Page 1

3" Elima-Matic Metallic Food Processing - ATEX

with Metallic Center Section

E3 Metallic Pumps

• Stainless Steel

Original Instructions

E3

1: PUMP SPECS2: INSTAL & OP3: EXP VIEW4: WARRANTY

Service & Operating Manual

Versa-Matic

800 North Main Street, Mansfield, OH 44902 USA • Phone: (419) 526-7296 • www.versamatic.com

VERSA-MATIC

®

• Warren Rupp, Inc. • A Unit of IDEX Corporation

© Copyright 2014 Warren Rupp, Inc. All rights reserved

Page 2

Safety Information

IMPORTANT

Read the safety warnings and instructions in this manual

before pump installation and start-up. Failure to comply with

the recommendations stated in this manual could damage the

pump and void factory warranty.

When the pump is used for materials that tend to settle out

or solidify, the pump should be ushed after each use to

prevent damage. In freezing temperatures the pump should be

completely drained between uses.

CAUTION

Before pump operation, inspect all fasteners for loosening

caused by gasket creep. Retighten loose fasteners to prevent

leakage. Follow recommended torques stated in this manual.

Nonmetallic pumps and plastic components are not UV

stabilized. Ultraviolet radiation can damage these parts and

negatively affect material properties. Do not expose to UV light

for extended periods of time.

WARNING

Pump not designed, tested or certied to be powered by

compressed natural gas. Powering the pump with natural

gas will void the warranty.

WARNING

When used for toxic or aggressive uids, the pump should

always be ushed clean prior to disassembly.

Before maintenance or repair, shut off the compressed air line,

bleed the pressure, and disconnect the air line from the pump.

Be certain that approved eye protection and protective clothing

are worn at all times. Failure to follow these recommendations

may result in serious injury or death.

Airborne particles and loud noise hazards. Wear eye and ear

protection.

In the event of diaphragm rupture, pumped material may enter

the air end of the pump, and be discharged into the atmosphere.

If pumping a product that is hazardous or toxic, the air exhaust

must be piped to an appropriate area for safe containment.

Take action to prevent static sparking. Fire or explosion can

result, especially when handling ammable liquids. The pump,

piping, valves, containers and other miscellaneous equipment

must be properly grounded.

This pump is pressurized internally with air pressure during

operation. Make certain that all fasteners are in good condition

and are reinstalled properly during reassembly.

kg

Use safe practices when lifting

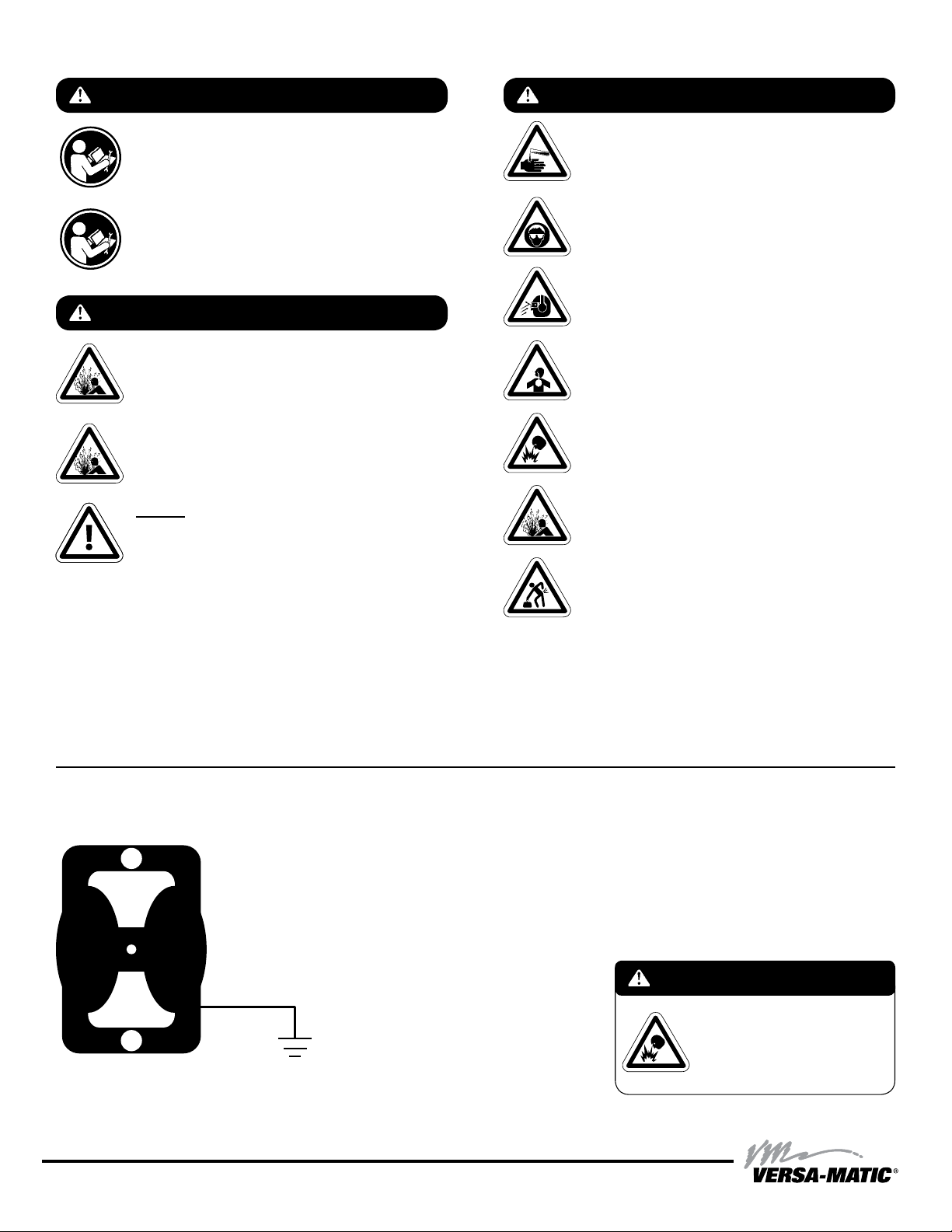

Grounding the Pump

To be fully groundable, the pumps must be ATEX Compliant. Refer to the nomenclature page for ordering information.

Optional 8 foot long (244 centimeters) Ground Strap is available for easy ground connection.

To reduce the risk of static electrical sparking, this pump must be grounded. Check the local

electrical code for detailed grounding instruction and the type of equipment required.

Refer to nomenclature page for ordering information.

WARNING

Take action to prevent static sparking.

Fire or explosion can result, especially

when handling ammable liquids. The

pump, piping, valves, containers or

other miscellaneous equipment must

be grounded.

ww w. ve rs am ati c. co m

e3mdlCsmATEXFP-rev0514

Page 3

Table of Contents

SECTION 1: PUMP SPECIFICATIONS ................1

• Nomenclature

• Performance

• Materials

• Dimensional Drawings

SECTION 2: INSTALLATION & OPERATION ......5

• Principle of Pump Operation

• Typical Installation Guide

• Troubleshooting

SECTION 3: EXPLODED VIEW ...........................8

• Composite Drawings

• Parts List

• Materials Code

1: PUMP SPECS2: INSTAL & OP3: EXP VIEW4: WARRANTY

SECTION 4: WARRANTY & CERTIFICATES ....12

• Warranty

• EC Declaration of Conformity - Machinery

• EC Declaration of Conformity - ATEX

• EC Declaration of Conformity - EC Regulation 1935/2004/EC

e3mdlCsmATEXFP-rev0514

ww w. ve rs am ati c. co m

Page 4

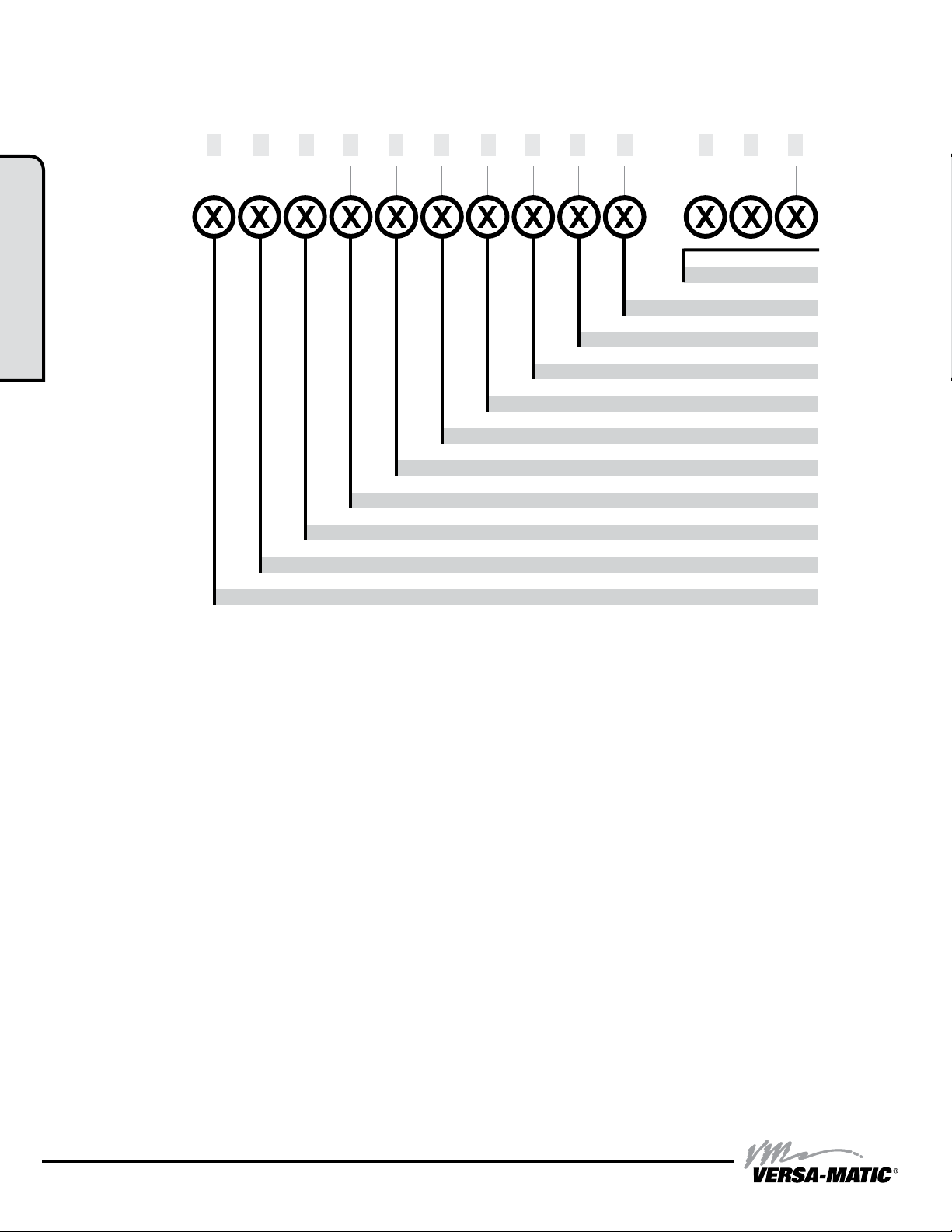

Explanation of Pump Nomenclature

Your Serial #: (ll in from pump nameplate) _____________________________________

1: PUMP SPECS

Your Model #:

(ll in from pump

nameplate)

__ __ __ __ __ __ __ __ __ __ __ __ __

Model #:

Options (if applicable)

Design Level

Construction Design

Valve Seat Material/Valve Seat O-Ring Material

Valve Ball Material

Diaphragm Series

Diaphragm Material

Non-Wetted Parts

Wetted Parts

Pump Size

Model

Model Pump Size Wetted Parts Non-Wetted Parts Diaphragm Material

E Elima-Matic 6 1/4" A Aluminum A Aluminum 1 Neoprene

U Ultra-Matic 8 3/8" C Cast Iron S Stainless Steel 2 Nitrile (Nitrile)

V V-Series 5 1/2" S Stainless Steel P Polypropylene 3 FKM (Fluorocarbon)

RE AirVantage 7 3/4" H Alloy C G Groundable Acetal 4 EPDM

1 1" P Polypropylene Z PTFE-coated Aluminum 5 PTFE

4 1-1/4" or 1-1/2" K Kynar J Nickel-plated Aluminum 6 Santoprene XL

2 2" G Groundable Acetal C Cast Iron 7 Hytrel

3 3" B Aluminum (screen mount) Q Epoxy-Coated Aluminum 9 Geolast

Y FDA Santoprene

Diaphragm Series Valve Ball Material Valve Seat/Valve Seat O-Ring Material Construction Design Miscellaneous Options

R Rugged 1 Neoprene 1 Neoprene 9 Bolted B BSP Tapered Thread

D Dome 2 Nitrile 2 Nitrile 0 Clamped CP Center Port

X Thermo-Matic 3 (FKM) Fluorocarbon 3 (FKM) Fluorocarbon ATEX ATEX Compliant

T Tef-Matic (2-piece) 4 EPDM 4 EPDM Design Level FP Food Processing

B Versa-Tuff (1-piece) 5 PTFE 5 PTFE A SP Sanitary Pump

F FUSION (one-piece 6 Santoprene XL 6 Santoprene XL C HP High Pressure

integrated plate) 7 Hytrel 7 Hytrel OE Original Elima-Matic

8 Polyurethane 8 Polyurethane F Flap Valve

9 Geolast 9 Geolast HD Horizontal Discharge

A Acetal A Aluminum w/ PTFE O-Rings 3A 3-A Certied

S Stainless Steel S Stainless Steel w/ PTFE O-Rings UL UL Listed

Y FDA Santoprene C Carbon Steel w/ PTFE O-Rings OB Oil Bottle

H Alloy C w/ PTFE O-Rings

T PTFE Encapsulated Silicone O-Rings

Y FDA Santoprene

*More than one option may be specied for a particular pump model.

1 • Model E3 Metallic Food Processing

ww w. ve rs am ati c. co m

e3mdlCsmATEXFP-rev0514

Page 5

Materials

Material Prole:

CAUTION! Operating temperature limitations are as follows:

Conductive Acetal: Tough, impact resistant, ductile. Good

abrasion resistance and low friction surface. Generally inert, with

good chemical resistance except for strong acids and oxidizing

agents.

EPDM: Shows very good water and chemical resistance. Has

poor resistance to oils and solvents, but is fair in ketones and

alcohols.

FKM: (Fluorocarbon) Shows good resistance to a wide range

of oils and sovents; especially all aliphatic, aromatic and

halogenated hydrocarbons, acids, animal and vegetable oils.

Hot water or hot aqueous solutions (over 70°F) will attack FKM.

Hytrel®: Good on acids, bases, amines and glycols at room

temperatures only.

Neoprene: All purpose. Resistance to vegetable oils. Generally

not affected by moderate chemicals, fats, greases and many

oils and solvents. Generally attacked by strong oxidizing acids,

ketones, esters and nitro hydrocarbons and chlorinated aromatic

hydrocarbons.

Nitrile: General purpose, oil-resistant. Shows good solvent, oil,

water and hydraulic uid resistance. Should not be used with

highly polar solvents like acetone and MEK, ozone, chlorinated

hydrocarbons and nitro hydrocarbons.

Nylon: 6/6 High strength and toughness over a wide

temperature range. Moderate to good resistance to fuels, oils

and chemicals.

Operating

Temperatures:

Max. Min.

190°F

88°C

280°F

138°C

350°F

177°C

220°F

104°C

200°F

93°C

190°F

88°C

180°F

82°C

-20°F

-29°C

-40°F

-40°C

-40°F

-40°C

-20°F

-29°C

-10°F

-23°C

-10°F

-23°C

32°F

0°C

Polypropylene: A thermoplastic polymer. Moderate tensile

and ex strength. Resists stong acids and alkali. Attacked by

chlorine, fuming nitric acid and other strong oxidizing agents.

PVDF: (Polyvinylidene Fluoride) A durable uoroplastic with

excellent chemical resistance. Excellent for UV applications.

High tensile strength and impact resistance.

Santoprene®: Injection molded thermoplastic elastomer with

no fabric layer. Long mechanical ex life. Excellent abrasion

resistance.

UHMW PE: A thermoplastic that is highly resistant to a broad

range of chemicals. Exhibits outstanding abrasion and impact

resistance, along with environmental stress-cracking resistance.

Urethane: Shows good resistance to abrasives. Has poor

resistance to most solvents and oils.

Virgin PTFE: (PFA/TFE) Chemically inert, virtually impervious.

Very few chemicals are known to chemically react with PTFE;

molten alkali metals, turbulent liquid or gaseous uorine and

a few uoro-chemicals such as chlorine triuoride or oxygen

diuoride which readily liberate free uorine at elevated

temperatures.

Maximum and Minimum Temperatures are the limits for which these materials can be operated.

Temperatures coupled with pressure affect the longevity of diaphragm pump components.

Maximum life should not be expected at the extreme limits of the temperature ranges.

180°F

82°C

250°F

121°C

275°F

135°C

180°F

82°C

150°F

66°C

220°F

104°C

32°F

0°C

0°F

-18°C

-40°F

-40°C

-35°F

-37°C

32°F

0°C

-35°F

-37°C

Metals:

Alloy C: Equal to ASTM494 CW-12M-1 specication for nickel and nickel alloy.

Stainless Steel: Equal to or exceeding ASTM specication A743 CF-8M for corrosion

resistant iron chromium, iron chromium nickel and nickel based alloy castings for

general applicaitons. Commonly referred to as 316 Stainless Steel in the pump industry.

For specic applications, always consult the Chemical Resistance Chart.

Note: This document is a high level guide. Please be aware that not all model and or material

combinations are possible for all sizes. Please consult factory or your distributor for specic details.

1: PUMP SPECS

AFTERMARKET PARTS

RIGHT PART, RIGHT NOW

Pumper Parts is your single source for parts that

t Air-Operated Double Diaphragm (AODD) pumps

• Wilden

• ARO

• Yamada

Designed to perform equal to or greater

than original equipment manufacture.

Pumper Parts and its products are not affiliated with any of the original equipment manufacturers referenced herein. All original equipment manufacturers’ names, colors, pictures, descriptions and part numbers are used for identification

purposes only. Pumper Parts® is a registered trade name of IDEX Corporation. All other trademarks, registered trademarks and product names are the property of their respective owners. Yamada® is a registered trademark of

Yamada Corporation. ARO® is a registered trade name of Ingersoll-Rand Company. Wilden® is a registered trade name of Wilden Pump and Engineering Company, a Dover Resources Company.

®

®

®

Phone: (419) 526-7296

info@pum perparts.com

www.pumperparts.com

e3mdlCsmATEXFP-rev0514

ww w. ve rs am ati c. co m

Model E3 Metallic Food Processing • 2

Page 6

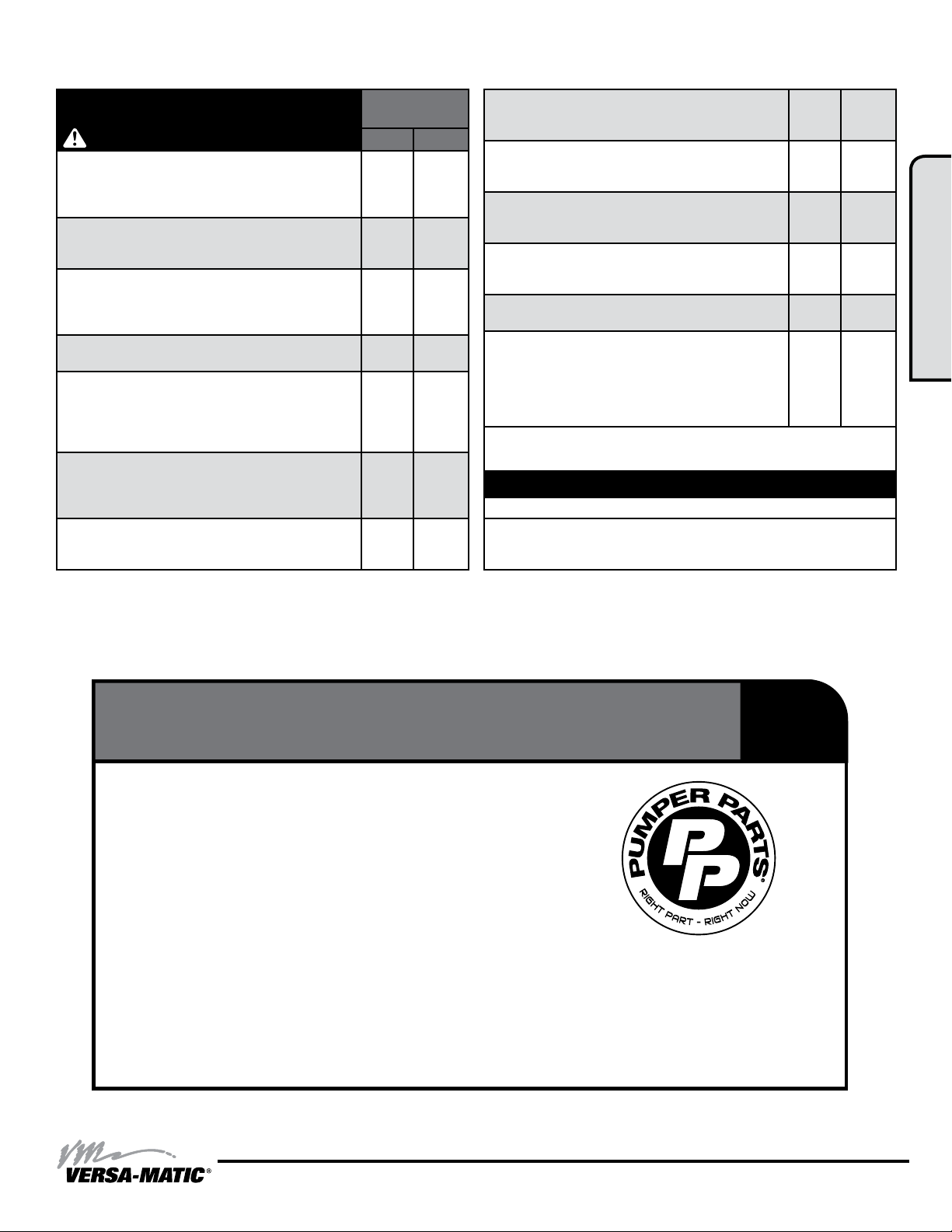

Performance

E3 3" Clamped - Food Processing

TPE Fitted

Flow Rate

Adjustable to ....... 0-234 gpm (886 lpm)

Port Size

Suction ................. 3" TRI-CLAMP

Discharge...............3" TRI-CLAMP

Air Inlet ......................1/2" NPT

Air Exhaust ................... 1" NPT

Suction Lift

Dry ........................20' (6.1 m)

Wet........................32' (9.8 m)

Max Solid Size (Diameter)

1: PUMP SPECS

........................3/8" (9.5 mm)

Max Noise Level .............96 dB(A)

Shipping Weights

Stainless................189 lbs (86 kg)

** Stainless Center add ..........50 lbs. (22.7 kg)

320

90

280

80

240

70

200

60

50

160

40

120

30

80

20

40

10

0

0

Meters Feet

10

140

9

120

8

7

100

6

80

5

60

4

Discharge Head in PSI

3

40

2

20

1

0

BAR

0

20

0 20

40

60

80

100

120

140

40 60 80 100 120 140 160 180 200 220 240

Displacement Per Stroke, 1.36 Gal. (5.1 L)

AIR CONSUMPTION IN SCFM

AIR PRESSURE IN PSI

160

180

SCFM M3/HR

20 34

40 68

60 102

80 136

100 170

120 204

140 238

160 272

180 306

Capacity in U.S. Gallons Per Minute

0

120 240 360 480 600 720 840

Capacity in Liters Per Minute

NOTE: Performance based on the following: PTFE tted pump, ooded suction, water at ambient

conditions. The use of other materials and varying hydraulic conditions may result in deviations in

excess of 5%.

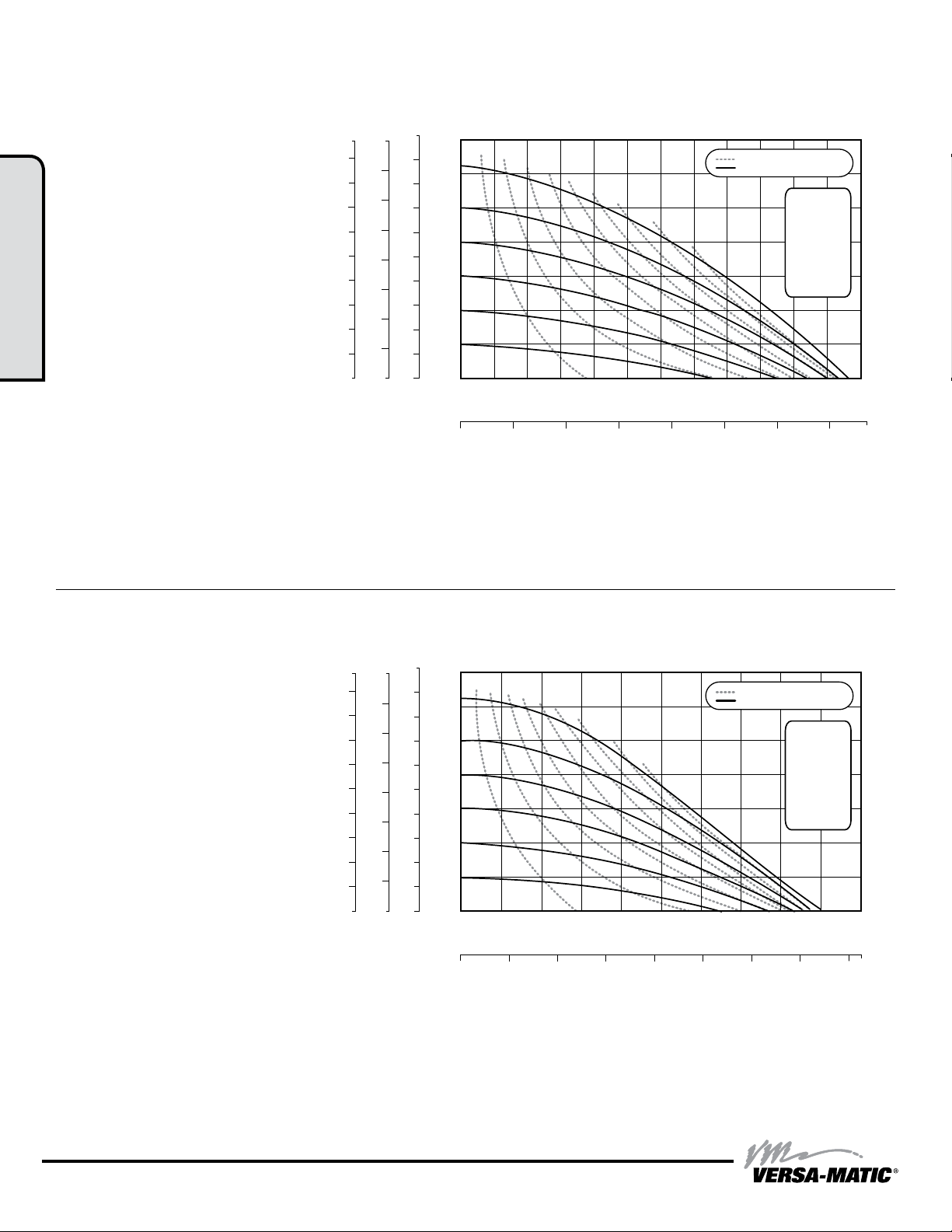

E3 3" Clamped - Food Processing

PTFE Fitted

Flow Rate

Adjustable to ....... 0-180 gpm (681 lpm)

Port Size

Suction ................. 3" TRI-CLAMP

Discharge...............3" TRI-CLAMP

Air Inlet ......................1/2" NPT

Air Exhaust ................... 1" NPT

Suction Lift

Dry ........................12' (3.7 m)

Wet........................32' (9.8 m)

Max Solid Size (Diameter)

........................3/8" (9.5 mm)

Max Noise Level .............95 dB(A)

Shipping Weights

Stainless................189 lbs (86 kg)

** Stainless Center add ..........50 lbs. (22.7 kg)

320

90

280

80

240

70

200

60

50

160

40

120

30

80

20

40

10

0

0

Meters Feet

10

140

9

120

8

7

100

6

80

5

60

4

Discharge Head in PSI

3

40

2

20

1

0

BAR

0

20

40

0 20

60

80

100

120

140

160

180

40 60 80 100 120 140 160 180 200

Capacity Per Stroke, 0.92 Gal. (3.5 L)

AIR CONSUMPTION IN SCFM

AIR PRESSURE IN PSI

SCFM M3/HR

20 34

40 68

60 102

80 136

100 170

120 204

140 238

160 272

180 306

Capacity in U.S. Gallons Per Minute

0

27018090

360 450 540 630 720

Capacity in Liters Per Minute

NOTE: Performance based on the following: PTFE tted pump, ooded suction, water at ambient

conditions. The use of other materials and varying hydraulic conditions may result in deviations in

excess of 5%.

3 • Model E3 Metallic Food Processing

ww w. ve rs am ati c. co m

e3mdlCsmATEXFP-rev0514

Page 7

Dimensional Drawings

279.40

8 7

6

5

4

3

C

3

2

1

D

B

E3 Metallic Food Processing

Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm).

21.41

543.79

11.38

288.93

1/2" NPT

AIR INLET

AIR EXHAUST

21.54

547.00

CLAMP DISCHARGE

1" NPT

3.57 O.D. TRI-

FLANGE

16.96

430.66

3.46

87.96

1: PUMP SPECS

29.76

755.90

32.01

813.05

2.31

58.67

R

.29

7.37

11.00

279.40

3.57 O.D. TRI-

CLAMP SUCTION

11.95

303.53

14.25

361.95

FLANGE

.40

10.16

2.30

58.42

10.00

254.00

e3mdlCsmATEXFP-rev0514

BOTTOM VIEW

ww w. ve rs am ati c. co m

Model E3 Metallic Food Processing • 4

Page 8

Principle of Pump Operation

SAFE AIR

EXHAUST

DISPOSAL

AREA

MUFFLER

Air-Operated Double Diaphragm (AODD) pumps are powered

by compressed air or nitrogen.

2: INSTAL & OP

The main directional (air) control valve

compressed air to an air chamber, exerting uniform pressure

over the inner surface of the diaphragm

the exhausting air

is directed through the air valve assembly(s) to an exhaust

port

.

④

As inner chamber pressure

pressure

together creating discharge on one side and suction on the

opposite side. The discharged and primed liquid’s directions

are controlled by the check valves (ball or ap)

The pump primes as a result of the suction stroke. The

suction stroke lowers the chamber pressure

the chamber volume. This results in a pressure differential

necessary for atmospheric pressure

through the suction piping and across the suction side check

valve and into the outer uid chamber

Suction (side) stroking also initiates the reciprocating

(shifting, stroking or cycling) action of the pump. The suction

diaphragm’s movement is mechanically pulled through its

stroke. The diaphragm’s inner plate makes contact with an

actuator plunger aligned to shift the pilot signaling valve.

Once actuated, the pilot valve sends a pressure signal to the

opposite end of the main directional air valve, redirecting the

compressed air to the opposite inner chamber.

(P2), the rod

from behind the opposite diaphragm

③

(P1) exceeds liquid chamber

connected diaphragms shift

⑤

distributes

①

. At the same time,

②

orientation.

⑥

(P3) increasing

(P4) to push the uid

.

⑦

5 • Model E3 Metallic Food Processing

SUBMERGED ILLUSTRATION

MUFFLER

LIQUID

LEVEL

SUCTION

LINE

Pump can be submerged if the pump materials of construction

are compatible with the liquid being pumped. The air exhaust

must be piped above the liquid level. When the pumped product

source is at a higher level than the pump (ooded suction

condition), pipe the exhaust higher than the product source to

prevent siphoning spills.

ww w. ve rs am ati c. co m

1" DIAMETER AIR

EXHAUST PIPING

e3mdlCsmATEXFP-rev0514

Page 9

Recommended Installation Guide

Available Accessories:

1. Surge Suppressor

2. Filter/Regulator

3. Air Dryer

Unregulated Air

Supply to Surge

Suppressor

1

Surge Suppressor

Pressure Gauge

Shut-Off Valve

Note: Surge Suppressor and

Piping must be supported after

the exible connection.

(Optional Piped Exhaust)

Flexible Connector

Vacuum

Gauge

Suction

Shut-Off Valve

Drain Port

Muffler

Pipe Connection

(Style Optional)

Flexible Connector

Pipe Connection

(Style Optional)

Drain Port

Flexible

Connector

Discharge

2

3

Filter Regulator

P/N: 020.V107.000

Air Dryer

Note: Pipe weight should not be supported

by pump connections.

CAUTION

Check

Valve

Shut-Off

Valve

Air Inlet

2: INSTAL & OP

The air exhaust should

be piped to an area

for safe disposition

of the product being

pumped, in the event of

a diaphragm failure.

Installation And Start-Up

Locate the pump as close to the product being pumped as possible. Keep the suction line length and number of ttings to a minimum. Do not reduce the suction line

diameter.

Air Supply

Connect the pump air inlet to an air supply with sufcient capacity and pressure to achieve desired performance. A pressure regulating valve should be installed to

insure air supply pressure does not exceed recommended limits.

Air Valve Lubrication

The air distribution system is designed to operate WITHOUT lubrication. This is the standard mode of operation. If lubrication is desired, install an air line lubricator

set to deliver one drop of SAE 10 non-detergent oil for every 20 SCFM (9.4 liters/sec.) of air the pump consumes. Consult the Performance Curve to determine air

consumption.

Air Line Moisture

Water in the compressed air supply may cause icing or freezing of the exhaust air, causing the pump to cycle erratically or stop operating. Water in the air supply can

be reduced by using a point-of-use air dryer.

Air Inlet And Priming

To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air ow as desired. If opening the valve

increases cycling rate, but does not increase the rate of ow, cavitation has occurred. The valve should be closed slightly to obtain the most efcient air ow to pump

ow ratio.

e3mdlCsmATEXFP-rev0514

ww w. ve rs am ati c. co m

Model E3 Metallic Food Processing • 6

Page 10

Troubleshooting Guide

Symptom: Potential Cause(s): Recommendation(s):

Pump Cycles Once

Pump Will Not Operate

/ Cycle

Pump Cycles and Will

Not Prime or No Flow

Pump Cycles Running

2: INSTAL & OP

Sluggish/Stalling,

Flow Unsatisfactory

Product Leaking

Through Exhaust

Premature Diaphragm

Failure

Unbalanced Cycling

Deadhead (system pressure meets or exceeds air

supply pressure).

Air valve or intermediate gaskets installed incorrectly. Install gaskets with holes properly aligned.

Bent or missing actuator plunger. Remove pilot valve and inspect actuator plungers.

Pump is over lubricated. Set lubricator on lowest possible setting or remove. Units are designed for lube free operation.

Lack of air (line size, PSI, CFM). Check the air line size and length, compressor capacity (HP vs. cfm required).

Check air distribution system. Disassemble and inspect main air distribution valve, pilot valve and pilot valve actuators.

Discharge line is blocked or clogged manifolds. Check for inadvertently closed discharge line valves. Clean discharge manifolds/piping.

Deadhead (system pressure meets or exceeds air

supply pressure).

Blocked air exhaust mufer. Remove mufer screen, clean or de-ice, and re-install.

Pumped uid in air exhaust mufer. Disassemble pump chambers. Inspect for diaphragm rupture or loose diaphragm plate assembly.

Pump chamber is blocked. Disassemble and inspect wetted chambers. Remove or ush any obstructions.

Cavitation on suction side. Check suction condition (move pump closer to product).

Check valve obstructed. Valve ball(s) not seating

properly or sticking.

Valve ball(s) missing (pushed into chamber or

manifold).

Valve ball(s)/seat(s) damaged or attacked by product. Check Chemical Resistance Guide for compatibility.

Check valve and/or seat is worn or needs adjusting. Inspect check valves and seats for wear and proper setting. Replace if necessary.

Suction line is blocked. Remove or ush obstruction. Check and clear all suction screens or strainers.

Excessive suction lift. For lifts exceeding 20’ of liquid, lling the chambers with liquid will prime the pump in most cases.

Suction side air leakage or air in product. Visually inspect all suction-side gaskets and pipe connections.

Pumped uid in air exhaust mufer. Disassemble pump chambers. Inspect for diaphragm rupture or loose diaphragm plate assembly.

Over lubrication. Set lubricator on lowest possible setting or remove. Units are designed for lube free operation.

Icing. Remove mufer screen, de-ice, and re-install. Install a point of use air drier.

Clogged manifolds. Clean manifolds to allow proper air ow

Deadhead (system pressure meets or exceeds air

supply pressure).

Cavitation on suction side. Check suction (move pump closer to product).

Lack of air (line size, PSI, CFM). Check the air line size, length, compressor capacity.

Excessive suction lift. For lifts exceeding 20’ of liquid, lling the chambers with liquid will prime the pump in most cases.

Air supply pressure or volume exceeds system hd. Decrease inlet air (press. and vol.) to the pump. Pump is cavitating the uid by fast cycling.

Undersized suction line. Meet or exceed pump connections.

Restrictive or undersized air line. Install a larger air line and connection.

Suction side air leakage or air in product. Visually inspect all suction-side gaskets and pipe connections.

Suction line is blocked. Remove or ush obstruction. Check and clear all suction screens or strainers.

Pumped uid in air exhaust mufer. Disassemble pump chambers. Inspect for diaphragm rupture or loose diaphragm plate assembly.

Check valve obstructed. Disassemble the wet end of the pump and manually dislodge obstruction in the check valve pocket.

Check valve and/or seat is worn or needs adjusting. Inspect check valves and seats for wear and proper setting. Replace if necessary.

Entrained air or vapor lock in chamber(s). Purge chambers through tapped chamber vent plugs. Purging the chambers of air can be dangerous.

Diaphragm failure, or diaphragm plates loose. Replace diaphragms, check for damage and ensure diaphragm plates are tight.

Diaphragm stretched around center hole or bolt holes. Check for excessive inlet pressure or air pressure. Consult Chemical Resistance Chart for compatibility

Cavitation. Enlarge pipe diameter on suction side of pump.

Excessive ooded suction pressure. Move pump closer to product. Raise pump/place pump on top of tank to reduce inlet pressure.

Misapplication (chemical/physical incompatibility). Consult Chemical Resistance Chart for compatibility with products, cleaners, temperature limitations

Incorrect diaphragm plates or plates on backwards,

installed incorrectly or worn.

Excessive suction lift. For lifts exceeding 20’ of liquid, lling the chambers with liquid will prime the pump in most cases.

Undersized suction line. Meet or exceed pump connections.

Pumped uid in air exhaust mufer. Disassemble pump chambers. Inspect for diaphragm rupture or loose diaphragm plate assembly.

Suction side air leakage or air in product. Visually inspect all suction-side gaskets and pipe connections.

Check valve obstructed. Disassemble the wet end of the pump and manually dislodge obstruction in the check valve pocket.

Check valve and/or seat is worn or needs adjusting. Inspect check valves and seats for wear and proper setting. Replace if necessary.

Entrained air or vapor lock in chamber(s). Purge chambers through tapped chamber vent plugs.

Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero ow.

(Does not apply to high pressure 2:1 units).

Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero ow.

(Does not apply to high pressure 2:1 units).

Disassemble the wet end of the pump and manually dislodge obstruction in the check valve pocket.

Clean out around valve ball cage and valve seat area. Replace valve ball or valve seat if damaged.

Use heavier valve ball material.

Worn valve ball or valve seat. Worn ngers in valve ball cage (replace part). Check Chemical

Resistance Guide for compatibility.

Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero ow.

(Does not apply to high pressure 2:1 units).

with products, cleaners, temperature limitations and lubrication.

Install Back pressure device (Tech bulletin 41r). Add accumulation tank or pulsation dampener.

and lubrication.

Check Operating Manual to check for correct part and installation. Ensure outer plates have not been

worn to a sharp edge.

For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388

7 • Model E3 Metallic Food Processing

ww w. ve rs am ati c. co m

e3mdlCsmATEXFP-rev0514

Page 11

Composite Repair Parts DrawingComposite Repair Parts Drawing - TPE Fitted

38

40

4142

2

3

12

15

19

33

25

32

37

34

35

26

27

30

31

14

29

28

20

22

21

18

24

17

13

16

11

8

5

7

9

10

4

23

39

6

11

3: EXP VIEW

36

40

41

42

e3mdlCsmATEXFP-rev0514

ww w. ve rs am ati c. co m

Model E3 Metallic Food Processing • 8

Page 12

Composite Repair Parts List - TPE Fitted

Air Valve Assembly

Item # Qty. Description

1 1 Valve Body (includes items 2-11) 031.V003.332 031.V003.110

2 1 Valve Body 095.V001.332 095.V001.110

3 1 Valve Body Gasket P24-202

4 1 Valve Sleeve 755.V005.148

5 6 O-ring 560.206.360

6 1 Valve Spool Assembly (Includes items 7) 775.V001.000

7 6 Glyde Ring Assembly P34-204F

8 1 Air Valve Screen P24-210 P34-210

9 2 End Cap Gasket P24-205

10 2 End Cap SP34-300

11 13 Mounting Screws (8 included on item 1) S1001

Center Section Assembly

Item # Qty. Description

12 1 Center Block Assembly (Includes item 13 & 14) P34-401NP SP34-400

13 2 Bearing Sleeve P34-404

14 2 Main Shaft O-Ring P34-403

15 2 Air Chamber 196.V006.332 196.V006.110

16 2 Air Chamber Gasket P79-109 P24-109A

17 8 Bolt SP34-110

18 1 Pilot Sleeve Assembly (include item 19) 755.V002.000

19 6 O-ring 560.101.358

20 1 Retaining Ring 675.037.080

21 1 Pilot Spool Assembly (Includes item 22) 775.V006.000

22 8 O-ring 560.023.358

23 1 Mufer 530.033.000

Diaphragm Assembly / Elastomers

Item # Qty. Description

24 1 Main Shaft P34-103

25 2 Diaphragm V305TPEFG V305TPEXLFG

26 2 Outer Diaphragm Plate SV302BFG

27 2 Inner Diaphragm Plate V302CDCNP SV302C

28 12 Bolt SV302G

29 12 Washer SV302GA

30 2 Bumper Washer P34-501

31 2 Back-Up Washer V302E

32 4 Valve Seat V356TPEFG V240TPEXLFG

33 4 Valve Ball V355TPEFG V241TPEXLFG

3: EXP VIEW

Item # Qty. Description Part Number

34 2 Water Chamber SV350FG

35 4 Large Clamp Half SV311A

36 4 Bolt SV311C

37 4 Large Wing Nut FG11D

38 1 Discharge Manifold SV351FG

39 1 Suction Manifold SV352FFG

40 8 Small Clamp Half SV354A

41 8 Bolt SV354B

42 8 Small Wing Nut FG30D

Wet End Assembly

Nickle Plated Stainless Steel

Nickle Plated Stainless Steel

FDA Hytrel FDA Santoprene

Part Number

Part Number

Part Number

9 • Model E3 Metallic Food Processing

ww w. ve rs am ati c. co m

e3mdlCsmATEXFP-rev0514

Page 13

Composite Repair Parts Drawing - PTFE Fitted

2

3

5

8

9

10

11

14

15

16

17

18

19

20

21

22

23

24

25

27

26

28

29

30

31

32

33

34

37

38

39

35

36

4041

41

38

40

11

13

12

7

6

4

BONDED DIAPHRAGM ASSEMBLEY

25

28

27

30

29

24

2

3

5

8

9

10

37

39

4041

11

7

28

29

24

30

25

27

BONDED DIAPHRAGM ASSEMBLEY

3: EXP VIEW

e3mdlCsmATEXFP-rev0514

ww w. ve rs am ati c. co m

Model E3 Metallic Food Processing • 10

Page 14

Composite Repair Parts List - PTFE Fitted

Air Valve Assembly

Item # Qty. Description

1 1 Valve Body (includes items 2-11) 031.V003.332 031.V003.110

2 1 Valve Body 095.V001.332 095.V001.110

3 1 Valve Body Gasket P24-202

4 1 Valve Sleeve 755.V005.148

5 6 O-ring 560.206.360

6 1 Valve Spool Assembly (Includes items 7) 775.V001.000

7 6 Glyde Ring Assembly P34-204F

8 1 Air Valve Screen P24-210 P34-210

9 2 End Cap Gasket P24-205

10 2 End Cap SP34-300

11 13 Mounting Screws (8 included on item 1) S1001

Center Section Assembly

Item # Qty. Description

12 1 Center Block Assembly (Includes item 13 & 14) P34-401NP SP34-400

13 2 Bearing Sleeve P34-404

14 2 Main Shaft O-Ring P34-403

15 2 Air Chamber 196.V006.332 196.V006.110

16 2 Air Chamber Gasket P79-109 P24-109A

17 8 Bolt SP34-110

18 1 Pilot Sleeve Assembly (include item 19) 755.V002.000

19 6 O-ring 560.101.358

20 1 Retaining Ring 675.037.080

21 1 Pilot Spool Assembly (Includes item 22) 775.V006.000

22 8 O-ring 560.023.358

23 1 Mufer 530.033.000

Diaphragm Assembly / Elastomers

Item # Qty. Description

PTFE Two Piece PTFE Bonded PTFE Two Piece PTFE Bonded

24 1 Main Shaft P34-103 P34-103 P34-103 P34-103

25 2 Diaphragm V305TF V305TX V305TF V305TX

26 1 Back Up Diaphragm V305TFB N/A V305TFB N/A

27 2 Outer Diaphragm Plate SV302TOFG SV302TOFG SV302TOFG SV302TOFG

28 2 Inner Diaphragm Plate V302TINP V302TINP SV302TI SV302TI

29 2 Bumper Washer P34-501 P34-501 P34-501 P34-501

30 2 Back-Up Washer V302E V302E V302E V302E

31 4 Valve Seat (See Material Chart Below) xV356xx XV356XX XV356XX XV356XX

32 4 Valve Ball V355TF V355TF V355TF V355TF

3: EXP VIEW

Item # Qty. Description Part Number

33 2 Water Chamber SV350FG

34 4 Large Clamp Half SV311A

35 4 Bolt SV311C

36 4 Large Wing Nut FG11D

37 1 Discharge Manifold SV351FG

38 1 Suction Manifold SV352FFG

39 8 Small Clamp Half SV354A

40 8 Bolt SV354B

41 8 Small Wing Nut FG30D

42 2 Diaphragm Seal Tape Kit (Not Pictured) 720.V006.000

Material "Ball P/N" Seat P/N

PTFE V355TF V356TF

Stainless Steel N/A SV356 (See Note 1 Below)

Wet End Assembly

Material Specications

Nickle Plated Stainless Steel

Nickle Plated Stainless Steel

Nickle Plated Air End Stainless Steel Air End

Part Number

Part Number

Part Number

Notes:

In addition to this seat, (4) V356T O-Rings are needed.

11 • Model E3 Metallic Food Processing

ww w. ve rs am ati c. co m

e3mdlCsmATEXFP-rev0514

Page 15

Written Warranty

5 - YEAR Limited Product Warranty

Quality System ISO9001 Certied • Environmental Management Systems ISO14001 Certied

Versa-Matic warrants to the original end-use purchaser that no product sold by

Versa-Matic that bears a Versa-Matic brand shall fail under normal use and service due to a defect in material

or workmanship within ve years from the date of shipment from Versa-Matic’s factory.

~ See complete warranty at http://www.versamatic.com/pdfs/VM%20Product%20Warranty.pdf ~

DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE • DECLARACION DE CONFORMIDAD • ERKLÄRUNG BEZÜGLICH EINHALTUNG DER VORSCHRIFTEN

MANUFACTURED BY:

FABRIQUE PAR:

FABRICADA POR:

HERGESTELLT VON:

FABBRICATO DA:

VERVAARDIGD DOOR:

TILLVERKAD AV:

FABRIKANT:

VALMISTAJA:

PRODUSENT:

FABRICANTE:

DICHIARAZIONE DI CONFORMITÀ • CONFORMITEITSVERKLARING • DEKLARATION OM ÖVERENSSTÄMMELSE

EF-OVERENSSTEMMELSESERKLÆRING • VAATIMUSTENMUKAISUUSVAKUUTUS • SAMSVARSERKLÄRING

DECLARAÇAO DE CONFORMIDADE

VERSA-MATIC

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 North Main Street

P.O. Box 1568

Mansfield, OH 44901-1568 USA

Tel: 419-526-7296

Fax: 419-526-7289

®

PUMP MODEL SERIES: E SERIES, V SERIES, VT SERIES, VSMA3, SPA15,

RE SERIES AND U2 SERIES

This product complies with the following European Community Directives:

Ce produit est conforme aux directives de la Communauté européenne suivantes:

Este producto cumple con las siguientes Directrices de la Comunidad Europea:

Dieses produkt erfüllt die folgenden Vorschriften der Europäischen Gemeinschaft:

Questo prodotto è conforme alle seguenti direttive CEE:

Dir produkt voldoet aan de volgende EG-richtlijnen:

Denna produkt överensstämmer med följande EU direktiv:

Versa-Matic, Inc., erklærer herved som fabrikant, at ovennævnte produkt er i overensstemmelse med bestemmelserne i Direkktive:

Tämä tuote täyttää seuraavien EC Direktiivien vaatimukstet:

Dette produkt oppfyller kravene til følgende EC Direktiver:

Este produto está de acordo com as seguintes Directivas comunitárias:

2006/42/EC

on Machinery, according

to Annex VIII

This product has used the following harmonized standards to verify conformance: EN809:1998+

Ce materiel est fabriqué selon les normes harmonisées suivantes, afin d’ en garantir la conformité:

Este producto cumple con las siquientes directrices de la comunidad europa:

Dieses produkt ist nach folgenden harmonisierten standards gefertigtworden, die übereinstimmung wird bestätigt:

Questo prodotto ha utilizzato i seguenti standards per verificare la conformita´:

De volgende geharmoniseerde normen werden gehanteerd om de conformiteit van dit produkt te garanderen:

För denna produkt har följande harmoniserande standarder använts för att bekräfta överensstämmelse:

Harmoniserede standarder, der er benyttet:

Tässä tuotteessa on sovellettu seuraavia yhdenmukaistettuja standardeja:

Dette produkt er produsert i overenstemmelse med fløgende harmoniserte standarder:

Este produto utilizou os seguintes padrões harmonizados para varificar conformidade:

AUTHORIZED / APPROVED BY:

Approuve par:

Aprobado por:

Genehmigt von:

approvato da:

Goedgekeurd door:

Underskrift:

Valtuutettuna:

Bemyndiget av:

Autorizado Por:

04/19/2012 REV 07 VMQR 044FM

e3mdlCsmATEXFP-rev0514

ww w. ve rs am ati c. co m

Dave Roseberry

Engineering Manager

A1:2009

DATE: August 10, 2011

FECHA:

DATUM:

DATA:

DATO:

PÄIVÄYS:

Model E3 Metallic Food Processing • 12

Page 16

EC DECLARATION OF CONFORMITY

in accordance with ANNEX VIII of Directive 94/9/EC - Equipment for use in Potentially Explosive Atmospheres

Date of Issue: 10 May 2014

Technical File No.: 203104000-1410/MER

Quality System Registration No: ISO 9001-2000

Directive: 94/9/EC 23 March 1994 Annex VIII

Conforming Apparatus: Air-Operated Metal

Double Diaphragm Pumps for Use In Potentially

Explosive Atmospheres

Hazardous Location Applied: 1. II 3/2GD c T5*

T5 fl uids up to 95° C

* When pumping non-conductive fl uids the internal surfaces that

contact the fl uid are restricted to Ex II 3GD c T5. The external

surfaces of the pump are still Ex II 2GD c T5.

2. I M2 c

fl uids up to 95° C

Pumps marked with equipment Category II 3/2 G

(internal 3 G / external 2 G), 2D, when used with

non-conductive fl uids. The pumps are Category II 2 G

when used for conductive fl uids.

Manufacture: Warren Rupp, Inc., A Unit of IDEX Corporation

800 North Main Street, P.O. Box 1568

Mans eld, OH 44901-1568

USA.

On File With: DEKRA Certi cation B.V. (0344)

Meander 1051

6825 MJ Arnhem

The Netherlands

Harmonized Standards Applied: EN 13463-1:2009 Non-Electrical Equipment

Potentially Explosive Atmospheres-Part 1 Basic

Methods and Requirements

EN 13463-5:2011 Non-Electrical Equipment for

Potentially Explosive Atmospheres-Part 5

Protection by Constructional Safety

Equipments: 1. Elima-Matic Series metal pumps for II 3/2GD c T5

2. Elima-Matic Series Cast Iron or Stainless Steel pumps

with Stainless Steel air center sections for I M2 c

We hereby certify that the equipment described above conforms with the protection requirements of Council Directive

94/9/EC of 23 March 1994 Annex VIII on the approximation of the laws of the Member States Concerning Equipment

and Protective Systems Intended for use in Potentially Explosive Atmospheres

DATE/OF REVISION/TITLE: Dave Roseberry

29 May 2014 Engineering Manager

VM_DofC_ATEX_Metallic_V_rev0514

Page 17

Declaration of Conformity

Manufacturer:

®

Warren Rupp, Inc.

Mansfield, Ohio, 44901-1568 USA

certifies that Elima-Matic

Food Processing and Sanitary Pump Models and Surge Suppressor

Models comply with the European Community Regulation

1935/2004/EC for Food Contact Materials.

Food Processing Pump Models: Surge Suppressor Models:

E4SJ5T5S0-FP-ATEX

E4SJ5T5S0-FP

E4SJYXYY0-FP

E4SJ7X770-FP

E1SPYX5S9C-FP

E1SP7X759C-FP

E1SP5T559C-FP

E5SP5T5S9C-FP

E5SPYX559C-FP

E5SP7X7S9C-FP

E1SJ5T559C-FP-ATEX

E1SJ7X759C-FP-ATEX

E1SJYX559C-FP-ATEX

E2SJ5T5S0C-FP-ATEX

E2SJ7X770C-FP-ATEX

E2SJ7D770C-FP-ATEX

E2SJYXYY0C-FP-ATEX

E2SSYXYY0C-FP-ATEX

E2SS7X770C-FP-ATEX

E3SJYXYY0C-FP-ATEX

E3SJ5T550C-FP-ATEX

E3SJ5T5S0C-FP-ATEX

E3SJ7X770C-FP-ATEX

E3SSYXYY0C-FP-ATEX

E3SS7X770C-FP-ATEX

E3SS5T550C-FP-ATEX

E3SS5T5S0C-FP-ATEX

, 800 N. Main Street, P.O. Box 1568,

®

Air-Operated Double Diaphragm

VTA1,NG1SS.

VTA25,NG1SS.

VTA1 1/2,NG1SS.

VTA40,NG1SS.

VTA2,NG2SS.

VTA50,NG2SS.

VTA3,NG2SS.

VTA80,NG2SS.

Sanitary Pump Models:

E4SJYXY40-SP

E4SJ7X750-SP

E2SJYXY40C-SP-ATEX

E2SJ7X750C-SP-ATEX

E4SJ5T550-SP-ATEX

E2SJ5T550C-SP-ATEX

E2SS5T550C-SP-ATEX

Signature of authorized person

David Roseberry

Printed name of authorized person

Revision Level: A

February 8, 2013

Date of issue

Engineering Manager

Title

May 2, 2013

Date of revision

Loading...

Loading...