Page 1

PWC – 7000

PureWaterCooler

SERVICE MANUAL

for

PureWaterCooler

by Vertex

Model 7000

™

Copyright 2012 Vertex Water Products

Page 2

PWC – 7000

PureWaterCooler

Table of Contents

1. Introduction

2. Cooler Set-up

3. Top Cover Removal

4. Remove/Replace Mechanical Float Valve Assembly

5. Removing/Replacing Control Panel and Circuit Board

6. Remove/Replace Hot Tank

7. Remove/Replace Spigot Internals

8. Draining Cooler Tanks

9. Remove/Replace Hot Tank Sensor

10. Remove/Replace Cold Temperature Switch and Sensor

11. Sanitization Procedure

12. Trouble Shooting

13. Specifications

14. Cooler Exploded View

15. Parts List

16. Schematics

Copyright 2012 Vertex Water Products

Page 3

PWC – 7000

PureWaterCooler

PWC-7000 Cooler

1. Introduction

The PWC-7000 line of point of use coolers are designed to give years of reliable service

The cooler has 2 spigots that dispense filtered water at 2 different temperature levels – hot

and cold temperature water. The cold tank holds 1.1 gallons of water and is

constructed of stainless steel. The main (room-temp) tank holds 4.4 gallons of water and can

be accessed for servicing the float mechanism and for cleaning by removing the cooler main

top cover (see section 3).

The hot tank is made of stainless steel and holds 1.0 gallons. It is important not to turn on the

hot tank when there is no water in it as this will damage the heating element.

The compressor is a sealed unit and is not serviceable in the field. The compressor can be

replaced by a qualified refrigeration technician with proper tools and equipment.

Please consult the factory if the compressor needs servicing.

CAUTION: If the compressor has been stopped by switching it off or unplugging power,

WAIT 10 MINUTES before turning the compressor on again. The compressor may stall

and burnout if powered back on without waiting.

The cooler makes clean water by filtration or by the reverse osmosis process. Water enters the

back of the cooler and then passes through the filtration system. A feed water ball valve is

located near the filters and must be turned to the on position to allow the unit to make water.

Electrical power is not required for the cooler to make purified water. CAUTION: The carbon

filtration versions of the cooler (PWC-7000F) should not be used with water hardness over

7 grains because of lime scale build up on the heating element. If hardness is higher than

7 grains, softening of the feed water is recommended or another option is to install

a “phosphate” filter to the filter system.

Copyright 2012 Vertex Water Products

Page 4

PWC – 7000

PureWaterCooler

2. Cooler Set-Up (for new cooler installation)

Feedwater/Drain Connections

-Feed Connection

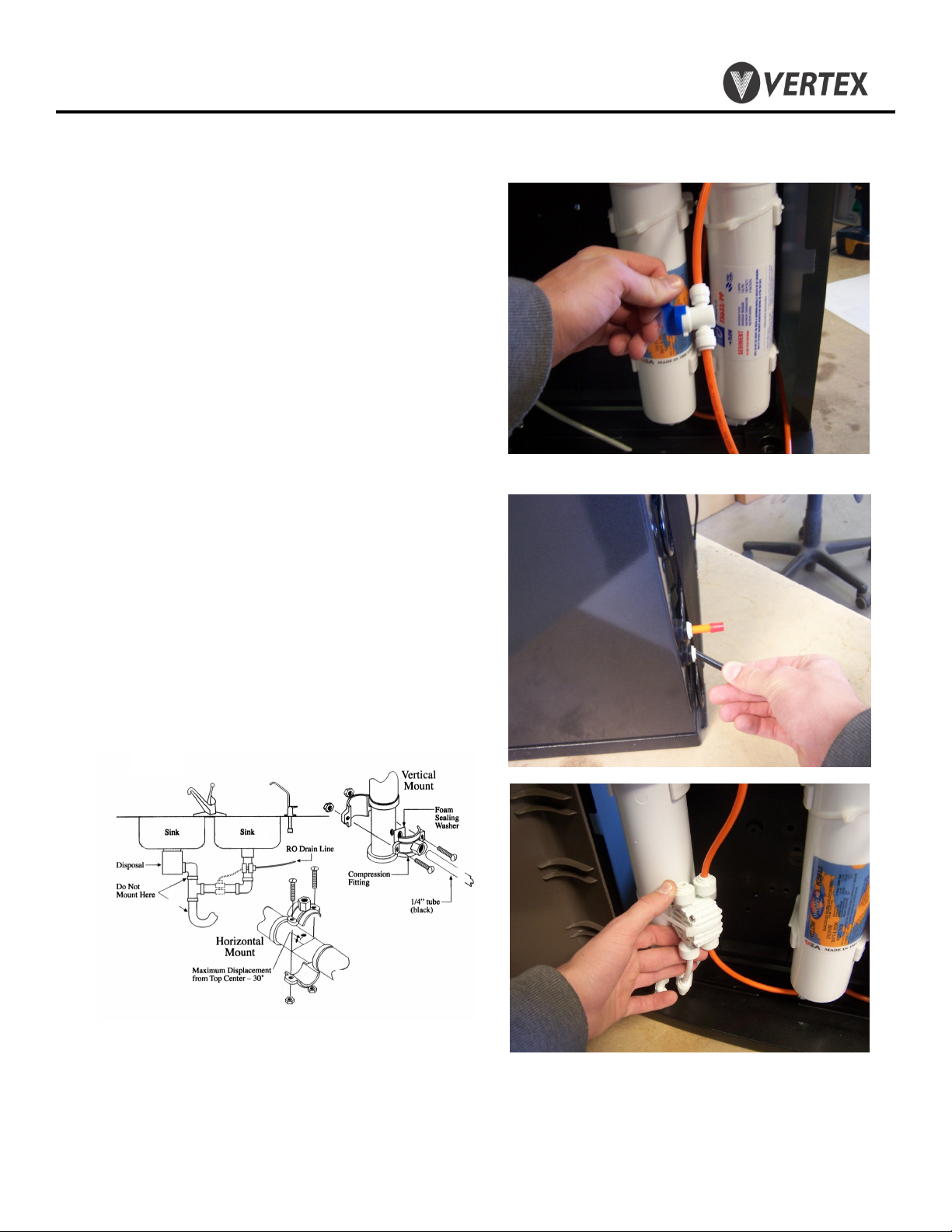

2.1 Open hinged door to access filter

compartment

2.5 Remove feed water plug (orange) from back

of cooler.

2.6 Connect supplied orange feed water tubing to

feed connector on back of cooler.

Copyright 2012 Vertex Water Products

Page 5

PWC – 7000

PureWaterCooler

2. Cooler Set-Up

2.4 Make feed water connection to cold water line.

A self piercing saddle valve is provided.

2.5 Flushing carbon fines from carbon filter.

Most carbon filters have fine particles of

carbon material in the filter that will be

swept into the water stream when the first

water flows through the filter. Although not

harmful, these carbon fines in the water are

unsightly. Flush the carbon fines out of the

filter before filling cooler tanks with the

following procedure.

cont.

Feedwater connection (RO & filtration coolers

(For use on copper tubing)

Use supplied self piercing saddle valve.

Connect to water inlet on cooler using 1/4”

tubing. Clamp saddle valve over copper feed

water line (cold water line only). Tighten

needle valve until tube is pierced. Retract

needle 1 -2 turns to start water flow.

)

2.6 Remove outlet line of carbon filter (bottom)

2.7 Attach 3 feet of ¼” tubing to the carbon filter

outlet port (flush tubing)

2.8 Place flush tubing in bucket to catch water

carbon fines.

Copyright 2012 Vertex Water Products

Page 6

PWC – 7000

PureWaterCooler

2. Cooler Set-Up

2.9 Turn on feed water at source and turn ball valve

at filter to “on” to let the water flush the filter.

2.10 Flush until water flows clear (1 – 2 gallons)

2.11 Remove flush line. Reconnect tank line to

outlet of carbon filter

2.12 WARNING: Do not turn on cooler hot power

until cooler tanks are full of water.

-Drain Connection

2.9 Drain Connection (for units equipped

with RO)

2.10 Remove drain plug (black) from back of

cooler

cont.

Figure 2.7

2.11 Connect supplied black tubing to

drain connector on back of cooler

2.12 Attach supplied drain saddle to a

standard 1 ½” drain pipe see fig. 1 below

Drain saddle connection method

Drain connection required only for cooler with reverse osmosis filtration

Figure 1

RO filter set showing autovalve.

The autovalve automatically turns off the

water flow when the tanks are full

Copyright 2012 Vertex Water Products

Page 7

PWC – 7000

PureWaterCooler

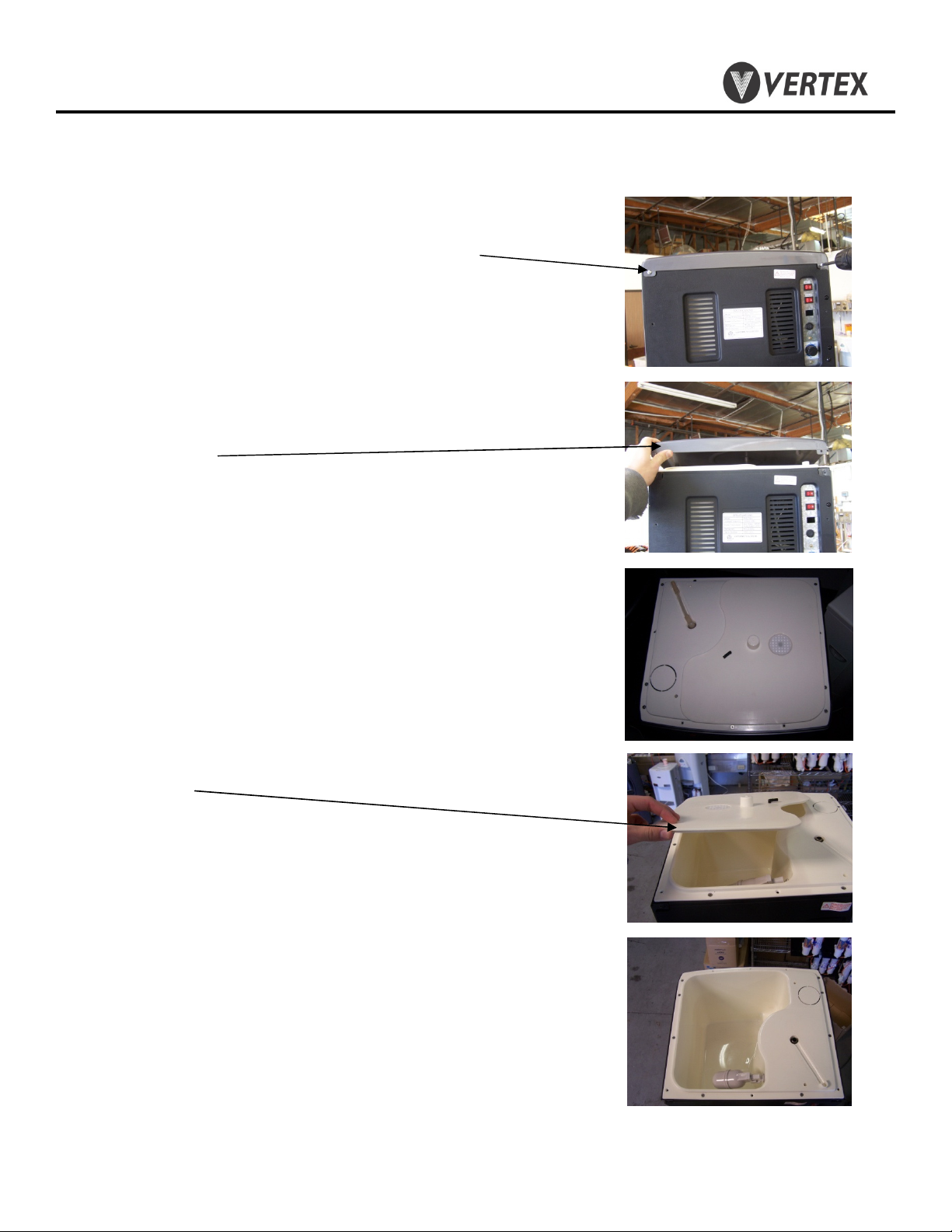

3. Top Cover Removal

3.1 Remove (2) screws on back of cooler top cover

3.2 Lift cover

3.3 Lift Lid

3.4 Room tank is now accessible for cleaning

and servicing other parts of the cooler.

3.5 Reinstall in reverse order

Copyright 2012 Vertex Water Products

Page 8

PWC – 7000

PureWaterCooler

4. Remove/Replace Mechanical Float Valve Assembly

4.1 Remove top lids from cooler as

performed in Section 3.

Remove Black Screws (4)

4.2 Remove Silver Screws (2)

4.3 Remove Back Panel

Copyright 2012 Vertex Water Products

Page 9

PWC – 7000

PureWaterCooler

4. Remove/Replace Mechanical Float Valve Assembly

4.4 Remove ¼” elbow from stem.

4.5 Remove nut from float assembly.

This is easily done by turning the float

while holding the nut.

4.6 Remove float mechanism from

main tank.

4.7 Complete Float assembly

(removed)

4.8 Reassembled in reverse order.

Copyright 2012 Vertex Water Products

Page 10

PWC – 7000

PureWaterCooler

5. Removing/Replacing Control Panel and Circuit Board

5.1 Place hand under control panel and pull up and out.

5.2 Disconnect connector from circuit board.

5.3 Remove screw from circuit board.

Copyright 2012 Vertex Water Products

Page 11

PWC – 7000

PureWaterCooler

6. Remove/Replace Hot Tank

6.1 Follow proper procedures for removing

float valve assembly as described in Section

4.

6.2 Remove control panel as in Section 5.

(Disconnecting wire not necessary)

6.3 Remove silicon tube connected to hot

tank, easily accessible through the control

panel opening.

6.4 Remove cup-holder panel on left side of

cooler. Reach into the cabinet through the

control panel opening and apply pressure on

the side of the cup-holder panel as well as on

its rear. The cup-holder panel will unclip on

the left side as seen in the picture. Then pull

the panel to the left to free the panel from the

cooler.

Copyright 2012 Vertex Water Products

Page 12

PWC – 7000

PureWaterCooler

6. Remove/Replace Hot Tank

cont.

6.5 Remove silicon tube connected to bottom of hot

tank by reaching through the cup-holder panel

opening.

6.6 Remove 2 screws on top of hot tank.

6.7 Remove 9 screws mounting main tank.

Copyright 2012 Vertex Water Products

Page 13

PWC – 7000

PureWaterCooler

6. Remove/Replace Hot Tank

6.8 Remove two black screws.

cont.

6.9 Disconnect four electrical connectors and silicon

tube from hot tank. Do not disconnect electrical

connectors from components on bracket.

6.10 While gently lifting the main tank up, swing the

hot tank out of the cooler. When the electrical

connectors connected to the bottom of the hot tank

are exposed, reach in through the cup-holder

opening and disconnect them. The hot tank is now

free from the cooler.

6.11 Reassemble in reverse order.

Copyright 2012 Vertex Water Products

Page 14

PWC – 7000

PureWaterCooler

7. Remove/Replace Spigot Internals

7.1 Remove control panel as in Section 5.

7.2 Unscrew lever assembly from spigot

body and remove.

7.3 Reassemble in reverse order.

Copyright 2012 Vertex Water Products

Page 15

PWC – 7000

PureWaterCooler

8. Draining Cooler Tanks

Completely draining the tanks is required when shipping the cooler

or when one the of the tanks needs replacing. This procedure will

allow you to remove all the water from the cooler.

8.1 There are 3 ports located on the back of the

cooler (one for each tank)

8.2 For all ports, using a flat head screwdriver, pry

the plug out until you can grasp it with your

fingers.

8.3 Remove the plug with fingers. Water will

pour from the port.

8.4 Drain any remaining water in the

system by depressing the spigots.

Copyright 2012 Vertex Water Products

Page 16

PWC – 7000

PureWaterCooler

9. Remove/Replace Hot Tank Sensor

There are two thermal sensors on the hot tank. The lower sensor controls the heating

element function and the upper sensor is for high temperature cut out. If the hot tank

is not working, one or both of the sensors may have failed in the open position. To

check for this condition, unplug the cooler from main power, disconnect one of the

electrical terminals on the sensor. Using an ohm meter, check for continuity. If there

is no continuity, the sensor is bad and must be replaced.

9.1 Remove the top and back of the cooler per

section 3 to gain access to the hot tank.

9.2 The hot tank does not have to be removed from

the cooler to change the sensors. It is recommended

that the sensors be replaced one at a time so as to avoid

confusion when rewiring.

9.3 Remove the two screws that hold each sensor

to the tank. The sensor can now be removed.

9.4 Remove the electrical terminals from the sensor.

9.5 Reassemble in reverse.

Copyright 2012 Vertex Water Products

Page 17

PWC – 7000

PureWaterCooler

10. Remove/Replace Cold Temperature Switch and Sensor

The cold temperature switch includes the thermal sensor which is attached to

the switch. The sensor probe (integral with the switch ) is inserted into the

receptacle at the top of the cold tank.

10.1 With top and back cover removed,

remove adjustment knob using a flat

head screwdriver

10.2 Loosen (2) screws holding the switch

to the mounting plate.

Copyright 2012 Vertex Water Products

Page 18

PWC – 7000

PureWaterCooler

10. Remove/Replace Cold Temperature Switch and Sensor

cont.

10.3 Remove cup-holder panel as in section 6.

10.4 Carefully remove the sensor probe from the

receptacle at the top of the cold tank.

10.5 Disconnect (2) electrical terminal wires.

10.6 Lift and remove switch assembly from

cooler.

10.7 Replace new switch in reverse order.

Copyright 2012 Vertex Water Products

Page 19

PWC – 7000

PureWaterCooler

11. Sanitization Procedure

The sanitization procedure is performed to reduce/eliminate any bacteriological

growth in the cooler tanks and dispensing plumbing. Bacteriological growth

can be the cause of some taste in the water.

The procedure is as follows:

1. Mix ½ teaspoon of common household bleach (5.25%) with 5 gallons of

clean water.

2. Unplug the cooler from the power source.

3. Drain all water from the cooler tanks.

4. Pour the sanitizing solution into the main (room temperature) tank until full.

5. Open all 3 spigots to allow sanitizing solution to fill the dispensing faucets.

Close the faucets.

6. Let the sanitizing solution stand in the cooler for 10 minutes.

CAUTION: Leaving the sanitizing solution in the cooler for more

than 10 minutes can cause taste problems in the water.

7. Completely drain the sanitizing solution from all the tanks.

8. Fill the main (room temp.) tank with clear tap water to rinse out the

sanitizing solution.

9. Completely empty the rinse water from the tanks.

10. The cooler is now sanitized and ready for use.

Copyright 2012 Vertex Water Products

Page 20

PWC – 7000

PureWaterCooler

12. Trouble Shooting

Water not cold from cold tank

(Water dispenses from spigot but is not cold)

Possible causes Solution .

1. Cooler not plugged in Make sure power cord is plugged

into wall socket

2. Power switch not on Make sure cold power button on

on front panel is on

3. Adjust temperature control The thermostat temperature control

adjustment is located on the right

rear of the cooler

4. All cold water has been drained Cooler needs time to recover.

wait 10 minutes until water cools

5. Water not dispensing from Cold tank is frozen. Turn down

cold spigot cold temperature adjustment

Copyright 2012 Vertex Water Products

Page 21

PWC – 7000

PureWaterCooler

12. Trouble Shooting

Cont.

No Hot Water from Hot Tank

Possible Causes Solution

1. Cooler not plugged in Make sure power cord is plugged

into wall socket

2. Power switch not on Make sure Hot power button on front

panel is on and illuminated

3. Electrical terminal Check to see that both wires are

disconnected connected to the heating element

terminals. These are located at the

bottom of the tanks

4. Heating element failure Check for continuity across hot tank

due to scaling heater terminals. To do this, unplug

unit from wall power. Disconnect one

of the connector at the heating element

terminals (at bottom of tank). Using

an ohm meter, check for continuity

across the 2 terminals. If there is no

continuity (open), the tank must be

replaced.

Copyright 2012 Vertex Water Products

Page 22

PWC – 7000

PureWaterCooler

12. Trouble Shooting

No Hot Water from Hot Tank

Possible causes Solution .

5. Thermal sensor failure The thermal sensors are attached to the

hot tank. The upper sensor is a 92 ºC

sensor and functions as an over heat

safety. The lower sensor is a 82 ºC

sensor and controls the heating element

function. The lower sensor would be the

problem if there was no hot water. To

see if the sensor is functioning properly,

first unplug the cooler from the wall.

Cont

cont.

.

remove the terminal from the sensor.

Using an ohm meter, check for continuity

If there is no continuity (open), replace

sensor

.

Copyright 2012 Vertex Water Products

Page 23

PWC – 7000

PureWaterCooler

12. Trouble Shooting

No Hot Water from Hot Tank

An indicator of a hot tank problem can also be the lights on the front

control panel. Below is a table of trouble shooting help.

If the Hot Tank is not heating and the front panel lights are:

Front Panel Lights Cause Check

Hot Power – on Heating element disconnected No Continuity across

Heating - on or burned out heating element

Cont

cont.

.

No lights at all Upper thermal sensor disconnected No Continuity across

Including cold power or burned out upper thermal sensor

Hot Power – on Lower thermal sensor No Continuity across

Keep Warm – on disconnected or burned out lower thermal sensor

Heating - off

Copyright 2012 Vertex Water Products

Page 24

brown

Cold switch

blue

Fuse

Hot switch

white

Hot Tank

red

Thermal Sensors

Cold thermostat adjustment

brown

blue

red

white

Circuit board/

Indicator panel

92 oC

white

yellow

82 oC

Compressor

yellow

red

yellow

yellow

yellow

VERTEX

Water Products

Montclair, California

None

Scale

10/10/09

Date

Wiring Diagram

For PWC-7000 Cooler

CL1-10001-13

Dwg. No.

Used on.

PWC-7000

Page 25

PWC – 7000

PureWaterCooler

13. Specifications

Voltage/Frequency 120 VAC/ 60 Hz

Weight (dry) 48 lbs.

Model PWC-7000

Total Water Capacity 6.3 gallons

Room temp. tank 4.2 gallons

Hot tank 1.0 gallons

Cold tank 1.1 gallons

Power Consumption Total 600 Watts

Hot Tank 500 Watts

Cold Tank 100 Watts

Temperature

Hot 180 ºF average

Cold (adjustable) 38 ºF average

Refrigerant R134a 36 mg.

Copyright 2012 Vertex Water Products

Loading...

Loading...