Versum Materials GASGUARD AP11 BSGS eV Asia, BULKGUARD eV, GASGUARD AP11 BSGS eV, BULKGUARD eV NA/EU Installation, Operation & Maintenance Manual

Installation / Operation / Maintenance

Manual

GASGUARD®

AP11 BSGS eV (Asia) /

BULKGUARD® eV (NA/EU)

Manual Part Number: 481319

Edition: Rev-1

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

The information and data contained herein are proprietary to Versum Materials, Inc. and

are not to be copied, reproduced, duplicated, or disclosed to others, in whole or in part,

without prior written consent of Versum Materials, Inc. The information and data should

be available only to those with a need to know. Versum Materials, Inc. makes no

representation that the information and data is appropriate for the recipient, and each

recipient needs to independently evaluate the appropriateness of the information and data

for its use.

This Installation and Operation Manual is subject to change without notification. For

current technical information please call Product Support at (866)624-7677 from

continental U.S., or write Versum Materials, Inc., 1919 Vultee Street, Allentown, PA

18103, Attention: Product Support.

Printed in the U.S.A.

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 2

Confidential and Proprietary Data

WARRANTY

Versum Materials, Inc. (hereinafter referred to as "Versum Materials") warrants that:

(A) Each new Versum Materials Delivery System is free from defects in material and

workmanship under normal use and service for a period of one year from the date of

delivery by Versum Materials to the first purchaser.

(B) Each new accessory is free from defects in material and workmanship under

normal use and service for a period of one (1) year from the date of delivery by Versum

Materials to the first purchaser.

If any product requires service during the applicable warranty period, the purchaser

should communicate directly with Versum Materials to determine appropriate repair.

Repair or replacement will be carried out at Versum Materials expense subject to the

terms of this warranty. It is the responsibility of the customer to perform routine

maintenance and periodic calibration.

In no event shall Versum Materials be liable for any incidental, indirect or consequential

damages in connection with the purchase or use of any Versum Materials product. This

warranty shall not apply to, and Versum Materials shall not be responsible for, any loss

arising in connection with the purchase or use of any Versum Materials product which

has been repaired by anyone other than an authorized Versum Materials service

representative or altered in any way so as, in Versum Materials judgment, to affect its

stability or reliability, or which has been subject to misuse or negligence or accident, or

which has the unit or lot number altered, effaced or removed, or which has been used

otherwise than in accordance with the instructions furnished by Versum Materials.

This warranty is in lieu of all other warranties, express or implied, and all other

obligations or liabilities on Versum Materials part, and Versum Materials neither assumes

nor authorizes any representative or other person to assume for it any other liability in

connection with the sale of Versum Materials equipment.

VERSUM MATERIALS DISCLAIMS ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION.

Address:

Versum Materials, Inc.

1919 Vultee Street

Allentown, PA 18103, U.S.A

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 3

Confidential and Proprietary Data

Revision Control Summary

Chapter Revision File Name

Chapter 1 – Safety Warnings

Rev-7 MNL000127.doc

Label updates

Chapter 2 – Installation

Rev-1 MNL000530.doc

Adding in Process Outlet C and D

Chapter 3 – Module Specifications

Rev-1 MNL000531.doc

Adding in Process Outlet C and D

Chapter 4 – Intentionally Left Blank

Rev-0 MNL000532.doc

Initial Release

Chapter 5 – Intentionally Left Blank

Rev-0 MNL000533.doc

Initial Release

Chapter 6 – Intentionally Left Blank

Rev-0 MNL000534.doc

Initial Release

Chapter 7 – System Description

Rev-1 MNL000535.doc

Adding new optional components

Chapter 8 – Operating Procedures

Rev-1 MNL000536.doc

Software procedure updates

Chapter 9 – Troubleshooting

Rev-0 MNL000537.doc

Initial Release

Chapter 10 – Maintenance

Rev-1 MNL000538.doc

Adding EFS

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 4

Confidential and Proprietary Data

Appendix A – Installation Drawing Package

Rev-1 MNL000539.doc

Updates for Cyl Flag, alarm matrix, PFD’s

Appendix B – Spare Parts List

Rev-1 MNL000540.doc

Updated Electrical Spares

Appendix C – PED Assessment

Rev-2 MNL000140.doc

Updated Company Name and Logo

Appendix D – Pre-Facilitation Checklist

Rev-0 MNL000541.doc

Initial Release

Appendix E – Startup and Commissioning Checklist

Rev-1 MNL000542.doc

Add EFS

Appendix F – ORI Checklist

Rev-0 MNL000543.doc

Initial Release

Appendix G – UV/IR Detector

Rev-0 MNL000544.doc

Initial Release

Appendix H – USB Barcode Reader

Rev-0 MNL000545.doc

Initial Release

Appendix I – Y-Cylinder Heaters Description

Rev-0 MNL000546.doc

Initial Release

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 5

Confidential and Proprietary Data

TABLE OF CONTENTS

Chapter 1 Safety Warnings

Section 1 Introduction .................................................................... 1-2

Section 2 Important Safety Warnings ............................................ 1-5

Section 3 Inert Gas Hazards ........................................................... 1-6

Section 4 Pressurized Fluids/Gases ................................................ 1-7

Section 5 Electrical Hazard ............................................................ 1-7

Section 6 Falling Equipment Hazard ............................................. 1-8

Section 7 Gas Cylinder Handling Hazard ...................................... 1-8

Section 8 Pinch Hazard .................................................................. 1-9

Section 9 Personal Protective Equipment ...................................... 1-9

Section 10 Hazard Warnings ............................................................ 1-12

Section 11 Typical Minimal Lockout or Tagout System Procedures 1-22

Section 12 Safety Signs and Labels ................................................. 1-27

Section 13 Equipment Safety Features ............................................ 1-36

Section 14 Safety Literature for Handling and Use of Gas Cylinders 1-38

Section 15 Safety Literature for Handling of Nitrogen Supply ....... 1-38

Chapter 2 Installation

Section 1 Receiving Inspection ...................................................... 2-2

Section 2 Unpacking and Handling ................................................ 2-2

Section 3 Module Installation ........................................................ 2-3

Section 4 Piping Connections ........................................................ 2-8

Section 5 Electrical and Pneumatic Connections ........................... 2-17

Section 6 Explosive Atmosphere (ATEX) Installations… ............. 2-46

Chapter 3 Module Specifications

Chapter 4 Intentionally Left Blank

Chapter 5 Intentionally Left Blank

Chapter 6 Intentionally Left Blank

Chapter 7 System Description

Section 1 System and Components ................................................ 7-2

Section 2 AP11 Controller ............................................................. 7-24

Section 3 Power I/O Enclosures ..................................................... 7-34

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 6

Confidential and Proprietary Data

Chapter 8 Operating Procedures

Section 1 Emergency Stop ............................................................. 8-2

Section 2 Starting a New System ................................................... 8-3

Section 3 System Shutdown and Startup ....................................... 8-11

Section 4 AP11 Controller Operations ........................................... 8-13

Section 4A Pre-Purge ........................................................................ 8-15

Section 4B Change Source Container ............................................... 8-20

Section 4C Post-Purge ...................................................................... 8-28

Section 4D Process Gas Conditioning .............................................. 8-33

Section 4E Process Gas Flow ........................................................... 8-36

Section 4F Stop and Restart Process Gas Flow ................................ 8-39

Section 4G Idle Mode ....................................................................... 8-45

Section 4H Manual Mode ................................................................. 8-46

Section 4I Tube Switching .............................................................. 8-51

Section 4J Change Y-Container or Drum Source ............................ 8-56

Section 4K Change ISO Container or Tube Trailer Source .............. 8-61

Section 5 AP11 Configuration Menu .............................................. 8-64

Chapter 9 Troubleshooting

Section 1 System Errors ................................................................. 9-2

Section 2 Typical Alarms ............................................................... 9-8

Section 3 J-T Process Heater Reset Procedure .............................. 9-15

Chapter 10 Maintenance

Section 1 Routine Maintenance ..................................................... 10-2

Section 2 Mechanical Integrity ...................................................... 10-8

Section 3 Electrical Maintenance and Test Procedures .................. 10-13

Section 4 Electrical Components Life Expectancy ......................... 10-15

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 7

Confidential and Proprietary Data

Appendix A Installation Drawing Package

Appendix B Spare Parts List

Section 1 Mechanical Spares ......................................................... APP B-2

Section 2 Electrical Spares ............................................................. APP B-3

Appendix C PED Assessment

Appendix D Pre-Facilitation Checklist

Appendix E Startup and Commissioning Checklist

Appendix F Operational Readiness Inspection Checklist

Appendix G UVIR Detector

Appendix H USB Barcode Reader

Appendix I Y-Cylinder Heaters Description

_______________________________________________________________________________________________________________

MNL000529 Revision 1 03/28/2018

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page C - 8

Confidential and Proprietary Data

Chapter 1

Safety Warnings

Section 1 Introduction

Section 2 Important Safety Warnings

Section 3 Inert Gas Hazards

Section 4 Pressurized Fluids / Gases

Section 5 Electrical Hazard

Section 6 Falling Equipment Hazard

Section 7 Gas Cylinder Handling Hazard

Section 8 Pinch Hazard

Section 9 Personal Protective Equipment

Section 10 Hazard Warnings

Section 11 Typical Minimal Lockout or Tagout System

Procedures

Section 12 Safety Signs and Labels

Section 13 Equipment Safety Features

Section 14 Safety Literature for Handling and Use of Gas

Cylinders

Section 15 Safety Literature for Handling and Use of Instrument

Nitrogen Supply

_______________________________________________________________________________________________________________

MNL000127 Revision 7 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 1

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Please read the following safety warnings carefully before installing the equipment.

1.1 Introduction

This section is meant to communicate to the user any hazards involved with the equipment.

The following paragraphs will define the hazard warnings used and describe the icons found in various

sections of the manual and on the equipment. The hazard warning labels used in the manual will

correlate with those used on the equipment.

1.1.1 Level or Intensity of Hazard

Indicates an immediate hazard, which if

not avoided, will result in death or

serious injury.

Indicates a potentially hazardous

situation, which if not avoided, could

result in death or serious injury.

1.1.2 Hazard Types (Symbols)

This symbol is a safety alert symbol.

This symbol represents asphyxiant, toxic or corrosive

gases. Gases used with the GASGUARD® can cause

personal injury or death.

Indicates a potentially hazardous

situation, which if not avoided, may

result in a minor or moderate injury. It

may also be use to alert against unsafe

practices.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 2

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

This symbol can represent one or more of the following

conditions:

Explosive gases! Gases used with the GASGUARD® can

cause an explosion when combined with air.

The formation for explosive gas mixtures of flammable gas

and air when exposed to an ignition source.

Pyrophoric gases which will ignite spontaneously without

the presence of an ignition source when exposed to air.

Energy release which may result from pneumatic or

hydraulic pressure rapidly escaping from a portion of the

equipment.

This symbol represents flammable gases. Gases used with

the GASGUARD® can cause flammable atmospheres.

This symbol represents PPE (Personal Protective

Equipment). Proper PPE shall be worn when working

with this system.

This symbol represents electrical shock hazard.

This symbol warns of potential strain or injury when

lifting cylinders.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 3

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

This symbol warns of a pinch hazard. This hazard exists

on cabinet doors equipped with automatic closers.

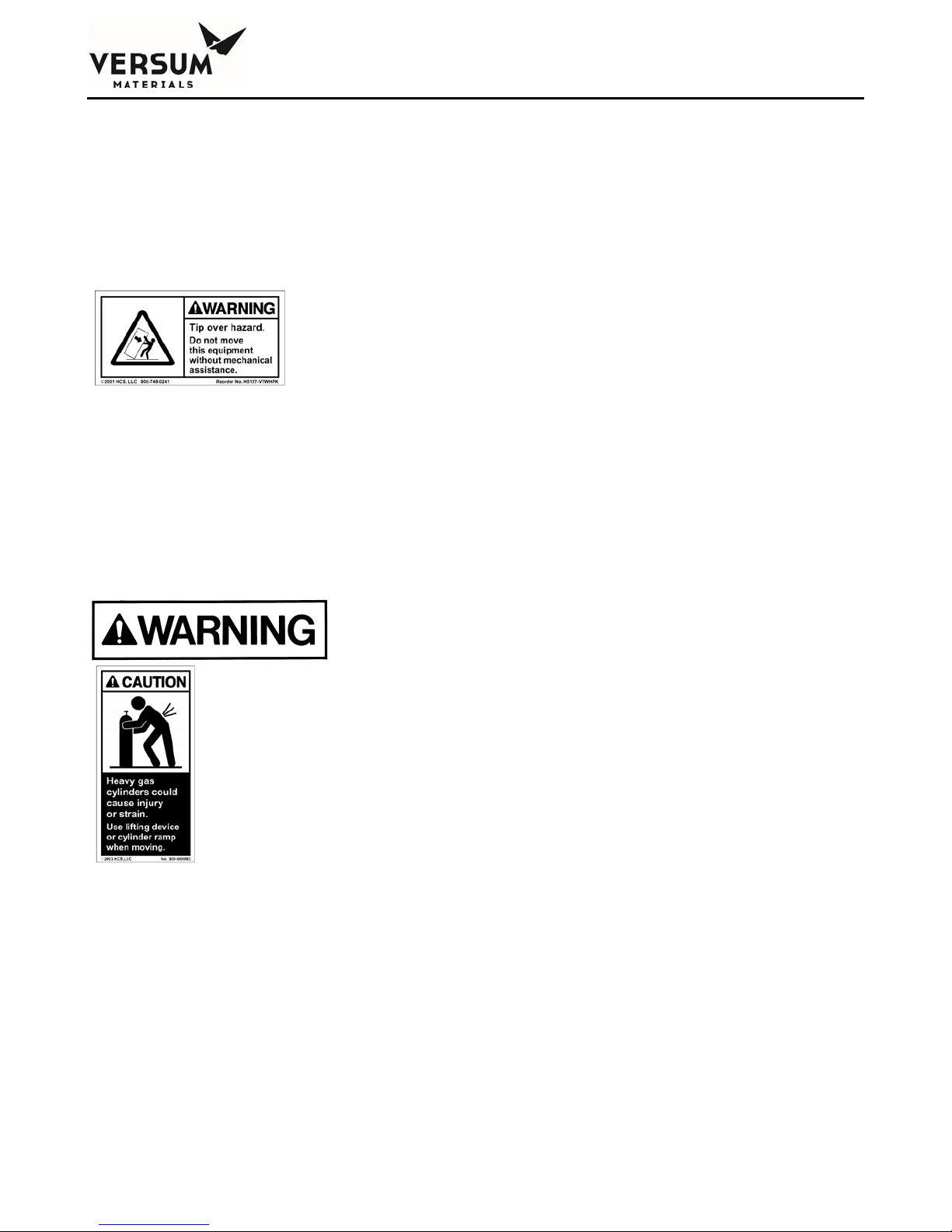

This symbol warns of the possibility of the

source system tipping over if it is not installed

properly. Personal injury could result.

This symbol indicates the need for head protection.

This symbol cautions against the improper

anchoring of cabinets.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 4

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.2 Important Safety Warnings

Failure to read, understand and follow the

safety information found in this section

could result in personal injury and death.

The operator must read and understand

this safety section before operating the

system. All operating and maintenance

personnel must receive training and

instruction by Versum Materials, Inc.

All cylinder storage areas must be

continually monitored with an air quality

monitor to prevent the danger of a

hazardous atmosphere.

Before using the system, review your

company's requirements for use of toxic,

corrosive, flammable, pyrophoric, oxidizers

and inert gas cylinders and electrically

powered equipment. You must be

thoroughly trained in your company's

safety procedures and safety equipment

(self-contained breathing apparatus,

emergency shutdown systems, plant alarm

locations, etc.)

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 5

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.3 Inert Gas Hazards

Do not use this device in any manner other

than specified in this manual.

Do not make any changes to the equipment

independently. INJURY or DEATH may

result from unauthorized modifications.

All modifications to equipment MUST be

approved in writing by an Versum

Materials, Inc.' Representative.

High concentrations of nitrogen, helium, or

other inert gases can cause an oxygen

deficient atmosphere in a confined area

which can cause DEATH. All personnel

must read and understand the material

safety data sheet(s) (MSDS) for the specific

gas(es) being used.

Oxygen concentrations of 19.5% or less can greatly increase the hazard of asphyxiation to personnel.

Before working in an area where nitrogen, helium or other inert gases could be present, check the area

with an oxygen monitor to be sure the oxygen concentration is between 19.5% and 23%. While

working in the area, the oxygen concentration needs to be monitored with a continuous oxygen

monitor. Always provide adequate ventilation in the work area to decrease the risk of an oxygen

deficient atmosphere.

Personnel in an oxygen deficient atmosphere will not realize they are being asphyxiated. Breathing of

pure inert gases will cause immediate unconsciousness. Symptoms of asphyxia include:

Rapid breathing

Nausea

Vomiting

Inability to move

Convulsive movements

Collapse

Abnormal pulse

Rapid fatigue

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 6

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Faulty judgment

Insensitivity to pain

Abnormal emotions

Remove any personnel in an oxygen deficient atmosphere to fresh air. Get medical attention

immediately. Positive pressure breathing apparatus must be worn by any rescuers entering a

suspected oxygen deficient atmosphere.

Nitrogen gas may accumulate in low or confined areas. All requirements of OSHA 1910.146

(Confined Space Guidelines) must be met when inert gases may be present in confined spaces. Self

contained breathing apparatus is required (cartridge or filter type gas masks cannot be used). See the

information on personal protective equipment in this section for details.

When entering a confined area or area which may contain high inert gas concentrations, a "Buddy

System" must be used. One person should remain outside the suspect area, but within view of the

other person. This method ensures that the other person can respond in the event of an emergency.

1.4 Pressurized Fluids / Gases

Pressurized gas and water sprinkler lines

can injure personnel and damage

equipment. Never tighten or loosen a fitting

when it is under pressure.

The house nitrogen supply lines can contain pressures of 100+ psig (6.9+ barg). The water sprinkler

lines contain pressures of 30 psig (2.1 barg). Exercise care when working around these lines. Ensure

that pressure has been vented before breaking any connection. Tag out and lock out the line before

doing any work. Follow Typical Minimal Lockout or Tagout System Procedures described by

Occupational Safety and Health Admin., Labor Para. 1910.147.

1.5 Electrical Hazard

Electric shock can cause personal injury or death.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 7

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

The control circuits for the system use 115/220 VAC, 50/60 Hz. Do not attempt to work on the system

without first turning the power off and tagging out and locking out the electrical supply disconnect

switch per plant lock out procedures. Follow the Typical Minimal Lockout or Tagout System

Procedures described by Occupational Safety and Health Admin., Labor Para. 1910.147.

1.6 Falling Equipment Hazard

This system is a top heavy device. If it is not

properly installed, it could fall and injure,

crush or kill personnel working in the area.

When moving and installing the system, extreme care needs to be taken to support it properly. Due to

the top heavy nature of the system, when moving or if not installed properly, it could tip over, injuring,

crushing or possibly killing personnel in the area. Moving and setting equipment shall be done only by

those persons having proper training and qualification in lifting and rigging.

1.7 Gas Cylinder Handling Hazard

Improper handling and storage of

compressed and liquefied gas cylinders could

cause injury or death.

Restrain gas cylinders during storage and use. Keep protective cap on cylinder when not dispensing

gas. Lifting gas cylinders could cause strain or injury. See Safetygrams found in the Safety section of

the Operation Manual.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 8

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.8 Pinch Hazard

A pinch hazard exists on cabinet doors

equipped with automatic closers.

1.9 Personal Protective Equipment

Personal protective equipment, as defined in

this section, must be worn when working

with this system.

Personal protective equipment is designed to protect personnel from inadvertent risk. The listed

personal protective equipment must be worn regardless of operator or technician level of training and

qualifications.

The minimum personal protective equipment required for operating and maintaining the

GASGUARD® system is dependent on the hazard category of the gas(es) being used. When a gas

meets more than one hazard category, the PPE for the most hazardous category must be used. Refer to

the hazard warnings in Section 1.10 for the hazards of the gas(es) being used.

In addition to the personal protective equipment, the following safety equipment is highly

recommended and is required when VERSUM MATERIALS, INC. personnel operate this equipment.

This equipment should be supplied by the customer prior to operating the GASGUARD® system.

Safety shower

Emergency phones

Eye wash

Gas leak detection system for gases to be used (ex: MDA)

The gas leak detection system must warn personnel (through visible and audible alarms located

near the gas cabinet) of a hazardous atmosphere. The gas sensor(s) need to be set up to alarm

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 9

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

at the lowest level of hazard of exposure. Upon activation of an alarm, follow the established

shutdown procedures for your system.

Scrubber with a pollution abatement system sized for maximum potential upset flow of

hazardous gas.

Adequate ventilation as described in section 3.7.

If you are unsure what personal protective

equipment list to follow for the gases being

used, DO NOT continue. Failure to

understand the hazards and use the proper

personal protective equipment may cause

INJURY or DEATH. Contact Versum

Materials, Inc. for the gas category.

Personal Protective Equipment for the gas categories follows:

Personal Protective Equipment for Toxics

Toxic gas leak detection (ex. MDA)

Self contained positive pressure breathing apparatus

Long sleeved Nomex suit

Safety glasses with side shields

Leather gloves

Safety shoes

NOTE: Most highly toxics (diborane, germane phosphine) are also

flammable. Nomex suit is not required for non-flammable toxics (ex:

nitrogen dioxide, boron trifluoride). All gases in Chapter 1 Section 12

using the warning sign with POISON GAS on the left and

FLAMMABLE GAS on the right REQUIRE the Nomex suit.

Personal Protective Equipment for Corrosives

Corrosive gas leak detector (ex. MDA)

Self contained positive pressure breathing apparatus

Level C acid suit (jacket with bib overalls)

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 10

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Safety glasses with side shields

Leather gloves

Safety shoes

NOTE: Either air quality monitoring or self contained breathing

apparatus is required for corrosive gases. Versum Materials, Inc.

recommends the use of both. It is not required to use both, however at

least one MUST be used at all times.

Personal Protective Equipment for Pyrophorics

Pyrophoric gas leak detection (ex: MDA)

Hard hat (fire hat with brim recommended)

Long sleeved Nomex suit

Face shield

Safety glasses with side shields

Leather gloves

Safety shoes

Personal Protective Equipment for Flammables

Hard hat (fire hat with brim recommended)

Long sleeved Nomex suit

Face shield

Safety glasses with side shields

Leather gloves

Safety shoes

Personal Protective Equipment for Inerts

Oxygen depletion monitor

Safety glasses with side shields

Leather gloves

Safety shoes

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 11

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.10 Hazard Warnings

The following hazard warnings detail system hazards. Follow the warnings to avoid personal injury or

death. Do not work on the system before reading and understanding the following warnings. The

hazard warnings include:

Toxic Gases Hazards

Corrosive Gases Hazards

Flammable and Pyrophoric Gases Hazards

Oxidizer Hazards

Inert Gas Hazards

Pressurized Gases

Cylinder Handling Hazards

Electrical Hazards

Not all of the gas related hazards may apply to your system. For example, you may not be using any

gases in the oxidizer class.

Some gases have more than one hazard. For

example, fluorine is toxic, corrosive and also an

oxidizer.

The Pressurized Gases Cylinder Handling Hazards and Electrical Hazard warnings apply to all

GASGUARD® systems.

The following is general information on

typical gas hazards. It is not a substitute for

training and use of Material Safety Data

Sheets by all operators.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 12

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.10.1 Toxic Gas Hazards

Many of the gases used in the GASGUARD®

system could cause personal INJURY OR

DEATH at very low concentrations.

Many of these gases provide no physical warning signs (i.e. coughing, throat irritation, burning

sensations, and shortness of breath) to alert personnel of exposure to toxic levels.

Personal protective equipment required for use with toxic gases is detailed in Chapter 1 Section 9 of

this manual.

A list of most of the toxic gases used in the GASGUARD® system follows:

Ammonia Hydrogen fluoride

Arsine Hydrogen sulfide

Boron trichloride Methyl chloride

Boron trifluoride Nitrogen dioxide

Carbon monoxide Nitrogen trifluoride

Chlorine Phosphine

Chlorine trifluoride Phosphine mixtures

Diborane Phosphorous pentafluoride

Diborane mixtures Silane

Dichlorosilane Silicon tetrachloride

Disilane Silicon tetrafluoride

Fluorine Sulfur tetrafluoride

Germane Trichlorosilane

Hydrogen bromide Tungsten hexafluoride

Hydrogen chloride

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 13

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.10.2 Corrosive Gas Hazards

Corrosives such as chlorine, fluorine and

ammonia will irritate and burn human tissue.

They can cause personal INJURY and DEATH.

Exposure to very small concentrations of corrosive gases can cause severe irritation of the eyes and

respiratory system. At higher concentrations, they can cause severe personal injury or death.

Chapter 1 Section 9 of this manual lists the personal protective equipment required for use with

corrosive gases.

A list of most of the corrosive gases used in the GASGUARD® system follows:

Ammonia Hydrogen chloride

Boron trichloride Hydrogen fluoride

Boron trifluoride Hydrogen sulfide

Chlorine Nitrogen dioxide

Chlorine trifluoride Phosphorous pentafluoride

Dichlorosilane Silicon tetrachloride

Fluorine Silicon tetrafluoride

Hydrogen bromide Tungsten hexafluoride

1.10.3 Flammable and Pyrophoric Gas Hazards

Flammable and pyrophoric gases could cause

fire, explosions, personal injury or death.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 14

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Pyrophoric gases will spontaneously ignite in air

Pyrophoric gases do not need a source of ignition to burn. However, low concentrations may

accumulate without pyrophoric ignition (i.e. silane can accumulate up to a concentration of 2 molar

percent [number of moles of silane per fixed volume of air] before spontaneous ignition occurs).

Pyrophoric gases will ignite in the presence of oxygen.

Flammable mixtures can burn or explode

Fire and explosion hazards can be controlled by preventing the formation of combustible fuel-oxidant

mixtures and by eliminating sources of ignition such as sparks, open flames or other heat sources.

Flammable mixtures will burn when ignited and can explode when the concentration is above the

lower explosive limit (LEL) and below the upper explosive limit (UEL) for that specific gas. Some

flammable gases may accumulate as pockets in enclosed areas and subsequently explode if an ignition

source is present. A flammable gas also presents an asphyxiating hazard in sufficient quantities to

reduce oxygen concentration below 19.5%, however fire/explosion is typically the primary hazard.

Adequate ventilation is necessary

Adequate ventilation helps reduce the possible formation of flammable mixtures in the event of a

flammable gas leak. See tables in Chapter 3 Section 7 which list the exhaust requirements per

enclosure size for all gases.

NOTE: To avoid any possible hazardous reactions (i.e. fire, explosion,

extremely corrosive or toxic mixtures) never vent incompatible gases out the

same duct!

Continually monitor the atmosphere

Continually monitoring the atmosphere with a gas leak detector will alert the operator to a flammable

or explosive atmosphere in the area.

NOTE: The installation of a hydride detector is strongly recommended for

silane and other pyrophoric gases to detect leaks or pockets of gas that may not

spontaneously ignite!

Versum Materials, Inc. strongly recommend installation of a hydride detector to detect gas pocketing

of pyrophoric gases.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 15

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Guidelines to avoid forming combustible mixtures

Avoid forming combustible mixtures by adhering to the following:

Do not admit flammable gases into an area that contains oxygen/air. Do not admit

oxygen/air into an area that contains flammable gases.

Maintain a small positive pressure in systems to prevent air from leaking into them when

the equipment is shut down.

Avoid venting of flammable gases through vents that do not contain an inert atmosphere.

Personal protective equipment required for use with pyrophoric and flammable gases is listed in

Chapter 1 Section 9. Note that the personal protective equipment (PPE) for pyrophorics differs from

the flammables. Be sure to use the proper PPE.

A list of most of the pyrophoric gases used in the GASGUARD® system follows:

Diborane Phosphine

Disilane Silane

A list of most of the flammable gases used in the GASGUARD® system follows:

Acetylene Germane

Ammonia Hydrogen

Arsine Hydrogen mixtures

Carbon monoxide Hydrogen sulfide

Diborane Methane

Diborane mixtures Methyl chloride

Dichlorosilane Methyl fluoride

Disilane Trichlorosilane

1.10.4 Oxygen and Other Oxidizer Hazards

Systems using oxygen or other oxidizers

(i.e. nitrous oxide, fluorine) have specific

guidelines for specifying equipment, materials

of construction and system cleanliness. Failure

to comply with materials of construction and

system cleanliness could result in injury or

death.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 16

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Follow safe practices when using oxygen or oxidizers (chlorine and fluorine)

Oxygen concentrations in excess of 23% significantly increase the hazard exposure to personnel and

equipment. Those materials which burn in air will burn more violently and explosively in

oxygen/oxidizer enriched atmospheres. Guidelines for oxygen systems are found in CGA Pamphlet G-

4.4. (Contact your gas supplier or the Compressed Gas Association to order CGA Pamphlets.) Only

those personnel who have read and understand the hazards of oxygen or oxidizers and safe practices

for these systems should be permitted to operate and maintain the system.

Use only equipment specifically designed for oxygen or oxidizer service.

Inappropriate materials of construction increase the danger of ignition of pipelines and controls. Pipe

sizing is just as important to ensure all velocity restrictions for oxygen or oxidizers are met. Do not

substitute components or equipment without considering these hazards. Refer to CGA Pamphlet G-4.4

for guidelines and specifications of oxygen systems. (Contact your gas supplier or the Compressed

Gas Association to order CGA Pamphlets.)

Maintain oxygen cleanliness at all times.

All equipment and piping in contact with oxygen or oxidizers must be cleaned to specifications

outlined in CGA Pamphlet G-4.1. (Contact your gas supplier or the Compressed Gas Association to

order CGA Pamphlets.) Failure to clean components and piping increases the danger of ignition and

fire. Note that the cleaning solvent must be thoroughly removed before the equipment can be placed

into service. Maintain cleanliness during assembly, installation, and repair.

No open flames, smoking, or sparks permitted near oxygen equipment.

Since many materials will burn in oxygen/oxidizer enriched atmospheres, the best method in

preventing fires is to eliminate sources of ignition. Where this control equipment is being used or

where concentrations of oxygen are greater than 23%, avoid open flames, sparks, or sources of heat.

Never weld on a pressurized line flowing oxygen or an oxidizer. Make sure signs are posted warning

personnel that oxygen or oxidizers are in use.

Do not substitute oxygen for compressed air.

Substituting oxygen for compressed air is dangerous. Explosions can occur when oxygen is

substituted for air. Chances are the instrument air equipment is not compatible or cleaned for oxygen

service. Oxygen used to clean off equipment or clothing could come in contact with a source of

ignition (spark, flame, or other) and ignite. In some cases, the elevated oxygen levels could linger

even after the source has been shut off. Never tie into an oxygen system for personal breathing

purposes.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 17

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

A list of most of the oxidizers used in the GASGUARD® system follows:

Chlorine Nitrogen trifluoride

Chlorine trifluoride Nitrous oxide

Fluorine Oxygen

1.10.5 Inert Gas Hazards

High concentrations of nitrogen, helium, or

other inert gases will cause an oxygen deficient

atmosphere in a confined area which can cause

DEATH. All personnel must read and

understand the Material Safety Data Sheet(s)

Oxygen concentrations of 19.5% or less can greatly increase the hazard of asphyxiation to personnel.

Before working in an area where nitrogen, helium or other inert gases could be present, check the area

with an oxygen monitor to be sure the oxygen concentration is between 19.5% and 23%. While

working in the area, the oxygen concentration needs to be monitored with a continuous oxygen

monitor. Always provide adequate ventilation in the work area to decrease the risk of an oxygen

deficient atmosphere. Read VERSUM MATERIALS, INC. Safetygram 17 "Dangers of Oxygen

Deficient Atmospheres" included in the safety literature in Section 1.14 of this manual.

(MSDS) for the specific gas(es) being used.

Any time an oxygen deficient atmosphere is suspected, the proper personal protective equipment must

be used. See the information on personal protective equipment in Chapter 1 Section 9 for details.

Personnel in an oxygen deficient atmosphere will not realize they are being asphyxiated. Breathing of

pure inert gases will cause immediate unconsciousness.

Symptoms of asphyxia include:

Rapid breathing

Nausea

Vomiting

Inability to move

Convulsive movements

Collapse

Abnormal pulse

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 18

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Rapid fatigue

Faulty judgment

Insensitivity to pain

Abnormal emotions

Remove any personnel in an oxygen deficient atmosphere to fresh air. Get medical attention

immediately. Use cardiopulmonary resuscitation if the victim is not breathing. Positive pressure

breathing apparatus must be worn by any rescuers entering a suspected oxygen deficient

atmosphere.

Nitrogen gas may accumulate in low or confined areas. All requirements of OSHA 1910.146

(Confined Space Guidelines. ) must be met when working with inert gases in confined spaces. Self

contained breathing apparatus is required (cartridge or filter type gas masks cannot be used). See the

information on personal protective equipment in this section for details.

When entering a confined area or area which may contain high inert gas concentrations, a "Buddy

System" must be used. One person should remain outside the suspect area, but within view of the

other person. This method ensures that the other person can respond in the event of an emergency.

Personal protective equipment required for use with inerts is listed in Chapter 1 Section 9.

A list of inert gases used in the GASGUARD® system follows:

Argon Halocarbon 115

Carbon Dioxide Halocarbon 116

Halocarbon 11 Helium

Halocarbon 12 Krypton

Halocarbon 13 Neon

Halocarbon 14 Nitrogen

Halocarbon 22 Perfluoropropane

Halocarbon 23 Sulfur Hexafluoride

Halocarbon 113 Xenon

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 19

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.10.6 Pressurized Gases

Any gas, in addition to those listed above,

used in the GASGUARD® system could

potentially displace the oxygen in the air

and cause asphyxiation.

Pressurized gas lines could injure personnel

and damage equipment. Never tighten or

loosen a fitting when it is under pressure.

The process and purge gas cylinders can contain pressures up to 2650 psig in the USA. In Europe,

cylinders can contain pressures up to 200 barg. A leak from a loose mechanical fitting, component or a

ruptured/failed component can expose the operator to a high pressure gas stream or projectile. Read

the cylinder handling warnings in Chapter 1 Section 1.10.7 and the safety literature on cylinder

handling in Chapter 1 Section 13.

The house nitrogen supply lines can contain pressures of 100+ psig (7+ barg). Exercise care when

working around these lines. Insure that pressure has been vented before breaking any connection. Tag

out and lock out the line before doing any work. Follow Typical Minimal Lockout or Tagout System

Procedures described by Occupational Safety and Health Admin., Labor Para. 1910.147 found in

Section 1.11.

1.10.7 Cylinder Handling Hazards

High pressure gas cylinders could be

extremely hazardous when not handled

properly.

Proper training, maintenance, leak testing and mechanical connection procedures can prevent operators

from being exposed to high pressure gas streams. Use the cylinder change out procedures in Chapter

8 Section 8.3.2, "Process Cylinder Procedures."

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 20

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

Do not use a wrench or other device to close diaphragm type cylinder valves. This could

cause diaphragm rupture and valve failure which could result in personal injury or death.

Contact your gas supplier for the maximum torque (ft./lbs. or N/m) allowed on diaphragm

type cylinder valves. Certain gases are supplied with cylinder valves without handwheels.

Use only the tool specified by your gas supplier to open and close diaphragm type cylinder

valves to avoid over torquing these valves.

If a cylinder valve protection cap is extremely difficult to remove, do not apply excessive

force or pry the cap loose. Attach a label to the cylinder identifying the problem and notify

the personnel responsible for returning cylinders about the defective cylinder. Obtain

another cylinder. Do not attempt to open a frozen cap as this would damage the cylinder

valve and could result in personal injury or death.

Do not rotate the cylinder using the cylinder valve handle. This may open the cylinder valve

and cause a high pressure gas leak.

NEVER replace the gas specified for use in the source system with another type of gas

cylinder. Incompatible gases could cause fires, explosions or extremely corrosive or toxic

mixtures which can cause personal injury or death. If another type of gas is required for

use in the gas source system, contact Versum Materials, Inc. immediately.

A valve outlet sealing cap must be supplied on all toxic, corrosive and pyrophoric gases.

Consult your gas supplier if there is no sealing cap on any of the above types of gas

cylinders.

Cylinder valves are available with removable flow restrictor orifices in the valve outlet for

use with gas cylinders. This flow restrictor orifice significantly limits the rate of release of

gas from the valve outlet during transportation, storage and use, due to a valve or system

failure. Verify that your gases are supplied in cylinders with valves that have the

appropriate flow restrictor orifice. Note that there are different size flow restrictor orifices

available. Verify that the correct size is being used for your specific situation. A quality

control program should be established to assure that your supplier has installed the correct

flow restrictor orifice in the valve outlet after the filling operation has been completed.

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 21

Confidential and Proprietary Data

Chapter 1 - Safety Warnings

1.10.8 Electrical Hazards

Electric shock could cause personal injury

or death.

The control circuits for the system use 115/220 VAC, 50/60 Hz. Do not attempt to work on the system

without first turning the power off and tagging out and locking out the electrical supply disconnect

switch per plant lock out procedures. Follow the Typical Minimal Lockout or Tagout System

Procedures described by Occupational Safety and Health Admin., Labor Para. 1910.147 found in

Chapter 1 Section 11 of this manual.

1.10.9 Purge Gas Backstream Hazard

Avoid low pressure condition in purge gas

cylinder to prevent a backstream hazard.

The purge gas system incorporates a pressure indicating gage which will provide the means of

displaying a low purge gas cylinder pressure condition (usually 200 psig [14 barg] minimum). The

cylinder should be changed out at this point to prevent process gas from backstreaming into the purge

gas cylinder.

1.11 Typical Minimal Lockout or Tagout System Procedures

NOTE: The following OSHA document is included to help you develop a lockout/tagout procedure

for the GASGUARD® System. A written procedure is required for any work performed under

lockout/tagout. It must be reviewed, approved and understood by all participants who are trained to

perform the work. (Occupational Safety and Health Admin., Labor Para. 1910.147)

Although OSHA does not have jurisdiction outside the United States of America, it is Versum

Materials, Inc. recommendation that Lockout, or Tagout procedures be followed, except where local

laws are more stringent.

General

Lockout is the preferred method of isolating machines or equipment from energy sources. To assist

employers in developing a procedure which meets the requirements of the standard, the following

_______________________________________________________________________________________________________________

MNL000127 Revision 8 07/27/2016

Gas Equipment

© Versum Materials, Inc. as of the revision and date shown. All rights reserved.

Page 1 - 22

Confidential and Proprietary Data

Loading...

Loading...