Page 1

VERTEX

Water Products

PureWaterCooler

Water Dispenser

OWNERS INSTALLATION

MANUAL

™

VERTEX WATER PRODUCTS

Countertop Models

PWC-400 F

PWC-400 R

Montclair, CA - USA

Page 2

Table of Contents

List of Figures

Figure 1. PWC 400 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 2

Figure 2. Flow Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 3

Figure 3. Back View of Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 4

Figure 4. Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 5-6

Figure 5. Saddle Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 7

Figure 6. Drain Connections for RO Filter Version . . . . . . . . . . . . . . pg. 7

Figure 7. Quick Connect Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 8

Figure 8. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 9-10

Figure 9. Tank Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 11

Figure 10. Leak Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 12

Figure 11. Filter Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 13

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1

2.0 Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1

3.0 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 2

4.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 5

5.0 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 9

6.0 Leak Detector System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 12

7.0 Filter Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 13

8.0 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 15

9.0 Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 16

10.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 17

11.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 18

Page 3

1.0 INTRODUCTION

The Vertex

PureWaterCooler™

products are a means to produce good-tasting,

safe water without using bottles of stored water. The model PWC 400 described here

is made for counter top use. Its low height permits it to fit under cabinets.

The PWC 400 is made as an “R” or an “F” version. The “R” version

uses reverse osmosis filtration to make good tasting, safe water from city water or

well water. This filter system consists of 5-micron sediment filter, a carbon (GAC)

10-micron filter and a 50-gallon per day RO membrane. The sediment filter removes

dirt, sand, and particles. The carbon filter removes the taste and odor of chlorine and

other pipeline odors. The reverse osmosis membrane removes molecular contaminants from the water including hardness minerals. The “R” version requires a water

feed line and a connection to the drain trap to remove the brine water with all the

rejected salts.

The ”F” version has the sediment and carbon filters described above,

but not the RO membrane; therefore, it does not need the drain connection. USE

CAUTION. The “F” version can only be used with softened water or water that has

less than 3.5 grains/gal. hardness (60 mg/l.) to prevent scaling of the heating elements

in the hot tank.

Please read all the instructions in this manual before operating the

PureWaterCooler™

.

2.0 RECEIVING THE COOLER

2.1 Unpacking (All Models)

The

PureWaterCooler™

is shipped completely assembled in a double carton.

Remove the top of the box and slide the cooler out. Save the box and packing materials for use in the event of a return.

2.2 Inspection

Inspect the cooler for obvious shipping damage. Look at the exterior panels to

see if they are dented or damaged.

–1–

Page 4

3.0 Description

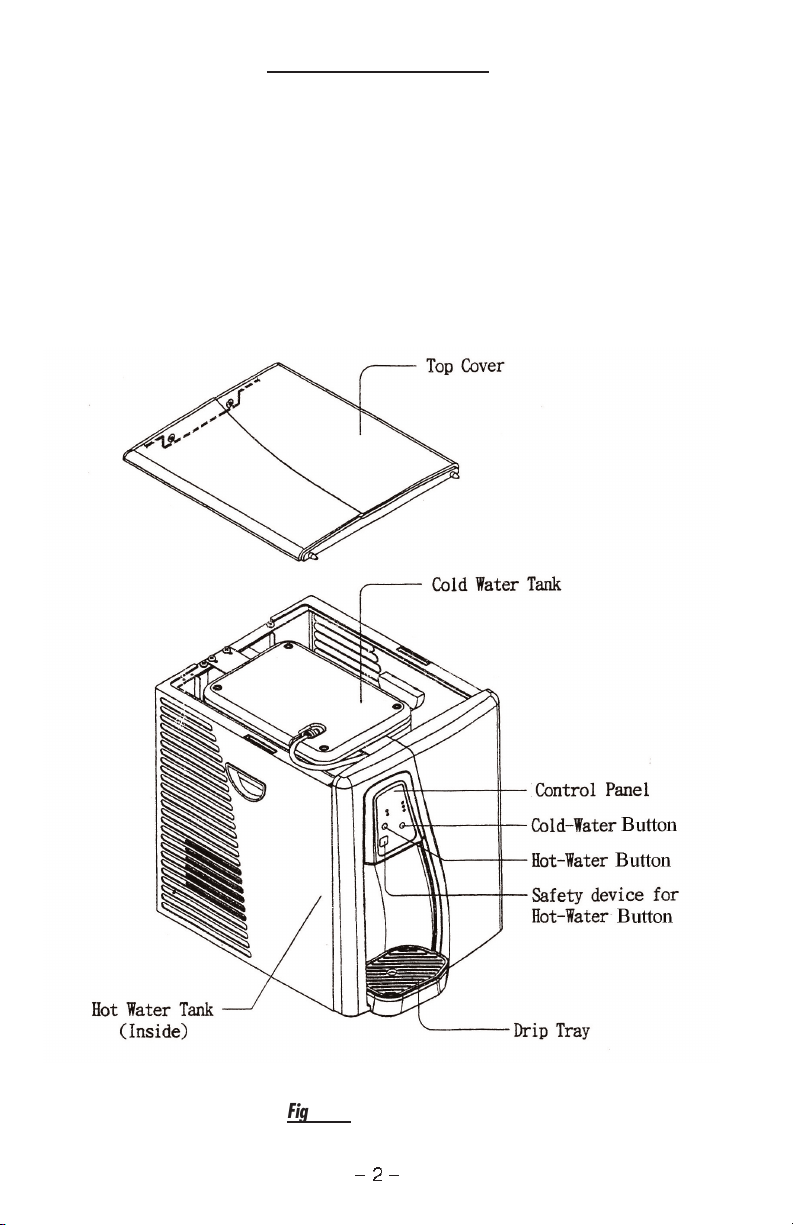

3.1 Assembly

TThe PWC 400 assembly drawing is shown in Figure 1. The cooler has two tanks.

There is a main holding water tank with a float switch which controls a solenoid valve on

the feed water line to maintain a constant level of filtered water. This water is cooled in the

holding tank with refrigerant coils. There is a separate hot water tank with an internal heater

coil which is fed by gravity with the cool water from the holding tank. The hot water tank

is directly beneath the cold water tank. The compressor and expansion valve are inside the

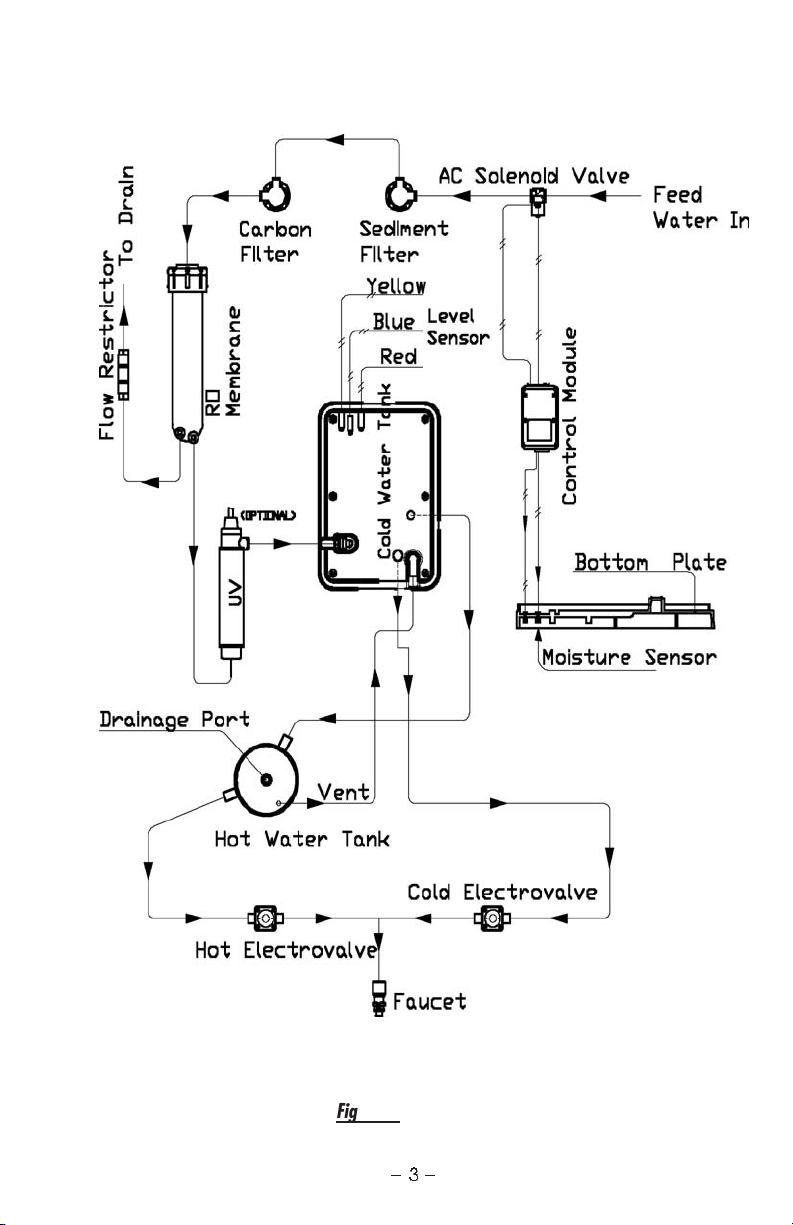

cabinet. The controls for the cooler are on the front panel. See Figure 2 for Flow

Schematic.

–2–

Figure 1.

PWC 400 Assembly

Page 5

–3–

Figure 2.

Flow Schematic

Page 6

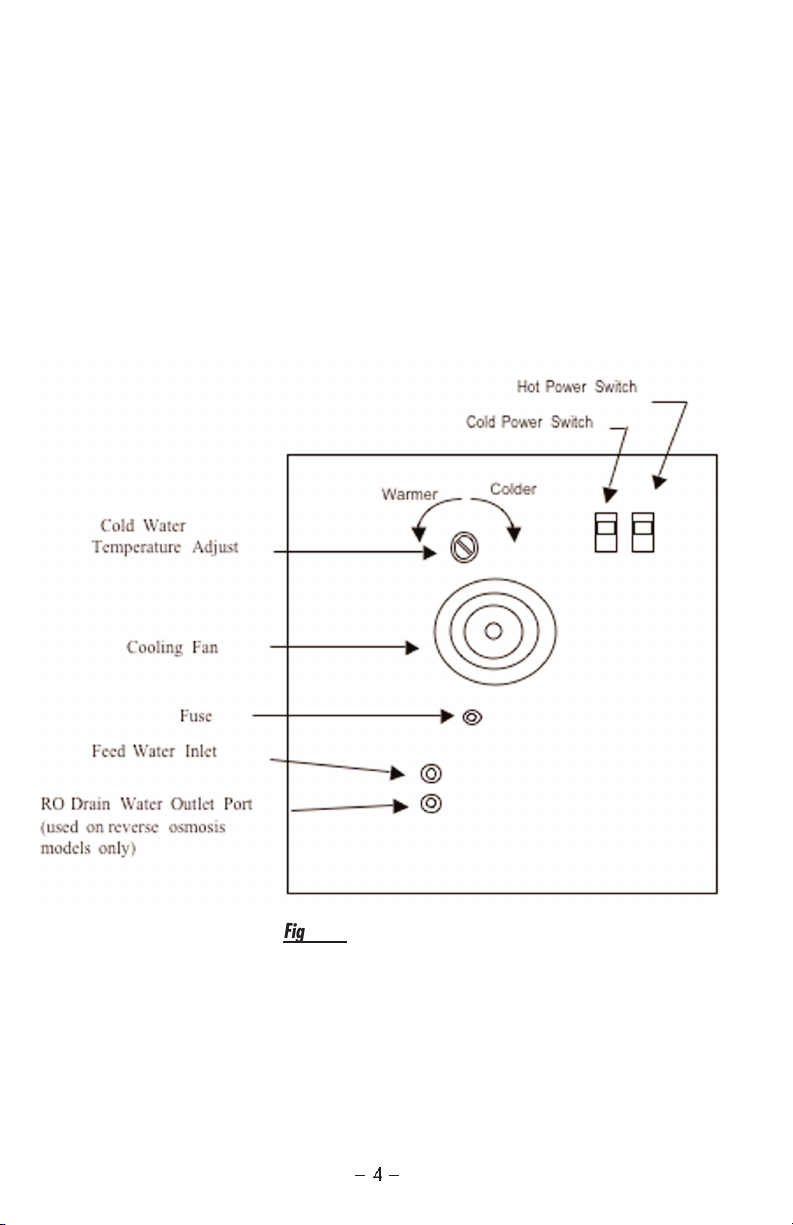

3.2 Rear View

On the back of the cooler are the main power switches; one for heating and one

for cooling. When heating or cooling is occurring, indicator lights on the front panel

will turn on. The hot temperature is fixed at a nominal 180°F and is controlled with

a thermostat mounted on the outside of the hot tank. The cold temperature can be

adjusted between 36°F and 54°F by a using a screw driver on the slot on the back.

Turn to the left to increase warmth and to the right to increase cold. DO NOT TURN

PAST THE STOPS. There is a cooling fan which exhausts to the rear, so a clearance

of 6-inches from a wall is required.

–4–

Figure 3.

Back View of Cooler

Page 7

–5–

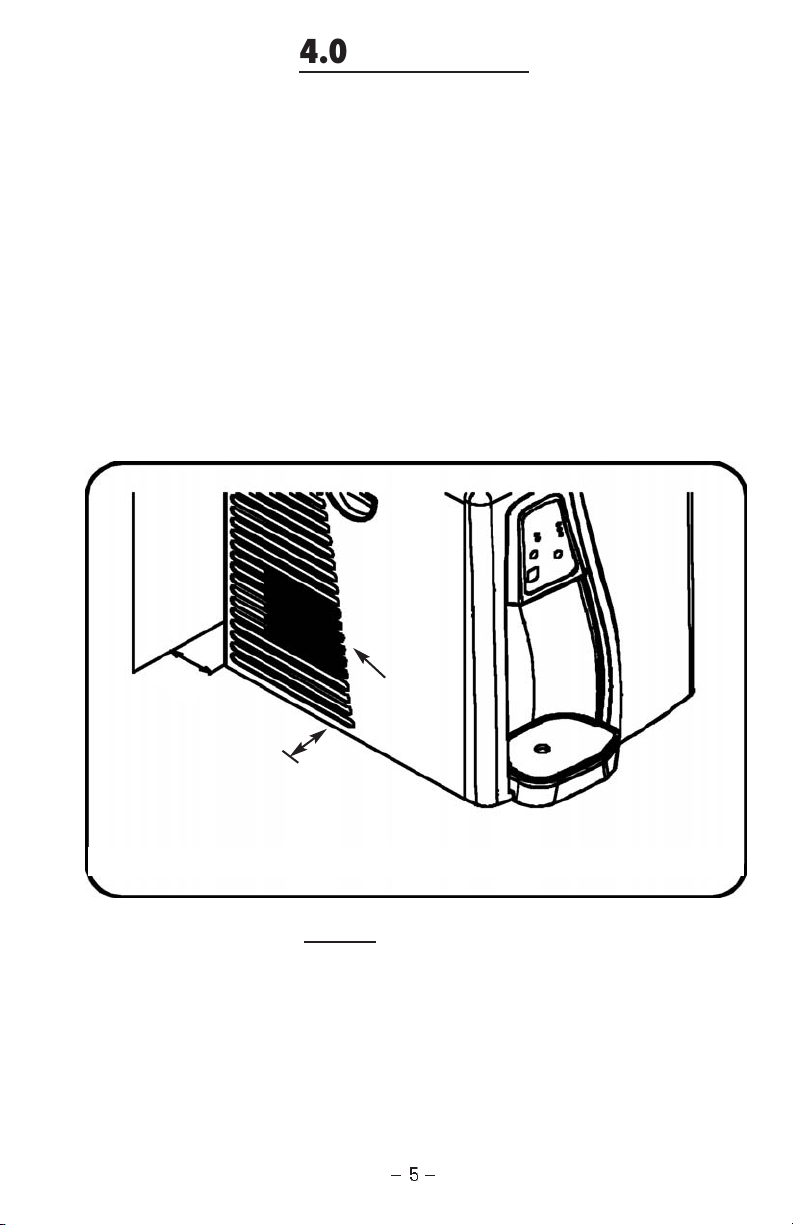

4.0 Installation

4.1 Positioning the Cooler

There are some precautions to take when positioning and using the

PureWaterCooler™

. See the items in Figure 4a and 4b. In addition, the cooler must

be located near the supply water, and for the “R” version with the reverse osmosis filter, there must be access to a drain trap to which the reject water from the RO is delivered. Normally, this can be found in a bathroom, or kitchen sink. Flexible 1/4-inch

plastic tubing may be used for the feed and discharge connections. Normally, these

connections should be within 25-feet of the cooler.

Important Note: Do not cover air intake vent as this will prevent proper chill-

ing from occurring.

Figure 4a.

Installation Precautions

6 in

4 in

Keep at least 6 in. distance between the cooler and the wall.

Air

Intake

vent

Page 8

4.2 Cooler Water Connections

When received, the water connections on the back have color coded tube sections

with red shipping caps on them. These tube sections must be removed before making

water connections. To remove the tube sections see Figure 8. The 1/4” plastic tubing

should be used for making the Feed Water and Drain connections. If hard copper tubing

is used for the Feed Water and Drain connections, the bulkhead fittings on the cooler must

be changed to metal fittings.

4.3 Feed Water Connections

To connect the feed water, used the supplied self-piercing saddle valve to connect to

the cold water supply line under the sink. Attach the 1/4” tubing to the compression fitting on the side of the valve. Clamp the saddle valve over the copper or plastic feed line

(cold water only). Turn the handle on the valve until the needle stem pierces the tube.

Then retract the needle 1-2 turns to start water flow. See Figure 5.

–6–

Figure 4b.

Installation Precautions

Do not place cooler next to

oven or dishwasher. Keep

out of direct sunlight

Be sure to use correct power

voltage. Plug power cord

directly into electrical socket

Page 9

4.4 Drain Connection (Applies to models wit Reverse Osmosis “R-version”)

The black drain line in the back must be hooked to the drain line ahead of the

normal sink water trap.

See Figure 6 below. Place the 2 part drain saddle on the drain pipe

before the drain trap. Allow proper space for the drilling operation. Tighten the saddle bolts evenly on both sides. Using the opening in the drain outlet saddle as a guide,

drill a 1/4” hole in the pipe. Clean any debris out of the drain saddle connection.

Connect the drain line to the cooler using the 1/4” black tubing supplied.

–7–

Figure 5.

Saddle Valve

Figure 6.

Drain Connection for RO Filter

Page 10

4.5 Quick Connect Fittings

The standard tubing connections on the PureWaterCooler™ are of Quick

Connect 0-ring seal design and manufacture. Use the tubing and follow the instructions below to make the connections. If you cut the tubing make sure it is a square

cut, fits squarely in the fitting and seals properly.

–8–

Figur

e 7.

Quick Connect Fittings

Page 11

5.0 Operation

5.1 Start Up

The PWC 400 Cooler is shipped to you complete and ready to operate. Connect all

tubing according to instructions.

b. Make sure Cold and Hot power switches at back of cooler are OFF before

plugging the cooler into 110-volt wall socket. (See Figure 8a)

c. Filter pre-flush. The carbon filter must be flushed of carbon fines before use.

Release the tubing from the carbon filter at the top of the tank. Run this to a container

to collect water. Let water run until it is clear. Unplug the power cord. Reconnect tubing. For complete instructions see Section 7.1.

d. Plug in the power cord. The feed water solenoid valve will open automatically

(a “click” can be heard from inside the cooler when this occurs).

e. Water will now start to flow through the filtration system and enter the water

tanks inside the cooler. DO NOT TURN ON THE HOT & COLD POWER YET!

f. When the ‘tank full’ light on the front panel (Figure 8b) comes on, the tanks are

full and water production has stopped.

1) For the “R” version with reverse osmosis, it will take 2 hours.

2) For the “F” standard filter version, it will take about 15 minutes.

–9–

Figure 8a.

Hot/Cold Power Switches

Figure 8b.

Control Panel

Page 12

–10–

g. Completely drain all of the water from the cooler using the hot water dispens-

ing button. After the first tank is drained, let the tanks refill and drain a second time in

the same manner. You must drain (2) complete tanks of water before use to ensure carbon fines and membrane preservative have been removed.

h. Once the cooler has refilled for the 3rd time, turn on hot power switch on the

back. Heating will start and the “Heating” light will come on the front panel.

i. Dispense hot water (Figure 8c). Hot water dispensing utilizes a child safety

device to help prevent accidental dispensing of hot water by young children. To operate

the hot water tap, first push the “key” button. Then within 30 seconds, push the hot

water tap button and hot water will be dispensed.

j. Turn on the cold power switch in the back. The compressor will start and

cooling will begin. The “cooling” light, located on the front panel, will come on.

k. To dispense cold water, push the Cold Water Tap button.

l. The temperature of cold water is set at midpoint at the factory. Using a flat screw-

driver, the temperature can be adjusted by turning the temperature control slot Clockwise

for colder and Counterclockwise for warmer (See Figure 3).

CAUTION: If you turn the COLD POWER button off, WAIT AT LEAST 3

MINUTES before turning on again to protect the compressor from damage.

Figure 8c.

Control Panel

Page 13

5.2 Tank Drain

Occasionally, it may be desirable to drain both tanks. There is a drain plug

on the bottom of the cooler frame. See Figure 9. First, make sure all power is off.

The cooler must be moved so that the water can be drained from the bottom into a

container to collect the water (about 11/4 gal).

–11–

Figur

e 9.

Tank Drain

Page 14

-12-

6.0 Leak Detection System

There is a water leak detection system installed in the cooler. If a water leak

should occur inside the cooler, power will automatically be shut off.

When power is cut off due to water leak:

a. Un-plug the cooler and remove the left side panel (See Figure 10).

b. Remove any excess water in the bottom lift and wipe the detection probes dry.

Replace.

c. Plug in the unit and check for leaks.

Figure 10.

Leak Detector

Page 15

-13-

7.0 Filter Replacement Procedure

The filter elements must be replaced at regular intervals to maintain the quality

of the water.

The “F” Model 400 has 2-stages of mechanical filtration. A 1st stage 5-micron

sediment filter and a 2nd stage activated carbon filter. Both stages must be replaced every

6-12 months.

The “R” Model 400 has the 2-stages of mechanical filtration plus an additional

50 GPD Reverse Osmosis membrane element. The 2 pre-filters must be replaced every 612 months. The Reverse Osmosis membrane must be replaced every 3 years. The RO unit

produces filtered water at a rate of 2 gal/hour.

Figur

e 11.

Filter Access

Page 16

-14-

7.1 Sediment and Carbon Filter Replacement Procedure

a. Unplug the cooler from the wall socket.

b. To access the filter compartment, remove the two screws that secure the

right side panel. (See Figure 11).

c. Remove the right side panel by sliding it backwards and then lifting the panel

out.

d. To remove the sediment and carbon filters, rotate the filter 90 degrees and pull

down.

e. Install a new carbon and sediment filter in the indicated positions.

Use these replacement filters for PWC 400 shipped before 03/01/2008:

1st stage sediment filter, P/N TF-4056

2nd stage Carbon filter, P/N TF-4057

Use these replacement filters for PWC 400 shipped after 04/01/08:

1st stage in-line sediment filter, P/N IFA-4035

2nd stage in-line carbon filters, P/N IFA-4034

f. On the Model 400F The carbon filter must be flushed of carbon fines before use.

Release the tubing from the carbon filter at the top of the tank. To access the

tank, remove the top cover by removing the two hold down screws and sliding

back the top (See Figure 1). Run this tubing to a container to collect water.

g. Plug in the power cord. The inlet water valve opens and water will run

through the filters. Let water run until it is clear. Unplug the cooler and reconnect tubing. Plug in the power cord.

Page 17

-15-

7.2 Stage 3 Reverse Osmosis Membrane Replacement

Use the same procedure as in paragraph 7.1 above section a-f. With

the cooler unplugged and the filter compartment open, disconnect the 3 tubes of the

RO filter housing. Remove the RO housing from the filter clips. Remove the cap

from the housing by unscrewing it.

Using a pair of pliers, remove the RO element from the housing by

grasping the tube end and pulling it out. Use RO filter replacement P/N ma-4203

(50 gpd TFC membrane). Insert the element into the housing with the double “o”ring end going in first, toward the bottom of the housing. Make sure the “o”-rings

are seated. Replace the cap. Reconnect the tubing and replace housing in filter clips.

Replace cover and plug in cooler. Flush 3 tanks of water before drinking to remove

preservative in the RO membrane.

8.0 Options

8.1 UV Stage

An additional stage is available for both models. The UV stage provides a UV

light which is continuously on when the cooler is plugged in. This option is installed at

the factory as an additional stage of the filter system. The UV light bulb must be

replaced once per year. The replacement part number is UV-4061.

Membrane Installation

Page 18

-16-

9.0 Trouble Shooting Guide

PPPPRRRROOOOBBBBLLLLEEEEMM

MM

CCCCAAAAUUUUSSSSEE

EE

SSSSOOOOLLLLUUUUTTTTIIIIOOOONN

NN

Panel not lit No Power • Check that power cord is

plugged in.

• Make sure “Full” light on panel

is lit.

• Then turn on cold and hot

power switches.

Note: Make sure “Full” light on

panel is lit before turning on cold

and hot power switches.

No Hot Water No Power

Temperature control sensor faulty

• First, check that front “Hot”

light is lit. If not, turn hot power

switch on back.

• Thermostatic controller on hot

tank may not be functioning.

• Check with Dealer

Unit shut off.

Panel not lit.

Shut down may be caused by

leak detector.

• Check that power plug is in.

• Check hot/cold power switch is

on.

• Slide side panel back. If water

is in bottom, there is a leak

detector shutdown, see section

6.0

Cold Water not cold enough. Unit is too close to wall so cool-

ing fan isn’t effective.

Refrigerant has leaked.

• Move unit 6 inches away from

wall.

• Make sure intake vent is not

blocked.

• Contact Dealer.

Water won’t come out of spigot. Air in line. • Turn the cold or hot dispenser

off and on several times to bleed

air out.

Will Not Cool Controls not set.

Thermostat in rear

• Turn on cold power switch on

back.

• Turn to right about 1/2 turn for

colder water.

Page 19

-18-

11.0 Specifications

Model No.

Voltage/Frequency

Dimensions

Weight (empty)

Hot Water Tank Capacity

Cold Water tank Capacity

Power Consumption

Electric Power Cord Length

PWC-400

AC110V

(L) 16 x (W) 13 x (H) 16 1/2

42 lb.

.25 gal.

1.0 gal.

Hot Water: 500W

Cold Water: 100W

6Ft.

Conforms to UL STD.399

- 17 -

Page 20

Vertex Water Products (“Manufacturer”) sell its products through independent retailer dealers (“Dealer”)

- 18 -

LIMITED WARRANTY

who re-sell to the end-user customer. In this limited warranty, “Vertex” refers to Vertex Water Products and

not to the Dealer.

WHO IS COVERED BY THIS WARRANTY

This limited warranty covers only the rst purchaser of the Vertex PureWaterCooler™ from a Dealer for

use by that purchaser, and is not transferrable. “Consumer Use” means personal residential household use

by a consumer or consumers. “Commercial Use” means all other uses, including (but not limited to) use for

commercial, income producing purposes and/or when purchased by a business and/or when purchased for use

in an ofce, business, or industrial setting. “Purchaser” means the end-user customer, and not a Vertex re-seller

Dealer.

PERIOD OF COVERAGE OF THIS WARRANTY

Manufacturer warrants the complete water cooler (“the unit”) against defects in material and workmanship,

subject to the exclusions described below, for a period of ONE YEAR, beginning on the later of either

(a) the date of purchase or (b) the date of manufacture as identied by the Vertex unit’s serial number.

Manufacturer additionally warrants the compressor for a period of THREE YEARS from the above date.

The purchaser must provide the original sales receipt as proof of the date of purchase. If the purchaser is

unable to produce the original sales receipt, the Warranty Period commencement date will be determined

by Manufacturer, in its sole and absolute discretion, based upon the unit’s serial number. This warranty

does not apply if the original serial number afxed by Manufacturer is removed, defaced, altered, obscured,

tampered with, or obliterated. If Manufacturer provides a replacement part or parts, or repairs a part or

parts, under this limited warranty, then the replacement part(s) or repaired part(s) will be covered under this

limited warranty for the time remaining under the original Warranty Period applicable to the part(s) repaired

or replaced.

The duration of ALL OTHER WARRANTIES, INCLUDING ANY AND ALL IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE RESTRICTED TO THE TWO-YEAR

LIMITED WARRANTY PERIOD. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to purchaser.

WHAT IS COVERED BY THIS WARRANTY

This limited warranty covers defects in materials or workmanship, subject to the exclusions below and for

the time period stated above. Manufacturer promises to repair or to replace, at Manufacturer’s sole and

absolute discretion, any part of this water cooler that proves to be inoperative due to a defect in material or

workmanship under normal use.

WHAT IS NOT COVERED BY THIS WARRANTY

This limited warranty does not extend to and expressly excludes:

• conditions, losses, malfunctions, or damages not resulting from defects in material or workmanship;

• conditions, malfunctions, losses, or damages or the inability to operate the Vertex unit resulting from

conditions beyond Manufacturer’s control, including but not limited to failure of the unit or any of its

parts due to damage caused by: improper installation; accident; re; ood; windstorm; acts of God;

rodent and/or insect infestation; vandalism; modication; alteration; combination with any other device

or machine; abuse and/or misuse of the unit; negligence by purchaser or third parties; any part of the

water system that has become fouled due to liming, dirt, unsatisfactory/unsanitary water conditions,

corrosion, or faulty plumbing; failure to install, maintain, assemble, mount or place the Vertex unit in

accordance with Manufacturer’s instructions and/or local, state, or national plumbing and electrical

codes; wear and tear expected to occur in the normal course of use, including but not limited to cosmetic

rust, scratches, dents or comparable and reasonably expected losses or damages; exposure to extreme

variations in ambient environmental conditions (including but not limited to changes in heat, humidity,

moisture, or exposure to sunlight).

• labor for installation or deinstallation of the unit or any of its parts; shipping of the unit or any of its parts

to Manufacturer for repair/replacement.

In addition to the above exclusions, this limited warranty does not apply if any of the following conditions

of operation are not met: System Pressure 35 - 100 psi, Temperature 40 - 100 degrees F, PH range 4 - 10,

Max TDS 1500 PPM Max., Turbidity <1.0NTU, Hardness <20gpg, R version: <3.5 gpg, F version, Iron

<0.1 mg/l, Manganese <0.1 mg/l, Hydrogen Suld e <0.00 mg/l.

Page 21

NO OTHER EXPRESS OR IMPLIED WARRANTY APPLIES

- 19 -

This limited warranty is the sole and exclusive warranty provided to the purchaser identied above. No

other express warranty, written or verbal, applies. No agent, employee, deal or other person or entity

is authorized to alter this limited warranty or make any other warranty on behalf of Manufacturer. The

terms of this limited warranty shall not be modied by the Manufacturer, the purchaser/end user, or their

respective successors or assigns.

WHAT WE WILL DO TO CORRECT PROBLEMS/ HOW TO GET WARRANTY PARTS

If the Vertex unit does not operate in accordance with the documentation provided to purchaser, or purchaser

have questions concerning purchaserr Vertex unit, please contact the Dealer from whom the unit was

purchased. If the original Dealer is not available or the purchaser does not know who the Dealer is, please

call or email the Manufacturer, Vertex, using the contact information provided below. We will try to nd

a Dealer in purchaserr geographical area to assist purchaser. If a Dealer cannot be conveniently located,

the Manufacturer, in its sole and absolute discretion, may offer two (2) options. First, we will attempt to

troubleshoot the issue with purchaser over the phone. If the purchaser is comfortable making a repair/

replacing a part, once we understand the problem and its solution, we will send the replacement part(s) for

the cooler. This warranty is for the replacement of part(s) ONLY; it does not cover the cost of labor

for either the Dealer or the end user/purchaser. The second option is that the end user/purchaser may,

after notifying Manufacturer and receiving written authorization/approval from Manufacturer to do so,

send the unit back to Manufacturer and we will repair it. The end user purchaser must pay the freight/

shipping costs to return the unit to Manufacturer. Manufacturer will pay the freight/shipping to return

the unit to the end user/purchaser following repair.

If the end user/purchaser contacts the Dealer and the Dealer repairs the unit pursuant to this limited

warranty, Manufacturer will provide parts to the Dealer at no charge; labor is not included in this limited

warranty.

The Dealer may, in his or her sole and absolute discretion, decide to repair the unit on-site or take the unit to

a shop to repair.

This limited warranty covers replacement or repair of parts only. Manufacturer will not replace the entire

unit if a part can be replaced or repaired to restore the unit to full operational function. On the rare occasion

that a unit cannot be restored to full operation by a part or parts, Manufacturer will replace the unit after the

end user/purchaser has shipped the unit to Manufacturer and Manufacturer has determined, in its sole and

absolute discretion, that the unit cannot be repaired and must be replaced. The end user/purchaser must

pay the freight/shipping costs to return the unit to Manufacturer. Manufacturer will pay the freight/

shipping to return the unit to the end user/purchaser following repair or will ship a new unit if repair is not

possible. If Manufacturer does provide a replacement unit, then the Warranty Period (as specied above) for

the replacement unit would begin at the time of its delivery to the end user/purchaser.

LIMITATION OF LIABILITY AND DISCLAIMER OF WARRANTIES

TO THE EXTENT PERMITTED BY LAW, IN NO EVENT SHALL MANUFACTURER BE LIABLE

TO PURCHASER OR ANY THRID PARTIES FOR ANY INCIDENTAL, SPECIAL, INDIRECT,

OR CONSEQUENTIAL DAMAGES, INCLUDING ANY ECONOMIC LOSS, WHETHER

RESULTING FROM NON-PERFORMANCE, USE, MISUSE, OR INABILITY TO USE THE

VERTEX UNIT. MANUFACTURER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY

DELAY IN PERFORMANCE AND IN NO EVENT, REGARDLESS OF THE FORM OF THE

CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT, WARRANTY, TORT,

INFRINGEMENT, NEGLIGENCE, STRICT LIABILTY, OTHER TORT OR ANY OTHER LEGAL

THEORY) SHALL MANUFACTURER’S ENTIRE LIABILTY EXCEED THE PRICE PAID BY THE

ORIGINAL PURCHASER FOR THE VERTEX UNIT. THE TERM “CONSEQUENTIAL DAMAGES”

SHALL INCLUDE, BUT NOT BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, BUSINESS

INTERRUPTION, LOSS OF USE OR REVENUE, COST OF CAPITAL, OR LOSS OR DAMAGE TO

PROPERTY OR EQUIPMENT.

Contact information:

Vertex Water Products 5138 Brooks Street Montclair, California 91763

800-627-2146 www.vertexwater.com email: inquiries@vertexwater.com

Page 22

VERTEX WATER PRODUCTS, Montclair, Calif.

PWCM-2 Rev. F 06/08

Copyright 2008 VERTEX INDUSTRIALS, INC.

Loading...

Loading...