Page 1

PWC – 400

PureWaterCooler

SERVICE MANUAL

for

PureWaterCooler™

by Vertex

Model PWC-400

P/N man-xxxx

Copyright 2008 Vertex Water Products

Page 2

PWC – 400

PureWaterCooler

Table of Contents

1. Introduction

2. Cooler Set-up

3. Remove Top Cover/Side Cover

4. Remove/Replace Float

5. Remove/Replace Hot Tank

6. Dispensing Solenoid – Remove/Replace

7. Circuit Board – Remove/Replace

8. Front Panel – Remove/Replace

9. Hot Tank Reset Button

10. Remove/Replace Hot Tank Thermal Sensors

11. Cold Temperature Adjustment

12. Sanitization Procedure

13. Trouble Shooting

14. Specifications

15. Cooler Exploded View

16. Parts List

Copyright 2008 Vertex Water Products

Page 3

PWC – 400

PureWaterCooler

PWC-400 Cooler

1. Introduction

The PWC-400 line of point of use counter-top coolers are designed to give years of reliable

Service. The cooler has a single spigot that dispenses filtered water at 2 different temperature

levels – hot and cold temperature water. The main (cold-temp) tank holds 3/4 gallons of water

and is constructed of FDA approved plastic. The cold tank can be accessed for servicing

the float mechanism and for cleaning by removing the cooler main top cover (see section 4).

The hot tank is made of stainless steel and holds 1/4 gallon of hot water. It is important not

to turn on the hot tank when there is no water in it as this will damage the heating element.

The compressor is a sealed unit and is not serviceable in the field. The compressor can be

replaced by a qualified refrigeration technician with proper tools and equipment.

Please consult the factory if the compressor needs servicing.

CAUTION: If the compressor has been stopped by switching it off or unplugging power,

WAIT 10 MINUTES before turning the compressor on again. The compressor may stall

and burnout if powered back on without waiting.

The cooler makes clean water by filtration or by the reverse osmosis process. Water enters the

back of the cooler and then passes through the filtration system. A feed water ball valve is

Located near the filters and must be turned to the on position to allow the unit to make water.

Electrical power is required for the cooler to make purified water. CAUTION: The carbon

filtration versions of the cooler (PWC-400F) should not be used with water hardness over

7 grains because of lime scale build up on the heating element. If hardness is higher than

7 grains, softening of the feed water is recommended or another option is to install

a “phosphate” filter to the filter system.

Copyright 2008 Vertex Water Products

Page 4

PWC – 400

PureWaterCooler

2. Cooler Set-Up

(for new cooler installation)

Feedwater/Drain Connections

-Feed Connection

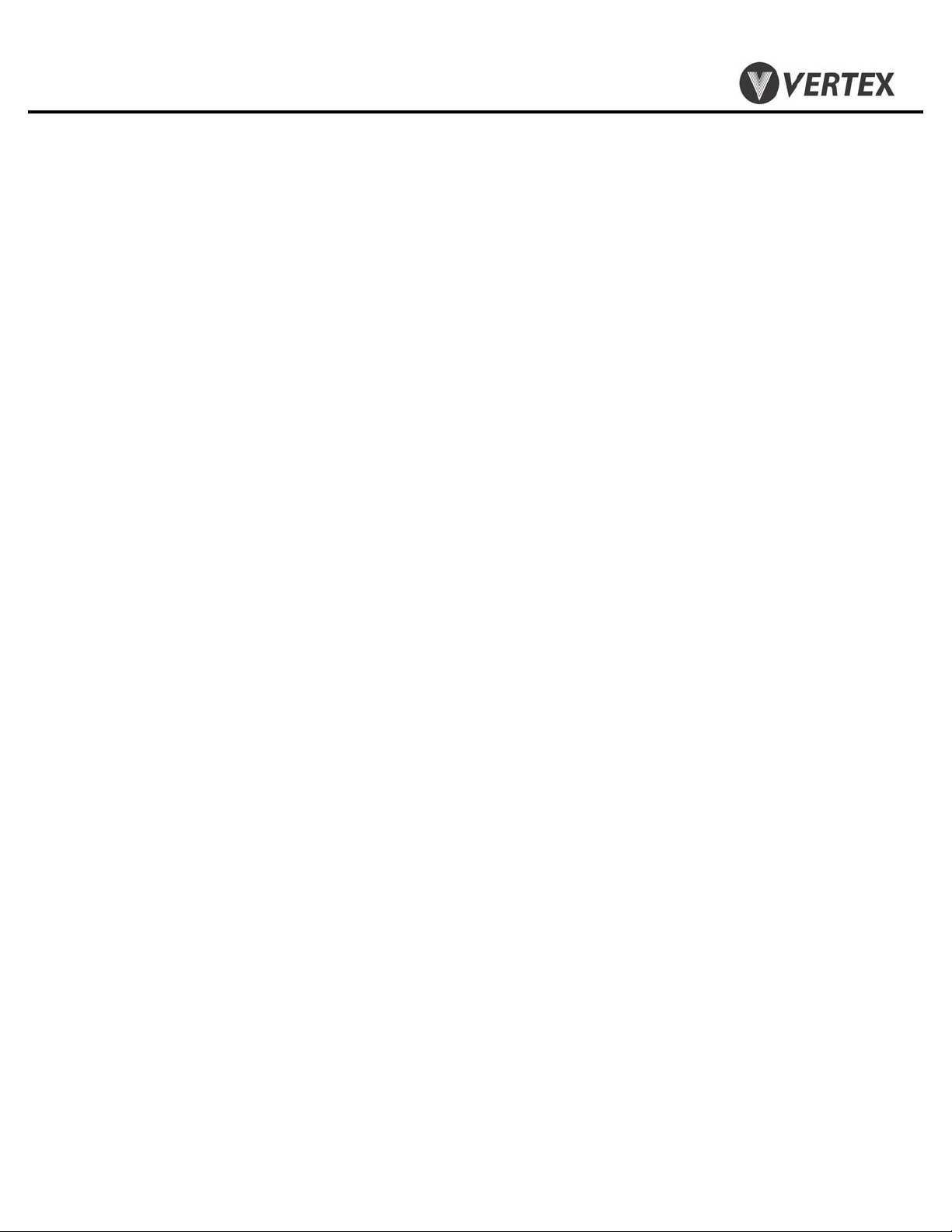

2.1 Remove 2 screws on back of right side panel

and remove right side panel.

2.2 Remove feed water plug (orange) from back

of cooler.

Copyright 2008 Vertex Water Products

Page 5

PWC – 400

PureWaterCooler

2. Cooler Set-Up cont.

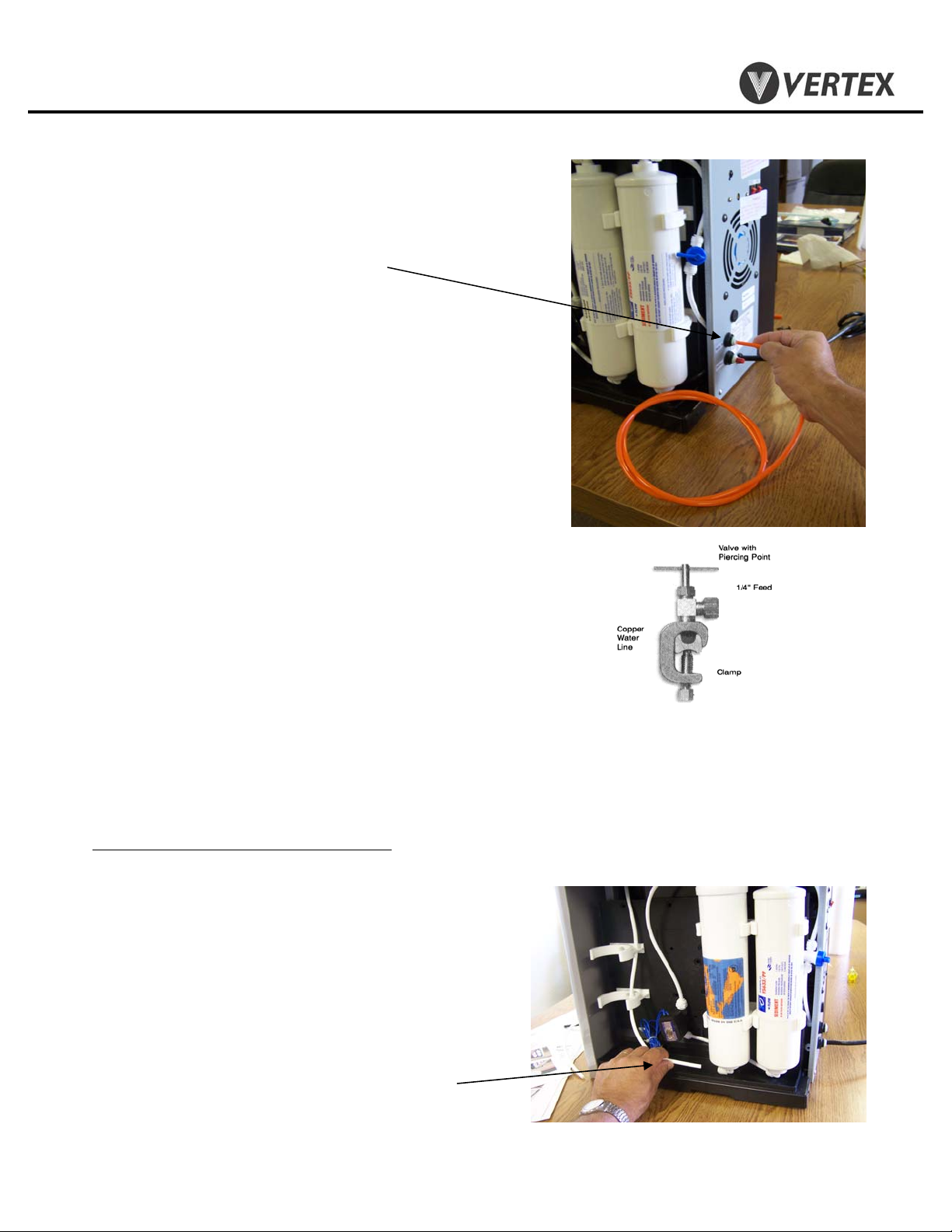

2.3 Connect supplied orange feed water tubing to

feed connector on back of cooler.

2.4 Make feed water connection to cold water line.

A self piercing saddle valve is provided.

2.5 Flushing carbon fines from carbon filter

.

Most carbon filters have fine particles of

carbon material in the filter that will be

swept into the water stream when the first

water flows through the filter. Although not

harmful, these carbon fines in the water are

unsightly. Flush the carbon fines out of the

filter before filling cooler tanks with the

following procedure

2.6 Remove outlet line of carbon filter (bottom)

Feedwater connection (RO & filtration coolers

(For use on copper tubing)

Use supplied self piercing saddle valve.

Connect to water inlet on cooler u sing 1/4”

tubing. Clamp saddle valve over copper feed

water line (cold water line only). Tighten

needle valve until tube is pierced. Retract

needle 1 -2 turns to start water flow.

)

Copyright 2008 Vertex Water Products

Page 6

PWC – 400

PureWaterCooler

2. Cooler Set-Up cont.

2.7 Attach 3 feet of ¼” tubing to the carbon filter

outlet port (flush tubing)

2.8 Place flush tubing in bucket to catch water

carbon fines

2.9 Turn on feed water at source and turn ball valve

at filter to “on” to let the water flush the filter.

2.10 Flush until water flows clear (1 – 2 gallons)

2.11 Remove flush line. Reconnect tank line to

outlet of carbon filter

2.12 WARNING: Do not turn on cooler hot power

until cooler tanks are full of water.

Figure 2.7

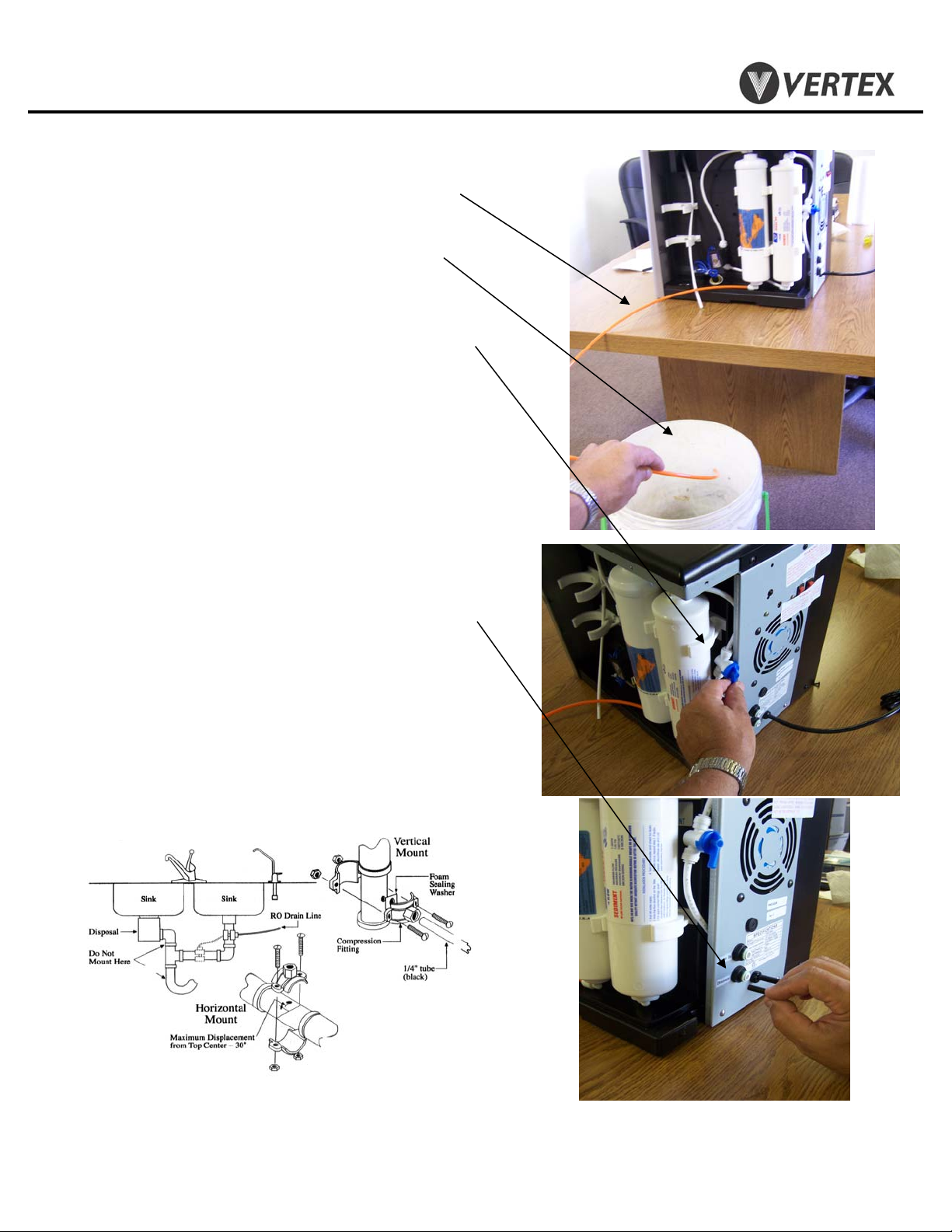

Drain Connection (for units equipped with RO)

2.13 Remove drain plug (black) from back of cooler

2.14 Connect supplied black water tubing to

drain connector on back of cooler

2.15 Attach supplied drain saddle to a

standard 1 ½” drain pipe see fig. 1 below

Drain saddle connection method

Drain connection required only for cooler with reverse osmosis filtration

Figure 1

Copyright 2008 Vertex Water Products

Page 7

PWC – 400

PureWaterCooler

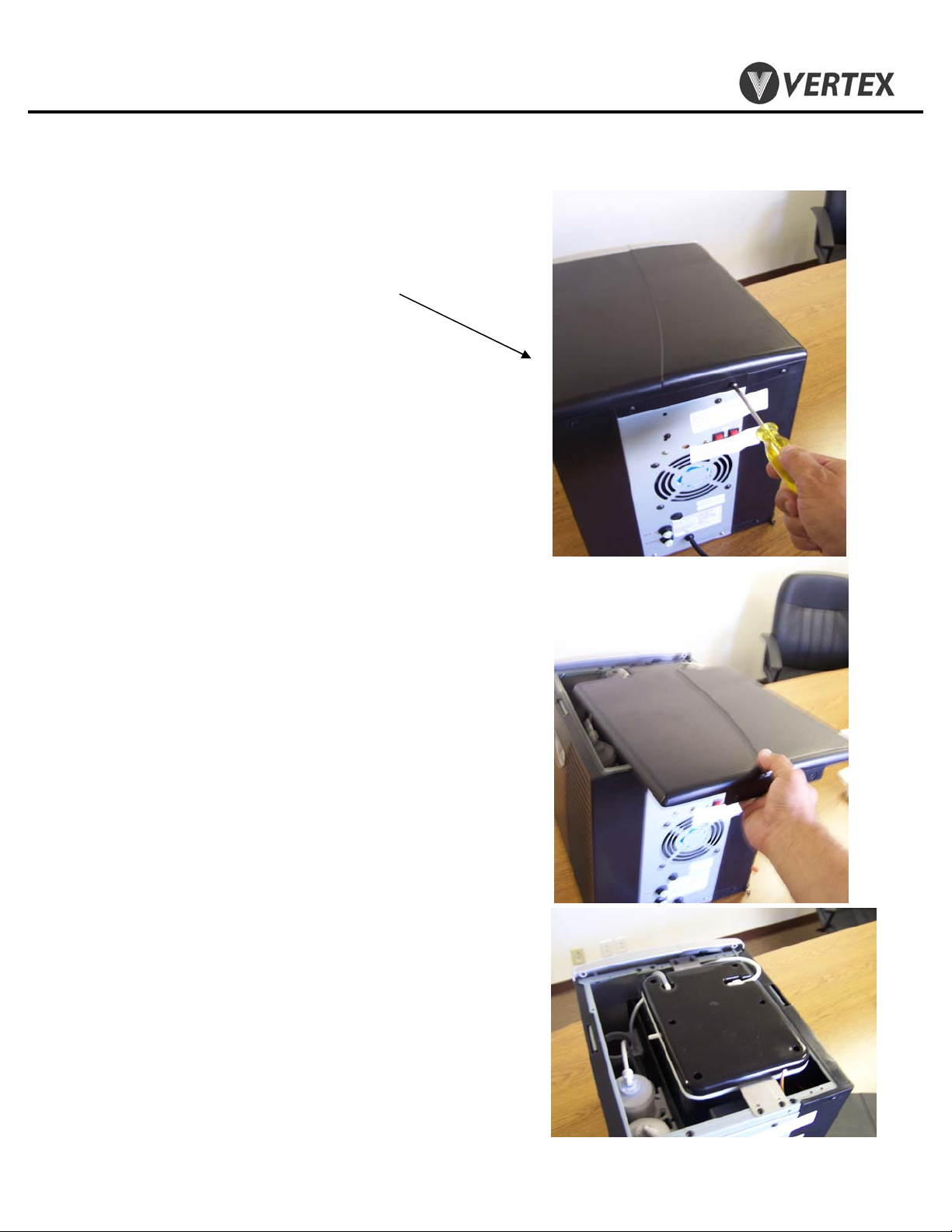

3. Top Cover/Side Panel Removal

3.1 Remove (2) screws on back of cooler top cover

3.2 Slide cover back and lift off.

3.3 Cold tank is now accessible for cleaning

and servicing other parts of the cooler.

3.4 Reinstall in reverse order

Copyright 2008 Vertex Water Products

Page 8

PWC – 400

PureWaterCooler

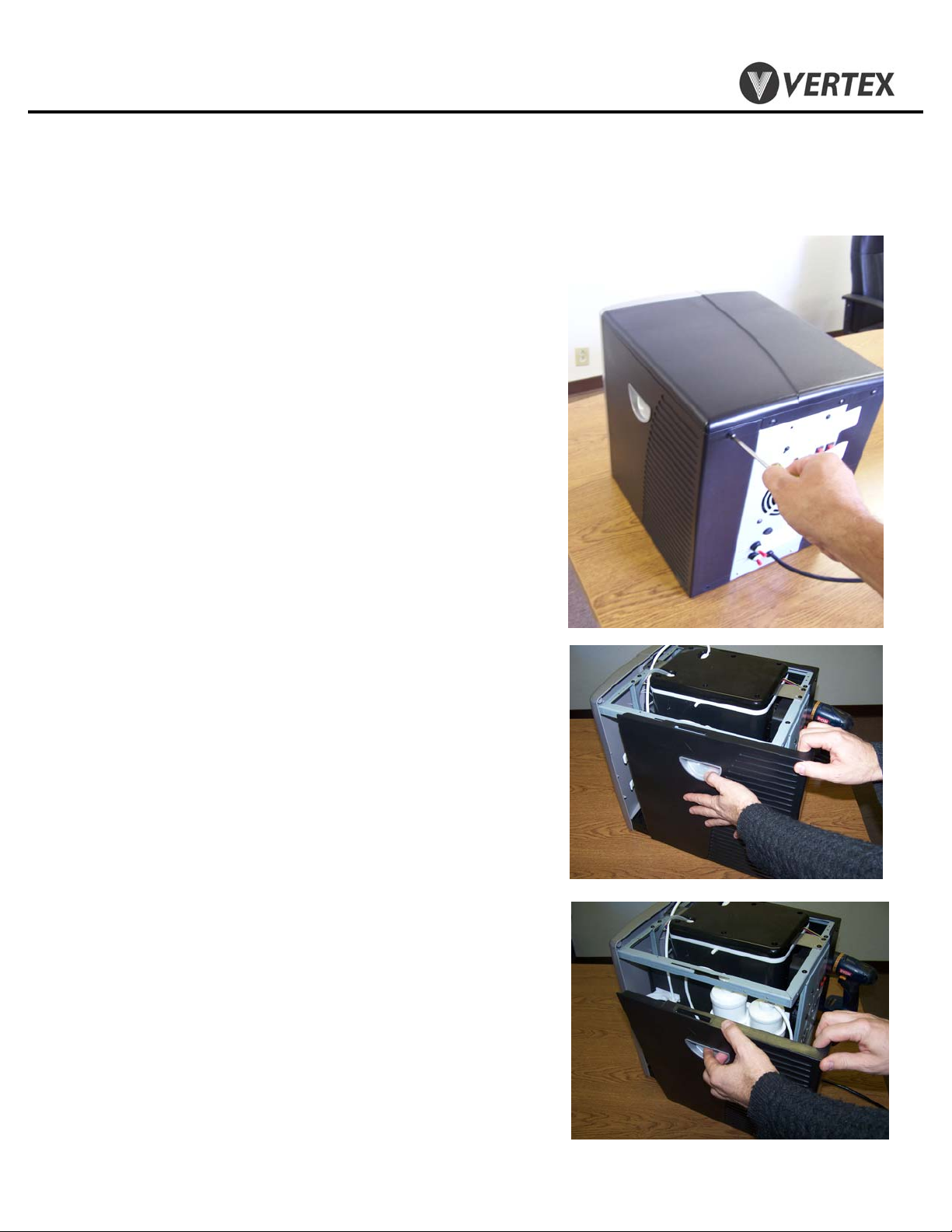

3. Top Cover/Side Panel Removal

3.5 Remove (2) screws on back of cooler side cover

Cont.

3.6 Slide side cover back about half way off until

tab in side cover lines up with slot in cooler

frame.

3.7 Once slot and tab are lined up, pull side cover

away from cooler.

3.8 Reinstall in reverse order

Copyright 2008 Vertex Water Products

Page 9

PWC – 400

PureWaterCooler

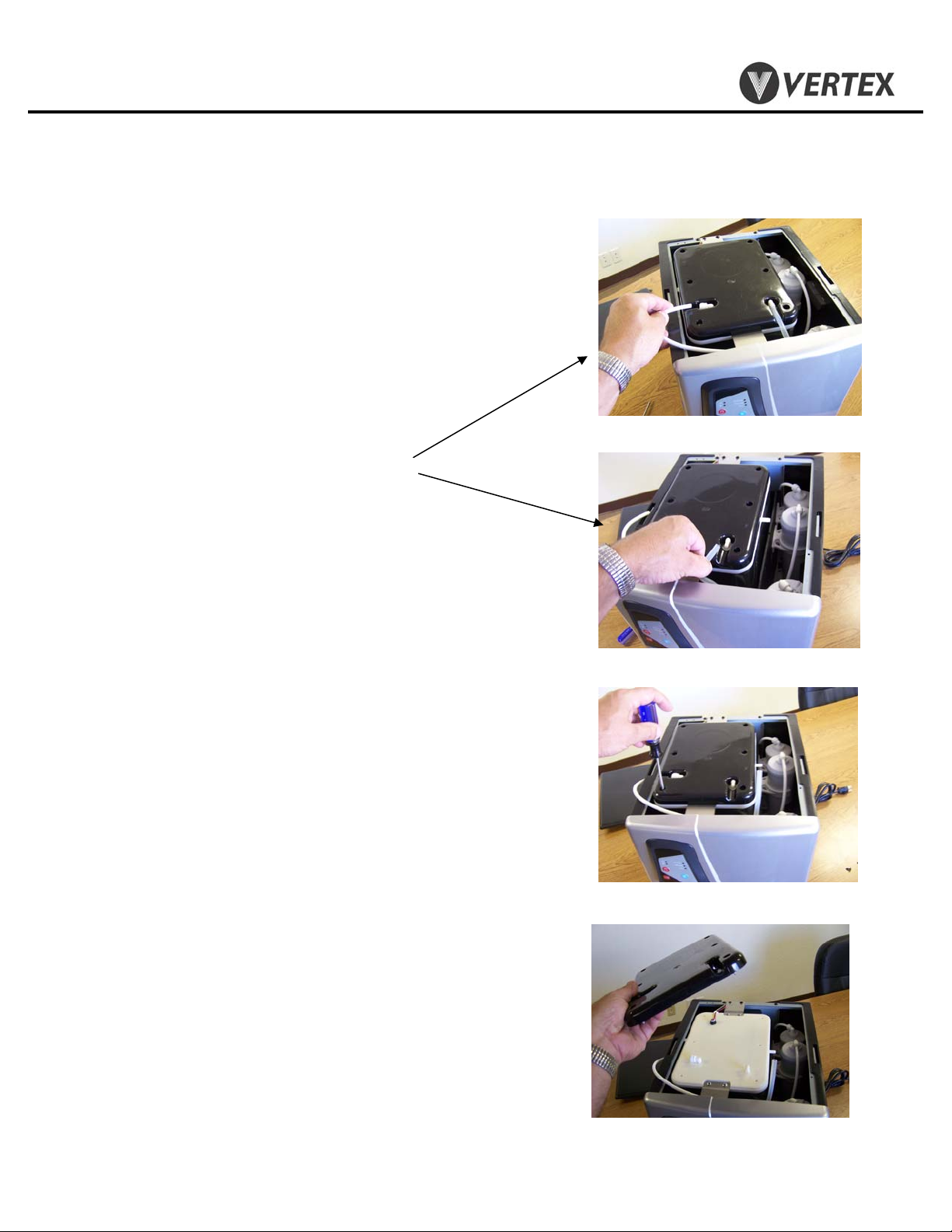

4. Remove/Replace Electro/Mechanical Float Assembly

4.1 Remove top cover (See section 3)

4.2 Remove tubing from top of cold tank

4.3 Remove screws from lid of cold tank. (6 plcs)

4.4 Remove outer lid of cold tank

Copyright 2008 Vertex Water Products

Page 10

PWC – 400

PureWaterCooler

4. Remove/Replace Electro/Mechanical Float Assembly

cont.

4.5 Disconnect electrical connector

4.6 Lift off inner lid of cold tank

4.7 To remove float, remove nut from float stem

4.8 Remove float assembly from inner lid.

4.9 Reinstall in reverse order.

Copyright 2008 Vertex Water Products

Page 11

PWC – 400

PureWaterCooler

5. Removing/Replacing Hot Tank.

5.0 Unplug power from wall

5.1 Drain water from cooler using front spigots

and by removing bottom drain plug.

5.2 Remove top cover and left and right side covers (sec. 3)

5.3 To gain access to the hot tank, the

filter bracket must be moved:

5.4 Remove water line from top of sediment filter

5.5 Put cooler on its’ left side

5.6 Remove 4 screws holding filter bracket to base

5.7 Set filter bracket aside to allow access to hot tank

Copyright 2008 Vertex Water Products

Page 12

PWC – 400

PureWaterCooler

5. Removing/Replacing Hot Tank

5.8 Remove wire from thermal sensors (4 places)

Cont.

5.9 Remove inlet tubing (Access from right side of

cooler)

5.10 Remove outlet tubing (Access from left side of

cooler)

Copyright 2008 Vertex Water Products

Page 13

PWC – 400

PureWaterCooler

5. Removing/Replacing Hot Tank

5.11 Remove vent tubing (top of hot tank)

Cont.

5.12 Remove the 2 screws that hold the tank from the

bottom of the cooler

5.13 Remove the hot tank from cooler

5.14 Remove (2) heating coil leads from hot tank

5.14 Remove Thermal sensors from hot tank. Save an

install on new hot tank.

5.16 Assemble hot tank in reverse order.

d

Copyright 2008 Vertex Water Products

Page 14

PWC – 400

PureWaterCooler

6. Dispensing Faucet Repair

6.1 Remove top and side covers of cooler (section 3)

6.2 Remove the control panel by grasping the bottom

of the panel and pulling out sharply.

6.3 Remove (4) electrical connectors from back of the

control panel. Set control panel aside.

Copyright 2008 Vertex Water Products

Page 15

PWC – 400

PureWaterCooler

6. Faucet Repair

Cont.

6.4 Remove hot water tubing from the left (hot) solenoid.

6.5 Remove screw holding solenoid/manifold assembly

to the front panel.

6.6 Remove solenoid/manifold assembly by lifting it

out of cooler. Disconnect cold water tubing from

cold water solenoid (right side).

Copyright 2008 Vertex Water Products

Page 16

PWC – 400

PureWaterCooler

6. Faucet Repair

6.7 Remove screw holding solenoid to manifold and

bracket. Slide solenoid off of manifold.

Cont.

6.8 Reassemble in reverse order.

Make note of the following:

a. Water flow through the solenoid is

directional. There is an arrow molded in

the side of the solenoid body showing

water flow direction. Make sure the solenoid

is oriented correctly. Water can leak from

the solenoid if not installed correctly

b. When installing electrical connectors into

the circuit board please note: the left

solenoids’ connector plugs into the left

socket on the circuit board (when you are

facing the circuit board). The right solenoid

plugs into the right

Copyright 2008 Vertex Water Products

Page 17

PWC – 400

PureWaterCooler

7. Remove/Replace Circuit Board

7.1 Remove dispensing control panel (section 6)

7.2 Remove circuit board cover

7.3 Remove (3) screws holding circuit board to panel

7.4 Re-assemble in reverse order

Copyright 2008 Vertex Water Products

Page 18

PWC – 400

PureWaterCooler

8. Remove Front Panel

8.1 Remove top and side covers of cooler (section 3)

8.2 Remove the control panel and dispensing solenoid

assembly (section 6.2)

8.3 Remove (2) screws from the top of the front panel. The

lower part of the front panel sets on two pins.

8.4 Lift front panel off of the two pins. Remove cover

8.5 Re-assemble in reverse order

Copyright 2008 Vertex Water Products

Page 19

PWC – 400

PureWaterCooler

9. Hot Tank Reset Button

9.0 To access the hot tank, remove the left side cover

per section 3.3

9.1 Observe that there are two circular sensors

attached to the hot tank. The upper one is the

main controller at 82 ºC and the lower sensor

is the over-temp cut off.

The power switch for the hot tank (at the back

of the cooler) should not be turned on until

water can be dispensed from the hot spigot. If

the hot power is turned on without water in the

hot tank the heating element will over heat. To

prevent this, the lower thermal sensor on the

hot tank will cut power to the heating element

before any damage takes place. If this happens

the switch on the thermal sensor can be reset to

operational mode manually by the following

procedure.

9.2 Make sure the power cord is unplugged.

9.3 Find the lower thermal sensor on the hot tank

9.4 Using a long thin object such as a screw driver

or a pen, depress the small button at the

center of the lower thermal switch. You should

feel a click when you depress the button. This

action resets the over-temp sensor.

Copyright 2008 Vertex Water Products

Page 20

PWC – 400

PureWaterCooler

10. Remove/Replace Thermal Sensor

10.0 The hot tank thermal sensors are located

on the outside of the hot tank. There are

two thermal sensors. The sensor located

higher on the hot tank controls the daily

operation of the heating element. The

lower thermal sensor is an overheat

safety switch and cuts power to the hot

tank should a malfunction occur and

the tank starts to overheat.

10.1 Unplug cooler from power source for

this operation.

10.2 Remove left side cover per sec. 3.3

10.4 There are (2) thermal sensors attached with

screws to the hot tank. The upper sensor automatically turns the heating element on and off

to maintain the water at 180 ºF. The lower

sensor is the over temperature sensor. This

sensor activates if the temperature on the tank

goes over 212 ºF. If this sensor is activated due

to a overheat condition, it will cut the power to

the heating element. If this happens, it can be

reset by pressing the button at the center of

the sensor.

To check if either thermal sensor is good, use a

continuity tester (ohm meter) to check for

continuity across the thermal sensor. Make

sure the thermal sensor is at ambient temperature

for this test. If there is no continuity, replace

the sensor.

10.5 To change either sensor, disconnect (2)

electrical terminals from sensor.

10.6 Remove (2) screws holding sensor to tank.

10.7 Install new thermal sensor, replace screws,

reconnect electrical terminals to sensor.

10.8 Replace left side cover.

Copyright 2008 Vertex Water Products

Page 21

PWC – 400

PureWaterCooler

11. Cold Tank Temperature Adjustment

11.0 The cold water temperature adjustment

is located on the back of the cooler in

the middle of the panel. An expansion

tube senses temperature in the cold

tank and open and closes the thermostat.

11.1 The cold adjustment is a shaft with a

screw driver slot on the end.

11.2 To make the water colder, using a

screw driver, rotate the shaft clockwise.

For warmer water rotate the shaft

counter clockwise. There are stops on

the adjustment shaft. DO NOT force

the control shaft over the stop. If this

happens, it will be necessary to replace

the temperature controller

270º Travel

STOP

WARMEST

COLDEST

STOP

Normal Travel is 270º

Copyright 2008 Vertex Water Products

Page 22

PWC – 400

PureWaterCooler

12. Sanitization Procedure

The sanitization procedure is performed to reduce/eliminate any bacteriological

growth in the cooler tanks and dispensing plumbing. Bacteriological growth

can be the cause of some taste and odor in the water.

The procedure is as follows:

1. Mix 1 teaspoon of common household bleach (5.25%) in 2 gallons of

clean water.

2. Unplug the cooler from the power source.

3. Drain all water from the cooler tanks.

4. Pour the sanitizing solution into the main (cold temperature) tank until full.

5. Open all spigots to allow sanitizing solution to fill the dispensing faucets.

Close the spigots.

6. Let the sanitizing solution stand in the cooler for 10 minutes.

CAUTION: Leaving the sanitizing solution in the cooler for more

than 10 minutes can cause taste problems in the water.

7. Completely drain the sanitizing solution from all the tanks per section 5

8. Fill the main (cold temp.) tank with clear tap water to rinse out the

sanitizing solution.

9. Completely empty the rinse water from the tanks.

10. The cooler is now sanitized and ready for filling with filtered water.

Copyright 2008 Vertex Water Products

Page 23

PWC – 400

PureWaterCooler

13. Trouble Shooting

Water not cold from cold tank

(Water dispenses from spigot but is not cold)

Possible causes Solution .

1. Cooler not plugged in Make sure power cord is plugged

into wall socket

2. Power switch not on Make sure cold power switch on

the back panel is on.

3. Adjust temperature control The thermostat temperature control

adjustment is located on the back

of the cooler. (see section 11)

4. All cold water has been drained Cooler needs time to recover.

wait 10-15 minutes until water cools

Copyright 2008 Vertex Water Products

Page 24

PWC – 400

PureWaterCooler

13. Trouble Shooting

Cont.

No Hot Water from Hot Tank

Possible Causes Solution

1. Cooler not plugged in Make sure power cord is plugged

into wall socket

2. Power switch not on Make sure Hot power switch on back

panel is on and hot power light on

front is illuminated

3. Electrical terminal Check to see that both wires are

disconnected connected to the heating element

terminals. These are located at the

bottom of the hot tank

4. Heating element failure Check for continuity across hot tank

due to scaling heater terminals. To do this, unplug

unit from wall power. Disconnect one

of the connector at the heating element

terminals (at bottom of tank). Using

an ohm meter, check for continuity

across the 2 terminals. If there is no

continuity (open), the tank must be

replaced.

Copyright 2008 Vertex Water Products

Page 25

PWC – 400

PureWaterCooler

13. Trouble Shooting Cont.

No Hot Water from Hot Tank cont.

Possible causes Solution .

5. Thermal sensor failure The thermal sensors are attached to the

hot tank. The upper sensor is a 96 ºC

sensor and functions as an over heat

safety. The lower sensor is a 82 ºC

sensor and controls the heating element

function. The lower sensor would be the

problem if there was no hot water. To

see if the sensor is functioning properly,

first unplug the cooler from the wall.

remove the terminal from the sensor.

Using an ohm meter, check for continuity

If there is no continuity (open), replace

sensor

as per section 10.

6. Hot tank turned on without The hot power should never be turned on

water in tank without water in the tank. If this happens,

the upper thermal sensor on the hot tank

will switch, cutting power to the hot tank.

This is a safety device to prevent the heating

element from burning itself out due to dry

heating. Once the hot tank cools off the

switch can be reset to operating condition.

See section 9.

Copyright 2008 Vertex Water Products

Page 26

PWC – 400

PureWaterCooler

13. Trouble Shooting Cont.

No Hot Water from Hot Tank cont.

An indicator of a hot tank problem can also be the lights on the front

control panel. Below is a table of trouble shooting help.

If the Hot Tank is not heating and the front panel lights are:

Front Panel Lights Cause Check

Hot Power – on Heating element disconnected No Continuity across

Heating - on or burned out heating element

No lights at all Lower thermal sensor Reset Press reset button /

Including cold power button disengaged or sensor No Continuity across

burned out thermal sensor –replace sensor

Hot Power – on Upper thermal sensor No Continuity across

Heating -- off disconnected or burned out lower thermal sensor

Copyright 2008 Vertex Water Products

Page 27

PWC – 400

PureWaterCooler

14. Specifications

PWC-400

Voltage/Frequency 120 VAC/ 60 Hz

Weight (dry) 48 lbs.

Total Water Capacity 1.5 gallons

Hot tank .5 gallons

Cold tank 1.0 gallons

Power Consumption Total 600 Watts

Hot Tank 500 Watts

Cold Tank 100 Watts

Temperature

Hot 180 ºF average

Cold (adjustable) 38 ºF average

Refrigerant R134a 36 mg.

Copyright 2008 Vertex Water Products

Page 28

4/09

Page 29

PWC-400 Part List

Item No. Description Part Number Item No. Description Part Number

P1 Top Cover cl4 9500 E1 Control Board, Rev C cl4 9529

P2 Front Panel cl4 9501 E1.1 Cntrl Brd w/beep snd, RevD,E cl4 9587

P3 Control Pnl/Fct Cover, Rev F cl4 9581 E1.2 Cntrl Brd w/beep snd, Rev F cl4 9580

P3 Cntrl Pnl/Fct Cover, Rev C,D cl4 9502 E2 Compressor cl1 9218

P4 Base cl4 9503 E3 Cold Temperature Switch cl4 9219

P5 Drip Tray Set cl4 9504 E4 Transformer cl4 9220

P6 Left Side Panel cl4 9505 E5 Power Cord cl4 9221

P7 Right Side Panel cl4 9506 E6 Control Box, Level Sensor cl4 9222

P8 Handle cl1 9235/EG E7 Fan cl4 9223

P9 Water Spout and T Manifold cl4 9508 E8 Condensor cl4 9224

P10 Cover, Circuit Board cl4 9509 E9 On/Off Switch cl1 9238

P10.1 Cover, Circt Brd, REV D,E,F cl4 9507 E10 Fuse Holder cl1 9252

P11 Strain Relief cl4 9510 E11 Fuse cl1 9262

P12 1/4" tubing cl4 9511 E12 Sol.Valve, Dspnsng,cold,24vd

E13 Wiring Harness cl4 9544

E14 Wire Harness cl4 9542

E15 Wire Harness cl4 9543

P16 Dispense Nozzle Cover cl4 9547 E16 Sol.Valve, Dspnsng,hot,24vdc cl4 9590

OBSOLETE REV E Control panel Assy cl4 9588

M1 Frame, Upper cl4 9512 REV F Control panel Assy cl4 9591

M2 Frame, Front cl4 9513

M3 Rear Panel cl4 9514 H1 Hot Tank cl4 9545

M4 Screw cl4 9515 H2 92 C Temperature sensor cl1 9277

M5 Screw cl4 9516 H3 82 C Temperature sensor cl2 9030

M6 Screen, Stainless 304 cl4 9528 H4 Screw cl4 9548

M7 Screw cl4 9517 H5 Screw cl4 9549

M8 Screw cl4 9518 H6 Stopper cl4 9555

M9 Bracket cl4 9519 H7 Insulating Foam cl4 9551

M10 Probe, Leak detector cl4 9520 H8 Silicon Tube cl4 9552

M11 H9 Silicon Tube, 175 x 4 elbow cl4 9553

M12 Screw cl4 9521 H10 Silicon Tube cl4 9554

M13 Dryer cl4 9522

M14 Screw cl4 9523

M15 Screw cl4 9524

M16 Screw cl4 9525

M17 Bracket cl4 9526

M18 Screw cl4 9527

M19

c cl4 9540

Vertex Water Products 2009

1 Rev F, 7/11

Page 30

PWC-400 Part List

Item No. Description Part Number Item No. Description Part Number

C1 Lid, Outer, Cold Tank cl4 9556 REV D, 7/09 1/4/2013

C2 Lid, Inner, Cold Tank cl4 9557 Updated 4/6/10

C3 Cold Tank Assembly cl4 9558 Updated 10/1/10

C4 Screw cl4 9559 Updated 12/31/10

C5 Silicon Tube cl4 9560 REV F, 7/11

C6 Level Sensor cl4 9579

C7 Capillary Tube cl4 9561

C8 Insulation cl4 9562

C9 Nut cl4 9578

C10 Fitting cl4 9563

C11 Insulation cl4 9564

C12 Insulation cl4 9565

C13 Insulation cl4 9566

C14 Bracket, Cold Tank cl4 9567

C15 Plug cl4 9568

C16 Screw cl4 9569

O1 Sticker, Cntrl Pnl, Rev C,D,E cl4 9573

O1 Sticker, Cntrl Pnl, Rev F cl4 9582

O2

O3 Double backed Tape cl4 9575

O4 Nut cl4 9576

O5 Solenoid Valve, 115 VAC cl2 9086

O6 Screw cl4 9570

O7 Filter Bracket cl4 9541

Fittng,Bulkhead

(nt usd aftr 8.09)

cl4 9574

Sediment Filter Cart.-rplcmnt ifa 4035

Carbon Filter Cart.-rplcment ifa 4034

Membrane, 50 gpd-rplcmnt ma 4203

UV bulb, 6 watt - rplcment uv 4061

O52 Straight, 1/4mpt x 1/4 tube md 2624

O53 Elbow, 1/4 mpt x 1/4 tube md 2625

O54 Bulkhead fitting, 1/4" dm 2733

O55 Stem Elbow, 1/4stem x 1/4t md 2626

O56 Filter Screen, 1/4"

Vertex Water Products 2009

2 Rev F, 7/11

Loading...

Loading...