Versum Materials Chemguard Genlll 050 Installation, Operation & Maintenance Manual

Installation / Operation / Maintenance

Manual

CHEMGUARD GenIII 050

Chemical Equipment

Manual Part Number: 477444

Edition: Rev-0

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

VersumMaterialsConfidential

The information and data contained herein are proprietary to Versum Materials, Inc. and

are not to be copied, reproduced, duplicated, or disclosed to others, in whole or in part,

without prior written consent of Versum Materials, Inc. The information and data

should be available only to those with a need to know. Versum Materials, Inc. makes no

representation that the information and data is appropriate for the recipient, and each

recipient needs to independently evaluate the appropriateness of the information and

data for its use.

This Installation and Operation Manual is subject to change without notification. For

current technical information please call Product Support at (866)624-7677 from

continental U.S., or write Versum Materials, Inc., 1919 Vultee Street, Allentown, PA

18103, attention: Product Support.

Printed in the U.S.A.

_______________________________________________________________________________________________________________

mnl000621 Revision 0 06/27/2019

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

VersumMaterialsConfidential

Page C - 2

Confidential and Proprietary Data

WARRANTY

Versum Materials, Inc. (hereinafter referred to as "Versum Materials") warrants that:

(A) Each new Versum Materials Delivery System is free from defects in material and

workmanship under normal use and service for a period of one year from the date of

delivery by Versum Materials to the first purchaser.

(B) Each new accessory is free from defects in material and workmanship under

normal use and service for a period of one (1) year from the date of delivery by Versum

Materials to the first purchaser.

If any product requires service during the applicable warranty period, the purchaser

should communicate directly with Versum Materials to determine appropriate repair.

Repair or replacement will be carried out at Versum Materials expense subject to the

terms of this warranty. It is the responsibility of the customer to perform routine

maintenance and periodic calibration.

In no event shall Versum Materials be liable for any incidental, indirect or consequential

damages in connection with the purchase or use of any Versum Materials product. This

warranty shall not apply to, and Versum Materials shall not be responsible for, any loss

arising in connection with the purchase or use of any Versum Materials product which

has been repaired by anyone other than an authorized Versum Materials service

representative or altered in any way so as, in Versum Materials judgment, to affect its

stability or reliability, or which has been subject to misuse or negligence or accident, or

which has the unit or lot number altered, effaced or removed, or which has been used

otherwise than in accordance with the instructions furnished by Versum Materials.

This warranty is in lieu of all other warranties, express or implied, and all other

obligations or liabilities on Versum Materials part, and Versum Materials neither

assumes nor authorizes any representative or other person to assume for it any other

liability in connection with the sale of Versum Materials equipment.

VERSUM MATERIALS DISCLAIMS ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION.

Address:

Versum Materials, Inc.

1919 Vultee Street

Allentown, PA 18103, U.S.A

_______________________________________________________________________________________________________________

mnl000621 Revision 0 06/27/2019

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

VersumMaterialsConfidential

Page C - 3

Confidential and Proprietary Data

Revision Control Summary

Chapter Revision File Name

Chapter 1 – Delivery and Inspection

Rev-0 MNL000622.doc

Initial Release.

Chapter 2 – Site Preparation

Rev-0 MNL000623.doc

Initial Release.

Chapter 3 – Installation

Rev-0 MNL000624.doc

Initial Release.

Chapter 4 – 38 Liter Bubbler Installation

Rev-0 MNL000625.doc

Initial Release.

Chapter 5 – Features and Components

Rev-0 MNL000626.doc

Initial Release.

Chapter 6 – System Operation

Rev-0 MNL000627.doc

Initial Release.

Chapter 7 – Maintenance and Calibration Procedure

Rev-0 MNL000628.doc

Initial Release.

Addendum A – LPE 14 Liter Bubbler Change Procedure

Rev-0 MNL000629.doc

Initial Release.

Addendum B – Gas Filter Setup

Rev-2 MNL000108.doc

AP to Versum update.

Appendix F – Gas Sensor Instruction

Rev-2 MNL000112.doc

AP to Versum update.

_______________________________________________________________________________________________________________

mnl000621 Revision 0 06/27/2019

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

VersumMaterialsConfidential

Page C - 4

Confidential and Proprietary Data

TABLE OF CONTENTS

Chapter 1 Delivery and Inspection

Section 1 Delivery .......................................................................... 1-2

Section 2 Inspection ....................................................................... 1-2

Chapter 2 Site Preparation

Section 1 Facility Preparation ........................................................ 2-2

Section 2 Facility Requirements .................................................... 2-4

Section 3 Tag and Lockout Routine ................................................ 2-16

Section 4 Spill Cleanup Routine ..................................................... 2-17

Chapter 3 Installation

Section 1 Introduction ..................................................................... 3-2

Section 2 Reference Documents ..................................................... 3-2

Section 3 Installation ....................................................................... 3-3

Section 4 Installing the ChemGuard® CG050 Cabinet ................... 3-4

Section 5 Connecting ChemGuard® Gas Lines ............................... 3-11

Section 6 Chemical Delivery Line Requirements ........................... 3-11

Section 7 Installing ChemGuard® Bulk Scale ................................. 3-16

Section 8 Communications ............................................................. 3-17

Section 9 Start-up and Initialization ................................................ 3-23

Section 10 System Configuration ...................................................... 3-28

Section 11 Manual Mode .................................................................. 3-30

Section 12 Regulator Adjustment ..................................................... 3-33

Section 13 Finishing the ChemGuard® Installation .......................... 3-34

Chapter 4 38 Liter Bubbler Installation

Section 1 38 Liter Bubbler Installation ........................................... 4-2

Section 2 Bubbler Valves ............................................................... 4-2

Section 3 Installation of the Bubbler and Valves ............................ 4-3

Section 4 Bubbler and System Leak Test - Setup ........................... 4-5

Section 5 Leak Test – Main Manifold -> Pressure Decay .............. 4-6

Section 6 Leak Test – Vapor Out -> Pressure Decay ...................... 4-6

Section 7 Leak Test – Sample Out/Purge Line -> Pressure Decay . 4-7

Section 8 Leak Test – 38L Bubbler/Outer Cooling Jacket -> Pressure Decay.4-7

Section 9 Leak Test – External Refill Line -> Pressure Decay ....... 4-8

Section 10 System Purge ................................................................... 4-9

Section 11 Install Bubbler Chiller Connections ................................ 4-9

Section 12 Entering Bubbler Liquid Weight ..................................... 4-10

Chapter 5 ChemGuard

Section 1 Overview ........................................................................ 5-2

Section 2 Component Description .................................................. 5-4

Section 3 Available Options ............................................................ 5-14

®

GEN III Features and Components

_______________________________________________________________________________________________________________

mnl000621 Revision 0 06/27/2019

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

VersumMaterialsConfidential

Page C - 5

Confidential and Proprietary Data

Chapter 6 System Operation

Section 1 Theory of Operation ........................................................ 6-2

Section 2 Description of Menu and Operations .............................. 6-4

Section 3 Operating Menu .............................................................. 6-5

Section 4 Alarm Types .................................................................... 6-19

Chapter 7 Maintenance & Calibration Procedures

Section 1 Introduction ..................................................................... 7-2

Section 2 Calibration and Testing ................................................... 7-2

Addendum A LPE 14 Liter Bubbler Change

Section 1 Safety Notes .................................................................... A-2

Section 2 Removing and Replacing the Bubbler ............................ A-3

Section 3 Change BULK Bubbler Operation .................................. A-4

Addendum B Gas Filter Setup

Appendix F Gas Sensor Instruction

_______________________________________________________________________________________________________________

mnl000621 Revision 0 06/27/2019

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

VersumMaterialsConfidential

Page C - 6

Confidential and Proprietary Data

Chapter 1 - Delivery and Inspection

_______________________________________________________________________________________________________________

MNL000622.doc Revision 0 6/17/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 1 - 1

Versum Materials Confidential

Chapter 1

Delivery and Inspection

Section 1 Delivery

Section 2 Inspection

Chapter 1 - Delivery and Inspection

_______________________________________________________________________________________________________________

MNL000622.doc Revision 0 6/17/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 1 - 2

Versum Materials Confidential

Chapter 1: Delivery and Inspection

1.1 Delivery

The ChemGuard® Gen III may be shipped in multiple packing boxes. The packing slip on the

outside of one of the cartons indicates the number of items in the order. A separate Shipping

Identification Sheet (SIS), or packing checklist, included with the manuals, identifies all

components in the shipment. Before unpacking, make sure your order includes the correct

number of packages.

This shipment includes one empty bubbler chemical container. You will need to order a

container or containers containing chemical. The contents of the packing boxes are:

• The ChemGuard

®

Gen III Cabinet

• One (1) empty bubbler chemical container

• Start-up kit (See Packing Checklist included with shipment)

• Shipping Identification Sheet (packing checklist)

• ChemGuard® Gen III Quality Inspection Records

NOTE: Save all cartons (along with foam supports and padding) for re-use in

case unit must be returned to Versum Materials, Inc.

1.2 Inspection

Be sure each item on the packing checklist is included in the shipment. Notify Versum

Materials, Inc. within 30 days if anything is missing. After 30 days, it is the customer’s

responsibility to purchase missing or damaged parts.

1. Verify that the part numbers on the items are the same as specified on the Shipping

Identification Sheet (SIS).

2. Keep the packing checklist for use in any future communication with Versum Materials,

Inc. Customer Service.

Chapter 2 - Site Preparation

MNL000623.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 1

Versum Materials Confidential

Chapter 2

Site Preparation

Section 1 Facility Preparation

Section 2 Facility Requirements

Section 3 Tag and Lockout Routine

Section 4 Spill Cleanup Routine

Chapter 2 - Site Preparation

MNL000623.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 2

Versum Materials Confidential

Chapter 2: Site Preparation

This chapter describes the space and clearances required to install ChemGuard®

CG050 systems along with specifications for power, gas, vacuum, cabinet

exhaust, reservoir vent and chemical delivery line.

Before the ChemGuard® CG050 unit can be installed, the customer must prepare

the location site as detailed in the following section to provide sufficient space and

clearance around the unit. Ensure the AC power, vacuum and gas sources are

available in close proximity to the unit. Please read the information in this chapter

carefully to avoid problems later.

The user of this product is responsible for compliance with all applicable

environmental laws and regulations including local governing agencies and

state/local laws (i.e., Clean Water Act, Clean Air Act, and Hazardous Waste

Laws).

The information and data contained herein are proprietary to Versum Materials,

Inc. and are not to be copied, reproduced, duplicated, or disclosed to others, in

whole or in part, without prior written consent of Versum Materials, Inc. The

information and data should be available only to those with a need to know.

Versum Materials, Inc. makes no representation that the information and data is

appropriate for the recipient, and each recipient needs to independently evaluate

the appropriateness of the information and data for its use. This information and

data were originally written in English.

ChemGuard® CG050 hazard location groups include Class I, Division II Groups B,

C, D (United States) and Group 2, Category 3 ATEX (Europe)

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

2.1 Facility Preparation

Determine a suitable location for ChemGuard® CG050 cabinet. Versum Materials,

Inc. recommends installing the cabinet in close proximity to:

• Your AC power source

• Your vacuum supply

• Your helium push gas and nitrogen purge gas supplies

Chapter 2 - Site Preparation

MNL000623.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 3

Versum Materials Confidential

Ensure that there is ample space to allow the cabinet doors to open completely and that there is

proper clearance around the unit. (See Table 2-1 for required cabinet clearances.) If an optional

fire extinguisher is installed, additional clearance may be required.

Table 2-1: Cabinet Clearances

PLACEMENT

CLEARANCES

Height

87 in. (2.209 meters)

Width

18 in. (457 mm)

Depth

Door open: 37 in. (940 mm)

Door closed: 21 in. (533 mm)

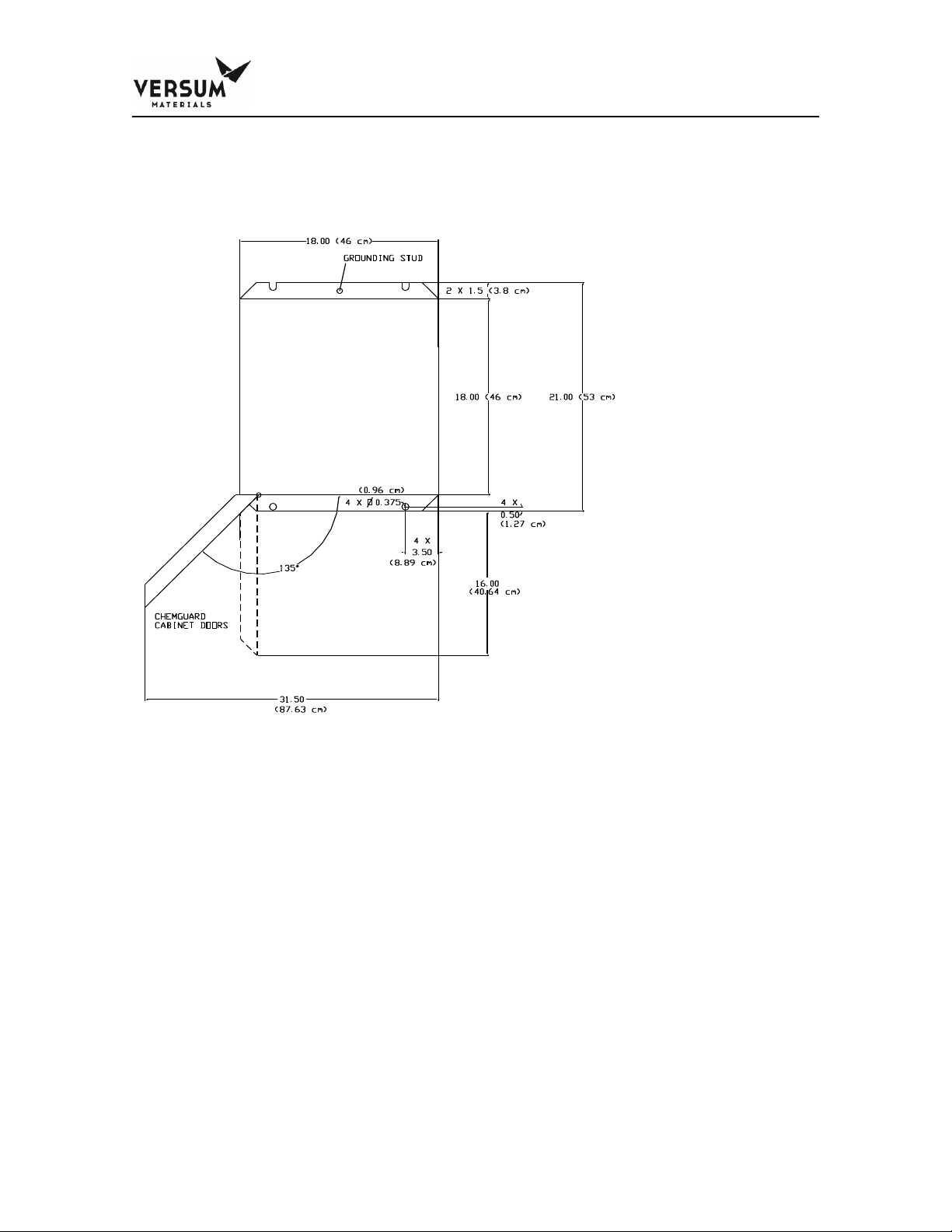

2.1.1 Bolt-Down and Ground Cabinet Requirements

Set the ChemGuard® CG050 cabinet over the bolt-down points and attach

securely. Verify ChemGuard® CG050 is in a level location where it can be

serviced easily, and is out of the main thoroughfare.

Per current United States UBC and SEMI S2-STANDARD requirements, floor

bolts must be at least Grade 5 (metric Grade 8.8), at a recommended minimum

length of 2.5 in. (6.35 cm).

1. Place the cabinet at the designated location.

2. Verify that there is enough room around the cabinet to fully open the door, or

perform maintenance tasks.

3. The ChemGuard® CG050 must be grounded in accordance with Article 250 Grounding, The National Electrical Code 2003. Refer to Figure 2-1 for the

location of the grounding lug. Versum Materials, Inc. recommends a ground

resistance of <1.0 Ohms.

Chapter 2 - Site Preparation

MNL000623.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 4

Versum Materials Confidential

Figure 2-1:

Earthquake Bolt-Down Pattern with Front Door Clearances

2.2 Facility Requirements

When selecting a location for the unit, ensure that the following facilities are

available to make connections on top of the cabinet.

• Environmental

• Electrical

• Supply gases

• Venturi Vacuum

Supply

• Exhaust and Vent

• Chemical Delivery Line

• Bulk Chemical Refill Line (from

BCD200, CG010 or CG310)

• Chemical Outlet

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 5

Versum Materials Confidential

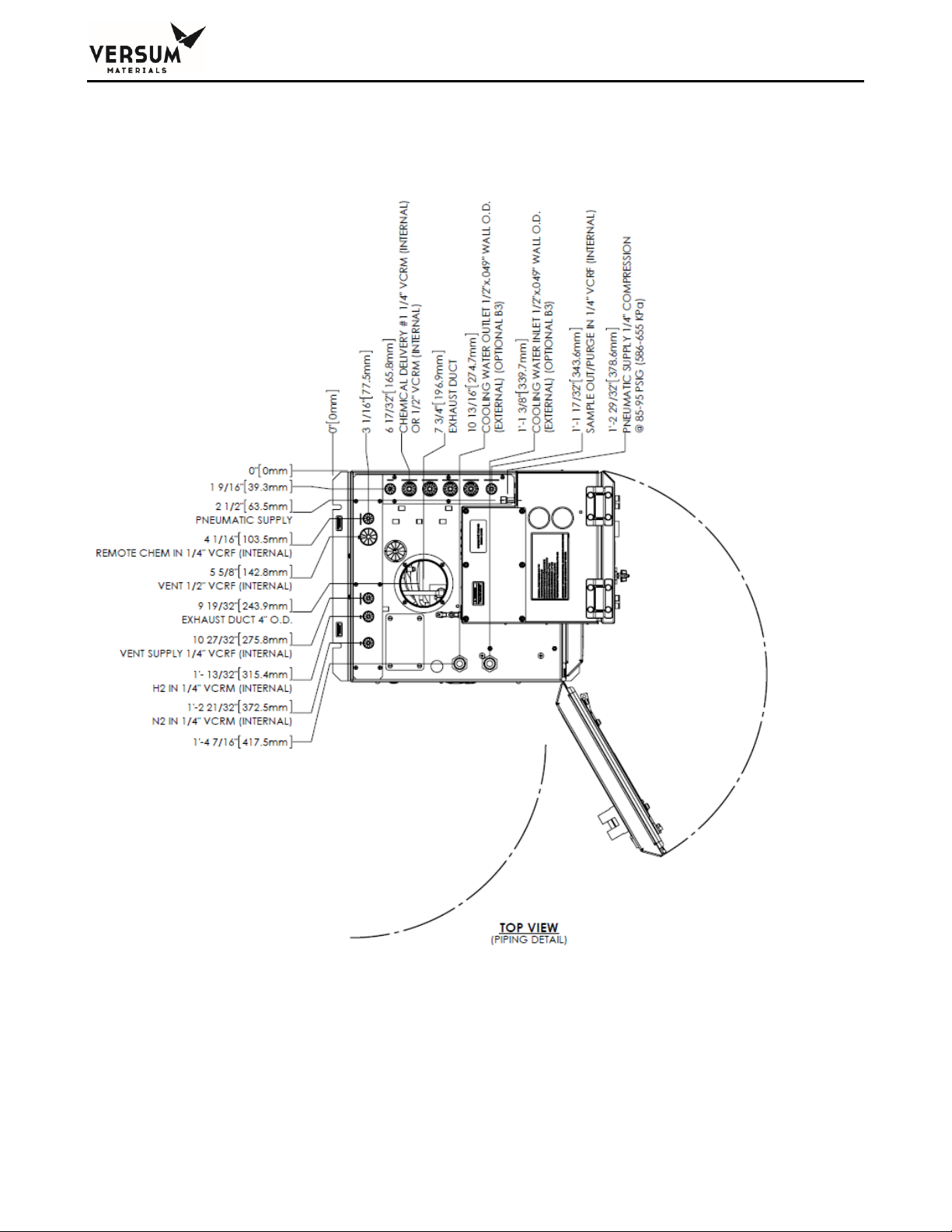

Figure 2-2:

CG050 GEN III Cabinet Connections, Top View

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 6

Versum Materials Confidential

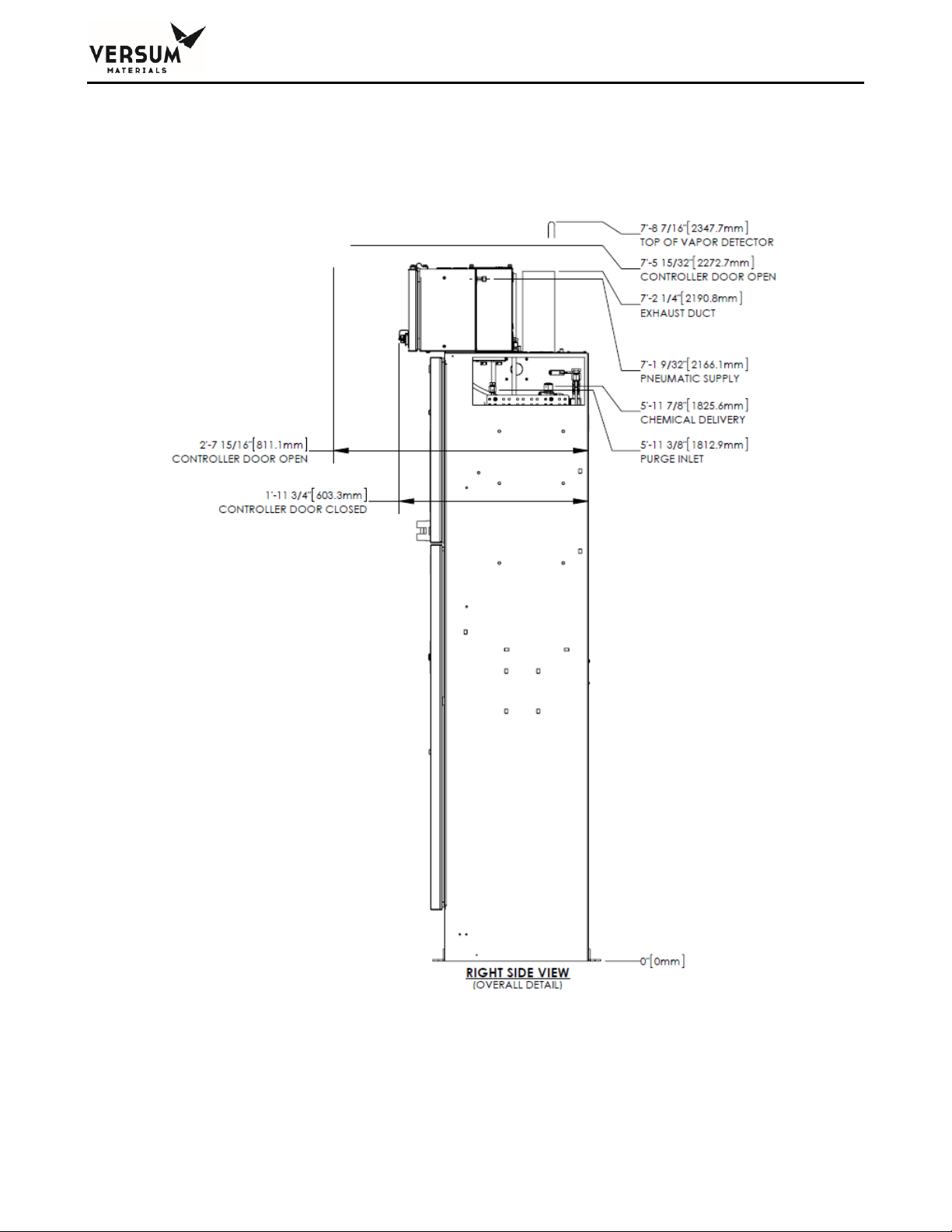

Figure 2-3:

CG050 GEN III Cabinet Connections, Right Side View

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 7

Versum Materials Confidential

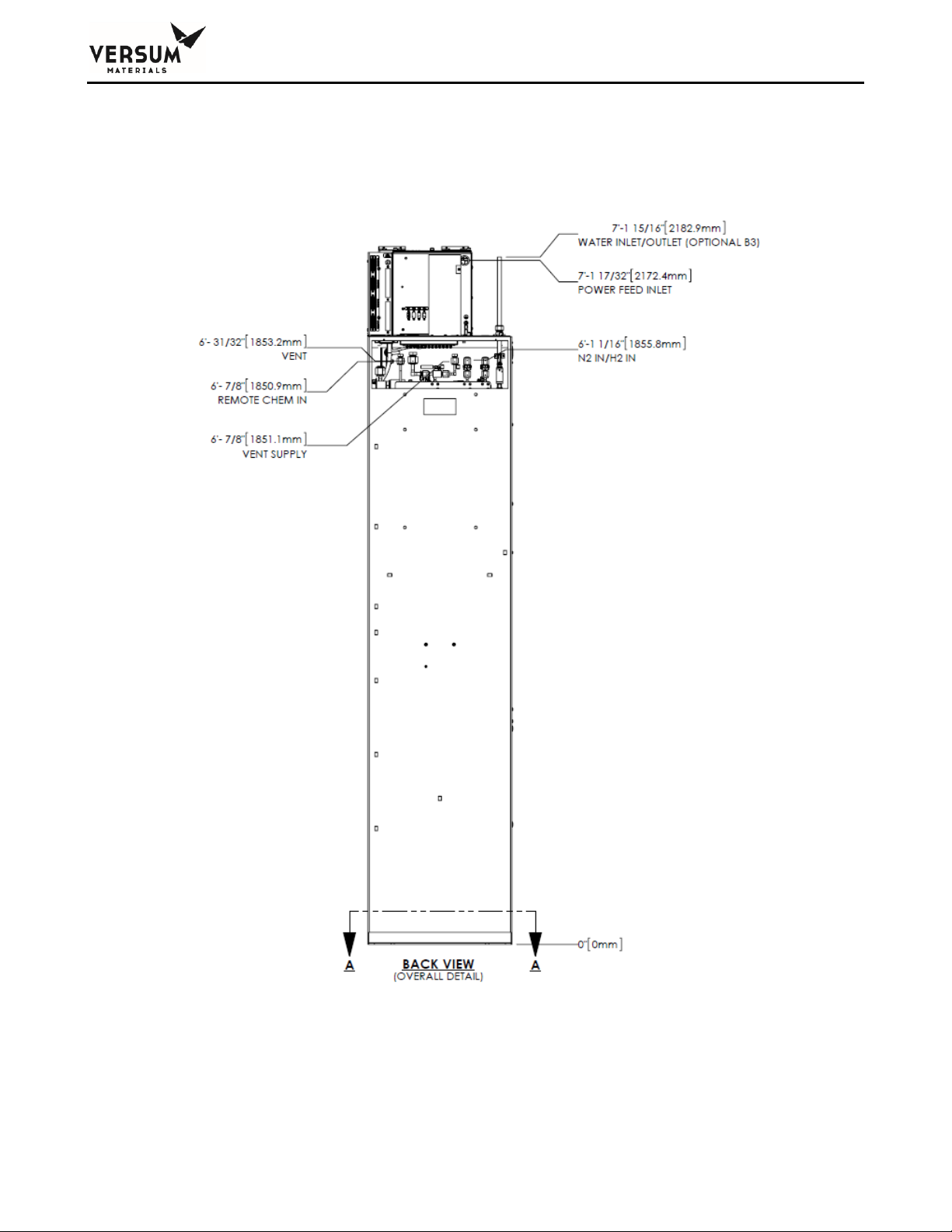

Figure 2-4:

CG050 GEN III Cabinet Connections, Back View

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 8

Versum Materials Confidential

2.2.1 Environmental Requirements

The customer is responsible for compliance with applicable environmental laws and

regulations, including local governing agencies and state/local laws (i.e. Clean Water Act,

Clean Air Act, Hazardous Waste Laws).

Table 2-2: Environmental Requirements

CONDITION

RANGE

Environmental

Operating Temperature: 0ºC to 40ºC

Humidity: 5% to 95% RH, non-condensing

Temperature must be compatible with chemical used.

Lighting

Minimum of 300 lux of illumination

2.2.2 Electrical Requirements

Versum Materials, Inc. recommends connection to an Uninterrupted Power Supply (UPS) and

a Ground-Fault circuit Interrupter (GFCI). Versum Materials, Inc. recommends that customer

electrically ground the ChemGuard® CG050 cabinet and plumbing.

SEMI S2 requires a lockout type circuit breaker setup for the AC power. OSHA standards

require customer to install lockout-type, 10K interrupt current (AIC) circuit breaker for AC

power. Recommend placement of breaker 1 – 10 meters (3 – 32 ft.) from BCD.

Per SEMI S2 requirements, all electrical work for ChemGuard® CG050 GEN III is Type 1 and

Type 2.

Type 1 = Equipment fully de-energized

Type 2 = Equipment is energized

S2 requires a lockout type circuit breaker setup for the AC power.

WARNING:

Live circuits are covered and/or insulated, Lockout / Tagout is required while work is performed at a remote

location to preclude accidental shock.

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 9

Versum Materials Confidential

Table 2-3: Electrical Requirements

CONDITION

RANGE

AC Power

100 - 240 VAC, 100 W @ 50 - 60 Hz; Single-Phase, 3 wires;

Neutral solidly grounded

125 VAC, 1000 W @ 50 - 60 Hz; Single-Phase, 3 wires;

Neutral solidly grounded, with Degasser Vacuum Pump option

2.2.3 Process Tool Interface and Life Safety Interconnect

The external interface cable hookup between ChemGuard® CG050 product line and OEM

Tool or Site Area Monitor System is customer responsibility. It is recommended to use multiconductors shield cable with twisted pairs, 22-20 AWG, 7x30 stranded, rated 300-600V RMS,

minimum 7-10 pairs (14-20 conductors) per interface.

Table 2-4: Digital I/O

DIGITAL INPUTS

DIGITAL OUTPUTS

Input current, On

4.07 mA min.5.3 mA

max.

Resistive

Load

1.0 A @ 30 VDC,

0.5 A @ 120 VDC

Input voltage, On

24.0 VDC ±20%

Switching

Power

30 W max.

Input current, Off

100 µA max.

Contact

material

Silver alloy, goldetched clad

Input voltage, Off

1.0 VDC max.

Protection

36V Zener

2.2.4 Supply Gases

The customer is required to supply all gases, filters, check-valves, and regulators. Ensure

that the required gases are available in close proximity to the ChemGuard® CG050

installation site. (see Chapter 3 for further details).

Ensure there are shutoff valves and filters for gas lines feeding the ChemGuard® CG050.

Ensure the correct gases are used for the process chemical and the properties of the gas are

correct for the process chemical (i.e. dry N2). (See Table 2-5).

To reduce the potential of flow fluctuations, the end-user must properly design the facilities

for the ChemGuard® CG050, i.e. incoming gas supplies and chemical delivery line layouts

with adequate line size, vertical rise, horizontal length between the ChemGuard® CG050 and

the process tool(s).

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 10

Versum Materials Confidential

To avoid potential process failures here are some guidelines the end users should consider

when facilitate ChemGuard® CG050 cabinets at central location.

• ChemGuard® CG050 cabinets centrally located and within close proximity to the

process tool (s) to minimize the vertical and horizontal length of the chemical delivery

lines.

• The incoming main gas supply to multiple ChemGuard® CG050 cabinets should be

properly sized to provide adequate pressure and flow before branching out to multiple

ChemGuard® CG050 cabinet connection points.

• After the main gas supply has been branched off to the individual ChemGuard®

CG050 cabinets, Individual gas supply lines are equipped with individual regulators,

check valves and isolation valves which have been properly sized to meet the

pressure and flow requirements of the process tool (s).

A gas filter is required on the houseline supplying the ChemGuard® CG050 push gas.

Failure to install a filter will void regulator and valve warranty if failed component found to

have particles embedded on the seat. See Addendum B for recommended setup.

Minimum filter specifications:

• Filter = 0.003 micron.

• Flow = 50 slpm.

• Material = Electropolished 316L Stainless Steel.

• Membrane = 316L Stainless Steel or PTFE.

• Leak Tested = 100% Helium leak tested to 5x10-9 atm cc/sec (3.8x10-9 Torr L/sec).

WARNING:

DO NOT deliver process/purge gases from a high pressure gas cylinder source. The supply gases must be

delivered from the house line gas source regulated to no more than 120 psig with flow not greater than

250 slpm.

A pneumatic supply of inert gas without oxygen is recommended for the controller. It is

strongly advised to not use clean dry air for pneumatic supply. The pneumatic supply may be

shared in the controller between the pneumatic solenoids and the enclosure

inerting/pressurizing service (Z-purge). Based on results from DC power harness testing,

clean dry air may promote the corrosion of electrical connectors for interconnecting power

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 11

Versum Materials Confidential

cables. The presence of oxygen enhances the corrosion effect and may result in deterioration

of controller performance.

Table 2-5: Supply Gases

H2 IN:

Process Supply

Gas

Hydrogen gas is Ultra High Pure semiconductor-grade recommended. Water

content < 10 ppb and O2 content < 2ppm.

Recommended to use Inert Gas Purifier model # SS2500KFI4RR or equivalent.

Required to install a 0.003 micron gas filter.

Regulated to 620 70 kPa (90 10 psig, 105 psiA)

Cabinet 6.35 mm ( ¼ in.) male VCR connection

Connects to H2 IN port (See Figure 2-2)

For moisture sensitive chemicals, gas requirements are as follows:

Recommended the Water content < 10 ppb and O2 content < 2ppm.

The customer is required to supply all gases with shut-off valves, regulators,

check-valves, filters and/or gas purifier in-line feeding the ChemGuard. Ensure

the required gases are available in close proximity to the ChemGuard installation

site.

WARNING: DO NOT connect high pressure gas cylinder directly to the cabinet

process/purge gas ports.

N2 IN:

Process Purge

Supply Gas

Nitrogen gas is Ultra High Pure semiconductor-grade recommended. Water

content < 10 ppb and O2 content < 2ppm.

Recommended to use Inert Gas Purifier model # SS2500KFI4RR or equivalent.

Required to install a 0.003 micron gas filter.

Install regulator at N2 IN supply port and regulate to 620 70 kPa (90 10 psig,

105 psiA)

Cabinet 6.35 mm ( ¼ in.) male VCR connection

Connects to N2 IN port (See Figure 2-2)

For moisture sensitive chemicals, gas requirements are as follows:

Recommended the Water content < 10 ppb and O2 content < 2ppm.

The customer is required to supply all gases with shut-off valves, regulators,

check-valves, filters and/or gas purifier in-line feeding the ChemGuard. Ensure

the required gases are available in close proximity to the ChemGuard installation

site.

WARNING: DO NOT connect high pressure gas cylinder directly to the cabinet

process/purge gas ports.

80 PSI 60 SLPM:

Venturi Vacuum

Supply Gas

Recommended teeing off the N2 Process Purge Gas Supply, see specifications

above

Install regulator at 80 PSI 60 SLPM supply port and regulate to 551 kPa (80 psig,

95 psiA) at 60 liters per minute

Cabinet 6.35 mm ( ¼ in.) female VCR connection

Connect to 80 PSI 60 SLPM port (See Figure 2-2)

NOTE: N2 @ 551 kPA results in 100 Torr vacuum with a, minimum 9.4 mm

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 12

Versum Materials Confidential

(3/8 in.) vent line

The customer is required to supply all gases with shut-off valves, regulators,

check-valves, filters and/or gas purifier in-line feeding the ChemGuard. Ensure

the required gases are available in close proximity to the ChemGuard installation

site.

SAMPLE

OUT/PURGE IN:

Purge Gas for

Outlet Manifold

Recommended teeing off the N2 Process Purge Gas Supply, see specifications

above

Install regulator at SAMPLE OUT/PURGE IN port and regulate to 140-275 kPa

(20-40 psig)

Cabinet 6.35 mm (¼ in.) female VCR connection

Connects to SAMPLE OUT/PURGE IN port (See Figure 2-2)

The customer is required to supply all gases with shut-off valves, regulators,

check-valves, filters and/or gas purifier in-line feeding the ChemGuard. Ensure

the required gases are available in close proximity to the ChemGuard installation

site.

NOTE: The Output Manifold allows the cabinet to feed the gas mixture to the

process tool as well as a sample/purge IN port simultaneously. Manual

sample/purge port is also available. The house line can be plumb and ready to

use by opening either of the manual valves

PNEUMATIC

SUPPLY

Nitrogen gas is semiconductor-grade or better is recommended.

Regulated to 620 70 kPa (90 10 psig)

Cabinet 6.35 mm ( ¼ in.) Swagelok connection

Connects to PNEUMATIC port, coarse filter recommended (See Figure 3-2)

A pneumatic supply of inert gas without oxygen is recommended for our

controllers. It is strongly advised to not use clean dry air for pneumatic

supply. The pneumatic supply may be shared in the controller between the

pneumatic solenoids and the enclosure inerting/pressurizing service (Z-purge).

Based on results from DC power harness testing, clean dry air may promote the

corrosion of electrical connectors for interconnecting power cables. The presence

of oxygen enhances the corrosion effect and may result in deterioration of

controller performance.

The customer is required to supply all gases with shut-off valves, regulators,

check-valves, filters and/or gas purifier in-line feeding the ChemGuard. Ensure

the required gases are available in close proximity to the ChemGuard installation

site.

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 13

Versum Materials Confidential

2.2.5 Exhaust and Vent Requirements

NOTE: Vent line can be installed to the facility exhaust if exhaust is connected to the

appropriate abatement system for the chemical used. Versum Materials, Inc.

recommends facility exhaust controls/abatement in lieu of on-board (localized)

controls/abatement system.

The reservoir vent function allows removal of pressure from the Reservoir Container. The

vent should be connected to the appropriate abatement system for chemical used. Ventilation

measurements should be made at a distance of four (4) duct diameters from the cabinet.

Versum Materials, Inc. recommends that ducting be made from zinc-plated steel, with

operation at static pressure of 0.7 in. of water.

NOTE: If your installation has the combustible, lower explosion limit (LEL) vapor-detector

option, see facilities requirements and Appendix F.

WARNING: Venturi exhaust

contains chemical vapor. Exhaust

must be connected to the

appropriate abatement system for

chemical used.

WARNUNG: Die Abgase

enthalten chemische Dämpfe.

Pumpenabgase müssen über ein

für das jeweilig Chemikal

geeignetes Abgassystem

abgeführt warden.

AVERTISSEMENT: Le tuyau

d’échappement de la pompe

contient des vapeurs chimiques.

Le tuyau d’échappement doit être

connecté à un système de

réduction adéquat au produit

chimique utilize

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 14

Versum Materials Confidential

Table 2-6: Exhaust and Vent Requirements

EXHAUST

101.6 mm (4 in.) diameter circular duct

Cabinet Exhaust Flow/Pressure Set Point: 850 Liter/minute (30 CFM) minimum

recommended

Connect to the appropriate abatement system for chemical used.

It is recommended to install the Exhaust line perpendicular and/or above the main

abatement duct. DO NOT ENTER BELOW THE MAIN ABATEMENT DUCT TO AVOID

LIQUID TRAP

VENT:

Venturi

Vacuum

Exhaust

Connect to the appropriate abatement system for chemical used

Cabinet 12.70 mm (½ in.) female VCR connection

Connects to VENT port (See Figure 2-2)

Vent line is to be connected directly to the main abatement duct and not the

ChemGuard exhaust duct.

It is recommended to install the Vent line perpendicular and/or above the main

abatement duct. DO NOT ENTER BELOW THE MAIN ABATEMENT DUCT TO AVOID

LIQUID TRAP

2.2.6 Chemical Vapor Delivery Line Requirements

The end user must have knowledge of process flow requirements, prepare flow calculations

for sufficient flow and have a carefully designed layout plan for the installation of the

ChemGuard® CG050 cabinet – preferably at a central location where the facilities will meet the

process tool requirements. Proper facilitation and installation will reduce and avoid potential

failures, tool downtime and rework costs.

Chemical delivery line to each process tool(s) should be designed and install with minimum

distance in vertical rise (height) and horizontal length between ChemGuard® CG050 cabinet

and the process tool (s) to meet process operating pressure and flow rate required of the

process tool (s). Refer to Chemical Delivery Line Requirements Postion paper _ DOC000140

NOTE: All chemical delivery line requirements are the customer’s responsibility. Versum

Materials, Inc. recommends installing coaxial Chemical Delivery Lines. Versum

Materials, Inc. recommends customer install a lockable shutoff valve on the

chemical delivery line, to comply with OSHA lockout/tagout requirements.

The customer provides the chemical delivery line. All bends should meet SEMATECH

standards for bend radius.

The chemical line should be helium leak-checked, purged, cleaned and certified prior to

installing and chemical introduction.

The chemical delivery line is connected to the chemical output manifold and is then directed

to the Process Tool’s chemical input manifold.

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 15

Versum Materials Confidential

Table 2-7: Chemical Delivery Line Requirements

CHEMICAL

DELIVERY

#1:

Vapor Flow

out to Tool

6.35 mm (¼ in.) male VCR connection

316L stainless steel, electro-polished line.

Connects to Chem Delivery #1 port (See Figure 2-2)

Bends should meet SEMATECH standards for bend radius. Versum Materials, Inc.

recommends inside electro-polish rating 10RA maximum.

Chemical Line should be Helium leak-checked, purged, and cleaned before installing

ChemGuard.

Optional Outer Coaxial Line (if required by customer or local regulations): 12.7 mm (½

in.) stainless steel.

Optional

Outer Coaxial

Line

Optional Outer Coaxial Line (if required by customer or local regulations): 12.7 mm (½ in.)

stainless steel.

Bends should meet SEMATECH standards for bend radius.

Specification for Outer Lines

• Stainless steel line

• The line should be welded

• Sharp edges should be removed and de-burred at breaks in the line to prevent stainless

steel inner line from being scratched or torn when routing through the outer line.

2.2.7 Installing the Optional Coaxial Chemical Delivery Lines

The Optional Coaxial Chemical Delivery Lines comprised of:

• Outer line, 12.7 mm (1/2 in.) stainless steel line.

• Inner line, 6.35 mm (1/4 in.) stainless steel line.

Specification for outer lines

• Stainless steel line

• The line should be welded

• Sharp edges should be removed and de-burred at breaks in the line to prevent

stainless steel inner line from being scratched or torn when routing through the outer

line.

2.2.8 Chemical Bulk Refill Line (from BCD200, CG010 or CG310)

The chemical refill line is an additional line, routed on top of the ChemGuard® CG050. It

allows the BULK reservoir container to be filled from an external source (i.e., ChemGuard®

BCD200, CG010 or CG310 cabinet).

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 16

Versum Materials Confidential

Table 2-8: Chemical Bulk Refill Line Requirements

REMOTE

CHEM IN:

Chemical

Bulk Refill

Line from

the

BCD200,

CG010 or

CG310

6.35 mm (¼ in.) female VCR connection

316L stainless steel, electro-polished line

Connects to REMOTE CHEM IN port (See Figure 2-2)

Bends should meet SEMATECH standards for bend radius. Versum Materials, Inc.

recommends inside electro-polish rating 10RA maximum.

Chemical Refill Line should be Helium leak-checked, purged, and cleaned before

installing ChemGuard.

Optional Outer Coaxial Line (if required by customer or local regulations): 12.7 mm (½

in.) stainless steel.

2.2.9 Sample/Purge Output Manifold

The Output Manifold allows the cabinet to feed the gas mixture to the process tool as well as

a sample/purge port simultaneously. Manual sample/purge port is also available. The house

line can be plumb and ready to use by opening either of the manual valves.

2.2.10 Coolant Supply/Return (optional)

The ChemGuard® CG050 is configured with a standard coolant supply and return lines with

overpressure protection, shutoff, and drain capability built into the cabinet. The temperature

of the bubbler is typically maintained at 18° C.

Table 2-9: Coolant Supply/Return Requirements

COOLANT

SUPPLY /

RETURN

Cabinet 12.70 mm (1/2 in.) Female NPT connection (See Figure 2-2)

Flow: 7.6 liters per minute (2 US gpm)

Pressure: Up to 2.75 barg (40 psig)

2.3 Tag and Lockout Routine

When performing certain maintenance procedures described in this manual, electrical power

to the ChemGuard® CG050 must be de-energized, using site lockout/tag out procedures.

Consult your company’s safety procedures for tagging and lockout instructions to be followed

when performing such maintenance.

It is the customer’s responsibility to ensure compliance with local electrical regulations

external to the equipment.

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 17

Versum Materials Confidential

Sequence of Lockout or Tagout System Procedure

1. Notify all affected employees that a lockout or tagout system is going to be utilized and

the reason therefore. The authorized employee shall know the type and magnitude of

energy that the machine or equipment utilizes and shall understand the hazards thereof.

2. If the machine or equipment is operating, shut it down by the normal stopping procedure

(depress stop button, open toggle switch, etc.).

3. Operate the switch, valve, or other energy isolating device(s) so that the equipment is

isolated from its energy source(s). Stored energy (such as that in springs, elevated

machine members, rotating flywheels, hydraulic systems, and air, gas, steam or water

pressure, etc.) must be dissipated or restrained by methods such as repositioning,

blocking, bleeding down, etc. (Type(s) of stored energy methods to dissipate or

restrain).

4. Lockout and/or tagout the energy isolating devices with assigned individual lock(s) or

tag(s) (Method(s) selected, i.e., locks, tags, additional safety measures, etc.)

5. After ensuring that no personnel are exposed, and as a check on having disconnected

the energy sources, operate the push button or other normal operating controls to make

certain the equipment will not operate (Type(s) of equipment checked to ensure

disconnections).

CAUTION

Return operating control(s) to neutral or off position after the test.

6. The equipment is now locked or tagged out.

2.4 Spill Cleanup Routine

In dealing with chemical spills/mitigating releases, always use proper personal protective

equipment, including gloves, face and eye protection, respirators, and protective clothing.

Due to various factors in each spill incident, it has been determined unsafe to provide generic

spill instructions for each type of chemical delivered by ChemGuard® CG050 cabinets. For

example, two spills of the same type of chemical could have two different spill procedures.

Therefore, in the event of a spill, we recommend immediately contacting your chemical

provider for specific chemical spill recommendations and environmental regulatory

Chapter 2 - Site Preparation

_______________________________________________________________________________________________________________

MNL000623.doc Revision 0 06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 2 - 18

Versum Materials Confidential

information. It is the responsibility of the customer to follow their EH&S procedures for

hazardous material cleanup.

In addition, consult your company’s environmental hazard/safety procedures for specific

instructions to be followed in the event of a chemical spill from ChemGuard® CG050 GEN III.

Chapter 3 - Installation

MNL000624.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 3 - 1

Versum Materials Confidential

Chapter 3

Installation

Section 1 Introduction

Section 2 Reference Documents

Section 3 Installation

Section 4 Installing the ChemGuard® CG050 Cabinet

Section 5 Connecting ChemGuard® Gas Lines

Section 6 Chemical Delivery Line Requirements

Section 7 Installing ChemGuard® Bulk Scale

Section 8 Communications

Section 9 Start-Up and Initialization

Section 10 System Configuration

Section 11 Manual Mode

Section 12 Regulator Adjustment

Section 13 Finishing the ChemGuard® Installation

Chapter 3 - Installation

MNL000624.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 3 - 2

Versum Materials Confidential

NOTE: Maintenance personnel shall make use of a step stool or small

ladder to safely access the ChemGuard® GEN III controller. Operating personnel

shall make use of a step stool to access the touch screen monitor as required.

3.1 Introduction

This chapter describes the installation of ChemGuard® CG050 GEN III cabinet.

Because each customer application may vary, these instructions are provided as a

guideline and should not be considered as comprehensive.

Please do not begin installing the ChemGuard® unless trained individuals are

present.

The ChemGuard® CG050 comes pre-calibrated and cabinet-tested. The

ChemGuard® Bulk Scale, dual float spill detector, combustible vapor detector

(option) and UVIR (option) are setup prior to leaving the factory. These items

should not require calibration during installation. Please contact Versum Materials,

Inc. if any of these components do not function properly.

NOTE: When highly flammable chemicals are used and present within

the equipment you must:

• Ensure the all connections made to the cabinet are leak tight.

• Use an inert gas purge to dilute the concentration of highly

flammable vapors in the exhaust header to which the vent

piping is connected.

• Use an inert gas purge to the vacuum pump gas ballast

connection.

3.2 Reference Documents

For Installation and P&ID system drawings, facilities inspection, pre-startup and

commissioning procedure and check-off/sign-off lists refer to;

• SW017054_Installation Drawing

• DOC000191 for the ChemGuard® CG050 GEN III P&ID Drawings

• V-TSA060_ChemGuard® Chemical Fill Matrix

Chapter 3 - Installation

MNL000624.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 3 - 3

Versum Materials Confidential

3.3 Installation

3.3.1 Pre-installation

This chapter describes items that should be identified and resolved prior to

installing ChemGuard®.

The end user must have knowledge of process flow requirements, prepare flow

calculations for sufficient flow and have a carefully designed layout plan for the

installation of the ChemGuard® cabinet – preferably at a central location where

the facilities will meet the process tool requirements. Proper facilitation and

installation will reduce and avoid potential failures, tool downtime and rework

costs.

Chemical delivery line to each process tool(s) should be designed and install with

minimum distance in vertical rise (height) and horizontal length between

ChemGuard® cabinet and the process tool (s) to meet process operating pressure

and flow rate required of the process tool (s).

• The maximum range that a standard ChemGuard® can deliver chemical is

dependent on the chemical and the pressure of the push gas. Contact

Versum Materials, Inc. for any specific delivery requirements beyond 250

meters of horizontal run and 10 meters of vertical run. These distances

could be increased contingent on bends and valve count in the system.

• Install ChemGuard® using the earthquake bolt down points. Verify that the

location has the stability and strength to permit the installation of support

bolts.

• Verify AC power is available for ChemGuard®. Power requirements are

described in Chapter 2.

• Verify all required gases are delivered to an area near the final position of

ChemGuard®. Refer to Chapter 2.

NOTE: All chemical delivery line requirements are the customer’s

responsibility.

• Gases required for ChemGuard® cabinet operation are described in

Chapter 2.

• The ChemGuard® CG050 GEN III cabinet uses venturi vacuum as the

vacuum source so no vacuum pump is required. The vapor pressure of the

chemical used in the ChemGuard® CG050 GEN III cabinet is high enough

Chapter 3 - Installation

MNL000624.doc Revision 0

06/25/2019

Chemical Equipment

© Versum Materials US, LLC. as of the revision and date shown. All rights reserved.

Confidential and Proprietary Data

Page 3 - 4

Versum Materials Confidential

for the venturi vacuum to completely remove all chemical vapors from the

lines during maintenance operations.

• The ChemGuard® requires an exhaust flow of 30 CFM. In addition to

cabinet exhaust, ChemGuard® contains a reservoir vent function that

permits the removal of pressure from the reservoir container. This vent

should be connected to the appropriate abatement system for the chemical

used.

• Coaxial chemical delivery lines are recommended for all process chemicals.

In the event that a leak or rupture occurs in the main delivery line, the liquid

will be contained and be prevented from entering the environment.

• The liquid from any leak will be contained in the ChemGuard® cabinet and

be detected by the spill detector, and container then relieved to prevent any

further spillage.

3.3.2 Available Configurations

The ChemGuard® CG050 GEN III cabinet is used in an epitaxial process.

Hydrogen gas is “bubbled” thru an onboard container typically containing

Trichlorosilane, (TCS) and vapor is then delivered to a Process Tool. This

application is limited to one ChemGuard® per tool or chamber.

3.4 Installing the ChemGuard® CG050 Cabinet

Verify that the cabinet is in a level location with enough clearance around it so that

its doors can be fully opened and so that it can be serviced easily.

Set the ChemGuard® cabinet over the bolt-down points and attach securely.

Per current United States UBC and SEMI requirements, floor bolts must be at

least Grade 5 (metric Grade 8.8), at a recommended minimum length of 2.5 in.

(6.35 cm).

The ChemGuard® must be grounded in accordance with Article 250 - Grounding,

The National Electrical Code 1993. See Figure 2-1 for the location of the

grounding lug. Versum Materials, Inc. recommends a ground resistance of <1

Ohms.

3.4.1 Electrical Connections

Versum Materials, Inc. recommends that the customer electrically ground

ChemGuard® cabinet and plumbing. OSHA standards require customer to install

lockout-type circuit breaker for AC power. Per SEMI S2-93A requirements, all

electrical work for ChemGuard® GEN III is Type 1 and Type 2.

Loading...

Loading...