Versaclean 200, 200H, 500, 500H, 1200MS User Manual

User Manual

VersaClean Portable Extractor

Portable Extractors

Models 200, 200H, 500, 500H, and 1200MS

VersaClean

15180 Josh Wilson Road

Burlington, WA 98233

800-932-3030 www.VersaCleanSystems.com

VersaClean Portable Extractors provide deep, rapid cleaning of carpets, upholstery and hard

surfaces. Heated models provide additional cleaning power. Lightweight, easy to use, and

adjustable for a wide range of carpet types and soiling conditions, the VersaClean Extractors

produce cleaner, drier carpets and surfaces.

Patents: http://www.LBpatents.com

READ AND SAVE THESE INSTRUCTIONS

Important Safety Instructions: Read All

Do not leave appliance when plugged in. Unplug

cord from outlet when not in use or servicing

machine.

Shown with optional wand and hoses

Do not use outdoors. This machine is for indoor use

only.

Do not allow to be used as a toy. Close attention is

necessary when used near children.

Use only as described in this manual. Use only

manufacturer’s recommended accessory tools.

Operators shall be adequately instructed on the use

of this machine.

This machine is not intended for use by persons,

including children, with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge.

Do not use with damaged cord or plug. If appl iance

is not working as it should, has been dropped,

damaged, left outdoors, or dropped in water , return

it to a service center for repair.

Do not pull or carry by cord, use cord as a handle,

close a door on cord, or pull cord around sharp

edges or corners. Do not run appliance over cord.

Keep cord away from heated surfaces.

Do not pull cord to unplug. To unplug, grasp the

plug, not the cord.

Do not handle plug or appliance with wet hands.

Do not put any object into openings. Do not use with

any opening blocked; keep free of dust, l int, hair and

anything that may reduce airflow.

Do not use without ball float screen in place.

Turn off all controls before unplugging.

07-02052E 1 VersaClean

Do not use to pick up flammable or combustible

liquids, such as gasoline, or use in areas where they

may be present.

Do not pick up any type of hazardous dust or toxic

materials.

Do not pick up anything that is burning or smoking,

such as cigarettes, matches, or hot ashes.

Do not point spray at yourself or in the direction of

others

Do not use this machine for dry vacuuming.

Do not operate machine in standing water.

Immediately unplug power cord from outlet if

machine leaks solution/foam or if machine tips over

while operating.

Release water pressure at accessory tool spray

nozzle before disconnecting solution hose.

Always stop machine on a level surface.

Use extra care when cleaning on stairs. Do not

wheel machine up or down stairs.

Connect to a properly grounded outlet only.

Extension cord must be 12/3 gauge and no longer

than 40 feet. Replace cord if ground plug becomes

damaged.

Do not use additional extension cords with machine.

Do not use machine if not in proper operating

condition.

Do not modify machine from its original design.

Get assistance when lifting machine.

All repairs must be performed by a qualified service

person. Use only manufacturer-supplied or

equivalent replacement parts.

Cautions: Risk of property damage

The warranty is valid from the date of purchase for one

year. This will cover parts and labor at an authorized

VersaClean or Sapphire Scientific distributor. The

warranty is only valid to the orginal purchaser and proof

of purchase is required. Modifying this unit or not

maintaining the machine as outlined in this manual will

void the warranty. See the full Limited Warranty

document for details.

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should

malfunction or break down, grounding provides a path of

least resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with cords

having equipment-grounding conductors and grounding

plugs. The plugs must be inserted into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING! Improper connection of the equipme n tgrounding conductor can result i n a risk of electric

shock. Check with a qualified electrician or service

person if you are in doubt as to whether the outlets

are properly grounded. Do not modify the plu gs

provided with the appliance – if the plugs do not fit

the outlets, have proper outlets installed by a

qualified electrician.

This equipment is for use on a circuit or circuits having a

nominal rating no more than 120V and is factoryequipped with a specific electric cord and plug to permit

connection to a proper electric circuit. Make sure that the

appliance is connected to outlets having the same

configuration as the plugs. No adaptor should be used

with this appliance. If the appliance must be reconnected

for use on a different type of electric circuit, the

reconnection should be made by qualified service

personnel.

CAUTION: Protect from freezing. Freezing may

damage internal components and will void warranty.

CAUTION: Do not use with water with over 3 grains

per gallon (51 miligrams per liter) of hardness. Use

with hard water could result in the formation of

mineral deposits inside pumps and fitting s. Damage

caused by mineral deposits will void warranty.

CAUTION: Use only to extract moisture. Do not

immerse end of vacuum hose in liquid.

CAUTION: Do not use as a dry vacuum. Dust

particles will damage the vacuum motors. Damage

caused by dry vacuuming will void the warranty.

CAUTION: To prevent the growth of mold and

mildew inside the tanks, always drain waste tank

completely and empty solution tank after use.

WARRANTY

Visit www.VersaCleanSystems.com to register your

purchase. Registration allows us to better assist you with

using, maintaining or servicing your equipment, as well

as to contact you in case we have important safety

information concerning your product.

CONTROLS

ON THE CONTROL PANEL (Fig. 3)

Includes rocker-type switches control blower, solution

pump, heat (on select models) and pumpout (on select

models).

ON THE BACK PANEL (Fig. 2H)

Pressure regulator. Select models. Turn clockwise to

increase solution pressure; turn counterclockwise to

decrease solution pressure.

200, 200H, 500 and 500H

OPERATING INSTRUCTIONS

For 1200MS operating instructions, see p. 4.

07-02052E 2 VersaClean

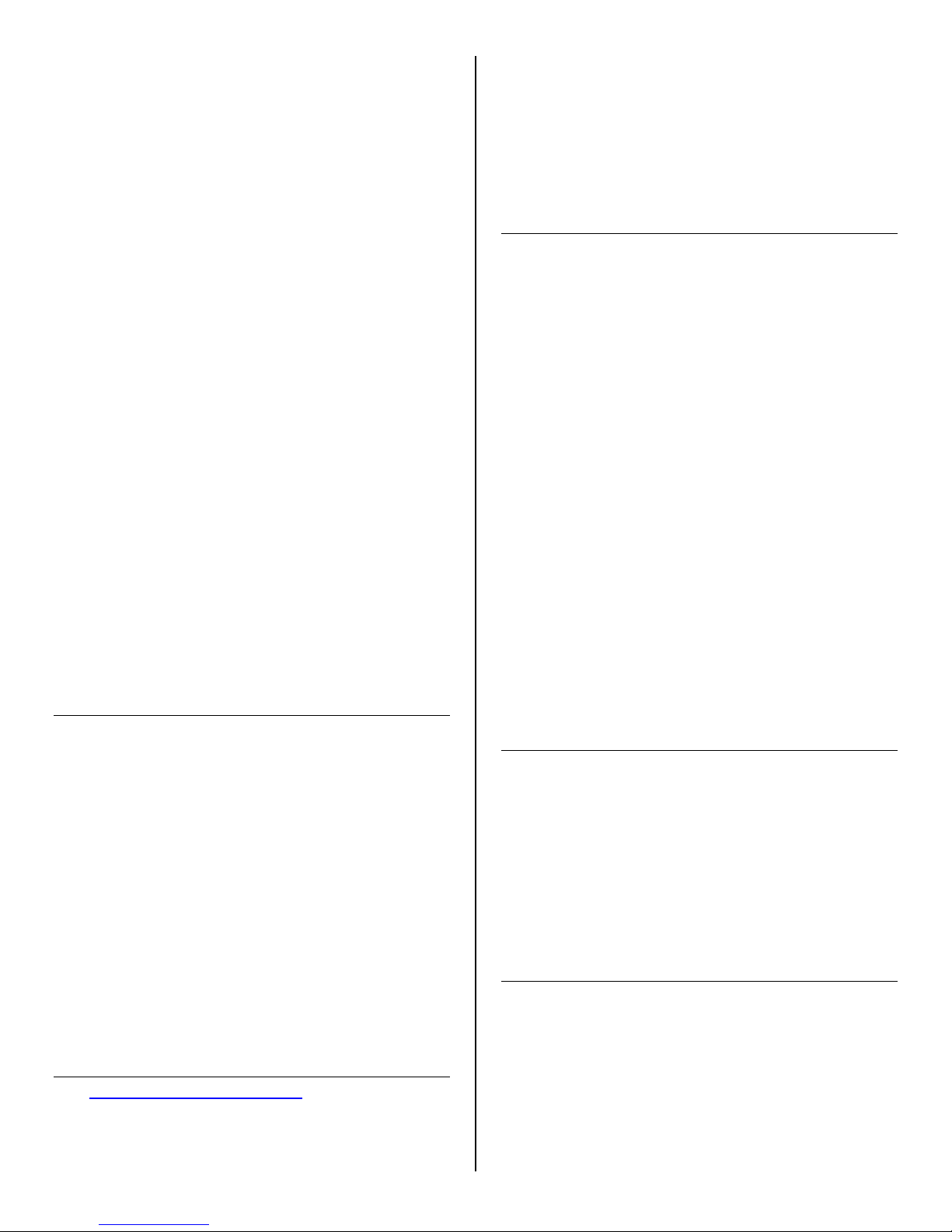

A

D

B

C

FIG. 1: Front View

A

Recovery tank cover

B

Vacuum hose attachment

C

Recovery tank gravity drain and gate-type valve

D

Solution hose quick-connect

IMPORTANT: Make sure to control the amount of foam

in the recovery tank. Excessive foam can allow moisture,

carpet fiber and other debris to be drawn through the

vacuum cutoff valve and cause damage to the vacuum

motors. Damage caused by moisture or debris will void

the product warranty. To help reduce foaming, use a

low-foam detergent. Foaming may also occur because of

residues left from previous cleanings . If this happens,

use a defoamer additive. Follow defoamer manufacturer

instructions for proper application.

1. Pre-mix cleaning solution with hot water in a

separate container. Pour mixed solution into the

solution tank of the machine.

2. Connect vacuum and solution hoses to machine and

attach to extraction wand or hand tool.

3. Plug power cord into a 3-pin grounded circuit. Keep

cords clear of your cleaning path. IMPORTANT:

Heated units have two cords and each cord should

be plugged into separate 3-pin grounded circuits.

The separate circuit indicator light will glow green

(Fig. 2F) when the cords are properly connected.

4. Switch on vacuum.

5. Switch on solution pump.

6. Switch on heat for heated solution (heated units

only).

7. Begin cleaning. Refer to industry-approved

procedures. NOTE: For heated units, it may require

several minutes for the solution to reach the

maximum temperature.

8. If equipped, solution pressure may be adjusted with

the pressure regulator knob (Fig. 2H). Monitor the

pressure gauge to ensure pressure is adequate.

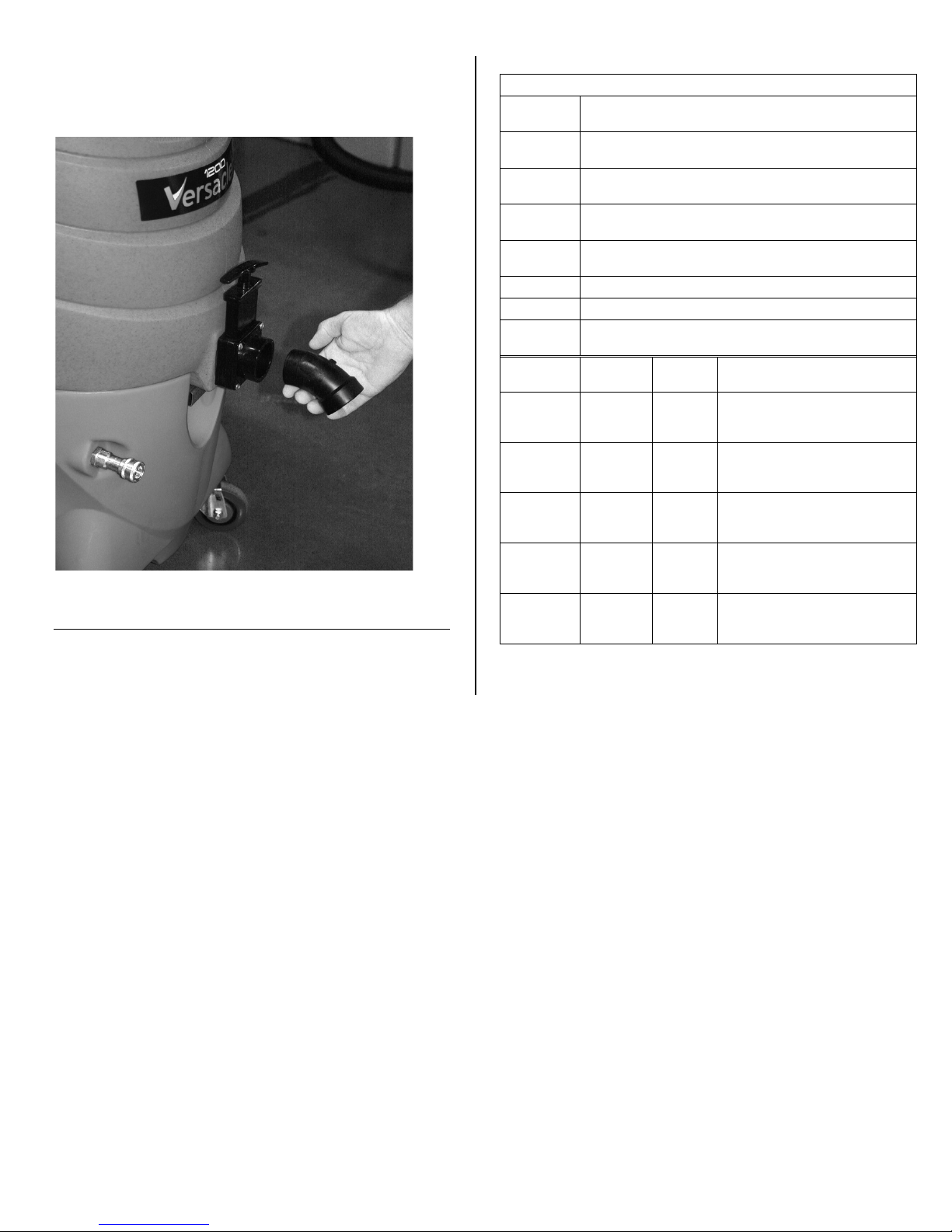

9. Use gravity drain to drain waste tank when full.

Attach diverter to direct flow downward (F ig. 7 ).

07-02052E 3 VersaClean

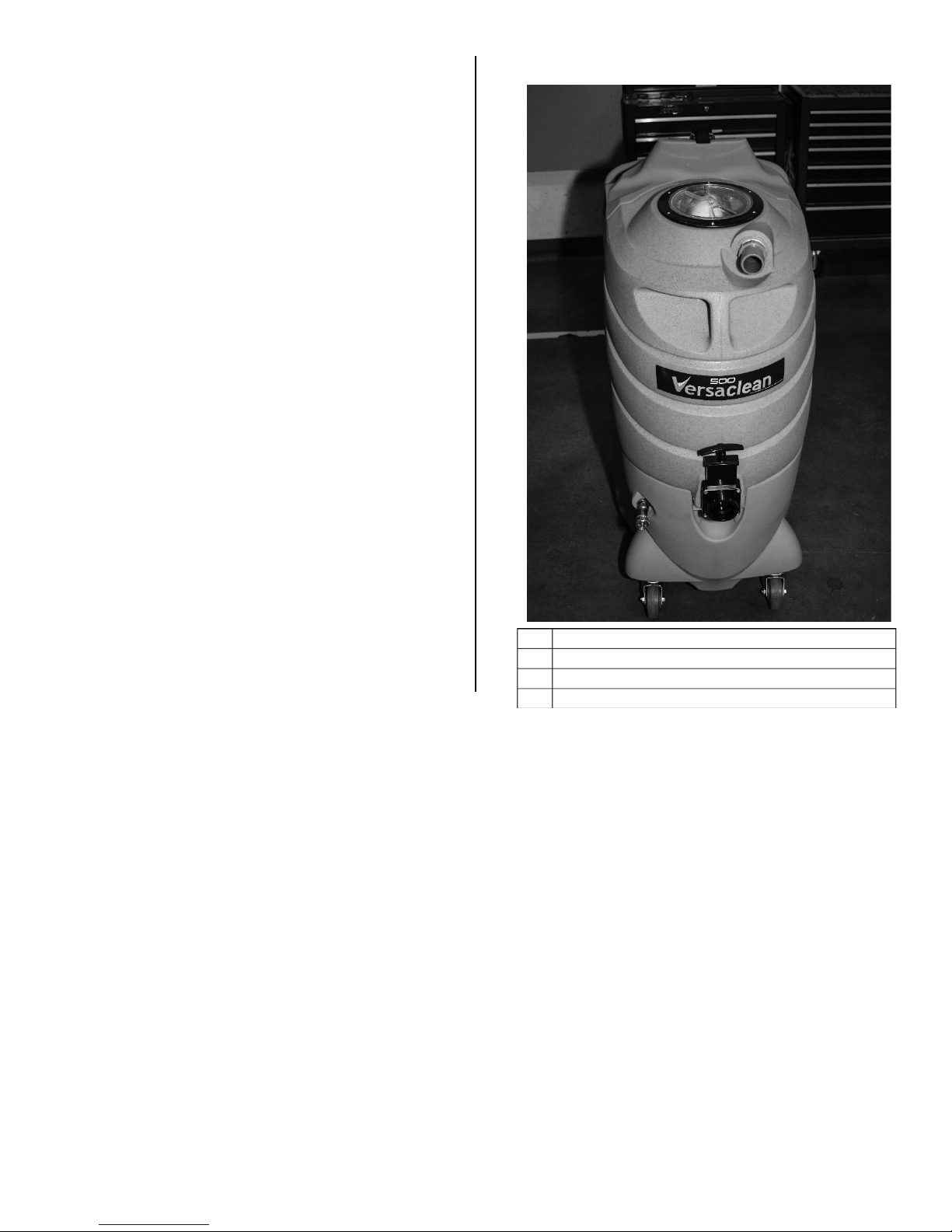

A

D

B

G

C

F

H

E

FIG. 2: Rear View

(Fig 2 detail)

A

I

J

A

Solution tank with clear hinged cover

F

Dual-circuit indicator light (select models)

B

Wand retention clip

G

Pressure gauge (select models)

C

Vacuum exhaust. Keep clear.

H

Pressure regulator (select models)

Auto-pumpout coupling (select models). Keep capped when not

in use.

E

Dual cords (select models)

J

Auto-Fill coupling (select models)

CAUTION: When the recovery tank reaches capacity,

an automatic float valve blocks vacuum intake (Fig.

5) and the vacuum motors will make a high pitched

noise. When this occurs, switch the machine off

immediately to prevent damage to the vacuum

motors.

10. When cleaning is completed, rinse solution tank with

clear water to ensure no detergents or rinse age nts

remain in the tank.

11. Empty and rinse the waste tank thoroughly. This will

help to prevent the formation of damaging deposits

and reduce the growth of odor-causing bacteria.

12. Turn on vacuum motor and allow it to run for 15

minutes to help remove any moisture from the

vacuum motors and help ensure long vacuum life.

1200MS OPERATING INSTRUCTIONS

IMPORTANT: Make sure to control foaming in the

vacuum system. Excessive foam can allow moisture,

carpet fiber and other debr i s to be drawn throu gh the

vacuum cutoff valve and cause damage to the vacuum

motors. Damage caused by moisture or debris will void

the product warranty. To help reduce foaming, use a

low-foam detergent. Foaming may also occur because of

residues left from previous cleanings . If this happens,

use a defoamer additive. Follow defoamer manufacturer

instructions for proper application.

1. Pre-mix cleaning solution with hot water in a

separate container. Pour mixed solution into the

solution tank of the machine or apply solution

directly to the cleaning surface as directed by

chemical manufacturer.

2. Connect vacuum and solution hoses to machine and

attach to extraction wand or hand tool.

3. Drain waste tank when full using gravity drain and

diverter (Fig. 7), or use the automatic pumpout

feature described below.

4. For auto-fill operation, attach fresh water supply to

freshwater inlet (Fig. 2J) and turn on water supply at

faucet. Tank will begin filling and automatically shut

off when full.

5. If auto-pumpout operation is desired, attach a

regular garden hose to auto-pumpout coupling (Fig.

D Product label and serial number I

07-02052E 4 VersaClean

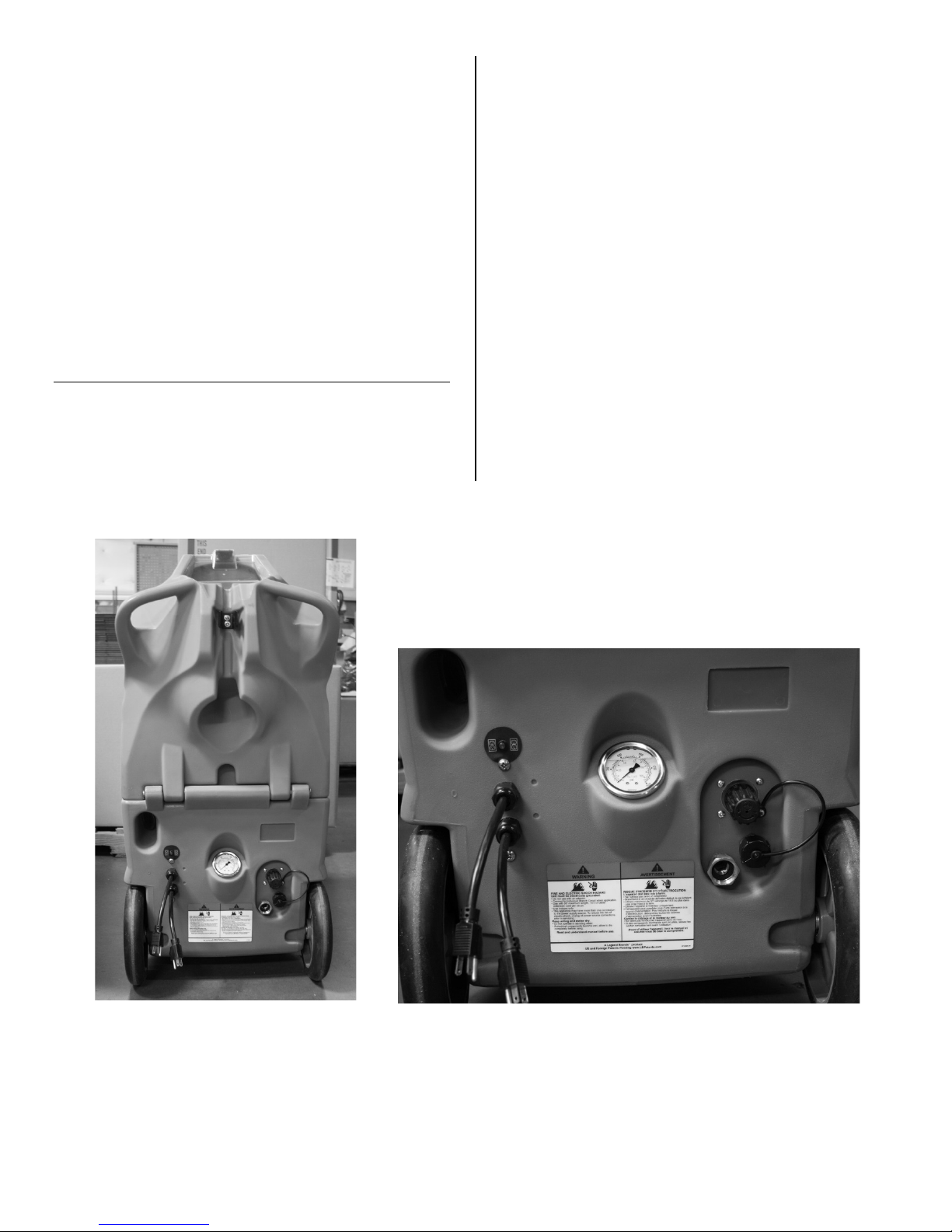

A

D

B

G

C

F

FIG. 3: Control Panel

E

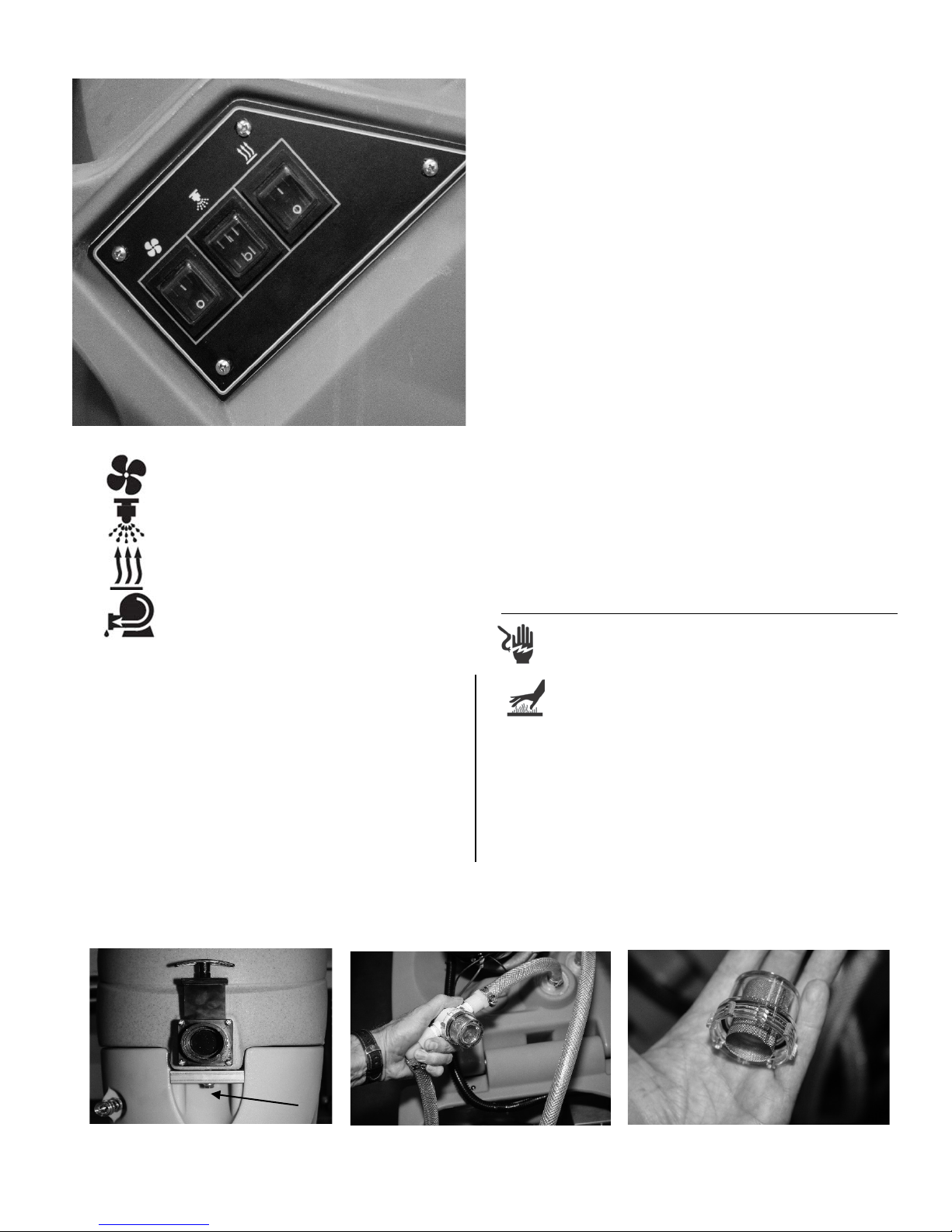

FIG. 4: Solution inlet filter cleaning

Remove

Unscrew

Rinse cap

9. If using the auto-pumpout feature, press the autopumpout switch (Fig. 3) to the On position.

10. Begin cleaning. Refer to industry-approved

procedures.

11. Solut ion pr es sur e m a y be adjusted w ith the pres s ure

regulator knob (Fig. 2H). Monitor the pressure gauge

to ensure pressure is adequate.

12. If not using the auto-pumpout feature, use the

gravity drain with divert er in place to empty waste

when tank is full (Fig. 7).

CAUTION: When the recovery tank reaches capacity,

an automatic float valve blocks vacuum intake (Fig.

5) and the vacuum motors will make a high pitched

noise. When this occurs, the machine should be

turned off immediately to prevent damage to th e

vacuum motor.

13. When cleaning is completed, rinse solution tank with

clear water to ensure no detergents or rinse agents

remain in the tank.

14. Empty and rinse the waste tank thoroughly. This will

help to prevent the formation of damaging deposits

Power ON/OFF

Solution pressure pump ON/OFF

Solution heater ON/OFF (select models)

and reduce the growth of odor-causing bacteria. Use

gravity drain to drain waste tank when full. Attach

diverter to direct flow downward (Fig. 7).

15. Turn on vacuum motor and allow it to run for 15

minutes to help remove any moisture from the

vacuum motors and help ensure long vacuum life.

Auto pumpout ON/OFF (select models)

2H), and place other end in suitable drain or large

container.

6. Insert both plugs into separate 3-pin grou nde d

circuits. Keep cords clear of your cleaning path. The

1200MS unit has two cords and each cord shou ld be

plugged into separate 3-pin grounded circuits. The

separate circuit indicator light will glow green (Fig.

2F) when the cords are properly connected.

7. Turn on VAC.

8. Turn on solution pump.

9/16 in.

nut with

wrench

and lift

open top.

MAINTENANCE (ALL UNITS)

WARNING: Unplug machine before servicing.

Possibility of electrical shock.

WARNING: Interior components may be hot

after operation. Let unit cool completely

before servicing.

DAILY OR AFTER EACH USE

Clean the solution inlet filter (Fig. 4) Loosen tank

attachment screw (Fig. 1) and open unit. Remove filter

cover and strainer screen (Fig. 4). Rinse strainer screen

clean in warm water. Replace strainer and retighten filter

cover.

inline filter

cap assembly

and remove.

and filter

assembly

clean and

reinstall.

07-02052E 5 VersaClean

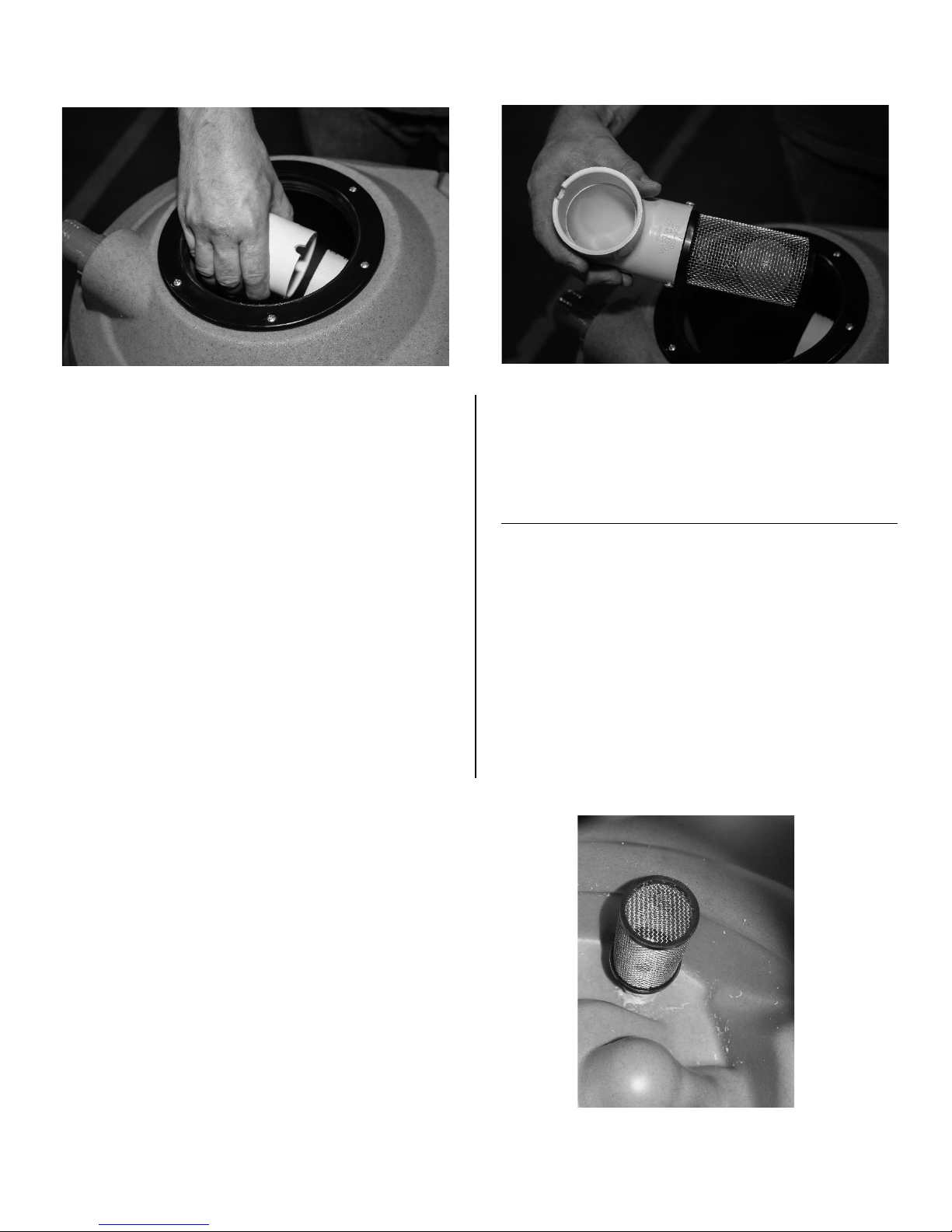

FIG. 5: Vacuum cutoff valve removal and cleaning

FIG. 6: Recovery tank strainer

Slide filter upward to remove. Rinse

filter clean with water and reinstall.

Clean vacuum ball float valve (Fig. 5). Empty recovery

tank, then open recovery tank lid. Grasp valve assembly

and pull gently toward the front of the unit, taking care

not to distort the strainer screen. Rinse assembly clean

and make sure float ball moves freely inside assembly.

Clean recovery tank strainer (Fig. 6, pumpout models

only). Remove strainer by gently rotating it and lifting

upward. Rinse filter clean with water and reinstall.

Reinstall strainer and vacuum ball float valve assembly

securely.

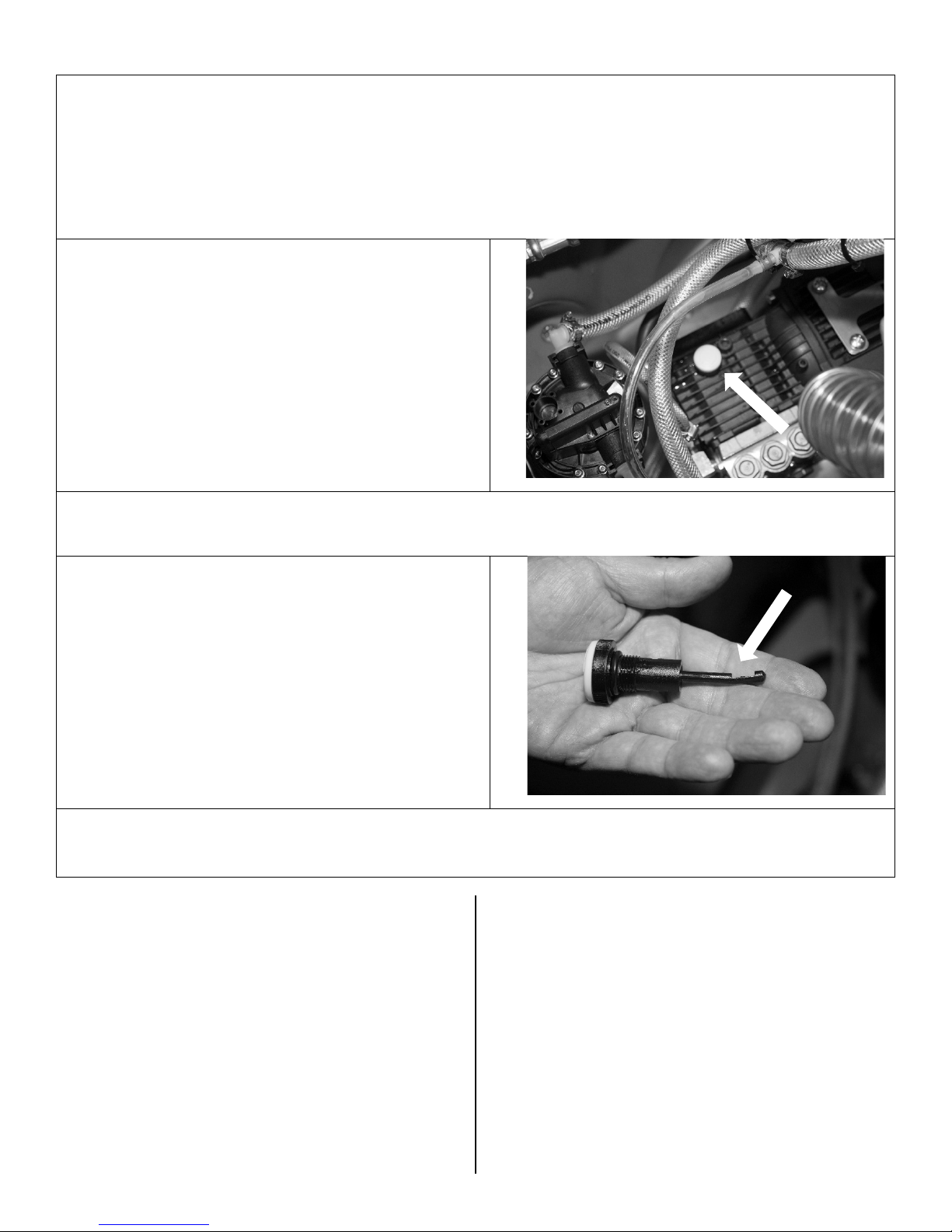

AS NEEDED

Lubricate pressure regulator O-ring (if equipped).

Access O-ring by unscrewing and removing pressure

regulator knob (Fig. 2H). Lubric ate wit h a suitable O-ring

lubricant.

Lubricate the solution line quick-connect coupling

(Fig. 1D) with a small amount of rust-inhibiting oil such

as LPS-3 or WD-40.

To maintain appearance, wipe interior and exterior

surfaces with a damp cloth. For deep cleaning and a

lasting, protective shine, use an aut omotive vinyl

cleaner/protectant produc t.

MAINTENANCE (1200MS ONLY)

IMPORTANT! Pump crankcase oil must be changed

after an initial 50-hour break-in period. Thereafter, oil

must be changed every 3 months or at 500 hour

intervals thereafter. Replace only with General Pump Oil

according to the pump model numbers listed below. SAE

30W. Order part no. 13-030/24-00490.

To change the oil, see "Changing the 1200MS Pressure

Pump Oil" below.

(pumpout models only)

07-02052E 6 VersaClean

Remove oil fill cap on pressure pump

Insert suction tube of transfer pump into oil fill hole. Pump out oil to a suitable waste / recycling receptacle.

After placing approximately 8 oz. of oil into the pump, check

t.

CHANGING THE 1200MS PRESSURE PUMP O IL

Tools required:

Manual transfer pump

Clean cloths

Suitable oil waste/recycling container

Verify both tanks are empty. Use a cloth to wipe out any residual moisture. Place clean cardboard or a pad behind unit

to protect handle. Remove retaining nut, hinge open unit and rest on pad.

Insert suction tube of transfer pump into bottle of fresh oil and pump approximatel 8 oz. of oil into pressure pump.

the oil level with the dipstick. Level should be within the

notched area on the dipstick. If necessary, add oil and

recheck with the dipstick until oil is at the correct level.

When filling is complete, reinstall install oil cap, close unit and reinstall retaining nu

The 1200MS is now ready for use.

07-02052E 7 VersaClean

Dispose of used oil appropriately.

ALL MODELS

Vacuum

motor

Solution / recovery tank 12 gal. | 37.9 l

Recovery tank: 10 gal. | 37.9 l

Rotomolded polyethylene housing and handle; 10 in. semipneumatic wheels.

Closed water

lift

One 25 ft. cord (non-heated units)

Two 1 ft. cords (select units) and two 14/3 25 ft. ext. cords

Drain valve

Gate type

Float shut-off

Ball type

Dimensions

(H × L × W)

Model

Features

Dry

weight

Amp draw

200

F439

200 PSI

73 lbs.

Circuit 1 13.5A

200H

F440

200 PSI

heater

80 lbs.

Circuit 1 14.2A

500

F441

500 PSI

94 lbs.

Circuit 1 13.5A

500H

F442

500 PSI

heater

102 lbs.

Circuit 1 14.2A

1200MS

F443

1000 PSI

111 lbs.

Circuit 1 12.5A

FIG. 7: Gravity drain diverter

SPECIFICATIONS

Capacity

Construction

Power cord

78-001

78-002

78-003

6.6 Ametek producing 659 peak air watts

137 in. | 348 cm

41.5 × 30.25 × 19.75 in. | 105.4 × 76.8 × 50.2 cm

33 kg

1750W

36 kg

42 kg

Circuit 2 12.5A

OPTIONS (PURCHASED SEPARATELY)

Wand and Vacuum Hose Kit (48-103): Wand, 25 ft. ¼ in.

solution hose and 25 ft. 1½ in. vacuum hose. HOSS-700

Rotary Cleaning Tool (67-025). Upholstery Pro (67-019)

78-004

78-005

1750W

43 kg

50 kg

Circuit 2 12.5A

Circuit 2 13.0A

07-02052E 8 VersaClean

Loading...

Loading...