Page 1

Reference

Manual

DOC. REV. 8/23/2010

EPM-14

(Cougar)

AMD LX 800 Based SBC with

Ethernet, Video, and

PC/104-Plus Interface

Page 2

WWW.VERSALOGIC.COM

12100 SW Tualatin Road

Tualatin, OR 97062-7341

(503) 747-2261

Fax (971) 224-4708

Copyright © 2013 VersaLogic Corp. All rights reserved.

Notice:

Although every effort has been made to ensure this document is error-free, VersaLogic makes no

representations or warranties with respect to this product and specifically disclaims any implied warranties of

merchantability or fitness for any particular purpose.

VersaLogic reserves the right to revise this product and associated documentation at any time without

obligation to notify anyone of such changes.

PC/104 and the PC/104 logo are trademarks of the PC/104 Consortium.

EPM-14 Reference Manual ii

Page 3

Product Release Notes

Rev 3 Release

Charlie release.

Implemented several manufacturability improvements.

See the EPM-14 support page for a list of BIOS and PLD changes.

Rev 2 Release

Beta release.

Rev 1 Release

Pre-production only. No customer shipments.

Support Page

The EPM-14 support page, at http://www.versalogic.com/private/cougarsupport.asp, contains additional

information and resources for this product including:

Reference Manual (PDF format)

Operating system information and software drivers

Data sheets and manufacturers’ links for chips used in this product

BIOS information and upgrades

Utility routines and benchmark software

This is a private page for EPM-14 users that can be accessed only be entering this address directly. It

cannot be reached from the VersaLogic homepage.

EPM-14 Reference Manual iii

Page 4

Contents

Introduction .....................................................................................................................1

Description.......................................................................................................................... 1

Technical Specifications ..................................................................................................... 2

EPM-14 Block Diagram ..................................................................................................... 3

RoHS-Compliance .............................................................................................................. 4

About RoHS........................................................................................................... 4

Warnings............................................................................................................................. 4

Electrostatic Discharge .......................................................................................... 4

Lithium Battery...................................................................................................... 4

Transient Voltage Suppression (TVS) Devices ..................................................... 5

Technical Support ............................................................................................................... 6

Repair Service........................................................................................................ 6

Configuration and Setup ................................................................................................7

Initial Configuration ........................................................................................................... 7

Basic Setup ......................................................................................................................... 7

CMOS Setup ..................................................................................................................... 10

Operating System Installation........................................................................................... 11

Physical Details.............................................................................................................12

Dimensions and Mounting................................................................................................ 12

Hardware Assembly............................................................................................. 14

Stack Arrangement Example ............................................................................... 14

External Connectors.......................................................................................................... 15

EPM-14 Connectors............................................................................................. 15

EPM-14 Connector Functions and Interface Cables............................................ 17

CBR-5011 Connectors......................................................................................... 18

CBR-5011 Connector Functions.......................................................................... 18

Jumper Blocks................................................................................................................... 19

Jumpers As-Shipped Configuration..................................................................... 19

Jumper Summary ................................................................................................. 20

System Features ...........................................................................................................21

Power Supply.................................................................................................................... 21

Power Connectors................................................................................................ 21

Power Requirements ............................................................................................ 22

Lithium Battery.................................................................................................... 22

CPU................................................................................................................................... 22

System RAM..................................................................................................................... 22

CMOS RAM ..................................................................................................................... 23

Clearing CMOS RAM ......................................................................................... 23

CMOS Setup Defaults ...................................................................................................... 23

Default CMOS RAM Setup Values..................................................................... 23

Saving CMOS Setup Parameters as Custom Defaults ......................................... 23

EPM-14 Reference Manual

iv

Page 5

Contents

Real Time Clock ............................................................................................................... 24

Setting the Clock.................................................................................................. 24

Interfaces and Connectors...........................................................................................25

Utility I/O Connector J7 ................................................................................................... 25

IDE.................................................................................................................................... 26

Serial Ports........................................................................................................................ 27

COM Port Configuration ..................................................................................... 27

Serial Port Connectors ......................................................................................... 27

COM3 RS-422/485 Line Driver Control ............................................................. 28

USB................................................................................................................................... 29

CompactFlash ................................................................................................................... 30

Programmable LED .......................................................................................................... 31

External Speaker ............................................................................................................... 31

Push-Button Reset............................................................................................................. 31

Video Interface ................................................................................................................. 32

Configuration....................................................................................................... 32

Video BIOS Selection.......................................................................................... 32

SVGA Output Connector..................................................................................... 32

LVDS Flat Panel Display Connector................................................................... 33

Compatible LVDS Panel Displays....................................................................... 34

Console Redirection............................................................................................. 34

Ethernet Interface.............................................................................................................. 35

BIOS Configuration............................................................................................. 35

Status LED........................................................................................................... 35

Ethernet Connector .............................................................................................. 35

CPU Temperature Monitor ............................................................................................... 36

PC/104 Expansion Bus .....................................................................................................36

PC/104 I/O Support ............................................................................................. 36

PC/104 Memory Support..................................................................................... 36

IRQ Support......................................................................................................... 36

DMA Support ...................................................................................................... 36

System Resources and Maps.......................................................................................37

Memory Map .................................................................................................................... 37

I/O Map............................................................................................................................. 37

Interrupt Configuration ..................................................................................................... 38

Special Registers ..........................................................................................................39

Special Control Register ................................................................................................... 39

PLD Revision and Type Register ..................................................................................... 39

Jumper and Status Register............................................................................................... 40

Appendix A – References.............................................................................................41

EPM-14 Reference Manual v

Page 6

Description

The EPM-14 is a feature-packed single board computer designed for OEM control projects

requiring fast processing and designed-in reliability and longevity (product lifespan). Its features

include:

AMD LX 800 microcontroller

with CS5536 companion chip

256 MB system RAM, soldered

on

CompactFlash site

10/100 Ethernet interface (dual)

Flat Panel Display support

MMX™ + 3DNow!™ graphics

PC/104-Plus expansion site

IDE controller, one channel,

ATA-5, UDMA33

Introduction

TVS devices on user I/O connections

(require connection to earth ground)

Three COM ports (two RS-232, one

RS-422/485)

Watchdog timer

Vcc sensing reset circuit (all rails

monitored, interrupt on fault)

PC/104-Plus compliant footprint

Field upgradeable BIOS with OEM

enhancements

Friction latch I/O connectors

1

Four USB 2.0/1.1 ports

The EPM-14 is compatible with popular operating systems such as Windows and Linux.

Most I/O ports are included on-board. Additional I/O expansion is available through the high-

speed PCI-based PC/104-Plus expansion site (which supports both PC/104 and PC/104-Plus

expansion modules).

The EPM-14 features high reliability design and construction, including friction latch I/O

connectors. It also features a watchdog timer, voltage sensing reset circuits and self-resetting

fuses on the 5V supply to user I/O, speaker, programmable LED, LVDS, and all USB ports.

All EPM-14 boards are subjected to functional testing and are backed by a limited two-year

warranty. Careful parts sourcing and US-based technical support ensure the highest possible

quality, reliability, service and product longevity for this exceptional SBC.

Customizing available

EPM-14 Reference Manual

1

Page 7

Technical Specifications

Specifications are typical at 25°C with 5.0V supply unless otherwise noted.

Board Size:

4.250" x 3.775" (PC/104 compliant)

Storage Temperature: -40° C to 85° C

Free Air Operating Temperature:

-40° C to +85° C EPM-14h

Power Requirements: (with 256 MB RAM,

keyboard and mouse, running Windows XP)

EPM-14h – AMD CPU +5.0V ± 5% @ 0.90A

(4.5W) typ.

+3.3V or ±12V may be required by some

expansion modules

System Reset:

Vcc sensing, resets when the 3.3V power rail

varies by more than +/- 10% of it’s optimal

value.

Watchdog timeout

DRAM Interface:

256 MB soldered on PC2700 compatible,

DDR 333 MHz RAM

Video Interface:

Up to 1600 x 1200 (32 bits)

Standard analog output

MMX™ + 3DNow!™ graphics

LVDS output for TFT FPDs

IDE Interface:

One channel, 44-pin keyed 2mm header.

Supports up to and including UDMA33.

Supports up to two IDE devices (hard drives,

CD-ROM, CompactFlash, etc.).

Ethernet Interface:

Two Intel 82551ER based Fast Ethernet

10/100 Controllers

Introduction

COM1–2 Interface:

RS-232, 16C550 compatible, 115k baud max.

COM3 Interface:

RS-422/RS-485, 16C550 compatible, 460k

baud max.

USB:

Four ports USB 2.0/1.1 protocol.

Counter/Timers:

Internal companion chip (CS5536) timers

only.

BIOS:

General Software Embedded BIOS© with

OEM enhancements

Field-upgradeable with Flash BIOS Upgrade

Utility

Bus Speed:

CPU Bus: 800 MHz (Celeron equiv.), 500

MHz actual

DRAM: PC2700 compatible, DDR 333 MHz

PC/104-Plus (PCI): 33 MHz

PC/104 (ISA): 8 MHz

Compatibility:

PC/104 – full compliance

Embedded-PCI (PC/104-Plus) – full

compliance, 3.3V signaling

Weight:

EPM-14h – 0.102 kg (0.226 lbs)

Generated Frequencies:

32KHz, 8.25MHz, 14.318MHz, 33MHz,

48MHz, 66MHz, 166.5MHz

Specifications are subject to change without notice.

EPM-14 Reference Manual 2

Page 8

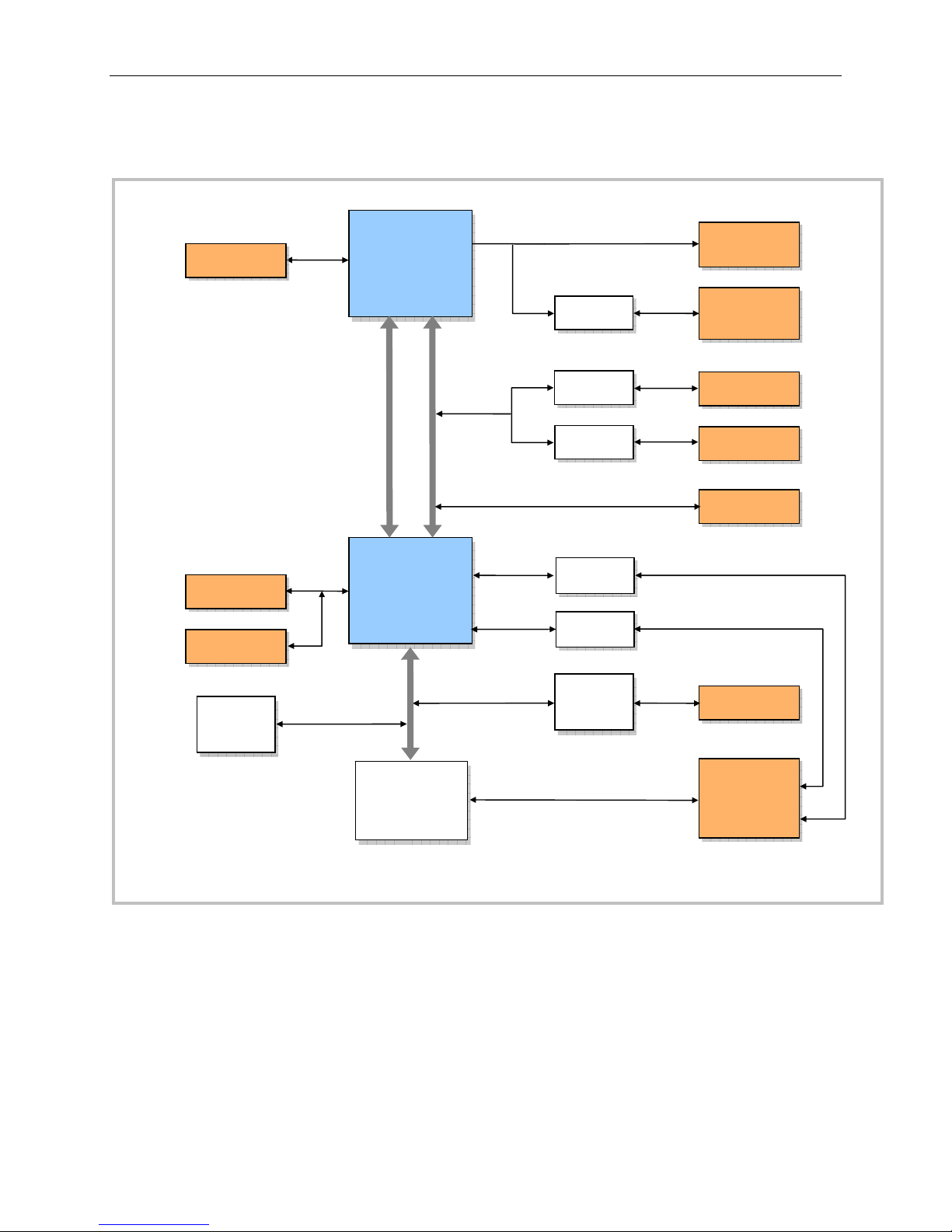

EPM-14 Block Diagram

Introduction

DDRAM

J8

44-pin IDE

J5

CompactFlash

AMD

LX 800

CPU

PCI, 3.3V

System Control

AMD

CS5536

I/O Companion

Video

TTL to LVDS

Ethernet

10/100

Ethernet

10/100

Speaker,

LED, Reset

USB 2.0

(4 Ports)

J4

Analog CRT

CBR-1201

J12

LVDS

CBR-2010 or

CBR-2011

J2

RJ45

J3

RJ45

J1

PC/104+ (PCI)

BIOS

LPC Bus

SMSC

LPC47N217

Super I/O

(2)

ISA Bridge

1 RS-422/485

Figure 1. EPM-14 Block Diagram

CPLD

2 RS-232,

J9

PC/104 (ISA)

J7

2mm 50-pin

to CBR-5011

Board

EPM-14 Reference Manual 3

Page 9

RoHS-Compliance

The EPM-14 is RoHS-compliant.

A

BOUT ROHS

In 2003, the European Union issued Directive 2002/95/EC regarding the Restriction of the use of

certain Hazardous Substances (RoHS) in electrical and electronic equipment.

The RoHS directive requires producers of electrical and electronic equipment to reduce to

acceptable levels the presence of six environmentally sensitive substances: lead, mercury,

cadmium, hexavalent chromium, and the presence of polybrominated biphenyls (PBB) and

polybrominated diphenyl ethers (PBDE) flame retardants, in certain electrical and electronic

products sold in the European Union (EU) beginning July 1, 2006.

VersaLogic Corporation is committed to supporting customers with high-quality products and

services meeting the European Union’s RoHS directive.

Warnings

Introduction

ELECTROSTATIC DISCHARGE

Electrostatic discharge (ESD) can damage boards, disk drives and other components. The circuit

board must only be handled at an ESD workstation. If an approved station is not available, some

measure of protection can be provided by wearing a grounded antistatic wrist strap. Keep all

plastic away from the board, and do not slide the board over any surface.

After removing the board from its protective wrapper, place the board on a grounded, static-free

surface, component side up. Use an antistatic foam pad if available.

The board should also be protected inside a closed metallic anti-static envelope during shipment

or storage.

Note The exterior coating on some metallic antistatic bags is sufficiently conductive to

cause excessive battery drain if the bag comes in contact with the bottom-side of

the EPM-14.

ITHIUM BATTERY

L

To prevent shorting, premature failure or damage to the lithium battery, do not place the board on

a conductive surface such as metal, black conductive foam or the outside surface of a metalized

ESD protective pouch. The lithium battery may explode if mistreated. Do not recharge,

disassemble or dispose of in fire. Dispose of depleted batteries promptly.

EPM-14 Reference Manual 4

Page 10

Introduction

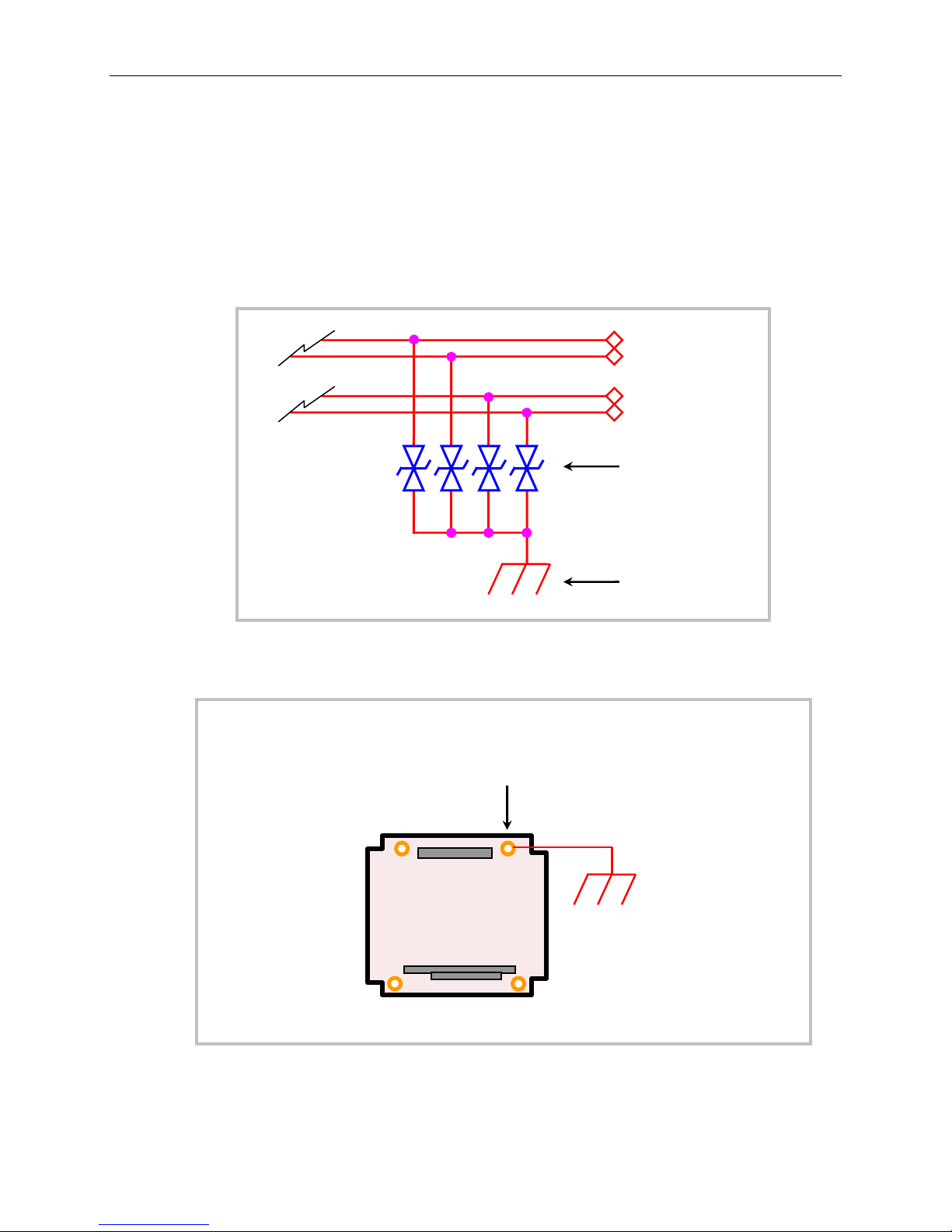

TRANSIENT VOLTAGE SUPPRESSION (TVS) DEVICES

The EPM-14 circuitry is protected from spike and surge damage by on-board transient voltage

suppression (TVS) devices on the user I/O signals. Figure 2 shows a typical example of TVS

circuitry.

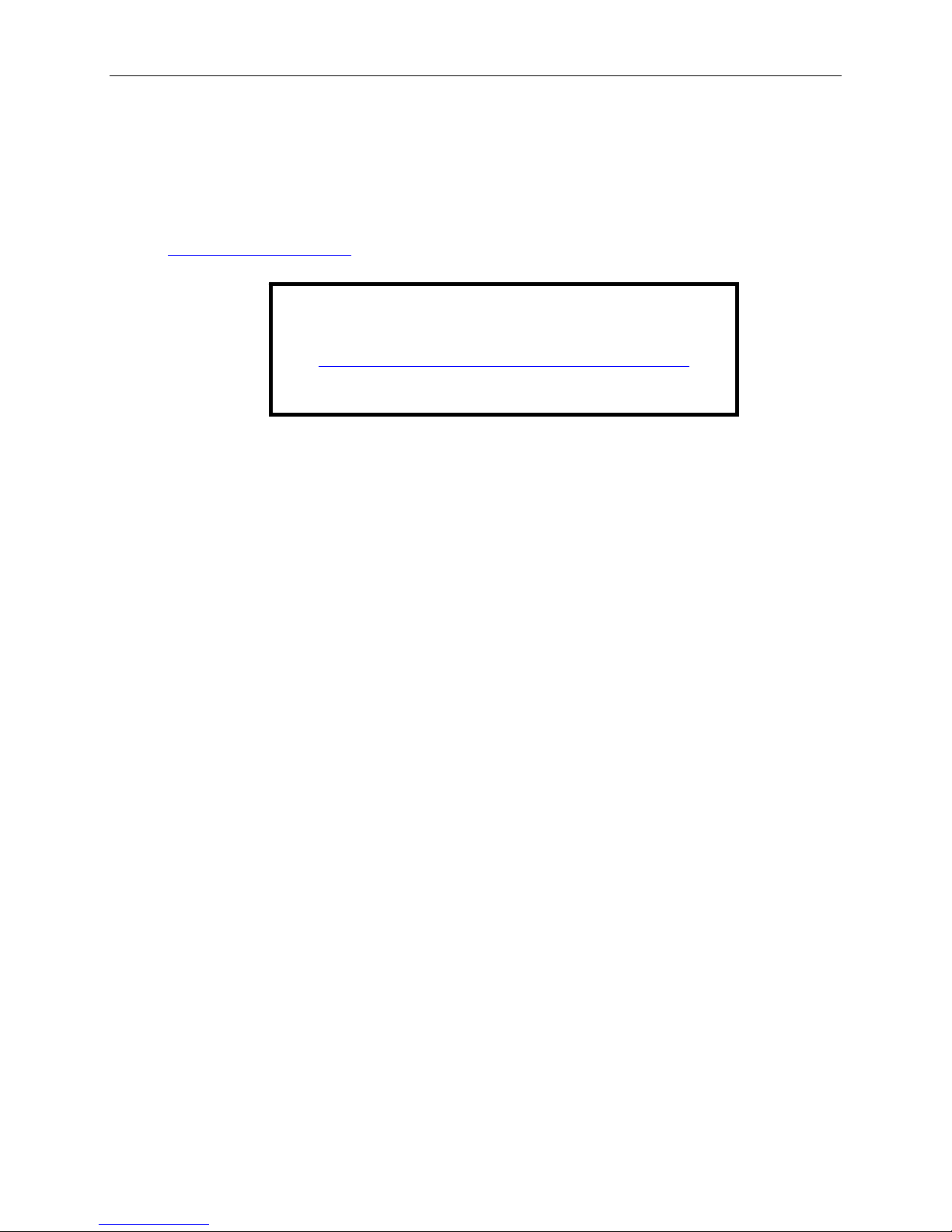

In order for the TVS devices to function properly, they must be connected to earth

ground. This connection is made at the board’s upper right mounting hole, as shown in Figure 3.

All other m

ounting holes are floating. Use m

etal standoffs or a grounding strap to connect the

lower right mounting hole to the enclosure chassis, which should be connected to earth ground.

User I/O Signal

User I/O Signal

User I/O Signal

User I/O Signal

TVS Devices

Earth Ground

Figure 2. Schematic Showing Typical TVS Circuitry

Only the upper right mounting hole

connects to the TVS devices. This hole

must be connected to earth for TVS

EPM-14

Cougar

EPM-14 Reference Manual 5

Figure 3. Attaching the EPM-14 to Earth Ground

Page 11

Technical Support

If you are unable to solve a problem with this manual please visit the EPM-14 Product Support

web page listed below. If you have further questions, contact VersaLogic technical support at

(503) 747-2261

Support@VersaLogic.com

EPAIR SERVICE

R

If your product requires service, you must obtain a Returned Material Authorization (RMA)

number by calling (503) 747-2261. VersaLogic’s standard turn-around tim

working days

. VersaLogic technical support engineers are also available via e-mail at

http://www.versalogic.com/private/cougarsupport.asp

after the product is received.

Introduction

.

EPM-14 Support Website

e for repairs is five

Please provide the following information:

Your name, the name of your company and your phone number

The name of a technician or engineer that can be contact if any questions arise.

Quantity of items being returned

The model and serial number (barcode) of each item

A detailed description of the problem

Steps you have taken to resolve or recreate the problem

The return shipping address

Warranty Repair All parts and labor charges are covered, including return shipping

charges for UPS Ground delivery to United States addresses.

Non-warranty Repair All non-warranty repairs are subject to diagnosis and labor charges,

parts charges and return shipping fees. Please specify the shipping

method you prefer and provide a purchase order number for invoicing

the repair.

Note Please mark the RMA number clearly on the outside of the box before

returning. Failure to do so can delay the processing of your return.

EPM-14 Reference Manual 6

Page 12

Initial Configuration

The following components are recommended for a typical development system.

EPM-14 single board computer

ATX power supply with motherboard and drive connectors

SVGA video monitor

Keyboard with USB connector

Mouse with USB connector

IDE hard drive

IDE CD-ROM drive

The following VersaLogic cables are recommended.

Video adapter cable (CBR-1201)

Utility I/O cable and board assembly (CBR-5011)

IDE data cable (CBR-4406); may also require 2mm to 0.1” adapter (CBR-4405)

Power adapter cable (CBR-1008)

You will also need a Windows (or other OS) installation CD.

Basic Setup

Configuration and Setup

2

The following steps outline the procedure for setting up a typical development system. The

EPM-14 should be handled at an ESD workstation or while wearing a grounded antistatic wrist

strap.

Before you begin, unpack the EPM-14 and accessories. Verify that you received all the items you

ordered. Inspect the system visually for any damage that may have occurred in shipping. Contact

Support@VersaLogic.com immediately if any items are damaged or missing.

Gather all the peripheral devices you plan to attach to the EPM-14 and their interface and power

cables.

It is recommended that you attach standoffs to the board (see Hardware Assembly) to stabilize the

a

board and m

Figure 4 shows a typical start-up configuration.

ke it easier to work with.

EPM-14 Reference Manual

7

Page 13

J10

CBR–1201

Configuration and Setup

EPM-14

“Cougar”

CBR–1008

ATX

Power Supply

Analog SVGA

CBR-5011

J4

J7

J8

CBR–4406

Figure 4. Typical Start-up Configuration

J2

J1

CD-ROM

Drive

Hard

Drive

USB Keyboard

USB Mouse

OS Installation

CD-ROM

1. Attach Cables and Peripherals

Plug the video adapter cable CBR-1201 into socket J4. Attach the video monitor interface

cable to the video adapter.

Plug the breakout board/cable CBR-5011 into socket J7. Plug the keyboard and mouse

into any USB ports at J2 on the breakout board.

Plug the hard drive data cable CBR-4406 into socket J8. Attach a hard drive and CD-

ROM drive to the connectors on the cable. If the hard drive is 3.5”, use the 2mm to 0.1”

adapter CBR-4405 to attach the IDE cable.

Attach an ATX power cable to any 3.5” drive (hard drive or CD-ROM drive).

Set the hard drive jumper for master device operation and the CD-ROM drive jumper for

slave device operation.

EPM-14 Reference Manual 8

Page 14

Configuration and Setup

2. Attach Power

Plug the power adapter cable CBR-1008 into connector J10. Attach the motherboard

connector of the ATX power supply to the adapter.

3. Review Configuration

Before you power up the system, double check all the connections. Make sure all cables

are oriented correctly and that adequate power will be supplied to the EPM-14 and

peripheral devices.

4. Power On

Turn on the ATX power supply and the video monitor. If the system is correctly

configured, a video signal should be present.

5. Change CMOS Setup Settings

Enter CMOS Setup by pressing Delete during the early boot cycle.

Select Basic Configuration and set or verify the following settings (see CMOS Setup for

p

a com

lete list of default settings):

DRIVE ASSIGNMENT ORDER | Drive C: Ide 0/Pri Master

ATA DRV ASSIGNMENT | Ide 0: 3 = AUTOCONFIG, LBA

ATA DRV ASSIGNMENT | Ide 1: 5 = IDE CDROM

BOOT ORDER | Boot 1st: CDROM

BOOT ORDER | Boot 2nd: Drive C:

Before saving the CMOS Setup settings, insert the Windows (or other OS) installation

disk in the CD-ROM drive so it will be accessed when the system reboots.

Press ESC and write the new parameters to CMOS RAM. The system will reboot.

6. Install Operating System

Install the operating system according to the instructions provided by the OS

manufacturer. (See Operating System Installation.)

Note If y

ou intend to operate the EPM-14 under Windows XP or Windows XP

bedded, be sure to use Service Pack 2 (SP2) for full support of the latest

Em

CS5536 I/O hub and its USB 2.0 features.

EPM-14 Reference Manual 9

Page 15

CMOS Setup

The default CMOS Setup parameters for the EPM-14 are shown below.

+------------------------------------------------------------------------------+

| System Bios Setup - Basic CMOS Configuration |

| (C) 2005 General Software, Inc. All rights reserved |

+---------------------------+--------------------+-----------------------------+

| DRIVE ASSIGNMENT ORDER: | Date:>May 06, 2008 | Typematic Delay : 250 ms |

| Drive A: (None) | Time: 00 : 00 : 00 | Typematic Rate : 30 cps |

| Drive B: (None) | NumLock: Disabled | Seek at Boot : None |

| Drive C: Ide 0/Pri Master +--------------------+ Show "Hit Del" : Enabled |

| Drive D: (None) | BOOT ORDER: | Config Box : Enabled |

| Drive E: (None) | Boot 1st: Drive C: | F1 Error Wait : Enabled |

| Drive F: (None) | Boot 2nd: (None) | Parity Checking : (Unused) |

| Drive G: (None) | Boot 3rd: (None) | Memory Test Tick : Enabled |

| Drive H: (None) | Boot 4th: (None) | Debug Breakpoints: (Unused) |

| Drive I: (None) | Boot 5th: (None) | Debugger Hex Case: Upper |

| Drive J: (None) | Boot 6th: (None) | Memory Test :StdLo FastHi |

| Drive K: (None) +--------------------+-----------------+-----------+

| Boot Method: Boot Sector | ATA DRV ASSIGNMENT: Sect Hds Cyls | Memory |

+---------------------------+ Ide 0: 3 = AUTOCONFIG, LBA | Base: |

| FLOPPY DRIVE TYPES: | Ide 1: 3 = AUTOCONFIG, LBA | 633KB |

| Floppy 0: Not installed | Ide 2: 3 = AUTOCONFIG, LBA | Ext: |

| Floppy 1: Not installed | Ide 3: 3 = AUTOCONFIG, LBA | 219MB |

+---------------------------+--------------------------------------+-----------+

+------------------------------------------------------------------------------+

| System BIOS Setup - Advanced Configuration |

| (C) 2005 General Software, Inc. All rights reserved |

+---------------------------------------+--------------------------------------+

| System Management Mode : Enabled | POST Memory Manager : Disabled |

| Splash Screen : Disabled | System Management BIOS : Enabled |

| Primary IDE UDMA : Enabled | Console Redirection : Auto |

| Firmbase Debug Console : None | UsbMassStorage : Enabled |

| Usb20 : Enabled | |

+---------------------------------------+--------------------------------------+

+------------------------------------------------------------------------------+

| System BIOS Setup - Custom Configuration |

| (C) 2005 General Software, Inc. All rights reserved |

+---------------------------------------+--------------------------------------+

| PCI INT A Assignment : IRQ 11 | ISA IRQ 3 : Disabled |

| PCI INT B Assignment : IRQ 11 | ISA IRQ 4 : Disabled |

| PCI INT C Assignment : IRQ 11 | ISA IRQ 5 : Disabled |

| PCI INT D Assignment : IRQ 9 | ISA IRQ 6 : Disabled |

| Write protect BIOS : Enabled | ISA IRQ 7 : Disabled |

| Video buffer size : 32 MB | ISA IRQ 9 : Disabled |

| Flat panel display : Disabled | ISA IRQ 10 : Disabled |

| Video refresh rate : 60 Hz | COM 1 enable/IRQ : IRQ4 |

| Video data width : 1 pix/clk | COM 2 enable/IRQ : IRQ3 |

| Primary video device : Auto | COM 3 enable/IRQ : Disabled |

| Memory Timings : Optimal | COM 3 mode : RS422 |

| CPU Temp threshold : 80*C | BIOS extension : Disabled |

| CPU overtemp IRQ : Disabled | Legacy USB support : Enabled |

| CPU/Memory speeds : 500/333 MHz | IDE cable type : 40-Wire |

+---------------------------------------+--------------------------------------+

Configuration and Setup

Basic CMOS Configuration

Features Configuration

Custom Configuration

EPM-14 Reference Manual 10

Page 16

Shadow Configuration

+------------------------------------------------------------------------------+

| System BIOS Setup - Shadow/Cache Configuration |

| (C) 2005 General Software, Inc. All rights reserved |

+---------------------------------------+--------------------------------------+

| Shadowing : Chipset | Shadow 16KB ROM at C000 : Enabled |

| Shadow 16KB ROM at C400 : Enabled | Shadow 16KB ROM at C800 : Disabled |

| Shadow 16KB ROM at CC00 : Disabled | Shadow 16KB ROM at D000 : Disabled |

| Shadow 16KB ROM at D400 : Disabled | Shadow 16KB ROM at D800 : Disabled |

| Shadow 16KB ROM at DC00 : Enabled | Shadow 16KB ROM at E000 : Enabled |

| Shadow 16KB ROM at E400 : Enabled | Shadow 16KB ROM at E800 : Enabled |

| Shadow 16KB ROM at EC00 : Enabled | Shadow 64KB ROM at F000 : Enabled |

+---------------------------------------+--------------------------------------+

Note Due to changes and improvements in the system BIOS, the information on your

monitor may differ from that shown above. The factory default date will

correspond to the BIOS build date.

Operating System Installation

The standard PC architecture used on the EPM-14 makes the installation and use of most of the

standard x86 processor-based operating systems very simple. The operating systems listed on the

VersaLogic OS Compatibility Chart

maker of the OS. Special optimized hardware drivers for a particular operating system, or a link

to the drivers, are available at the EPM-14 Product Support web page at

http://www.versalogic.com/private/cougarsupport.asp

use the standard installation procedures provided by the

Configuration and Setup

.

Note An operating system installed on a different type of computer is not guaranteed to

work on the EPM-14. This is referred to as a “foreign” installation. A hard disk that

was used to boot a different computer cannot necessarily be moved to the EPM-14

and expected to boot. Even when porting an OS image from one revision of the

EPM-14 to another, performance might fail or be impaired. For the best results,

perform a fresh installation of the OS on each system. This restriction does not

apply if you are producing multiple identical systems.

EPM-14 Reference Manual 11

Page 17

Dimensions and Mounting

The EPM-14 complies with all EBX standards which provide for specific mounting hole and

PC/104-Plus stack locations as shown in the diagram below.

0.150

3.575

3.375

3.275

+

0.125 DIA x4

Use 3mm or #4

standoffs

Physical Details

3.050

+

3

3.175

0.100

0.000

-0.200

-0.550 –0.200

Caution The single board computer must be supported at all four mounting points to

prevent excessive flexing when expansion modules are mated and detached. Flex

damage caused by excessive force on an improperly mounted circuit board is not

covered under the product warranty.

EPM-14 Reference Manual

+

0.000

Figure 5. EPM-14 Dimensions and Mounting Holes

(Not to scale. All dimensions in inches.)

+

3.150

3.350 3.700

0.200

12

Page 18

Physical Details

0

5

1

0.50

1.87

0.44

.06

Figure 6. EPM-14 Height Dimensions

(Not to scale. All dimensions in inches.)

.50

5.10

.57

1.17

1.9

EPM-14 Reference Manual 13

1.38

0.06

Figure 7. CBR-5011 Dimensions and Mounting Holes

Page 19

Physical Details

HARDWARE ASSEMBLY

The EPM-14 uses PC/104 and PC/104-Plus connectors so that expansion modules can be added

to the top of the stack. PC/104 (ISA) modules must not be positioned between the EPM-14 and

any PC/104-Plus (PCI) modules on the stack.

The entire assembly can sit on a table top or be secured to a base plate. When bolting the unit

down, make sure to secure all four standoffs to the mounting surface to prevent circuit board

flexing. Standoffs are secured to the top circuit board using four pan head screws. Standoffs and

screws are available as part number VL-HDW-101.

An extractor tool is available (part number VL-HDW-201) to separate the PC/104 modules from

the stack. Use caution when using the extractor tool not to damage any board components.

TACK ARRANGEMENT EXAMPLE

S

EPM-14 Reference Manual 14

Figure 8. Stack Arrangement Example

Page 20

External Connectors

r

EPM-14 CONNECTORS

J2

Ethernet 1

J1

PC/104-Plus

Battery

Earth Ground

Reference Point

J4

SVGA

Physical Details

J3

Ethernet 0

J5

CompactFlash

2

1

J10

10

Powe

9

= Pin 1

Figure 9. EPM-14 Connectors – Top Side

CPU

J9

PC/104

J8

IDE

J7

COM 1-3, USB 1-4,

PLED, IDE LED,

Reset Button,

Speaker

EPM-14 Reference Manual 15

Page 21

Physical Details

J12

LVDS

= Pin 1

Figure 10. EPM-14 Connectors – Bottom Side

EPM-14 Reference Manual 16

Page 22

Physical Details

EPM-14 CONNECTOR FUNCTIONS AND INTERFACE CABLES

The following table notes the function of each connector, as well as mating connectors and

cables, and the page where a detailed pinout or further information is available.

Table 1: Connector Functions and Interface Cables

Connector Function

J1 PC-104-Plus AMP 1375799-1 – – 0.450 3.138 36

J2 Ethernet 1 RJ45 Crimp-on Plug – – 0.055 3.115 35

J3 Ethernet 0 RJ45 Crimp-on Plug – – 3.100 2.637 35

J4 SVGA Video

Output

J5 CompactFlash Type I or Type II

J7 COM 1-3, USB 1-

4, reset, PLED,

IDE LED, speaker

J8 IDE Hard Drive,

CD-ROM Drive

J9 PC/104 AMP 1375795-2 – – 0.050 0.200 36

J10 Main Power Input Berg 69176-010 (housing)

J12 LVDS 20-pin, PanelMate 1.25mm CBR-2010

Mating Connector

FCI 89361-712LF or

FCI 89947-712LF

Compact Flash

FCI 89947-350LF CBR-5009A

FCI 89947-144LF CBR-4406

+ Berg 47715-000 (pins)

Transition

Cable

CBR-1201 1’ 12-pin 2mm IDC to

– – 1.100 2.172 30

to CBR-5011

CBR-4405

CBR-1008 Interface from standard

or

CBR-2011

Cable Description Pin 1 Location1

15-pin HD D-Sub VGA

12” 2mm 50-pin to 50pin

18” 2mm IDE cable

2

2mm to 0.1” adapter

ATX power supply

18-bit TFT FPD using

20-pin Hirose

18-bit TFT FPD using

20-pin JAE

x coord. y coord.

2.957 1.937 32

3.551 2.172

3.303 1.937 26

0.205 -0.068 21

-0.028 1.538 33

1. The PCB origin is the mounting hole to the lower left, as oriented in Figure 9.

2. CBR-4405 44-pin to 40-pin adapter required to connect to 3.5-inch IDE drives with 40-pin connectors.

3. Connectors J6 and J11 are for factory use only.

Page

EPM-14 Reference Manual 17

Page 23

CBR-5011 CONNECTORS

Physical Details

SP1

Speaker

49

50

J1

Breakout Board

Adapter

1 5

J4

COM3

J3

COM1 (Top)

COM2 (Bottom)

1

2

J2

USB1

USB2

USB3

USB4

J5

USB4

D1

IDE (Top)

PLED (Bottom)

S1

Reset

= Pin 1

Figure 11. CBR-5011 Connectors

CBR-5011 CONNECTOR FUNCTIONS

Connector /

Component

D1 IDE and Programmable LEDs Dialight 552-0211 LEDx2 T1 3/4 PC Mount Red/Green

J1 High Density Connector FCI 98414-F06-50ULF 2mm, 50 pins, keyed, friction latch

J2 USB 1-4 USB Type A USB Type A

J3 COM1-2 Kycon K42X-E9P/P-A4N Dual stacked DB-9 male

J4 COM3 Conta-Clip 10250.4 5 pin screw terminal

J5 USB 4 Molex 87758-1016 2mm, 10 pin header

S1 Reset Button E-Switch 800SP9B7M6RE Right angle momentary switch

SP1 Speaker Challenge Elec. DBX05LF-PN Miniature speaker

Function Part Number Description

header

EPM-14 Reference Manual 18

Page 24

Jumper Blocks

JUMPERS AS-SHIPPED CONFIGURATION

V1

1 2 3

Physical Details

2 4 6

1 3 5

Figure 12. Jumper Block Locations – As Shipped Configuration

V1

V2

V2

V3

2

V3

1

EPM-14 Reference Manual 19

Page 25

JUMPER SUMMARY

Physical Details

Table 2: Jumper Summary

Jumper

Block

V1

V2[1-2]

V2[3-4]

V2[5-6]

V3

Description

CMOS RAM and Real Time Clock Erase

[1-2] – Normal

[2-3] – Erase CMOS RAM and Real-Time Clock

CompactFlash Master Selector

In – CompactFlash Module is IDE Master

Out – CompactFlash Module is IDE Slave

General Purpose Input

In – CPU reads bit as 1

Out – CPU reads bit as 0

Video BIOS Selector

In – Primary Video BIOS selected

Out – Secondary Video BIOS selected

The secondary video BIOS is field-upgradeable using the BIOS upgrade

utility. See www.versalogic.com/private/cougarsupport.asp

information.

COM3 RS-422/485 Termination

In – 100 Ohm Termination Active

Out – COM3 Unterminated

for more

As

Shipped Page

[1-2] 23

In 30

In 40

In 32

In 27

EPM-14 Reference Manual 20

Page 26

Power Supply

POWER CONNECTORS

Main power is applied to the EPM-14 through a 10-pin polarized connector, with mating

connector Berg 69176-010 (Housing) + Berg 47715-000 (Pins). See the table below for the

connector pinout.

Warning! To prevent severe and possibly irreparable damage to the system, it is critical that

the power connectors are wired correctly. Make sure to use both +5VDC pins and

all ground pins to prevent excess voltage drop. Some manufacturers include a pin-1

indicator on the crimp housing that corresponds to pin-10 of the pinout shown in

Figure 13.

System Features

e

Table 3: Main Pow

J10

Signal

Pin

Name

1 GND Ground

2 +5VDC Power Input

3 GND Ground

4 +12VDC Power Input

5 GND Ground

6 -12VDC Power Input

7 +3.3VDC Power Input

8 +5VDC Power Input

9 GND Ground

10 +5VDC Power Input

r Connector Pinout

Description

4

Figure 13 shows the VersaLogic standard pin numbering for this type of 10-pin power connector

and the corresponding mating connector.

J10

EPM-14 Reference Manual

Some manufacturers include

a pin-1 indicator that

corresponds to pin-10 of the

power connector pinout

10

8

6

4

2

9

7

5

3

1

Figure 13. J10 and CBR-1008 Pin Numbering

10

8

6

4

2

9

7

5

3

1

CBR-1008

21

Page 27

System Features

Note: The +3.3VDC, +12VDC and -12VDC inputs are required only for expansion

modules that require these voltages.

OWER REQUIREMENTS

P

The EPM-14 requires only +5 volts (±5%) for proper operation. The voltage required for the

RS-232 ports are generated with a DC/DC converter. Low-voltage supply circuits provide power

to the CPU and other on-board devices.

The exact power requirement of the EPM-14 depends on several factors, including peripheral

connections, type and number of expansion modules, and attached devices. For example, driving

long RS-232 lines at high speed can increase power demand.

ITHIUM BATTERY

L

Warning! To prevent shorting, premature failure or damage to the lithium battery, do not

place the board on a conductive surface such as metal, black conductive foam or

the outside surface of a metalized ESD protective pouch. The lithium battery may

explode if mistreated. Do not recharge, disassemble or dispose of in fire. Dispose

of used batteries promptly.

Normal battery voltage should be at least 3.0V. If the voltage drops below 3.0V, contact the

factory for a replacement (part number HB3/0-1). The life expectancy under normal use is

approximately 10 years.

CPU

The Geode LX 800 microcontroller has a 32-bit, low-voltage AMD x86 microprocessor at its

core. The maximum clock rate is 500 MHz actual, with 800 MHz (Celeron equivalent)

performance. The LX 800 features 64 kb of L1 cache, 128 kb of L2 cache, DDR SDRAM

support, and an integrated display controller. The CPU has a typical power consumption of 1.6W.

System RAM

The EPM-14 has one soldered-on DDR memory module with the following characteristics:

Size 256 MB

Voltage 2.6V

Type PC2700 compatible (DDR 333 MHz)

Note CMOS settings default to DDR 333 MHz. Settings to DDR 400 MHz are available,

but VersaLogic only guarantees operation at the default settings.

EPM-14 Reference Manual 22

Page 28

CMOS RAM

CLEARING CMOS RAM

A jumper may be installed into V1[2-3] to erase the contents of the CMOS RAM and the realtime clock. When clearing CMOS RAM: 1) Power off the EPM-14. 2) Remove the jumper from

V1[1-2], install it on V1[2-3] and leave it for four seconds. 3) Move the jumper to back to

V1[1-2]. 4) Power on the EPM-14.

CMOS Setup Defaults

The EPM-14 permits users to save custom CMOS defaults, which override factory defaults. This

allows the system to boot with user-defined settings if CMOS RAM is cleared or corrupted. The

factory defaults remain available for restoration in the main BIOS Setup screen. All CMOS Setup

defaults can be customized, except the time and date. The CMOS Setup defaults can be updated

with the Flash BIOS Update (FBU) Utility, available from the General BIOS Information

Warning! If the CMOS Setup default settings make the system unbootable and prevent the user

from entering CMOS Setup, the EPM-14 needs to be serviced by the factory.

System Features

page.

EFAULT CMOS RAM SETUP VALUES

D

After the CMOS RAM is cleared, the system will load default CMOS RAM parameters the next

time the board is powered on. The default CMOS RAM setup values will be used in order to boot

the system whenever the main CMOS RAM values are blank, or when the system battery is dead

or has been removed from the board.

AVING CMOS SETUP PARAMETERS AS CUSTOM DEFAULTS

S

To save CMOS Setup parameters to custom defaults, you will need a DOS bootable floppy with

the FBU utility on it.

1. Boot the EPM-14 and enter CMOS Setup by pressing Delete during the early boot cycle.

2. Change the CMOS parameters as desired and configure the floppy drive as the first boot

device:

DRIVE ASSIGNMENT ORDER | Drive A: USB Floppy

Basic CMOS Configuration | BOOT ORDER | Boot 1st: Drive A:

3. Save the settings and exit CMOS Setup.

4. Reboot the system from the DOS boot floppy.

5. Run FBU and select Save CMOS contents. A file named CMOS.BIN is created and

saved to the floppy.

6. Select the FBU option Load Custom CMOS defaults. A directory of the floppy is

displayed.

7. Select the CMOS.BIN file and press the P key to program the new CMOS defaults.

8. Reboot the system from the hard disk. The custom CMOS parameters are now saved as

defaults.

EPM-14 Reference Manual 23

Page 29

Real Time Clock

The EPM-14 features a battery-backed 146818-compatible real-time clock/calendar chip. Under

normal battery conditions, the clock maintains accurate timekeeping functions when the board is

powered off.

ETTING THE CLOCK

S

The CMOS Setup utility (accessed by pressing the Delete key during a system boot) can be used

to set the time/date of the real-time clock.

System Features

EPM-14 Reference Manual 24

Page 30

Utility I/O Connector J7

A number of interfaces on the EPM-14 are grouped together and made accessible through utility

I/O connector J7. A breakout cables and board combination, CBR-5011, is available from

VersaLogic that provides discrete connectors for each of the interfaces; however, you may wish

to create a custom cable that surfaces only the interfaces required by your application.

The 50-pin I/O connector incorporates the COM ports, and the reset button and speaker

interfaces. Table 4 illustrates the function of each pin.

J7

CBR-5011

Pin

Connector Pin

1

2

3 Top DB9 2 Receive Data

4 7 Request to Send

5 3 Transmit Data 31

6 8 Clear to Send

7 4 Data Terminal Ready

8 9 Ring Indicator 34 B2 Data -

9 5 Ground

10

11

12 Bottom DB9 2 Receive Data

13 7 Request to Send

14 3 Transmit Data 39

15 8 Clear to Send

16 4 Data Terminal Ready

17 9 Ring Indicator 42 3

18 5 Ground

19

20

21 Top T3 Data + 46

22

23

24

25 Top-Middle TM3 Data + 50

26 TM2 Data -

COM1

J3

COM2

J3

USB1

J2

USB2

J2

1 Data Carrier Detect

6 Data Set Ready

1 Data Carrier Detect

6 Data Set Ready

T4 Ground 44

T1 +5V Protected 45

T2 Data - 47

TM4 Ground 48

TM1 +5V Protected 49

Interfaces and Connectors

Table 4: J7 I/O Connector Pinout

Signal

J7

CBR-5011

Pin

Connector Pin

27

28

29 Bottom-Middle BM3 Data +

30

32

33 Bottom B3 Data +

35

36

37

38

40

41 1

43 2

USB3

J2

USB4

J2

(Reserved)

PBRESET

S1

COM3

J4

PLED

D1

IDE LED

D1

Speaker

SP1

(Reserved)

BM4 Ground

BM1 +5V Protected

BM2 Data -

B4 Ground

B1 +5V Protected

– Ground

– Not connected

1 Pushbutton Reset

2 Ground

RS-422

TxD+

5

TxD-

4

Ground

RxD+

RxD-

3 Programmable LED

1 +5V Protected

4 IDE LED

2 +5V Protected

– Speaker Drive

– Ground

– Ground

5

Signal

RS-485

No connect

No connect

No connect

TRx3+

TRx3-

EPM-14 Reference Manual

25

Page 31

IDE

Interfaces and Connectors

One IDE interface is available to connect up to two IDE devices, such as hard disks and CDROM drives. If the on-board CompactFlash is configured for use, only one other IDE device can

be attached to the IDE controller. Connector J8 provides the interface to the IDE controller.

Jumper V2[1-2] determines if the CompactFlash plugged into J5 is the master device or slave.

Use CMOS Setup to specify the drive parameters of the attached drives.

Warning! Cable length must be 18" or less to maintain proper signal integrity.

Table 5: IDE Hard Drive Connector Pinout

Pin Signal Name Function Pin Signal Name Function

1 Reset- Reset signal from CPU 23 DIOW I/O write

2 Ground Ground 24 Ground Ground

3 DD7 Data bus bit 7 25 DIOR I/O read

4 DD8 Data bus bit 8 26 Ground Ground

5 DD6 Data bus bit 6 27 IORDY I/O ready

6 DD9 Data bus bit 9 28 Ground Ground

7 DD5 Data bus bit 5 29 DMACK- DMA acknowledge

8 DD10 Data bus bit 10 30 Ground Ground

9 DD4 Data bus bit 4 31 INTRQ Interrupt request

10 DD11 Data bus bit 11 32 NC No connection

11 DD3 Data bus bit 3 33 DA1 Device address bit 1

12 DD12 Data bus bit 12 34 CBLID- Cable type identifier

13 DD2 Data bus bit 2 35 DA0 Device address bit 0

14 DD13 Data bus bit 13 36 DA2 Device address bit 2

15 DD1 Data bus bit 1 37 CS0 Chip select 0

16 DD14 Data bus bit 14 38 CS1 Chip select 1

17 DD0 Data bus bit 0 39 PDLED IDE LED

18 DD15 Data bus bit 15 40 Ground Ground

19 Ground Ground 41 Power +5.0 V

20 NC Key 42 Power +5.0 V

21 DREQ DMA request 43 Ground Ground

22 Ground Ground 44 NC No connection

EPM-14 Reference Manual 26

Page 32

Serial Ports

The EPM-14 features three on-board 16550-based serial channels located at standard PC I/O

addresses. COM1 and COM2 are RS-232 (115.2K baud) serial ports. IRQ lines are chosen in

CMOS Setup. COM3 operates in RS-422 or RS-485 mode. IRQ lines are chosen in the CMOS

Setup. Each COM port can be independently enabled or disabled in CMOS Setup.

For information on setting the COM ports to high-speed baud rates, see the AMD LX 800 Data

Book (COM1 and COM2) or the AMD CS5536 Companion Device Data Book (COM3).

COM

PORT CONFIGURATION

There are no configuration jumpers for COM1 and COM2 since they only operate in RS-232

mode. Jumper V3 is used to enable the RS-422/485 termination resistor for COM3. The

termination resistor should be enabled for RS-422/485 endpoint station. It should be disabled for

the RS-485 intermediate station.

ERIAL PORT CONNECTORS

S

See the Connector Location Diagrams on pages 15 for connector and cable information. The

pinouts of the DB9M connectors apply

CBR-5011.

Interfaces and Connectors

to the serial connectors on the VersaLogic breakout board

These connectors use IEC 61000-4-2-rated TVS com

Table 6: COM1-2 Pinout – CBR-5011 Connector J3

COM1 COM2

Top DB9

J3 Pin

1 10 DCD

2 11 RXD*

3 12 TXD*

4 13 DTR

5 14 Ground

6 15 DSR

7 16 RTS

8 17 CTS

9 18 RI

Bottom DB9

J3 Pin

Table 7: COM3 Pinout – CBR-5011 Connector J4

J4 Pin RS-422 RS-485

1 Ground No connect

2 RxD- TRxD3 RxD+ TRxD+

4 TxD- No connect

5 TxD+ No connect

ponents to help protect against ESD damage.

RS-232

EPM-14 Reference Manual 27

Page 33

Interfaces and Connectors

COM3 RS-422/485 LINE DRIVER CONTROL

The COM3 line driver is controlled by manipulating the RS422/485 Transmit/Receive Control

Register (1D3h). RS-485 support is provided but limited to manual flow control. COM3 is set to

RS-485 receive mode when COM 3 Mode is set to RS485 ManuFC in CMOS. To enable RS-485

transmit mode, set bit D2. Clearing bit D2 will enable receive mode.

RS422/485 (Read/Write) 1D3h

D7 D6 D5 D4 D3 D2 D1 D0

Reserved Reserved Reserved Reserved Reserved COM3TE485 COM3RE4XX COM3TE422

Table 8: RS-422/485 Transmit/Receive Control Register Bit Assignments

Bit Mnemonic Description

D7-D3 – Reserved – These bits have no function.

D2 COM3TE485 COM3 RS-485 Transmit Enable — Controls RS-485 transmit on COM3.

0 = Disable

1 = Enable

D1 COM3RE4XX COM3 RS-485/422 Receive Enable — Controls RS-485/422 receive on COM3.

0 = Disable

1 = Enable

D0 COM3TE422 COM3 RS-422 Transmit Enable — Controls RS-422 transmit on COM3.

0 = Disable

1 = Enable

EPM-14 Reference Manual 28

Page 34

USB

Interfaces and Connectors

The USB interface on the EPM-14 is OHCI (Open Host Controller Interface) and EHCI (Enhance

Host Controller Interface) compatible, which provides a common industry software/hardware

interface. The EHCI controller is still available for use by the operating system when the “Usb20”

feature is disabled, but booting from USB 2.0 devices or using them in a DOS environment may

be slower.

The USB controllers use PCI interrupt INTD#. CMOS Setup is used to select the IRQ line routed

to each PCI interrupt line.

There are four USB ports, all connected through the utility I/O connector at J7. The CBR-5011

breakout board provides four USB type-A connectors at location J2, and an alternate 4-pin

connection for USB4 at location J5.

Table 9: USB Pinout – CBR-5011 Connector J2

Pin Signal Name Function

1 USBPxPWR +5V (Protected)

2 USBPx– Data –

3 USBPx+ Data +

4 GND Ground

Table 10: USB Pinout – CBR-5011 Connector J5

CBR-5011

J5 Pin

1 USBP4PWR +5V (Protected)

2 – No connect

3 USBP4– Channel 4 Data –

4 – No connect

5 USBP4+ Channel 4 Data +

6 – No connect

7 GND Cable Shield

8 – No connect

9 – No connect

10 IDE_LED IDE LED

Signal

Name

Function

These connectors use IEC 61000-4-2-rated TVS components to help protect against ESD damage.

EPM-14 Reference Manual 29

Page 35

CompactFlash

Connector J5 provides a socket for a Type I or Type II CompactFlash (CF) module. This IDE

based interface operates on the same channel as the IDE interface. The CF interface supports

operation in DMA mode.

The following CF modules have been tested and qualified as bootable devices by VersaLogic.

Part numbers with a suffix of -3500 are RoHS-compliant.

Interfaces and Connectors

Table 11. Qualified Bootable CF Modules

Manufacturer Density Mfg Part Number

Hagiwara 1 GB CF1-1GMDG(H00AA)

Hagiwara 512 MB CF1-512MDG(H00AA)

Silicon Systems 128 MB SSD-C12M-3012

Silicon Systems 128 MB SSD-C12M-3500

Silicon Systems 256 MB SSD-C25M-3012

Silicon Systems 256 MB SSD-C25MI-3012

Silicon Systems 256 MB SSD-C25M-3500

Silicon Systems 256 MB SSD-C25MI-3500

Silicon Systems 512 MB SSD-C51M-3012

Silicon Systems 512 MB SSD-C51MI-3012

Silicon Systems 512 MB SSD-C51M-3500

Silicon Systems 512 MB SSD-C51MI-3500

Silicon Systems 1 GB SSD-C01G-3012

Silicon Systems 1 GB SSD-C01G-3500

Silicon Systems 2 GB SSD-C02G-3012

Silicon Systems 2 GB SSD-C02GI-3012

Silicon Systems 2 GB SSD-C02G-3500

Silicon Systems 4 GB SSD-C04GI-3012

EPM-14 Reference Manual 30

Page 36

Programmable LED

Connector J7 includes an output signal for attaching a software controlled LED. Connect the

cathode of the LED to J7, pin 44; connect the anode to +5V. An on-board resistor limits the

current to 15 mA when the circuit is turned on. A programmable LED is provided on the

CBR-5011 breakout board.

To turn the LED on and off, set or clear bit D7 in I/O port 1D0h. When changing the register,

make sure not to alter the value of the other bits.

The following code examples show how to turn the LED on and off. Refer to page 36 for further

ation.

inform

LED On LED Off

MOV DX,1D0H MOV DX,1D0H

IN AL,DX IN AL,DX

OR AL,80H AND AL,7FH

OUT DX,AL OUT DX,AL

External Speaker

Connector J7 includes a speaker output signal at pin 48. The CBR-5011 breakout board provides

a Piezo electric speaker.

Interfaces and Connectors

Push-Button Reset

Connector J7 includes an input for a push-button reset switch. Shorting J7 pin 37 to ground

causes the EPM-14 to reboot.

This connector uses IEC 61000-4-2-rated TVS components to help protect against ESD damage.

A reset button is provided on the CBR-5011 breakout board.

EPM-14 Reference Manual 31

Page 37

Video Interface

An on-board video controller integrated into the chipset provides high performance video output

for the EPM-14.

ONFIGURATION

C

The video interface uses PCI interrupt INTA*. CMOS Setup is used to select the IRQ line routed

to INTA*.

The EPM-14 uses shared memory architecture. This allows the video controller to use variable

amounts of system DRAM for video RAM. The amount of RAM used for video is set with a

CMOS Setup option.

The EPM-14 supports two types of video output, SVGA and LVDS Flat Panel Display. A CMOS

Setup option is used to select which output is enabled after POST.

IDEO BIOS SELECTION

V

Jumper V2[5-6] can be removed to allow the system to boot from the secondary video BIOS.

Unlike the primary video BIOS, the secondary video BIOS can be reprogrammed in the field.

Interfaces and Connectors

SVGA

OUTPUT CONNECTOR

See the diagram on page 15 for the location of connector J4. An adapter cable, part number CBR-

1201, is available to translate J4 into a standard 15-pin D-Sub SVGA connector.

ge.

This connector uses IEC 61000-4-2-rated TVS components to help protect against ESD dam

Table 12: Video Output Pinout

J4

Signal

Pin

Name

1 GND Ground 6

2 RED Red video 1

3 GND Ground 7

4 GREEN Green video 2

5 GND Ground 8

6 BLUE Blue video 3

7 GND Ground 5

8 HSYNC Horizontal sync 13

9 GND Ground 10

10 VSYNC Vertical sync 14

11 CRT_SCL DDC data clock line 15

12 CRT_SDA DDC serial data line 12

Function

Mini DB15

Pin

a

EPM-14 Reference Manual 32

Page 38

Interfaces and Connectors

LVDS FLAT PANEL DISPLAY CONNECTOR

The integrated LVDS flat panel display in the EPM-14 is an ANSI/TIA/EIA-644-1995

specification-compliant interface. It can support up to 24 bits of RGB pixel data plus three bits of

timing control (HSYNC/VSYNC/DE) on the four differential data output pairs. The LVDS clock

frequency ranges from 25 MHz to 112 MHz.

CMOS Setup provides several options for standard LVDS flat panel types. If these options do not

match the requirements of the panel you are attempting to use, contact Support@VersaLogic.com

for a custom video BIOS.

The 3.3V power provided to pins 19 and 20 of J9 is protected by a 1 amp fuse.

See the connector location diagram on page 15 for pin and connector location information.

Table 13: LVDS Flat Panel Display Pinout

J12

Signal

Pin

Name

1 GND Ground

2 NC Not Connected

3 LVDSA3 Diff. Data (+)

4 LVDSA3# Diff. Data 3 (-)

5 GND Ground

6 LVFSCLK0 Differential Clock (+)

7 LVDSCLK0# Differential Clock (-)

8 GND Ground

9 LVDSA2 Diff. Data 2 (+)

10 LVDSA2# Diff. Data 2 (-)

11 GND Ground

12 LVDSA1 Diff. Data 1 (+)

13 LVDSA1# Diff. Data 1 (-)

14 GND Ground

15 LVDSA0 Diff. Data 0 (+)

16 LVDSA0# Diff. Data 0 (-)

17 GND Ground

18 GND Ground

19 +3.3V Protected Power Supply

20 +3.3V Protected Power Supply

Function

EPM-14 Reference Manual 33

Page 39

Interfaces and Connectors

COMPATIBLE LVDS PANEL DISPLAYS

The following flat panel displays are reported to work properly with the integrated graphics video

controller chip used on the EPM-14.

Table 14: Compatible Flat Panel Displays

Manufacturer

eVision Displays xxx084S01 series 8.4” 800 x 600 18-bit LVDS TFT

au Optronix B084SN01 8.4” 800 x 600 18-bit LVDS TFT

eVision Displays xxx104S01 series 10.4” 800 x 600 18-bit LVDS TFT

au Optronix B104SN01 10.4” 800 x 600 18-bit LVDS TFT

eVision Displays xxx141X01 series 14.1” 1024 x 768 18-bit LVDS TFT

Sharp LQ121S1LG411 12.1” 800 x 600 18-bit LVDS TFT

Model Number

Panel

Size

Resolution

Interface

Panel

Technology

CONSOLE REDIRECTION

The EPM-14 can be operated without using the on-board video output by redirecting the console

to COM1. CMOS Setup and some operating systems such as DOS can use this console for user

interaction.

In the Features Configuration screen, there is an option to control console redirection. This option

can be set to Auto or Redirect. When set to Auto, the console will not be redirected to COM1

unless a signal is detected from the terminal by pressing CRTL-C or ENTER.. When set to

Redirect, the console will be directed to COM1.

Notes on console redirection:

When console redirection is enabled, you can access CMOS Setup by typing Ctrl-C.

The decision to redirect the console is made early in BIOS execution and cannot be

changed later.

The redirected console uses 115200 baud, 8 data bits, 1 stop bit, no parity, and no flow

control.

The default console redirection setting is Auto. The default can be reloaded without

entering BIOS setup by discharging CMOS contents.

Null Modem:

The following diagram illustrates a typical DB9 to DB9 RS-232 null modem adapter. Pins 7 and

8 are shorted together on each connector. Unlisted pins have no connection.

System 1 <--> System 2

Name Pin Pin Name

----------------------- TX 3 <--> 2 RX

RX 2 <--> 3 TX

RTS 7 <--> 1 DCD

CTS 8

DSR 6 <--> 4 DTR

DCD 1 <--> 7 RTS

8 CTS

DTR 4 <--> 6 DSR

EPM-14 Reference Manual 34

Page 40

Ethernet Interface

The EPM-14 features two Intel 82551ER Fast Ethernet controllers on-board. While these

controllers are not NE2000-compatible, they are widely supported. Drivers are readily available

to support a variety of operating systems. See VersaLogic website for latest OS support.

CONFIGURATION

BIOS

Ethernet interface 0 (J3) uses PCI interrupt INTA# and Ethernet interface 1 (J2) uses PCI

interrupt INTB#. CMOS Setup is used to select the IRQ line routed to each PCI interrupt line.

TATUS LED

S

Each Ethernet controller has a two-colored LED located next to its RJ-45 connector to provide an

indication of the Ethernet status as follows:

Green LED (Link):

ON Active Ethernet cable plugged in

OFF Active cable not plugged in

or cable not plugged into active hub

Interfaces and Connectors

Yellow LED (Activity):

ON Activity detected on cable

OFF No Activity detected on cable

THERNET CONNECTOR

E

Board-mounted RJ-45 connectors are provided to make connections with Category 5 Ethernet

cables. The 82551ER Ethernet controller auto-detects 10BaseT/100Base-TX connectors.

These connectors use IEC 61000-4-2-rated TVS components to help protect against ESD damage.

Table 15: RJ45 Ethernet Connector

J2/J3

Signal

Pin

Name Function

1 T+ Transmit Data +

2 T- Transmit Data 3 R+ Receive Data +

4 IGND Isolated Ground

5 IGND Isolated Ground

6 R- Receive Data 7 IGND Isolated Ground

8 IGND Isolated Ground

EPM-14 Reference Manual 35

Page 41

CPU Temperature Monitor

A thermometer circuit constantly monitors the die temperature of the CPU. This circuit can be

used to detect over-temperature conditions which can result from fan or heat sink failure or

excessive ambient temperatures.

The system can be configured to generate an interrupt when the temperature exceeds the BIOS

programmed threshold. Contact the factory for information on reading and writing to the

thermometer circuits.

PC/104 Expansion Bus

EPM-14 has limited support of the PC/104 bus. Most PC/104 cards will work, but be sure to

check the requirements of your PC/104 card against the list below.

Interfaces and Connectors

PC/104

I/O SUPPORT

The ISA I/O ranges listed below are supported. The I/O ranges allocated to COM ports 1-3 are

available to ISA when the on-board COM port function is disabled in CMOS Setup.

• 100h – 1CFh

1DFh – 1EFh

200h – 3AFh

3E0h – 3F5h

3F7h – 47Fh

490h – 4CFh

4D2h – 777h

77Ch – AFFh

• When on-board COM ports are enabled in CMOS Setup: COM1 (0x3F8-0x3FF), COM2

(0x2F8-0x2FF), COM3 (0x3E8-0x3EF).

PC/104

MEMORY SUPPORT

Memory ranges supported:

• C8000h-DBFFFh

SUPPORT

IRQ

The following IRQs are available on the PC/104 bus:

• IRQ 3, IRQ 4, IRQ 5, IRQ 6, IRQ 7, IRQ 9, and IRQ 10

Each of the seven IRQs must be enabled in CMOS Setup before they can be used on the ISA bus.

Because ISA IRQ sharing is not supported, make sure that any IRQ channel used for an ISA

device is not used elsewhere. For example, if ISA IRQ 4 is enabled, you must use a different IRQ

for COM1. There are three mutually exclusive IRQ domains: PCI, ISA, and on-board COM ports.

SUPPORT

DMA

The current revision of the board does not support PC/104 DMA.

EPM-14 Reference Manual 36

Page 42

Memory Map

The lower 1 MB memory map of the EPM-14 is arranged as shown in the following table.

Various blocks of memory space between C0000h and FFFFFh can be shadowed. CMOS Setup is

used to enable or disable this feature.

I/O Map

The following table lists the common I/O devices in the EPM-14 I/O map. User I/O devices

should be added using care to avoid the devices already in the map as shown in the following

table.

System Resources and Maps

Table 16: Memory Map

Start Address End Address Comment

E0000h FFFFFh System BIOS

DC000h DFFFFh Reserved

C8000h DBFFFh PC/104

C0000h C7FFFh Video BIOS

A0000h BFFFFh Video RAM

00000h 9FFFFh System RAM

6

Table 17: I/O Map

I/O Device Standard I/O Addresses

Special Control Register 1D0h

PLD Revision and Type Register 1D1h

Jumper and Status Register 1D2h

Reserved 1D4h – IDCh

COM/ISA IRQ Routing 1DDh – 1DEh

Primary Hard Drive Controller 1F0h – 1F7h

COM3 Serial Port 3E8h – 3EFh

COM2 Serial Port 2F8h – 2FFh

COM1 Serial Port 3F8h – 3FFh

Note The I/O ports occupied by on-board devices are freed up when the device is

disabled in the CMOS setup. This does not apply to SPI and Reserved registers.

EPM-14 Reference Manual

37

Page 43

Interrupt Configuration

The EPM-14 has the standard complement of PC type interrupts. Four non-shared interrupts are

routed to the PC/104 bus, and up to four IRQ lines can be allocated as needed to PCI devices. The

following tables show the default and allowed interrupt settings. There are no interrupt

configuration jumpers. All configuration is handled through CMOS Setup. If your design needs

to use interrupt lines on the PC/104 bus, IRQ5 and IRQ10 are recommended. (IRQ3 and IRQ4 are

normally used by COM ports on the main board.)

z = default setting | = allowed setting

Source

Timer 0

Keyboard

Slave PIC

COM1

COM2

COM3

RTC

Mouse

Math Chip

IDE PATA

IDE SATA

ISA IRQ10

ISA IRQ3

ISA IRQ4

ISA IRQ5

ISA IRQ6

ISA IRQ7

ISA IRQ9

PCI INTA#

PCI INTB#

PCI INTC#

PCI INTD#

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

z

z

z

System Resources and Maps

Table 18: EPM-14 IRQ Settings

IRQ

| z {

z | |

| | |

|

|

|

|

|

|

|

{

|

|

|

|

| |

| |

| |

z

|

| | z

| | z

| | z

z | |

z

z

z

z

|

|

|

|

|

EPM-14 Reference Manual 38

Table 19: PCI Interrupt Settings

z = default setting | = allowed setting

PCI Interrupt

Source

Video

USB 2.0

USB 1.1

Ethernet 0

Ethernet 1

INTA# INTB# INTC# INTD#

z

z

z

z

z

Page 44

Special Registers

Special Control Register

SCR (Read/Write) 1D0h

D7 D6 D5 D4 D3 D2 D1 D0

PLED Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Table 20: Special Control Register Bit Assignments

Bit Mnemonic Description

D7 PLED Light Emitting Diode – Controls the programmable LED on connector J7.

0 = Turns LED off

1 = Turns LED on

D6-D0 – Reserved – These bits have no function.

PLD Revision and Type Register

REVTYP (Read-only) 1D1h

7

D7 D6 D5 D4 D3 D2 D1 D0

PLDREV4 PLDREV3 PLDREV2 PLDREV1 PLDREV0 Reserved PLDCUST PLDDEV

This register is used to indicate the PLD code revision level and model of the EPM-14.

Table 21: Revision and Type Register Bit Assignment

Bit Mnemonic Description

D7-D3 PLDREV PLD Revision Level – Represents the EPM-14 PLD revision level. These bits are

read-only.

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 PLD Revision Level

0 0 0 0 1 3.01

D2 – Reserved – This bit has no function.

D1 PLDCUST Custom PLD – Indicates whether the EPM-14 has a custom PLD. This bit is

read-only.

0 = Standard PLD

1 = Custom PLD

D0 PLDDEV PLD in Development – Indicates whether the EPM-14 PLD is in development.

This bit is read-only.

0 = PLD not in development

1 = PLD in development

EPM-14 Reference Manual

39

Page 45

Jumper and Status Register

JSR (Read-only) 1D2h

D7 D6 D5 D4 D3 D2 D1 D0

Reserved Reserved Reserved Reserved Reserved GPI VB_SEL Reserved

Table 22: Jumper and Status Register Bit Assignments

Bit Mnemonic Description

D7-D3 – Reserved – These bits have no function.

D2 GPI

D1 VB_SEL

D0 – Reserved – This bit has no function.

General Purpose Input – Indicates the status of V2[3-4]. This bit is read-only.

0 = Jumper out

1 = Jumper in

Video BIOS Selection – Indicates the status of jumper V2[5-6]. This bit is

read-only.

0 = Jumper out, Secondary Video BIOS selected

1 = Jumper in, Primary Video BIOS selected

Special Registers

EPM-14 Reference Manual 40

Page 46

Appendix A – References

PC Chipset Advanced Micro Devices (http://amd.com/us-en/)

AMD LX 800 Processor

AMD CS5536 Companion

Device

Ethernet Controller Intel Corporation

Intel 82551ER

Super I/O SMSC

SMSC LPC47N217

PC/104 Specification PC/104 Consortium

PC/104 Resource Guide

PC/104-Plus Specification VersaLogic Corporation

PC/104 Resource Guide

General PC Documentation Microsoft Press

The Programmer’s

PC Sourcebook

General PC Documentation Powell’s Books

The Undocumented PC

(http://www.smsc.com)

(http://developer.intel.com/sites/developer)

(www.controlled.com/pc104)

(www.versalogic.com)

(www.microsoft.com/learning/books)

(www.powells.com)

A

EPM-14 Reference Manual

41

Loading...

Loading...