Page 1

1.Introduction

1.1.Highlight Features

■ Space saving, only 55mm panel depth required

■ Higher sampling rate (100mS) results in better control performance

■ Protect the load from thermal shock (unwanted rapid temperature rise) using the excellent ramp

rate feature

■ Protect the heating element from excess current during power-up using the soft start function

■ Easy to read 0.4” / 10mm LED display showing SV/PV at a glance

■ NEMA-4 IP65 front panel protection when used with panel gasket or IP63 without

1.2.Specification

Input signal : User programmable. refer to table 1.

■ Thermocouple (T/C) : industry standard thermocouple types, J, K, T, E, B, R, S, N, C (ITS-90).

■ Pt100 : Excitation 180uA. 2 or 3 wire connection (ITS-90 α=0.00385).

■ Voltage : -60mVdc to 60mVdc or -10Vdc to 10Vdc.

■ Current : 0mA to 24mA

Measuring range : User programmable. Maximum range refer to table 1.

Measuring accuracy : refer to Table 1. the accuracy is tested under the operating condition of

24°C±3°C.

*Factory Setting

Note 1 : Accuracy is not guaranteed between 0 and 400°C (0 and 752°F) for type B.

Table 1 Input Signal

Sampling rate : 100mS

Control Output :

■ Relay output : 5A/240Vac (Resistive load)

■ Pulsed Voltage output : DC 0/24V (Resistive load 1.2K ohms Min.)

■ Current output : 4~20mA (Resistive load 600 ohms Max.)

■ Voltage output : 0~10V ( Resistive load 600 ohms Min.)

Control Mode : PID with auto-tune, P with manual reset or On/Off with hysteresis available.

■ Proportional Band : 0.0~300.0% (0.0 % = On/Off mode)

■ Integral Time : 0.0~3000 sec.

■ Derivative Time : 0.0~1000 sec.

■ Cycle Time : 0~60 sec.

■ Hysteresis : 0~9999

Ramp Function :

■ Ramp rate : 0~9999 unit/minute or unit/second (0 = disable the ramp function)

Accuracy

±1°C

±1°C

±1°C

±1°C

±2°C

(Note1)

±2°C

±2°C

±2°C

±2°C

±0.2°C

±0.2°C

±4μA

±0.01mV

±2mV

Maximum Range

-50 to 1000°C (-58 to 1832°F)

-50 to 1370°C (-58 to 2498°F)

-270 to 400°C (-454 to 752°F)

-50 to 750°C (-58 to 1382°F)

0 to 1800°C (32 to 3272°F)

-50 to 1750°C (-58 to 3182°F)

-50 to 1750°C (-58 to 3182°F)

-50 to 1300°C (-58 to 2372°F)

-50 to 1800°C (-58 to 3272°F)

-200 to 850°C (-328 to 1562°F)

-200 to 600°C (-328 to 1112°F)

-24mA~24mA

-60mV~60mV

-10V~10V

Input signal

Thermocouple J

Thermocouple K*

Thermocouple T

Thermocouple E

Thermocouple B

Thermocouple R

Thermocouple S

Thermocouple N

Thermocouple C

Pt100 (DIN)

Pt100 (JIS)

mA

mV

Voltage

F4 Process Controller

Installation and Operation Guide

Alarm Output : 5A/240Vac (Resistive load)

Alarm Function : Energized / De-energized with 0~30000 Sec. / Min. delay

■ No alarm

■ Process high alarm

■ Process low alarm

■ Deviation high alarm

■ Deviation low alarm

■ Inside deviation band alarm

■ Outside deviation band alarm

Alarm Mode :

■ Normal mode

■ Standby mode

■ Latch mode

■ Standby and Latch mode

Communication :

■ Interface : Half duplex based on EIA RS-485

■ Protocol : ModBus RTU mode

■ Data format :

Start bit : 1

Data bit : 8

Parity : None

Stop bit : 2

■ Baud Rate : 2400, 4800, 9600, 19200 bps

Power supply : 100~240 Vac, 50/60 Hz / 24Vdc

Power consumption : 4VA Max.

Common mode rejection ratio : >80dB.

Operating temperature : 0 to 50°C

Humidity : 0 to 85% RH (Non-Condensing)

Electromagnetic compatibility (EMC) : En 50081-2, En 50082-2

Dimension : 48x48x55 mm (WxHxD).

Housing material : ABS plastic. UL 94V0

Weight : 100g

1.3.Ordering information

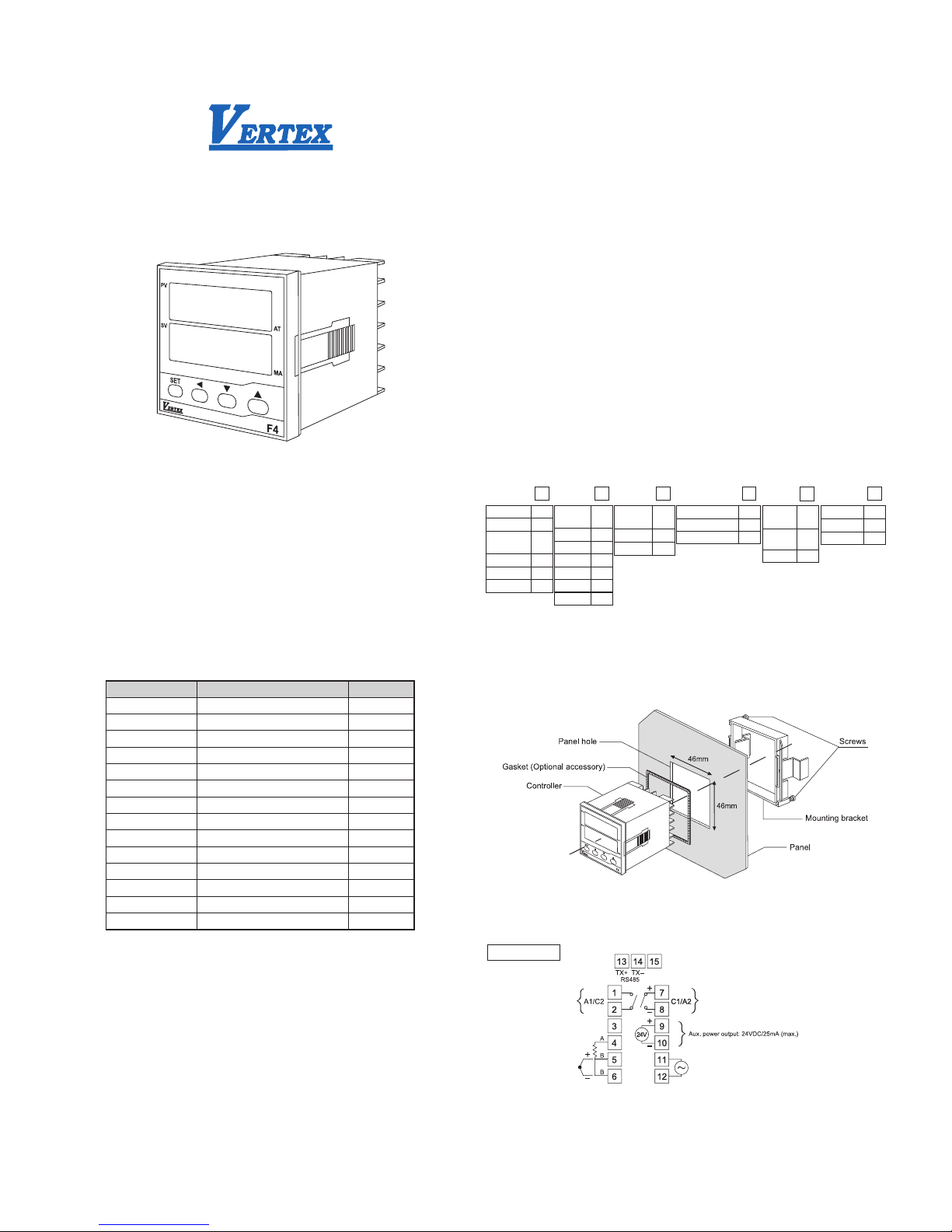

2.Installation

2.1.Panel mounting

1.Prepare the panel cutout with proper dimensions (45.5 X 45.5 mm)

2.Insert the controller into the panel cutout from the front of the panel.

3.Secure the controller by pushing the mounting bracket into the controller from the rear side.

4.Tighten the screws of the mounting bracket slightly if the controller is not firmly secured

Figure 1. Panel mounting

2.2.Connections and wiring

AC power supply

-0.0

+0.5

-0.0

+0.5

Input

T/C

PT100

(RTD)

0-60mV DC

0-10V DC

0-24mA DC

Code

T

D

L

V

M

Output 1

(Alarm2)

Relay

SSR

4~20mA

0-10V

Other

Alarm 2

Code

R

P

M

V

O

A

Alarm 1

(Output2)

Alarm 1

Relay

Code

A

R

Communication

None

RS-485

Code

N

C

Power

Supply

100~240

Vac

24 Vdc

Code

A

D

Protection

IP 63

IP 65

Code

3

6

F4

Control output 1 (can be converted to 2nd Alarm)

Relay output : 5A/240Vac (Resistive load)

Pulsed Voltage output : DC 0/24V (Resistive load 1.2K ohms Min.)

Current output : 4~20mA (Resistive load 600 ohms Max.)

Voltage output : 0~10V ( Resistive load 600 ohms Min.)

Relay output :

5A/240Vac (Resistive load)

Power supply : 100~240 Vac, 50/60 Hz

Alarm 1 output

(can be converted to 2nd output)

Page 2

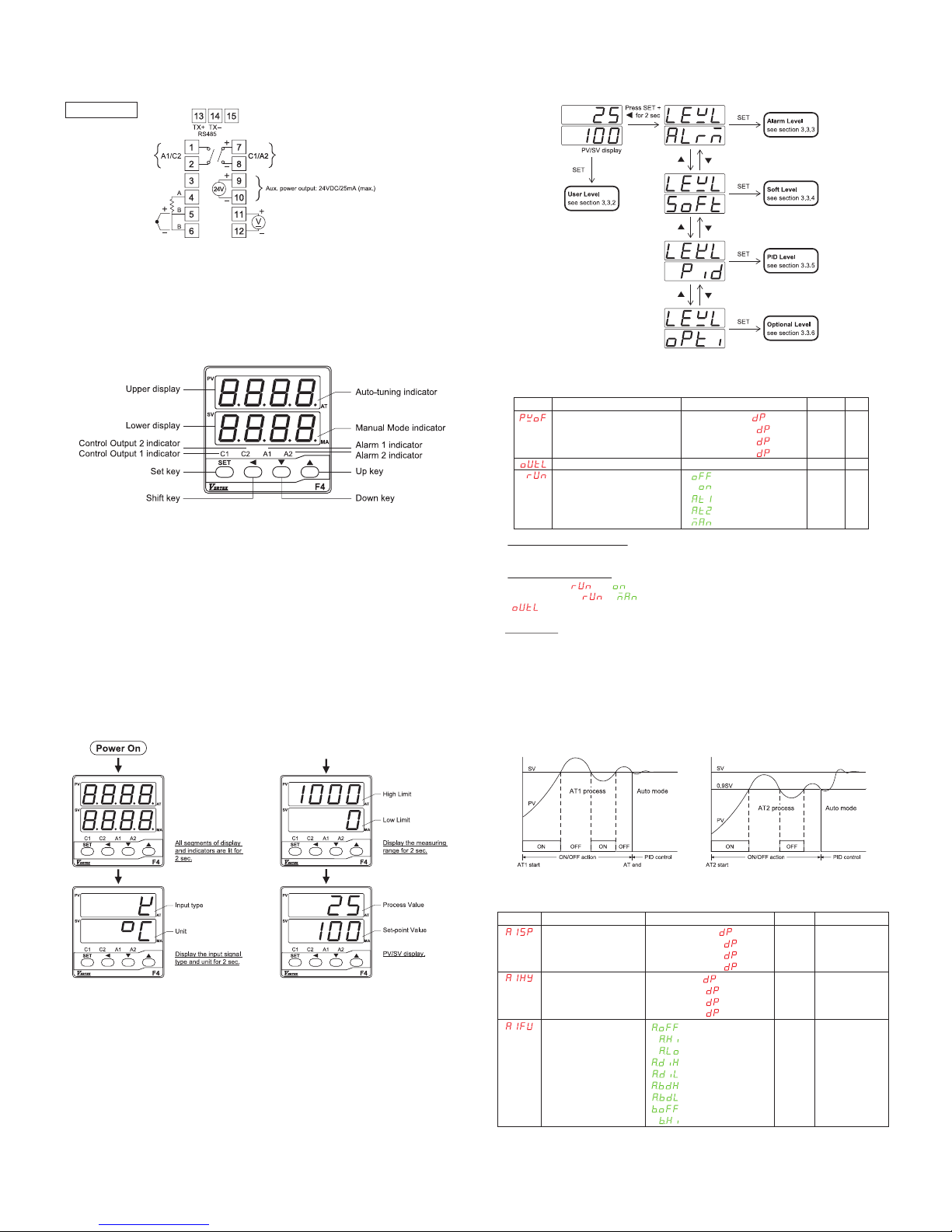

Figure 5. Menu flowchart

3.3.2.User Level

Process value offset correction

The value to be added to the PV to correct the sensor offset error.

Control output percentage

In Auto mode ( = ), it shows the percentage of power applied to the control output.

In Manual mode ( = ), the upper display will show the process value (PV) and

“ ” alternately and the “MA” indicator is lit. The value of percentage can be changed manually.

Control mode

Select the control mode to be

Off – Standby mode. Both control output and alarm are turned off.

On – Auto mode (closed loop control). In this mode, the control output percentage is determined

by PID algorithm or ON/OFF action.

AT1 – Auto-tuning mode 1. In this mode, the controller will tune the PID parameters automatically

at SV. The process will oscillate around the SV during AT1 process (Figure 6). Use AT2

mode if overshooting beyond the normal process is likely to cause damage.

AT2 – Auto-tuning mode 2. In this mode, the controller will tune the PID parameters automatically

at (SV-10%). The process will oscillate around (SV-10%) during AT2 process (Figure 6).

Man – Manual mode (open loop control). In this mode, the control output can be set manually.

Figure 6. Auto-tuning Process

3.3.3.Alarm Level

Display Description

Alarm 1 set-point

Alarm 1 hysteresis

Alarm 1 function

Range

-1999~9999 ( =0000)

-199.9~999.9 ( =000.0)

-19.99~99.99 ( =00.00)

-1.999~9.999 ( =0.000)

0~9999 ( =0000)

0~999.9 ( =000.0)

0~99.99 ( =00.00)

0~9.999 ( =0.000)

Default

10

0

Unit

unit

unit

DC power supply

Figure 2. Terminal connections

Wiring precaution:

Inverter, mechanical contact relays, arc welders, and ignition transformers are all common sources

of electrical noise in an industrial environment, so always keep signal wires away from those

noise-generating devices.

3.Operation

3.1.Front panel description

Figure 3. Front panel description

■ PV ( Upper display ) : Display the process Value, parameter index code or error code

■ SV ( Lower display ) : Display the set point value or the set value of parameter

■ C1 : Control output 1 indicator

■ C2 : Control output 2 indicator

■ A1 : Alarm 1 indicator

■ A2 : Alarm 2 indicator

■ AT : Auto-tuning indicator (The right-most decimal point of upper display)

■ MA : Manual mode indicator (The right-most decimal point of lower display)

Keypad description

■ SET key : Use to menus navigation and set value registration

■ Shift key : Shift the digit of numeral

■ Down key : Decreases the parameter value or change the setting

■ Up key : Increases the parameter value or change the setting

■ SET + Shift key for 2 sec. : Enter set up mode

■ SET + up key : Return to PV/SV display

■ Shift + Down key on powering up : set all parameters to default setting

3.2.Powering up procedure

Figure 4. Powering up procedure

3.3.Configuration

3.3.1.Menu Flowchart

After powering up procedure, the controller stays in PV/SV display. The upper display shows the

process value (measuring value) and the lower display shows the set point value (target value). All

the configurable parameters are located in different levels and can be accessed by keypad

operation as shown in figure 5.

Display Description

Process value offset correction

Control output percentage

Control mode

Range

-1000~1000 ( =0000)

-100.0~100.0 ( =000.0)

-10.00~10.00 ( =00.00)

-1.000~1.000 ( =0.000)

0.0~100.0%

: Off

: On

: AT1

: AT2

: Man

Default

0

N/A

On

Unit

Unit

%

N/A

Control output 1 (can be converted to 2nd Alarm)

Relay output : 5A/240Vac (Resistive load)

Pulsed Voltage output : DC 0/24V (Resistive load 1.2K ohms Min.)

Current output : 4~20mA (Resistive load 600 ohms Max.)

Voltage output : 0~10V ( Resistive load 600 ohms Min.)

Relay output :

5A/240Vac (Resistive load)

Alarm 1 output

(can be converted to 2nd output)

DC24V

: A.oFF

: A.Hi

: A.Lo

: A.diH

: A.diL

: A.bdH

: A.bdL

: b.oFF

: b.Hi

A.diH N/A

Page 3

*All the alarm 2 parameters are only shown when the control output is set as 2nd alarm action.

Alarm 1 set-point, Alarm 2 set-point

The set point of alarm even

Alarm 1 hysteresis, Alarm 2 hysteresis

The hysteresis of alarm action

Alarm 1 function, Alarm 2 function

Select the alarm function

A.oFF – Alarm action off.

A.Hi – Process high alarm with Form A contact

A.Lo – Process low alarm with Form A contact

A.diH – Deviation high alarm with Form A contact

A.diL – Deviation low alarm with Form A contact

A.bdH – Deviation band high alarm with Form A contact

A.bdL – Deviation band low alarm with Form A contact

b.oFF – Alarm action off

b.Hi – Process high alarm with Form B contact

b.Lo – Process low alarm with Form B contact

b.diH – Deviation high alarm with Form B contact

b.diL – Deviation low alarm with Form B contact

b.bdH – Deviation band high alarm with Form B contact

b.bdL – Deviation band low alarm with Form B contact

Figure 7. Alarm function

Alarm 1 mode, Alarm 2 mode

Select the alarm mode as

None – Disable the alarm mode

Stdy – Standby mode. When selected, prevents an

alarm on power up. The alarm is active after

alarm condition has been cleared and then

alarm occurs again.

LAtH – Latch mode. When selected, the alarm output

and indicator latch as the alarm occurs. The

alarm output and indicator will not change its

state even if the alarm condition has been

cleared unless the power is off.

StLA – Both standby and Latch mode are applied.

Figutr 8 shows the result of different alarm modes

applied on Deviation Band High Alarm with alarm

hysteresis set to 0.

Alarm 1 delay time, Alarm 2 delay time

Alarm delay time is set to postpone the alarm action

by the setting time. Figure 8. Alarm Mode

3.3.4.Soft Level

: b.Lo

: b.diH

: b.diL

: b.bdH

: b.bdL

: None

: Stdy

: LAtH

: StLA

oFF, 00.01~99.59

Same as Alarm1 set-point

Same as Alarm1 set hysteresis

Same as Alarm1 function

Same as Alarm1 mode

Same as Alarm1 delay time

Alarm 1 mode

Alarm 1 delay time

Alarm 2 set-point*

Alarm 2 set hysteresis*

Alarm 2 function

Alarm 2 mode*

Alarm 2 delay time*

None

oFF

10

0

A.diL

None

oFF

N/A

HH.MM/MM.SS

Unit

Unit

N/A

N/A

HH.MM/MM.SS

Description

Ramp rate

Soft start time

Range

oFF, 1~9999 (0.1~999.9)

oFF, 00.01~99.59

Default

oFF

oFF

Unit

Unit / sec.(min)

Minutes : Seconds

Display

Cut-off function

: None

: Low

: High

: High/Low

None N/A

Description

Input signal type

Range

: J type

: K type

: T type

: E type

: B type

: R type

Default

K type

Unit

N/A

Display

Description

Proportional band

Integral time

Derivative time

Manual reset

Anti-reset windup

Hysteresis for ON/Off control

Cycle time

Cooling proportional band

Dead band

Cooling cycle time

Range

0.0~300.0

oFF,1~3000

oFF,1~1000

0.0~51.0

0.0~100.0

0~1000 (0.0~100.0)

0~60

0.0~300.0

-1000~1000(-100.0~100.0)

1~60

Default

5.0

240

60

0.0

50.0

0

15

5

0

15

Unit

%

Sec.

Sec.

%

%

uint

Sec.

%

°C, °F or Engineering Unit

Sec.

Display

Ramp rate

The controller can act as either a fixed set point

controller or as a single ramp controller. If the ramp

rate is set to a value other than “oFF”, the process

will increase or decrease at the setting rate during

initial power up or with set point change. The ramp

rate is in degree per min. or sec. depends on the

time scale set in PTME.

Figure 9. Ramp Function

Soft start time

Soft start time can be programmed in situation where

100% output is not allowed at power up. The time

duration for the output to rise from 0% to 100% is

defined as soft start time.

Figure 10. Soft Start

3.3.5.PID Level

Proportional band

Set the proportional band in percentage of SPAN (High limit - Low limit). It can be set automatically

by auto-tuning process.

Integral time

Set the integral time constant in repetitions per second. It can be set automatically by auto-tuning

process.

Derivative time

Set the derivative time constant in second. It can be set automatically by auto-tuning process.

Manual reset

For PID control, this value is set automatically after auto-tuning process. For P control, it is used to

compensate the deviation between process value and set point.

Anti-reset windup

The anti-reset windup (ARW) inhibits the integral action

until the process value is within the band thus reducing

overshoot on start-up. The ARW can be set

automatically by auto-tuning process and then can be

changed manually if required

Hysteresis for ON/OFF control

In ON/OFF control (Proportional band set to 0.0%), the

control output turns On/Off with respect to the set point.

Therefore, the control output would change frequently in

response to a slight change in process value. This might

shorten the service life of the output device. To prevent Figure 11. ON/OFF Control Action

this, a hysteresis is provided in the ON/OFF control.

Cycle time

Set the control output cycle time. It is recommended to set to 15 sec. for Relay output and set to

1 sec. for pulsed voltage output.

Cooling proportional band

Set the cooling proportional band in percentage of SPAN (High limit – Low limit). It can be set

automatically by auto-tuning process. Set to 0.0 for ON/OFF control mode.

Dead band

This setting defines the area in which both heating and cooling outputs are inactive, known as dead

band, or the area in which they are both active, known as overlap. A positive value results in a dead

band, while a negative value results in an overlap.

Cooling cycle time

Set the cooling output cycle time. It is recommended to set to 15 sec. for Relay output.

3.3.6.Option Level

Low scale for linear input

High scale for linear input

: S type

: N type

: C type

: PT100 (DIN)

: PT100 (JIS)

: mA

: mV

: V

-1999~9999

-1999~9999

0

1000

Unit

Unit

Page 4

Error protection

0000

0001

0010

0011

A1 / C2

OFF

OFF

ON

ON

C1 / A2

OFF

ON

OFF

ON

Unit

Decimal point

Control action

Low limit

High limit

Digit filter

Time scale

Error protection

Security lock

Setpoint offset

Communication ID

Baud rate

: °C

: °F

: Engineer

0000

000.0

00.00 (for linear input signal only)

0.000 (for linear input signal only)

: Dir

: Rev

Refer to table 1.

Refer to table 1.

0.0~99.9

: HH.MM

: MM.SS

0000

0001

0010

0011

0000

0001

0010

0011

0100

0101

0110

-1999~9999 (

=0000)

-199.9~999.9 (

=000.0)

-19.99~99.99 (

=00.00)

-1.999~9.999 (

=0.000)

1~247

: 2.4K

: 4.8K

: 9.6K

:19.2K

°C

0000

Rev

0

1000

0.0

HH.MM

0000

0110

0

247

19.2K

N/A

N/A

N/A

Unit

Unit

Sec.

N/A

N/A

N/A

Unit

N/A

bps

Thermocouple

RTD

0~24 mA

-60~60 mV

-10~10 V

G1

Linked

Open

X

X

X

GA1

Linked

Linked

Linked

Linked

Open

GB1

Open

Open

Open

Open

Linked

GY

Open

Open

Linked

Open

Open

Input signal type

Select the input signal type. The available input signal types are :

Thermocouple : J K T E B R S N C

RTD : PT100 (JIS standard) or PT100 (DIN standard)

Linear : 0~24mA, -60~60 mV or 0~10 V

Please note that the internal gaps on the main board of F4 controller should be configured in

accordance with input signal.

X : don’t care

Figure 12. Gaps Allocation

Low scale for linear input

Select the low scale corresponding to low linear input signal. The default low linear input signal

(INL) for mA, mV and V is 4.00mA, 0.00mV and 0.00V separately. This parameter is only showed

when the input signal type is set to linear. (See also the cut-off function for further detail)

High scale for linear input

Select the high scale corresponding to high linear input

signal. The default low linear input signal (INH) for mA,

mV and V is 20.00mA, 50.00mV and 10.00V separately.

This parameter is only showed when the input signal

type is set to linear. (See also the cut-off function for

further detail)

Cut-off function

The Cut-off function is used to limit the process value of

linear input signal within the boundary whenever the

input signal is out of the high/low limit range (set by Hilt

and LoLt). The cut-off function can be set to “Low”,

“High” or “High/Low”, set to “None” disables the cut-off

function. The cut-off function has no effect for input

signal other than linear input. Figure 13. Scale and Cut-off Function

Only the security lock is open to change, all other parameters are locked

Only the security lock and set point value is changeable. all the other

parameters are locked

The user level is open to change.

The user and alarm levels are open to change.

The user, alarm, and soft levels are open to change.

The user, alarm soft and PID levels are open to change.

All parameters are open to change.

Security lock

0000

0001

0010

0011

0100

0101

0110

Range: 0 ~ 3

Unit: N/A

PV scale calculation:

Where

IN: the linear input signal.

INH: the high calibration of linear input signal. It is set in calibration parameters (mAL, mVL and VL).

INL: the low calibration of linear input signal. It is set in calibration parameters (mAH, mVH and VH).

Example:

For a 4~20mA input signal, the INL is set by mAL=4.00mA and the INH is set by mAH=20.00mA.

Set SCAL=0.0 SCAH=100.0 (Of course, you may select other scale value and decimal point to

alter the resolution) and LoLt=0.0 HiLt=100.0.

For a 12mA input, the PV will be 50.0.

For a 22mA input, the PV will be 112.5 with cut-off function set to “None” or 100.0 with cut-off

function set to “High” or “High/Low”.

For a 0mA input, the PV will be -25.0 with cut-off function set to “None” or 0.0 with cut-off function

set to “Low” or “High/Low”.

Unit

Select the process value indication in °C or °F when the input signal type is set to thermocouple or

PT100. Select engineer unit for linear input (mA, mV or V).

Decimal point

Select the decimal point position. The setting 00.00 and 0.000 is available for linear input only.

Control action

Dir – Direct action used for cooling process

Rev – Reverse action used for heating process

Low limit

Set the low limit of measuring range. When the PV goes below the low limit, the PV display flashing

indicates a low limit error. The control output and alarm will be set according to the Error Protection.

High limit

Set the high limit of measuring range. When the PV goes beyond the high limit, the PV display

flashing indicates a high limit error. The control output and alarm will be set according to the Error

Protection.

Digit filter

Set the time constant for digit filter (the first order filter). It is useful when the process value is too

unstable to be read.

Figure 14. Digit Filter

Time scale

Set the time scale used for alarm delay time and ramp rate.

HH.MM – The alarm delay time is in hour and minute / The ramp rate is in per minute.

MM.SS – The alarm delay time is in minute and second / The ramp rate is in per second.

Error protection

Set the control output and alarm status whenever an error occurred. (refer to 4 Error Message)

Security lock

The security lock is useful to lock out the parameters from unauthorized changed

Set point offset

Shift the set point value with an offset. The actual control target is shifted with this offset from set

point value but not added to SV display.

Communication ID

Set the ID number in the communication network

Baud rate

Set the communication baud rate.

( )

SCALSCALSCAH

INLINH

INLIN

PV +−

−

−

=

Page 5

Display

Flashing

Error Description

Sensor break or open

Input signal has out of A/D

converter range

The content of EEPROM is

corrupt

Fail to complete the auto-tuning

process within 2 hours

The PV is out of range

Correction

1. Check the sensor is connected and input signal

type is selected correctly.

2. Replace the sensor

1. Check the sensor is connected and input signal

type is selected correctly.

2. Replace the sensor.

3. Return to the supplier for repairing

1. Return to default setting by pressing shift and

down keys simultaneously while power on. And

reconfigure the parameters

2. Return to the supplier for repairing

1. Retry the auto-tuning again.

2. Improve the control process to have fast response

or use manual tuning instead of auto-tuning

1. Check the sensor is connected and input signal

type is selected correctly

2. Check the polarity of sensor is connected correctly

3. Check the high/low limit is set properly.

4. Replace the sensor

4.Error Message

Loading...

Loading...