Page 1

VS

™

II

VS

Versa-Sense™II

Electronic Leak Detector

Versa-Sense™ II

Electronic Leak Detector

SPECIFICATIONS

115 Volt Units

Power Supply: 100 VAC or 110-120VAC, 50 Milliamp, Current Draw

Output Supply: 110-120VAC, 100 Watt Power, Maximum (1 Amp)

220Volt Units

Power Supply: 220-240VAC, 25 Milliamp, Current Draw

Original Instructions

Output Supply: 220-240VAC, 100 Watt Power, Maximum (.5 Amp)

ITEM PART DESCRIPTIONS AND PART NUMBERS

P29-800TF10 Electronic Leak Detector W/ 10' Leads and PTFE Probes

P29-800 Electronic Leak Detector (Unit Only)

P29-804 10' Lead and PTFE Probe (Two Required Per Unit)

VS

Service & Operating Manual

Versa-Matic

A Unit of IDEX Corporation

800 N. Main St.

Mansfield, OH 44902

Phone: (419) 526-7296

versamatic.com

800 North Main Street, Mansfield, OH 44902 USA • Phone: (419) 526-7296 • www.versamatic.com

VERSA-MATIC

®

• Warren Rupp, Inc. • A Unit of IDEX Corporation

© Copyright 2013 Warren Rupp, Inc. All rights reserved

Page 2

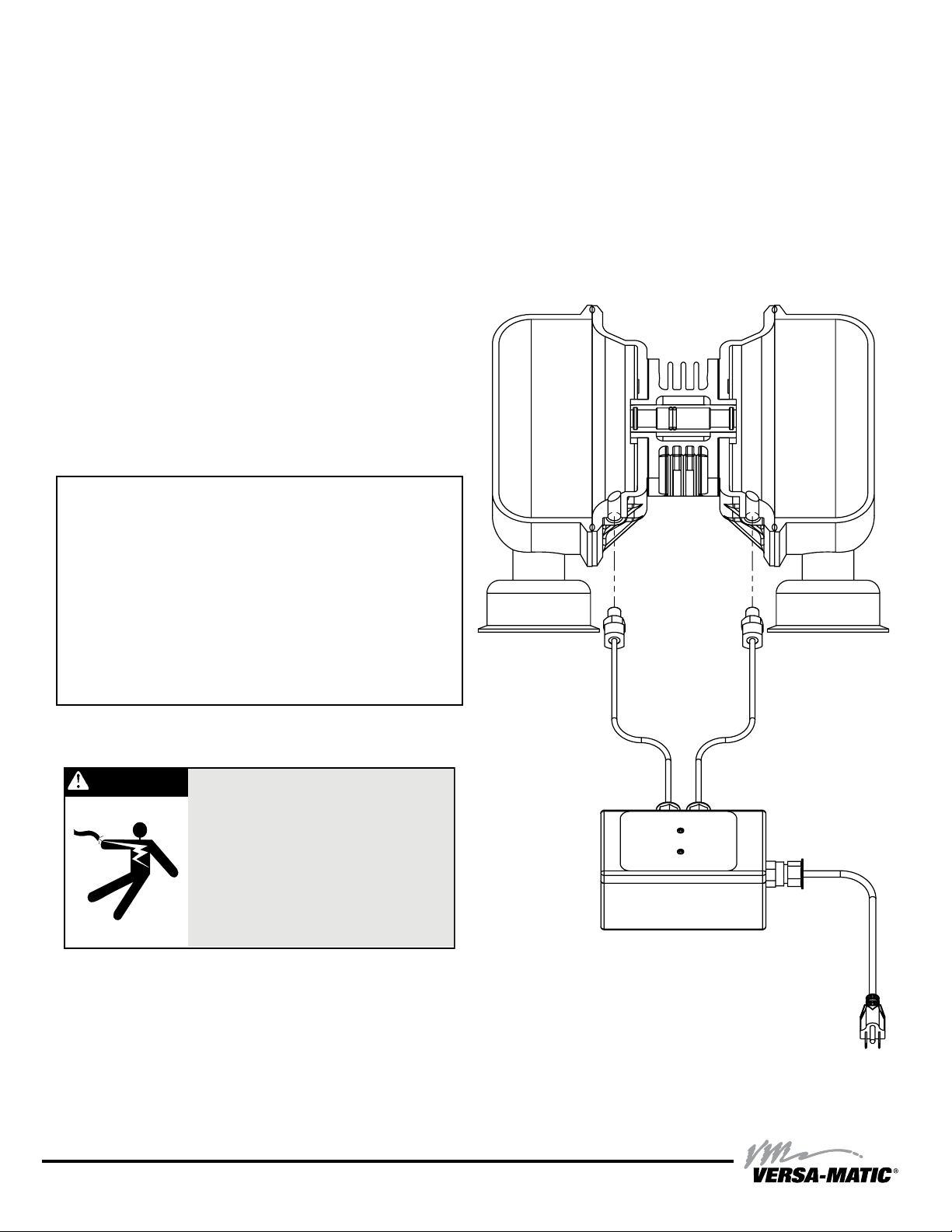

Versa-Sense II Electronic Leak Detector

To install the probe, first back-twist the cable

counterclockwise to avoid wire twist when the

probe is threaded clockwise into the 1/4" NPT

boss ports. Apply PTFE tape or a small amount of

thread sealant to the threads prior to insertion.

Probe Installation

The VERSA-SENSE II Electronic Leak Detector

consists of a modular control unit encased in a

watertight enclosure and two detection probes. All

of these items are wired together as noted on the

schematic illustration Figure A and Figure D.

The VERSA-SENSE II Electronic Leak Detector

senses pumped liquid entering the air chambers of

the pump and works on the principle of conduc-

tance. The probes are installed into the bottom

boss on the air chambers (E1, E4, E2, E3, and U2

pump models.) When the diaphragm fails, the

probe is exposed to the pumped liquid. This pro-

duces a low current change of 1.2 volts DC (<1 mil-

liamp) which signals the control unit. One of the two

indicator lights signal which diaphragm has failed,

and which air chamber has been contaminated by

pumped fluid.

To install the probe, first back-twist the cable

counterclockwise to avoid wire twist when the

probe is threaded clockwise into the 1/4" NPT

boss ports. Apply PTFE tape or a small amount of

thread sealant to the threads prior to insertion.

VERSA-SENSE II Electronic Leak Detector

Probe Installation

PUMP

10’

LEAD

WIRES

PROBE

ASSEMBLY

NOTE: The VERSA-SENSE II Leak Detector will

detect any moisture that pools at the bottom of

the air chamber. Air supplies with high moisture

content will deposit the moisture at the bottom

of the pump's inner chamber. This will cause

the probe to send false signals of diaphragm

rupture to the control unit. When the leak

detector is used to detect diaphragm failure it is

recommended that an air line dryer be installed

in the air line supply line to lessen the chance of

false signals.

WIRING ILLUSTRATION

Figure A

LOAD

LOAD

PICTOGRAM

FOR FUSE FU1

POWER PROTECTION

DRY CONTACT

ALARM OUTPUTS

TO PROBE

PICKUP

BOARD

AC OR DC

220V/5A

MAX

OUTPUTS

C6C5

12

TS2

C7

1

TS1

FU1

.5A

250V

P1

CR1 CR2

FU2

1A

250V

FU3

1A

250V

POWER

RTN

OPTIONAL

EXTERNAL

OUTPUT

JUNCTION FOR

SOLENOID

VALVES OR

SIGNALS

LINE

VO LTAGE

SELECT

INSERT SCREW DRIVER

IN SLOT AND SLIDE TO

CHANGE VOLTAGE

CAUTION:

REMOVE

POWER FIRST

115/230VAC

50/60 Hz

L1 L2 G

115V

100-120VAC

(HOT)

100-120VAC

(HOT)

AC Neutral

Load will be energized

when LED 1 is illmunated

This load is fused by FU2

AC Neutral

Load will be energized

when LED 2 is illmunated

This load is fused by FU3

OUTPUTS

C6C5

12

TS2

LOAD

LOAD

Options

Conductivity

The control unit can be easily wired to an audible

alarm or pump shutdown device. For example you

can connect the leak detector unit to a solenoid,

which can shut the air supply off to the pump, or

sound an alarm by routing the external device into

the leak detector unit. The wires can enter through

one of the three port holes in the leak detection unit.

The output connection terminal has 100 watt power

output and each chamber has independent connec-

tions. If combining the two chambers, a four wire

lead spliced before the external device would be

necessary (See output connection terminal Figure B.)

The leak detector probes work under the principle

of conductance. Not all pumped liquid is conduc-

tive. If the diaphragm fails, the pumped product will

conduct (complete the circuit) and signal the box

and the warning light will come on.

Sensitivity of the detector can be adjusted by the

adjusting knobs R5 and R6. (See Figure C.) These

adjustment knobs work independently for each side

(chamber). They can be moved with a small screw

driver. These sensitivity knobs are also important in

setting to detect conductance fluid at the sensitivi-

ty most required. The sensitivity range of the detec-

tor is adjustable from OHM (2,000 Micro MHO) to

100,000 OHM (10 Micro MHO).

When sensing low conductivity, turning the screws

clockwise increases probe sensitivity.

UP

DOWN

UP

DOWN

ALMLO

ALMHI

ALMLO

ALMHI

SW1

TS1

R5

INC-

SENS

CW

INC-

SENS

CW

R6

SW2

2HC1HC

C3

Conductive/Non-Conductive Switch Information

Note: Pumps containing driver fluid should be filled with

conductive or non-conductive fluid, depending on the fluid

pumped. The driver fluid should be opposite of the pumped

product in order to determine diaphragm failure and light

warning LED signal(s). This is adjusted inside the box in

the following manner:

SW1 DOWN (LED 1) = LED on w/presence of

conductive fluid and off w/absence of conductive fluid.

SW1 UP (LED 1) =LED on w/absence of conductive

fluid and off w/absence of conductive fluid.

— OR —

SW2 DOWN (LED 2) = LED on w/presence of

conductive fluid and off w/absence of conductive fluid.

SW2 UP (LED 2) = LED on w/absence of conductive

fluid and off w/absence of conductive fluid.

When sensing low conductivity, turning the

screws clockwise increases probe sensitivity.

WIRING ILLUSTRATION

Figure B

WIRING ILLUSTRATION

Figure C

The VERSA-SENSE II Electronic Leak Detector consists of

modular control unit encased in a watertight enclosure and

two detection probes. All of these items are wired together

as noted on the schematic illustration Figure A and Figure D.

The VERSA-SENSE II Electronic Leak Detector senses

pumped liquid entering the air chambers of the pump and

works on the principle of conductance. The probes are

installed into the bottom boss on the air chambers (E1, E4,

E2, E3, and U2 pump models.) When the diaphragm fails,

the probe is exposed to the pumped liquid. This produces a

low current change of 1.2 volts DC (<1 milliampere) which

signals the control unit. One of the two indicator lights signal

which diaphragm has failed, and which air chamber has been

contaminated by pumped uid.

NOTE: The VERSA-SENSE II Leak Detector will detect

any moisture that pools at the bottom of the air chamber. Air supplies with high moisture content will deposit

the moisture at the bottom of the pump's inner chamber. This will cause the probe to send false signals of

diaphragm rupture to the control unit. When the leak

detector is used to detect diaphragm failure it is recommended that an air line dryer be installed in the air line

supply line to lessen the chance of false signals.

WARNING

Hazardous voltage. This Leak

Detector is an electrical device. It should

be wired by only qualified, licensed

electricians. The cover should never be

removed except by authorized, licensed

electricians. Failure to heed this warning

may result in electric shock, personal

lasting injury or death.

Power shall be disconnected before

enclosure is opened.

Enclosure shall be closed before power

is restored.

Probe Installation

To install the probe, rst back-twist the cable counterclockwise to avoid wire twist when the probe is threaded

clockwise into the 1/2-20 UNF boss ports. Apply PTFE

tape or a small amount of thread sealant to the threads

prior to insertion.

DETECTOR CONTROL UNIT

(NEMA1, 2, 3, 4, 4x, 5, 12 & 12)

WIRING ILLUSTRATION

Figure A

PUMP

PROBE

ASSEMBLY

10’

LEAD

WIRES

VERSA-SENSE II

P/N P29-800

ww w .ve r sam at ic. c om

vs2sm-rev0513

Page 3

Options Conductivity

LOAD

LOAD

PICTOGRAM

FOR FUSE FU1

POWER PROTECTION

DRY CONTACT

ALARM OUTPUTS

TO PROBE

PICKUP

BOARD

AC OR DC

220V/5A

MAX

OUTPUTS

C6C5

12

TS2

C7

1

TS1

FU1

.5A

250V

P1

CR1 CR2

FU2

1A

250V

FU3

1A

250V

POWER

RTN

OPTIONAL

EXTERNAL

OUTPUT

JUNCTION FOR

SOLENOID

VALVES OR

SIGNALS

LINE

VO LTAGE

SELECT

INSERT SCREW DRIVER

IN SLOT AND SLIDE TO

CHANGE VOLTAGE

CAUTION:

REMOVE

POWER FIRST

115/230VAC

50/60 Hz

L1 L2 G

115V

100-120VAC

(HOT)

100-120VAC

(HOT)

AC Neutral

Load will be energized

when LED 1 is illmunated

This load is fused by FU2

AC Neutral

Load will be energized

when LED 2 is illmunated

This load is fused by FU3

OUTPUTS

C6C5

12

TS2

LOAD

LOAD

Options

Conductivity

The control unit can be easily wired to an audible

alarm or pump shutdown device. For example you

can connect the leak detector unit to a solenoid,

which can shut the air supply off to the pump, or

sound an alarm by routing the external device into

the leak detector unit. The wires can enter through

one of the three port holes in the leak detection unit.

The output connection terminal has 100 watt power

output and each chamber has independent connec-

tions. If combining the two chambers, a four wire

lead spliced before the external device would be

necessary (See output connection terminal Figure B.)

The leak detector probes work under the principle

of conductance. Not all pumped liquid is conduc-

tive. If the diaphragm fails, the pumped product will

conduct (complete the circuit) and signal the box

and the warning light will come on.

Sensitivity of the detector can be adjusted by the

adjusting knobs R5 and R6. (See Figure C.) These

adjustment knobs work independently for each side

(chamber). They can be moved with a small screw

driver. These sensitivity knobs are also important in

setting to detect conductance fluid at the sensitivi-

ty most required. The sensitivity range of the detec-

tor is adjustable from OHM (2,000 Micro MHO) to

100,000 OHM (10 Micro MHO).

When sensing low conductivity, turning the screws

clockwise increases probe sensitivity.

UP

DOWN

UP

DOWN

ALMLO

ALMHI

ALMLO

ALMHI

SW1

TS1

R5

INCSENS

CW

INCSENS

CW

R6

SW2

2HC1HC

C3

Conductive/Non-Conductive Switch Information

Note: Pumps containing driver fluid should be filled with

conductive or non-conductive fluid, depending on the fluid

pumped. The driver fluid should be opposite of the pumped

product in order to determine diaphragm failure and light

warning LED signal(s). This is adjusted inside the box in

the following manner:

SW1 DOWN (LED 1) = LED on w/presence of

conductive fluid and off w/absence of conductive fluid.

SW1 UP (LED 1) =LED on w/absence of conductive

fluid and off w/absence of conductive fluid.

— OR —

SW2 DOWN (LED 2) = LED on w/presence of

conductive fluid and off w/absence of conductive fluid.

SW2 UP (LED 2) = LED on w/absence of conductive

fluid and off w/absence of conductive fluid.

When sensing low conductivity, turning the

screws clockwise increases probe sensitivity.

WIRING ILLUSTRATION

Figure B

WIRING ILLUSTRATION

Figure C

The control unit can be easily wired to an audible alarm

or pump shutdown device. For example, you can connect

the leak detector unit to a solenoid, which can shut the

air supply off to the pump, or sound an alarm by routing

the external device into the leak detector unit. The wires

can enter through one of the three port holes in the leak

detector unit. The output connection terminal has 100 watt

power out put and each chamber has independent connections. If combining the two chambers, a four wire lead

spliced before the external device would be necessary.

(See output connection terminal Figure B.)

The leak detector probes work under the principle of conductance. Not all pumped liquid is conductive. If the diaphragm

fails, the pumped product will conduct (complete the circuit)

and signal the box and the warning light will come on.

Sensitivity of the detector can be adjusted by the adjusting

knobs R5 and R6. (See Figure C) These adjustment knobs

work independently for each side (chamber). The can be

moved with a small screw driver. These sensitivity knobs are

also important in setting to detect conductance uid at the

sensitivity most required. The sensitivity range of the detector

is adjustable from OHM (2,000 Micro MHO) to 100,000 OHM

(10 Micro MHO).

When sensing low conductivity, turn the screws clockwise

increases probe sensitivity.

vs2sm-rev0513

ww w .ve r sam at ic. c om

Versa-Sense II

Page 4

Versa-Sense II Schematic

VERSA-MATIC®PUMP COMPANY

A Unit of IDEX Corporation

Versa-Matic® and Versa-Sense™ are registered tradenames and trademarks of IDEX Corporation.

Versa-Sense II Schematic

CAUTION

FOR 220 VOLT UNITS:

Plug in only to 220 volt systems. Do not have

power to the cord (do not have it plugged in)

when connecting to the box terminals.

CAUTION

FOR 115 VOLT UNITS:

Plug in only to 100 volt systems. Do not have

power to the cord (do not have it plugged in)

when connecting to the box terminals.

WIRING ILLUSTRATION

Figure D

Versa-Sense II

ww w .ve r sam at ic. c om

vs2sm-rev0513

Loading...

Loading...