®

VersaPulse® Select™

SERVICE MANUAL

This service manual is to be used in conjunction with the operator manual for the product. The

operator manual contains important information regarding instrument description, location of

controls, specifications, and normal operating procedures.

®

DANGER

VISIBLE AND INVISIBLE LASER RADIATION.

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION.

HOLMIUM:YAG LASER: 2.1 MICROMETERS

MAX OUTPUT 5 JOULES 250 µs PULSE

Nd:YAG LASER: 1.06 MICROMETERS

MAX. OUTPUT 2 JOULE 350 µs PULSE

DIODE LASER: 650 NANOMETERS

MAX OUTPUT 5 MILLIWATTS

CLASS IV LASER PRODUCT

Santa Clara, CA 95051

DANGER

®

2400 Condensa Street

(408) 764-3000

VISIBLE AND INVISIBLE LASER RADIATION.

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION.

HOLMIUM:YAG LASER: 2.1 MICROMETERS

MAX OUTPUT 5 JOULES 250 µs PULSE

DIODE LASER: 650 NANOM ETERS

MAX OUTPUT 5 MILLIWATTS

CLASS IV LA SER PRODUCT

®

0621-499-01

DEC. 95

®

®

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual cannot be copied

in whole or part without the express written permission of Coherent, Inc. Permitted copies must carry the

same proprietary and copyright notices as were affixed to the original.

Please note that while every effort has been made to ensure that the data given is accurate, the information,

figures, illustrations, tables, specifications, and schematics are subject to change without notice.

Coherent and the Coherent Logo are registered trademarks of Coherent, Inc.

Please direct all inquiries about this manual to:

Coherent, Inc.

Technical Support B-35

2400 Condensa Street

Santa Clara, CA 95051

(408) 764-3638

© Coherent, Inc 01/94, 07/94, 08/95, 10/95, 12/95

0621-499-01

®

DISCLAIMER

Coherent service manuals are written specifically for use by Coherent service engineers who have received

formal training in the servicing of Coherent equipment, and by customers who have taken and passed a

Coherent certification service training course for the equipment being serviced. Information on certification

service training courses offered to customers can be obtained by contacting the Technical Training Coordinator at 800-367-7899.

Coherent does not accept responsibility for personal injury or property damage resulting from the servicing

of Coherent equipment by its customers or by third parties, except where such injury or property damage is a

direct result of Coherent's negligence. Customers, by accepting the service manual, agree to indemnify

Coherent against any claims alleging personal injury or property damage resulting from the servicing of

Coherent equipment by the customer or by third parties, except where such injury or property damage is a

direct result of Coherent's negligence. These limitations include situations where Coherent personnel are

advising customers on the repair of Coherent equipment over the telephone.

The servicing of Coherent equipment by persons who have not passed a current Coherent certification

service training course for that equipment will void Coherent's product warranty.

®

VersaPulse Select Service Manual Disclaimer 0621-499-01 12/95

®

®

REVISION INFORMATION

This is the DEC '95 release of the Versapulse Select Service Manual. Contact Coherent Medical Group Technical Support to determine if this is the most current release of this service manual.

Each page of this manual has a MM/YY date at the bottom. This indicates the release date for the individual

page. Note that when the manual is updated, not all of the pages are necessarily updated, so some pages

may have a MM/YY earlier than the release date for the manual (the release date for the manual is the MM/

YY that appears on the cover and in the first sentence of this revision information page). The following list

provides a complete list of the release date information, by section, for this release of the service manual.

Cover page, copyright page, disclaimer page, this page, table of contents page or pages are all dated with the

release date of the manual (12/95).

SECTION 1 Pages 1-1, 01/94

Pages 1-2, 12/95

SECTION 2 Pages 2-1,4,6 12/95. All other pages 03/94.

SECTION 3 Pages 3-1 thru 3-10 12/95. All other pages, 03/94.

SECTION 4 Pages 4-4 Thru 4-17, 4-22 Thru 4-30, 12/95.

All other pages, 01/94

SECTION 5 All pages, 12/95

SECTION 6 All pages, 12/95

SECTION 7 FSB's released for this service manual are listed in the Versapulse Select FSB

Index. Each time an FSB for this manual is released or updated the Index is

also updated and distributed with the FSB. The current Index is placed

behind the single sheet that makes up Section 7, and the FSB's are placed in

order behind the Index. Contact Coherent Medical Group Technical Support

for the date of the most current FSB Index.

SECTION 8 Page 8-1,12, 10/95

Pages 8-2 thru 8-11, 8-13 thru 8-18, 01/94

Pages 8-19 thru 8-30, 08/95

.

VersaPulse Select Service Manual Revision Information 0621-499-01 12/95

®

Table Of Contents

DISCLAIMER .................................................................................................................................................. 3

REVISION INFORMATION ........................................................................................................................ 4

1.0 GENERAL INFORMATION ............................................................................................................... 1

1.1 USE OF THIS MANUAL .......................................................................................................................1

1.2 CONVENTIONS USED IN THIS MANUAL.......................................................................................1

1.3 SERIAL NUMBERS ............................................................................................................................... 2

2.0 INSTALLATION ....................................................................................................................................1

2.1 INSTALLATION INSTRUCTIONS......................................................................................................1

3.0 CALIBRATION & ADJUSTMENT ....................................................................................................1

3.1 OVERVIEW............................................................................................................................................ 1

3.1.1 Safety Precautions ..................................................................................................................................1

3.2 System Check Out .................................................................................................................................. 2

3.3 Energy Monitor and Automatic Laser Calibration..............................................................................5

3.4.1 Making Test Burns .................................................................................................................................. 7

3.4.2 Adjusting the YAG Channel Optics .......................................................................................................7

3.4.3 YAG Channel Check Out and Adjustment Procedure......................................................................... 8

3.5 AIMING BEAM ADJUSTMENT ........................................................................................................10

3.6 PERIODIC MAINTENANCE REQUIREMENTS............................................................................ 13

4.0 THEORY OF OPERATION.................................................................................................................. 1

4.1 INTRODUCTION ...................................................................................................................................1

4.1.1 Operational Overview ............................................................................................................................. 1

4.1.2 Functional Overview ...............................................................................................................................2

4.2 POWER SWITCHING, CONDITIONING, DISTRIBUTION .......................................................... 5

4.2.1 Input Power..............................................................................................................................................5

4.2.2 Circuit Breaker on, Keyswitch off .........................................................................................................5

4.2.3 Turn on ..................................................................................................................................................... 5

4.2.4 Shutdown..................................................................................................................................................6

4.2.5 Low Voltage Power Supplies................................................................................................................... 6

4.3 COOLING................................................................................................................................................7

4.4 CONTROL ELECTRONICS ................................................................................................................. 9

4.4.1 Overview...................................................................................................................................................9

4.4.2 Main Processor ...................................................................................................................................... 10

4.4.3 Shutter / Footswitch / Remote Interlock Circuits............................................................................... 11

4.4.4 Servo Motor Control Circuit ................................................................................................................ 13

4.4.5 HVPS & PFN Control Circuits ............................................................................................................14

4.4.6 Energy Monitor Circuits.......................................................................................................................17

4.4.7 Touch Screen & Remote Control Circuits ........................................................................................... 18

4.4.8 Aiming Diode Laser Circuit..................................................................................................................20

4.4.9 Fiber and Blast Shield Position Sense Circuits ...................................................................................21

4.4.10 Service Attenuator Circuit .................................................................................................................. 22

4.4.11 Coolant Temperature and Conductivity Monitoring Circuits.........................................................23

4.4.12 Low Energy Attenuator Circuit ......................................................................................................... 24

4.4.13 DC Power Supply Voltage Monitoring Circuits.................................................................................24

4.4.14 Safety Processor....................................................................................................................................25

4.5 FLASH LAMP POWER CIRCUITS.................................................................................................. 27

4.6 OPTICS .................................................................................................................................................27

4.7 SOFTWARE.......................................................................................................................................... 29

®

®

®

5.0 TROUBLESHOOTING ........................................................................................................................ 1

5.1 OVERVIEW............................................................................................................................................. 1

5.1.1 Service Philosophy..................................................................................................................................1

5.1.2 Safety Precautions ..................................................................................................................................2

5.2 INTERIOR ACCESS & PART LOCATIONS.....................................................................................3

5.3 SERVICE MODE ................................................................................................................................. 12

5.4 FAULT ISOLATION............................................................................................................................14

5.4.1 TURN-ON AND SHUTDOWN FAULT ISOLATION ...................................................................... 15

5.4.2 "NO FAULT CODE REPORTED" FAULT ISOLATION ...............................................................15

5.4.3 "FAULT CODE REPORTED" FAULT ISOLATION .....................................................................15

6.0 SELECTED PARTS ................................................................................................................................ 1

8.0 SCHEMATICS AND DRAWINGS .................................................................................................... 1

®

1.0 GENERAL INFORMATION

1.1 USE OF THIS MANUAL

This manual contains service instructions for the Coherent VersaPulse Select series of Holmium:YAG surgical

lasers. The content of this manual is intended solely for use by Coherent Medical Group Field Service Engineers

and Coherent trained and certified customer technicians. Coherent, Inc. can not be responsible for service or

repairs attempted by uncertified persons, and the use of this manual by such persons is prohibited.

This manual is to be in conjunction with the Coherent Operator Manual for the VersaPulse Select. The operator

manual contains important information regarding instrument description, location of controls, specifications,

and normal operating procedures.

®

As necessary, Coherent Medical Group Service Technical Support releases Field Service Bulletins for the

Versapulse Select series. These bulletins supplement the information in this manual. As they are released, the

bulletins become a part of this manual (Section 7).

1.2 CONVENTIONS USED IN THIS MANUAL

Within the text, logic signals that are active low ("notted") will appear inside of slash marks, as illustrated below.

/BRHOK/

These signals are "active", or true, when the logic level is low. When the logic signal /BRHOK/ is low, the BRH

loop is "OK" (complete). When the logic signal /BRHOK/ is high, the BRH loop is not OK (open).

In most of the schematic diagrams such signals are indicated by the more usual solid line above the signal name,

as illustrated below.

BRHOK

The schematics in this manual do not include individual numbers for the logic elements or operational amplifiers

within a single component. For example, U1 below contains two operational amplifiers. The top op amp would

be referred to as U1-1 ( its output is pin 1), and the other would be referred to as U1-7.

VersaPulse Select Service Manual

0621-499-01 01/94

GENERAL INFORMATION

1-1

®

®

2

U1

3

6

U1

5

1.3 SERIAL NUMBERS

Serial numbers for the Versapulse Select are in the format,

MYPHWVXXXX

1

7

where M is the month produced

Y is the last digit of the year produced

P is a number indicating maximum system power

H is the number of laser heads installed (1, 2, 3, or 4)

W is a number indicating the mix of rods installed

V is a number indicating power supply configuration

XXXX is the number of the laser built

W: 1= Holmium only

2= Erbium only

3= Nd:Yag only

5= Nd/Ho combo

(a is January, b is February, etc..)

(4 is 1994., etc..)

(6=60w, 4=45w, 3=30w)

(See Below)

(1= 208VAC single phase)

(0001, 0002, etc..)

GENERAL INFORMATION

1-2

VersaPulse Select Service Manual

0621-499-01 12/95

®

2.0 INSTALLATION

2.1 INSTALLATION INSTRUCTIONS

These installation instructions are provided for use by Coherent Service Engineers who have completed

certification service training on the VersaPulse Select. Installation by untrained persons is a potential hazard

to the person or persons doing the installation, others present, and to the equipment itself. In addition,

improper installation is a potential hazard to the user, persons present during use, and patient.

Perform the following steps to install a VersaPulse Select system.

®

1. Check for proper site set up. This includes proper AC service and adequate space for the console.

AC power configuration: The VersaPulse Select requires 220 VAC ±10%, 50/60 Hz, 30 amp single

phase electrical service. The power cord is a 26 foot cable with 3 conductors. A terminal board

behind the right side cover allows for tapping of the isolation transformer to the setting closest to the

incoming electrical service. The system can be hard wired to electrical service or installed to electrical

service with a plug and receptacle. The plug and receptacle are shipped in the site preparation kit.

Console dimensions and weight: The console measures 39" l x 18" w x39" h. It weighs approximately

325 lbs. A minimum of 18" of air space is required around the unit to provide adequate cooling air

circulation.

The system requires approximately 2.5 gallons of deionized water for its closed loop cooling system.

The coolant must be added as described in this procedure.

Complete specifications for the VersaPulse Select are included in the VersaPulse Select Operator

Manual. Contact Technical Support in Palo Alto, CA, if there are any questions concerning site

preparation.

2.) Check the crate/carton for any shipping damage.

VersaPulse Select Service Manual

0621-499-01 12/95

INSTALLATION

2-1

®

®

CARDBOARD TOP COVER

STRAP

WOODEN RAMPS

CARDBOARD SIDE COVER

STRAP

FOAM

Accessories

Removable

wooden ramp (2)

INSTALLATION

2-2

Front lifting bolts

(2, 3/4ths)

LIFTING BAR (2)

As the bolts turn, the lifting bar is raised or lowered. The system

ships with the lifting bar up. The bar must be lowered and removed,

then the system is rolled down the wooden ramps to remve it from

the crate base.

FIGURE 2.1 SHIPPING CRATE

WOODEN

BASE

Rear lifting bolts

(2, 5/8ths)

VersaPulse Select Service Manual

0621-499-01 12/95

03/94

The shipper is responsible for any damage to the system in shipment. If the crate/carton appears to

be damaged, report the damage to the customer and shipper.

3.) Remove the console and accessories from the crate.

Refer to drawing 2-1. Remove the straps, remove the top cover, remove the side cover, remove the

protective foam, remove the accessories box, then locate and remove the two wooden ramps stored in

the base. Lower the lift plates (2) by turning the bolt at each end of each lift plate (5/8" and 3/4"

bolts). Loosen the bolts all the way, then remove the bolts and lift plate. Remove the front fence from

the base by removing the four wing nuts that secure it to the base. Install the ramps onto the base,

then roll the unit down the ramps.

4.) Move the system to its installation location.

The VersaPulse Select rolls best when pushed from the front handles. The front wheels swivel, the

rears wheels do not.

6.) Open/remove covers and do a visual inspection of the interior.

®

®

Refer to Section 5 for information on removing the covers. Open the front cover, then remove the top

and two side covers. Inspect the interior carefully for loose or broken electrical connections, loose or

broken plumbing connections, or any indication of shipping damage.

7.) Set up for site AC.

Measure the voltage of the site electrical service at the point where the VersaPulse Select will be

connected. The three connections include an earth ground and two hot mains. Measure line voltage

across the two hot mains. Mains voltage must be between 200 and 240 VAC, 50/60 Hz. Confirm that

the circuit is rated for 30 amps.

The isolation transformer has two secondaries: one operates the turn-on circuitry and the other

provides AC to the low voltage power supply, display power supply, fan and pump. These

secondary loads (not the turn-on circuitry) are rated for 220 VAC supply input. The isolation

transformer is tapped to allow a range of AC line inputs ( 200 to 240 VAC) to be stepped up or down

to result in a secondary voltage at or near 220 VAC to these secondary loads. The various taps on the

isolation transformer are wired out to terminal board TB1 on the right side on the system. The

tapping is done by changing the connections at the terminal board.

POWER CORD

TB1

MAINS TO CIRCUIT BREAKER

VersaPulse Select Service Manual

0621-499-01 12/95

03/94

MAINS (from F1)

MAINS ( from F2)

120

120

100

100

ISOLATION

XFORMER

(primary)

EARTH GROUND TO

GROUNDING STUD

FIGURE 2-2 TB1 TAPPING

INSTALLATION

2-3

®

8.) Connect to AC service.

CAUTION: Once connected to site electrical service lethal voltages are present inside the unit. The

AC power is present at the circuit breaker, main contactor and isolation transformer. In addition, the

isolation transformer secondary outputs are hot. Review and understand the safety subtopic in

Section 5 before proceeding.

The system can be hard wired to electrical service, but is more typically connected by a plug to an

electrical outlet.

If the system is to be hard wired, the customer must provide an electrician to wire the cord end into

the electrical service outlet.

If the system is to be plugged into an electrical receptacle, the appropriate receptacle should already

be installed by the customer's electrician. The installing engineer connects the plug to the end of the

VersaPulse Select electrical cable.

9.) Add coolant.

®

Add coolant (deionized water) to the fill reservoir. The coolant will drain out of the fill reservoir and

into the main reservoir. The system uses approximately 2.5 gallons of coolant. Most of the coolant

can be added at this time - until the fill reservoir level stays up. The system coolant level will be

"topped off" after the system is turned on (in a later step).

9.) Initial power application.

CAUTION: Once the circuit breaker is turned on lethal voltages are present throughout the system.

With the side covers still removed, turn on the electrical service and turn on the circuit breaker on the

VersaPulse Select. Wait a few minutes, observing for any indication of failure of mains or turn-on

components.

10.) Initial turn on.

CAUTION:

• The system will fire during the turn-on sequence if SW3 (Autocal) on the CPU PCB is up

and the BRH plug is installed. Only those persons required should be present during this

portion of the installation

• The cooling fan blades are not covered. The fan is located on top of the heat exchanger. It

operates whenever the system is turned on. Keep tools, system parts and body parts clear of

the fan blades.

Turn the keyswitch to the START position, then release it to the ON position. The system will go

through its start up sequence. Observe for normal start up, and for any indication of leaks in the

cooling system.

INSTALLATION

2-4

VersaPulse Select Service Manual

0621-499-01 12/95

11.) Add coolant.

With the system turned on, top off the fill reservoir. Cycle the machine off and on several times,

adding coolant as necessary until the fill reservoir level stays up to approximately half full as the

system runs.

12.) Operational and Safety Checkout.

Attach a test fiber, remote interlock plug, and footswitch, then check system operation as follows:

a.) Footswitch, remote control (if included) and remote interlock plugs connect properly to jacks.

b.) Fiber attaches to the fiber port.

c.) Touch screen display matrix is operating properly.

d.) Touch screen inputs are functional.

®

®

e.) Remote control (if installed) display and input buttons are functional.

f.) Aiming beam responds to off, low, medium, and high settings.

CAUTION: The remaining operational tests include firing the system and attempts to fire the system

with one disabling condition. Select a low power setting and direct the test fiber output into a

calibrated power meter.

g.) Fire into the meter for several seconds, noting the power reading on the meter.

i.) Confirm that the total energy display value has incremented, then confirm that the value clears

back to zero when RESET is touched.

j.) Disconnect the footswitch and confirm that the "ATTACH FOOTSWITCH" message appears on the

display.

k.) Reconnect the footswitch, then disconnect the fiber and confirm that an "ATTACH FIBER"

message appears on the display. Depress the footswitch and confirm the system will not fire.

l.) Reconnect the fiber, then disconnect the remote interlock plug and confirm the " REMOTE

INTERLOCK" message appears on the display.

m.) Reconnect the remote interlock plug, then go to STANDBY. Depress the footswitch and confirm

the system will not fire.

n.) Pull the blast shield out, then confirm the "REPLACE BLAST SHIELD" message appears on the

display. Depress the footswitch and confirm the system will not fire.

o.) Reinsert the blast shield.

VersaPulse Select Service Manual

0621-499-01 12/95

03/94

INSTALLATION

2-5

®

®

13.) Confirm the power calibration.

Connect a good test fiber onto the fiber port and direct the fiber output towards the head of your

calibrated power meter, then, for each operating point, fire the system into the meter, confirming that

displayed power remains within ± 10% of the power indicated on the meter (typically, the power

calibration will be much more accurate than ±10%). If the power calibration is not better than ±10% at

all operating points, refer to Section 3 for instructions on system calibration.

14.) Check the fiber focus using a test fiber.

Two test fibers are shipped with the system. Check the fiber focus as described in Section 3, topic 3.2,

step 3.

15.) Replace all covers and prepare the system for demonstration to the customer.

16.) Demonstrate the system installation to the customer.

17.) (for U.S. Field Service) Fill out and mail the "self mailer" installation quality audit report.

INSTALLATION

2-6

VersaPulse Select Service Manual

0621-499-01 12/95

®

3.0 CALIBRATION & ADJUSTMENT

3.1 OVERVIEW

This section includes a System Checkout Procedure, Energy Monitor Calibration Procedure, a YAG Channel

Adjustment Procedure and an Aiming Beam Adjustment Procedure. The procedures assume the reader has

successfully completed a Coherent service training course on the Versapulse Select series.

The System Check Out, Topic 3.2, is an operational check of the system. It confirms that the system turns on

properly, responds properly to operator inputs, provides the full range of pulse energies and pulse rates, delivers

average power within ±10% of the displayed average power, delivers the multiplexed YAG beam into the center

on an attached fiber, and provides an adjustable aiming beam through the fiber. It also checks system coolant level

and consumables (i.e., air filter, DI filter and particulate filter).

®

The Energy Monitor Calibration Procedure, Topic 3.3, calibrates the voltage output of the three energy monitor

circuits to the field service engineer's calibrated power meter.

The YAG Channel Adjustment Procedure, Topic 3.4, is done when the System Check Out Procedure indicates

a problem with one or more of the YAG channels. It provides adjustment procedures for the channel cavities and

relay optics.

Aiming Beam Adjustment, Topic 3.5, provides information on adjusting the aiming beam optics to get the aiming

beam out through the fiber. See Section 6 for required tools.

3.1.1 Safety Precautions

Lethal voltages and laser emission are the primary dangers to the servicing engineer. In addition to the general

safety precautions which always apply when working on electronics and lasers, the servicing engineer must be

aware of the following specific precautions:

Only Coherent certified VersaPulse Select Service Engineers should attempt any service on this

system.

Even with the keyswitch and the breaker in the "OFF" position there are potentially lethal voltages

present inside the console. Always disconnect the main electrical service before working on the

console.

Versapulse Select Service Manual

0621-499-01 03/94

12/95

CAL & ADJUST

3-1

®

®

Storage capacitors inside the system are capable of holding a lethal charge, even after power has

been removed from the unit. A charge level indicator bulb located on the PFN PCB mounted across

the top of the main storage capacitor flashes at a rate proportional to the level of charge on the main

charging capacitor. Do not rely on this indicator to determine that the main charging capacitor has

been discharged. Before contacting the main charging capacitor, disconnect the system from primary

power and use a shorting probe to discharge the capacitor to ground.

Do not touch the YAG Cavity Module when the system is on - IT IS A SHOCK HAZARD. The

YAG Cavity Module is electrically isolated from the chassis and can be at a voltage potential much

higher than ground.

Whenever the footswitch is pressed a single pulse is fired immediately, before the shutter opens,

to dump any charge remaining on the charge capacitor. The laser cavity that fires is the one directly

opposite the one that the servo mirror is pointing towards. The energy is dependent upon how much

charge remains on the capacitor. Since the relay mirror is not directed towards the channel, the beam

will be directed away from the first turning mirror (usually towards the mounting screws for the

plano mirrors on the OC wall.

The Ho:YAG, Er:YAG and Nd:YAG laser light is invisible to the human eye. Because the YAG

laser energy can not be seen, there is no visible indication of the primary or reflected beam. Eye

protection that attenuates the Ho:YAG, Nd:YAG and Er:YAG wavelengths to a safe level must be

worn by all persons in the area of the laser system, whenever the laser is being serviced.

The YAG laser light and its reflections are potential burn hazards and can ignite flammable

materials. Use extreme caution when operating the system with covers opened or removed. The

covers contain the beam and reflections safely within the console. Only those persons required

should be present during servicing, and eye protection that safely attenuates the Ho:YAG, Nd:YAG

and Er:YAG wavelengths must be worn by all present.

The Ho:YAG, Er:YAG and Nd:YAG laser light and its reflections are potential hazards to the eye.

Use extreme caution when operating the system with the covers opened or removed. The covers

contain the beam and reflections safely within the console. Only those persons required should be

present during servicing and eye protection that safely attenuates the Ho:YAG, Er:YAG and Nd:YAG

wavelengths should be worn by all those present.

3.2 SYSTEM CHECK OUT

This system check out confirms that the laser is functioning properly.

1.) Open the front door and defeat the door interlock, then turn the system on and allow it to go through

autocalibration. After autocalibration is completed, place the system in service mode.

If the system fails to pass autocalibration, there is something wrong; continue on to step 2 to gather

more information about why the system failed autocalibration.

CAL & ADJUST

3-2

VersaPulse Select Service Manual

0621-499-01 03/94

12/95

2. Check rod calibration values.

Go to the second service screen and note the cap voltage values displayed for each of the four

channels at minimum (low point) and maximum (high point).

The HVPS maximum output is 1500 VDC, so each rod must be capable of making its

maximum pulse energy (high point) at less than 1500 VDC. Typical values at high point are

from 1280 to the low 1400's. Typical voltages for low point are in the 700 to 900 VDC range.

For Nd:YAG the typical values at high point are from 500 to 800 VDC, and typical low point

values are from 200 to 400 VDC.

As the rod temperature increases (during use), its output will tend to drop off for a given cap

voltage. The software compensates for this effect, so as the rod temperature increases, it is

normal to see the cap charge voltage required at a particular pulse energy increase. Since the

system goes through its autocalibration at turn on, when the rods tend to be cooler, the cap

charge voltages found during autocal will tend to be lower than those that might be required

during sustained, high duty cycle operation. Thus, a channel with a cap charge voltage in the

mid to high 1400's @ 2.8 Joules at turn on may require a cap charge voltage higher than the

HVPS can provide to make 2.8 Joules during operation.

®

®

If the system has failed to complete autocalibration or channel performance appears poor, perform

the YAG Channel Adjustments (Topic 3.4).

3. Inspect debris shield and clean/replace as required.

4. Check the power supply voltages, coolant temperature and coolant conductivity.

5. Check the fiber focus using a test fiber.

If the system passes autocalibration and channel performance appears normal (service screen min/

max cap charge values are good), check for proper alignment of the beam into the fiber. This is done

using a special test fiber (0621-675-01). The fiber proximal end is coated with a red ink (Berol 8800

red marker) that records an impression of the YAG beam footprint where it enters the end of the

fiber. The laser is fired into the test fiber, then the fiber end is examined using a hand held 100X

microscope. A good alignment will result in a "concentric" footprint, i.e., the footprint will be

approximately centered in the fiber core and be well away from the cladding that surrounds the fiber.

a.) Install a test fiber in the 100X fiber examination microscope and examine its surface to confirm that

it is unused.

b.) Install the test fiber at the fiber port, then turn on the system and go to service mode.

c.) Turn on all the rods, select 850 cap volts and a pulse rate of 20 Hz.

d.) Fire the laser for approximately one second.

Versapulse Select Service Manual

0621-499-01 03/94

12/95

CAL & ADJUST

3-3

®

®

e.) Remove the fiber and examine it in the microscope. The burn and cladding will be easily

visualized if the other end of the test fiber is pointed towards a light source. The burn should be

approximately centered in the fiber optic and be well away from contact with the fiber cladding, as

shown in the drawing below. If the system fails this check, perform the YAG Channel Adjustments

(Topic 3.4.).

Cladding

Core

Footprint

ACCEPTABLE

Examining the test fiber end with the 100x microscope - The footprint will not always be circular,

but it should be approximately centered in the fiber and away from contact with the cladding.

FIGURE 3.1 EXAMINING THE TEST FIBER BURN

* If spot size is large, check individual YAG channels for proper alignment. Spot size should be less

than 210 µm in diameter and no closer than 70 µm from the cladding.

6. Confirm the calibration

Once the system passes steps 1 through 3, attach an Infratome fiber (nonsterile fibers for service

purposes are available through Technical Support) to the fiber port and direct its output into a

calibrated power meter. Go to user mode and fire the system to confirm that the measured power (as

seen on the power meter) is within ±10% of displayed average power across the range of pulse

energies and pulse rates.

7. Check consumable parts. Replace as necessary.

NOT ACCEPTABLE

NOT ACCEPTABLE

Check/replace the air filter. The air filter is mounted on the bottom of the system, held in place by a

removable bracket. A dirty filter should be cleaned or replaced.

Replace the DI filter after 6 months of use, or when the system has coolant conductivity faults.

Check/replace the coolant particulate filter. Replace the filter when it is visibly discolored.

8. Perform functional and safety checks.

a.) Attach a fiber.

CAL & ADJUST

3-4

VersaPulse Select Service Manual

0621-499-01 03/94

12/95

®

b.) Confirm that the aiming beam is visible at the fiber output and that the aiming beam intensity

properly responds to touch screen intensity control.

c.) Place the system in STANDBY, then depress the footswitch. Confirm the system does not fire.

d.) Go to READY and fire the system a number of times, verifying that the system displays the

cumulative energy. Stop firing, then press "clear" and verify the counter returns to zero.

e.) Unplug the footswitch and verify the system goes to STANDBY and displays "Attach footswitch".

f.) Open the front door and verify the system shuts down. Defeat the interlock and confirm that the

system turns back on.

g.) Remove the fiber optic. Verify that the system goes to STANDBY and "Attach fiber" is displayed.

Replace the fiber optic and verify that the fault clears.

h.) Remove the blast shield. Verify that the system goes to STANDBY and "Install blast shield" is

displayed. Replace the fiber and confirm that the fault clears.

®

i.) Check the operation of the keyswitch. It should turn the system on, turn the system off, and only

be removable when the system is switched off.

j.) Confirm that the emergency off button shuts the system down.

3.3 ENERGY MONITOR AND AUTOMATIC LASER CALIBRATION

The energy monitor calibration adjusts the three energy monitor circuits to output 2.2 volts per Joule of energy

as measured on a calibrated power meter at the output of an attached fiber. The automatic laser calibration (also

referred to as "autocalibration" and "autocal") is run to allow the system to determine and store the capacitor

voltages required to provide the maximum and minimum pulse energies for each rod.

1. Set up.

Open the front door of the VersaPulse Select and defeat the door interlock. Connect a known good

test fiber to the fiber port and direct its output into a calibrated power meter. Connect an oscilloscope

probe to CPU PCB TP2 (ENERGYI).

2. Turn on the system and go to service mode.

3. Turn off three rods, leaving one on. Select 40 Hz, then go to READY.

4. Adjust the cap voltage for a fiber output of 10 watts (1 Holmium head).

Fire the laser into the power meter, adjusting cap voltage up/down to get 10 watts of average power

at the power meter. Once the charge voltage is set to provide a consistent power meter reading of 10

watts, stop firing and leave the cap charge at that setting.

Versapulse Select Service Manual

0621-499-01 03/94

12/95

CAL & ADJUST

3-5

®

The system software has a 2.2 volts/Joule conversion factor written into it, so the energy monitor

circuit must be calibrated to output 2.2 volts for a 1 Joule pulse. With 40 Hz selected, but only one

rod on, the actual pulse rate will be 40/4 = 10 Hz. Since 1 Watt= 1 Joule/sec, 10 Watts = 10 Joules/

second,i.e. each pulse is 1 Joule.

5.) Calibrate ENERGY II.

Attach the scope probe to TP3.

Fire the laser, adjusting CPU PCB R8 to adjust the amplitude of the positive pulses on the oscilloscope

screen to approximately 2.22 volts (the pulse will be about 2 mseconds in width, with a relatively

"square" profile). Once the pulses are of the correct amplitude, release the footswitch.

6.) Calibrate ENERGY I

Move the probe to TP2, then adjust as in step 5 above, using CPU PCB R7.

7.) Calibrate ENERGY III

®

Move the probe to TP4, then adjust as in step 5 above, using CPU PCB R9.

8.) Turn all the rods back on, then confirm the calibration.

Turn the system back on (CPU PCB SW3 in its up position so the system will go through its

autocalibration), then fire the laser into the power meter across its range of operating points,

confirming that delivered power as measured by the power meter is always within ±10% of selected

power.

3.4 YAG CHANNEL ADJUSTMENTS

When properly adjusted the YAG channel will meet each of the following three criteria.

•␣The cavity HR will be positioned to direct the YAG output to the center of the first relay mirror, and

the cavity OC will be positioned to provide maximum power for that HR position.

• The first relay mirror and second (plano) relay mirror will direct the YAG energy off the two

folding mirrors so that it is centered through the wedge optic apertures and centered into the

proximal end of the fiber.

• Each YAG beam will be coaxial with the other YAG channels, confirmed at the second wedge optic

aperture and at the fiber port.

The adjustment procedure for a single channel follows. The procedure is a complete check out and alignment for

a single channel. The procedure is meant to be done in the order given, from beginning to end.

CAL & ADJUST

3-6

VersaPulse Select Service Manual

0621-499-01 03/94

12/95

®

It may often be appropriate to do less than the complete adjustment, but in such a case the field service engineer

must consider the possible effect of doing only a portion, i.e., the adjustment may have an effect on some other

portion of the alignment. As an example, If a single channel is only slightly out of center at the fiber port, it can

usually be corrected by simply adjusting the first relay mirror (using the fiber detector signal) and then confirming

the adjustment using a test fiber burn and second wedge optic burn.

When replacing a damaged optic, it should not be necessary to do the entire procedure - try to bring the system

back into alignment by just adjusting the optic that was replaced.

3.4.1 Making Test Burns

(Refer to figures 3.2 and 3.3) Checking out and aligning the YAG channels requires making burns on photopaper

to check alignment. The Alignment Aperture and Cross Hair Aperture are two special purpose tools used when

making burns.

In general, when making burns, lower pulse energies and fewer total pulses are better. As the total energy into

a burn increases, the footprint becomes "blurred". In some cases it will be necessary to get a "multiplexed

footprint", i.e., the paper is burned by more than one channel, allowing the YAG beam positions to be compared.

In other cases a single channel burn will be required. The service engineer can select the channels to be fired, a

cap charge voltage and a pulse rate at the service screens. Setting a lower pulse rates allows the footswitch to be

operated to obtain just a single pulse from a channel, or from each selected channel.

®

The alignment aperture is used to center the YAG beam(s) in front of the second wedge optic. It holds a piece of

burn paper (covered on both sides with plastic to contain splatter). A good burn will fall inside the aperture (the

aperture will not clip the beam). The tool is keyed with two small posts that fit into holes on the face of the second

wedge optic housing block. To use the aperture, slide burn paper and plastic in through the side, then insert it

on the second wedge optic housing.

The cross hair aperture is used to align an individual cavity (OC and HR) into the center of the first relay mirror.

To install it, the first relay mirror mount is removed, then the aperture slides into a hole in the wall directly behind

the spot the channel first relay mirror was mounted (insert from the outside of the wall, so that it is further from

the channel OC). The aperture has two small wires running across it that block a small portion of the beam

(perpendicular to each other and crossing in the center of the aperture). The resulting burn will have the cross

hairs superimposed on it. The cavity optics are adjusted to center the burn in the cross hairs.

3.4.2 Adjusting the YAG Channel Optics

(Refer to figure 3.4) The channel HR, OC and relay mirrors all have the same basic adjustment mechanics. The

mirror is held in a mirror mount by a metal retainer. The mount attaches to one of the optics bench walls by a single

mounting screw with spring. The spring pulls the mount towards the wall - two adjusting screws and a ball

bearing hold the mount out away from its mounting surface against the tension of the spring. One adjusting

screws provides horizontal movement and the other provides vertical movement.

A locking nut is threaded onto each adjusting screw. To unlock the screw for adjustment back the locking screw

away from the collar. Once adjustment is complete, lock down the adjustment screw by turning the nut down

against the collar. As is common in such mechanical lock down set ups, the locking down process will change

the adjustment a bit, so use the locking down to bring the optic to its optimum position. It is best to use the hex

wrench to hold the adjusting screw in place while tightening down the locking nut with the box end wrench. The

adjusting screws require a 7/64th hex head wrench. The locking nuts require a 7/16th box end wrench.

Versapulse Select Service Manual

0621-499-01 03/94

12/95

CAL & ADJUST

3-7

®

®

The channel HR and OC must first be aligned to each other through the length of the YAG rod in order to achieve

lasing. Once the two mirrors are aligned to provide a usable output (will make a burn on photopaper), the two

optics are adjusted together to "walk" the YAG output so that it is centered in the first relay mirror. Finally, the

HR is adjusted to peak the power out of the cavity into the center of the first relay mirror.

The channel first and second (plano) relay mirrors are adjusted to center the channel YAG beam through the

wedge optics and into the center of the fiber port. The first relay mirror is the fine adjustment (it is concave, and

provides less positional change to the beam downstream at the fiber port). The second relay mirror is a gross

adjustment, it moves the beam much more than the first relay mirror. In general, unless the beam is grossly out

of center at the second wedge aperture, the second relay mirror should not be adjusted.

There are also two turning mirrors that steer all the YAG channels off the servo mirror down towards the fiber

port. These mirrors do not normally require adjustment. Obviously, adjusting one of these mirrors will affect all

four YAG channels. The adjustment and mounting scheme is the same as that for the channel optics.

3.4.3 YAG Channel Check Out and Adjustment Procedure

1. Remove the optics bench cover.

2. Examine the optics for any visual sign of damage. Replace damaged HR, OC, or Relay mirrors.

To replace a channel relay mirror, HR, or OC, first remove the mirror mount by carefully removing

the mounting screw (it has a spring around its shaft to place tension on the mount) while supporting

the mount. Once the mount is free, set it down face up and remove the retainer (held in place by

three hex head screws) that hold the optic. The old optic can then be removed and the new optic

inserted (five ball bearings inside the mounting hole center the optic in the hole). Reinstall the

retainer, then the mirror mount. Note that the mount should return to its former position, since the

adjustment screws were not moved.

3. Examine the end of the rod for visual damage.

The rod will be illuminated by the flash lamp when the unit is on (if not, the flash lamp has failed or

the simmer supply circuitry has a problem). Replace a damaged rod or failed flash lamp by replacing

the brick assembly.

4. Center and peak the cavity output into the first relay mirror.

When the cavity OC and HR are correctly aligned the YAG beam will be centered in the relay mirror

directly across from the OC, and the cavity power output will be peaked.

a.) Remove the first relay mirror mount and install the cross hair aperture (as described in

3.4.1).

b.) Make a burn (single channel) through the cross hair aperture onto a piece of burn paper.

c.) Examine the burn to determine if the YAG beam is centered.

CAL & ADJUST

3-8

VersaPulse Select Service Manual

0621-499-01 03/94

12/95

®

The burn should be centered over the cross hairs. If not, adjust ("walk" as described

in the following subparagraph) the OC/HR positions to bring the burn into center,

rechecking as necessary as in step "b" above. Continue adjustment until the burn

footprint is centered in the cross hairs.

"Walking" the beam refers to the method of adjusting the OC and HR in the

same direction and distance, so that the two mirrors remain in the same

orientation with each other, but are brought to a new orientation with

respect to the rod. Each mirror mount has a horizontal and a vertical

adjustment screw. For example, to walk the beam "up" with respect to the

hole, the OC vertical adjustment would be turned in, then the HR vertical

adjustment would be turned out the same amount (don't be fooled as to the

direction to turn the adjustment screw by the fact that the two screws are

mounted in opposite directions - one screw is being turned in and the other

is being turned out, but because the screws are mounted in opposite

directions the screws rotate in the same direction).

d.) Once the burn has been centered in the cross hairs, remove the cross hair aperture and

place the power meter head behind the hole, so that the YAG energy through the hole will

strike the power meter head. Fire the laser into the head and adjust the OC to peak the cavity

power output.

®

e.) Replace the cross hair aperture and recheck the beam centering through the hole as in step

"b" above. Some slight readjustment of the HR may be necessary to recenter the burn in the

cross hairs.

f.) Repeat steps "d" and "e" until the power is peaked and the burn is centered in the cross

hairs, with the HR and OC adjustment mechanisms locked down.

5. Center the YAG beam through the wedge optics and into the fiber port.

For each channel, two optics are adjusted to position the YAG beam down the intended optical path

into the center of the fiber; the first relay mirror and the second (plano) relay mirror.

The second relay mirror seldom needs to be adjusted. It provides a much wider range of

movement of the beam than the first relay mirror. The four second relay mirrors are all

mounted on the cavity OC wall. Although the second relay mirror mounts are shaped

differently than the other channel mirror mounts, the mounting and adjusting hardware is

the same - each is held in place by a spring loaded mounting screw and each has a horizontal

and vertical adjusting screw with locking nut.

The first relay is normally the only adjustment needed to get the YAG beam centered through

the wedge optics and centered into the fiber port.

a.) Use the test aperture to check the YAG channel centering into the second wedge optic opening.

Examine the burn and proceed as follows:

An acceptable burn is to be centered and no clipping should be seen. If the burn is

acceptable, go on to step "b" below.

Versapulse Select Service Manual

0621-499-01 03/94

12/95

CAL & ADJUST

3-9

®

®

An unacceptable burn will be well off center (more than a fourth of the burn is

clipped) In this case, the second relay mirror must be adjusted to bring the YAG

beam closer to the center of the aperture as described below.

Make a slight adjustment to the second relay mirror, then check the result by

making a burn on photopaper at the second wedge optic. Because a number

of burns may be required to complete the adjustment, using the test aperture

can slow things down (the aperture would have to be reloaded with a clean

piece of paper after each shot). As an alternative, find a second channel that

is already centered in the aperture, and then use the service screen to turn

that channel on as well as the channel to be adjusted. When the laser is fired

the two channels will each fire in turn. Instead of using the aperture, make

the burns on a larger piece of paper held in front of the aperture, moving to a

clean spot for each check. The known good channel becomes the reference adjust the second relay mirror for the channel out of adjustment until the

burn footprints are on top of each other. Once the channel is roughly

positioned over the aperture, lock down the mirror and go on to step "b"

below.

b.) Align the YAG beam into the fiber port using the Fiber Alignment Detector Box.

Insert the service attenuator into the beam path (switch is on the Shutter PCB). Connect the

fiber alignment detector box to the fiber port and oscilloscope. Select a 40 Hz pulse rate

(really 10 Hz since only one channel is on), then adjust as indicated in the subparagraph

below.

Fire the laser while observing the oscilloscope. Each laser pulse will produce a

square pulse on the screen (≈ 2 mseconds pulse width). Make slight adjustments to

the channel first relay mirror to peak the amplitude of the pulses on the oscilloscope.

c.) Check the burn into the second wedge optic using the test aperture.

The beam must be unclipped. If not, repeat steps "a" and "b" above until both pass with the

adjustments mechanisms locked down.

6. Do a burn footprint into the test aperture with all four channels turned on.

The resulting burn footprint should be circular in shape and contained in the aperture (no clipping).

7. Perform the system checkout as outlined in Topic 3.2

3.5 AIMING BEAM ADJUSTMENT

The aiming beam can be adjusted by repositioning the aiming diode mount or by adjusting the position of the

folding mirror (the mirror that directs the aiming beam onto the beam combiner). In either case, observe the

aiming beam output from the fiber and adjust to obtain a full spot of bright red light (no doughnut).

CAL & ADJUST

3-10

VersaPulse Select Service Manual

0621-499-01 03/94

12/95

FIGURE 3.2 : USING THE TEST APERTURE

®

®

Insert the test aperture

here, in the mounting hole for the

second wedge optic, inserting the

two key posts on the aperture into

the two holes on the mount.

FIGURE 3.3: USING THE CROSS HAIR APERTURE

Remove the channel first relay

mirror mount, then insert the

cross hair aperture in the hole

from the back (further away

from the OC).

Towards fiber

Burn paper

Towards laser

Clear plastic over

burn paper, slides

into slot on the

test aperture.

CROSS HAIR APERTURE

BURNS THROUGH THE CROSS HAIR APERTURE:

Out in vertical

and horizontal.

Versapulse Select Service Manual

0621-499-01 03/94

Servo Mirror

Out in vertical Properly

centered

CAL & ADJUST

3-11

®

®

SIDE VIEW

LOCKING NUT

ADJUSTING SCREW

(typical, 2 per mount)

MOUNTING SCREW

(one per mount)

Ball bearing is the

pivot point about which

the optic mount is moved

by the two adjusting screws

Mounting Screw

threads into this

hole.

INSIDE SURFACE

(towards wall)

MOUNTING

WALL

OPTIC RETAINER

OUTSIDE SURFACE

(away from wall)

Rounded end of the adjusting screws contact

the optic mount here.

MIRROR

MOUNT

MIRROR

FIGURE 3.4: ADJUSTMENT AND REPLACEMENT OF THE CHANNEL OPTICS

CAL & ADJUST

3-12

VersaPulse Select Service Manual

0621-499-01 03/94

3.6 PERIODIC MAINTENANCE REQUIREMENTS

The systems require the following periodic maintenance:

ANNUALLY (AS REQUIRED):

Perform a general visual inspection of the electrical, mechanical, and optical components.

Check/clean the air filter. The air filter is mounted on the bottom of the system, held in place by a

removeable bracket. A dirty filter should be cleaned (vacuum) or replaced if damaged.

Replace the DI cartridge after 12 months of use, or when the system has coolant conductivity faults.

Check/replace the coolant particulate filter. Replace the filter when it is visibly discolored.

Check the blastshield optic and replace if required.

Cooling system level check. The cooling system fill reservoir is located on the top of the laser. The

top cover must be removed in order to gain access to the reservoir. Use deionized water, with the

system running, to bring the coolant level up to half full in the fill reservoir. Cycle the system off/on

several times, adding deionized water as necessary until the level stays up.

®

®

Calibration and adjustment:

Energy monitor and automatic laser calibration (see Section3).

If the lamp voltage exceeds 750 VDC for Nd:Yag or 1450 VDC for Ho:Yag replace the

flashlamps as required.

Yag channel adjustments (see Section3).

Check alignment (especially at the transimpedance amp) to fiber.

Perform the Operational and Safety Checkout (see Section 2.1 step 12).

Versapulse Select Service Manual

0621-499-01 03/94

CAL & ADJUST

3-13

®

4.0 THEORY OF OPERATION

4.1 INTRODUCTION

4.1.1 Operational Overview

The Versapulse Select family of Holmium YAG laser systems is designed for use in surgical applications. The

treatment laser delivers pulsed 2100 nm wavelength energy (invisible) through a user attached disposable

delivery fiber in response to the depression of an attached footswitch. The pulses continue until the

footswitch is released. A diode laser provides a visible (red, 650 nm) aiming beam. An equipment description,

specifications and detailed user operating instructions are included in the Versapulse Select Operator

Manual.

®

A key is required to turn the system on. At turn-on the system undergoes a series of self tests (approximately

30 seconds), then, if no malfunctions are detected during the self tests, goes to its STANDBY condition. If the

self testing process detects any malfunction, an error message will be displayed and the system will not be

enabled until the fault condition clears.

Once the unit is in STANDBY the user selects the desired operating parameters through a touch screen

display, or on a wired remote control (available as an option). Controls include aiming beam intensity, pulse

energy and pulse rate. Selections are displayed on the screen.

Aiming beam intensity can be turned off or adjusted for high, low or medium.

Pulse energy and pulse rate combine to determine the average power.

(ENERGY/PULSE)*(PULSES/SECOND) = Average Power in Watts

Pulse energy is adjustable, in increments, from .5 to 2.8 Joules. Pulse rate is adjustable, in increments, from 5

to 40 Hz. The combination of pulse energy and pulse rate define an operating point. Not all combinations of

pulse energy and pulse rate are valid, and the operating points available vary with the different Versapulse

Select models available. Consult the Operator Manual for detailed information on the operating points for a

particular model.

A total energy display with a clear function allows the user to keep track of the total energy used from the last

time the display was cleared.

A delivery system fiber is attached to a fiber port on the front of the system console. The delivery fiber is a

consumable item. It comes in a number of styles to meet the requirements of various applications (angled,

etc.). The system will not fire without a delivery fiber attached.

Versapulse Select Service Manual

0621-499-01 01/94

THEORY OF OPERATION

4-1

®

®

Once the system operating parameters are selected, the user selects the READY mode, positions the fiber

output at the treatment site, then depresses the footswitch to deliver treatment pulses at the rate and energy

selected. The treatment delivery will continue until the footswitch is released. Note that the Versapulse Select

does not require any ramp up firings before delivering treatment pulses - the shutter opens and treatment

delivery begins without delay.

Fault monitoring continues for as long as the system is turned on, and any detected fault is reported on the

touch screen.

An emergency off button is located on the console next to the key switch. Depressing it will turn the system

off.

4.1.2 Functional Overview

There are several models of Versapulse Select in (or planned for) production. The primary difference between the models is the maximum average power available. The Versapulse Select can hold up to four

Ho:YAG rods. The maximum average power the system provides is determined by the number of rods used.

The lower power systems do not have all four rods installed. The remainder of this subtopic will describe the

Versapulse Select with four rods installed. Lower power systems operate in the same manner, but with fewer

rods.

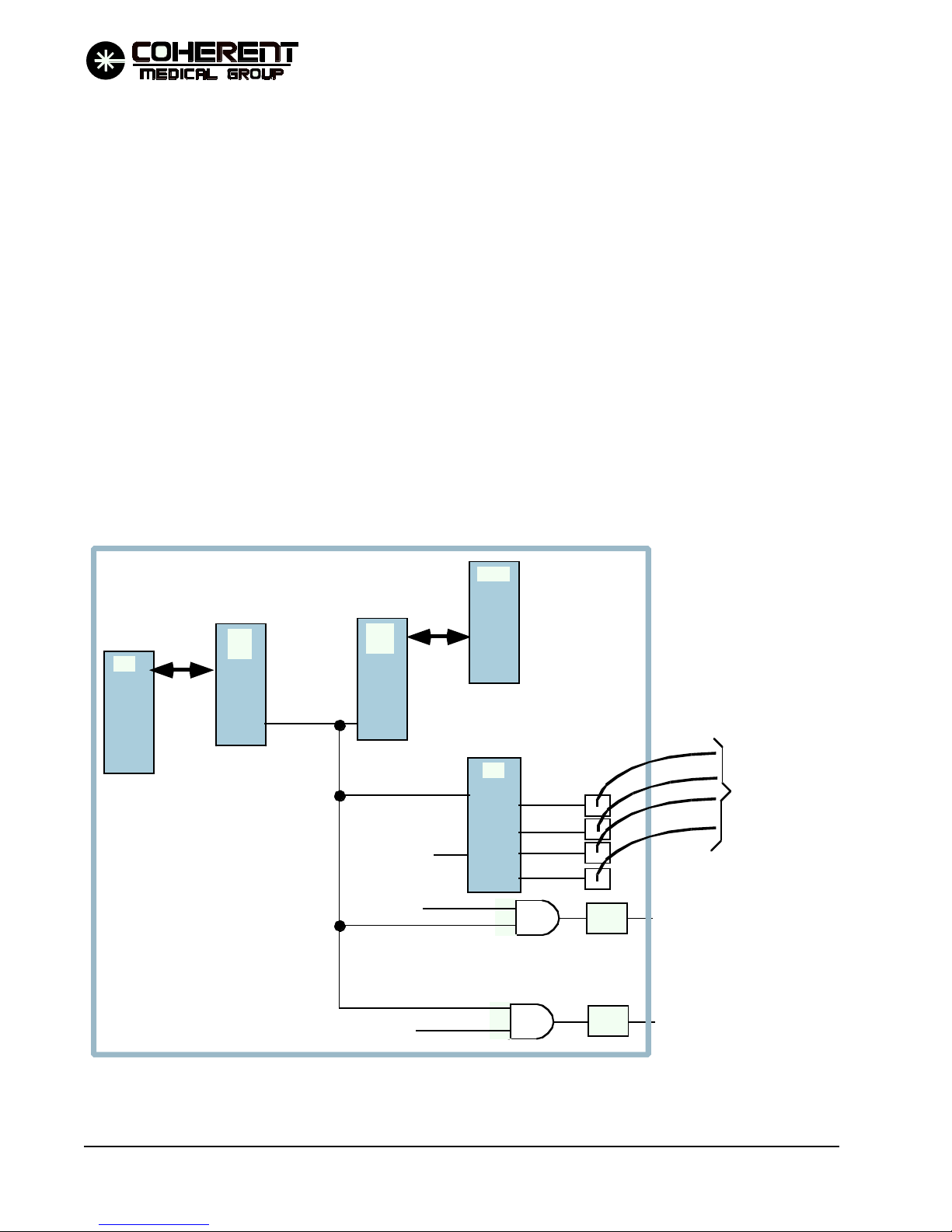

Refer to the Versapulse Select Simplified Block Diagram. The Versapulse Select has four identical Ho:YAG

cavities arranged in a 2x2 matrix. Each cavity includes its own rod, flash lamp, high reflector, output coupler

and set of two relay mirrors. The rods are operated sequentially - never together - thus each rod is capable of

producing the maximum selectable pulse energy (2.8 Joules). Each rod delivers every fourth pulse. This

sequential firing allows the Versapulse Select to provide four times the pulse rate as could be provided by a

single rod, increasing the maximum average power available by the same factor (four).

For example, at the 40 Hz pulse rate, each rod is operating at 10 Hz, and is producing 1/4th of the average

power. As a result, the Versapulse Select provides higher selectable pulse rates and higher average powers

without requiring the extreme rod cooling as would be required in a single rod system at the same operating

point.

The use of multiple heads results in a number of advantages over previous surgical Ho:YAGs: Versapulse

Select is smaller and lighter; it has a much simpler and more reliable cooling system; and it can operate at

much higher pulse rates, resulting in higher average powers.

While the use of multiple heads provides all the above mentioned user advantages, it also results in several

design challenges:

Flash lamp supply switching - The Versapulse Select uses a capacitor discharge to supply the current

required to flash the lamps. The voltage level of the charge on the capacitor determines the amount

of light energy out of the lamp, and therefore the pulse energy out of the rod. A vendor supplied high

voltage power supply charges the capacitor between pulses. Using four heads requires a method of

switching the charging supply current between the four flash lamps. The Versapulse Select uses

SCR's to switch the charging supply current between the four heads.

THEORY OF OPERATION

4-2

Versapulse Select Service Manual

0621-499-01 01/94

®

Multiplexing the beams - Merging the four Ho:YAG beam paths requires a more complicated optical

scheme. Versapulse Select uses a servo positioned rotating mirror to assemble the four Ho:YAG

beams into a single beam path. The servo system must re-position the mirror between pulses,

pointing the mirror towards the head that will be flashed.

Control - In general, the microprocessing demands of the Versapulse Select are greater than that of a

single head system. The Versapulse Select uses two Motorolla 68000 microprocessors - a main

processor and safety processor.

For the purposes of this discussion, the Versapulse Select is divided into the following functional subsystems.

The remaining topics in this section provide a detailed description of each subsystem.

Power Switching, Conditioning, Distribution (4.2) - Provides switching and conditioning of the

primary power input, converts the AC line voltage to DC voltages used within the system and

distributes the various voltages throughout. It includes the turn-on and turn-off circuitry. It does not

include the high voltage power supply (HVPS).

Cooling (4.3) - The cooling system removes heat from the Ho:YAG cavities and two beam dumps. It

is a closed loop distilled/de-ionized water system including a pump, reservoir tank, fill tank, heat

exchanger, variable speed fan, D/I filter, flow switch, temperature sensor and conductivity sensor.

®

Control Electronics (4.4) - The control electronics executes the software instructions to provide

overall control of the Versapulse Select. It includes a main processor (Mµp) and independent safety

processor (Sµp), associated circuits (DIO, ADC, DAC), a touch screen display, and a number of optoelectronic and electro-mechanical devices.

Flash Lamp Supply Circuits (4.5) - The flash lamp supply starts and simmers the four flash lamps,

responds to control electronics commands to charge the main charging capacitor and to discharge the

capacitor through the selected flash lamp. It includes the HVPS, the main charging capacitor, isolated

trigger circuits, lamp select SCR's, electric field transformer, flash lamps and the simmer supply.

The flash lamps are simmered at a low current between flashes (the rods are not simmered - the flash

lamps are kept on in order to allow SCR turn on). The simmer power supply provides the simmer

current to each of the four lamps and supplies a transformer used to generate an electric field to

ionize the flash lamps.

The Ho:YAG pulses of laser energy are controlled by command signals from the control electronics.

Prior to each pulse the control electronics sends a charge command to the HVPS. The command

indicates the voltage level to which the main charging capacitor is to be charged. The higher the

capacitor charge voltage, the more energy will be produced in the laser pulse. The HVPS charges the

capacitor to the indicated voltage then sends a charge complete signal back to the control electronics.

To get a pulse of treatment energy the control electronics triggers the SCR for the cavity that has been

selected for firing. The SCR turn-on creates a discharge path for the main charging capacitor through

the selected flash lamp.

Optics (4.6) - The optics include the portions of the system that operate on the Ho:YAG beams and/

or diode aiming beam. There are four separate and identical Ho:YAG cavities arranged in a 2 x 2

matrix. Each includes a rod, flash lamp, high reflector, output coupler, and two relay mirrors. The

relay mirrors direct the Ho:YAG output from the OC towards the surface of a servo positioned

mirror. The servo positioned mirror is used to multiplex the four separate Ho:YAG beams into a

single beam path. The remainder of the beam path includes the following optical components.

Versapulse Select Service Manual

0621-499-01 01/94

THEORY OF OPERATION

4-3

®

®

Folding Mirrors - 2 folding mirrors direct the beam output from the servo mirror towards the

fiber focusing lens.

First Wedge Optic - The wedge optic front and back surfaces each reflect a small portion

(≈.2%) of the YAG energy back towards an imaging mirror. The imaging mirror is positioned

to direct these reflections upon two pyrodetectors mounted on the Single Solenoid PCB, one

sample to each pyro. The pyro circuitry translates the energy sample into a voltage

proportional to the energy of the Ho:YAG pulse.

Low Energy Attenuator - The LE attenuator is inserted into the beam path to allow the

Versapulse Select to deliver a lower range of pulse energies. This function is currently used

on dual wavelength lasers if holmium energy is less than .5 j or Neodymium power less than

25 W is selected.

Second Wedge Optic - A second wedge optic is required to check the power after the LP

attenuator. Although two samples are reflected off the wedge, only one is used. An imaging

mirror directs the sample towards a pyrodetector mounted on the Dual Solenoid PCB. The

pyro circuitry translates the energy sample into a voltage proportional to the energy of the

Ho:YAG pulse. The low power attenuator function is not implemented by current software.

Service Attenuator - The service attenuator is inserted into the beam path to attenuate the

beam before it enters the fiber focus assembly. This prevents damage to the attached fiber

alignment detector as the system is fired to do the fiber focus alignment. It is operated by a

switch inside the unit accessible to the service engineer. The system will not operate in user

mode if the service attenuator is left in the beam path.

Safety Shutter - Blocks the treatment beam path when de-energized.

Aiming Beam Diode, Folding Mirror, and Combiner Optic - Aiming beam is provided by a

650 nm diode laser. The user can select high, low, or medium intensity; or turn the aiming

beam off. The folding mirror and combiner are adjusted to place the aiming beam coaxial

with treatment beam.

Fiber Focus Lens - Focuses the beam into the end of the fiber.

Blast Shield - Protects the fiber focus lens from debris ejected from the proximal end of the

fiber in the event of a fiber failure.

Delivery Fiber - A number of delivery fibers are available for use with the Versapulse Select,

each providing features suiting it to certain applications, such as orthopedic, endoscope,

laparoscope, laser assisted disk surgery, etc.. The fibers are designed for a single use and are

not repairable.

Software (4.7) - Separate sets of instructions are provided for the main processor and safety

processor, i.e., the two processors do not execute the same instruction sequence - the main processor

is primarily involved with operating the system in response to user inputs, while the safety processor

is exclusively involved with monitoring for and responding to any potential unsafe condition. The

two software programs require inputs from the other, i.e., they are designed to run concurrently, and

communicate back and forth through a shared memory. The software instructions are stored in

EPROM's on the Controller PCB. Software upgrades can be accomplished by replacing the software

EPROMs. Different software versions are required for different Versapulse Select models.

THEORY OF OPERATION

4-4

Versapulse Select Service Manual

0621-499-01 01/94

12/95

®

4.2 POWER SWITCHING, CONDITIONING, DISTRIBUTION

4.2.1 Input Power

Refer to 8 - 2. The Versapulse Select operates off of 200- 240 VAC line voltage. The main circuit breaker is

rated at 30 amps. The mains and ground inputs are wired into TB1. From TB1, the two mains run to the

circuit breaker, and then through a line filter (US systems may not include the line filter). From the line filter

the mains lines parallel out to two different areas.

Through F1/F2 and TB1 to the primary side of isolation transformer T1. TB1 allows tapping of

isolation transformer T1 to match the incoming line voltage. The transformer has two secondary

windings. One is the unswitched 24 VAC turn-on supply. The other is a switched 220 VAC supply

to the fan, pump and DC supplies.

Through the main contactor to the high voltage power supply.

®

4.2.2 Circuit Breaker on, Keyswitch off

Refer to 8-2. When the circuit breaker is turned on, the AC mains voltage is applied to contacts 1 and 3 of the

main contactor and across the primary of isolation transformer T1. Transformer T1 has two secondaries; a

switched secondary and an unswitched secondary.

The unswitched secondary is the 24 VAC supply for the turn-on circuitry. The switched secondary is the 220

VAC supply to the fan, pump, DC power supply, and display power supply. Note that even with the

keyswitch off, there are dangerous voltages present inside the unit.

With the keyswitch in the OFF position, the SW1-A OFF contact of the key switch is closed and the SW1-A

START contact is open. The main contactor is de-energized and its contacts (L1, L2, L3) are open. K1 and K2

are de-energized.

4.2.3 Turn on

Refer to 8-2. To turn the unit on, the keyswitch is turned to the START position, then released to the ON

position.

When the key switch is turned to the START position, it closes its SW1-A START contacts and opens its SW1A OFF contacts. 24 VAC is available from the unswitched secondary of the transformer to the control windings of K1 and the main contactor. Both energize.

When the main contactor energizes, its four sets of contacts close. Contacts L1 and L2 close to apply primary

power to the high voltage power supply (HVPS). Contact L3 closes to apply the switched secondary current

to the fan, pump, display power supply and low voltage power supply. SW4 closes to complete a portion of

the "hold on" current loop to the control winding of the main contactor.

Versapulse Select Service Manual

0621-499-01 01/94

12/95

THEORY OF OPERATION

4-5

®

®

Shortly after the pump begins running the water flow switch SW3 will close, allowing K2 to energize. Once

K2 is energized the main contactor hold on loop is complete, and the main contactor will remain energized

with the release of the keyswitch from the START position to the ON position. Note that if the keyswitch is

released to the ON position before K2 energizes, the system will turn off.

The interlocked design of the turn-on circuitry prevents re-starting of the system without the user re-starting

with the keyswitch.

4.2.4 Shutdown

Refer to 8-2. The system will turn off if any of the following occur.

Keyswitch moved to OFF position

Emergency Off button pressed

Turn off or trip of main circuit breaker

Blown F1 or F2 line fuse

Blown F3

Open T1 thermal switch

Front door opened (intermock switch)

Loss of coolant flow

Loss of facility power

4.2.5 Low Voltage Power Supplies

Refer to 8-3. A vendor supplied low voltage power supply provides +5 VDC, ±12 VDC, and +24 VDC for use

throughout the system. It operates from the 220 VAC supply voltage from the secondary of T1. A 250V 5

amp fuse is mounted on the power supply. The 5 VDC and ±12 VDC lines are routed to the CPU PCB. The

24 VDC is routed to the CPU PCB and Shutter PCB. From the CPU PCB the 5 VDC supply is routed out to

the touch screen display, remote control and Shutter PCB.

The vendor supplied HVPS includes a +15 VDC voltage output that is used on the HVPS side of the isolation

circuits of the CPU PCB (U8, U9, U11, U99, U100, U48, U47, U41, U101, U13, U14).

CPU PCB U60 is a voltage regulator that develops a 5 VDC supply (5V ENCOD) for the Servo Motor PCB.

THEORY OF OPERATION

4-6

Versapulse Select Service Manual

0621-499-01 01/94

12/95

®

4.3 COOLING