Page 1

REV. 7/13/2017

Fox

Hardware

Reference

Manual

(VL-EPM-19)

DMP Vortex86DX2 SoC-based

SBC with dual Ethernet, Video,

USB, SATA, Counter/Tim ers,

Mini PCIe, microSD, GPIO,

SPX, and PC/104-Plus Interface

Page 2

WWW.VERSALOGIC.COM

12100 SW Tualatin Road

Tualatin, OR 97062-7341

(503) 747-2261

Fax (971) 224-4708

Copyright © 2015-2017 VersaLogic Corp. All right s r eser ved.

Notice:

Although every effort has been made to ensure this document is error-free, VersaLogic makes no

representations or warranties with respect to this product and specifically disclaims any implied warranties

of merchantability or fitness for any particular purpose.

VersaLogic reserves the right to revise this product and associated documentation at any time without

obligation to notify anyone of such changes.

PC/104 and the PC/104 logo are trademarks of the PC/104 Consortium.

EPM-19 Hardware Reference Manual ii

Page 3

Product Release Notes

VersaTech KnowledgeBase

Release 1.01 July 2015 Update Web links

Release 1.0 December 2015 First production release

Technical Support

The EPM-19 support page, at

https://versalogic.com/support/product_support.asp?ProductID=271

information and resources for this product including:

Reference Manuals (PDF format)

Operating system information and software drivers

Data sheets and manufacturers’ links for chips used in this product

BIOS information and upgrades

Utility routines and benchmark software

VersaAPI Version 1.2.x

, contains additional

This is a private page for EPM

directly. It cannot be reached from the VersaLogic homepage.

The VersaTech KnowledgeBase is an invaluable resource for resolving technical issues with

your VersaLogic product.

If you have additional questions, contact VersaLogic Technical Support at (503) 747-2261.

VersaLogic support engineers are also available via e-mail at Support@VersaLogic.com

REPAIR SERVICE

If your product requires service, you must obtain a Returned Material Authorization (RMA)

number by calling (503) 747-2261.

Provide the following information:

Your name, the name of your company, your phone number, and e-mail address

The name of a technician or engineer that can be contacted if any questions arise

Quantity of items being returned

The model and serial number (barcode) of each item

-19 users that can be accessed only be entering this address

.

A detailed description of the problem

Steps you have taken to resolve or recreate the problem

The return shipping address

EPM-19 Hardware Reference Manual iii

Page 4

Warranty Repair All parts and labor charges are covered, including return shipping

Note:

so can delay the processing of your return.

The exterior coating on some metallic antistatic bags is sufficiently conductive to cause

excessive battery drain if the bag comes in contact with the bottom-side of the EPM-19.

Non-warranty Repair All non-warranty repairs are subject to diagnosis and labor charges,

Mark the RMA number clearly on the outside of the box before returning. Failure to do

RoHS Compliance

The EPM-19 is RoHS-compliant.

ABOUT ROHS

In 2003, the European Union issued Directive 2002/95/EC regarding the Restriction of the use of

certain Hazardous Substances (RoHS) in electrical and electronic equipment.

The RoHS directive requires producers of electrical and electronic equipment to reduce to

acceptable levels the presence of six environmentally sensitive substances: lead, mercury,

cadmium, hexavalent chromium, and the presence of poly-brominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE) flame retardants, in certain electrical and electronic products

sold in the European Union (EU) beginning July 1, 2006.

charges for UPS Ground delivery to United States addresses.

parts charges and return shipping fees. Specify the shipping method

you prefer and provide a purchase order number for invoicing the

repair.

VersaLogic Corporation is committed to supporting customers with high-quality products and

services meeting the European Union’s RoHS directive.

Cautions

ELECTROSTATIC DISCHARGE

Electrostatic discharge (ESD) can damage boards, disk drives and other components. The circuit

board must only be handled at an ESD workstation. If an approved station is not available, some

measure of protection can be provided by wearing a grounded antistatic wrist strap. Keep all

plastic away from the board, and do not slide the board over any surface.

After removing the board from its protective wrapper, place the board on a grounded, static-free

surface, component side up. Use an antistatic foam pad if available.

The board should also be protected inside a closed metallic anti-static envelope during shipment

or storage.

LITHIUM BATTERY

To prevent shorting, premature failure or damage to the lithium battery, do not place the board on

a conductive surface such as metal, black conductive foam or the outside surface of a metalized

ESD protective pouch. The Lithium battery may explode if mistreated. Do not recharge,

disassemble, or dispose of in fire. Dispose of used batteries promptly.

Note:

EPM-19 Hardware Reference Manual iv

Page 5

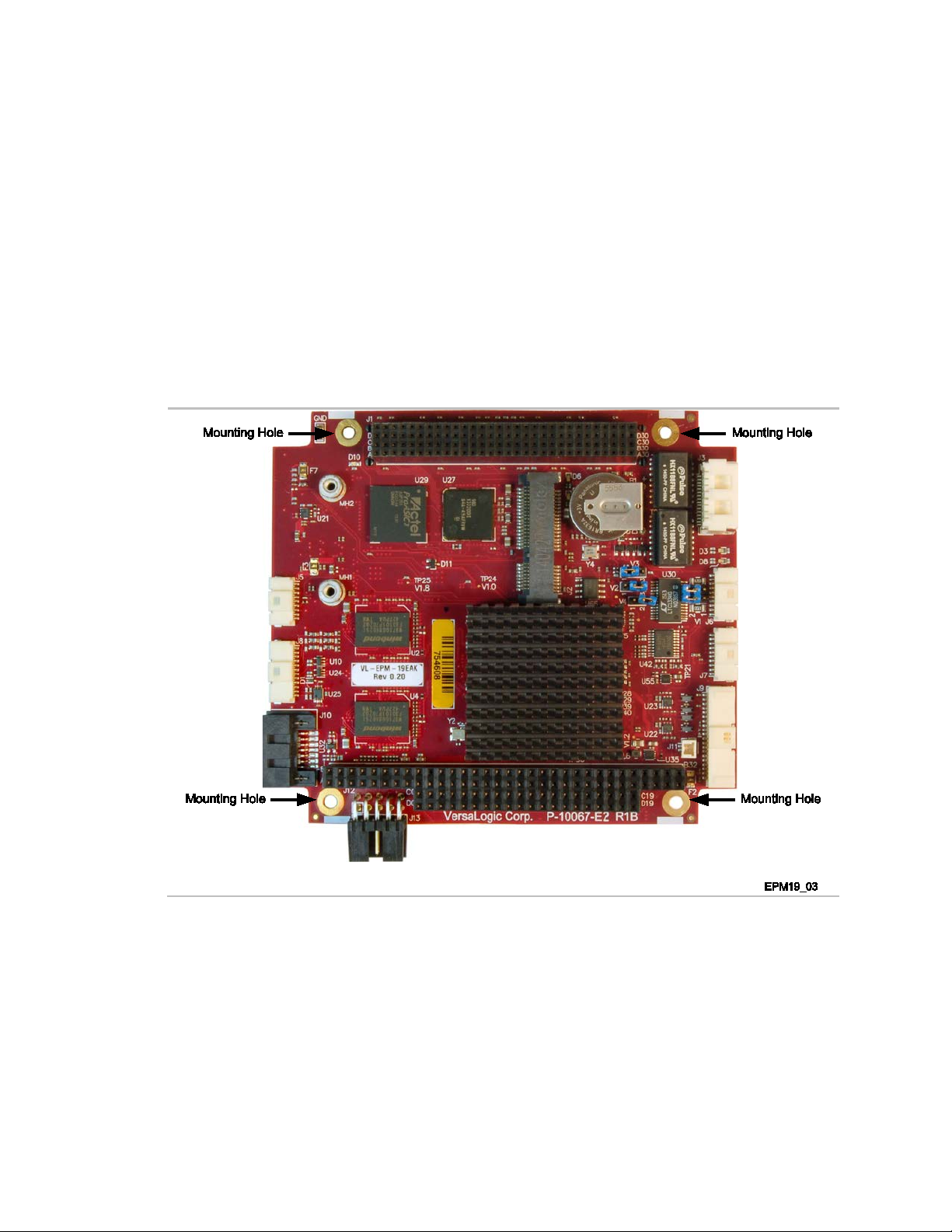

MOUNTING SUPPORT

The single board computer must be supported at all four mounting points to prevent excessive

flexing when expansion modules are attached and removed. Flex damage caused by excessive

force on an improperly mounted circuit board is not covered under the product warranty. See

page 5 for more details.

ARTH GROUND REQUIREMENT

E

All mounting standoffs should be connected to earth ground (chassis ground). This provides

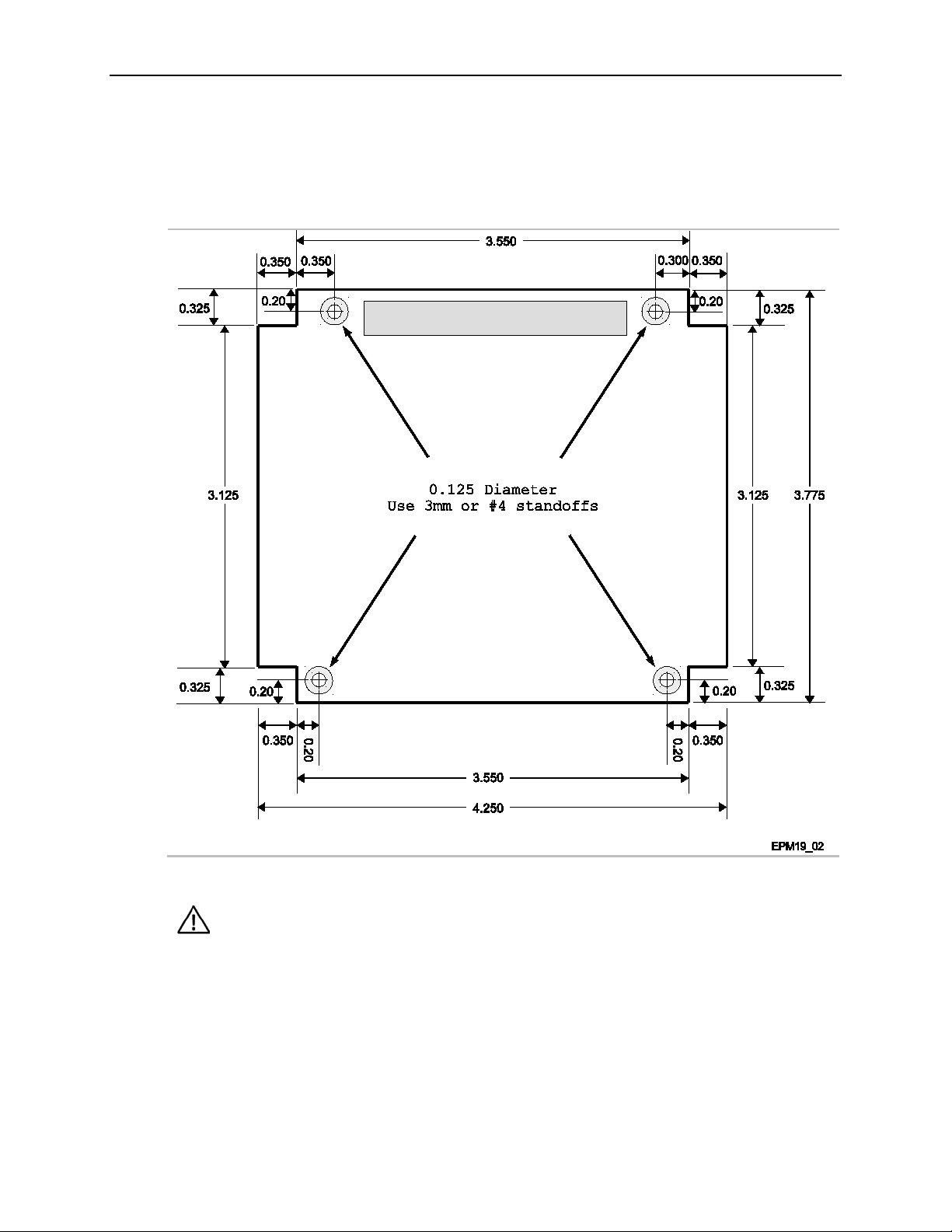

proper grounding for EMI purposes. Figure 1 shows the locations of the board’s mounting holes.

All mounting holes identified in Figure 1 must be connected to earth ground.

Figure 1. Attaching the EPM-19 to Earth Ground

EPM-19 Hardware Reference Manual v

Page 6

Contents

Introduction ................................................................................................................... 1

Description .......................................................................................................................... 1

Technical Specifications ..................................................................................................... 3

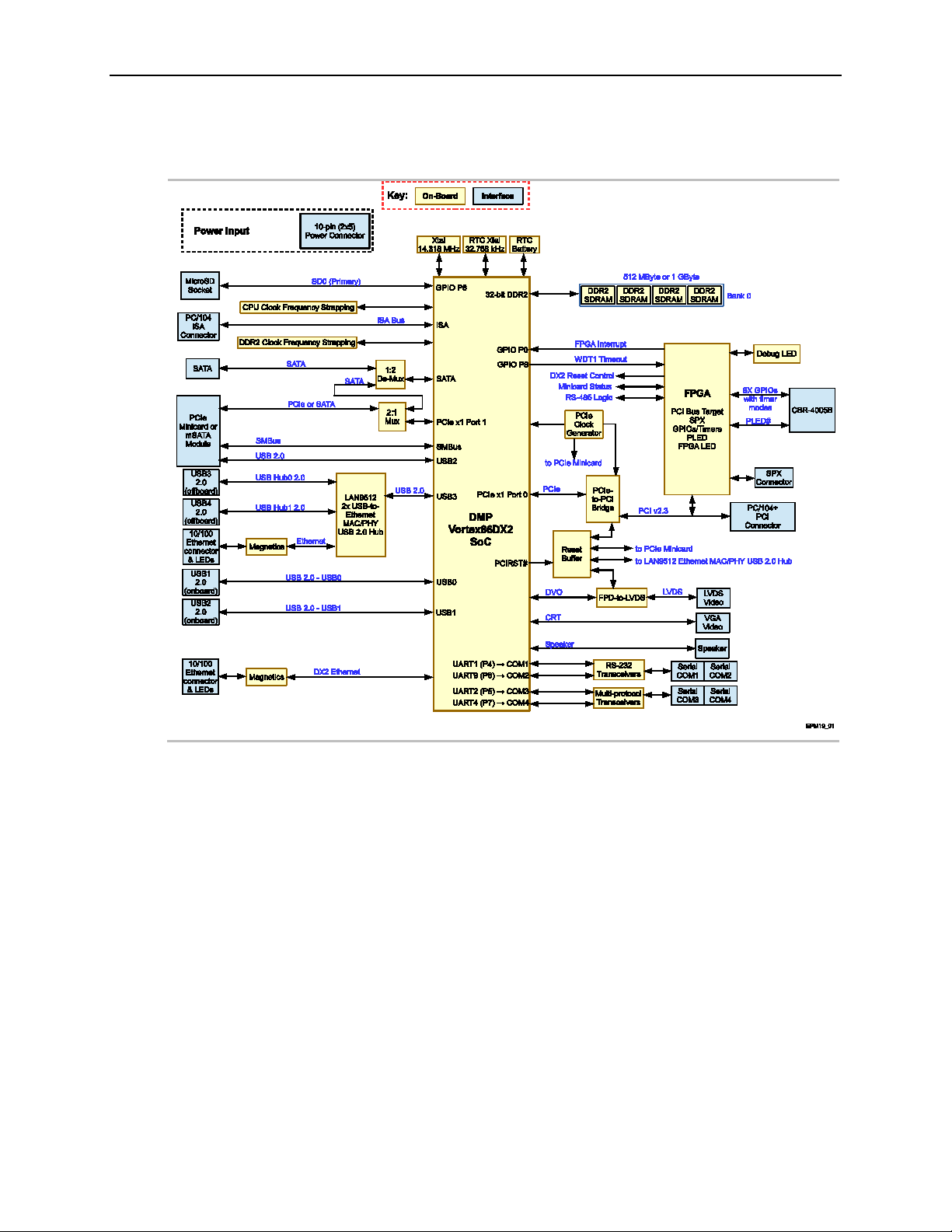

EPM-19 Block Diagram ..................................................................................................... 4

Dimensions and Mounting .................................................................................................. 5

Hardware Assembly ............................................................................................... 5

Related Documents ............................................................................................................. 6

Configuration and Setup ............................................................................................... 7

Initial Configuration ........................................................................................................... 7

Basic Setup ......................................................................................................................... 7

Jumper Blocks .................................................................................................................... 9

Jumpers Blocks in the As-Shipped Configuration................................................. 9

Jumper Summary ................................................................................................. 10

BIOS Setup Program......................................................................................................... 10

CMOS/Non-volatile RAM ................................................................................... 10

Clearing CMOS RAM ......................................................................................... 11

Operating System Installation ........................................................................................... 12

ACPI Version Setting .......................................................................................... 12

Windows XP Considerations ............................................................................... 12

Linux Considerations ........................................................................................... 12

Board Features ............................................................................................................ 13

CPU ................................................................................................................................... 13

DMA Controller .................................................................................................. 13

Watchdog Timers................................................................................................. 13

Real-time Clock ................................................................................................... 13

Vortex86DX2 SoC On-chip Temperature Sensor ............................................... 14

System RAM ..................................................................................................................... 14

I/O Interfaces .................................................................................................................... 14

Power Delivery ................................................................................................................. 15

Main Power Connector ........................................................................................ 15

Cabling ................................................................................................................. 16

Battery Power Options ......................................................................................... 16

VL-CBR-0203 External Battery Module ............................................................. 17

Cabling ................................................................................................................. 18

Operating the Board without a Battery ................................................................ 19

Switches ............................................................................................................................ 20

Push-Button Reset ............................................................................................... 20

LEDs/Indicators ................................................................................................................ 20

Programmable LED ............................................................................................. 21

External Speaker ............................................................................................................... 21

Mass Storage Interfaces ............................................................................................. 22

SATA ................................................................................................................................ 22

EPM-19 Hardware Reference Manual vi

Page 7

Contents

microSD Socket ................................................................................................................ 23

Multi-purpose I/O ......................................................................................................... 25

USB ................................................................................................................................... 25

PCIe Mini Card / mSATA ................................................................................................ 25

mSATA Activity LED ......................................................................................... 27

Booting from a PCIe Minicard ............................................................................ 27

PCIe Mini Card LEDs ......................................................................................... 28

User I/O Connector ........................................................................................................... 29

Cabling ................................................................................................................. 30

Serial Ports .................................................................................................................. 31

Serial Port Connectors ...................................................................................................... 31

Serial Port Connector Pinouts ............................................................................. 32

Cabling ................................................................................................................. 32

Serial Port Assignment ..................................................................................................... 33

COM3/COM4 Hardware Configuration ........................................................................... 34

Video Interfaces ........................................................................................................... 35

Configuration ....................................................................................................... 35

VGA Interface .................................................................................................................. 36

Cabling ................................................................................................................. 37

LVDS Flat Panel Display Connector ................................................................................ 38

Cabling ................................................................................................................. 39

Compatible LVDS Panel Displays ...................................................................... 39

BIOS Settings for Boot Display Devices .......................................................................... 40

Console Redirection ......................................................................................................... 40

Enabling Synchronous Display Output ............................................................................ 41

Network Interfaces ...................................................................................................... 42

Controller Configuration ..................................................................................... 42

Ethernet Connectors ............................................................................................ 42

Cabling ................................................................................................................. 43

On-Board Ethernet Status LEDs .......................................................................... 44

Off-Board Ethernet Status LEDs ......................................................................... 44

Expansion Interfaces .................................................................................................. 45

SPX™ Expansion Bus ...................................................................................................... 45

Cabling ................................................................................................................. 46

VersaLogic SPX Expansion Modules ................................................................. 46

PC/104 Expansion Bus ..................................................................................................... 46

PC/104-Plus PCI Expansion Interface ................................................................. 47

System Resources and Maps ..................................................................................... 48

CBR-4005B Paddleboard ............................................................................................ 49

CBR-4005B Paddleboard ................................................................................................. 49

CBR-4005B Connectors and Indicators .............................................................. 49

User I/O Connector .............................................................................................. 50

Cabling ................................................................................................................. 51

Auxiliary I/O Connector ...................................................................................... 51

Dimensions and Mounting Holes ........................................................................ 52

EPM-19 Hardware Reference Manual vii

Page 8

Contents

Appendix A – References.................................................. Error! Book m ar k not defined.

Figures

Figure 1. Attaching the EPM-19 to Earth Ground ............................................................. v

Figure 2. VL- EPM-19 Fox Single Board Computer (Top Side) ....................................... 1

Figure 3. VL- EPM-19 Fox Single Board Computer (Bottom Side) ................................. 2

Figure 4. EPM-19 Block Diagram ..................................................................................... 4

Figure 5. EPM-19 Dimensions and Mounting Holes ......................................................... 5

Figure 6. Jumper Block Locations ..................................................................................... 9

Figure 7. Location of the V3 Clear CMOS Jumper ......................................................... 11

Figure 8. Location and Pin Orientation of the Main Power Connector ........................... 15

Figure 9. Location and Pin Orientation of the External Battery Connector ..................... 17

Figure 10. VL-CBR-0203 Latching Battery Module ....................................................... 17

Figure 11. Location of the V4 Battery Saver Jumper ...................................................... 18

Figure 12. Location of the V2 No Battery Mode Jumper ................................................ 19

Figure 13. Locations of the LEDs/Indicators ................................................................... 20

Figure 14. Location of the SATA Port ............................................................................. 22

Figure 15. Location of the microSD Socket..................................................................... 23

Figure 16. Location of the mSATA Activity LED ........................................................... 27

Figure 17. Location of PCIe Mini Card LEDs ................................................................. 28

Figure 18. Location and Pin Orientation of User I/O Connector ..................................... 29

Figure 19. Location and Pin Orientation of Serial Port Connectors ................................ 31

Figure 20. COM3/COM4 End-point Termination Jumpers ............................................. 34

Figure 21. VGA Connector Location and Pin Configuration .......................................... 36

Figure 22. Location of the LVDS Connector ................................................................... 38

Figure 23. Wiring for a DB9 to DB9 RS-232 Adapter for Console Redirection ............. 40

Figure 24. Location and Pin Orientation for the J3 Ethernet Connector ......................... 42

Figure 25. Location of Ethernet Status LEDs D3 and D8 ................................................ 44

Figure 26. J5 SPX Connector Location and Pin Configuration ....................................... 45

Figure 27. CBR-4005B Connectors ................................................................................. 49

Figure 28. Location and Pin Orientation of the User I/O Connector ............................... 50

Figure 29. Location and Pin Orientation of Auxiliary I/O Connector ............................. 51

Figure 30. CBR-4005B Dimensions and Mounting Holes .............................................. 52

Tables

Table 1: Technical Specifications for all EPM-19 Configurations ..................................... 3

Table 2: Jumper Summary ................................................................................................ 10

Table 3: Memory Configurations of EPM-19 Board Models ........................................... 14

Table 4: J13 Power Connector Pinout .............................................................................. 16

EPM-19 Hardware Reference Manual viii

Page 9

Contents

Table 5: Expansion Current Limits ................................................................................... 16

Table 6: Battery Saver Jumper Truth Table ...................................................................... 18

Table 7: No Battery Mode Jumper Truth Table ................................................................ 19

Table 8: PCIe Mini Card / mSATA Pinout ....................................................................... 25

Table 9: Primary Boot Device Truth Table ....................................................................... 27

Table 10: PCIe Mini Card LED States .............................................................................. 28

Table 11: J9 I/O Connector Pinout and Pin Orientation ................................................... 30

Table 12: J7 COM1/COM2 Connector Pinout ................................................................. 32

Table 13: J6 COM3/COM4 Connector Pinout ................................................................. 32

Table 14: Recommended Serial Port Settings for Vortex86DX2 BIOS ........................... 33

Table 15: COM3/COM4 Termination Jumpers ................................................................ 34

Table 16: J8 VGA Video Output Pinout ........................................................................... 37

Table 17: J15 LVDS Flat Panel Display Connector Pinout .............................................. 39

Table 18: Compatible LVDS Interface TFT-Technology Flat Panel Displays ................. 39

Table 19: BIOS Settings for Boot Display Devices and Corresponding Resolutions ...... 40

Table 20: Ethernet Connector Pinout ................................................................................ 43

Table 21: On-board Ethernet Status LEDs (D3 and D8) ................................................. 44

Table 22: SPX Connector Pinout ...................................................................................... 46

Table 23: PC/104 ISA I/O, IRQ, and Memory Resources ................................................ 47

Table 24: User I/O Connector Pinout ............................................................................... 50

Table 25: Auxiliary I/O Connector Pinout ........................................................................ 51

EPM-19 Hardware Reference Manual ix

Page 10

1

Description

The EPM-19 is a feature-packed single board computer designed for OEM control projects

requiring fast processing, with two memory density options and designed-in reliability and

longevity (product lifespan).

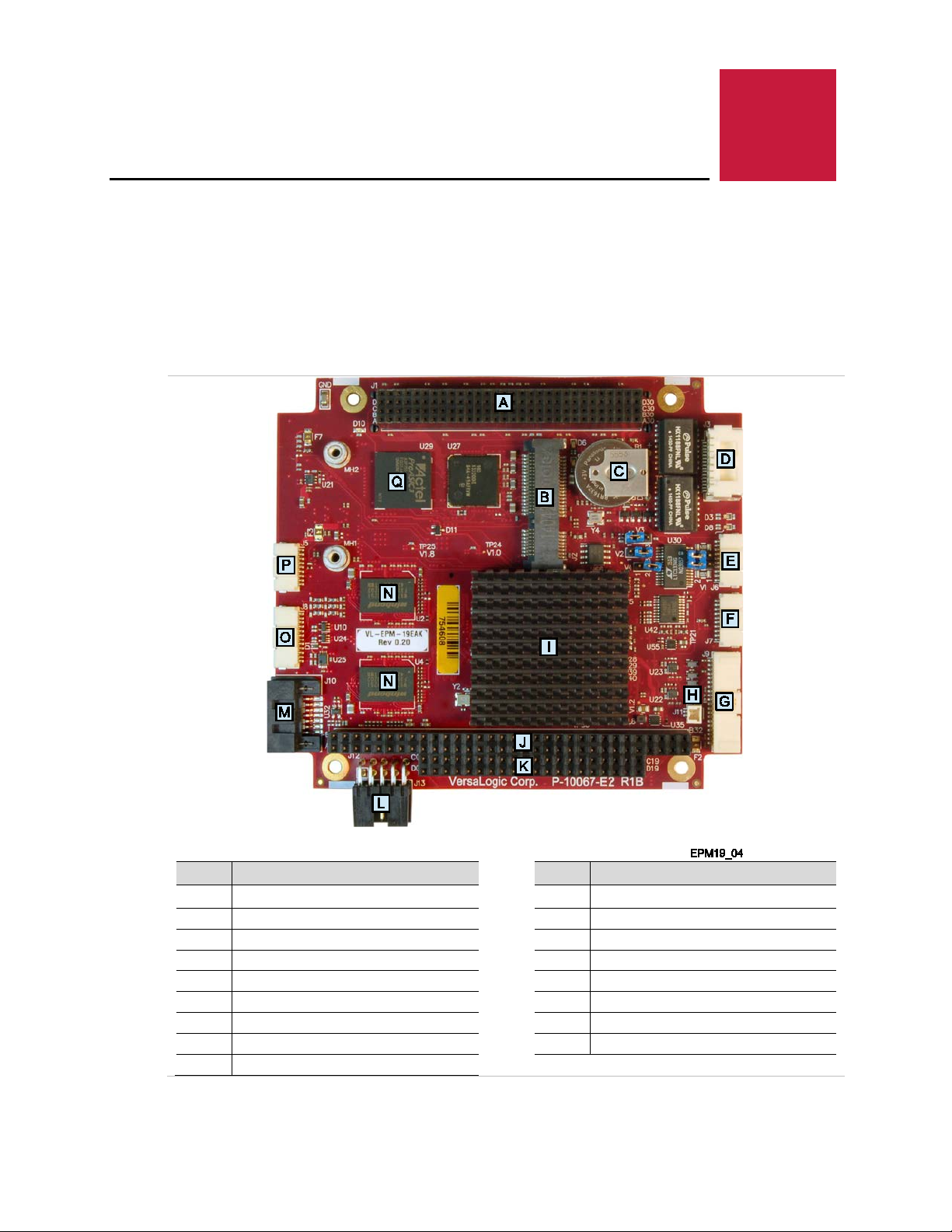

Figure 2 shows the connectors and major components on the top side of the board. Figure 3

shows the connectors and major components on the bottom side of the board.

Introduction

EPM-19 Hardware Reference Manual 1

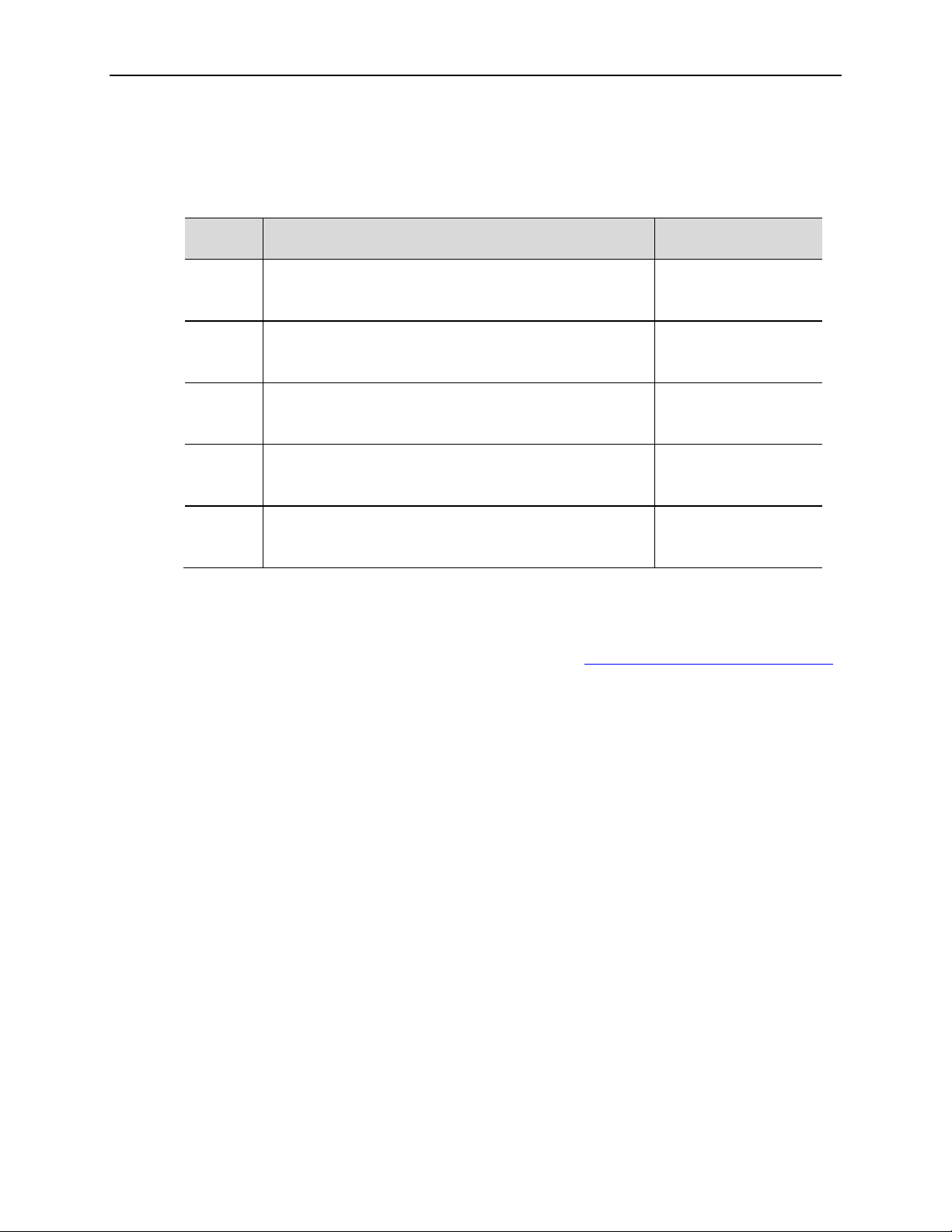

Item Description

A

PC/104-Plus (PCI) connector

B PCIe Minicard/mSATA connector K PC/104 (ISA) connector

C Battery L Main power connector

D Ethernet port 0/1 connector M SATA connector

E COM3/COM4 connector N DRAM devices

F COM1/COM2 connector O VGA connector

G User I/O [CBR-4005B mating connector] P SPX connector

H External battery connector Q FPGA device

I Vortex86DX2 SoC

Figure 2. VL- EPM-19 Fox Single Board Computer (Top Side)

Item Description

J PC/104 (ISA) connector

Page 11

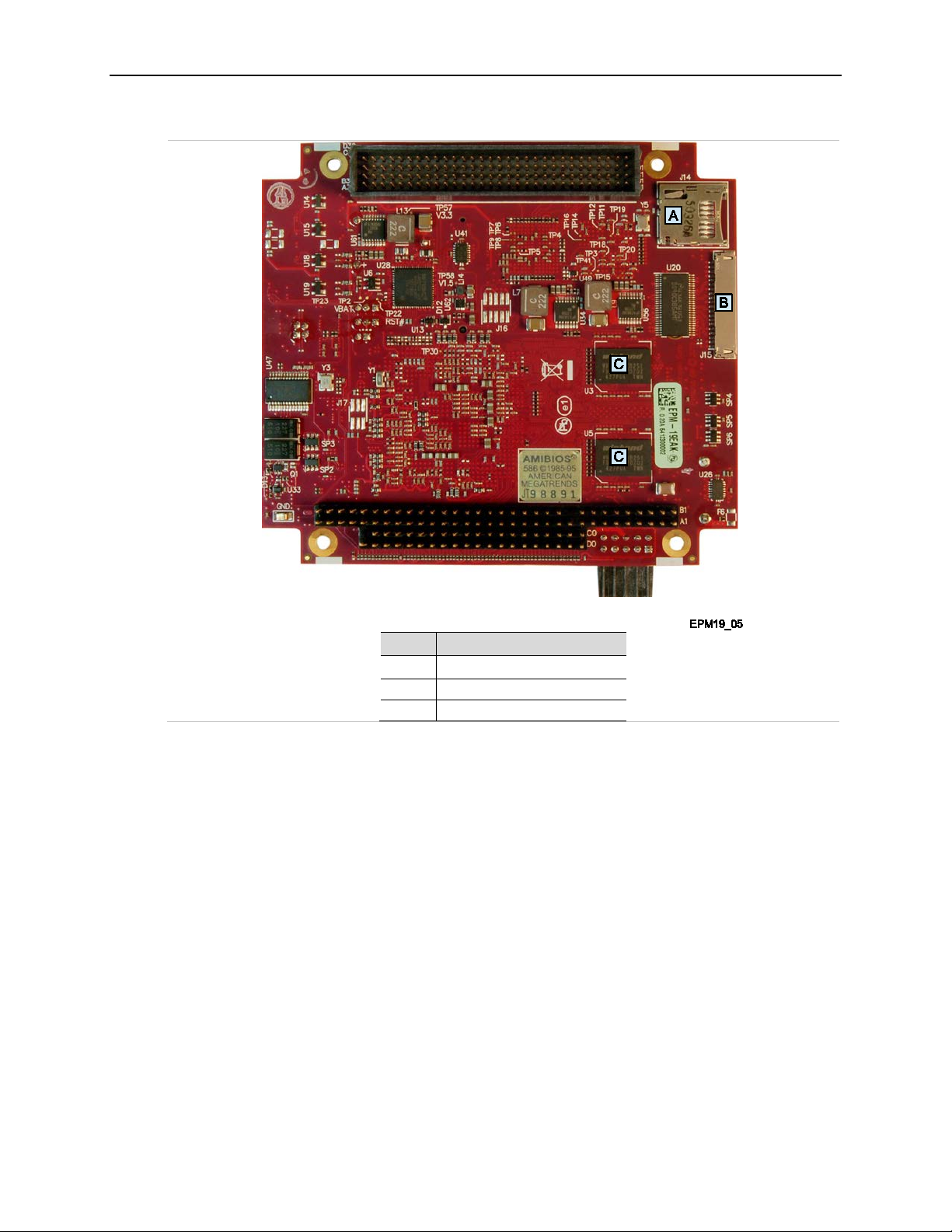

Introduction

Item Description

A microSD socket

B LVDS connector

C DRAM devices

Figure 3. VL- EPM-19 Fox Single Board Computer (Bottom Side)

EPM-19 boards are subjected to 100% functional testing and are backed by a limited five-year

warranty. Careful parts sourcing and US-based technical support ensure the highest possible

quality, reliability, service and product longevity for this exceptional SBC.

EPM-19 Hardware Reference Manual 2

Page 12

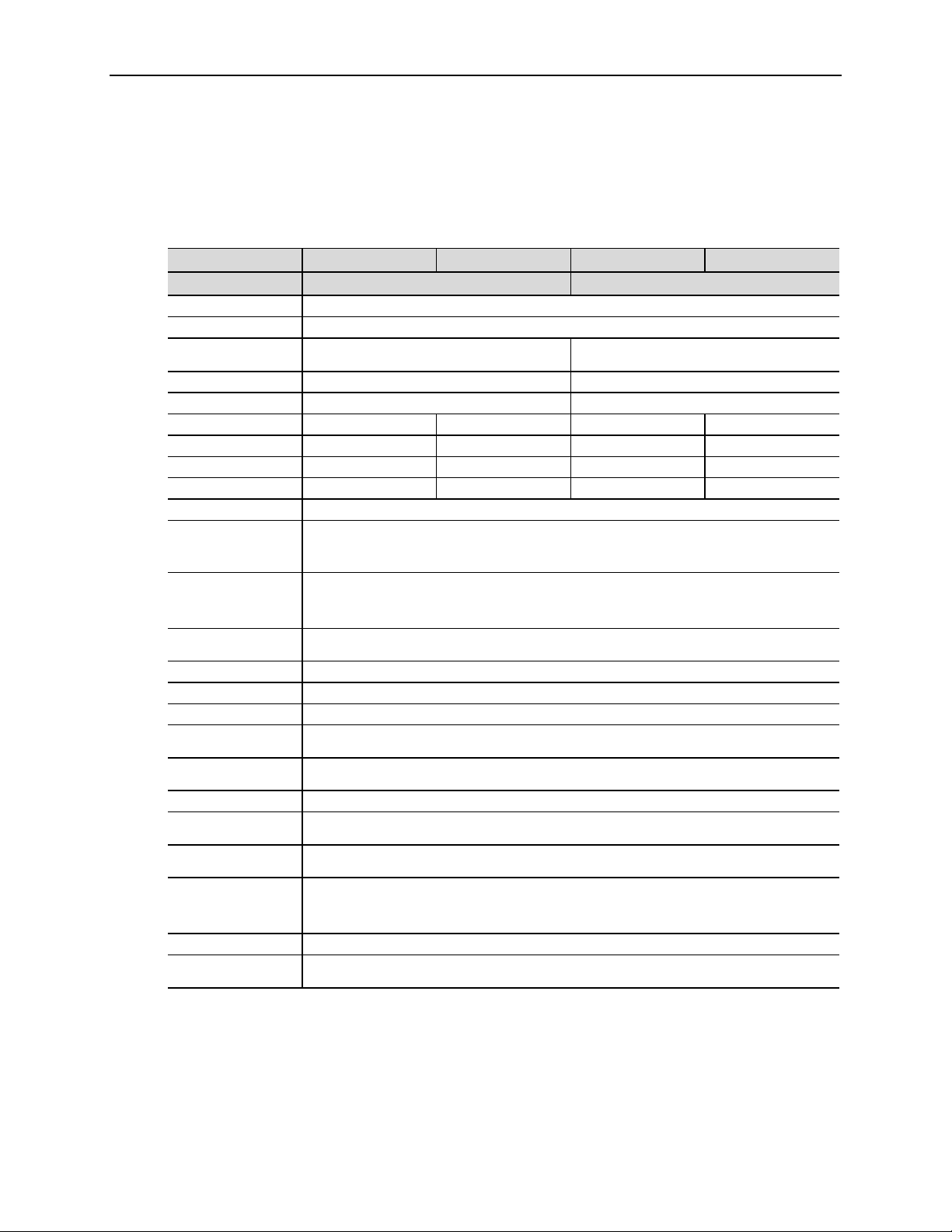

Technical Specifications

temperature (Note)

• Video BIOS supports up t o 1024x768 resolut i on with 32-bi t color

limited to 1024x768 (LVDS panel maximum supported resolution)

Video BIOS support for 640x480, 800x480, 800x600, 1024x600, and 1024x768

Vcc sensing; resets when the 5V, 3.3V, 1.8V, 1.5V, 1. 2V , or 1.0V power rails vary by more than

± 10% of their optimal val ues .

Supports SPI and SPX devices. Supports up to two SPX modules, including low cost analog

signals)

bus speed

SPX™ – full compliance

Generated

100 MHz, 50 MHz, 33 MHz, 29.49 MHz, 25 MHz, 14.318 MHz, 8 MHz, 4 MHz, 2 MHz, 1 MHz,

Specifications are typical at 25 °C with 5.0V supply, unless otherwise noted. Specifications are

subject to change without notice.

Table 1: Technical Specifications for all EPM-19 Configurations

Item VL-EPM-19SAK VL-EPM-19SBK VL-EPM-19EAK VL-EPM-19EBK

(Standard Temperature) (Extended Temperature)

Board size 4.250 inches x 3.775 inches

Storage temperature -40 °C to 85 °C

Free air operating

CPU clock 933 MHz 800 MHz

Memory clock 333 MHz 300 MHz

Memory size 512 MB 1 GB 512 MB 1 GB

Idle power 5.3 W 5.3W 5.0 W 5.0 W

Typical power 5.5 W 5.6 W 5.3 W 5.4 W

Max power 5.8 W 5.9 W 5.7 W 5.8 W

Input Voltage +5 VDC ±5%

Introduction

0 °C to + 60 °C -40°C to +85 °C

Analog VGA output

Digital Video output

System Reset

Ethernet interface Two auto-detect 10BaseT/100BaseT X ports

COM1-2 interface RS-232, 16C550 compatible, 115k baud max.

COM3-4 interface RS-232/422/485, 16C550 compati bl e, 460k baud max.

SPI interface

GPIO/Timers

BIOS AMI Vortex86DX2 BIOS

PC/104-Plus (PCI)

bus speed

PC/104 (ISA)

Compatibility

Weight 0.50 lb (0.22 kg)

frequencies

Notes: Derate -1.1°C per 305m (1,000 ft .) above 2,300m (7,500 ft.).

• With VGA driver support s up to 1920x1440. Synchronous display use causes VGA to be

• LVDS video output

• Support for 18-bit or 24-bit single c hannel LV DS flat panel displays

•

and digital modules.

Three 8254-compatible timer/counters (FPGA functions, six muxed with the eight GPIO

33 MHz

8 MHz

• PC/104 – full compl i ance

• Embedded-PCI (PC/104-Plus) – full compli ance, 3.3V signaling

•

32.768 kHz

EPM-19 Hardware Reference Manual 3

Page 13

EPM-19 Block Diagram

Introduction

Figure 4. EPM-19 Block Diagram

EPM-19 Hardware Reference Manual 4

Page 14

Dimensions and Mounting

The EPM-19 must be supported at all four mounting points to prevent

not covered under the product warranty.

The EPM-19 complies with the PC/104 standard which provides for specific mounting hole and

PC/104-Plus stack locations as shown in Figure 5.

Introduction

Figure 5. EPM-19 Dimensions and Mounting Holes

(Not to scale. All dimensions in inches.)

CAUTION:

excessive flexing when expansion modules are attached and removed. Flex

damage caused by excessive force on an improperly mounted circuit board is

HARDWARE ASSEMBLY

The EPM-19 mounts on four hardware standoffs using the corner mounting holes. These

standoffs are secured to the underside of the circuit board using pan head screws.

EPM-19 Hardware Reference Manual 5

Page 15

The entire assembly can sit on a table top or be secured to a base plate. When bolting the unit

http://www.vortex86.com/?p=16

USB 2.0 Hub and 10/100

down, make sure to secure all standoffs to the mounting surface to prevent circuit board flexing.

An extractor tool is available (part number VL-HDW-201) to separate the PC/104 modules from

the stack.

Related Documents

The following documents available are on the EPM-19 Product Support Web Page:

EPM-19 Programmer’s Reference Manual – provides information on the board’s resources

(memory, I/O, and IRQs), a description of the FPGA’s registers, and programming

information for the board’s hardware interfaces.

EPM-19_EBX-18 BIOS Reference Manual – provides information on accessing and

configuring settings in the BIOS Setup utility. All BIOS menus, submenus, and

configuration options are described.

VersaAPI Installation and Reference Guide – describes the shared library of API calls for

reading and controlling on-board devices on certain VersaLogic products.

Additional documents:

Introduction

Overview of Vortex86DX2

Ethernet Controller

ILAN9512 Data sheet

PC/104 Specification

PC/104-Plus Specification

http://ww1.microchip.com/downloads/en/DeviceDoc/9512.pdf

http://www.versalogic.com/products/PC104/index.asp

http://www.versalogic.com/products/PC104/index.asp

EPM-19 Hardware Reference Manual 6

Page 16

2

Initial Configuration

The following components are recommended for a typical development system.

EPM-19 single board computer

ATX power supply with motherboard and disk drive connectors

VGA video monitor

USB Keyboard

USB Mouse

SATA hard drive

The following VersaLogic cables and accessories are recommended.

VGA Video adapter cable (CBR-1204)

Configuration and Setup

User I/O cable (CBR-4005) and accompanying paddleboard (CBR-4005B)

Power adapter cable (CBR-1008)

VL-CBR-0702 – SATA data cable

VL-CBR-0401 – ATX to SATA power adapter

You will also need a Windows (or other OS) installation CD/DVD and corresponding drive.

Basic Setup

The following steps outline the procedure for setting up a typical development system. The

EPM-19 should be handled at an ESD workstation or while wearing a grounded antistatic wrist

strap.

Before you begin, unpack the EPM

you ordered. Inspect the system visually for any damage that may have occurred in shipping.

Contact support@versalogic.com

Gather all the peripheral devices you plan to attach to the EPM-19 and their interface and power

cables.

It is recommended that you attach standoffs to the board now to stabilize the board and make it

easier to work with. (Refer to the section titled “Hardware Assembly” on page 5.)

1. Connect Power

-19 and accessories. Verify that you received all the items

immediately if any items are damaged or missing.

EPM-19 Hardware Reference Manual 7

Plug the power adapter cable CBR-1008 into connector J13. Attach the motherboard

connector of the ATX power supply to the adapter.

To use the Lithium Battery with the EPM

to connecting pin 1 and pin 2. Refer to the section titled “

for more information.

-19, move the jumper on V4 from being stored on pin 1

Battery Saver Jumper” on page 18

Page 17

Configuration and Setup

If you intend to operate the EPM-19 under Windows XP or Windows XP Embedded, be sure to

use Service Pack 3 (SP3).

2. Attach Cables and Peripherals

Plug the video adapter cable CBR-1204 into connector J8. Attach the video monitor (VGA

DB15) interface cable to the video adapter.

Connect the CBR-4005B paddleboard to the EPM-19 using a CBR-4005 cable

Plug USB keyboard and mouse into any of the available USB ports on the CBR-4005B

paddleboard.

Plug a USB DVD-ROM drive into any of the available USB ports on the CBR-4005B

paddleboard. To avoid potential device delays and excessive power consumption through

the USB ports, use an external power supply for the USB CD-ROM drive.

Plug the SATA data cable VL-CBR-0702 into the SATA connector (J10). Attach a SATA

hard drive to the other end of the cable.

Attach the SATA power adapter cable VL-CBR-0401 to the ATX power supply and SATA

drive.

3. Review Configuration

Before you power up the system, double check all the connections. Make sure all cables are

oriented correctly and that adequate power will be supplied to the EPM

-19 and peripheral

devices.

4. Power On

Turn on the ATX power supply and the video monitor. If the system is correctly configured,

a video signal should soon be present.

5. Change BIOS Setup utility settings

Enter the BIOS Setup utility by pressing <Delete> during the early boot cycle.

Verify that the desired primary boot device is listed as such. Refer to Table 9 on page 27 for

more information.

Before saving the BIOS Setup utility settings, insert the Windows (or other OS) installation

disk in the DVD-ROM drive so it will be accessed when the system reboots.

Press <F10> and write the new parameters to CMOS RAM. The system will reboot.

6. Install an Operating System

Install the operating system according to the instructions provided by the operating system

manufacturer. (See Operating System Installation.)

Note:

EPM-19 Hardware Reference Manual 8

Page 18

Jumper Blocks

JUMPERS BLOCKS IN THE AS-SHIPPED CONFIGURATION

Configuration and Setup

Figure 6. Jumper Block Locations

EPM-19 Hardware Reference Manual 9

Page 19

JUMPER SUMMARY

Out – COM3 End-point termination disabled (default)

• Out – COM4 End point termination disabled (default)

• 2-3 – Clear CMOS RAM

• 2-3 – Battery is installed (default)

• 1-2 – Battery is connected

Configuration and Setup

Table 2: Jumper Summary

Jumper

Block

COM3 Rx End-point termination

V1 [1-2]

V1 [3-4]

V3

V2

V4

• In – COM3 End-point termination enabled

•

COM4 Rx End-point termination

• In – COM4 End-point termination enabled

CMOS RAM Clear

• 1-2 – Normal mode (default)

No Battery Mode

• 1-2 – Battery has been removed

Battery Saver

• 1 only (or jumper is removed) (default)

BIOS Setup Utility

The EPM-19 permits users to modify the BIOS Setup utility defaults. Refer to the

EPM-19_EBX-18 BIOS Reference Manual (available on the EPM-19 Product Support Web Page

for information on accessing and configuring settings in the BIOS Setup utility. All BIOS

menus, submenus, and configuration options are described in the EPM-19_EBX-18 BIOS

Reference Manual.

Description Reference

Table 15, page 34

Table 15, page 34

Clearing CMOS RAM,

page 11

Operating the Board

without a Battery, page 19

Battery Saver Jumper,

page 18

)

CMOS/NON-VOLATILE RAM

The Vortex86DX2 SoC contains a small amount of CMOS/Non-volatile RAM to store the BIOS

Setup utitlity settings. If you have modified BIOS Setup utility settings and the board fails to

boot, clear the CMOS/Non-volatile RAM to restore the default BIOS settings.

EPM-19 Hardware Reference Manual 10

Page 20

Configuration and Setup

Integrator’s Note:

If clearing the contents of CMOS RAM fails to restore the board to proper operation and you are

unable to enter the BIOS Setup utility, the EPM-19 needs to be serviced by the factory.

CLEARING CMOS RAM

To clear the contents of CMOS RAM and the Real-Time Clock:

1. Power off the EPM-19.

2. Remove the V3 jumper from its default position (connecting pins 1-2) and install it on pins

2-3. Figure 7 shows the location of the V3 jumper block.

3. Leave the jumper in place for at least five seconds.

4. Move the jumper to back to its default position, connecting pins 1-2.

5. Power on the EPM-19.

Figure 7. Location of the V3 Clear CMOS Jumper

EPM-19 Hardware Reference Manual 11

Page 21

Operating System Installation

Integrator’s Note:

The EPM-19 board supports only the 32-bit versions of Windows 7 and Windows Embedded

Standard 7 (WES7).

An operating system installed on a different type of computer is not guaranteed to work on the

each system. This restriction does not apply if you are producing multiple identical systems.

Integrator’s Note:

The EPM-19 board has been tested extensively with Windows 7 and seems to operate reliably

required by the OS.

The standard PC architecture used on the EPM-19 makes the installation and use of most of the

standard x86 processor-based operating systems relatively simple. The operating systems listed

on the VersaLogic OS Compatibility Chart

the maker of the OS. Special optimized hardware drivers for a particular operating system, or a

link to the drivers, are available at the

Note:

EPM-19. This is referred to as a “foreign” installation. A hard disk that was used to boot a

different computer cannot necessarily be moved to the EPM-19 and expected to boot. Even

when porting an OS image from one revision of the EPM-19 to another, performance might fail

or be impaired. For the best results, perform a fresh installation of the operating system on

EPM-19 Product Support Web Page.

Configuration and Setup

use the standard installation procedures provided by

ACPI VERSION SETTING

The ACPI version will need to be configured in the BIOS Setup utility as follows:

For Windows 7, set the ACPI version to V3.0. (Windows 7 requires version 2.0 or later.)

For Windows XP, set the ACPI version to V1.0 (Windows XP may function with version 2.0

but has not been fully tested.)

with the ACPI version set to V3.0. Other operating systems may have unique requirements for

setting the supported ACPI version. ACPI can be disabled in the BIOS Setup utility if it is not

WINDOWS XP CONSIDERATIONS

When Windows XP is loaded on an mSATA card, it may be necessary to change the IDE

Operate Mode setting in the BIOS Setup utility from Legacy Mode to Native Mode for the

operating system to boot properly.

INUX CONSIDERATIONS

L

If the microSD card is installed prior to board power-up, the board will expect to boot from the

microSD card because it appears as the Primary IDE device. If that is not the desired

configuration (that is, you want to boot from SATA or mSATA and use the microSD card as

storage device), you can fix this by modifying the GRUB root= boot argument from sdaX to

sdbX while the SD card is inserted. If Knoppix is installed to the SATA using Flash Install

utility instead of HD install, it won't use GRUB. Knoppix uses isolinux and is able to detect the

drive upon which Knoppix is installed.

EPM-19 Hardware Reference Manual 12

Page 22

CPU

DDR2 memory controller

10/100 Ethernet MAC Controller

3

Board Features

The DMP Electronics Vortex86DX2 System-On-a-Chip (SoC) contains a 32-bit x86 (486DX

enhanced) microprocessor that also integrates the following:

Embedded 2 MB BIOS flash memory

PCIe bus running at 2.5 GHz

ISA bus interface

Real Time Clock

Peripheral controllers with DMA and

interrupt timer/counter

DMA

CONTROLLER

The DMA circuitry incorporates the functionality of two 82C37 DMA controllers with seven

independently programmable channels. The Master DMA Controller (DMA-1) corresponds to

DMA Channels 0-3 that are hardwired to 8-bit count-by-byte transfers and the Slave DMA

Controller (DMA-2) corresponds to Channels 5-7 that are hardwired to 16-bit count-by-word

“address shifted” transfers. DMA Channel 4 is used to cascade the two controllers and will

default to cascade mode as it cannot be used for any other purpose. In addition to accepting

requests from DMA slaves, the DMA controller also responds to requests that are initiated by

software.

The Vortex86DX2 provides the timing control and data size translation for the DMA transfer

between memory (ISA or DRAM) and the ISA bus I/O. Also, the DX2 is ISA-compatible with

24-bit addressing. For information on programming the DMA controller, contact

Support@VersaLogic.com

.

GPU

COM ports (FIFO UART)

USB 2.0 host controller

IDE controller (SD and SATA)

Watchdog timers

WATCHDOG TIMERS

The watchdog timers use the RTC frequency (32.768 kHz) for a 24-bit counter, providing a time

range from 30.5 μs to 512 seconds with a resolution of 30.5 μs. When the timer is enabled and

its count reaches the programmed value, a system reset, NMI, or IRQ may occur as selected

using the Watchdog Configuration sub-menu in the BIOS Setup utility.

EAL-TIME CLOCK

R

The EPM-19 features a battery-backed real-time clock/calendar. Under normal battery use

EPM-19 Hardware Reference Manual 13

conditions, the clock maintains accurate timekeeping functions when the board is powered off.

The BIOS Setup utility can be used to set the time/date of the real-time clock.

Page 23

VORTEX86DX2 SOC ON-CHIP TEMPERATURE SENSOR

Contact the factory for information on reading and writing to the thermometer circuits.

System RAM

The EPM-19 is equipped with 512 MB or 1 GB of 1.8 V DDR2 memory soldered to the board.

EPM-19SAK — Standard temperature 512 MB 333 MHz

EPM-19SBK — Standard temperature 1 GB 333 MHz

EPM-19EAK — Extended temperature 512 MB 300 MHz

EPM-19EBK — Extended temperature 1 GB 300 MHz

I/O Interfaces

The EPM-19 board’s I/O interfaces and their associated connectors are described in later

chapters as follows:

Board Features

Table 3: Memory Configurations of EPM-19 Board Models

Board Model Installed Memory Size M emory Clock

Mass Storage Interfaces (SATA and microSD), beginning on page 22

Multi-purpose I/O (USB, PCIe MiniCard / mSATA, User I/O), beginning on page 25

Serial Ports, beginning on page 31

Video Interfaces (VGA, LVDS), beginning on page 35

Network Interfaces (Ethernet), beginning on page 42

Expansion Interfaces (SPX, PC/104), beginning on page 45

EPM-19 Hardware Reference Manual 14

Page 24

Power Delivery

The +3.3 VDC, +12 VDC and -12 VDC inputs on the power connector are only required for

PC/104-Plus and PC/104 expansion modules that require these voltages.

MAIN POWER CONNECTOR

Figure 8 shows the location and pin orientation of the main power connector.

Board Features

Figure 8. Location and Pin Orientation of the Main Power Connector

CAUTION:

To prevent severe and possibly irreparable damage to the system, it is c r it ical

that the power connector is wired correctly. Make use of all +5 VDC pins and

all ground pins to prevent excess voltage drop.

Note:

EPM-19 Hardware Reference Manual 15

Page 25

Table 4 lists the pinout for power connector.

1

Ground

2

+5 VDC

3

Ground

4

+12 VDC

5

Ground

6

-12 VDC

7

+3.3 VDC

8

+5 VDC

9

Ground

10

+5 VDC

+3.3 V

3 A

+5 V

4 A

+12 V

1 A

-12 V

0.5 A

To prevent shorting, premat ure failure or damage to the Lithium bat tery, do not

the battery in fire. Dispose of used batteries promptly.

Table 4: J13 Power Connector Pinout

Board Features

Pin Signal

Pin Signal

Table 5 lists the maximum current available for expansion for the power supply voltages.

Table 5: Expansion Current Limits

Voltage Maximum Expansion Current

CABLING

An adapter cable, part number CBR-1008, is available for connecting the EPM-19 to an ATX

power supply.

If your application requires a custom cable, the following information will be useful:

EPM-19 Board Connector Mating Connector

FCI 78207-110HLF FCI 69176-010LF

BATTERY POWER OPTIONS

The battery circuit on the EPM-19 provides power for the Real-Time Clock (RTC) and power to

store BIOS Setup utility settings in CMOS RAM.

CAUTION:

place the board on a conductive surface such as metal, black conductive foam

or the outside surface of a m etalized ESD protective pouch. The Lithium

battery may explode if mistreated. Do not rechar ge, disassemble, or dispose of

Nominal battery voltage is 3.0V. If the voltage drops below 2.7V, contact the factory for a

replacement. The life expectancy under normal use is approximately five years.

EPM-19 Hardware Reference Manual 16

Page 26

Board Features

The EPM-19 has multiple options for providing battery power:

Use the on-board battery

Use the battery supplied with the CBR-4005B paddleboard

Use an external battery, connected to the board through the J11 external battery connector.

Figure 9 shows the location and pin orientation of the external battery connector.

Figure 9. Location and Pin Orientation of the External Battery Connector

VL-CBR-0203 EXTERNAL BATTERY MODULE

The VL-CBR-0203 external battery module is compatible with the EPM-19. For more

information, contact

EPM-19 Hardware Reference Manual 17

Sales@VersaLogic.com.

Figure 10. VL-CBR-0203 Latching Battery Module

Page 27

Board Features

Battery is disconnected

(not discharging)

CABLING

If your application requires a custom cable, the following information will be useful:

EPM-19 Board Connector Mating Connector

Molex 501331-0207 Molex 501330-0200

Battery Saver Jumper

The EPM-19 includes a “Battery Saver” jumper at location V4. This jumper keeps the Lithium

battery from discharging (keeping it disconnected) before the EPM-19 board is in the customer’s

hands and ready to be used. The default configuration of the jumper is a no-connect position

(placed only on pin 1). Figure 11 shows the location of the V4 Battery Saver Jumper.

Table 6: Battery Saver Jumper Truth Table

V4 Jumper Position Condition

Pin 1 only (default)

Pin 1-2 Battery is connected

EPM-19 Hardware Reference Manual 18

Figure 11. Location of the V4 Battery Saver Jumper

Page 28

Board Features

OPERATING THE BOARD WITHOUT A BATTERY

The EPM-19 enables you to operate the board without a battery for applications when no battery

is required. Using this setting will delay the board’s booting process after power on for

approximately 5 seconds. This is an application requirement to give the RTC crystal time to start

up.

Table 7: No Battery Mode Jumper Truth Table

V2 Jumper Position Condition

Pin 2-3 (default) Battery is inst al l ed or will be used

Pin 1-2 Battery is not present and not in use

Figure 12. Location of the V2 No Battery Mode Jumper

To operate the board without the Lithium battery, perform the following steps:

1. Power down the EPM-19.

2. Remove the battery connection to the SoC RTC well. This is done by removing the V4

jumper leaving pins 1 and 2 unconnected if you want to keep the battery with the product

(otherwise the on-board battery would have to be unsoldered). You can store the V4

jumper in its default position connected only to pin 1.

3. Make certain there are no other batteries connected to the board; that is, either attached

to the J11 external battery connector or on the CBR-4005B paddleboard. If you are

using the CBR-4005B paddleboard, remove the battery from its socket.

4. Set the V2 jumper to pins 1-2. (Always make sure the battery is disconnected when this

jumper setting is used or it will drain the battery and delay booting of the board.)

5. Power up the EPM-19. The board takes approximately five seconds to begin the boot

sequence after the power switch is turned on when the battery is not in use. This delay is

necessary for the RTC crystal operation to stabilize before the board reset is released.

EPM-19 Hardware Reference Manual 19

Page 29

Switches

PUSH-BUTTON RESET

User I/O connector J9 includes an input for a push-button reset switch. Shorting J9, pin 18 to

ground causes the EPM-19 to reboot.

A reset button is provided on the CBR-4005B paddleboard. See Figure 27 on page 49 for the

location of the reset button on the CBR-4005B paddleboard.

LEDs/Indicators

Figure 13 shows the locations of the boards LEDs/indicators.

Board Features

LED(s) Description For more information, see…

D10 mSATA activity LED Page 27

D6/D5 PCI Mini Card LEDs Page 28

D3/D8 Ethernet s tatus LEDs Page 44

Figure 13. Locations of the LEDs/Indicators

EPM-19 Hardware Reference Manual 20

Page 30

PROGRAMMABLE LED

User I/O connector J9 includes an output signal for attaching a software controlled LED.

Connect the cathode of the LED to J9, pin 16; connect the anode to +5V. An on-board resistor

limits the current to 15 mA when the circuit is turned on. A programmable LED is provided on

the CBR-4005B paddleboard. See Figure 27 on page 49 for the location of the Programmable

LED on the CBR-4005B paddleboard.

For instructions on how to switch the Programmable LED on and off, refer to the EPM-19

Programmer’s Reference Manual (available on the EPM-19 Product Support Web Page

External Speaker

A miniature 8 Ω speaker can be connected between user I/O connector J9, pin 15 (SPKR#) and

J9, pin 13 (V3P3). A speaker is provided on the CBR-4005B paddleboard. See Figure 27 on

page 49 for the location of the speaker on the CBR-4005B paddleboard.

Board Features

).

EPM-19 Hardware Reference Manual 21

Page 31

Integrator’s Note:

Only one SATA port is available on the Vortex86DX2 chip, so only the J10 SATA port or the J2

card installed, the mSATA card uses the single SATA port.

4

SATA

The EPM-19 provides a 1.5 Gbit/s SATA port. Power to the SATA drive is usually provided by

the ATX power supply. Note that the standard SATA drive power connector is different from

the typical 4-pin Molex connector used on IDE drives. Most current ATX power supplies

provide SATA connectors, and many SATA drives provide both types of power connectors. If

the power supply you are using does not provide SATA connectors, adapters are available.

Mass Storage Interfaces

mSATA port can be used; both cannot be used at the same time. Whenever J2 has an mSATA

Figure 14. Location of the SATA Port

EPM-19 Hardware Reference Manual 22

Page 32

microSD Socket

The EPM-19 includes a microSD socket on the underside of the board. The VL-F41 series of

microSD cards provide solid-state storage of 2 GB, 4 GB, or 8 GB. The microSD socket

accommodates cards with up to 32 GB of storage capacity. No drivers are needed, as the device

interface is abstracted as a standard parallel IDE drive on the master IDE channel.

Mass Storage Interfaces

Figure 15. Location of the microSD Socket

Note the following when using a microSD card with the EPM-19:

The microSD card interface is not hot-pluggable. A microSD card will not be recognized as

part of the system if it is not plugged in before power is applied to the board or before a

push-button reset is applied. This is not a limitation of the EPM

-19 board; it is a limitation of

the DX2 chip.

When a microSD card is inserted at power-up, the default boot setting is to boot from it (it is

primary), so if you don’t press <F11> right after applying power to the board, you will not be

able to select an alternate boot option; the board will “stall” for the lack of an operating

system (OS) if there isn’t one present on the microSD card.

The boot order can be changed in the BIOS Setup utility.

EPM-19 Hardware Reference Manual 23

Page 33

Mass Storage Interfaces

If you remove the microSD card at any time and allow the board to boot without the card

installed, the boot order setting will be cleared and you will have to set it up again the next

time you use a microSD card.

If you remove the microSD card while the board is powered on and the OS attempts to access

a file on the “drive” (that is, the microSD card) the results are unpredictable. The best case

scenario is that the drive drops out (as it would in Windows Explorer when running

Windows 7 from a SATA drive and using the microSD as an additional hard drive).

However, if Windows does not try to access the microSD card while you have it out and you

put it back in (again, in Windows 7 at least) the system does not appear to have noticed it

was ever removed.

EPM-19 Hardware Reference Manual 24

Page 34

USB

Note:

as non-bootable FAT32 drives.

Note:

PCIe Mini Cards using small (512 byte or below) I/O address ranges may not be accessible.

Pin

Signal Name

Function

Signal Name

Function

1 WAKE#

Wake Reserved

Not connected

2 3.3VAUX

3.3V auxiliary source

+3.3V

3.3V source

3 NC

Not connected

Reserved

Not connected

4 GND

Ground GND

Ground

5 NC

Not connected

Reserved

Not connected

6 1.5V

1.5V power

+1.5V

1.5V power

7 NC

Not connected

Reserved

Not connected

5

Multi-purpose I/O

The USB interface on the EPM-19 is OHCI (Open Host Controller Interface) and EHCI

(Enhanced Host Controller Interface) compatible, which provides a common industry

software/hardware interface. The USB controller can be enabled or disabled in the BIOS Setup

utility. The board has four USB ports:

Two hub ports routed to the J9 user I/O connector. Table 11 page 30 lists the USB port

signals routed to the J9 user I/O connector.

Two additional non-hub ports are also routed to the J9 user I/O connector.

Some USB mass storage devices cause long delays or reboot cycles when formatted

The USB interfaces at connector J9 are accessible using a CBR-4005B paddleboard or by using a

custom cable.

All four USB ports use IEC 61000-4-2-rated TVS components to protect against ESD damage.

PCIe Mini Card / mSATA

The socket at location J2 accepts a full-height PCI Express Mini Card or an mSATA module.

The PCIe Mini Card interface includes one PCIe x1 lane, one hubbed USB 2.0 channel, and the

SMBus interface. The socket is compatible with plug-in Wi-Fi modems, GPS receivers, Flash

data storage, and other cards for added flexibility. For more information on PCIe Mini Cards

offered by VersaLogic, contact

To secure a Mini Card or mSATA module to the on-board standoffs, use two M2.5 x 6mm pan

head Philips nylon screws. These screws are available in quantities of 10 in the VL-HDW-108

hardware kit from VersaLogic.

J2

PCIe Mini Card

Sales@VersaLogic.com.

Table 8: PCIe Mini Card / mSATA Pinout

PCIe Mini Card

mSATA

mSATA

8 NC Not connected Reserved Not connected

9 GND Ground GND Ground

EPM-19 Hardware Reference Manual 25

Page 35

Multi-purpose I/O

Pin

Signal Name

Function

Signal Name

Function

10 NC

Not connected

Reserved

Not connected

11 REFCLK-

Reference clock input –

Reserved

Not connected

12 NC

Not connected

Reserved

Not connected

13 REFCLK+

Reference clock input +

Reserved

Not connected

14 NC

Not connected

Reserved

Not connected

17 NC

Not connected

Reserved

Not connected

18 GND

Ground GND

Ground

19 NC

Not connected

Reserved

Not connected

20 W_DISABLE#

Wireless di sable

Reserved

Not connected

21 GND

Ground GND

Ground

22 PERST#

Card reset

Reserved

Not connected

23 PERn0

PCIe receive –

+B

Host receiver diff. pair +

25 PERp0

PCIe receive +

-B

Host receiver diff. pair –

26 GND

Ground GND

Ground

27 GND

Ground GND

Ground

28 1.5V

1.5V power

+1.5V

1.5V power

29 GND

Ground GND

Ground

30 SMB_CLK

SMBus clock

Two Wire I/F

Two wire I/F clock

31 PETn0

PCIe transmit –

-A

Host transmitt er di ff. pair –

33 PETp0

PCIe transmit +

+A

Host transmitter di ff. pair +

34 GND

Ground GND

Ground

35 GND

Ground GND

Ground

36 USB_D-

USB data –

Reserved

Not connected

37 GND

Ground GND

Ground

38 USB_D+

USB data +

Reserved

Not connected

39 3.3VAUX

3.3V auxiliary source

+3.3V

3.3V source

42 LED_WWAN#

Wireless WAN LED

Reserved

Not connected

Note 1

Note 1

45 NC

Not connected

Vendor

Not connected

46 LED_WPAN#

Wireless P AN LED

Reserved

Not connected

47 NC

Not connected

Vendor

Not connected

48 1.5V

1.5V power

+1.5V

1.5V power

49 Reserved

Reserved DA/DSS

Device activity (Note 2)

50 GND

Ground GND

Ground

51 Reserved

Reserved GND

Ground (Note 3)

52 3.3VAUX

3.3V auxiliary source

+3.3V

3.3V source

Notes:

1. This pin is not grounded on the EPM-19 since it can be used to detec t the presence of an mSAT A module

pull-down enabled in the EPM-19 FPGA to keep the SATA channel mux from switc hi ng when J2 i s empty.

2. This signal drives the blue LE D activity indicator at loc ation D10 in the lower right corner of the board (refer to

3. Some PCIe modules use this signal as a s econd Mini Card wireless disable input. On t he E PM-19, this signal is

used as the default indicator for mSATA versus PCIe Mini Card detection.

J2

15 GND Ground GND Ground

16 NC Not connected Reserved Not connected

24 3.3VAUX 3.3V auxiliary source +3.3V 3.3V source

32 SMB_DATA SMBus data Two Wire I/F Two wire I/F data

PCIe Mini Card

PCIe Mini Card

mSATA

mSATA

40 GND Ground GND Ground

41 3.3VAUX 3.3V auxiliary source +3.3V 3.3V source

43

44 LED_WLAN# Wireless LAN LED Reserved Not connected

versus a PCIe Mini Card. Grounding this pi n i s available as an option on custom boards, but this pin already has a

Figure 16). This LED lights with mSATA disk ac t i vi t y, i f supported by the mSATA module.

GND

mSATA detect (

)

GND/NC

EPM-19 Hardware Reference Manual 26

Ground/not connected (

)

Page 36

Multi-purpose I/O

Note:

attached, the BIOS Setup utility will not recognize any device attached to the SATA connector.

SATA ACTIVITY LED

M

Figure 16 shows the location of the mSATA activity LED. This LED indicates activity on the

mSATA interface. Not all mSATA drives provide this disk activity signal. Note that the FPGA

register bit for the DEBUG_LED needs to be cleared (set to 0) in order for this signal to reflect

the MSATA_DAS signal from the mSATA interface. Until that is done, it reflects the status of

the FPGA programming (set to 1 when the FPGA is programmed and reset properly). Refer to

the EPM-19 Programmer’s Reference Manual (available on the

EPM-19 Product Support Web

Page) for information on FPGA registers.

Figure 16. Location of the mSATA Activity LED

BOOTING FROM A PCIE MINICARD

The MSATA_DETECT (J2 pin 43) signal is non-functional as an option for the PCIe Minicard

mux selection. This signal has a pull-down internal to the FPGA to prevent it from floating high

(which enables it). The FPGA default is to use J2 pin 51 as the mux enable signal

(PRES_DISABLE2#) which works with all of our Minicards.

The result of this condition is that certain combinations of bootable devices may not yield

expected results. Table 9 is a matrix of acceptable boot device configurations.

Table 9: Primary Boot Device Truth Table

Installed Bootable Devices

microSD card mSATA c ar d External SATA Drive USB Flash Drive

Yes Don’t c are Don’t care Don’t care microSD card

No Yes Don’t care Don’t care mSATA card

No No Yes Don’t care External SATA drive

No No No Yes USB Flash Drive

The primary boot

device will be…

Only one SATA port is available on the Vortex86DX2 SoC. If an mSATA device is

EPM-19 Hardware Reference Manual 27

Page 37

Multi-purpose I/O

Illuminates when the 3.3 V power to the Mini Card is on. It alerts users to not hot-

powered successfully.

Note: These LEDs will illuminate when the associated device is installed and capabl e of transmitting. Thei r function is

determined by the installed device.

PCIE MINI CARD LEDS

Two dual-colored PCIe Mini Card LEDs are provided on the EPM-19 at locations D6 and D5.

Table 10 lists the states of the LEDs. Figure 17 shows the location of the PCIe Mini Card LEDs.

Table 10: PCIe Mini Card LED States

LED Color Status (when lit)

Green

D6

Yellow

Green

D5

Yellow

Activity on Wi reless PAN (Note)

plug the Mini Card. Because the Vortex86DX2 processor does not support sleep

modes, the power is always on to the PCIe Mini Card socket when the board is

Activity on Wireless WAN (Note)

Activity on Wireless LAN (Note)

Figure 17. Location of PCIe Mini Card LEDs

EPM-19 Hardware Reference Manual 28

Page 38

User I/O Connector

The 40-pin J9 I/O connector incorporates the signals for the following:

Four USB ports

Eight GPIO lines (these are functionally muxed with six timer I/O signals per FPGA

registers)

Three LEDs (two Ethernet link status LEDs and a programmable LED)

Power switch

Push-button reset switch

Speaker output

This connector uses IEC 61000-4-2-rated TVS components to help protect against ESD damage.

Figure 18 shows the location and pin orientation of the user I/O connector.

Multi-purpose I/O

Figure 18. Location and Pin Orientation of User I/O Connector

EPM-19 Hardware Reference Manual 29

Page 39

Table 11 provides the pinout of the user I/O connector.

Pin

Signal

Pin

Signal

1

+5 V (V5_USB01)

2

GND

3

USB0_P

4

USB1_P

5

USB0_N

6

USB1_N

17

No connect

18

RST_BTN#

19

GND

20

GND

21

Reserved

22

V_BATT

23

Reserved

24

RETURN_BATT

25

GND

26

GND

27

FPGA GPIO1

28

FPGA GPIO2

29

FPGA GPIO3

30

FPGA GPIO4

EPM-19 Board Connector

Mating Connector

Table 11: J9 I/O Connector Pinout and Pin Orientation

7 +5V (V5_USB23) 8 GND

9 USB2_P 10 USB3_P

11 USB2_N 12 USB3_N

13 +3.3 V 14 GND

15 SPKR# 16 PLED#

Multi-purpose I/O

31 GND 32 GND

33 FPGA GPIO5 34 FPGA GPIO6

35 FPGA GPIO7 36 FPGA GPIO8

37 +3.3 V 38 GND

39 ETH0 LED 40 ETH1 LED

C

ABLING

An adapter cable, part number CBR-4005A, is available for connecting the CBR-4005B

paddleboard to the EPM-19. This is a 12-inch, Pico-Clasp 40-pin to 40-pin cable

If your application requires a custom cable, the following information will be useful:

Molex 501571-4007 Molex 501189-4010

EPM-19 Hardware Reference Manual 30

Page 40

6

The EPM-19 includes four on-board 16550-based serial channels located at standard PC I/O

addresses. Each COM port can be independently enabled or disabled in BIOS Setup.

All four COM ports by default are set to RS-232 mode

COM1 and COM2 are RS-232 (up to 115.2K baud) serial ports. There are no hardware

configuration jumpers for COM1 and COM2 because they only operate in RS-232 mode.

IRQ lines are chosen in the BIOS Setup utility.

COM3 and COM4 can be operated in RS-232 or RS-422/485 mode. IRQ lines are chosen in

the BIOS Setup utility.

Additional non-standard baud rates are also available through the BIOS Setup utility.

Serial Port Connectors

Figure 19 shows the location and pin orientation of the serial port connectors.

Serial Ports

EPM-19 Hardware Reference Manual 31

Figure 19. Location and Pin Orientation of Serial Port Connectors

Page 41

SERIAL PORT CONNECTOR PINOUTS

—

—

Table 12: J7 COM1/COM2 Connector Pinout

Pin RS-232 Si g nal Port

1 RTS1

2 TXD1#

3 CTS1

4 RXD1#

5 GND

6 RTS2

7 TXD2#

8 CTS2

9 RXD2#

10 GND

Table 13: J6 COM3/COM4 Connector Pinout

Pin RS-232 Si g nal RS-422/RS-485 Signal Port

1 RTS3 TXD3_P

2 TXD3# TXD3_N

3 CTS3 RXD3_P

4 RXD3# RXD3_N

5 GND GND

6 RTS4 TXD4_P

7 TXD4# TXD4_N

8 CTS4 RXD4_P

9 RXD4# RXD4_N

10 GND GND

Serial Ports

COM1

Vortex86DX2 UART1

COM2

Vortex86DX2 UART9

COM3

Vortex86DX2 UART2

—

COM4

Vortex86DX2 UART4

—

CABLING

An adapter cable, part number CBR-1014, is available for routing the J7 and J6 signals to 9-pin

d-sub connectors. This is a 12-inch, Pico-Clasp 10-pin to two 9-pin D-sub connector cable.

If your application requires a custom cable, the following information will be useful:

EPM-19 Board Connector Mating Connector

Molex 501331-1007 Molex 501330-1000

EPM-19 Hardware Reference Manual 32

Page 42

Serial Port Assignment

EPM-19 COM Port #

(Note)

Vortex86DX2

Serial Port/UART #

Integrator’s Note:

During verification testing, the COM ports displayed data compare errors intermittently while

system heavily-loaded.

The EPM-19 only supports the use of the Vortex86DX2 Serial Ports 1, 2, 4, and 9, so all other

serial ports are disabled and not available in the BIOS Setup Utility. Table 14 lists the

recommended settings for the Vortex86DX2 serial ports.

Table 14: Recommended Serial Port Settings for Vortex86DX2 BIOS

COM1 3F8h 4 1

COM2 2F8h 10 9

COM3 3E8h 3 2

COM4 2E8h 11 4

Note: COM ports are numbered to m atch EPM-19 I/O connector COM numbering.

running CPU-intensive burn-in tests on a moderate-to-heavily loaded system. Since IRQ priorities

and small data FIFOs are involved here, users are cautioned to expect some lost COM port data

(particularly on the lower-priority IRQ COM ports) when they use multiple COM ports with the

Serial Ports

I/O Address IRQ

EPM-19 Hardware Reference Manual 33

Page 43

COM3/COM4 Hardware Configuration

Jumper

Position

Jumper block V1[1-2] enables the RS-422/485 termination resistor for COM3. Jumper V1[3-4]

enables the RS-422/485 termination resistor for COM4. The termination resistor should be

enabled for an RS-422 or RS-485 endpoint station; it should be disabled for RS-232 and RS-485

non-endpoint receivers.

Table 15: COM3/COM4 Termination Jumpers

Function Jumper In Jumper Out

Serial Ports

1-2 COM3 Rx End-point Termination

3-4 COM4 Rx End-point Termi nat i on

Note: RS-485 non-endpoints do not require termination. If receivers are mid-line, remove this t ermination jumper.

RS422/485 (Note)

RS422/485 (Note)

RS-232 (default)

RS-232 (default)

Figure 20. COM3/COM4 End-point Termination Jumpers

EPM-19 Hardware Reference Manual 34

Page 44

7

Video Interfaces

An on-board video controller integrated into the Vortex86DX2 SoC provides high performance

video output for the EPM-19.

ONFIGURATION

C

The EPM-19 uses shared memory architecture. This allows the video controller to use variable

amounts of system DRAM — 8 MB, 16 MB (default), 32 MB, or 64 MB — for video RAM.

The amount of RAM used for video is set with a BIOS Setup utility option.

The EPM-19 supports two types of video output: VGA and LVDS flat panel display. A BIOS

Setup utility sub-menu (Boot Display Device) selects which output is enabled through POST.

The operating system will then take over based on the Graphic Utility CRT or LCD selection. If

the Boot Display Device selected provides incorrect timing information for an attached LCD

panel and the Graphics Utility is set to LCD, you may not see video on the output.

Refer to Table 19 on page 40 for a list of BIOS settings for boot display devices and their

corresponding resolutions.

EPM-19 Hardware Reference Manual 35

Page 45

VGA Interface

Figure 21 shows the location and pin orientation of the J8 VGA video output connector. This

connector uses IEC 61000-4-2-rated TVS components to help protect against ESD damage

Video Interfaces

Figure 21. VGA Connector Location and Pin Configuration

EPM-19 Hardware Reference Manual 36

Page 46

Table 16 lists the signals of the VGA video output connector.

Table 16: J8 VGA Video Output Pinout

Pin Signal (Function) DB-15 Pin

1 Ground 6

2 RED (Red video) 1

3 Ground 7

4 GREEN (Green video) 2

5 Ground 8

6 BLUE (Blue video) 3

7 Ground 5

8 HSYNC (Horizontal sync) 13

9 Ground 10

10 VSYNC (Vertical sync) 14

11 CRT_SCL (DDC data clock line) 15

12 CRT_SDA (DDC seria l data line) 12

Video Interfaces

CABLING

An adapter cable, part number CBR-1204, is available to translate J8 into a standard 15-pin DSub VGA connector. This is a 12-inch, 12-pin Pico-Clasp to 15-pin VGA cable.

If your application requires a custom cable, the following information will be useful:

EPM-19 Board Connector Mating Connector

Molex 501568-1207 Molex 501330-1200

EPM-19 Hardware Reference Manual 37

Page 47

LVDS Flat Panel Display Connector

The integrated LVDS Flat Panel Display in the EPM-19 is an ANSI/TIA/EIA-644-1995

specification-compliant interface. It can support up to 24 bits of RGB pixel data plus three bits

of timing control (HSYNC/VSYNC/DE) on the four differential data output pairs.

The BIOS Setup utility provides a sub-menu (Boot Display Device) with several options for

standard LVDS Flat Panel types. If these options do not match the requirements of the panel you

are attempting to use, contact

Figure 22 shows the location of the LVDS connector. The 3.3 V power provided to pins 19 and

20 is protected by a 1 A power switch.

Support@VersaLogic.com for a custom video BIOS.

Video Interfaces

Figure 22. Location of the LVDS Connector

EPM-19 Hardware Reference Manual 38

Page 48

Table 17 lists the pinout of the J15 LVDS flat panel display connector.

Manufacturer

Model Number

Resolution

Table 17: J15 LVDS Flat Panel Display Connector Pinout

Pin Signal Name Function

1 GND Ground

2 GND Ground

3 LVDSA3 Differential Data 3 (+)

4 LVDSA3#

5 GND Ground

6 LVDSCLK0 Differential Clock (+)

7 LVDSCLK0#

8 GND Ground

9 LVDSA2 Differential Data 2 (+)

10 LVDSA2#

11 GND Ground

12 LVDSA1 Differential Data 1 (+)

13 LVDSA1#

14 GND Ground

15 LVDSA0 Differential Data 0 (+)

16 LVDSA0#

17 GND Ground

18 GND Ground

19 +3.3V Protected power supply

20 +3.3V Protected power supply

Differential Data 3 (-)

Differential Clock (-)

Differential Data 2 (-)

Differential Data 1 (-)

Differential Data 0 (-)

Video Interfaces

CABLING

Several LVDS cables are available from VersaLogic:

VL-CBR-2015 — 20-inch LVDS/Flat Panel cable, 24-bit (Hirose)

VL-CBR-2016— 20-inch LVDS/Flat Panel cable, 18-bit (JAE)

VL-CBR-2017 — 20-inch LVDS cable, 24-bit (Hirose)

C

OMPATIBLE LVDS PANEL DISPLAYS

The following flat panel displays are reported to work properly with the integrated graphics

video controller chip used on the EPM-19.

Table 18: Compatible LVDS Interface TFT-Technology Flat Panel Displays

NEC NL8048BC-19-02 800 x 400

AUO G104SN03 800 x 600

NEC NL10276BC24-13 1024 x 768

EPM-19 Hardware Reference Manual 39

Page 49

BIOS Settings for Boot Display Devices

Boot Display Device

Determined by VGA display device (when

VGA connected) or set to 800 x 600

Table 19: BIOS Settings for Boot Display Devices and Corresponding Resolutions

Video Interfaces

BIOS Setting for

VBIOS

CRT Determined by VGA display device

Panel0 640 x 480

Panel1 800 x 480

Panel2 800 x 600

Panel3 1024 x 600

Panel4 1024 x 768

Console Redirection

The EPM-19 can be operated without using the on-board video output by redirecting the console

to an available COM port. In the BIOS Setup utility, the Remote Access Configuration submenu provides the ability to control console redirection. When console redirection is enabled,

you can access the BIOS Setup utility by typing <Ctrl>-<C>.

The default settings for the redirected console are as follows:

Serial Port Number: [COM1]

Base Address, IRQ: [3F8h, 4]

Serial Port Mode: [115200, 8, n, 1] (115,200 baud, 8 data bits, no parity, 1 stop bit)

Resolution

Flow control: [None]

Terminal Type: [ANSI]

Figure 23 shows the wiring for a DB9-to-DB9 adapter for console redirection of an RS-232 serial

port.

Figure 23. Wiring for a DB9 to DB9 RS-232 Adapter for Console Redirection

EPM-19 Hardware Reference Manual 40

Page 50

Enabling Synchronous Display Output

The BIOS allows for enabling synchronous display outputs. When Synchronous Display is set to

Enabled (disabled by default), the same video signal is present on both the J8 VGA (“CRT” per

the Graphic Utility) connector as well as the J15 LVDS (“LCD” per the Graphic Utility)

connector. The resolution setting must be 1024x768 or lower for the desktop to be displayed

properly on the VGA monitor and it should be optimized for the LCD display in use. This

limitation exists because both outputs share the same video memory contents, so the LCD panel

timing and resolution has to be prioritized (as it is much less flexible than a VGA monitor that

often handles various timings and resolutions).

To change from a synchronous display setup (VGA CRT connected to J8 and a flat-panel display

connected to J15) to a VGA-only configuration, follow these steps:

1. Leave both display devices connected.

2. Use the BIOS Setup utility to change the Synchronous Display option from Enabled to

Disabled. Save the changes and exit the BIOS Setup utility.

3. Reboot the board and allow the operating system to load. A video signal will be present

on the VGA during BIOS loading, but the video signal switches to the LCD panel output

after POST (as the OS loads since LCD was the previous OS setting).

Video Interfaces

4. In the video driver Graphic Utility, select the CRT output (instead of the LCD output),

apply that setting, and exit the program.

5. Power down the board and disconnect the flat-panel display from connector J15 (if the

option is no longer desired).

6. Power up the board. Use the BIOS Setup utility to set the Boot Display Device to either

VBIOS or CRT if it is set for a Panel #, then save the changes and exit the BIOS Setup

utility. The board will then reboot and the video output will be present on the VGA

CRT.

EPM-19 Hardware Reference Manual 41

Page 51

8

Network Interfaces

The EPM-19 features two auto-detect 10BaseT/100BaseTX Ethernet ports.

ONTROLLER CONFIGURATION

C

The Ethernet controller resident to the Vortex86DX2 SoC can be enabled or disabled in the

BIOS Setup utility. The second Ethernet port is implemented through the LAN9512 (USBbased) device. That interface can be configured through your operating system.

THERNET CONNECTORS

E