Page 1

Reference

Manual

DOC. REV. 3/16/2009

EPM-4

(Lynx)

AMD ÉlanSC520 processor

module with 10/100 Ethernet,

and PC/104-Plus interface.

Page 2

EPM-4

AMD ÉlanSC520 processor

module with 10/100 Ethernet,

and PC/104-Plus interface

MEPM4

Page 3

Product Release Notes

This page includes recent changes or improvements that have been made to this

product. These changes may affect its operation or physical installation in your

application. Please read the following information.

Rev 5 Release

• EPM-4h model release – RoHS extended temperature version.

Rev 4 Release

• PC/104 (ISA) connector keyed to better comply with standard. PC/104 connector soldered instead of

press-fit.

• Physically smaller fuse at F1 with same protection value.

• 3.0V battery.

Rev 3 Release

• EPM-4g model release – Initial RoHS version.

Rev 2 Release

• Initial public release.

Support Page

The EPM-4 Support Page, at http://www.VersaLogic.com/private/lynxsupport.asp contains additional

information and resources for this product including:

• Reference Manual (PDF format)

• Operating system information and software drivers

• Data sheets and manufacturers’ links for chips used in this product

• BIOS information and upgrades

• Utility routines and benchmark software

Note: This is a private page for EPM-4 users only. It cannot be reached through our web site. You must

enter this address dire

ctly to find the support page.

Page 4

Model EPM-4

AMD Élan processor module with 10/100 Ethernet,

and PC/104-Plus interface

REFERENCE MANUAL

VERSALOGIC CORPORATION

WWW.VERSALOGIC.COM

3888 Stewart Road

Eugene, OR 97402

(541) 485-8575

Fax (541) 485-5712

Contents Copyright ©2009

All Rights Reserved

Notice:

Although every effort has been made to ensure this document is error-free, VersaLogic makes no

representations or warranties with respect to this product and specifically disclaims any implied

warranties of merchantability or fitness for any particular purpose.

VersaLogic reserves the right to revise this product and associated documentation at any time

without obligation to notify anyone of such changes.

PC/104 and the PC/104 logo are trademarks of the PC/104 Consortium.

Page 5

Page 6

Table of Contents

Introduction .....................................................................................................................1

Description .......................................................................................................................... 1

Technical Specifications..................................................................................................... 2

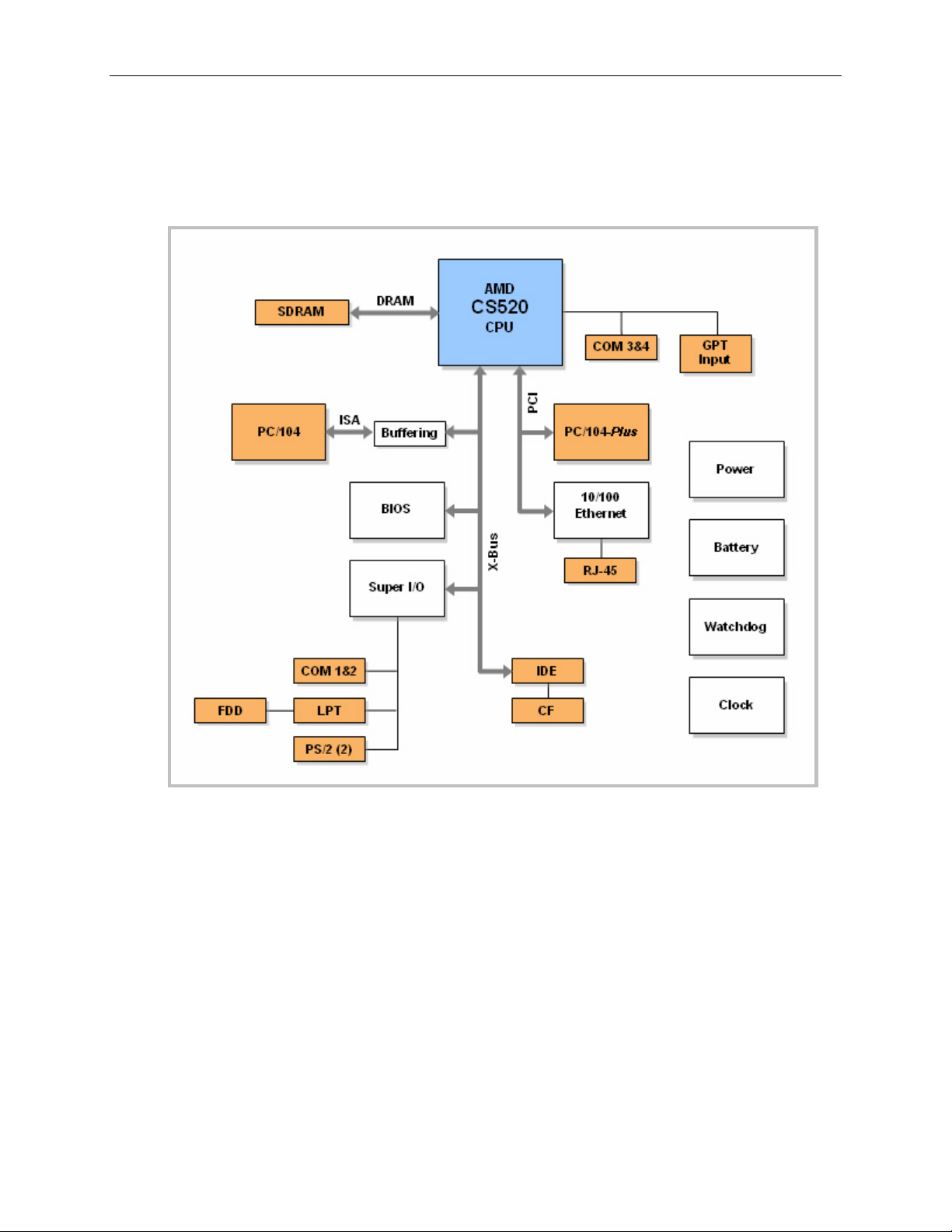

EPM-4 Block Diagram .......................................................................................................3

RoHS-Compliant Version...................................................................................................4

About RoHS...........................................................................................................4

RoHS Compliant Cables........................................................................................4

Technical Support...............................................................................................................5

Repair Service........................................................................................................ 5

Configuration / Operation...............................................................................................7

Overview............................................................................................................................. 7

Electrostatic Discharge ..........................................................................................7

Lithium Battery...................................................................................................... 7

Initial Configuration and Setup...........................................................................................8

Recommended Components..................................................................................8

CMOS Setup / Boot Procedure...........................................................................................9

Console Redirection.......................................................................................................... 10

CMOS Setup / IDE Configuration....................................................................................11

IDE....................................................................................................................... 11

IDE setup .............................................................................................................11

CMOS Setup / Advanced Configuration ..........................................................................12

D0000h 64k page function...................................................................................12

PLD register base I/O .......................................................................................... 12

Force Ethernet 10-BaseT .....................................................................................12

PS/2 Mouse (IRQ12) ...........................................................................................13

LPT1 (0378h).......................................................................................................13

Parallel Port Mode...............................................................................................13

CPU Speed...........................................................................................................13

Cache Mode......................................................................................................... 13

Write Buffer.........................................................................................................13

GP Bus Timings................................................................................................... 13

COM1 (03F8h) RS-232.......................................................................................14

COM2 (02F8h) RS-232.......................................................................................14

COM3 (03E8h) RS-422/485................................................................................14

COM4 (02E8h) RS-422/485................................................................................14

GP Timer 0, GP Timer 1, Watchdog Timer.........................................................14

PCI Interrupt A, B, C, and D ...............................................................................14

Using Custom CMOS Defaults......................................................................................... 15

Reference.......................................................................................................................17

Physical Dimensions.........................................................................................................17

Height Dimensions ..............................................................................................18

Hardware Assembly............................................................................................. 19

Stack Arrangement ..............................................................................................19

External Connectors.......................................................................................................... 20

iii

Page 7

Table of Contents

Connector Location Diagram............................................................................... 20

Connector Functions and Interface Cables..........................................................21

Jumper Block Locations ...................................................................................................22

Jumper Summary................................................................................................. 23

Power Supply....................................................................................................................24

Power Connectors................................................................................................24

Power Requirements............................................................................................25

Lithium Battery.................................................................................................... 25

CPU...................................................................................................................................26

System RAM.....................................................................................................................26

Memory................................................................................................................26

CMOS RAM.....................................................................................................................26

Clearing CMOS RAM.........................................................................................26

Default CMOS RAM Setup Values.....................................................................26

Real Time Clock............................................................................................................... 26

Setting the Clock.................................................................................................. 26

Battery Backed Static RAM..............................................................................................27

Serial Ports........................................................................................................................27

COM Port Configuration.....................................................................................27

COM3 and COM4 RS-485 Mode Line Driver Control.......................................27

IDE Hard Drive / CompactFlash / CD-ROM Interface ....................................................28

Utility Connector (J7)....................................................................................................... 29

Keyboard/Mouse Interface .................................................................................. 30

Programmable LED............................................................................................. 30

External Speaker..................................................................................................30

Push-Button Reset................................................................................................30

General-Purpose Timer Inputs.............................................................................30

Parallel / Floppy Port ....................................................................................................... 31

Parallel Port Operation.........................................................................................31

Floppy Port Operation .........................................................................................31

Parallel / Floppy Port Pinout................................................................................ 31

Ethernet Interface.............................................................................................................. 32

BIOS Configuration.............................................................................................32

Status LED...........................................................................................................32

Ethernet Connector..............................................................................................32

Watchdog Timer...............................................................................................................33

Expansion Bus ..................................................................................................................34

PC/104-Plus (PCI Bus).......................................................................................34

PC/104 (ISA Bus)................................................................................................ 34

I/O Configuration................................................................................................. 34

Memory and I/O Map .......................................................................................................36

ÉlanSC520 Memory Mapped Configuration Region (MMCR) Registers...........36

Memory Map .......................................................................................................36

I/O Map................................................................................................................ 37

Interrupt Configuration.....................................................................................................38

Special Control Register................................................................................................... 39

Revision Indicator Register...............................................................................................40

Map and Paging Control Register..................................................................................... 41

Appendix A — CBL/CBR-5009 .....................................................................................43

iv

Page 8

Table of Contents

Appendix B — References ...........................................................................................45

v

Page 9

Introduction

Description

The EPM-4 (Lynx) is a 486-based processor board in a compact PC/104-Plus format. It is

specifically designed for OEM control projects requiring compact size, high reliability, and long

product lifespan / availability. Its features include:

• AMD ÉlanSC520 microcontroller

• 133 MHz

• 64 MB system RAM

• 10/100 dual-speed Ethernet

• Battery Backed SRAM Option

• Real time clock

• PC/104, PC/104-Plus expansion

interface

• IDE controller

• Two general purpose timer inputs

• Watchdog timer

• Reconfigurable BIOS defaults

• Console redirected to COM port if no

VGA

• CompactFlash Socket

• Four COM ports

• Two RS-232

• Two RS-422/485

• Parallel Port/Floppy Interface

• Vcc sensing reset circuit

• Flash BIOS with OEM enhancements

• Ethernet Remote boot capability

• Single supply (+5V) operation

• Customizing available

• Batteryless operation (possible)

• Extended temperature options (100MHz)

• Transient Voltage Suppressor Devices

rd

party boot code not included

3

1

• Keyboard, mouse, AT motherboard

peripherals

The EPM-4 is a complete computer system in one board. It may be used alone or with expansion

modules. It features a PC/104-Plus expansion interface for fast PCI-based interface to a wide

variety of PC/104 and PC/104-Plus stacking modules. This card is designed to be used primarily

as an Ethernet node processor card.

It is fully compatible with popular operating systems including Windows 95/98/NT/NTE/, CE,

QNX, Linux, RT-Linux, and other Real Time Operating Systems (see the VersaLogic OS

Compatibility Chart).

On-board I/O includes 10/100 Mbit Ethernet, IDE, four COM ports, floppy and two generalpurpose timer inputs.

This exceptional processor card was designed from the ground up for OEM applications with

longevity and reliability as the main focus. It is fully supported by the VersaLogic design team.

Both hardware and software (BIOS) customization are available in quantities as low as 25 pieces.

Each board is subjected to 100% functional testing and is backed by a limited two-year warranty.

EPM-4 Reference Manual Introduction – 1

• RoHS-compliant version available

Page 10

Technical Specifications

Technical Specifications

Specifications are typical at 25°C with 5.0V supply unless otherwise noted.

Board Size:

3.55" x 3.775" (PC/104 standard).

Storage Temperature:

–40° C to 85° C

Operating Temperature:

EPM-4c, g 0° C to +60° C (100 FPM airflow)

EPM-4e, h -40° C to +85° C (free air, extended temperature versions)

Power Requirements: (with keyboard, mouse, and hard drive running DOS)

EPM-4c, g 133 MHz +5V ±5% @ 0.94A

EPM-4e, h 100 MHz +5V ±5% @ 0.84A, extended temperature versions

+3.3V or ±12V may be required by some expansion modules

System Reset:

Vcc sensing, resets below 4.70V typ.

Watchdog timeout

BBSRAM Interface:

2 MB option mapped into high memory

IDE Interface:

Industry standard 2mm 44-pin non-latching style, CompactFlash socket.

LPT/Floppy Interface:

Supports one floppy drive or parallel port.

Ethernet Interface:

Autodetect 10BaseT/100BaseTX based on Intel 82551ER. 12K transmit/receive buffer.

COM1 and COM2 Interface:

RS-232, 16C550 compatible, 115K baud max.

COM3 and COM4 Interface:

RS-422/485, 16C550 compatible, 460K baud max.

Connectors:

Utility: 2mm 50-pin shrouded

IDE: 2mm 44-pin

Floppy/LPT: 2mm 20-pin shrouded

Ethernet: RJ45

Power: 0.1” 10-pin

CompactFlash Type II socket

BIOS: General Software embedded BIOS with OEM enhancements

Field upgradeable with Flash BIOS Upgrade Utility

Bus Speed:

PCI, PC/104-Plus: 33 MHz, Revision 2.0

PC/104: 8 MHz, Revision 2.5

Compatibility:

PC/104 – Fully functional with most PC/104 devices. See the Expansion Bus section for details.

Embedded-PCI (PC/104-Plus) – Full compliance, 3.3V or 5V modules

RoHS: EPM-4g, h – Full compliance

Weight:

EPM-4c, g – 0.117 kg (0.275 lbs)

EPM-4e, h – 0.116 kg (0.255 lbs)

Specifications are subject to change without notice.

Introduction – 2 EPM-4 Reference Manual

Page 11

EPM-4 Block Diagram

EPM-4 Block Diagram

EPM-4 Reference Manual Introduction – 3

Page 12

RoHS-Compliant Version

RoHS-Compliant Version

The EPM-4g and EPM-4h are RoHS-compliant. These models are functionally identical to the

non-RoHS version of the boards.

BOUT ROHS

A

In 2003, the European Union issued Directive 2002/95/EC regarding the Restriction of the use of

certain Hazardous Substances (RoHS) in electrical and electronic equipment.

The RoHS directive requires producers of electrical and electronic equipment to reduce to

acceptable levels the presence of six environmentally sensitive substances: lead, mercury,

cadmium, hexavalent chromium, and the presence of polybrominated biphenyls (PBB) and

polybrominated diphenyl ethers (PBDE) flame retardants, in certain electrical and electronic

products sold in the European Union (EU) beginning July 1, 2006.

VersaLogic Corporation is committed to supporting customers with high-quality products and

services meeting the European Union’s RoHS directive.

OHS COMPLIANT CABLES

R

Adapter cables for the EPM-4 are available in RoHS compliant and RoHS noncompliant versions.

Compliance or noncompliance is indicated by the part number prefix. “CBR” indicates RoHS

compliance. “CBL” indicates RoHS noncompliance. For applications that require RoHS

compliance, use only the RoHS compliant (“CBR” version) cables. Availability of RoHS

noncompliant cables may be limited.

Introduction – 4 EPM-4 Reference Manual

Page 13

Technical Support

If you have problems that this manual can’t help you solve, first visit the EPM-4 Product Support

web page below. If you have further questions, contact VersaLogic for technical support at

(541) 485-8575. You can also reach our technical support engineers via e-mail at

Support@VersaLogic.com

EPAIR SERVICE

R

If your product requires service, you must obtain a Returned Material Authorization (RMA)

number by calling (541) 485-8575.

http://www.VersaLogic.com/private/lynxsupport.asp

Technical Support

.

EPM-4 Support Website

Please provide the following inform

ation:

• Your name, the name of your company, and your phone number

• The name of a technician or engineer who we can contact if we have questions

• Quantity of items being returned

• The model and serial number (bar code) of each item.

• A description of the problem

• Steps you have taken to resolve or repeat the problem

• The return shipping address

Warranty Repair

All parts and labor charges are covered, including return shipping

charges for UPS Ground delivery to United States addresses.

Non-warranty Repair

All non-warranty repairs are subject to diagnosis and labor charges,

parts charges, and return shipping fees. We will need to know what

shipping method you prefer for return back to your facility, and we

will need to secure a purchase order number for invoicing the repair.

Note: Please mark the RMA number clearly on the outside of the box before

returning. Failure to do so can delay the processing of your return.

EPM-4 Reference Manual Introduction – 5

Page 14

Page 15

Overview

ELECTROSTATIC DISCHARGE

Warning! Electrostatic discharge (ESD) can damage boards, disk drives, and other

After removing the board from its protective wrapper, place the board on a

Configuration / Operation

components. The circuit board must only be handled at an ESD workstation. If an

approved station is not available, some measure of protection can be provided by

wearing a grounded anti-static wrist strap. Keep all plastic away from the board,

and do not slide the board over any surface.

grounded, static-free surface, component side up. Use an anti-static foam pad if

available.

The board should also be protected during shipment or storage by keeping inside a

closed metallic anti-static envelope.

2

Note: The exterior coating on some metallic anti-static bags is sufficiently conductive to

cause excessive battery drain if the bag comes in contact with the bottom side of

the EPM-4.

ITHIUM BATTERY

L

Warning! To prevent shorting, premature failure, or damage to the lithium battery, do not

place the board on a conductive surface such as metal, black conductive foam, or

the outside surface of a metalized ESD protective pouch. The lithium battery may

explode if mistreated. Do not recharge, disassemble, or dispose of in fire. Dispose

of used batteries promptly.

EPM-4 Reference Manual Configuration / Operation – 7

Page 16

Initial Configuration and Setup

Initial Configuration and Setup

The following list describes the components recommended for setting up a typical development

system.

ECOMMENDED COMPONENTS

R

• EPM-4 Board and cable kit

• ATX Power Supply

• EPM-VID-3 for video support

• Keyboard with PS/2 connector, mouse

• Ethernet Network

• IDE Hard Drive

• Floppy Drive

Configuration / Operation – 8 EPM-4 Reference Manual

Page 17

CMOS Setup / Boot Procedure

• Turn power on.

• Press the DEL key the instant that video is displayed (during the memory test).

• Verify default CMOS Setup information as shown below.

• Insert bootable floppy disk into floppy drive.

• Reset computer using push button reset.

• See VersaLogic KnowledgeBase article VT1476 – EPM-4 CMOS Setup Reference

more information about these parameters.

Basic CMOS Configuration

+------------------------------------------------------------------------------+

| System Bios Setup - Basic CMOS Configuration |

| (C) 2002 General Software, Inc. All rights reserved |

+---------------------------+--------------------+-----------------------------+

| DRIVE ASSIGNMENT ORDER: | Date:>JAN 1, 1980 | Typematic Delay : 250 ms |

| Drive A: Floppy 0 | Time: 00 : 00 : 00 | Typematic Rate : 30 cps |

| Drive B: (None) | NumLock: Disabled | Seek at Boot : None |

| Drive C: IDE 0/Pri Master +--------------------+ Show "Hit Del" : Enabled |

| Drive D: (None) | BOOT ORDER: | Config Box : Enabled |

| Drive E: (None) | Boot 1st: Drive A: | F1 Error Wait : Enabled |

| Drive F: (None) | Boot 2nd: Drive C: | Parity Checking : (Unused) |

| Drive G: (None) | Boot 3rd: (None) | Memory Test Tick : Enabled |

| Drive H: (None) | Boot 4th: (None) | Debug Breakpoints: (Unused) |

| Drive I: (None) | Boot 5th: (None) | Debugger Hex Case: Upper |

| Drive J: (None) | Boot 6th: (None) | Memory Test : StdLo FastHi |

| Drive K: (None) +--------------------+-----------------+-----------+

| (Loader): (Unused) | ATA DRV ASSIGNMENT: Sect Hds Cyls | Memory |

+---------------------------+ Ide 0: 3 = AUTOCONFIG, LBA | Base: |

| FLOPPY DRIVE TYPES: | Ide 1: 3 = AUTOCONFIG, LBA | 633KB |

| Floppy 0: 1.44 MB, 3.5" | Ide 2: Not installed | Ext: |

| Floppy 1: Not installed | Ide 3: Not installed | 63MB |

+---------------------------+--------------------------------------+-----------

Custom Configuration

+------------------------------------------------------------------------------+

| System BIOS Setup - Custom Configuration |

| (C) 2002 General Software, Inc. All rights reserved |

+---------------------------------------+--------------------------------------+

| D0000h 64k page function : ISA bus | COM1 (3F8h) RS-232 : IRQ4 |

| PLD register base I/O : 0E0h | COM2 (2F8h) RS-232 : IRQ3 |

| Force Ethernet 10-BaseT : Disabled | COM3 (3E8h) RS-422/485 : Disabled |

| PS/2 Mouse (IRQ12) : Enabled | COM4 (2E8h) RS-422/485 : Disabled |

| LPT1 (378h) : Disabled | GP Timer 0 : Disabled |

| Parallel Port Mode : FDD | GP Timer 1 : Disabled |

| CPU Speed : 133 MHz | Watchdog Timer : Disabled |

| Cache Mode : Wr-back | PCI Int A : IRQ11 |

| Write Buffer : Enabled | PCI Int B : IRQ11 |

| GP Bus Timings : Normal | PCI Int C (Ethernet) : IRQ11 |

| Console Redirection : Auto | PCI Int D : IRQ11 |

+---------------------------------------+--------------------------------------+

CMOS Setup / Boot Procedure

for

+

Note: Due to changes and improvements in the system BIOS, the information on your

monitor may differ from that shown above.

EPM-4 Reference Manual Configuration / Operation – 9

Page 18

Console Redirection

Console Redirection

If there is no video device detected during boot up, BIOS keyboard and screen I/O can be

redirected to the COM2 RS-232 serial port. CMOS configuration can be modified over this

redirected console. ANSI or VT102 terminal emulation is recommended.

When console redirection is enabled, press CTRL-C on the terminal emulator to enter CMOS

Setup; the BIOS ignores DEL from a PS/2 keyboard. This is normal operation of the Lynx.

COM2 is configured for standard serial port communication:

• 9600 Baud

• Parity: None

• Flow Control: None

• Data Bits: 8

• Stop Bits: 1

Console redirection remains active when POST completes and the operating system boots. Textbased operating systems such as DOS and Linux can be controlled over this connection.

To enable console redirection, there must be no video device detected, the console redirection

option in Custom Configuration must be set to Auto, and there must be a terminal (such as

Windows HyperTerm) detected at COM2.

Configuration / Operation – 10 EPM-4 Reference Manual

Page 19

CMOS Setup / IDE Configuration

IDE

The Lynx has a single IDE channel to connect up to two hard disks, CompactFlash modules

or CD-ROM drives. This basic IDE interface operates using PIO mode 0, resides on the ISA

bus, and does not support the drive address register at I/O address 3F7h. It has been tested

successfully on a wide variety of operating systems.

SETUP

IDE

IDE devices include hard disk drives, CD-ROM drives, and some CompactFlash modules.

There are 3 fields in the Basic CMOS Configuration screen that are relevant to IDE setup:

IDE Drive Geometry, Drive Assignment Order, and Boot Order.

IDE Drive Geometry

Most desktop PCs have two IDE channels, each capable of supporting two IDE devices

in a slave/master configuration or a single IDE device in a single (or master only)

configuration.

In the IDE Drive Geometry list:

CMOS Setup / IDE Configuration

IDE 0 corresponds to primary channel, master/single drive.

IDE 1 corresponds to primary channel, slave drive.

IDE 2 corresponds to secondary channel, master/single drive.

IDE 3 corresponds to secondary channel, slave drive.

The Lynx uses the first IDE channel only. IDE 2 and IDE 3 are unused

All modern IDE devices use LBA mode. When setting up an IDE device, leave the drive

geometry set to LBA mode unless your hard drive requires a different mode.

CD-ROM drives that will be used as boot devices should be set accordingly in the Drive

Geometry list.

Drive Assignment Order

After a hard drive has been declared in the IDE Drive Geometry field, it must be

assigned a DOS drive letter, even if you are not using the DOS operating system.

Normally, "Drive C:" will be assigned to the IDE device that you wish to boot from.

Do not attempt to assign a drive letter to a CD-ROM drive. The drivers required to use

these devices will automatically assign a drive letter to the device when loaded.

Boot Order

This field allows you to specify the order in which the BIOS looks for boot devices.

EPM-4 Reference Manual Configuration / Operation – 11

Page 20

CMOS Setup / Advanced Configuration

Usually, the drive you specify here corresponds to the declaration in the Drive

Assignment Order field.

A CD-ROM drive can be inserted into the boot order by selecting “CDROM” at the

desired boot order position.

CMOS Setup / Advanced Configuration

D0000H 64K PAGE FUNCTION

Default: ISA bus

ISA bus

Memory accesses to the D0000h page will be sent to the ISA bus for use by PC/104

expansion modules. This setting is required when flashing the BIOS with the FBU utility.

BIOS Ext

The D0000h page is mapped to sector 1 in the flash chip, which may contain 3rd party

Ethernet boot code or any other BIOS extension (not included). If there is a such an

extension present, it will be called by the BIOS. The BIOS extension can be programmed

into the flash chip with the FBU utility. For remote booting via Ethernet, the

recommended boot ROM is Managed PC Boot Agent from Argon Technology

Corporation.

RAM

System RAM is exposed in the D0000h page.

PLD

REGISTER BASE I/O

Default: 0E0h

Specifies the location of the PLD register in I/O space. It can be moved to 1E0h in case of an

address conflict within add-in module.

ORCE ETHERNET 10-BASET

F

Default: Disabled

When enabled, this will disable the Ethernet media data rate auto-negotiation and force it to 10BaseT mode.

Note: Some drivers will put the Ethernet back into auto-negotiation mode.

Configuration / Operation – 12 EPM-4 Reference Manual

Page 21

CMOS Setup / Advanced Configuration

PS/2 MOUSE (IRQ12)

Default: Enabled

When disabled, IRQ12 is freed for other devices.

LPT1

(0378H)

Default: IRQ7

Allows you to disable or specify the IRQ used by LPT1 on the SMSC FDC37B727 Super I/O.

When disabled, the IRQ and I/O space are freed.

ARALLEL PORT MODE

P

Default: SPP

This option allows the user to change the communication mode of the parallel port. The options

are: SPP, SPP/EPP1.9, ECP, ECP/EPP1.9, Printer, SPP/EPP1.7, ECP/EPP1.7, and FDD. The

FDD option must be set if a floppy drive is used.

SPEED

CPU

Default: 133 MHz

The maximum clock rate for the ÉlanSC520 Microcontroller is 133 MHz. It can optionally be set

to 100 MHz for a slight power savings. If an extended temperature board version is detected, the

default will change to 100 MHz.

ACHE MODE

C

Default: Write-Back

The 16 kb L1 cache can be configured for either write-through or write-back mode. This option

controls the CACHE_WR_MODE in the CPUCTL register (MMCR offset 02h).

RITE BUFFER

W

Default: Enabled

When the write buffer is enabled, it buffers all write activity from the CPU, PCI bus, or GP bus.

This option controls the WB_ENB bit in the DBCTL register (MMCR offset 40h).

BUS TIMINGS

GP

Default: Normal

The GP (ISA) bus timings may need to be slowed to accommodate ISA Plug-n-Play cards. This

option modifies registers in the GP Bus Controller, MMCR offsets C08h through C10h.

EPM-4 Reference Manual Configuration / Operation – 13

Page 22

CMOS Setup / Advanced Configuration

COM1 (03F8H) RS-232

Default: IRQ4

Allows you to disable or specify the IRQ used by internal UART1 on the ÉlanSC520

Microcontroller. When disabled, the IRQ and I/O space are freed.

COM2

Default: IRQ3

(02F8H) RS-232

Allows you to disable or specify the IRQ used by internal UART2 on the ÉlanSC520

Microcontroller. When disabled, the IRQ and I/O space are freed.

COM3

Default: Disabled

(03E8H) RS-422/485

Allows you to disable or specify the IRQ used by UART1 on the SMSC FDC37B727 Super I/O.

When disabled, the IRQ and I/O space are freed.

COM4

Default: Disabled

(02E8H) RS-422/485

Allows you to disable or specify the IRQ used by UART2 on the SMSC FDC37B727 Super I/O.

When disabled, the IRQ and I/O space are freed.

TIMER 0, GP TIMER 1, WATCHDOG TIMER

GP

Default: Disabled

These internal SC520 devices can be disabled or enabled by assigning an IRQ. Enabling these

devices only sets up the IRQ assignment; it is up to the user to set up device operation. Refer to

the ÉlanSC520 Microcontroller User's Manual for details.

INTERRUPT A, B, C, AND D

PCI

Default: IRQ11

These options allow manual IRQ routing of PCI devices.

Note: PCI devices can share an interrupt. In most cases, the cost of doing this is slightly decreased

system performance and slightly increased interrupt response time.

Configuration / Operation – 14 EPM-4 Reference Manual

Page 23

Using Custom CMOS Defaults

The Lynx BIOS has the capability to store CMOS defaults in the on-board flash chip. This

storage area is non-volatile, enabling the Lynx to run with user-specified CMOS defaults without

a battery installed.

If custom defaults are specified, they will be used instead of the factory defaults any time CMOS

memory needs to be reset. CMOS is reset when any of the following occur:

• CMOS memory is found to be corrupt or uninitialized at boot time

• CMOS contents are erased by FBU during a BIOS upgrade

• The Lynx was powered on without a battery, or without a sufficiently charged battery

There are 4 options on the main BIOS setup screen that control CMOS defaults.

• Save CMOS as custom defaults

Saves the current CMOS settings to the custom defaults. These settings will be used any

time CMOS is reset. If there are already custom defaults specified, they will be

overwritten.

Using Custom CMOS Defaults

• Reset CMOS to custom defaults

Discards the current CMOS settings and uses the saved custom defaults. This operation

will fail if no custom defaults have been previously saved.

• Clear custom defaults (use factory defaults)

Deletes custom CMOS settings stored in flash. Factory default settings will be used any

time CMOS is reset.

• Reset CMOS to factory defaults

Discards the current CMOS settings and uses factory defaults, even if custom

defaults have been specified. If CMOS is later reset, custom defaults will be used if

available.

Warning! Take care in saving custom CMOS defaults, as you must be able to get back to the

main BIOS setup screen to undo any mistakes. For example, it would be a mistake

to disable a COM port that is required for console redirection when there is no

video device available.

EPM-4 Reference Manual Configuration / Operation – 15

Page 24

Page 25

Physical Dimensions

The EPM-4 complies with all PC/104-Plus standards. Dimensions are given below to help with

pre-production planning and layout.

3.575

3.370

2.330

0.150

Reference

3.050 3.470

3

3.070

0.400

0.000

-0.200

3.570

3.350

3.150

0.000

0.200

-0.250

Figure 1. Dimensions

(Not to scale. All dimensions in inches.)

EPM-4 Reference Manual Reference – 17

3.300

Page 26

Physical Dimensions

HEIGHT DIMENSIONS

0.44

0.42

Figure 2. Height Dimensions

(Not to scale. All dimensions in inches.)

0.51

0.44

0.06

Reference – 18 EPM-4 Reference Manual

Page 27

Physical Dimensions

HARDWARE ASSEMBLY

The EPM-4 uses pass-through PC/104 and PC/104-Plus connectors so that expansion modules

can be added to the top or bottom of the stack. PC/104 (ISA) modules must NOT be positioned

between the Lynx and any PC/104-Plus (PCI) modules on the stack. The PC/104 pass-through

connector on the EPM-4 Rev 4 is keyed (pins B10 and C19 missing) to provide greater

compatibility with other PC/104 compliant devices.

The entire assembly can sit on a tabletop or it can be secured to a base plate. When bolting the

unit down, make sure to secure all four standoffs to the mounting surface to prevent circuit board

flexing. Standoffs are secured to the top circuit board using four pan head screws. Refer to the

drawing on page 17 for dimensional details.

An extractor tool is available (part num

stack.

TACK ARRANGEMENT

S

ber VL-HDW-201) to separate the modules from

the

Figure 3. PC/104 Card Added to Top of Stack

EPM-4 Reference Manual Reference – 19

Page 28

External Connectors

External Connectors

CONNECTOR LOCATION DIAGRAM

Figure 4. Connector Locations

On the EPM-4 Rev 4 and above, the pass-through PC/104 (ISA) connector is keyed (pins B10

and C19 missing) for greater compatibility with PC/104 devices, as shown in the figure below.

Pin Side of ISA Connector

C19

B32

A32

C19

D19

Pin numbering begins on the

side with a larger row offset

Note: For rows A and B, pin numbers begin at 1.

For rows C and D, pin numbers begin at 0.

B10

B1

A1

C0

D0

Figure 5. PC/104 (ISA) Connector Keying

Reference – 20 EPM-4 Reference Manual

Page 29

External Connectors

CONNECTOR FUNCTIONS AND INTERFACE CABLES

The table below notes the function of each connector, as well as mating connectors and cables,

and the page where a detailed pinout or further information is available.

Note: VersaLogic adapter cables for the EPM-4 are available in RoHS compliant and

RoHS noncompliant versions. Compliance or noncompliance is indicated by the

part number prefix. “CBR” indicates RoHS compliance. “CBL” indicates RoHS

noncompliance. For applications that require RoHS compliance, use only the RoHS

compliant (“CBR” version). Availability of RoHS noncompliant cables may be

limited.

Table 1: Connector Functions and Interface Cables

Connector

J1 PC/104-Plus

J2 LPT / Floppy

J3 PLD Reprogramming

Port (Factory use Only)

J4 Ethernet

J5 CompactFlash Type I & II

J6 IDE Interface

J7

J8 Main Power Input Berg 69176-010 (Housing) +

J9 PC/104 AMP 1375795-2 __ __ 34 .050 0.200

COM Ports, Keyboard,

Mouse, GP Timer inputs,

Power LED, Push-button

reset, PC speaker, LED

Function

Mating

Connector

AMP 1375799-1

FCI 89947-720

DB-25 to floppy

__ __ __ __ .450 2.525

RJ45

__

FCI 89947-144 (IDC)

FCI 89947-350LF

Berg 47715-000 (Pins)

Transition

Cable

__ __ 34 .450 3.139

CBL/CBR-2003

CBL/CBR-2501

__ __ 32 3.935 2.545

__ __ 28 __ __

CBL/CBR-4404

CBL/CBR-4405

CBL/CBR-5009A

CBL/CBR-1008 Interface from industry

Cable

Description

12” 2mm latching LPT

Floppy adapter cable

12” 2mm IDE cable

2mm to 0.1” adapter

12” 2mm latching 50pin to 50-pin

standard ATX power

supply

‡Pin 1 Location

X Coord. Y Coord.

Page

31 -0.071 2.465

28 3.050 2.247

29 3.265 2.270

24 .0250 -0.050

‡ Relative to lower left hand mounting hole. See page 17.

EPM-4 Reference Manual Reference – 21

Page 30

Jumper Block Locations

Jumper Block Locations

Note: The diagram below shows the as-shipped configuration for jumpers on Rev. 4.xx

and earlier boards. On Rev. 5.xx and later boards, no jumper is installed on V3.

Figure 6. Jumper Block Locations

Reference – 22 EPM-4 Reference Manual

Page 31

JUMPER SUMMARY

Jumper Block Locations

Table 2: Jumper Summary

Jumper

Block

V1

V2

V2

V3

Rev. 4.xx

and earlier

V3

Rev. 5.xx

and later

V4[1-2]

V4[3-4]

Description

Battery Power Jumper

[1-2] In – Discharge CMOS Memory

[2-3] In – Standard Operation

COM3 configuration

[1-2] In and [3-4] In – RS-485 Endpoint

[1-2] In and [3-4] Out – RS-485 Intermediate

[1-2] Out and [3-4] In – RS-422

COM4 configuration

[5-6] In and [7-8] In – RS-485 Endpoint

[5-6] In and [7-8] Out – RS-485 Intermediate

[5-6] Out and [7-8] In – RS-422

CompactFlash Master/Slave Section

In — Master IDE Device

Out — Slave IDE Device

CompactFlash Master/Slave Section

In — Slave IDE Device

Out — Master IDE Device

System BIOS Selector

In — Run Time System BIOS occupies E0000h to FFFFFh

Out — Master System BIOS occupies E0000h to FFFFFh

Note:

The Run Time System BIOS is field upgradeable using the BIOS upgrade

utility. See www.VersaLogic.com/private/lynxsupport.asp for further information.

General Purpose Input Bit

In — Bit D0 in SCR register reads as 1

Out — Bit D0 in SCR register reads as 0

As

Shipped Page

[2-3] In 26

[1-2] In

[3-4] In

[5-6] In

[7-8] In

In 28

Out 28

In —

In —

27

27

EPM-4 Reference Manual Reference – 23

Page 32

Power Supply

Power Supply

POWER CONNECTORS

Main power is applied to the

EPM-4 through a 10-pin polarized connector. Mating connector Berg

69176-010 (Housing) + Berg 47715-000 (Pins). See the table below for connector pinout and

page 20 location information.

Warning!

To prevent severe and possibly

irreparable damage to the system, it is critical that

the power connectors be wired correctly. Make sure to use all three +5VDC pins

and all four ground pins to prevent excess voltage drop. Some suppliers include a

pin-1 indicator on the crimp housing that corresponds to pin-10 of the pinout.

Table 3: Main Power Connector Pinout

J8

Signal

Pin

Name

1 Ground Ground

2 +5VDC Power Input

3 Ground Ground

4 +12VDC Power Input

5 Ground Ground

6 –12VDC Power Input

7 +3.3VDC Power Input

8 +5VDC Power Input

9 Ground Ground

10 +5VDC Power Input

Description

Note: The +3.3VDC, +12VDC, and –12VDC inputs are only required for expansion

modules that require these voltages.

Some manufacturers include a pin-1 indicator on the crimp housing that corresponds to pin-10 of

the J8 power connector.

Some manufacturers include

a pin-1 indicator here that

J8

4

2

3

1

corresponds to pin-10 of the

power connector pinout

10

8

6

9

7

5

10

9

8

6

4

2

7

5

3

1

CBL/CBR-1008

Figure 7. J8 and CBL/CBR-1008 Pin Numbering

Reference – 24 EPM-4 Reference Manual

Page 33

Power Supply

POWER REQUIREMENTS

The EPM-4 only requires +5 volts (±5%) for proper operation. The voltage required for the RS232 ports is generated with an on-board DC/DC converter. A variable low-voltage supply circuit

provides power to the CPU and other on-board devices.

The exact power requirement of the EPM-4 depends on several factors peripheral connections,

type and number of expansion modules, and attached devices. For example, AT keyboards

typically draw their power directly from the

EPM-4, and driving long RS-232 lines at high speed

can increase power demand. Reducing the CPU speed from 133 MHz to 100 MHz via the BIOS

settings will save approximately 0.5 W.

ITHIUM BATTERY

L

Warning! To prevent shorting, premature failure, or damage to the lithium battery, do not

place the unit on a conductive surface such as metal, black conductive foam, or the

outside surface of a metalized ESD protective pouch. The lithium battery may

explode if mistreated. Do not recharge, disassemble, or dispose of in fire. Dispose

of used batteries promptly.

Batteries of different voltages are used on different revisions of the EPM-4, as shown below:

EPM-4 Revision Battery Type

Rev 4 and above 3.0V 2.5V T-HB3/5-2

Rev 2 3.5V 3.0V T-HB3/5-3

Min. Operating

Voltage

Reorder Part No.

If the operating voltage drops below the minimum, contact the factory for a replacement. Life

expectancy under normal use is approximately 10 years.

EPM-4 Reference Manual Reference – 25

Page 34

CPU

CPU

The ÉlanSC520 Microcontroller has a 32-bit, low-voltage AMD Am5x86 microprocessor at its

core. The maximum clock rate is 133 MHz. The Am5x86 has 16 kb of unified cache that supports

write-back and write-through policies. It is a high-performance 486 CPU achieving performance

results equal to a Pentium 75.

System RAM

MEMORY

The EPM-4 has 64MB of SDRAM soldered on board.

• Storage Capacity 64 MB

• Voltage 3.3 Volt

• Error Detection Code Not supported

• Error Correction Not supported

• Speed 66 MHz, 60 ns

CMOS RAM

CLEARING CMOS RAM

Jumper V1 can be moved to position [1-2] for 30 seconds to erase the contents of the CMOS

RAM. Be sure to move the jumper back to position [2-3] for normal operation.

Note: Operation of the board with jumper V1 in the erase position [1-2] is not supported

or recommended.

EFAULT CMOS RAM SETUP VALUES

D

After the CMOS RAM is cleared, the system will load default CMOS RAM parameters the next

time the board is powered on. The default CMOS RAM setup values will be used in order to boot

the system whenever the main CMOS RAM values are blank, or when the system battery is dead

or has been removed from the board.

Real Time Clock

The EPM-4 features a year 2000 compliant, battery-backed 146818 compatible real time

clock/calendar chip. Under normal battery conditions, the clock will maintain accurate

timekeeping functions during periods when the board is powered off.

ETTING THE CLOCK

S

The CMOS Setup utility (accessed by pressing the [DEL] key during a system boot) can be used

to set the time/date of the real time clock.

Reference – 26 EPM-4 Reference Manual

Page 35

Battery Backed Static RAM

The EPM-4 can be ordered with an optional 2 MB of Battery Backed Static RAM (BBSRAM).

This BBSRAM is powered by the boards RTC battery when main power is turned off. Jumper

V1, which is used to clear CMOS RAM, does not affect the BBSRAM.

The BBSRAM is located at the absolute address of (0x08000000) in one continuous 2 MB block.

Serial Ports

The EPM-4 features two on-board 16550 based serial channels located at standard PC I/O

addresses. COM1 and COM2 are RS-232 (115.2K baud) serial ports.

COM3 and COM4 can be operated in RS-422 or RS-485 modes. Two additional non-standard

baud rates are also available (programmable in the normal baud rate registers), up to 460K baud.

Interrupt assignment for each COM port is handled in CMOS Setup, and each port can be

independently enabled or disabled.

All four serial ports are protected against ESD damage. This protection exceeds 15KV human

body model.

Battery Backed Static RAM

PORT CONFIGURATION

COM

There are no configuration jumpers for COM1 and COM2 because it only operates in RS-232

mode.

Jumper V2 is used to configure COM3 and COM4 for RS-422/485 operation. See page 23 for

p

er configuration details.

jum

COM3

AND COM4 RS-485 MODE LINE DRIVER CONTROL

The TxD+/TxD– differential line driver can be turned on and off by manipulating the DTR

handshaking line.

The following code example shows how to turn the line driver for COM3 on and off:

mov dx,03ECh ; Point to COM3 Modem Control register

in al,dx ; Fetch existing value

or al,01h ; Clear bit D0

out dx,al ; Turn DTR on (enables line driver)

in al,dx ; Fetch existing value

and al,0FEh ; Set bit D0

out dx,al ; Turn DTR off (disables line driver)

EPM-4 Reference Manual Reference – 27

Page 36

IDE Hard Drive / CompactFlash / CD-ROM Interface

IDE Hard Drive / CompactFlash / CD-ROM Interface

One IDE interface is available to connect up to two IDE devices, such as hard disks, CD-ROM

drives or CompactFlash (CF) media. Use CMOS Setup to specify the drive parameters of the

attached drives.

An activity indication LED is provided on the EPM-4. The yellow LED of D5 (See page 22) will

show that activity

m 44-pin connector (J6) and a CF socket (J5) are provide on the board. Jumper V3

A 2m

determines if the CF media plugged into J5 is the IDE Master or slave (see Table 2).

Note: The IDE port is a sim

Warning! Cable length must be 18" or less to maintain proper signal integrity. The grounds in

is detected on the IDE interface.

le interface compatible with PIO mode 0.

p

this connector should not be used to carry motor current.

Table 4: IDE Hard Drive Connector Pinout

J6

Pin

1 HRST* Host Reset Reset signal from CPU

2 Ground Ground Ground

3 IDE7 DATA 7 Data bit 7

4 ID8 DATA 8 Data bit 8

5 ID6 DATA 6 Data bit 6

6 ID9 DATA 9 Data bit 9

7 ID5 DATA 5 Data bit 5

8 ID10 DATA 10 Data bit 10

9 ID4 DATA 4 Data bit 4

10 ID11 DATA 11 Data bit 11

11 ID3 DATA 3 Data bit 3

12 ID12 DATA 12 Data bit 12

13 ID2 DATA 2 Data bit 2

14 ID13 DATA 13 Data bit 13

15 ID1 DATA 1 Data bit 1

16 ID14 DATA 14 Data bit 14

17 ID0 DATA 0 Data bit 0

18 ID15 DATA 15 Data bit 15

19 Ground Ground Ground

20 NC NC No connection

21 IDEDRQ IDEDRQ DMA/Request

22 Ground Ground Ground

23 IOWR* HOST IOW* I/O write

24 Ground Ground Ground

25 IORD* HOST IOR* I/O read

26 Ground Ground Ground

27 RDY Ready Wait control

28 HAEN ALE Address latch enable

29 IDEDACK IDEACK DMA/Ack.

30 Ground Ground Ground

31 HINT HOST IRQ10 IRQ10

32 XI16* HOST IOCS16* Drive register enabled

33 PA1 HOST ADDR1 Address bit 1

34 NC NC No connection

35 PA0 HOST ADDR0 Address bit 0

36 PA2 HOST ADDR2 Address bit 2

37 ECS0* HOST CS0* Reg. Access chip select 0

38 ECS1* HOST CS1* Reg. Access chip select 1

39 NC NC No connection

40 Ground Ground Ground

41 5V Power Power

42 5V Power Power

43 Ground Ground Ground

44 NC NC No connection

Signal

Name

IDE

Signal Name Function

Reference – 28 EPM-4 Reference Manual

Page 37

Utility Connector (J7)

The 50-pin utility connector (J7) incorporates the COM ports, keyboard and mouse, generalpurpose inputs, and the reset button and speaker. Table 5 shows the function of each pin and the

pinout to the connectors of the CBL/CBR-5009 I/O board.

J7

CBR-5009

Pin

Connector Pin

1

2

3 (Top) 2 Receive Data

4 7 Request to Send

5 3 Transmit Data 29 – Ground Ground

6 8 Clear to Send

7 4 Data Terminal Ready

8 9 Ring Indicator 32 – Ground Ground

9 5 Ground

10

11

12 (Bottom) 11 Receive Data

13 16 Request to Send

14 12 Transmit Data 38

15 17 Clear to Send

16 13 Data Terminal Ready

17 18 Ring Indicator 41

18 14 Ground

19

20 5 TxD+ (1) 45 B3 Ground

21

22

23

24

25

COM1

J3

COM2

J3

COM3

J6

(1) Do not connect to these pins in RS-485 mode.

(2) The Pushbutton Reset signal (PBRST#) is also routed to pin 2 of J2 (CBL/CBR-5009). A

pushbutton can be attached to pins 2 and 1 (Ground) of J2.

(3) Pin 2 of D1 (CBL/CBR-5009) is connected to +5V (Protected), which provides power to the IDE

LED. Pin 4 of D1 is connected to Ground.

1 Data Carrier Detect

6 Data Set Ready

10 Data Carrier Detect

15 Data Set Ready

1 Ground Ground 44

4 TxD– (1) 46 B5 Keyboard Clock

– Ground Ground 47

2 RxD– TxD/RxD– 48

3 RxD+ TxD/RxD+ 49

– Ground Ground 50

Table 5: Utility Connector Pinout

Signal

RS-422 RS-485

J7

CBR-5009

Pin

Connector Pin

26

27 5 TxD+ (1)

28 4 TxD– (1)

30 2 RxD– TxD/RxD–

31 3 RxD+ TxD/RxD+

33

34

35 T3 Ground

36 T5 Mouse Clock

37

PBRESET (2)

39

40

42 5 GP Timer Input 0

43

GP Timer

Keyboard

PLED (3)

COM4

J5

Mouse

J4

S1

Inputs

J2

J4

D1

Speaker

SP1

Utility Connector (J7)

Signal

RS-422 RS-485

1 Ground Ground

T4 +5V (Protected)

T1 Mouse Data

1 Pushbutton Reset

2 Ground

3 Ground

4 GP Timer Input 1

– Ground

B4 +5V (Protected)

B1 Keyboard Data

1 +5V (Protected)

3 Programmable LED

– +5V (Protected)

SP1+ Speaker Drive

EPM-4 Reference Manual Reference – 29

Page 38

Utility Connector (J7)

KEYBOARD/MOUSE INTERFACE

A standard PS/2 keyboard and mouse interface is accessible through connector J7.

This device is protected against ESD damage by IC 61000-402 rated transient voltage suppressor

components.

ROGRAMMABLE LED

P

The high-density I/O connector J7 includes an output signal for attaching a software controlled

LED. Connect the cathode of the LED to J7[48]; anode to J7[47]. An on-board resistor limits the

current to 15 mA when the circuit is turned on.

The 5V supply for this feature is protected by a self resetting fuse. This 1 Amp fuse is used to

protect KB, mouse, speaker, and LED.

The programmable LED is controlled by the PIO24 pin on the ÉlanSC520 microcontroller. It can

be turned on and off by writing the word 0100h to MMCR offsets 0C3Ah and 0C36h,

respectively.

The MMCR base address defaults to DF00:0 (segment : offset address).

The external LED is duplicated with an on-board LED. The green LED in D5 (See page 22) is

also controlled by

the PIO24 pin.

Note: The LED is turned on by

the BIOS during system startup. This causes the light to

function as a "power on" indicator if it is not otherwise controlled by user code.

XTERNAL SPEAKER

E

A miniature 8 ohm speaker can be connected between J7[49] and J7[50].

The 5V supply for this feature is protected by a self resetting fuse. This 1 Amp fuse is used to

protect KB, mouse, speaker, and LED.

USH-BUTTON RESET

P

A normally open, momentary action push-button reset switch can be connected between J7[37]

and J7[38]. Shorting J7[37] to ground will cause the EPM-4 to reboot.

ENERAL-PURPOSE TIMER INPUTS

G

Two flexible general-purpose timer inputs can be used for timing and counting applications. Each

timer is capable of generating an interrupt, selectable via the BIOS Custom Configuration screen.

For more information, see chapter 17 in the ÉlanSC520 Microcontroller User’s Manual.

Reference – 30 EPM-4 Reference Manual

Page 39

Parallel / Floppy Port

Parallel / Floppy Port

PARALLEL PORT OPERATION

The EPM-4 includes a standard bi-directional/EPP/ECP compatible LPT port which resides at the

PC standard address of 378h. The port can be enabled or disabled and interrupt assignments can

be made via the CMOS setup screen. The LPT mode is also set via the CMOS setup screen.

This connector uses IEC 61000-4-2-rated TVS components to help protect against ESD damage.

LOPPY PORT OPERATION

F

The parallel port can be used as a floppy disk interface. Select “FDD” as the LPT mode in CMOS

Setup and connect a floppy disk drive to the parallel port cable (CBL/CBR-2003) using the

floppy disk cable (CBL/CBR-2501). The diagram below shows how to connect the drive.

EPM-4

J2

VL-CBL/CBR-2003

ARALLEL / FLOPPY PORT PINOUT

P

Table 6: LPT1 Parallel / Floppy Port Pinout

J2

Pin

1 Strobe DS0* Out

2 Auto feed RPM Out

3 Data bit 1 INDEX* In/Out

4 Printer error HDSEL* In

5 Data bit 2 TRK0* In/Out

6 Reset FDIR Out

7 Data bit 3 WP* In/Out

8 Select input STEP* Out

9 Data bit 4 RDATA* In/Out

10 Data bit 5 DSKCHG In/Out

11 Data bit 6 N.C. In/Out

12 Data bit 7 MTR0* In/Out

13 Data bit 8 N.C. In/Out

14 Ground GND —

15 Acknowledge DS1* In

16 Ground GND —

17 Port Busy MTR1* In

18 Ground GND —

19 Paper End WDATA* In

20 Select WGATE* In

DB-25 connectors

Centronics

Signal

Floppy

Signal

Floppy

VL-CBL/CBR-2501

Signal

Direction

EPM-4 Reference Manual Reference – 31

Page 40

Ethernet Interface

Ethernet Interface

The EPM-4 features an industry-standard 10baseT / 100baseTX Ethernet interface based on the

Intel 82551ER Ethernet controller. This PCI based interface chip is widely supported. Drivers are

readily available to support a variety of operating systems such as QNX, VxWorks and other

RTOS vendors.

CONFIGURATION

BIOS

The Ethernet interface shares PC/104-Plus interrupt “INTC”. The CMOS Setup screen is used to

select the IRQ line routed to INTC*.

TATUS LED

S

Two colored LEDs (D1) located next to the RJ-45 connector provide an indication of the Ethernet

status as follows:

Green LED (Link / Activity)

• ON Active Ethernet cable plugged into J4.

No Tx/Rx data activity.

• OFF Cable not plugged into J4

Cable not plugged into active hub

• BLINKING Active Ethernet cable plugged into J4.

Tx or Rx data activity detected on the cable

Yellow LED (Speed)

• ON 100baseTx (Fast) detected on Ethernet cable.

• OFF 10BaseTx (Slow) detected on Ethernet cable.

E

THERNET CONNECTOR

A board-mounted RJ-45 connector is provided to make connection with category 5 Ethernet

cable. The Ethernet controller will autodetect 10BaseT/100BaseTX connections.

Table 7: RJ45 Ethernet Connector

J4

Signal

Pin

Name Function

4 IGND Isolated Ground

5 IGND Isolated Ground

6 R– Receive Data –

3 R+ Receive Data +

7 IGND Isolated Ground

8 IGND Isolated Ground

2 T– Transmit Data –

1 T+ Transmit Data +

This device is protected against ESD damage by IEC 61000-4-2 rated transient voltage

suppressor components.

Reference – 32 EPM-4 Reference Manual

Page 41

Watchdog Timer

There is a flexible watchdog timer integrated into the ÉlanSC520 Microcontroller. It supports a

time-out period up to 30 seconds, and can generate an interrupt, NMI, or system reset when timeout occurs. The watchdog registers are protected by write key sequences.

See the following pseudo code as a simple example of watchdog operation.

MMCR_base = DF00:0h ; segment:offset address

WDTMRCTL = MMCR_base + 0CB0h

MemWrite WDTMRCTL, 03333h ; Key sequence to allow write access to

; control

MemWrite WDTMRCTL, 0CCCCh ; register. These are 16-bit memory writes.

MemWrite WDTMRCTL, 0C010h ; Enable watchdog timer. 4 second timer.

; Reset on timeout.

Begin program loop

; seconds to complete.

MemWrite WDTMRCTL, 0AAAAh ; Key sequence to reset the timer

; countdown

MemWrite WDTMRCTL, 05555h ; These are 16-bit memory writes.

End program loop

Watchdog Timer

; perform useful instructions here that

; will never take more than 4

For detailed programming instructions for the integrated watchdog timer, see chapter 19 of the

ÉlanSC520 Microcontroller User's Manual, and chapter 16 of the Register Set Manual.

EPM-4 Reference Manual Reference – 33

Page 42

Expansion Bus

Expansion Bus

The EPM-4 will accept up to eight expansion modules, up to four of which can be PC/104-Plus

(PCI) expansion modules. The EPM-4 uses 3.3V PCI signaling but is 5V tolerant.

PC/104-P

LUS (PCI BUS)

PC/104-Plus modules can be secured directly to the top or bottom of the EPM-4. Make sure to

correctly configure the "slot position" jumpers on each PC/104-Plus module appropriately.

PC/104 modules must not be positioned between the EPM-4 and any PC/104-Plus modules on

the stack.

The EPM-4 is compliant with revision 2.0 of the PC/104-Plus spec. and can support four bus

master capable PC/104-Plus modules.

The BIOS automatically allocates I/O and memory resources. However, manual PCI Interrupt

routing will be used.

PC/104

(ISA BUS)

PC/104 modules are stacked on top the EPM-4. 16-bit modules first followed by 8-bit PC/104

modules.

The ÉlanSC520 Microcontroller uses a General-Purpose (GP) bus that is implemented as the ISA

bus on the Lynx. The GP bus is similar in function to the ISA bus, but not functionally identical.

Nearly all PC/104 devices in use today will work on the Lynx without modification.

Here is a summary of the differences between a legacy ISA bus and the GP bus implementation

on the Lynx.

• Only DMA channels 5 and 6 are available to PC/104 devices

• IRQ15 is not available to PC/104 devices

• PC/104 bus devices cannot initiate bus access cycles. The ÉlanSC520 Microcontroller is

always the master of the ISA bus.

• Address pipelining is not supported.

• IOCHK, REFRESH, and NOWS signals are not supported.

• MEMR and SMEMR are tied together. MEMW and SMEMW are tied together.

For a more detailed description of the GP bus and its differences from a standard ISA bus, see

chapter 13 in the ÉlanSC520 Microcontroller User's Manual.

Note: On the EPM-4 Rev 4 and above, the pass-through PC/104 (ISA) connector is keyed

(pins B10 and C19 missing) for greater compatibility with the PC/104 standard.

See Figure 5 for details.

CONFIGURATION

I/O

PC/104–Plus Modules

No hardware configuration is necessary except to jumper the expansion module for the correct

slot number.

Reference – 34 EPM-4 Reference Manual

Page 43

Expansion Bus

PC/104 Modules

PC/104 I/O modules should be addressed in the 104h – 3FFh address range. Care must be taken

to avoid the I/O addresses shown in the On-Board I/O Devices table on page 37. These ports are

used by

on-board peripherals and video devices.

EPM-4 Reference Manual Reference – 35

Page 44

Memory and I/O Map

Memory and I/O Map

ÉLANSC520 MEMORY MAPPED CONFIGURATION REGION (MMCR) REGISTERS

Much of the functionality incorporated into the ÉlanSC520 Microcontroller, such as the

watchdog timer, CPU speed control, and general-purpose timer, can be controlled and monitored

through the Memory Mapped Configuration Region (MMCR) registers. The MMCR registers

occupy 4KB of memory space. For convenience, these registers are made available at boot time in

the first megabyte of system RAM, at DF000h.

Wherever the MMCR is located, its 4KB footprint will cover and take precedence over the

underlying memory space function. For example, when the D0000h page function is set to ISA

bus, DF000h through DFFFFh will instead by occupied by the MMCR. For this reason, the

maximum BIOS extension size is reduced from 64KB to 60KB.

In the event of an address conflict, the MMCR base address can be moved at any time with an I/O

write to the Configuration Base Address Register (CBAR), located at I/O address FFFCh. Refer

to the ÉlanSC520 Register Set Manual for further details.

EMORY MAP

M

The lower 1 MB memory map of the EPM-4 is arranged as shown in the following table.

Table 8: Memory Map

Start

Address

E0000h FFFFFh System BIOS

DF000h DFFFFh MMCR Registers (see note)

D0000h DEFFFh ISA memory, BIOS extension, or RAM

C0000h CFFFFh Reserved for Video BIOS

A0000h BFFFFh Reserved for Video RAM

00000h 9FFFFh System DRAM

End

Address Comment

Note: Default location. If MMCR is relocated, this memory space is allocated to ISA

memory, BIOS extension, or RAM, depending on how the D0000h page function

is set in CMOS Setup.

Reference – 36 EPM-4 Reference Manual

Page 45

Memory and I/O Map

I/O MAP

The following table lists the common I/O devices in the EPM-4 I/O map. User I/O devices should

be added in the 104h – 3FFh range, using care to avoid the devices already in the map as shown

below.

Table 9: On-Board I/O Devices

I/O Device

See ÉlanSC520 register set manual 000h-0FFh

Special Control Register 0E0h

Revision Indicator Register 0E1h

Map and Paging Control Register 0E3h

Primary IDE Controller 1F0h – 1F6h

COM 4 Serial Port 2E8h – 2EFh

COM 2 Serial Port 2F8h – 2FFh

COM 3 Serial Port 3E8h – 3EFh

Floppy Disk Controller 3F0h – 3F7h

COM1 Serial Port 3F8h – 3FFh

CBAR FFFCh-FFFFh

Standard

I/O Addresses

Note: I/O ports occupied by on-board devices are freed up when the device is disabled in

CMOS Setup.

EPM-4 Reference Manual Reference – 37

Page 46

Interrupt Configuration

Interrupt Configuration

Default interrupt settings on the Lynx have been selected to maintain PC/AT compatibility. They

can be re-routed to satisfy customer constraints. Use the custom configuration screen in BIOS

setup to configure IRQ’s on the Lynx Not all devices can use all IRQ’s. Refer to Figure 8 for a

description of allowable IRQ assignm

ents for each device.

Figure 8. Interrupt Circuit Diagram

Components Group:

COM1, COM2, GP Timers, Watchdog,

PCI Interrupts.

COM3, COM4, LPT1

Available on PC/104 (ISA) bus Default IRQ assignments:

0 Timer 0

1 Keyboard

2 Slave PIC cascade

3 COM2

4 COM1

5 Unused

6 Floppy drive

7 Unused

8 Real-Time Clock

9 Unused

10 Unused

11 PCI Interrupt A,B,C,D

12 PS/2 Mouse

13 Math Co-processor

14 IDE controller

15 Unused

Reference – 38 EPM-4 Reference Manual

Page 47

Special Control Register

Special Control Register

SCR (READ/WRITE) 00E0h

D7 D6 D5 D4 D3 D2 D1 D0

Reserved Reserved SB-SEL Reserved Reserved Reserved Reserved GPI

Table 10: Special Control Register Bit Assignments

Bit Mnemonic Description

D7-D6 — Reserved — These bits have no function.

D5 SB-SEL BIOS Selector Input — Indicates the status of jumper V4[1-2]

SB-SEL = 0 Jumper V4 [1-2] = Out (Master BIOS)

SB-SEL = 1 Jumper V4 [1-2] = In (Run Time BIOS)

Note: This general purpose bit is read-only.

D4-D1 — Reserved — These bits have no function.

D0 GPI General Purpose Input — Indicates the status of TTL input

GPI = 0 Jumper V4 [3-4] = Out

GPI = 1 Jumper V4 [3-4] = In

Note: This bit is a read-only bit.

EPM-4 Reference Manual Reference – 39

Page 48

Revision Indicator Register

Revision Indicator Register

REVIND (READ ONLY) 00E1h

D7 D6 D5 D4 D3 D2 D1 D0

PC4 PC3 PC2 PC1 PC0 REV1 REV0 ET

This register is used to indicate the revision level of the EPM-4 product.

Bit Mnemonic Description

D7-D3 PC4-PC0 Product Code — These bits are hard coded to represent the product type. The

EPM-4 will always read as 11011. Other codes are reserved for future products.

PC4 PC3 PC2 PC1 PC0 Product Code

1 1 0 1 1 EPM-4

Note: These bits are read-only.

D2-D1 REV1-REV0 Revision Level — These bits are represent the EPM-4 circuit revision level.

REV1 REV0 Revision Level

0 0 Current product release

0 1 Reserved

1 0 Reserved

1 1 Reserved

Note: These bits are read-only.

D0 ET Extended Temperature — This bit indicates whether the board is an extended

temperature version or not.

0 – EPM-4c – Standard Temperature

1 – EPM-4e – Extended Temperature

Note: This bit is read-only.

Reference – 40 EPM-4 Reference Manual

Page 49

Map and Paging Control Register

MPCR (READ/WRITE) 00E3H

D7 D6 D5 D4 D3 D2 D1 D0

FPGEN Reserved Reserved Reserved Reserved PG2 PG1 PG0

Table 11: Map and Paging Control Register Bit Assignments

Bit Mnemonic Description

D7 FPGEN FLASH Paging Enable — Enables a 64KB page frame from E0000h to

EFFFFh. Used to gain access to the on-board FLASH memory.

FPGEN = 0 FLASH page frame disabled.

FPGEN = 1 FLASH page frame enabled.

Note: When FPGEN = 1, the Page Select bits are used to access various blocks within

the FLASH. The "D0000h 64k page function" in CMOS Setup must be set to "ISA Bus".

D6-D3 — Reserved — These bits have no function.

D2-D0 PG2-PG0 Page Select — Selects which 64K block of FLASH will be mapped into the page

frame.

Memory Range within

PG2 PG1 PG0 FLASH

0 0 0 000000h to 00FFFFh

0 0 1 010000h to 01FFFFh

0 1 0 020000h to 02FFFFh

0 1 1 030000h to 03FFFFh

1 0 0 040000h to 04FFFFh

1 0 1 050000h to 05FFFFh

1 1 0 060000h to 06FFFFh

1 1 1 070000h to 07FFFFh

.

Map and Paging Control Register

EPM-4 Reference Manual Reference – 41

Page 50

Page 51

Appendix A — CBL/CBR-5009

A

CBL/CBR-5009 Connectors

Figure 9. CBL/CBR-5009 Connector and Component Locations

Table 12: Connector/Component Functions, and Interface Cables

Connector /

Component

D1 Power and Programmable LEDs Dialight 552-0211 LEDx2 T1 3/4 PC Mount Red/Red

J1 High Density Connector FCI 98414-F06-50U 2mm, 50 pins, keyed, latching header

J2 Timer and Reset input Conta-Clip 10250.4 5 pin screw terminal

J3 COM1, COM2 Kycon K42-E9P/P-A4N Dual stacked DB-9 male

J4 PS/2 Keyboard and Mouse Kycon KMDG-6S/6S-S4N Dual stacked PS/2 female

J5 COM4 Conta-Clip 10250.4 5 pin screw terminal

J6 COM3 Conta-Clip 10250.4 5 pin screw terminal

R1 Resistor DigiKey P332CCT-ND 332 ohms

S1 Reset Button E-Switch 800SP9B7M6RE Right angle momentary switch

SP1 Speaker Challenge Electronics DBX05 Miniature speaker

Function Part Number Description

EPM-4 Reference Manual Appendix A — CBL/CBR-5009 – 43

Page 52

Map and Paging Control Register

CBL/CBR-5009 Dimensions and Mounting

Figure 10. CBL-5009 Dimensions and Mounting

CBL/CBR-5009 Schematic

MKPWR

J1

XDSR1

1

2

XRTS1

3

PLED#

1 3

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

414442

43

45

47

49

GRN

5

7

9

R1 332

OR

LED

D1

2 4

MKPWR

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

46

48

50

XCTS1

XRI1

XDCD2

XRXD2*

XTXD2*

XDTR2

TX3+

TRX3+

TX4-

TRX4-

MSD1

MSC5

TMRIN1

TMRIN0

KBD1

KBC5

PLED#

SPKO#

COM1

COM2

COM3

COM4

Figure 11. CBL/CBR-5009 Schematic

SPKO#

MKPWR

SP1

SPEAKER

XDCD1

XRXD1*

XTXD1*

XDTR1

XDSR2

XRTS2

XCTS2

XRI2

TX3TRX3-

TX4+

TRX4+

PBRST#

PBRST#

1

S1

3 2

T2T4T1T3T5T6B1B2B3B4B5

J4

M1M2M3M4M5

DUAL PS/2

MTH3

1

XDCD1

XRXD1*

XTXD1*

TOP BOTTOM

XDTR1

XDSR1

XRTS1

XCTS1

XRI1

TX3+

TX3TRX3+

TRX3-

TX4+

TX4TRX4+MKPWR

TRX4-

B6

MTH4

MTH2

MTH1

1

1

1

1

1

1

1

TMRIN0

TMRIN1

PBRST#

XDCD2

1

10

XRXD2*

2

11

XTXD2*

3

12

XDTR2

4

13

5

14

XDSR2

6

15

XRTS2

7

16

XCTS2

8

17

XRI2

9

18

19

20

21

22

J6

5

5

4

JTB251-01-05

4

3

3

2

2

1

1

5

J5

5

4

JTB251-01-05

4

3

3

2

2

1

1

5

J2

5

4

JTB251-01-05

4

3

3

2

2

1

1

DUAL DB9

J3

Appendix A — CBL/CBR-5009 – 44 EPM-4 Reference Manual

Page 53

Appendix B — References

Integrated 32-bit CPU Advanced Micro Devices, (www.amd.com/epd)

ÉlanSC520

Ethernet Controller Intel Corporation

82551ER

PC/104 Specification PC/104 Consortium

PC/104 Resource Guide

PC/104-Plus Specification PC/104 Consortium

PC/104 Resource Guide

General PC Documentation Microsoft Press

The Programmer’s PC

Sourcebook

General PC Documentation Powell's Books

The Undocumented PC

, (www.intel.com/design)

, (www.pc104.org)

, (www.pc104.org)

(www.microsoft.com/learning/books)

(www.powells.com)

B

EPM-4 Reference Manual Appendix B — References – 45

Loading...

Loading...