Page 1

DATA SHEET, SERVICE & OPERATING MANUAL

DATA SHEET, SERVICE & OPERATING MANUAL

DATA SHEET, SERVICE & OPERATING MANUALDATA SHEET, SERVICE & OPERATING MANUAL

AIR OPERATED

AIR OPERATED

AIR OPERATED AIR OPERATED

DOUBLE DIAPHRAGM PUMP

DOUBLE DIAPHRAGM PUMP

DOUBLE DIAPHRAGM PUMPDOUBLE DIAPHRAGM PUMP

Full Flow

Full Flow

Full FlowFull Flow

High Pressure Series

High Pressure Series

High Pressure SeriesHigh Pressure Series

Table of Contents

Performance Curve 1

Dimensions 1

Engineering Data & Temperature limitations 2

Explanation of Pump Nomenclature 2

Principle of Pump Operation 3

Installation guide 3

Troubleshooting 4

Recycling 4

Important Safety Information 4

Warranty 5

Service 5

Air Valve Overhaul 5

Wet-side Overhaul 5

Parts List 6

Assembly Drawing 7

Technical Notes 8

Technical Notes 9

Service / Maintenance Log 10

HG-CF-998 Rev. D - 03/27/03

Page 2

DATA SHEET, SERVICE & OPERATIN G MANUAL

DATA SHEET, SERVICE & OPERATIN G MANUAL

DATA SHEET, SERVICE & OPERATIN G MANUALDATA SHEET, SERVICE & OPERATIN G MANUAL

N25

N25

N25N25

AIR OPERATED

AIR OPERATED

AIR OPERATED AIR OPERATED

DOUBLE DIAPHRAGM PUMP

DOUBLE DIAPHRAGM PUMP

DOUBLE DIAPHRAGM PUMPDOUBLE DIAPHRAGM PUMP

Full Flow High Pressure Series

Full Flow High Pressure Series

Full Flow High Pressure SeriesFull Flow High Pressure Series

N25 Full Flow High Pressure Pump

Performance based on water at ambient temperature

All business conducted subject to Blagdon Pump. Terms and Conditions of Sale, available on request.

BLAGDON PUMP

BLAGDON PUMP

BLAGDON PUMPBLAGDON PUMP

A Unit of IDEX Corporation

HG-CF-998 Rev. D - 03/27/03

Performance Curve

IMPORTANT

6017 ENTERPRISE DRIVE, EXPORT,

PENNSYLVANIA 15632-8969, USA.

TEL. : (1) 724-327-7867 FAX. : (1) 724-733-4786

Web Site : www.blagdonpump.com

E-Mail : sales@blagdonpump.com

DISTRIBUTOR

Page 1

Page 3

FLUID CONNECTIONS CAPACITY MAX SOLIDS MAX DISCHARGE HEAD DISPLACEMENT/STROKE

1” NPT (F) 0 - 33 US Gall ons / Mi nut e

(0 - 125 Liters/Minute)

1/8”

(3 mm)

536 ft

(163 Meters)

0.13 US Gallons

(0.475 Liters)

Materials

Buna-n - General purpose, oil resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should not

be used with highly polar solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM - Shows very good water and chemical resistance. Has poor resistance to oils and solvents, but is fair on

ketones and alcohols.

Neoprene - All purpose. Resistant to vegetable oil. Generally not affected by moderate chemicals, fats greases

and many oils and solvents. Generally attacked by strong oxidising acids, ketones, esters, nitro hydro carbons and

chlorinated aromatic hydrocarbons.

Santoprene® - Injection moulded thermoplastic elastomer with no fabric layer. Long mechanical flex life.

Excellent abrasion resistance.

Virgin PTFE - Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE : molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine

trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

Viton® - Shows good resistance to a wide range of oils and solvents : especially all alphatic, aromatic and

halogenated hydrocarbons, acids, animal and vegetable oils. Hot water or aqueous solutions(over 700F) will attack

Viton®.

Polypropylene

Maximum Minimum Optimum

190oF

212oF

100

170oF

212oF

100

212oF

100

212oF

100

150oF

Operating Temperatures

o

C

88

o

C

o

C

77

o

C

o

C

o

C

o

C

65

-10oF

o

C

-23

-10oF

o

C

-23

-10oF

o

C

-23

-10oF

o

C

-23

-35oF

o

C

-37

+32oF

o

C

0

-40oF

o

C

-40

50o to 140oF

o

to 60oC

10

50o to 212oF

o

to 100oC

10

50o to 130oF

o

to 54oC

10

50o to 212oF

o

to 100oC

10

50o to 212oF

o

to 100oC

10

75o to 212oF

o

to 100oC

24

TYPICAL CODE = N25. 01. A A. B 3. N N S

MODEL - N25

VALVE SEATS

DESIGN LEVEL

S : STAINLESS STEEL

WETTED COMPONENTS

A : ALUMINUM

S : STAINLESS STEEL

CHECK VALVES

NON - WETTED COMPONENTS

A : ALUMINUM

T : PTFE

N : NEOPRENE

CHECK VALVE

B : BALL

W : WEIGHTED BALL

DIAPHRAGMS

T : PTFE

N : NEOPRENE

MODEL DESIGNATION

TECHNICAL DATA

METALLIC SERIES - FULL FLOW 2:1 N25

Maximum Delivery: 33 gpm Installation: Surface mounted

Max. Working Pressure: 116 psi Accessories Included: Exhaust air Silencer

Max. Solid Particle Size: 1/4” Shipping Weights:

Air Inlet: 3/8” NPT (F) Aluminum 56 lb

Temperature Limits: Determined by Elastomers Stainless Steel / Aluminum 76 lb

Suction Lift (Dry): 20’ Shipping Dimensions: 18” x 19” x 12”1/4

Suction Lift (Wet): 25’ Fluid Inlet/Outlet: 1” NPT (F)

HG-CF-998 Rev. D - 03/27/03

Page 2

Page 4

PRINCIPLE OF PUMP

OPERATION

This ball type c heck valve p ump is powered b y

compressed air and is a 2:1 ratio design. The

inner side of one diaphragm chamber is alternately pressurised while simultaneously exhausting the other inner chamber. This causes

the diaphra gms, which a re connected b y a common rod secured by plates to the centers of the

diaphragms, to move in a reciprocating action.

(As one diaphragm performs a discharge stroke

the other diaphragm is pulled to perform the

suction stroke in the opposite chamber.) Air

pressure is app lied over the entir e inner surface

of the diaphragm while liquid is discharged

from the opposite side of the diaphragm. The

diaphragm operates in a balanced condition

during the discharge stroke which allows the

pump to be operated at discharge heads of over

500 feet (152 meters) of water.

For maximum diaphragm life, keep the pump as

close to the liquid being pumped as possible.

Positive suction head in excess of 10 feet of

liquid (3.048 meters) may require a back pressure regulating device to maximize diaphragm

life.

Alternate pressurising and exhausting of the

diaphragm chamber is performed by an externally mounted, pilot operated, 2 way type

distibuti on valve. When the spool sh ifts to one

end of the valve block body, inlet pressure is

applied to one chamber and the other diaphragm

chamber exha usts. When th e spool shift s to the

opposite end of the valve body, the pressure to

the chambers is reversed. This alternating move-

Installation Guide

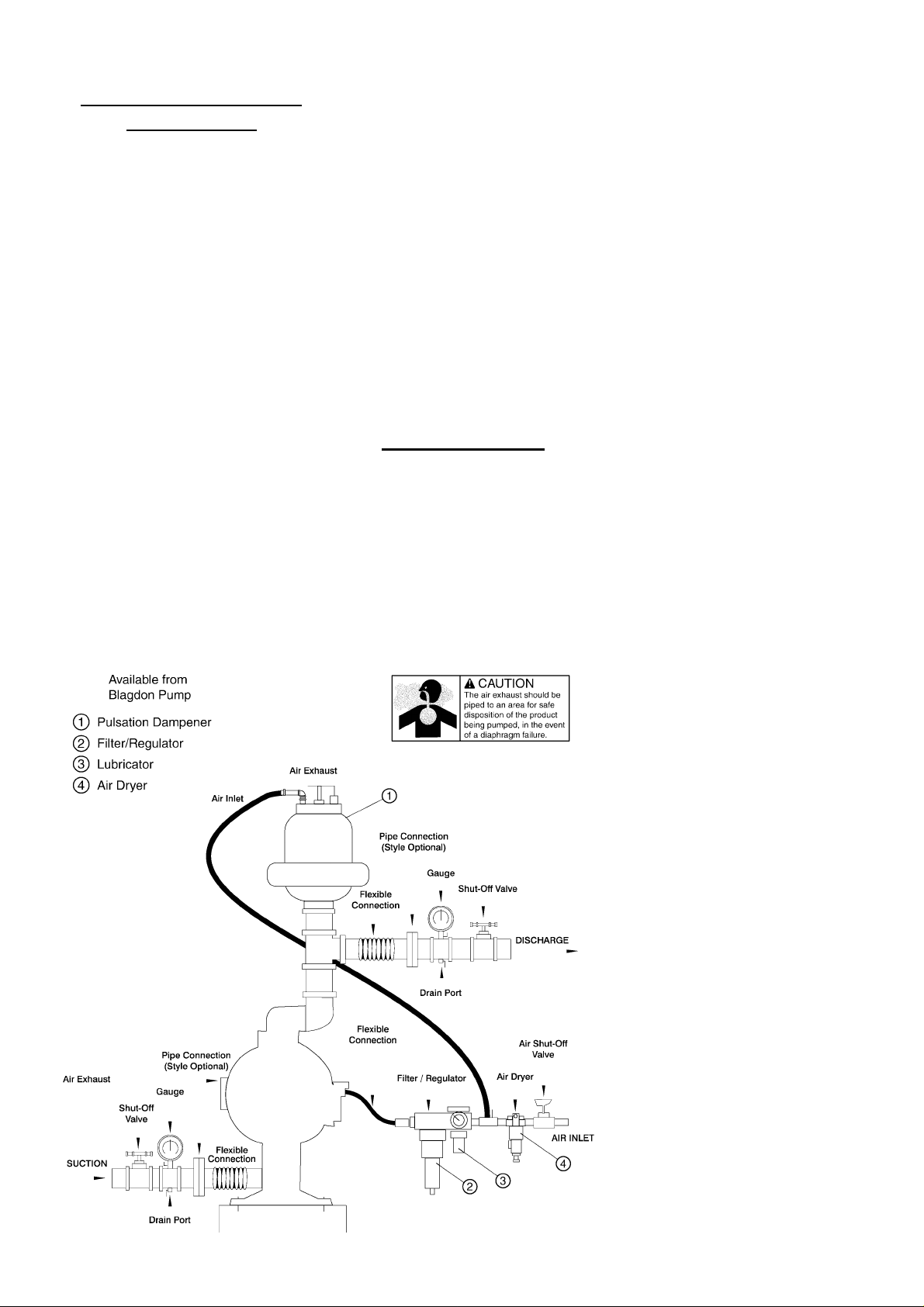

Fig. 1

ment of the spool inside the valve body is controlled by a pilot air pressure signal held against

the diaphragm connecting rod, between seals in

the diaphragm shaft bushes. This signal is released, triggering the movement of the spool,

when pilot holes in the diaphragm connecting

rod align with the held pilot signal, sending the

signal to exhaust, which in-turn causes a pressure imbalance around the spool, sending it to

the opposite en d of the valve b ody. This si mutaneously sends inlet pressure to the opposite

chamber.

The chambers are connected with manifolds

with a suction and discharge check valve for

each chamber, maintaining flow in one direction

through the pump. The 2:1 ratio discharge pressure is generated by simultaneously delivering

air inlet pressure to alternate sides of a central

air diaphragm, the chambers either side of this

central diaphragm are pressurised and exhausted

in conjunction wi th the main diaphragm chambers.

INSTALLATION

The typical installation shown in FIG. 1 is only a

guide to selecting and installing system

components. Your installation will depend on

the type of fluid being pumped and your

application needs. To reduce the risk of serious

bodily injury and damage to property, never use

fluids in this pump which are not compatible

with the wetted components. Contact your local

distributor or the manufacturer for system design

assistance & compatibility if necessary.

Mount the pump in an upri ght position. Failur e

to ensure an upright pos ition may result in loss

of or poor priming ch aracteristics. Ensure the

pump is securely moun ted to avoid movement

and possible risk of bodily injury.

PRESSURE The pump delivers double the

pressure at the discharge outlet as the air

pressure applied at the air inlet.

NOTE: Pressure Regulator (H) should be

installed where air supply could exceed 125

psi.

SAFETY

Your BLAGDON PUMP is a high

performance unit capable of achieving

high output s at high efficien cies. However, as

is common with pneumatic equipment, the

pump efficienc ies is reliant upon the air being

clean, dry and filtered. Failure to comply with

these requirements may lead to loss of

performance and reduced component life and in

extreme cases, permanent damage to the pump.

To avoid leaks, ensure that all fluid connections

are tight. The use of PTFE thread tape co rrectly

applied should be used to ensure 100%

leakproof connections. Failure to ensure

100% sealability of the suction connection

could adversely affect suction performance.

If you are pumping hazardous fluids, or

operating the pump in an enclosed area, it is

essential that the exhaust from the pump is

piped away to a safe location. When pumping

hazardous fluids the above instructions must be

adhered to in order to ensure safe operating

procedures. (Under certain operating

conditions the failure of internal components

can lead to the pumped fluid being exhausted

via the pump exh aust outlet).

WARNING

NEVER place your hands over or near the

pump suction inlet. Powerful suction could

cause serious bodily injury.

FLUSH THE PUMP This pump was

tested with water containing an oil-based rust

inhibitor. If thi s solution could c ontaminate or

react with the fluid you are pumping, flush the

pump thoroughly with a solvent/detergent to

clean internal components. The solvent/

detergent must be compatible with the pump

materials of con struct ion. Ca re shou ld b e taken

to flush the pump each time it is disassembled

for maintenance or repair.

CAUTION Ensure that only the

recommended grade of lubricating oil is used.

BLAGDON PUMPS require an SAE 10

lubricating oi l. Other grades of oil may ca use

the Air Logic Syst em to operate intermi ttently,

thereby causin g a loss of output and failure to

operate.

If the pump accelerates or is running too fast

due to a lack of fluid, then stop it immediately

by shutting off the air supp ly. A dry pump will

accelerate to a high speed causing wear to

elastomers.

If the fluid you are pumping tends to dry up or

set when it is no t moving, then flush th e pump

as often as necessary to prevent the fluid from

drying in the pump. Drain the pump thoroughly

before storing.

If feasible, invert pump to allow any fluid to

drain from the no n- r eturn valves

.

HG-CF-998 Rev. D - 03/27/03

Page 3

Page 5

TROUBLE SHOOTING GUIDE

NOTE :- Check all solutions before dismantling the pump.

PROBLEM CAUSE SOLUTION

Pump will not start Air valve assembly malfunction/Siezure

Obstructed fluid line.

Obstructed diaphragm chamber.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Air connected to exhaust.

Erratic flow Diaphragm failure on one side.

Valve ball not seating.

Suction leakage.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Pump strokes but will not

discharge

Excessive suction lift.

Suction line leakage.

Valve ball not seating correctly or damaged.

Suction line or strainer clogged.

Diaphragm failure.

Fluid discharged from air

exhaust

Diaphragm Failure.

Loose frontplate.

Intermitten t str oke rate Over lubrication

Diaphragm shaft seal failure.

Air valve system malfunction.

Valve ball not seating / partially obstructed.

Check carrier for freedom of movement. Clean, oil & replace.

Clean line or increase line size.

Remove obstruction.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Re-connect to air inlet.

Replace diaphragm.

Check and remove obstruction.

Check and correct.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Shorten suction line.

Check and correct.

Check and remove obstruction / replace.

Clear.

Replace diaphragm.

Replace diaphragm.

Re-Torque to manual specifications.

Shut-down pump. Remove air connection

into pump & introduce a small quantity of degreasing agent into air valve and replace

line. Run pump until clear.

Replace seals.

Check all seals in valve chest assembly.

Clear obstruction.

WARNING!

Read these safety warnings and

instructions in this manual

and start-up of the pump. It is t he responsibility

of the purchaser to retain this manual for

reference. Failure to comply with the

recommendations stated in this manual will

damage the pump, and void factory warranty.

completely, before installation

WARNING!

Before doing any maintenance

on the pump, be certain all

from the pump, suction, discharge, piping, and

all other openings and connections. Be certain

the air supply is locked out or made

non-operational, so that it cannot be started

while work is being done on the pump. Be

certain that approved eye protection and

protective clothing are worn all times in the

vicinity of the pump. Failure to follow these

recommendations may result in serious injury or

death.

pressure is completely vented

WARNING!

Airbo rne part icles a nd loud noise

hazards. Wear ear and eye protection.

WARNING!

Before maintenance or repair,

shut off the com-pressed air line,

nect the air line from the pump. The discharge

line may be pressurized and must be bled of its

pressure.

bleed the pressure, and discon-

WARNING!

Take action to prevent static

sparking. Fire or explosion can

flammable liquids. The pump, piping, valves,

containers or other miscellaneous equipment

must be grounded.

result, especially when handling

IMPORTANT!

This pump is pressurized

internally with air pressure

certain that all bolting is in good condition and

that all of the correct bolting is reinsta lled dur ing

assembly.

during operation. Always make

WARNING!

When used for toxic or

aggressive fluids, the pump

prior to disassembly.

should always be flushed clean

WARNING!

In the event of diaphragm rupture, pump ed materia l may enter

discharged into the atmosphere. If pumping a

product which is hazardous or toxic, the air

exhaust must be piped to an appropriate area for

safe disposition.

the air end of the pump, and be

CAUTION!

Before pump operation, inspect

all gasketed fasteners for loose-

torque loose fasteners to prevent leakage. Follow

recommended torques stated in this manual.

ness caused by gasket creep. Re-

RECYCLING

Many components of KREMLIN

air operated double diaphragm

materials. We encourage pump users to recycle

worn out parts and pumps whenever possible,

after any hazardous pumped fluids are

thoroughly flushed.

pumps are made of recyclable

HG-CF-998 Rev. D - 03/27/03

Page 4

Page 6

IMPORTANT!

Read these instructions

completely, before

is the responsibility of the purchaser t o

retain this manual for reference.

Failure to comply with the

recommendations stated in this

manual will damage the pump, and

void factory warranty.

installation and start-up. It

SERVICE

The following sections give a general

overview on how to service all models of

BLAGDON Diaphragm Pumps. For

details on individual part numbers,

quantities, materials, etc., please consult

the parts list supplied with the pump.

NOTE : Before commencing any

service or maintenance work on the

pump, ensure that the air supply has

been disconnected o r isolated.

AIR VALVE SYSTEMS

PNEUMATIC TYPE Remove the 4

screws securing the valve block to the

valve chest, together with an y associated

gaskets or seals.

Remove slide valve plate & slide valve

from the valve block ass embly. Clean al l

parts thoroughly and inspect for

excessive wear, replacing where

necessary.

The slide valve and valve plate contact

faces should be flat and free from

scratches. A light polishing on a flat

surface with a fine abrasive paper will

remove most scratches.

If excessive wear is suspected in the

valve block bore or valve carrier, remove

the valve block plugs and withdraw the

valve carrier. Check valve block plug orings for wear or attack & replace where

required.

Clean the valve carrier & valve block

bore with white spirits to remove any oil

films.

NOTE : The nominal diametrical

clearance between th e valve carrier and

the valve block block bore should be

0.002” - 0.0035”. A cl earance in excess

of this will cause the valve system to run

erratically.

Apply a light grease to the valve block

plug O-rings when re-assembling into the

valve block bore. Any damage to the Oring may cause the valve system to

malfunction.

Re-assemble the valve block assembly &

re-torque in accordance to the settings

shown in the parts list.

In the event of a complete air-side

overhaul, the pump should be disassembled down to the centre section

assembly as described later in the “WetSide Overhaul” section.

With the valve block assembly

dismantled, remove the inner covers

where appropriate.

A careful note of the position of all

related seals and gaskets should be made

to facilitate re-assembly.

Remove diaphragm shaft bushes, where

appropriate, and check all seal s and ‘O’

rings for wear or damage. If worn,

replace immediately.

NOTE:- The integrity of the diaphr agm

shaft seals is essential for the correct

functioning of all pneumatically

actuated valve systems.

Check the diaphragm shaft for e xcessive

wear as this will result in premature seal

failure. Replace as required. Lubri cate

all components and re-assemble as

detailed above, in reverse order. Ensure

the correct position of all components

detailed in all sectional assembly

drawings.

WET-SIDE OVERHAUL

REPLACING BALL VALVES

Remove discharge manifold from pump

assembly together with associated valve

balls, seats and ‘O’ rings.

NOTE :- The orientation of the val ve

seat relative to the valve ball should be

noted as incorrect positioning may

result in a performance loss.

Turn pump th rough 180

suction manifold. Clean and inspect the

components. Check for any wear or

damage and replace as required .

NOTE :- Ball or valve seat wear may

result in loss of performance and

suction lift.

Re-assemble the valve balls/seats and

ensure manifolds are adequ ately torqued

to the settings shown in the parts list.

REPLACING DIAPHRAGMS

Remove both suction and discharge

manifolds as detailed in the previous

section, removing all ball valves, seats

and ‘O’ rings.

Loosen and remove both outer covers

from the pump assembly. The

orientatio n of the covers should be noted

o

and remove the

so as to facilitate re-assembly.

Holding one of the frontplates in a vice,

(‘soft jaws’ should be fitted), or with an

adjustable spanner, loosen and remove

the frontplate from the opposite end.

Remove the diaphragm, backplate and

bumpstop from diaphragm shaft.

Carefully withdraw the diaphragm shaft

from the centre section and hold the free

end in a vice, holdin g between the flats

machined on the end. Loosen and

remove the frontplate and remove the

diaphragm together with backplate and

bumpstop (where fitted).

NOTE :- Care should be taken with all

plastic, coated and hygienic pumps, so

that the surface of the frontplate is not

damaged.

Thoroughly clean all part s and check for

wear, damage, swelling, cracking,

delamination and chemical attac k.

Replace components where required.

NOTE :- R ubber diaphragms should be

replaced if they are worn to such an

extent that the fabric re-enforcing is

evident on the surface of the diaphragm.

For pumps fitted with PTFE diaphragms,

a light coating of grease should be

applied to the back-up diaphragm prior to

re-assembly.

Before re-assembly, it is advisable to

check the condition of the diaphragm

shaft seal/’O’ rings for wear or attack. If

either is evident, it is recommended that

they be replaced.

Assemble the diaphragms onto the shaft

in a reverse sequence to their removal.

Care should be taken as to the orientation

of the diaphragm relative to the front and

back plates. All diaphragms have “AIR

SIDE” molded onto one side. The

backplate must be fitted adjacent to the

AIR SIDE of the diaphragm.

HG-CF-998 Rev. D - 03/27/03

Page 5

Page 7

PARTS LIST

HG-CF-998 Rev. D - 03/27/03

REF

No.

Page 6

PART NUMBER QTY

DESCRIPTION

ALUMINIUM ST. STEEL COMMON

1 40-225 BASE LEG

2 1B034 CAP - BASE LEG

3 D490 SKT CAP SCREW M8 x 16

4 25-106 25-108 SUCTION MANIFOLD

5 SEE TABLE O-RING

6 SEE TABLE VALVE SEAT

7 SEE TABLE VALVE BALL

8 25-084 25-073 OUTER COVER

9 25-094 BUMPSTOP

10 SEE TABLE DIAPHRAGM - FLUID

11 25-086 INNER COVER - FLUID SIDE LH

12 25-107 25-109 DISCHARGE MANIFOLD

13 G242 O-RING

14 D216 C’SUNK SKT CAP SCREW M8 x 20

15 25-110 INNER COVER - AIR CHAMBER LH

16 25-092 DIAPHRAGM - AIR CHAMBER

17 25-111 INNER COVER - AIR CHAMBER RH

18 40-113 VALVE CHEST

19 40-046 ELBOW

20 25-085 INNER COVER - FLUID SIDE RH

21 25-080 SPACER

22 25-083 THRUST WASHER

23 25-104 AIR HOSE - LH

24 25-102 BACKPLATE - AIR CHAMBER

25 25-082 LOCKING PLATE

26 25-105 AIR HOSE - RH

27 25-103 SWIVEL ELBOW ADAPTOR

28 D222 SKT CAP SCREW M8 x 30

29 C165 SPRING WASHER M8

30 D114 SKT CAP SCREW M8 x 35

31 C013 WASHER M8

32 A005 HEX. HD. BOLT M8 x 35

33 B003 NUT M8

34 SA10104 FRONTPLATE ASSY.

35 1A007 BACKPLATE

36 1A009 BUMPSTOP

37 40-047 SILENCER

38 G339 O-RING

16

12

48

16

24

PARTS LIST - cont.

REF

No.

2

4

4

1

4

4

4

2

1

2

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

4

8

8

2

2

1

1

8

ALUMINIUM ST. STEEL COMMON

39 D337 SKT CAP SCREW M8 x 40

40 G243 O-RING

41 25-081 DIAPHRAGM SHAFT

42 50-206 SHAFT SEAL

43 25-090 SPACER BUSH

44 G373 O-RING

45 G189 O-RING

46 25-089 SHAFT BUSH

47 25-091 SHAFT SEAL

48 G245 O-RING

49 G367 O-RING

50 40-204 GASKET

51 40-005 VALVE PLATE

52 40-004 SLIDE VALVE

53 H501 CIRCLIP

54 40-207 VALVE BLOCK PLUG

55 G512 O-RING

56 40-192 VALVE CARRIER

57 40-218 VALVE BLOCK

REF DESCRIPTION BUNA-N EPDM VITON NEOPRENE POLYESTER QTY

10 DIAPHRAGM 25-014 25-012 25-013 25-023 25-015 2

7 VALVE BALL 1A049 1A080 1A081 1A079 - 4

7 VALVE BALL - WEIGHTED 1A072 1A092 1A093 1A091 - 4

6 VALVE SEAT 25-011 25-009 25-010 25-029 - 4

5 O-RING G068 G069 G070 G067 - 4

REF DESCRIPTION PTFE ST.STEEL QTY

10 DIAPHRAGM+SUPPORT 25-016+25-014 - 2

7 VALVE BALL 1A002 1A197 4

6 VALVE SEAT 25-097 4 5 O-RING G431 - 4

- These items are available in a recommended spares kit. Please refer to your local stockist / distributor for details.

- These items are available in a recommended spares kit - SA10459 - Air side Kit, including Seal Guide (see Technical Notes)

Seal Guide can be ordered separately if required, Note part No. 25-114

- These items are available as Sub-Assy spare :- SA10463

Santoprene is a registered tradename of Monsanto Corp.

PART NUMBER QTY

DESCRIPTION

4

2

1

2

1

1

2

2

6

2

2

1

1

1

2

2

2

1

1

ELASTOMER TABLE

SANTOPRENE®

25-045

-

-

-

Page 8

HG-CF-998 Rev. D - 03/27/03

Page 7

Sectional General Assembly :- N25 Full Flow 2:1 Metallic Pump

Refer to page 6 : Parts List table for item Ref. Nos.

Page 9

HG-CF-998 Rev. D - 03/27/03

TECHNICAL NOTES :-

Removal of Diaphragm Shaft :-

After first removing manifolds and air-hoses, remove both outer covers (8), followed by frontplates (34), fluid

diaphragms (10), backplates (35) and bumpstops (9 & 36). Separate Spacer/Covers Assy. from Valve Chest

Assy. by removin g 8 of f M8 x 35 bolts a nd s lidin g eit her ha lve f rom s haft. Diap hra gm Shaft c an no w be r em oved

together with air- chamber diaphragm and l ocking p late etc. Assem bly is re verse of rem oval, af ter first f itting seal

guide supplied in a ir side kit SA10459 into en d of diaphragm shaf t as shown above before sliding valve chest

centre over shaft. T his will allo w shaft to p ass thr o’ centr e withou t dam aging s eals. If air- cham ber diaphr agm has

been removed from shaft apply a small amount of Loctite grade 242 to locking plate (25) prior to refitting.

Page 8

Page 10

TECHNICAL NOTES :-

Spacer Cover on

left.

Valve Block on right

Air Hose connections :-

NOTES :-

On assembly, ensure these arrows are in-line on items 15 & 17. Air Hoses

(items 23 & 26) are connected as shown, air chamber inner cover L.H. (11)

connects to fluid cham ber inner cover L.H. (17) and air cham ber inner cover

(15) connects to fluid cha mber inner cover (20) when looking fr om the Valve

Block side of pump.

HG-CF-998 Rev. D - 03/27/03

Page 9

Page 11

Service / Maintenance Log

Date Details Completed

Contact Phone / Fax No.

BLAGDON PUMP

BLAGDON PUMP

BLAGDON PUMPBLAGDON PUMP

HG-CF-998 Rev. D - 03/27/03

A Unit of IDEX Corporation

Contact Information

6017 ENTERPRISE DRIVE, EXPORT,

PENNSYLVANIA 15632-8969, USA.

TEL. : (1) 724-327-7867 FAX. : (1) 724-733-4786

Web Site : www.blagdonpump.com

E-Mail : sales@blagdonpump.com

Page 10

Page 12

HG-CF-998 Rev. D - 03/27/03

Loading...

Loading...