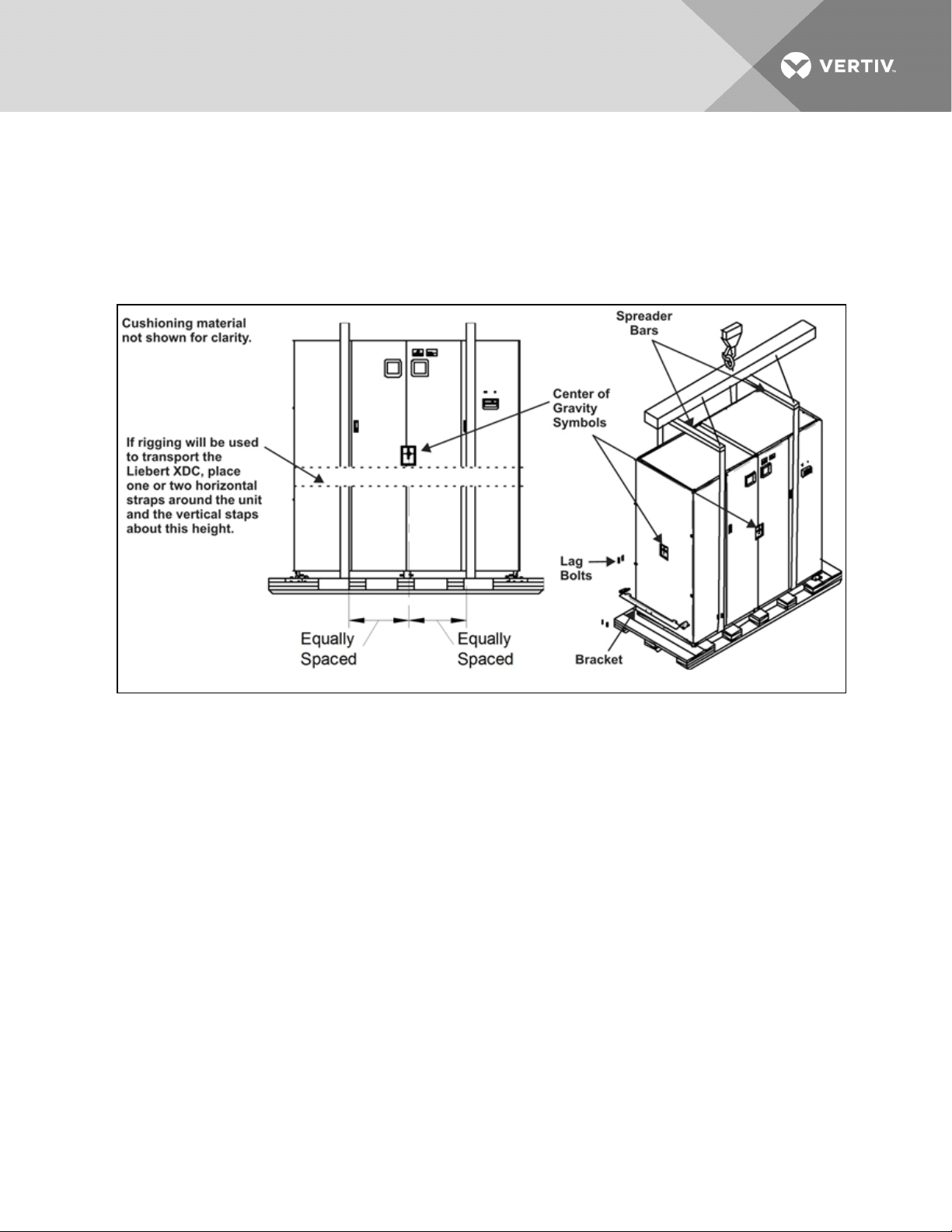

2.3.4 Removing the Unit from the Skid using Rigging

1. Use the center of gravity indicators on the unit to position the slings. The slings must be

equally spaced on either side of the center of gravity indicator (see Figure 2.4 on the facing

page).

2. Place slings under the unit using spaces provided between the skid deck boards.

NOTE: Unit is shown without outer packaging. These instructions may be applied with the outer

packaging in place.

3. Use spreader bars or an equivalent method to ensure proper protection of the unit.

4. Ensure that the panels, if attached, are well protected from the slings with cushioning material.

NOTE: If rigging is to be used to move the unit closer to the site for installation, place one or two

horizontal straps around the unit and vertical straps at mid height.

5. Remove the 12 lag bolts and two brackets that secure the unit to the skid.

NOTE: Each lag bolt is 1-1/2" (38mm) long. They can be removed with a 9/16" socket or wrench.

Vertiv | Liebert® XDC™ User Manual | 12

Page 13

6. Lift the unit off of the skid to an elevation point where the skid is not supporting the weight of

the unit.

7. Remove the skid from under the unit.

NOTE: Depending on final installation location and the method of moving the Liebert XDC, the skid may

need to remain under the unit.

Figure 2.4 Removing the unit from the skid using rigging

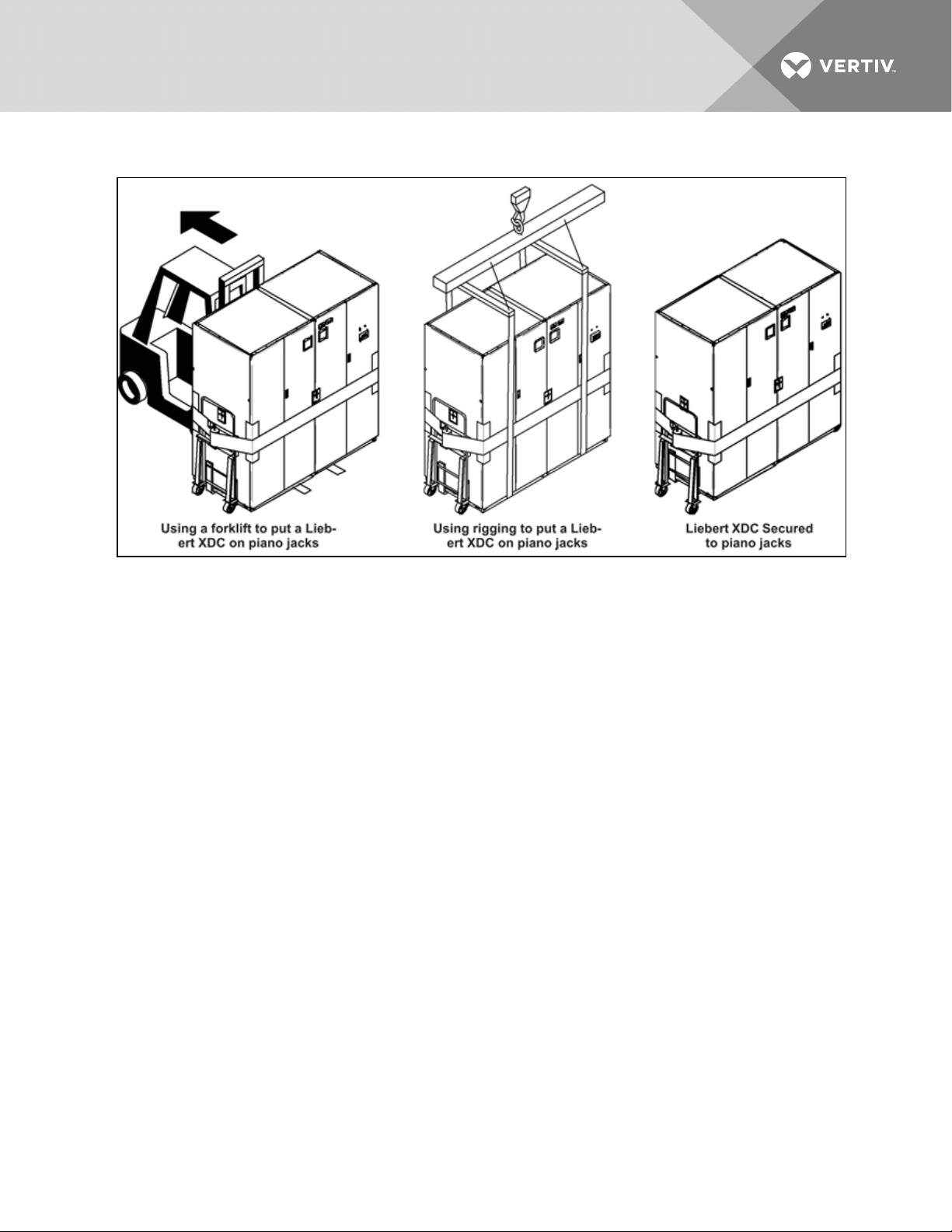

2.3.5 Moving the Liebert XDC Using Piano Jacks

1. Elevate the Liebert XDC with a lifting mechanism, such as a forklift or rigging.

1. Position one piano jack at each end of the Liebert XDC.

2. Lower the unit to a height suitable for placing it on the piano jacks.

3. Put protective material between the Liebert XDC and the piano jacks and straps.

4. Secure the Liebert XDC to the piano jacks.

5. Release the the Liebert XDC from the straps securing it to the lifting mechanism and move the

mechanism away from the unit.

Using the piano jacks, at least two properly trained and qualified personnel can move the unit.

Vertiv | Liebert® XDC™ User Manual | 13

Page 14

Figure 2.5 Securing the Liebert XDC to piano jacks

2.3.6 Removing the Unit from the Piano Jacks

1. Lower the Liebert XDC as far as the piano jacks will allow.

2. Undo all strapping holding the piano jacks to the unit.

3. Lift one end of the Liebert XDC off one piano jack with a pry bar or similar device, taking care

not to damage the unit’s cabinet.

4. Repeat step 3 to remove the piano jack from under the opposite end of the Liebert XDC.

5. Remove all material used to protect the unit from the piano jacks and strapping.

Vertiv | Liebert® XDC™ User Manual | 14

Page 15

3 INSTALLATION

3.1 Mechanical Considerations

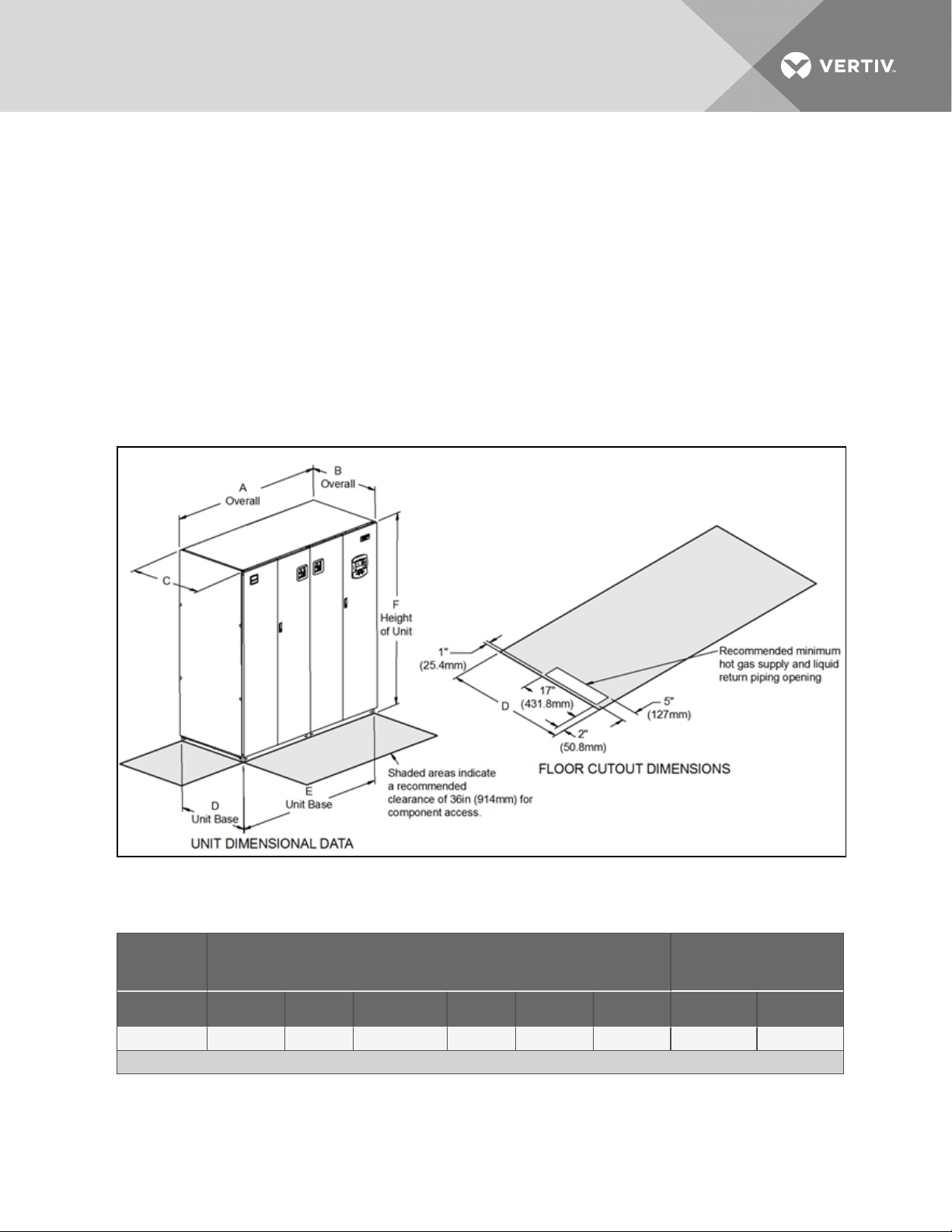

3.1.1 Positioning the Liebert XDC

Install the Liebert XDC according to the site specific documentation and secure the unit to the floor.

The Liebert XDC can be installed near a wall or another Liebert XDC. However, there must be at least

3feet(92cm) clearance in front of the Liebert XDC as service access for components in the unit.

NOTE: During installation of the Liebert XDC, the top, bottom, front and left side of the unit must be

accessible.

Figure 3.1 Dimensional data

Table 3.1

Liebert XDC dimensions, weight

Air-Cooled

Model

50/60Hz A B* C D E F Domestic Export

XDC160 74 (1880) 34 (864) 33-1/ 8 (841) 33 (838) 72 (1829) 78 (1981) 1975 ( 896) 2109 (957)

*Dimension does not include the bezel ofthe disconnectswitch, the handle or the control bezel.

Vertiv | Liebert® XDC™ User Manual | 15

Dimensional Data, inches (mm)

Shipping Weight

lb. (kg)

Page 16

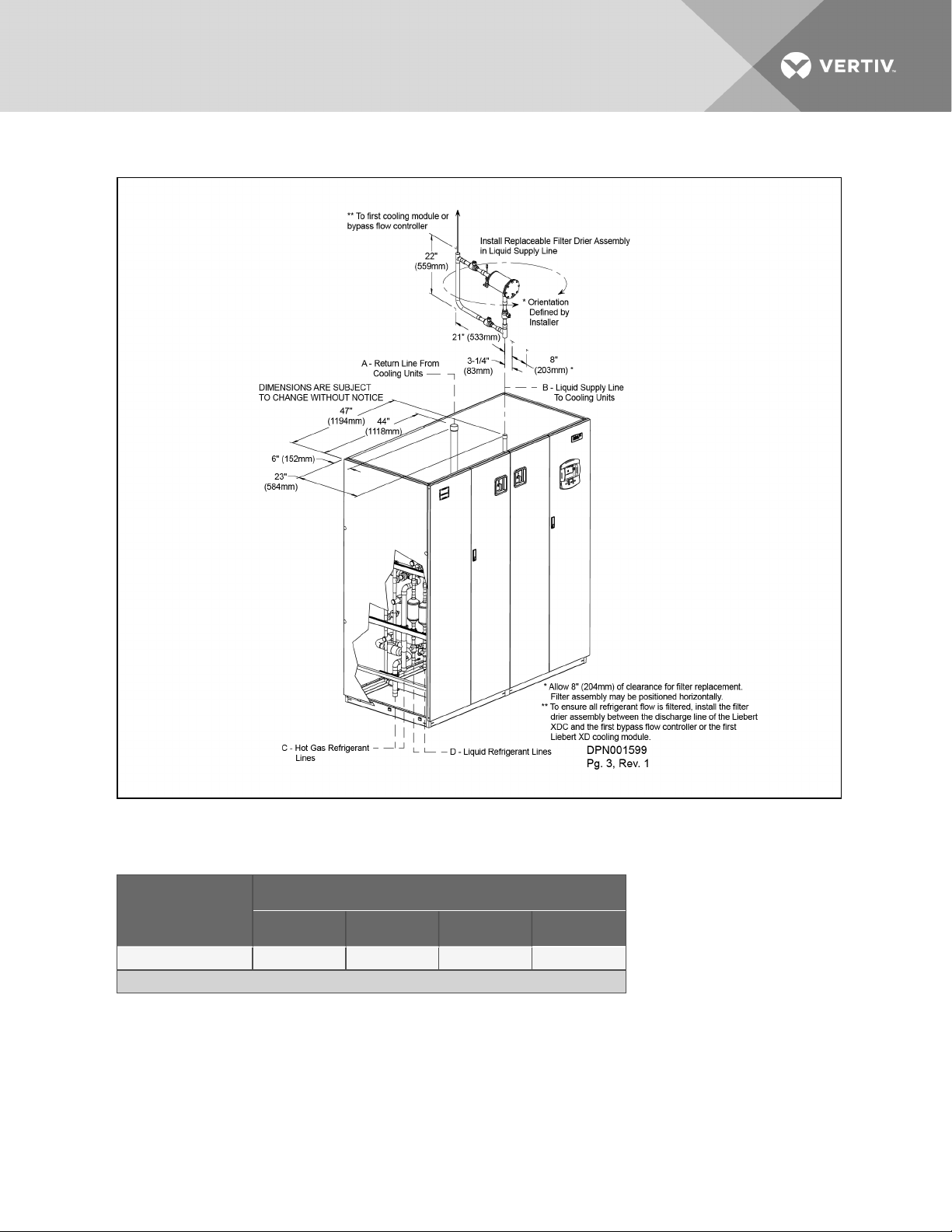

Figure 3.2 Piping locations

Table 3.2

Liebert XDC piping connection sizes

Piping Outlet Connection Sizes, OD Cu, inches

50/60Hz

A B C D

XDC160 2-1/8 1-1/8 1-3/8 7/8

Source: DPN001599

Vertiv | Liebert® XDC™ User Manual | 16

Page 17

3.1.2 Placing the Liebert XDC on a Floor Stand

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves,

shoes and glasses should attempt to move, lift, remove packaging from or prepare unit for

installation.

Read all of the following instructions before attempting to move, lift, remove packaging from or

preparing unit for installation.

The water/glycol floor stand can be located beneath the Liebert XDC unit or can be installed

nearby.

NOTE: Consult the factory if the Liebert XDC is not installed on the water/glycol condenser floor stand

to prevent exceeding the maximum piping distances.

Refer to the floor stand installation sheet shipped inside the water regulating valve package.

1. Move the floor stand assembly to its installation area and uncrate the unit.

2. Position the floor stand in its final location.

3. Insert leveler pads into each floor stand leg.

4. Level the top of the floor stand to the specified height with the flanged adjusting nut.

5. Tighten jam nuts on all legs against flanged adjusting nuts.

6. Using an appropriate lifting device or method, raise the Liebert XDC and move it above the

floor stand.

7. Align the welded tabs on top of the floor stand with the inside of the unit frame base (see Detail

A in Figure 3.3 on the next page).

8. Maintaining the alignment of the Liebert XDC and the floor stand, lower the Liebert XDC onto

the floor stand.

9. Connect the hot gas refrigerant lines from the Liebert XDC to the floor stand with 1-3/8" tubing

(see Figure 3.3 on the next page andFigure 3.4 on page20).

10. Connect the liquid refrigerant lines as shown from the Liebert XDC unit to the floor stand with

7/8" tubing (see Figure 3.3 on the next page andFigure 3.4 on page20).

11. Connect the water lines as shown with the provided valving (see Figure 3.3 on the next page

andFigure 3.4 on page20).

12. Connect capillary lines from each water regulating valve to condensers in the floor stand (see

Figure 3.3 on the next page andFigure 3.4 on page20).

Capillary length is limited to 48" (1219mm).

13. Check the pipes for leaks and evacuate air from all pipes.

14. Insulate all water/glycol lines.

15. Charge each condenser loop with R-407C (see Table 4.15 on page57).

Vertiv | Liebert® XDC™ User Manual | 17

Page 18

Figure 3.3 Water/glycol Liebert XDC on a floor stand—positioning and piping connections

Vertiv | Liebert® XDC™ User Manual | 18

Page 19

Table 3.3

Liebert XDC water/glycol piping connection sizes

Model Piping Outlet Connection Sizes, OD Cu, inches

50/60Hz A B C D

1

E

2

F

XDC160 2-1/8 1-1/8 1-3/8 7/8 2-1/2 2-1/8 or 2-5/8

1. Threaded female connection

2. 2-1/8" for 1" water r egulatingvalve; 2-5/8" for 1- 1/4" water regulating valve

Source: DPN00141 9 Rev. 2

Vertiv | Liebert® XDC™ User Manual | 19

Page 20

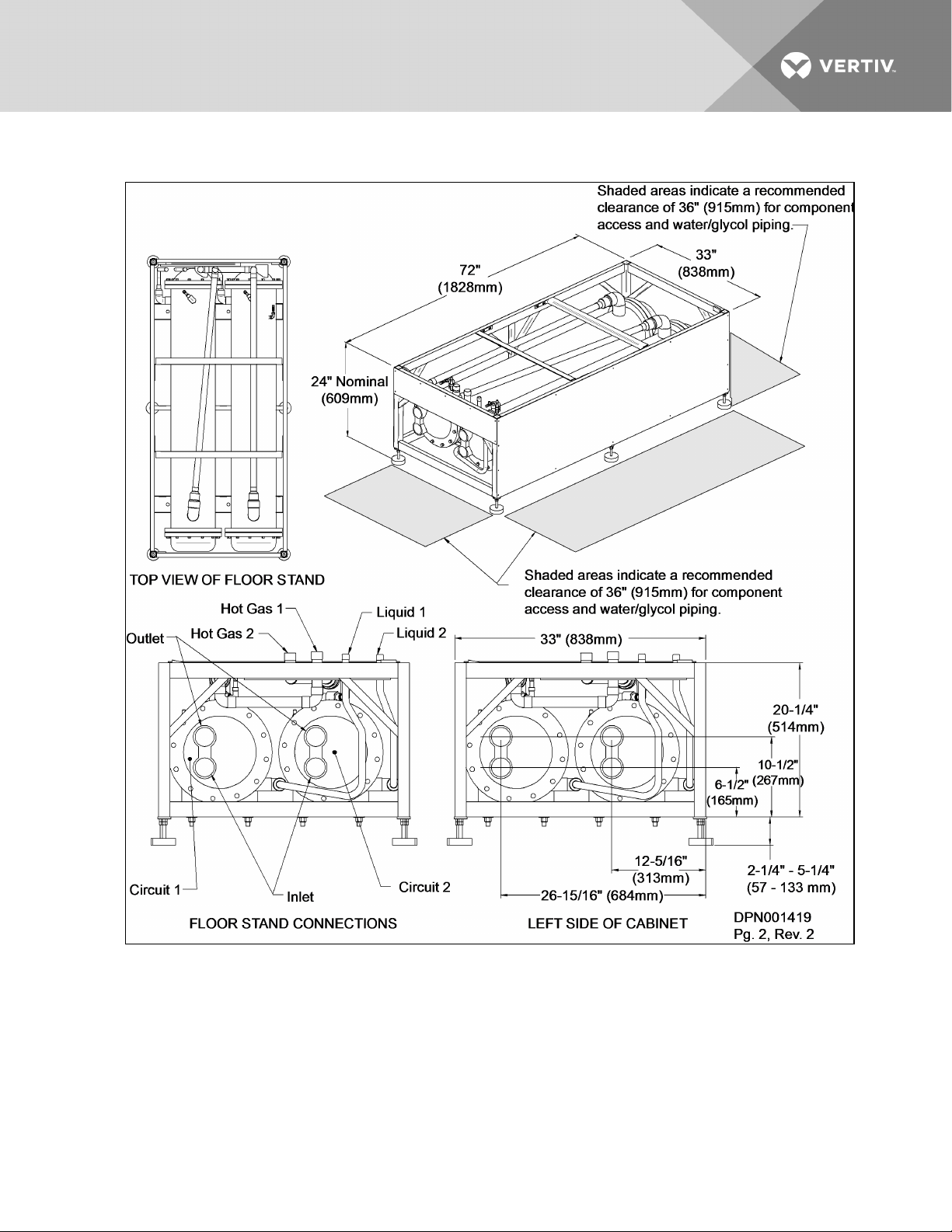

Figure 3.4 Piping locations—floor stand and valve assembly

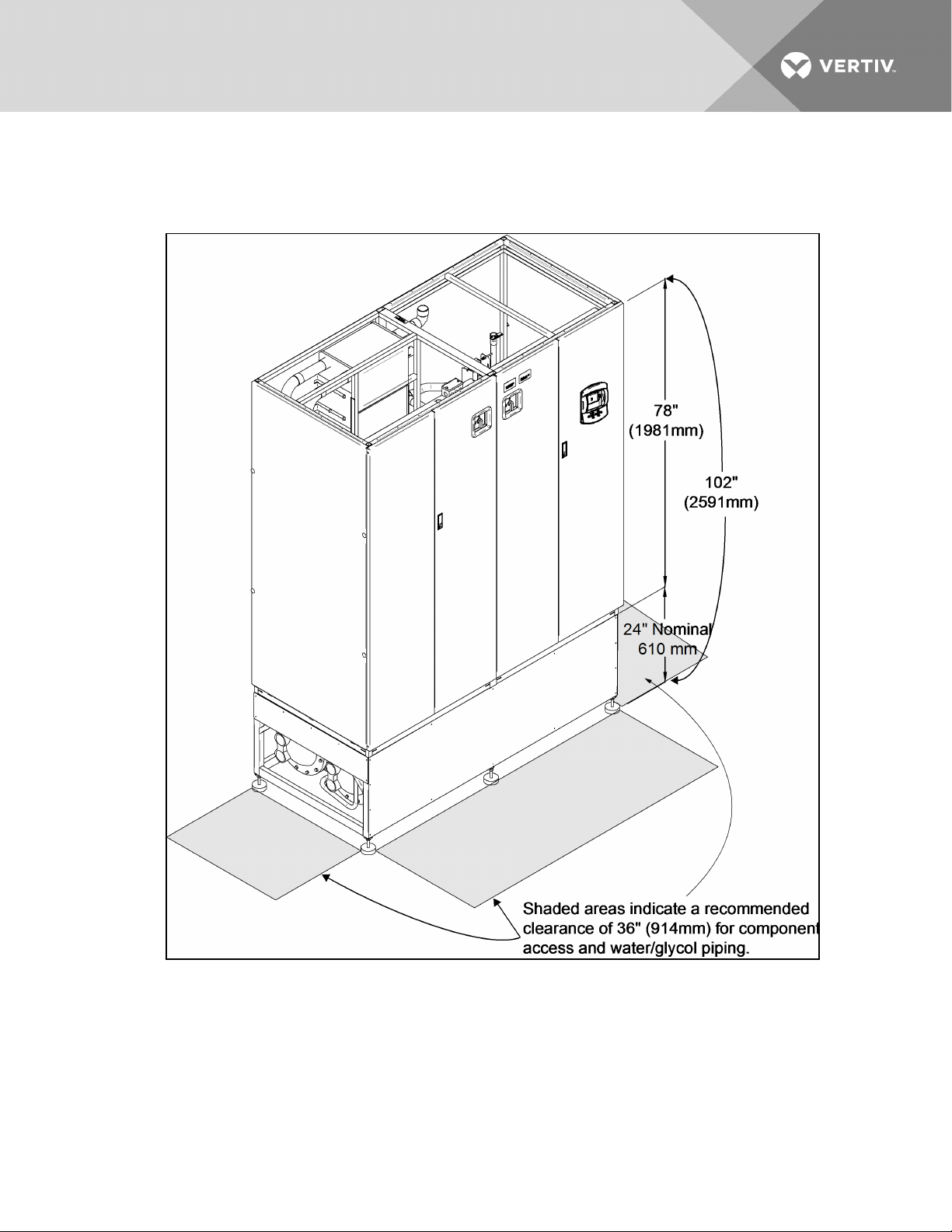

3.1.3 Positioning the Liebert XDC with Floor Stand

Install the Liebert XDC according to the site-specific documentation and secure the unit to the floor.

The Liebert XDC can be installed near a wall or another Liebert XDC. There must be at least 3 feet

(914mm) clearance in front of the Liebert XDC for service access. When the Liebert XDC is combined with

the optional water/glycol floor stand, Vertiv recommends leaving 3 feet (914mm) of clearance on the left

side of the unit.

Vertiv | Liebert® XDC™ User Manual | 20

Page 21

A Liebert XDC on a floor stand is 102 inches (2591 mm) high (see Figure 3.5 below). The unit can be raised

or lowered 1.5 inches (38.1 mm) with the leveling feet.

Figure 3.5 Dimensions and clearances for Liebert XDC on floor stand

Vertiv | Liebert® XDC™ User Manual | 21

Page 22

3.2 Electrical Considerations

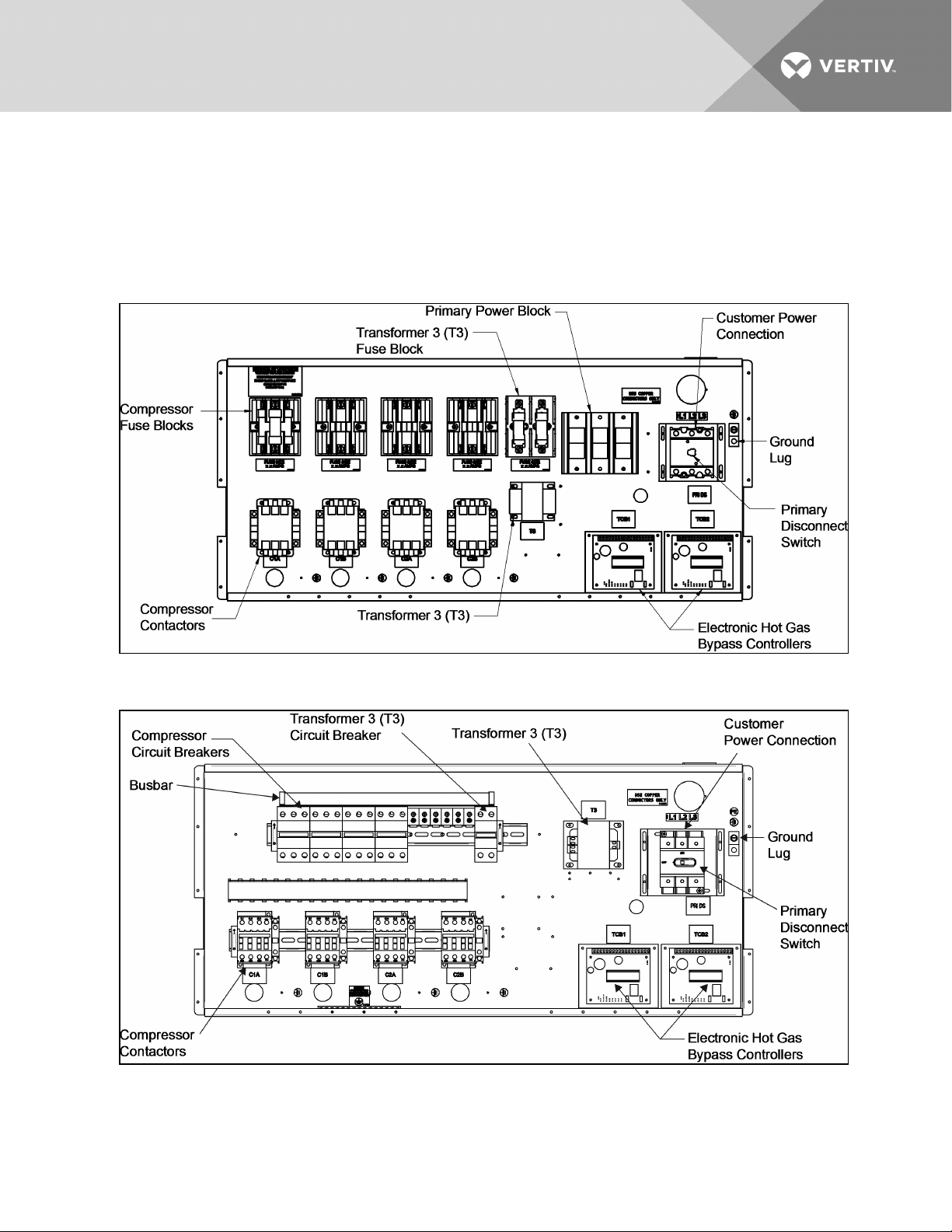

3.2.1 High Voltage Connections

Make sure the actual supply voltage and frequency correspond to the voltage and frequency indicated

on the Liebert XDC’s rating plate.

Connect cables for high voltage supply to the electrical box in the Liebert XDC according to Figure 3.1 on

page15, Figure 3.7 on page24 and Figure 3.8 on page25 and make sure that the phases are correctly

connected.

WARNING! Risk of electric shock. Can cause death and injury.

Disconnect all local and electric remote power supplies before working within.

WARNING! Risk of electrical shock, short circuit and/or control malfunction. Can cause

equipment damage injury and death.Damage to wiring or components can make unit unsafe to

operate.Use caution when installing wiring to prevent damage to factory wiring.Install

protective bushings in wiring knockouts as required to protect wiring from sharp edges.Do not

disturb factory wiring or route field-installed wiring over electrical terminals.Use NEC Class 1

wiring for all hazardous voltage electrical power supplies.Check and retighten all wiring

connections before starting the unit.

NOTE: Before beginning to install the Liebert XDC, read all instructions, verify that all the parts are

included and check the nameplate to be sure the Liebert XDC voltage matches available utility power.

Follow all local codes.

Vertiv | Liebert® XDC™ User Manual | 22

Page 23

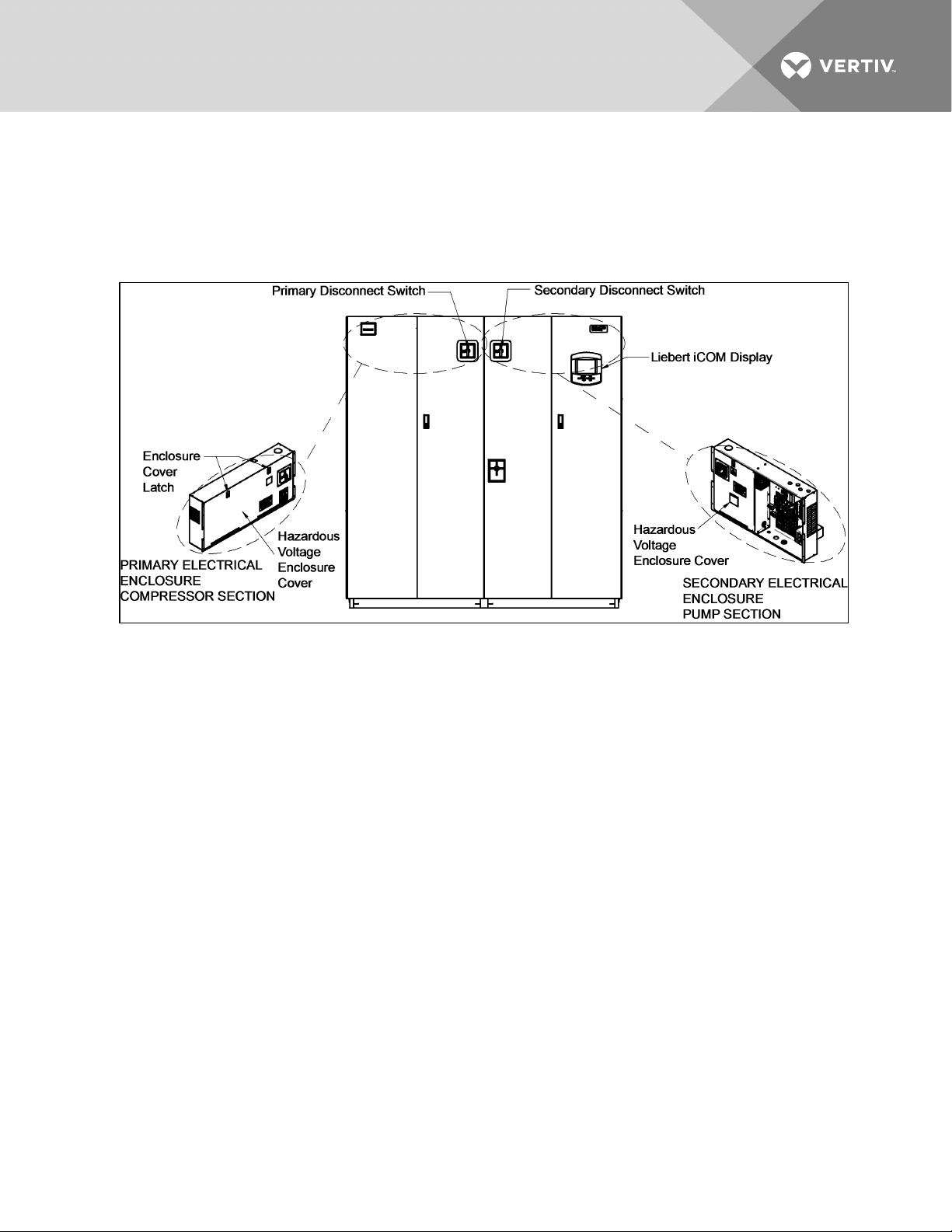

3.2.2 Connecting High-Voltage Cables

1. Turn the Liebert XDC’s primary disconnect switch to the Off position (see Figure 3.6 below).

Open the front doors and push down on the enclosure cover latch to open the hazardous

voltage enclosure cover.

Figure 3.6 Front view of Liebert XDC and electrical enclosures

Vertiv | Liebert® XDC™ User Manual | 23

Page 24

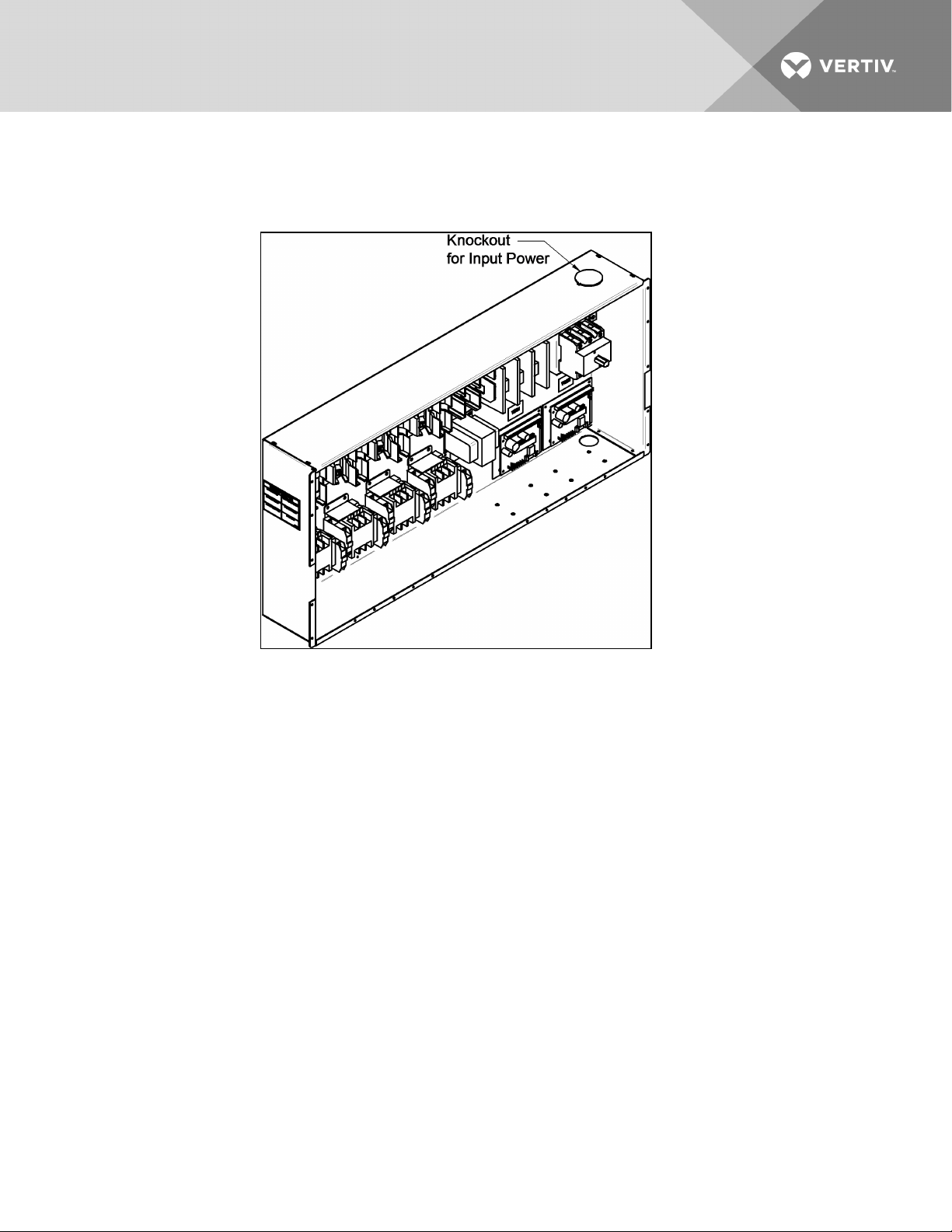

2. Determine which knockouts in the electrical enclosure will be used and remove them (see

Figure 3.7 below).

Figure 3.7 Electrical enclosure knockout locations for field wiring

Vertiv | Liebert® XDC™ User Manual | 24

Page 25

3. Route the input hazardous voltage electrical power wiring through the top right knockout on

the primary electrical enclosure (see Figure 3.7 on the previous page) to the disconnect

switch L1, L2 and L3 (see Figure 3.8 below). Observe proper phasing.

4. Connect the ground wire to the ground lug (see Figure 3.8 below andFigure 3.10 on the next

page for 60Hz models and Figure 3.9 below andFigure 3.11 on the next page for 50Hz models).

Figure 3.8 60Hz models, high voltage connections—primary disconnect switch

Figure 3.9 50Hz models high voltage connections—primary disconnect switch

Vertiv | Liebert® XDC™ User Manual | 25

Page 26

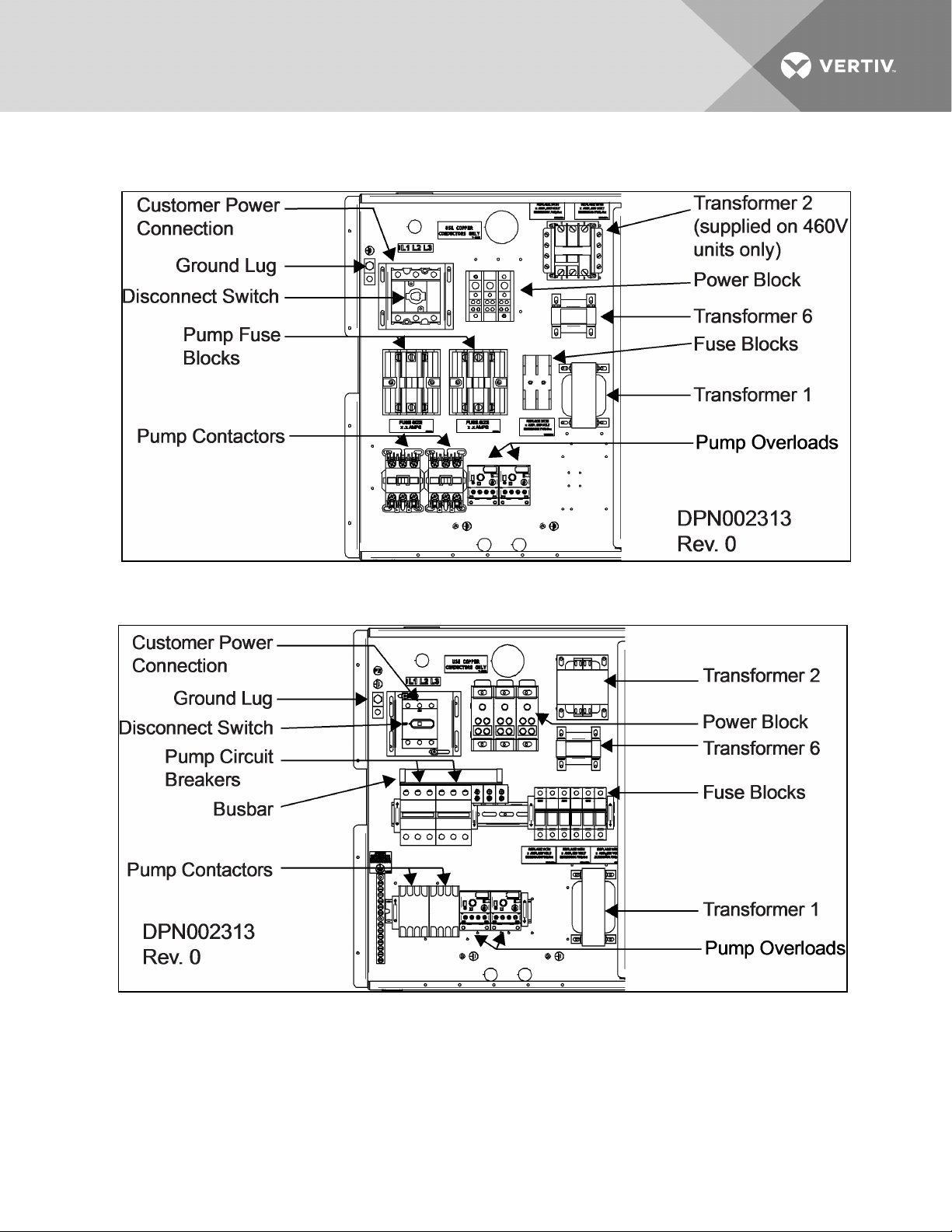

Figure 3.10 60Hz models high voltage connections—secondary disconnect switch

Figure 3.11 50Hz models high voltage connections—secondary disconnect switch

Vertiv | Liebert® XDC™ User Manual | 26

Page 27

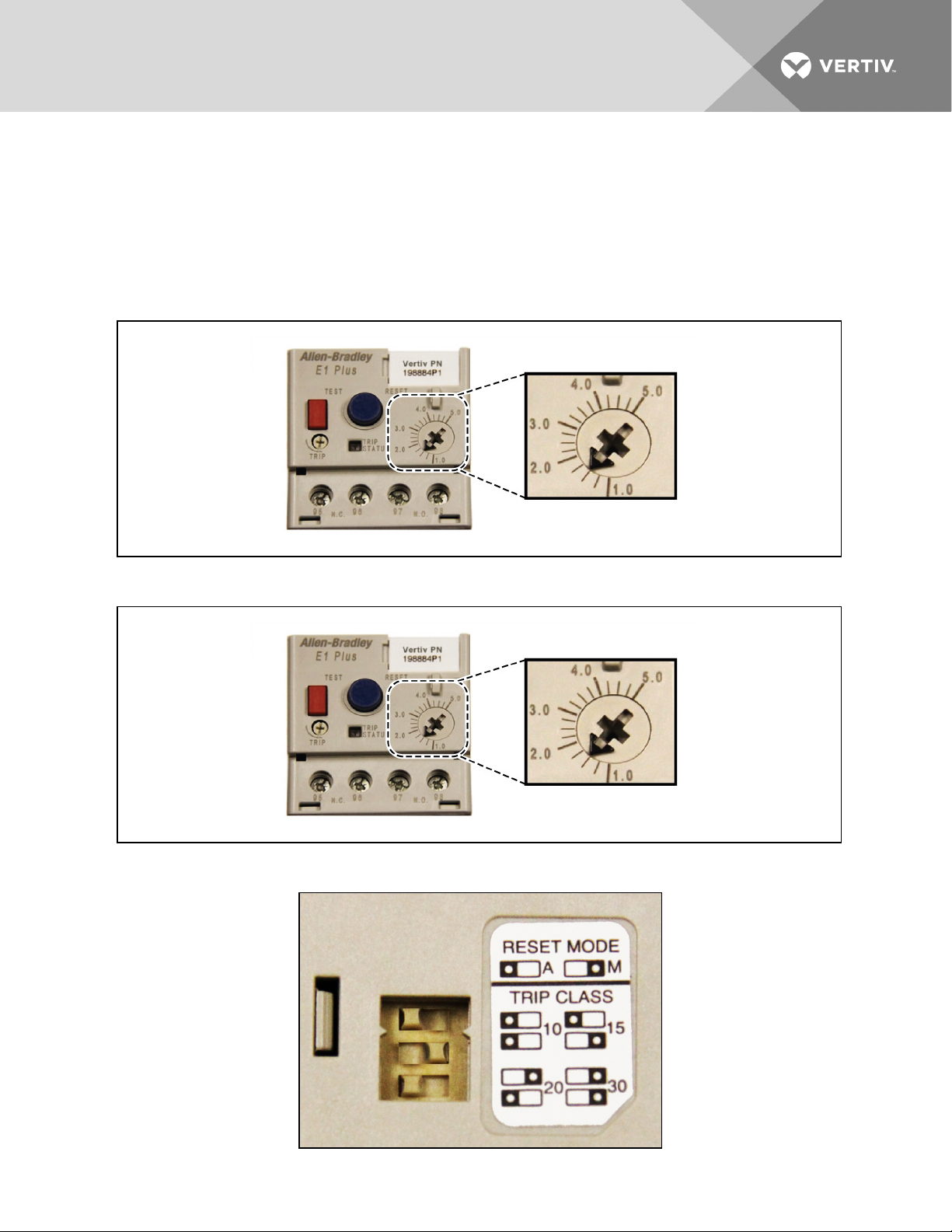

3.3 External Pump Overloads

The Liebert XDC is shipped with external pump overload with trip point settings and DIP switch settings

for normal operations. The trip points are in increments of 0.25A and should not be changed from the

factory settings. For 460V 60Hz and 380-400V 50Hz units, the trip point is set at 1.5A (Figure 3.12 below).

See Figure 3.14 below for factory DIP switch settings for normal operation with reset mode set as

automatic and Trip Class 20.

Figure 3.12 460V 60Hz and 400V 50Hz factory setting external pump overload trip point

Figure 3.13 208V factory setting external pump overload trip point

Figure 3.14 Factory DIP switch settings

Vertiv | Liebert® XDC™ User Manual | 27

Page 28

3.4 Extra Low Voltage Connections

Extra Low Voltage (ELV) power output is 30V and 100VA or less.

1. Turn off all unit power before connecting cables or wires. Failure to do so may damage this

equipment.

2. Route low voltage electrical connections through the appropriate knockouts as shown in

Figure 3.17 on page31.

3. User interface and temperature/humidity sensor wire is NEC Class 2. All electrical installation

must comply with all national, state and local requirements.

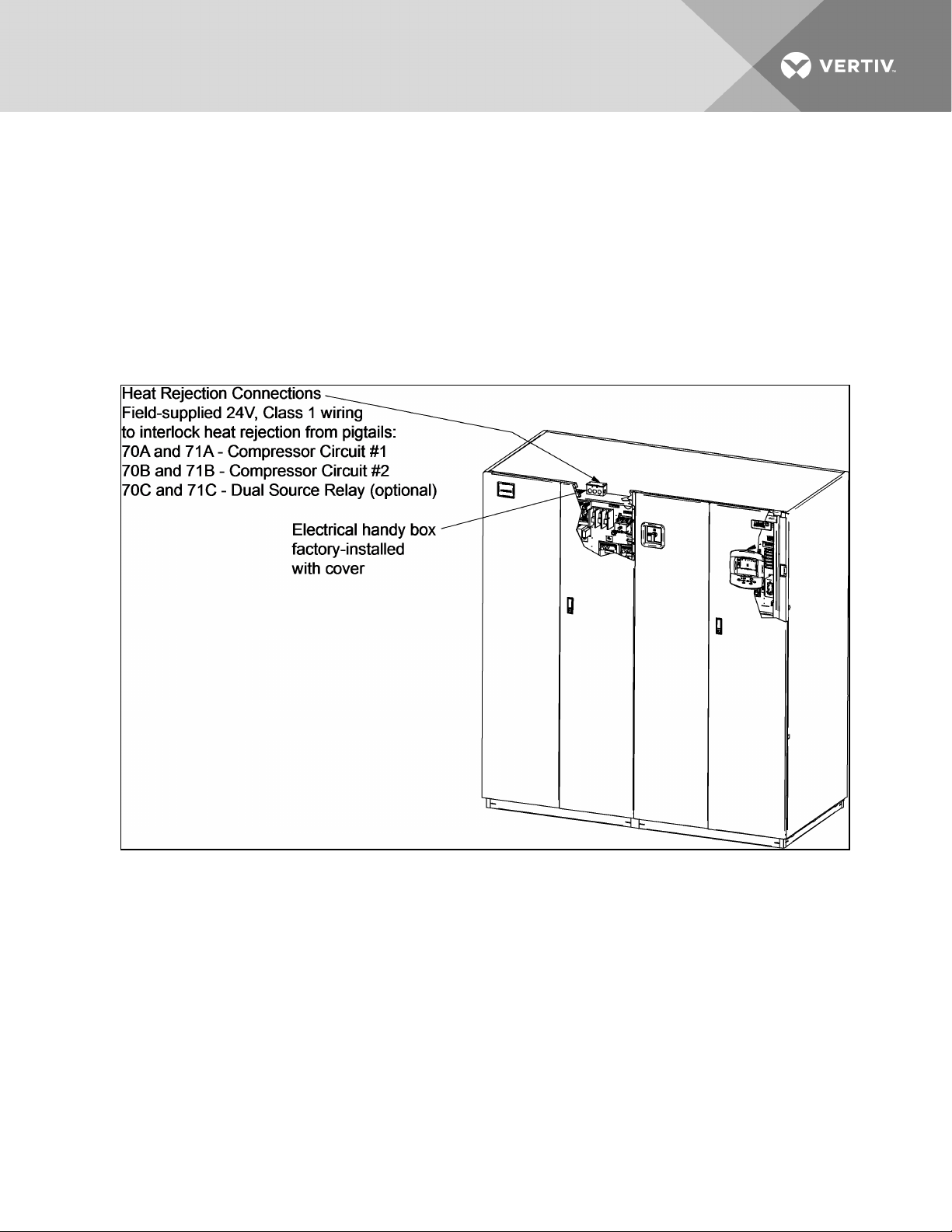

Figure 3.15 Liebert XDC heat rejection connection points

Vertiv | Liebert® XDC™ User Manual | 28

Page 29

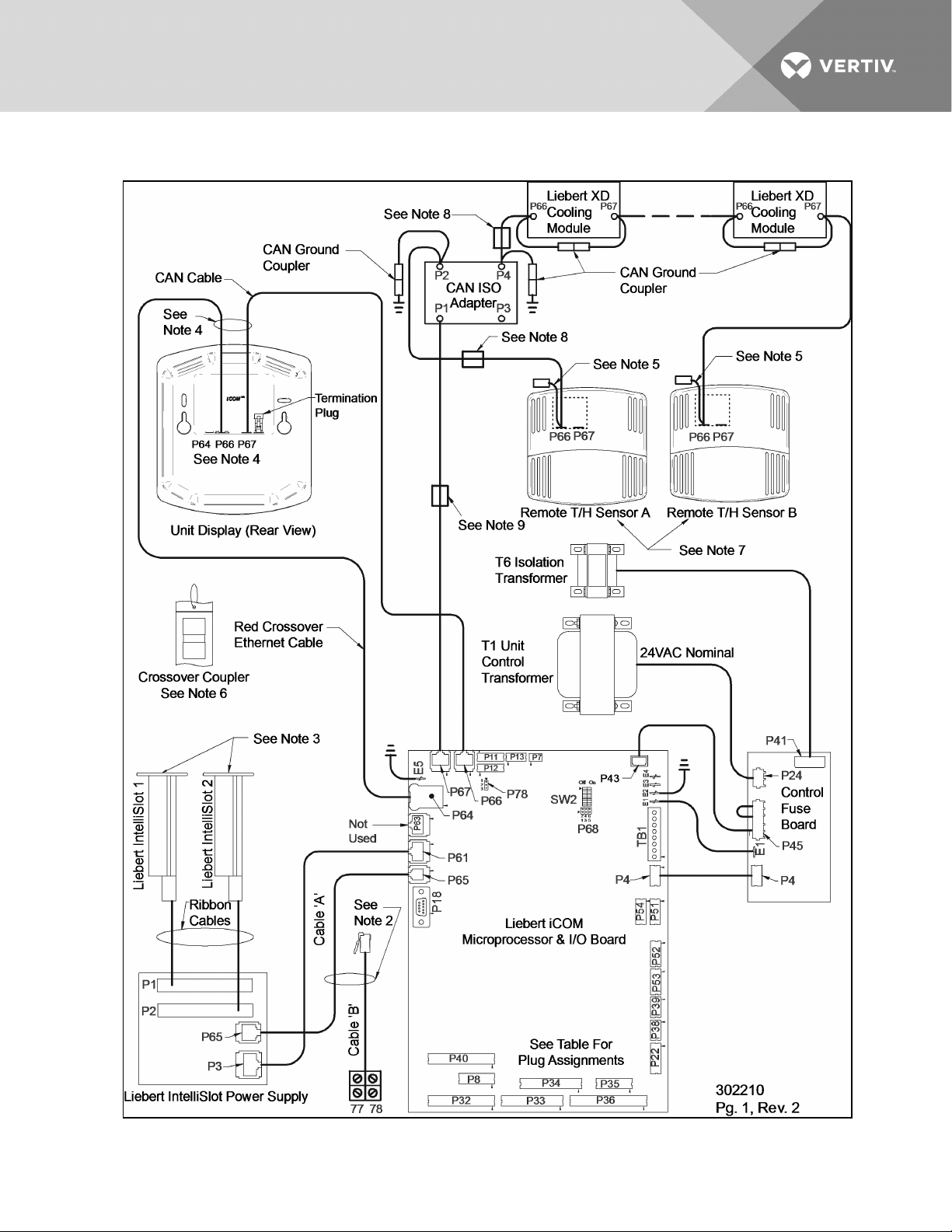

Figure 3.16 Connecting remote temperature/humidity sensors

Vertiv | Liebert® XDC™ User Manual | 29

Page 30

Notes on Figure 3.16 on the previous page

1. See unit electrical schematic, installation and user manuals.

2. Cables A and B provided with each unit. Only one is used as follows:

a. Liebert IntelliSlot-Based Communications—Cable A is pre-connected to P65 on the

microprocessor and I/O board and P65 on Liebert IntelliSlot power supply.

b. Non-Liebert IntelliSlot-Based Communications—Cable B is pre-connected to Terminals

77 & 78 but must be exchanged with Cable A at P65 on the microprocessor and I/O

board.

3. Install applicable Liebert IntelliSlot cards.

4. Both cables (P64 and P66) are required.

5. It is not necessary to connect ground coupling on end of cable connected to Sensor A or B.

6. A crossover coupler is provided for unit-to-unit (U2U) networking. Unplug the red cable from

P64 on the microprocessor and I/O board and connect to one side of the crossover coupler.

The first customer connection point is to P64 on the microprocessor and I/O board. The

second customer connection point is to the other side of the crossover coupler. This connects

the microprocessor and I/O board and display to the private U2U network.

7. The remote sensors are interchangeable as to which connects to the Liebert XD cooling

module and which connects to P2 on CAN ISO.

8. Field-install cables with factory-installed ferrite beads (when provided, typical two places).

Each cable must make three passes through the ferrite bead. Locate the ferrite bead on top of

the electric box. See instruction sheet provided with the cable assembly.

9. Factory-installed ferrite bead (when provided). Cable passes through ferrite bead three times.

Vertiv | Liebert® XDC™ User Manual | 30

Page 31

Figure 3.17 Electrical enclosure knockout locations for Extra Low Voltage connections

Field Connections—All Units

• Place Sensor A in the higher-temperature portion of the cold aisle where the Liebert XD

modules are located. Alternatively, it may be placed on the return air side of the primary air

mover (e.g., Liebert DS™) in the room if it represents the conditions where all the Liebert XD

cooling modules are located. Do not install the sensor where ambient air might cause false

readings, for example, near unsealed doors, windows and similar areas.

1. Unpack the two remote temperature/humidity sensors and cables.

One sensor is labeled Sensor A and the other, Sensor B. The sensor cables are interchangeable;

each bears labels indicating Sensor End and Unit End.

2. Connect the Sensor End of one of the supplied sensor cables to P66 on Sensor A (see Figure

3.16 on page29).

3. Connect the Unit End of the sensor cable to P4 on the CAN Isolator inside the Liebert XDC (see

Figure 3.16 on page29). Secure the terminal plug on the cable shield to the into the terminal

plug adjacent to P2 (see Figure 3.16 on page29).

4. Connect the Sensor End of the second sensor cable to P66 on Sensor B (see Figure 3.16 on

page29).

5. Connect the Unit End of the cable to P4 on the CAN Isolator inside the Liebert XDC (see Figure

3.16 on page29). Secure the terminal plug on the cable shield to the terminal plug adjacent to

P4 (see Figure 3.16 on page29).

Vertiv | Liebert® XDC™ User Manual | 31

Page 32

Field Connections—Optional for All Units

• Connect optional field wiring from remote devices to Remote Alarm Device, Common Alarm

Output, IGM and Remote Shutdown, if applicable. See terminal strip descriptions in Figure 3.18

on the facing page.

Field Connections—Air-Cooled Units only

Connect field wiring to heat rejection connection terminals on the handy box as shown in Figure 3.15 on

page28.

Vertiv | Liebert® XDC™ User Manual | 32

Page 33

Figure 3.18 Extra Low Voltage field connection points

Vertiv | Liebert® XDC™ User Manual | 33

Page 34

DIP Switch and Jumper Settings for remote sensors

The Liebert XDC is shipped with jumpers and DIP switch settings for normal operations. See Figure 3.19

below.

Figure 3.19 DIP switch and jumper settings for remote sensors

3.5 Remote Sensor Installation—Proper Placement

Placement of the two remote temperature/humidity sensors is critical to effective cooling of the

conditioned space.

The remote sensors must be installed in areas where conditions are representative of the space

conditioned by the Liebert XDC. Vertiv recommends installing the sensors in different areas near the

cooling modules served by the Liebert XDC. If the return air side of the primary air mover, such as a

Liebert DS, represents the conditions where the Liebert XD cooling modules are located, one sensor could

be placed there. Vertiv suggests placing the other sensor on the wall opposite the heat load area (see

Figure 3.20 on the facing page for guidance).

Vertiv | Liebert® XDC™ User Manual | 34

Page 35

Figure 3.20 Suggested remote sensor placement

Do not install the sensors where ambient air might cause false readings, for example, near unsealed doors

or windows, or areas with stagnant air.

Vertiv | Liebert® XDC™ User Manual | 35

Page 36

This page intentionally left blank.

Vertiv | Liebert® XDC™ User Manual | 36

Page 37

4 PIPING AND FILLING WITH REFRIGERANT: R-134A AND R-407C CIRCUITS

4.1 European Union Fluorinated Greenhouse Gas Requirements

Stationary air conditioning, refrigeration, heat pump equipments and stationary fire protection systems in

the European Community market and operating with fluorinated greenhouse gases (f-gas), such as

R407C, R134a, R410A, must comply with the F-Gas Regulation: (EC) No. 842/2006 (F-gas). The regulation

prohibits, among other actions, venting fluorinated greenhouse gases to the atmosphere.

The F-Gas Regulation requires operators to use all measures that are technically feasible and do not

entail disproportionate cost to prevent leakage of these gases, to test for leakage regularly and to recover

f-gas before disposing of equipment, as well as during service and maintenance.

Refer to the full regulation for additional details.

4.2 Recommended Pipe Size

NOTE: Follow all local codes on maximum length and size of refrigerant lines.

Connect the main pipes between the Liebert XDC and the Liebert XD cooling modules according to site

specific documentation and the configuration guide for the Liebert XD system.

Elbows and restrictions shall be minimized for proper operation.

Table 4.1

Supply, return pipe sizes for Liebert XD refrigerant loop

Pipe Function Size/Equivalent Pipe Length

Liebert XDC s upply line, from Liebert XDC

supply to far thest Liebert XD cooling module

Liebert XDC r eturn line, from farthest coolingmodule to Liebert

XDC return

From any model Liebert XDO/ Liebert XDH supply to supply line

of L iebert XDC

From any model Liebert XDO/ Liebert XDH return to r eturn line

of L iebert XDC

From any model Liebert XDV/Liebert XDCF supply to s upply line

of L iebert XDC

From any model Liebert XDV/Liebert XDCF return toreturn line

of L iebert XDC

1-1/8" OD (1.025" ID) for lengths up to 60 feet

1-3/8" OD (1.265" ID) for lengths over 60 butless than175 feet

2-1/8" OD (1.985" ID) for lengths upto 60 feet

2-5/8" OD (2.465" ID) for lengths over 60 but less than 175 feet

1/2" OD (0.4 30" ID) for lengths up to 10 feet

7/8" OD (0.785" ID) for lengths over 10 but less than 25 feet

7/8" OD (0.785" ID) for lengths upto 10 feet

1-1/8" OD (1.025" ID) for lengths over 10 but less than 25 feet

1/2" OD (0.4 30" ID) for lengths up to 10 feet

5/8" OD (0.545" ID) for lengths over 10 butless than35

5/8" OD (0.545" ID) for lengths upto 10 feet

7/8" OD (0.785" ID) for lengths over 10 but less than 35 feet

Vertiv | Liebert® XDC™ User Manual | 37

Page 38

4.3 Liebert XDC Interconnection With Liebert XD Cooling Module

All piping must be ASTM (American Society for Testing and Materials) Type ACR copper pipe.

The Liebert XDC may be connected to Liebert XD cooling modules with either Liebert’s XD prefabricated

piping assembly or with rigid, off-the-shelf piping. In either setup, piping for the Liebert XD system is

arranged in a manner similar to piping for a chilled water system. Liebert XD cooling modules are

connected in parallel between main return and supply pipes going to and from the Liebert XDP/Liebert

XDC. Figure 4.1 below represents a typical configuration. For piping details, refer to Liebert’s XD System

Design Manual, SL-16655. The guidelines provided for pipe size must be strictly followed. Failure to size

the main lines and connection lines adequately may result in reduced cooling capacity. The critical

aspects of pipe sizing are related to refrigerant volume and pressure drop. Both must be minimized.

Figure 4.1 Liebert XD system diagram

4.4 Piping Installation Method

The assembly and connection means used for piping in the Liebert XD system are similar to those used

for conventional refrigeration systems. All piping should be installed with high-temperature brazed joints.

Soft soldering is not recommended.

During brazing, the lines must be filled with flowing dry nitrogen to prevent excessive oxidation and scale

formation inside the piping. Prevailing good refrigeration practices must be employed for piping supports,

leak testing, dehydration and charging. Failure to use good system practices may result in damage to the

system. Refer to the ASHRAE refrigeration handbook for general good-practice refrigeration piping.

Insulate all piping lines to prevent condensation in applications where the dew point approaches the

R-134a refrigerant temperature.

Vertiv recommends venting the pressure relief valves for both the R-134a and R-407C sides outside the

conditioned space where it is open to the atmosphere. The R-134a side relief valve is inside the Liebert

XDC unit at the top of the receiver. The R-407C water/glycol-cooled side relief valves are located at each

condenser beneath the Liebert XDC unit in the floor stand. The R-407C air-cooled relief valves are

located outside within the air-cooled system.

Vertiv | Liebert® XDC™ User Manual | 38

Page 39

4.4.1 Piping Installation—R-134a Pumped Circuit

Vertiv recommends venting the relief pressure of the Liebert XDC (located at the top of the receiver)

outside of the conditioned space where it is open to the atmosphere.

4.4.2 Bypass Flow Controllers

Two bypass flow controllers are required to ensure the Liebert XDC pumps operate within the optimum

range. These devices are added to the field piping and simulate the flow of additional cooling modules.

Each bypass flow controller must be installed with one shutoff valve to allow the controller to be disabled

when cooling modules are added to a Liebert XD system.

Bypass flow controllers should be connected between the main supply and the main return lines of the

field piping. The connection points to the main supply and return lines should be in a convenient and

accessible location between the Liebert XDP/Liebert XDC and the first Liebert XD module in the circuit.

See Figure 4.2 below andFigure 4.3 on the next page for piping details of the bypass flow controller.

Refer to Table 4.2 below to determine the number of bypass flow controllers needed to be open to

provide proper refrigerant flow, based on the total nominal cooling capacity of the cooling modules in

each Liebert XD system.

Table 4.2

Bypass flow controllers for a Liebert XDC-based system

Required Number of Open

System Load kW

Cumulative Module Model Size

32 to 63 N/A

64 to 95 2

96to 127 1

128 to 1 60 0

Bypass Flow Controllers

Liebert XDC

Figure 4.2 Bypass flow controller details, dimensions

Vertiv | Liebert® XDC™ User Manual | 39

Page 40

Figure 4.3 Bypass flow controller arrangement

Figure 4.4 Bypass flow controller piping

Vertiv | Liebert® XDC™ User Manual | 40

Page 41

4.5 Piping Details—Shutoff/Isolation Valves

Isolation valves must be installed on the Liebert XDC’s refigerant circuit to permit maintenance on the

unit (see Figure 4.5 below.)

Figure 4.5 General piping details

Evacuation and Leak Check—R-134a Pumped Circuit

1. Open all service valves, including those located outside of the Liebert XDC.

2. Attach a jumper hose from one of the Schrader valve fittings on a pump outlet before the

check valve to a Schrader valve fittings after the check valve.

3. Place 150 psig (1034kPa: 10.34 bars) of dry nitrogen with a tracer of R-134a in the system.

NOTE: Risk of overpressurization. Can cause equipment damage.

Do not exceed 150 psig (1034 kPa; 10.34 bars) in the R-134a circuit.

4. Check the system for leaks with a suitable leak finder on the pumps’ suctions lines.

5. After completion of the leak testing, release the test pressure (per local code) and connect to

vacuum pump(s) at the Schrader valves.

6. After four hours of pulling a deep vacuum, check the vacuum level and if it has not changed,

break the vacuum with dry nitrogen.

7. Pull a second vacuum to 500 microns or less. Recheck the vacuum level after 2 hours.

Insulation

NOTE: Piping should not be insulated before it has been checked for leaks. Applying good insulation

to pipes before checking for leaks would prevent easy detection of leaks.

Insulate all piping between the Liebert XDC and cooling modules to prevent condensation where the

piping passes through non-conditioned areas.

4.6 Filling the Pumped Circuit—R-134a

1. Connect a charging manifold to the Schrader valve fittings on the pump suctions lines.

Vertiv | Liebert® XDC™ User Manual | 41

Page 42

2. Purge the hoses.

3. Calculate the amount of R-134a refrigerant needed to charge the system, using the values in

Table 4.3 below, Table 4.4 below, Table 4.5 on the facing page and Table 4.6 on the facing

page; for assistance, refer to Calculating Refrigerant Charge—Example on page44. The

section includes a worksheet to calculate system refrigerant charge requirements.

4. Weigh in the calculated charge.

5. After adding the calculated charge, allow the system to sit 15 to 30 minutes to reach

equilibrium. Observe the refrigerant level through the sight glasses of the receiver.

6. If the refrigerant level is improper, the charge must be adjusted.

If the level is too high or too low, recalculate the required charge and reduce or increase the

amount as needed to reach the proper level.

NOTE: All lengths in Table 4.4 below, Table 4.5 on the facing page and Table 4.6 on the facing page

are actual pipe lengths, not equivalent pipe lengths.

NOTE: System refrigerant volume calculations derived from Table 4.3 below, Table 4.4 below, Table

4.5 on the facing page and Table 4.6 on the facing page are based on a fully loaded system.

Additional charge may be required for lightly loaded systems.

Table 4.3

System R-134a charge for a Liebert XDC with any model Liebert

XDH/Liebert XDO/Liebert XDV/Liebert XDCF

Refrigerant Charge,

lb. (kg)

157 lb. (65.7kg) Liebert XDC

3.55 lb. ( 1.61kg) Liebert XDO

2.32 lb. (1.05kg) Liebert XDV

5.32 lb. ( 2.41 kg) Liebert XDH

1.41 lb. (0.64kg) Liebert XDCF

4.0 lb. (1 .81kg) Liebert XDR

Per Liebert XD Unit

(Excludes Connector Lines

to and from Liebert XD Cooling Module)

Table 4.4

System refrigerant charge for the supply and return mains

Refrigerant Charge,

lb/foot (kg/m)

0.45 (0.67) Main supply actual lengthper 1-1/8" OD copper tubing

0.68 (1.01) Main supply actual lengthper 1-3/8" OD copper tubing

0.28 (0.42) Main return actual lengthper 2-1/8" OD copper tubing

0.43 (0.64) Main return actual lengthper 2-5/8" OD copper tubing

Supply/Return Main Length and Diameter

Vertiv | Liebert® XDC™ User Manual | 42

Page 43

Table 4.5

R-134a refrigerant charge for hard-piped connector lines to and from any model Liebert XDH/Liebert

XDO/Liebert XDV/Liebert XDCF

Refrigerant Charge,

lb/foot (kg/m)

0.08 (0.12) 1/2" OD Liebert XDO/L iebert XDH/Liebert XDV/Liebert XDCF/Liebert XDR supply connector actuallength

0.13 (0.19) 5/8" OD copper tubing Liebert XDV/Liebert XDCF supply connector actual length

0.26 ( 0.39) 7/8" OD L iebert XDO/Liebert XDH/Liebert XDR supply connector actual length

0.02 (0.03) 5/8" OD copper tubing Liebert XDV/Liebert XDCF return connector actual length

0.04 (0.06) 7/8" OD copper tubingLiebert XDV/Liebert XDCF return connector actual length

0.04 (0.06) 7/8" OD copper tubingLiebert XDH/Liebert XDO/Liebert XDR return connector actual length

0.07 (0.1) 1-1/8" OD copper tubing Liebert XDH/Liebert XDO/Liebert XD R return connector actual length

Hard-Piped Connector Length and Diameter

Table 4.6

R-134a refrigerant charge for Liebert XD Flex Pipe connector lines to and from any model Liebert

XDO/Liebert XDH/Liebert XDV/Liebert XDCF

Refrigerant

Charge, lb. (kg)

Supply Line Diameter 1/2"

0.3 lb. (0.14) 4 ft. Liebert XD Flex Pipe L iebert XDH/Liebert XDO/Liebert XDV/Liebert XDCF/Liebert XDR s upply

0.5 lb. (0.23) 6 ft. Liebert XD Flex Pipe L iebert XDH/Liebert XDO/Liebert XDV/Liebert XDCF/Liebert XDR s upply

0.7 lb. (0.32) 8 ft. Liebert XD Flex Pipe Liebert XDH/Liebert XDO/L iebert XDV/L iebert XDCF/Liebert XDR supply

0.8 lb. ( 0.36) 10 ft. Liebert XD Flex Pipe Liebert XDH/Liebert XDO/Liebert XDV/L iebert XDCF/Liebert XDR supply

Return Line Diameter 5/8"

0.01 lb. (0.01) 4 ft. Liebert XD Flex Pipe existing Liebert XDV sys tems

0.02 lb. (0.01) 6 ft. Liebert XD Flex Pipe existingLiebert XDV systems

0.03 lb. (0.01) 8 ft. Liebert XD Flex Pipe existing Liebert XDV sys tems

0.03 lb. (0.01) 1 0 ft. Liebert XD Flex Pipe existingLiebert XDV systems

Return Line Diameter 1"

0.13 lb. (0.06) 4ft L iebert XD Flex Pipe Liebert XDH/L iebert XDO/Liebert XDV/Liebert XDCF/Liebert XDR supply

0.2 lb. (0.096) 6ft Liebert XD Flex Pipe Liebert XDH/Liebert XDO/Liebert XDV/L iebert XDCF/Liebert XDR supply

0.27 lb. (0.126) 8ftLiebert XD Flex Pipe L iebert XDH/Liebert XDO/Liebert XDV/Liebert XDCF/Liebert XDR s upply

0.33 lb. (0.15) 10ft L iebert XD Flex Pipe Liebert XDH/Liebert XDO/Liebert XDV/L iebert XDCF/Liebert XDR supply

Metal L iebert XD Flex Pipe Connector L ength

Vertiv | Liebert® XDC™ User Manual | 43

Page 44

4.6.1 Calculating Refrigerant Charge—Example

Using Table 4.3 on page42,Table 4.4 on page42,Table 4.5 on the previous page andTable 4.6 on the

previous page, calculate the refrigerant charge of the individual sections of your Liebert XD system. Add

the calculated charge amounts to determine the amount of R-134a refrigerant required for one system

combining a Liebert XDC with Liebert XD cooling modules (Liebert XD CoolFrame, Liebert XDH, Liebert

XDO and Liebert XDV). The example below combines one Liebert XDC with 20 Liebert XDV8 cooling

modules.

Table 4.7

Calculating refrigerant charge—example

Components

Liebert XDC 1 157 157

Liebert XDV8 Cooling Modules 20 2.32 46.4

Supply Main, 1-1/8" 100 0.45 45

Return Main, 2-1/8" 100 0.28 28

Liebert XDV 1 /2" supply Liebert XD Flex Pipes 20 0.8 16

Liebert XDV 5/8" return Liebert XD Flex Pipes 20 0.03 0.6

Number ofUnits

or Piping Length, feet

Pounds

Per Component

Total 293

Table 4.8

Worksheet to calculate refrigerant charge

Components

Number ofUnits

or Piping Length

Pounds

Per Component

Total, lb.

Total

Total

Vertiv | Liebert® XDC™ User Manual | 44

Page 45

4.6.2 Piping for Direct Expansion (DX) Circuit—R-407C Air-Cooled Units

WARNING! Risk of refrigerant system explosion or rupture from overpressurization. Can cause

equipment damage, injury or death.

Installer must install a 400 psig pressure relief valve in each of the two R-407C refrigerant

circuits of the Liebert XDC system. Do not install shutoff valves between the compressors and

the pressure relief valves.

For systems requiring EU CE compliance, the pressure relief valves must be CE-certified by a

notified body to the EU Pressure Equipment Directive.

4.7 Install Double Discharge Risers

For air-cooled systems, double discharge risers must be installed in the hot gas lines that have vertical

heights of 15 feet (4.6m) or more (see Figure 4.6 below). This will allow proper oil return to the

compressors when the system is running at low loads. A double riser system is constructed of a large

diameter riser with a trap at the base and a riser with a smaller diameter in parallel.

At full-load operation, the refrigerant vapor flows up both risers at velocities that are adequate to carry

the oil. At low loads, refrigerant vapor velocities are lower and the trap at the bottom of the riser becomes

filled with oil. When this happens, refrigerant flows up only the smaller riser.

The trap at the top of the riser must be tied into the top of the line to prevent oil from filling the larger

riser. For each double riser used, the maximum height of the riser must not exceed 15 feet (4.6m). Multiple

risers must be installed in series as the height of the hot gas line increases. Total maximum height of the

hot gas line must not exceed 60 feet (18.3m).

Horizontal discharge lines should be pitched downward in the direction of flow to aid in oil drainage with

downward pitch of at least 1/2 inch in 10 feet (13mm in 3m).

Figure 4.6 Double discharge riser layout

Vertiv | Liebert® XDC™ User Manual | 45

Page 46

Contact your local Liebert representative for factory approval whenever a refrigerant piping run exceeds

200 feet (60m) equivalent length or when condensers must be installed below the level of the cooling coil.

For Air-Cooled Liebert Lee-Temp / Flood Back Head Pressure Control Units Only

WARNING! Risk of explosive discharge from high-pressure refrigerant. Can cause injury or

death.

This unit contains fluids and/or gases under high pressure.

Relieve pressure before working with piping.

NOTICE

Risk of refrigerant contamination. Can cause equipment damage and operational problems.

Refrigerant R-407C is a blend of three components and must be introduced and charged from

the cylinder only as a liquid.

Refrigerant R-407C uses a POE (polyolester) lubricant. Do not open the compressor unit

piping to the atmosphere for more than 15 minutes. The compressors contain POE oil that is

very hygroscopic; it quickly absorbs water from the atmosphere. The longer the compressor

piping is open to the atmosphere, the harder it will be to fully evacuate. If left open too long, the

POE oil may need to be replaced before achieving the required vacuum level.

POE oils also have a property that makes them act as a solvent in a refrigeration system.

Maintaining system cleanliness is extremely important because the oil will tend to bring any

foreign matter back to the compressor. Refer to the ASHRAE refrigeration handbook for

general good-practice refrigeration piping.

Table 4.9

Receivers and head pressure kits for Liebert Lee-Temp condensers

Outdoor Ambient

°F (°C)

-30 to 100 (- 34 to 38) DCSL415 2

-30 to 105 (-34 to41) DCSL616 2

35 to 105 (2 to 41) D CSL616 2

1. 120V heater

2. 230V heater

Condenser

Model 50/60Hz

Condenser

Qty

Receiver

Part #

185010G21/G4

179713G11/G2

181610G21/G4

Receiver

Qty

2

2 179711 G1 2

2

1 179711G2 2

2

2 179711 G1 2

Head

Pressure Kit

Head

Pressure

Kit Qty

Vertiv | Liebert® XDC™ User Manual | 46

Page 47

Figure 4.7 Installation data—Liebert Lee-Temp, one-circuit, four-fan model

Vertiv | Liebert® XDC™ User Manual | 47

Page 48

Figure 4.8 Installation data—Liebert Lee-Temp, one-circuit, high ambient six-fan model

Vertiv | Liebert® XDC™ User Manual | 48

Page 49

Figure 4.9 Liebert XDC piping schematic and Liebert Lee-Temp heater pad wiring

Vertiv | Liebert® XDC™ User Manual | 49

Page 50

Figure 4.10 General arrangement air-cooled Liebert XDC Liebert Lee-Temp Control

Vertiv | Liebert® XDC™ User Manual | 50

Page 51

Table 4.10

Recommended refrigerant line sizes, DX R-407C, OD copper

Liebert XDC 160

Equivalent

Length, ft., (m)

50 (15) 1-1/8 7/8

100 (30) 1-1/8 1-1/8

150 (45) 1-3/8 1- 1/8

200 (60) 1-3/8 1- 1/8

* Double risers are required when hot gas vertical rise is 1 5ft. (4.6m) or more (see Install Double Discharge Risers on page45).

Source: DPN000937, Pg. 3, Rev. 11

*Hot Gas Line, in. Liquid Line,in.

Vertiv | Liebert® XDC™ User Manual | 51

Page 52

Figure 4.11 DCSL616 piping connections—two refrigerant circuits connected for parallel flow

Vertiv | Liebert® XDC™ User Manual | 52

Page 53

Table 4.11

Recommended refrigerant line sizes for DCSL616

Liebert XDC 160

Equivalent

Length, ft., (m)

50 (15) 1-1/8 7/8

100 (30) 1-1/8 1-1/8

150 (45) 1-3/8 1-1/8

200 (60) 1-3/8 1-1/8

* Double risers are required when hot gas vertical rise is 1 5 feetor more (see Install Double Discharge Risers on page45).

Source: DPN000937, Pg. 4, Rev. 11

*Hot Gas Line, in. Liquid Line, in.

Figure 4.12 DCSL616 piping connections—two refrigerant circuits connected for parallel refrigerant

flow

Vertiv | Liebert® XDC™ User Manual | 53

Page 54

4.7.1 Air-Cooled Condenser with Liebert Lee-Temp “Flooded Condenser” Head Pressure Control System—R-407C (DX) Circuit

The Liebert Lee-Temp system consists of a modulating type head pressure control valves and insulated

receivers with heater pads to ensure operation at ambient temperatures as low as -30°F (-34.4°C).

Liebert Lee-Temp Piping

Two discharge lines and two liquid lines must be field-installed between the indoor unit and the outdoor

condenser. See 4.6.2 on page45 and 4.6.2 on page45 for details.

Liebert Lee-Temp Control Materials Supplied

• Built-in, pre-wired condenser control box

• Air-cooled condenser

• Piping access cover to be reinstalled when piping is complete

• Bolts—four per leg (3/8" x 5/8")

• Terminal block for two-wire, 24V interlock connection between unit and condenser

• Condensate legs—four with one-fan, six on two-and three-fan models and eight on four-fan

models

• Bolts—used to mount receiver (3/8" x 1-1/4")

• Liebert Lee-Temp system:

• Insulated storage receiver—one per circuit

• Head pressure control assembly (head pressure valves and check valves) - one per

circuit

• Service valve—one per circuit

• Pressure relief valve—one per circuit

• Liquid level sight glasses

NOTE: Liebert Lee-Temp heater pads require a separate, continuous electrical source. See nameplate

on unit for proper voltage.

Evacuation and Leak Check—R-407C (DX) Circuit (Air and Water/Glycol Systems)

1. If unit power is available, open the unit’s liquid line and hot gas valve solenoid valves using the

Tandem Bank 1 and Tandem Bank 2 evacuation function in the Liebert iCOM’s Service Menu. If

power is not available to the unit, a field-supplied 24VAC/75VA power source must be directly

connected to each of the unit’s solenoid valves..

NOTE: The procedures above allow the technician to use 24VAC power and controls to open liquid line

solenoid valve(s) for the dehydration process. If no power is at the unit disconnect, the technician is to

use a separate 24VAC source rated at 75 VA and connect to the system liquid line solenoid valve(s)

directly.

2. Attach refrigerant gauges to the suction and discharge service valves of the compressor.

3. Open all compressor service valves, including those located outside the Liebert XDC.

4. Connect the tank of dry nitrogen to the Schrader valves on the liquid lines and the hot gas

lines.

5. Pressurize the system circuit(s) to 150 PSIG (1034 kPa; 10.34 bars) with dry nitrogen with a

trace of refrigerant. Check the system for leaks with a suitable leak finder.

Vertiv | Liebert® XDC™ User Manual | 54

Page 55

6. After completion of leak testing, release the test pressure (per local code) and connect to

vacuum pump(s) at the Schrader valves on the liquid lines and on the hot gas lines.

NOTE: There is a check valve in the discharge line and Liebert Lee-Temp piping assembly of each

circuit. Ensure that all pressure has been relieved before starting the vacuum pump.

7. Place a jumper hose from the service valve fitting on the outlet of the receiver and the

schrader fitting on the discharge header of the condenser. Front-seat the service valve two (2)

turns.

8. After 4 hours of pulling a deep vacuum, check the vacuum levels and, if they have not

changed, break the vacuum with dry nitrogen.

9. Pull a second and third vacuum to 500 microns or less. Recheck the vacuum level after 2 hours.

10. Once a system has achieved 500 microns, turn off evacuation, close the receiver service valve

and remove the jumper hose.

4.8 Filling the Direct Expansion (DX) Circuit—R-407C

NOTE: If necessary, refer to Installation Checklist on page59 to ensure that the system has been

properly checked out and is ready to be filled with refrigerant.

Any recommended volumes will be approximate. The user must verify that all circuits of the system

have been adequately filled.

For Air-Cooled Liebert Lee-Temp / Flood Back Head Pressure Control Units Only

NOTE: Proper safety equipment and proper refrigeration tools are required. Check unit nameplate for

correct refrigerant type before topping off or recharging a system.

NOTE: Refrigerant R-407C is a blend of three components, and must be introduced and charged from

the cylinder only as a liquid.

Refrigerant R-407C uses a POE (polyolester) lubricant. Do not open the compressor unit piping to the

atmosphere for more than 15 minutes. The compressors contain POE oil that is very hygroscopic; it

quickly absorbs water from the atmosphere. The longer the compressor piping is left open to the

atmosphere, the harder it will be to fully evacuate. If left open too long, the POE oil may need to be

replaced before achieving the required vacuum level.

Refrigerant charging requires unit operation. Refer to Checklist for Liebert XDC Startup on page111.

1. Calculate the amount of charge for the R-407C side of the system. Refer to Table 4.13 on the

next page, Table 4.14 on the next page, Table 4.15 on page57 and Figure 4.13 on page57.

2. Weigh in as much of the calculated R-407C charge as possible by utilizing tank heaters on the

refrigerant bottles before starting the unit.

NOTICE

Risk of improper operation. Can cause equipment damage.

Before proceeding to step Turn Off the main power to the unit. below, the R-134A side must be

charged with the calculated refrigerant charge.

There also must be enough room heat to start the system the system (64kW minimum). If not,

running the compressors alone could cause the heat exchanger to freeze and burst.

3. Turn Off the main power to the unit.

4. Disconnect either the low-voltage wires from the #2 compressor contactors holding coils or

remove the high-voltage fuses for the #2 compressor bank.

Vertiv | Liebert® XDC™ User Manual | 55

Page 56

5. Turn On the Liebert iCOM controller by pressing the On/Off push button on the front of the

Liebert iCOM display (see Figure 6.1 on page61).

6. Set the Min Room Temperature Setpoint to a minimum value of 50°F (10°C) (see Figure 6.7 on

page70.

NOTE: The pumps must establish flow before the compressors will start. If the pumps lose flow, the

compressors will turn Off. The pressure in the system must be at or above 65psig (448kPa) for the

compressor(s) to start. A minimum of 30psig (207kPa) must be maintained for the compressor(s) to

continue to operate. The compressor(s) will shut off if the pressure drops to 20psig (138kPa) or lower.

7. Weigh in the rest of the calculated charge.

8. Once Tandem Bank 1 is completely charged, repeat steps Turn Off the main power to the unit.

on the previous page through7. above for Tandem Bank 2.

Table 4.12

Indoor unit refrigerant

charge—R-407C

Model50/60 Hz Charge/Circuit, lb. (kg)

Liebert XDC160 17.5 (8.0)

Table 4.13

Outdoor air condenser charge—R-407C

Outdoor Ambient, °F (°C Model 50/60 Hz Receiver Part # Charge / Circuit, lb. (kg)

-30 to 100 (- 34 to 38) DCSL415

-30 to 105 (-34 to41) DCSL616

35 to 105 (2 to 41) DCSL616

1. 120V

2. 230V

185010G21/G4

179713G11/G2

181610G21/G4

2

2

2

Table 4.14

Air-cooled systems - liquid line charge - R-407C refrigerant per 100ft

(30m) of Type ACR copper tube

O.D., inches Liquid Line, lb. (kg) Hot Gas Line, lb. ( kg)

3/8 3.7 (1.7) -

1/2 6.9 (3.1 ) -

5/8 11.0 (5.0 2.2 ( 1.0)

3/4 15.7 (7.1 ) 3.1 (1.4 )

7/8 23.0 (10.4) 4.5 (2.0)

1-1/8 39.3 ( 17.8) 7.8 (3.5)

1-3/8 59.8 (27.1 11 .8 (5.4)

1-5/8 — 16.7 (7.6)

200 (91)

254 (115)

164 (75)

Vertiv | Liebert® XDC™ User Manual | 56

Page 57

Table 4.15

Indoor water/glycol-cooled module – R-407C refrigerant charge

Model 60 Hz Charge / Circuit, lb. (kg)

Liebert XDC 1 60 30.0 (13.2) per circuit

4.9 System Refrigerant Charges Over 55lb. (24.9kg) Require Additional Oil

4.9.1 Liebert XDC DX R-407C Circuit Volume

NOTICE

Risk of improper lubrication. May cause equipment damage.

Liebert XDCs refrigerant R-407C circuits with refrigerant charges over 55lb. (24.9kg) require

additional oil. See Figure 4.13 below for the amount required for various charge levels.

Once the system has been fully charged with refrigerant, use a hand pump to add the

additional oil at the suction side of the system while the system is running.

The amount of oil added by field service must be recorded on a tag attached at the tandem,

(the amount added along with the date it was added). This will be documented on a tag

located at the tandem compressor and marked “Oil Added Field Service Record.” Refer to the

Liebert XDC user manual, SL-16673, available at www.VertivCo.com.

Figure 4.13 Additional oil requirements for refrigerant charge

Vertiv | Liebert® XDC™ User Manual | 57

Page 58

To calculate the oil required, use the following formula:

Additional Oil Required per Circuit = (Refrigerant Charge * 0.4 - 22)

Enter the refrigerant charge in pounds to determine the oil required in ounces

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system

damage.

Failure to use oil types, viscosities and quantities recommended by the compressor

manufacturer may reduce compressor life and void the compressor warranty. See oil types

specified in Table 4.16 below.

• Do not mix polyol ester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

Consult Vertiv or the compressor manufacturer if questions arise.

Table 4.16

Compressor oil types

Refrigerant Type

Compressor Type

R-407C

CopelandScroll and Digital Scroll POE OIL - ISO 32 Viscosity

Use Copeland®POE Oil ULTRA 22 CC, Mobil EAL Ar ctic 22 CC, Copeland brand U ltra 22 CC, Copelandbrand Ultra 32 CC, Copeland brand Ultra 323MAF, Mobil EA L™Arctic 22 CCor Uniqema RL32-3MAF or other Copeland-approved oil.

Vertiv | Liebert® XDC™ User Manual | 58

Page 59

5 INSTALLATION CHECKLIST

1. Unpack and check received material.

2. Position Liebert XDC and secure to floor.

3. Wire high voltage connections.

4. Wire low voltage connections.

NOTE: Risk of unintended pump start. Can cause equipment damage.

Do not install the pump fuses for 60Hz until the system is fully charged with refrigerant. Do not remove

the locking mechanisms from 50Hz circuit breakers until the system is fully charged with refrigerant.

Operating the pumps without a full refrigerant charge can result in equipment damage.

5. Connect Liebert XD cooling module piping to Liebert XDC.

6. Check all circuits of the system for leaks.

7. Hold a vacuum on all circuits of the system.

8. Charge the system with refrigerant.

9. Make sure that all piping has proper insulation.

10. Use double risers in DX hot gas lines that are 15 feet (4.6m) or more in height.

Vertiv | Liebert® XDC™ User Manual | 59

Page 60

This page intentionally left blank.

Vertiv | Liebert® XDC™ User Manual | 60

Page 61

6 LIEBERT ICOM CONTROL—FIRMWARE VERSION XP1.00.009.STD

6.1 Liebert iCOM Components and Functions

The Liebert iCOM controller layout is shown in Figure 6.1 below; the keyboard functions are defined in

Table 6.1 on the next page. The Liebert iCOM controller on the Liebert XDC displays the Unit View only.

Figure 6.1 Liebert iCOM display components

Vertiv | Liebert® XDC™ User Manual | 61

Page 62

Table 6.1

Keyboard icons and functions

Icon

Key Name Function

On/Off Key Controls the operational state ofthe cooling unit.

Alarm Key Silences an alarm.

HelpKey A ccesses integrated Help menus.

ESCape Key Returns tothe previous display view.

Enter Key Confirms all s elections andselects icons or text.

Increase Key

(Up Arrow)

Moves upward in a menu or increases the value of a selected parameter.

Decrease Key

(Down Arr ow)

Left and Right

Arrow Keys

Upper LED BlinkingRed—Active, unacknowledgedalarm exists

Upper LED SolidRed—Active, acknowledged alarm exists

Moves downward in a menu or reduces the value ofa selectedparameter.

Navigates throughtext and sections of the display.

Vertiv | Liebert® XDC™ User Manual | 62

Page 63

Table 6.1 Keyboard icons and functions (continued)

Icon

Key Name Function

Amber—Power is available to the unit; unit is NOT operating

Lower LED

Green—Unit is operating with no alarms

6.2 Display Lamp Indicators

• The Green lamp will be On only when the Liebert XDC is On and running with no alarms.

• The Red lamp will be On if the unit is On and running with an active alarm, or if the unit is shut

down because of a certain alarm.

• The Red lamp will flash while an alarm is being annunciated. The Red lamp will stop flashing

and the beeper in the display will stop beeping when the ALARM SILENCE / ? key is pressed.

• The Amber lamp will be On if the Liebert XDC has been shut down at the I/O switch or if the

unit has been shut down by an alarm condition.

6.3 Navigating Through the Liebert iCOM Display

The Liebert iCOM displays icons and text for monitoring and controlling your Liebert cooling unit. Figure

6.2 on the next page shows the Liebert iCOM’s home screen for the Liebert XDC.

Vertiv | Liebert® XDC™ User Manual | 63

Page 64

Figure 6.2 Liebert iCOM default home screen for Liebert XDC

6.3.1 Accessing Menus and Settings

Viewing Data

No password is required to view data or settings.

To view data:

1. From the home screen, press the Enter key to view the User Menu (see 6.7 on page68).

2. Press Enter again to highlight the first icon.

3. Use the keyboard’s arrow keys to move to the icon for the data you wish to view.

4. Once that icon is highlighted, press Enter again to open that menu.

• If a password is required, see Entering the Password on the facing page.

• If a menu has more than one screen, the Liebert iCOM display will have text at the top

similar to this: (page 1 of 2).

5. Press Enter to select the first line of data.

6. Use the Up and Down arrow keys to scroll to the desired data point.

7. Press ESC to move back to higher level menus.

6.3.2 Cooling Module Overview

The Liebert iCOM will display an overview of all connected cooling modules. It does not display a system

view, which would include units other than the cooling modules.

NOTE: The Liebert iCOM control screens display a setting to select a system view, but the Liebert XDC

does not support a system view.

Vertiv | Liebert® XDC™ User Manual | 64

Page 65

To display an overview of all connected coolig modules:

1. At the default home screen on the Liebert iCOM, press the down arrow. This will display the

first 10 modules’ outlet temperature and capacity levels. Press ESC to return to the unit view.

Figure 6.3 Cooling module overview, first 10 modules

2. Press the down arrow button again to display the next 10 modules’ outlet temperature and

capacity levels.

3. Press ESC to return to the default home screen.

6.3.3 Entering the Password

Most settings in the Liebert iCOM are protected by factory-set passwords. The User Menu password is

1490. The Service Menu password is 5010. To enter the password:

1. From the home screen, press the Enter key to view the User Menu (see 6.7 on page68).

2. Press Enter again to highlight the first icon.

3. Use the keyboard’s arrow keys to move to the icon for the data you wish to change.

4. Once that icon is highlighted, press Enter again to open that menu.

5. Press Enter to highlight the Password line.

6. With the Password line highlighted, press Enter to highlight the first digit in the password.

7. Enter the password, 1490.

Use the Up and Down arrow keys to select a numeral for the first digit of the password.

Move to the next digit of the password with the Right arrow key.

Select the numerals for all four digits with the same process.

8. After all four digits of the password have been entered, press the Enter key.

Vertiv | Liebert® XDC™ User Manual | 65

Page 66

NOTE: Do not press the ESC key or the Liebert iCOM will move to the previous screen and the

password must be re-entered before changes may be made.

Figure 6.4 Entering the password

6.4 Changing Liebert iCOM’s Display Settings

No password is required to change the way Liebert iCOM displays data. The Display Setup controls how

the unit shows data, such as temperature, date and time.

To change the display settings:

1. From the home screen, press the Enter key to view the User Menu (see 6.7 on page68).

2. Press Enter again to highlight the first icon.

3. Use the keyboard’s arrow keys to move to the Display Setup icon.

4. Once that icon is highlighted, press Enter again to open that menu.

5. Press the Enter key to select the first setting.

Either change that setting or navigate to another setting with the Up and Down arrow keys.

6. Once the desired setting is highlighted, press the Enter key to access that parameter’s display

setting options.

7. Use the Up and Down arrow keys to make changes.

8. Press the Enter key to accept the changes.

9. Press the ESC key twice to return to Liebert iCOM’s user menu.

Vertiv | Liebert® XDC™ User Manual | 66

Page 67

Figure 6.5 Display setup screen

6.5 Changing Operational Settings

Changes to the Liebert XDC’s operation settings in the Set Alarms and Setpoints menus require a

password. The User Menu password is 1490. The Service Menu password is 5010.

1. From the home screen, press the Enter key to view the User Menu (see 6.7 on the next page).

2. Press Enter again to highlight the first icon.

3. Use the keyboard’s arrow keys to move to the icon for the data you wish to change.

4. Once that icon is highlighted, press Enter again to open that menu.

If a password is required, see Entering the Password on page65.

5. After entering the password, use the Up and Down arrow keys to scroll to and highlight the

operational setting to be changed.

6. Press Enter to highlight the values for that setting.

7. Use the Up and Down arrow keys to change the value.

8. Press Enter to accept the change. (The value will no longer be highlighted.)

9. Press ESC to deselect the operational setting. (The setting will no longer be highlighted.)

10. Press ESC again to move to previous screens.

6.6 Graphical Data Record

The Graphical Data Record charts the average temperature from Sensors A and B, the average dew point

from Sensors A and B, the supply refrigerant temperature and the supply refrigerant control point.

The temperature scales can be changed to expand or compress the data.

The time scale also can be altered to any of several selectable values.

Vertiv | Liebert® XDC™ User Manual | 67

Page 68

NOTE: Changing the time scale eliminates all previous graphical data and the unit will begin recording

new data.

6.7 Liebert iCOM User Menu Icons and Legend

Table 6.2 Liebert iCOM User Menu Icons Descriptions

item descri ption item descri ption

Setpoints - View and change operational

setpoints

Spare Parts List - Contains spare parts

available ons ite

Event L og - Lists last 400 events and

alarms. View Only

Graphic Data Record - Displays average

temperature from Sensors A and B, the

average dewpoint from Sensors A andB,

the supply refrigerant temperature and the

supply refrigerant control point graphs;

Data is View Only; Display scale is

adjustable

View Network - Shows status of all

connected units; View Only

Set Alarms - Allows user to change

settings for alarms

Sensor Data - Shows r eadings of sensors;

View Only

Active Alarms - Lists all current alarms ;

View Only

Display Setup - Change settings for

display: language and time

TotalRun Hours - Records the r un time of

all components andallows settingof limits

on run time; View Only

XDIO - D isplays readings for the individual

smar t modules; View Only

Service Contacts - Contains key contact

information for service

NOTE: Menu shows icons only; text is explanatory and does not appear on the Liebert iCOM display.

Vertiv | Liebert® XDC™ User Manual | 68

Page 69

Figure 6.6 Liebert XDC User Menu screen

6.8 Liebert iCOM User Menu Screens

User menus report general cooling unit operations and status. User Menu screens employ a coding that

begins in “U” and is followed by parameters and information, such as settings. Gaining access to some User

Menu screens requires entering a password; the User Menu password is 1490.

Check www.VertivCo.com for the latest Liebert iCOM user manual updates, SL-18835.

Vertiv | Liebert® XDC™ User Manual | 69

Page 70

Figure 6.7 Setpoints, page 1 of 2

Min Room Temperature Setpoint—Sets the minimum room temperature the unit will attempt to maintain.

If the temperature falls below this point, unit will raise the refrigerant temperature to reduce the amount

of cooling.