Page 1

C-RING TOOL VA0278

Rev H 4-30-2010

OPERATING MANUAL

1798 Sherwin Avenue

Des Plaines, IL 60018 U.S.A.

EMAIL: vertex@leggett.com

PHONE: 847-768-6139 FAX: 847-768-7192

Page 2

Operational Instructions for Vertex C-Ring Tool VA0278

Rev H 4-30-2010

Vertex Fasteners is committed to providing our customers with world-class customer

service and support. Our dedicated regional sales/service technicians are Vertex employees.

They know the product, the business, and their customers, and are there to serve you. Vertex

also has a well-trained staff of customer service, production and engineering professionals that

are ready and able to assist you.

This and other manuals are available on our website: WWW.VERTEXFASTENERS.COM

MAINTENANCE

Most problems with tools are a result of:

1. Normal wear and tear to components due to high usage.

2. Lack of proper lubrication.

3. Dirt or water that may enter the tool via air lines.

4. Defective rings.

LUBRICATION

1. The C-Ring tool VA0278 is designed for long, trouble free use with minimal in-line

lubrication. (If an in-line lubricator is used, it should be set at a minimal rate of flow.)

2. When lubricating tool, Pneumatic Fastening Tool Oil, Vertex part number VC0340 is

recommended. When oiling, a couple of drops of oil should be placed through the

airline fitting. Excess oil in tool will attract dirt, lint, and the tape used to collate rings,

preventing smooth operation. Cycle tool to expel excess oil.

3. When servicing or repairing tool a high grade lithium grease, Vertex part number

VH0214 is recommended for all o-rings and moving parts.

AIR FILTER AND REGULATOR

1. The airline should always contain a filter and regulator unit to provide tool with a

constant flow of clean, dry air. Moisture and contaminates entering tool will decrease

the serviceable life of tool.

2. The regulator should be set between 70 and 90 psi (4.8 to 6.2 bar). Never operate

tool over 100 psi (6.9 bar).

TIPS ON EXTENDING TOOL LIFE

1. Always use Vertex brand fasteners and always use Vertex genuine parts when

replacing worn or broken parts. Generic fasteners, and parts may shorten tool life

and will void your tool warranty.

2. Use tool at minimum amount of air pressure needed to do the work at hand. Excess air

pressure will reduce the life of tool.

3. Keep tool clean and dry and always use clean dry air.

4. Avoid dropping tool, a primary reason for parts replacement.

Page 3

Rev H 4-30-2010

HELPFUL HINTS FOR FIELD SERVICE OF TOOL JAMS

SAFETY FIRST – Always disconnect tool from air supply before attempting to clear a jam or

servicing tool.

The most common reason for jamming problems is worn parts. Common parts that see a lot of

wear are the jaws, pusher assembly and the pusher spring.

Note: refer to correct tool schematic for location of parts and correct part numbers.

TROUBLESHOOTING

Inside diameter of ring too large after clinching

• Latch worn – replace latch

• Latch spring broken – replace latch spring

• Low power

1. Air pressure too low – check air pressure setting

2. Air leaks in supply hose – replace hose

3. Air leak in tool – see repair section

• Worn jaws (helix, cam surface, bolt holes, jaw bushings) – replace jaws

• Worn rollers – replace rollers

• Defective rings –

1. Wire too hard

2. Rough surface

3. Cut-off burrs

4. Wrong rings. Return samples of rings to your Vertex Fasteners representative

for testing.

Inside diameter of ring too small after clinching

• Wrong jaws – replace jaws

• Jaw stops worn or polished off – replace jaws

Ring points not entering opposite jaw (Figure A)

• Tip of jaw broken off – replace jaws

• Mismatched jaws

1. Jaws should be replaced only in pairs

• Defective rings

1. Points not equal

2. Ring not symmetrical

3. Cut-off burrs

Return samples of rings to your Vertex Fasteners

representative for testing.

• Ring point not entering jaw A – Correct by chamfering tip of the

helix that the ring is entering as shown in Figure B.

• Rings only curling in one jaw – replace jaws

Page 4

Rev H 4-30-2010

Ring tear drops instead of forming

• Latch worn – replace latch

• Latch spring bent or broken (spring must hold latch tightly against

end of side plate and against jaws) – replace latch spring

• Feeder blade worn – replace feeder blade

• Defective rings

1. Burrs

2. Twisted

3. Not symmetrical

4. Wrong rings. Return samples of rings to your Vertex Fasteners representative

for testing.

Rings jam

• Magazine

1. Damaged magazine – replace magazine

2. Too many shims (ring passes under shoe without raising shoe; no control of ring)

– adjust see repair section

3. Too few shims (ring must be forced under shoe which “bottoms out” and may

deflect magazine) – adjust see repair section

4. Worn shoe – replace shoe

5. Frequent jamming can cause the shoe hole in the magazine to increase in size –

replace the magazine

6. Loose or lost rear magazine mounting screw (magazine is not supported

properly) – tighten or replace mounting screw

• Damaged or bent rail – replace rail

• Pusher spring defective – replace spring

• Feeder blade worn, broken or bent – replace feeder

blade

• Ring groove in jaw worn – replace jaw

• Defective rings

1. Burrs

2. Rings skewed on stick

3. Rings out of line on stick

4. Rings twisted

5. Rings not symmetrical

6. Poor tape to ring adhesion

7. Wrong rings. Return samples of rings to your Vertex Fasteners representative

for testing.

Rings don’t feed down magazine

• Pusher spring defective – replace spring

• Damaged magazine – replace magazine

• Damaged or bent rail – replace rail

Page 5

Rev H 4-30-2010

• Damaged pusher – replace pusher

• Defective rings

1. Undersized (tight on magazine)

2. Burrs

3. Rings twisted

4. Rings skewed on stick

5. Rings out of line on stick

6. Poor tape to ring adhesion

7. Wrong rings. Return tool and sample rings to your Vertex Fasteners

representative for testing.

Ring spitting

• Air pressure too high – verify air pressure

• Pusher spring loose – replace spring

• Magazine

1. Damaged magazine – replace magazine

2. Too many shims (ring passes under shoe without raising shoe; no control of ring)

– adjust see repair section

3. Too few shims (ring must be forced under shoe which “bottoms out” and may

deflect magazine) – adjust see repair section

4. Worn shoe – replace shoe

• Damaged or bent rail – replace rail

• Worn jaws – replace jaws (replace only in sets)

• Build up of material in jaw helix – remove build up of material

• Defective rings –

1. Burr on outside curve of ring

2. Rings skewed on stick

3. Rings out of line on stick

4. Rings not symmetrical

5. Rings twisted opposite to jaw helix

6. Wrong rings. Return samples of rings to your Vertex Fasteners representative

for testing.

Page 6

Rev H 4-30-2010

Ring Defects

Vertex Fasteners Hog Ring Tools are designed to operate with rings manufactured to standard

tolerances. Defective rings can be the cause of many ring-forming problems. Never use rings

that are too loose or otherwise defective. Below are some examples of defects that can

occur.

REPAIR

Note: Mineral spirits is recommended for cleaning tool and parts. Do not allow

rubber of handle to soak in mineral spirits as this will cause the rubber to

swell over time and become loose on tool. Wipe off immediately, dry parts

thoroughly before reassembly, use adequate ventilation.

Page 7

Rev H 4-30-2010

Internal Components of VA0278 C-Ring Tool

Page 8

Rev H 4-30-2010

Jaws, magazine and pusher assembly

To Disassemble

1. Remove nylock nuts VH0488, washers VH0221, and latch spring VC8102 from

the jaw screws VH0489.

2. Remove screws VH0491 from rear of feeder guide rail.

3. Remove jaw screws from tool this will allow magazine and pusher assembly,

latch VC8128 and jaws VC8129 and VC8130 with jaw bushings VC8107 to be

removed from tool.

4. Remove button head screw VH0033 from rail and magazine.

To Reassemble

1. Mount latch VC8128 onto side plate opposite magazine.

2. Install jaw bushings VC8107 into jaws VC8129 and VC8130. Lubricate bushings

with lithium grease VH0214 before installing.

3. Place jaws with bushings between side plates VC8123.

4. Slide magazine into position between spring spool bracket VC8127 and side

plate. Attach magazine assembly to rear of feeder guide rail using screw

VH0033 and blue Loctite (243). But do not tighten completely.

5. Insert jaw screws VH0489 through spring spool bracket, magazine, side plate,

jaw bushing, side plate, latch spring and washers. Secure with nylock nuts. Do

not over tighten, jaws must pivot freely.

6. Reattach feeder guide rail to rear of tool using screws VH0491.

7. Tighten button head screw VH0033.

Page 9

Rev H 4-30-2010

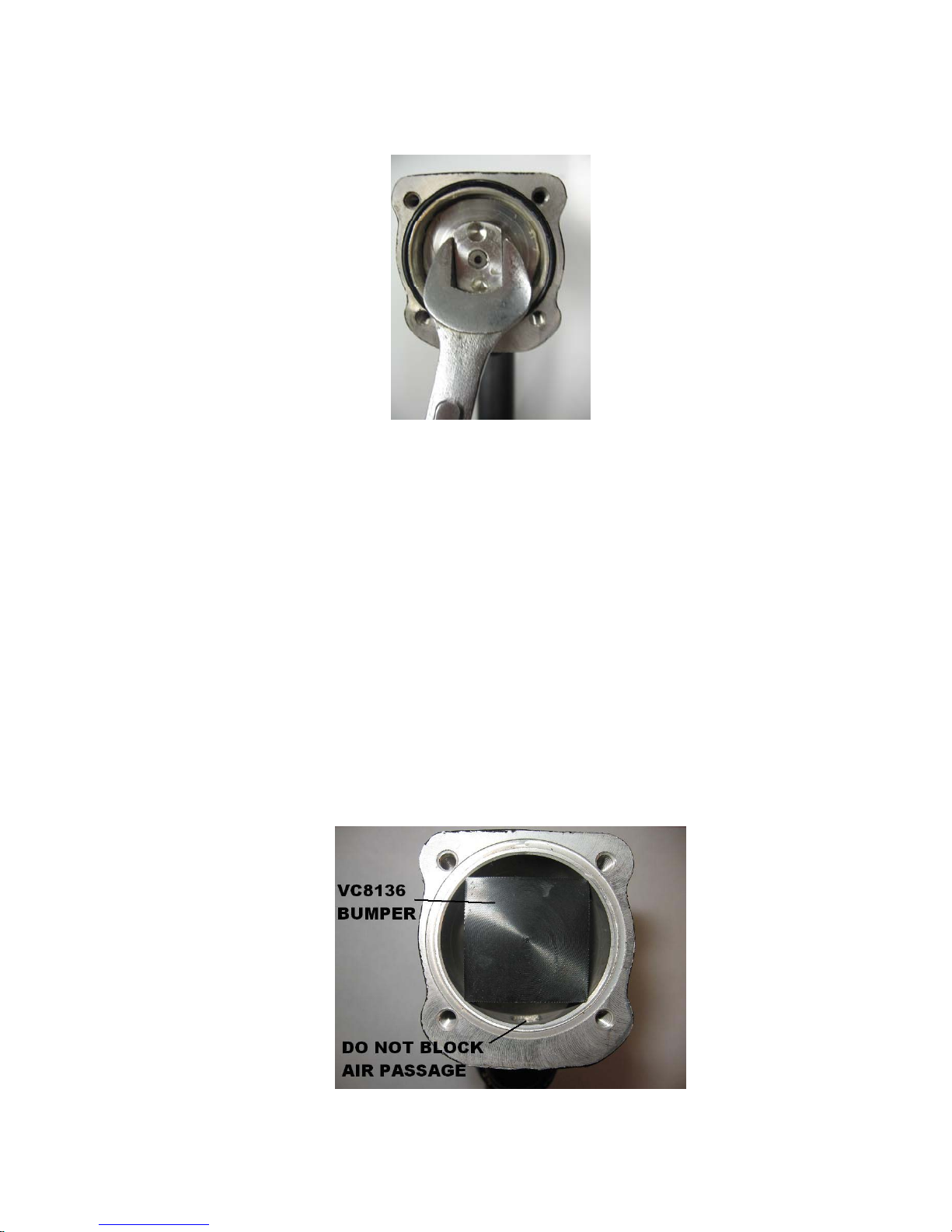

Piston and Piston Rod

To Disassemble

1. Disassemble jaws, magazine and pusher assembly as outlined above.

2. Remove button head screw VH0033 from trigger guard VC8116.

3. Remove (2) screws VH0032 with nylock nuts VH0490.

4. Remove side plates, trigger guard, trigger and roll pins. VC8123, VC8116,

VC8106 and VH0500.

5. Remove (4) rollers VC8104.

6. Remove remaining (2) screws VH0491 from rear of tool.

7. Remove end plate VC8108 and o-ring VH0496.

8. Remove bumper VC8136.

9. Push piston rod VC8125 towards rear of tool exposing piston VC8122.

10. Place tool into vise by clamping down on flat areas of piston rod (do not over

tighten vise jaws).

11. Apply heat if needed to breakdown thread lock adhesive on threaded end of

piston rod.

Page 10

Rev H 4-30-2010

12. Remove piston VC8122 with 9/16” open end or adjustable wrench.

13. Piston rod may now be removed from front of tool.

14. Remove o-ring VH0540.

15. Remove piston rod o-ring VH0464 from front of tool using o-ring pick.

To Reassemble

1. Install o-ring VH0464 into housing thru front of tool.

2. Slide piston rod VC8125 into front of tool. Be careful not to damage o-ring

VH0464 when pushing piston rod into housing, use lubrication.

3. Slide o-ring VH0540 onto piston rod from rear of tool.

4. Place o-ring VH0461 onto piston VC8122.

5. Lubricate piston o-ring liberally with grease VH0214.

6. Clean threads of piston rod and apply thread locker (Loctite 2760 “Red”) to

threads.

7. Slide piston with o-ring into housing end, aligning piston with piston rod. Be

careful not to damage piston o-ring when inserting piston, use grease VH0214.

8. Use 9/16” open end or adjustable wrench to tighten piston while holding flat

areas of piston rod.

9. Install bumper VC8136 by pushing into housing.

Page 11

Rev H 4-30-2010

10. Place o-ring VH0496 into o-ring groove of housing.

11. Place end plate on rear of tool, properly aligned to housing and secure with (2)

screws VH0491, leaving mounting area for feeder guide open.

12. Place rollers VC8104 on roller pins VH0499. Grease will hold rollers in place

while assembling rest of tool.

13. Slide side plates into place on housing (slight force may be used to place side

plates onto housing).

14. Insert (2) screws VH0032 from magazine side of tool and install nylock nuts

VH0490.

15. Assemble trigger VC8106 and trigger guard VC8116 to side plates VC8123

with (3) roll pins VH0500.

16. Reassemble jaws, magazine, pusher assembly and remaining hardware as

outlined above.

Pusher and pusher spring

To Disassemble

1. Disassemble jaws, magazine and pusher assembly as outlined above.

2. Remove button head screw VH0033 from pusher VC8113 and spring VC8109.

3. Hold spring bracket VC8127 in vise by the ears, it is not necessary to remove

bracket from guide rail VC8119.

4. Drive slotted spring pin VH0498 thru bracket and spring VC8109. Remove old

spring.

To Reassemble

1. Mount new spring VC8109 onto spring bracket VC8127 using slotted spring pin

VH0498. Make sure spring is properly orientated (see diagram).

2. Attach spring VC8109 onto pusher VC8113 with button head screw VH0033

(feed spring thru large opening in pusher).

3. Reassemble jaws, magazine and pusher assembly as outlined above.

Page 12

Rev H 4-30-2010

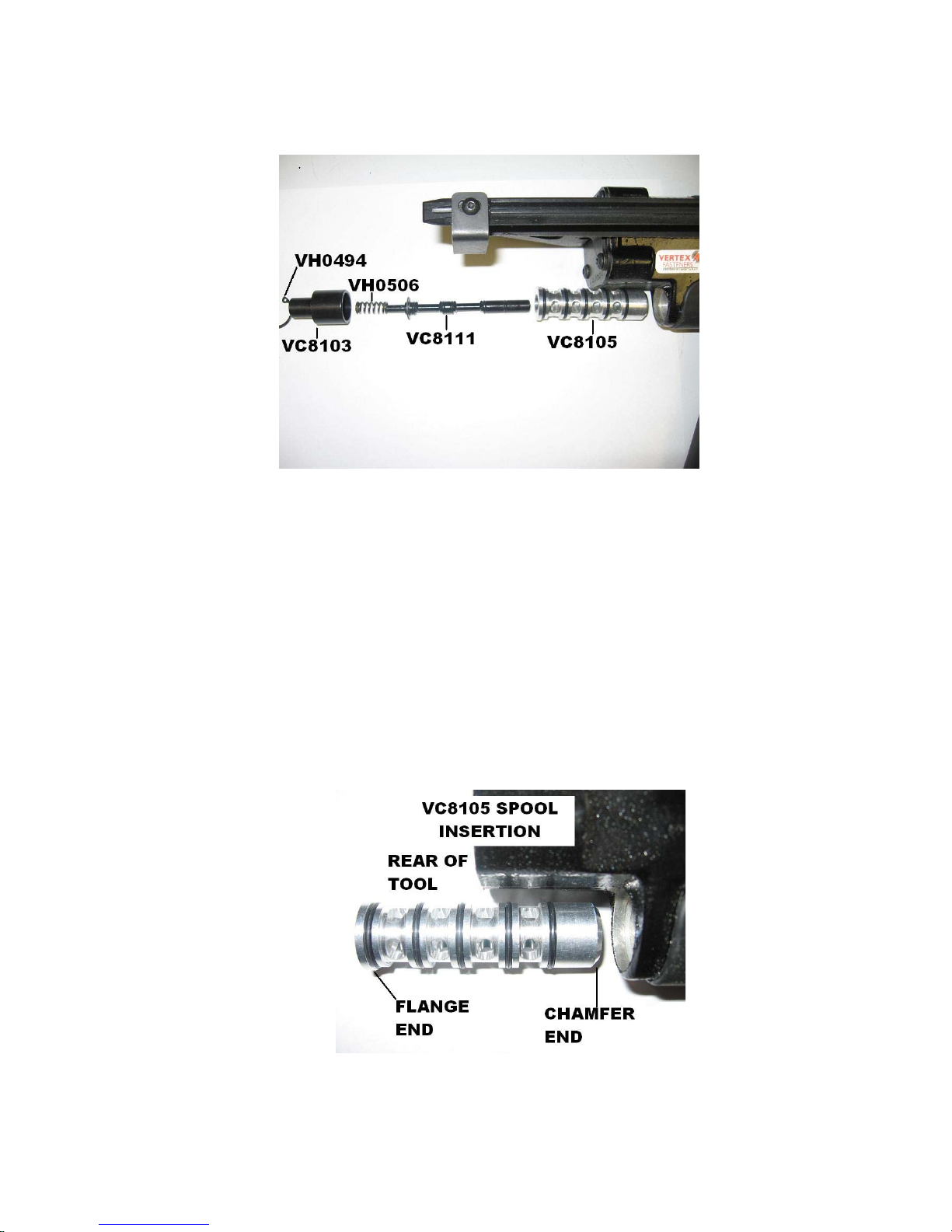

Valve

To Disassemble

1. Remove retaining ring VH0494, deflector VC8103 and spring VH0506.

2. Pull Valve rod VC8111 straight back out of tool.

3. Replace (5) o-rings VH0462.

4. Remove spool VC8105 by using long drift pin punch. From front of tool tap spool

out of body of tool. Note: The spool should never need replacement unless

physically damaged due to corrosion abuse etc.

5. Replace (5) o-rings VH0005.

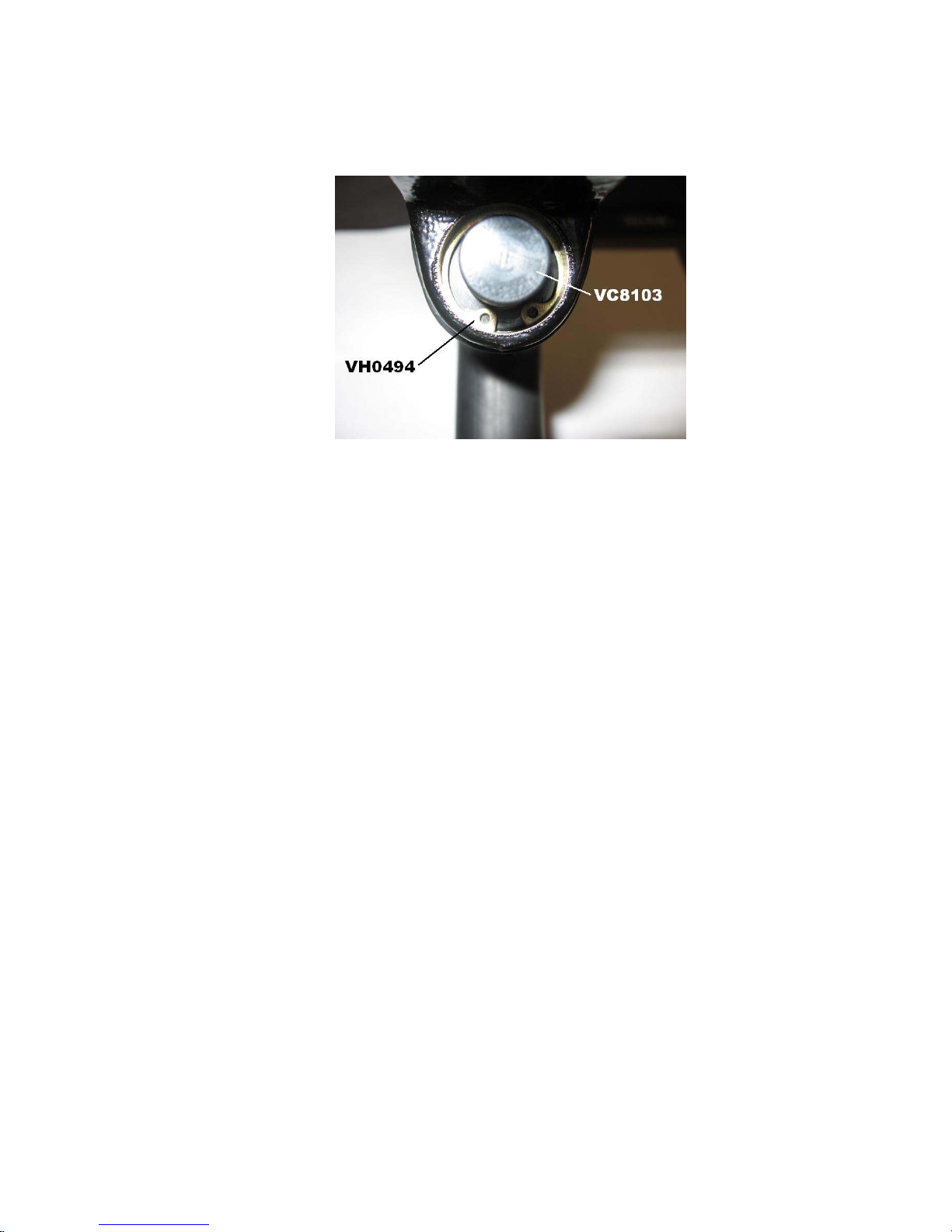

To Reassemble

1. Use plenty of grease VH0214 on spool VC8105 and o-rings VH0005.

2. Insert spool into body from the rear, (see diagram for orientation) using deflector

VC8103 tap spool into place until flange of spool seats firmly in body.

3. Use light amount of grease VH0214 on valve rod VC8111 and o-rings VH0462.

4. Insert valve rod VC8111 into spool VC8105 until e-ring VH0497 seats against the

back of spool.

Page 13

Rev H 4-30-2010

5. Replace spring VH0506 onto end of valve rod VC8111.

6. Replace deflector VC8103 and hold in place with retaining ring VH0494. Make

sure that retaining ring snaps into internal groove of body.

Converting to Left Hand Tool

1. Remove (2) jaw screws VH0489, nuts VH0488, washers VH0221, latch spring

VC8102 and latch VC8128.

2. Remove (4) screws VH0491.

3. Remove magazine and pusher assembly.

4. Remove jaws VC8129 and VC8130 with bushings VC8107 and replace back in

opposite way.

5. Move latch VC8128 to opposite side.

6. Place magazine and pusher assembly on other side.

7. Replace latch spring and fasteners.

Page 14

REV

DESCRIPTION

BY

APPD

DATE

MATERIAL:

HEAT TREATMENT:

FINISH:

VERTEX FASTENERS INC.

3714 JARVIS AVENUE

SKOKIE, IL 60076 U.S.A.

DWG. NO.

SCALE

DATE

APPD

DWN BY

2003

C

TOL. UNLESS

SPECIFIED

INCHES

.X =

`.030

.XX =

`.015

.XXX =

`.005

ANGLES

`1/2~

1-13-04

C

C-RING TOOL ASSEMBLY

VC8000

JMW

THIS DOCUMENT AND THE DATA DISCLOSED HEREIN OR HEREWITH IS NOT TO BE REPRODUCED, US ED, OR DISCLOSED IN

WHOLE OR IN PART TO ANYONE WITHOUT THE PERMISSION OF VERTEX FASTENERS INC.

VC8100 HOUSING

1

VC8101

BLADE, FEEDER 1

VC8102 SPRING, LATCH

1

VC8103 DEFLECTOR

1

VC8104 ROLLER

4

VC8105 SPOOL 1

VC8106 TRIGGER

1

VC8107 BUSHING, JAW

2

VC8108

PLATE 1

VC8109 CONSTANT FORCE SPRING 1

VC8110 GUARD

1

VC8111 VALVE ROD

1

VC8112 MAGAZINE

1

VC8113 PUSHER

1

VC8114 SPRING

2

VC8115 CLIP, ANTI-BACKUP

1

VC8116 GUARD, TRIGGER 1

VC8117 SHIM, MAGAZINE, .010

AR

VC8119 RAIL, FEEDER GUIDE

1

VC8122 PISTON

1

VC8123 SIDE PLATE 2

VC8124 SHOE, MAGAZINE

1

VC8125 ROD, PISTON

1

VC8127 BRACKET, SPRING SPOOL

1

VC8128 LATCH

1

VC8129

JAW, UPPER 1

VC8130 JAW, LOWER

1

VC8131 LABEL, WARNING 1

VC8136

BUMPER 1

VC9124

LABEL 2

VH0005

O'RING, #016

VH0032 SHCS, 10 - 24 x 1 2

VH0033

BHCS, 10 - 32 x 1/4

3

VH0221

WASHER, 1/4

2

VH0459

PIN, SLOTTED SPRING, 3/32 x 3/8

2

VH0462

O-RING, #008

VH0464

O-RING, 011

1

VH0467

PIN, SLOTTED, 3/32 x 7/16

1

VH0486 PAN HEAD, 6 - 19 x 1/4 3

VH0488

NUT, NYLOCK, 1/4 - 28

2

VH0489

SHCS, 1/4 - 28 x 1 1/2

2

VH0490

NUT, NYLOCK, 10 - 24

2

VH0491 BHCS, 10 - 24 x1/2

4

VH0493

BRONZE SLEEVE BEARING

1

VH0494

RETAINING RING

1

VH0496

O-RING 030

1

VH0497

E-RING

1

VH0498

PIN, SLOTTED SPRING, 3/32 x 3/4

2

VH0499

PIN, DOWEL, 3/16 x 1/2

2

VH0500 PIN, SLOTTED SPRING, 1/8 x 11/16 3

VH0506

SPRING

1

VH0540

O-RING, #203

1

VH0641

O-RING, #218

-

PART # DESCRIPTION QT

A

ECN 400

JMW 8-6-04

B

ECN 433 REM VC8131 NOISE

SUP. & VH0014 PIN

JMW 12-22-04

C

ECN 605

JMW 1-9-06

D

D

ECN 723, WAS VH0495

JMW 11-14-06

E

ECN 748, CHANGE O-RING

QTY -, PART OF ASSY

JMW 1-26-07

/ ORDER NO. VA0278

MAR

VH0033

VH0032

VH0489

VH0486

VC8110

VC8112

VH0486

VC8115

VH0467

VC8114

VC8124

VC8109

VC8127

VH0033

VC8106

VC8116

VH0459

VC8119

VC8125

VC8101

VC8107

VC8130

VH0005

VH0462

VH0493

VC8122

VH0496

VC8108

VH0491

VH0494

VC8103

VH0506

VC8111

VH0497

VC8105

VC8100

VC8129

VC8107

VH0488

VC8102

VH0500

VC8128

VH0499

VC8104

VC8123

VH0490

VC8123

VC8117

VH0033

VC8113

VH0498

VH0221

VC8131

VC9124

VH0464

VH0540

MAR

MAR

VC8136

USE LOCTITE 2760

MAR

VH0641

MAR

MAR

Rev H 4-30-2010

Page 15

Rev H 4-30-2010

RECOMMENDED SPARE PARTS LIST

PART # DESCRIPTION NO. OF TOOLS

VC8100 HOUSING 0 0 1

VC8101 BLADE, FEEDER 1 2 3

VC8102 SPRING, LATCH 1 2 4

VC8103 DEFLECTOR 0 1 2

VC8104 ROLLER 4 8 16

VC8105 SPOOL 0 1 2

VC8106 TRIGGER 1 2 3

VC8107 BUSHING, JAW 2 4 6

VC8109 SPRING, CF 1 2 4

VC8110 GUARD 0 1 2

VC8111 VALVE ROD 0 1 2

VC8112 MAGAZINE 0 1 2

VC8113 PUSHER 0 1 2

VC8114 SPRING, SHOE 2 4 6

VC8115 CLIP, ANTI-BACKUP 1 2 3

VC8117 SHIM, MAGAZINE, .010 2 8 12

VC8119 RAIL, FEEDER GUIDE 0 1 2

VC8122 PISTON 0 1 2

VC8124 SHOE, MAGAZINE 0 1 2

VC8125 ROD, PISTON 0 0 1

VC8128 LATCH 1 2 3

VC8129 JAW, UPPER 1 2 3

VC8130 JAW, LOWER 1 2 3

VC8136 BUMPER 0 0 1

VH0005 O-RING, SPOOL 0 5 10

VH0032 SHCS, 10-24 X 1 2 2 4

VH0033 BHCS, 10-32 X 1/4 2 4 8

VH0221 WASHER 2 4 8

VH0459 PIN, SLOTTED SPRING 2 4 6

VH0462 O-RING, VALVE 5 10 20

VH0464 O-RING 0 2 4

VH0486 PAN HEAD, 6-19 X 1/4 1 2 4

VH0488 NUT, NYLOCK 2 4 8

VH0489 SHCS, 1/4-28 X 1 1/2 1 2 4

VH0490 NUT, NYLOCK 2 4 6

VH0491 BHCS, 10-24 X 1/2 2 4 8

VH0493 BUSHING 0 0 1

VH0494 RETAINING RING 0 0 1

VH0641 O-RING, PISTON 1 2 4

VH0496 O-RING 1 2 4

VH0497 E-RING, VALVE 0 1 2

VH0498 PIN, SLOTTED SPRING 1 2 4

VH0499 PIN, ROLLER 2 4 8

VH0500 PIN, ROLL 1 2 3

VH0506 SPRING, VALVE 0 1 2

VH0540 O-RING 0 1 2

1 5 10

Loading...

Loading...