versa INSERTO DOMINO XXS, INSERTO DOMINO USS, INSERTO SEAT DOMINO Series, INSERTO DOMINO US, INSERTO DOMINO UUS Product Technical Specification

...

www.versainserto.com

PRODUCT TECHNICAL SHEET

INSERTO SEAT DOMINO

This Technical Sheet is to be intended as an integral section of the Inserto Seat Range Instruction Manual.

Before use, it is essential for the professional operator to explain all procedures for a correct commissioning and

a proper maintenance.

1. Commissioning

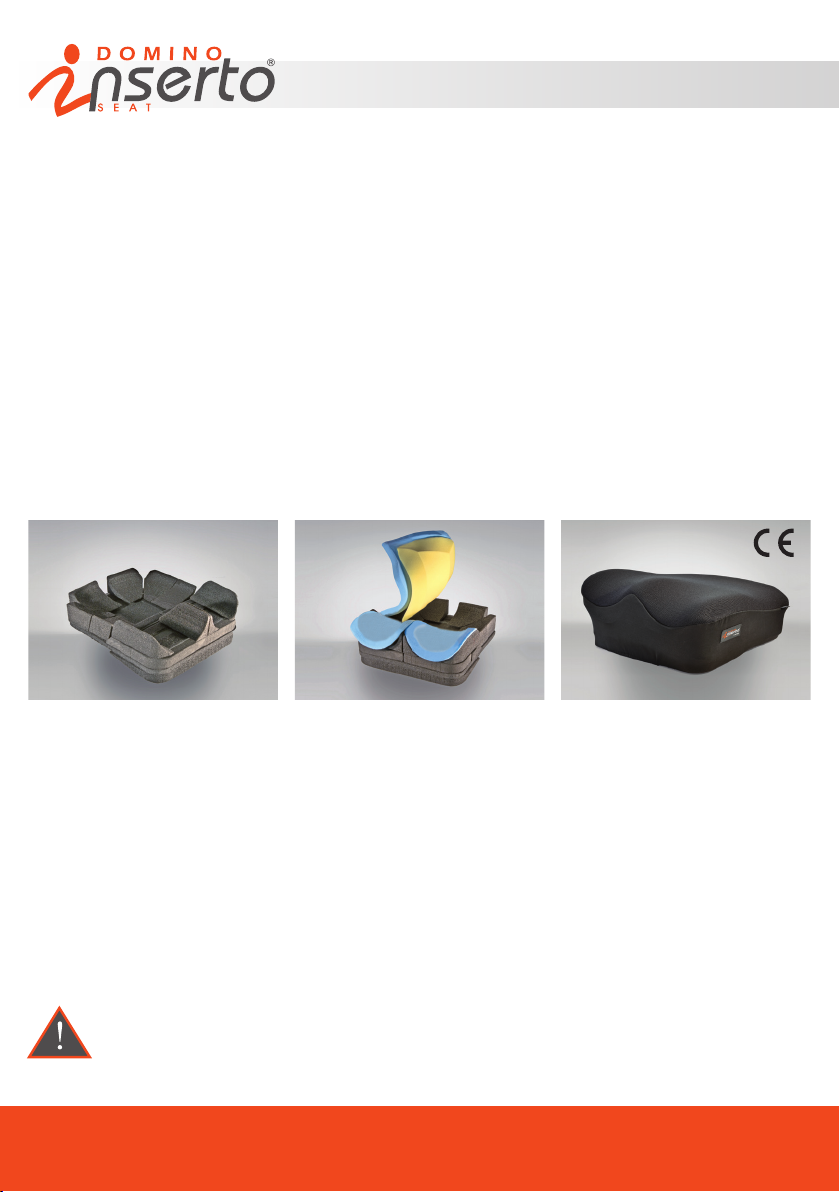

The pelvis positioning system Inserto Seat Domino of Inserto seat Range comes in a form of a kit:

1) A structural kit composed by a at base of construction and 17 closed cells polyethylene inserts, modular

and congurable, useful to individually support or correct the posture of the pelvis during the life time use;

2) A kit of padding (Free Shapes) composed as follows:

- in the posterior part by two overlapped pads: one superior pad made of an open celled foam with low spring

back action to enhance the maximum comfort and the best adaptation as to the body shapes weather to the

structural kit and an inferior pad of anti-decubitus memory foam for the highest protection from decubitus sores.

- in the anterior part by two independent pads (RH side and LH side) made of an open celled foam with low

spring back action to allow a natural position of the thighs.

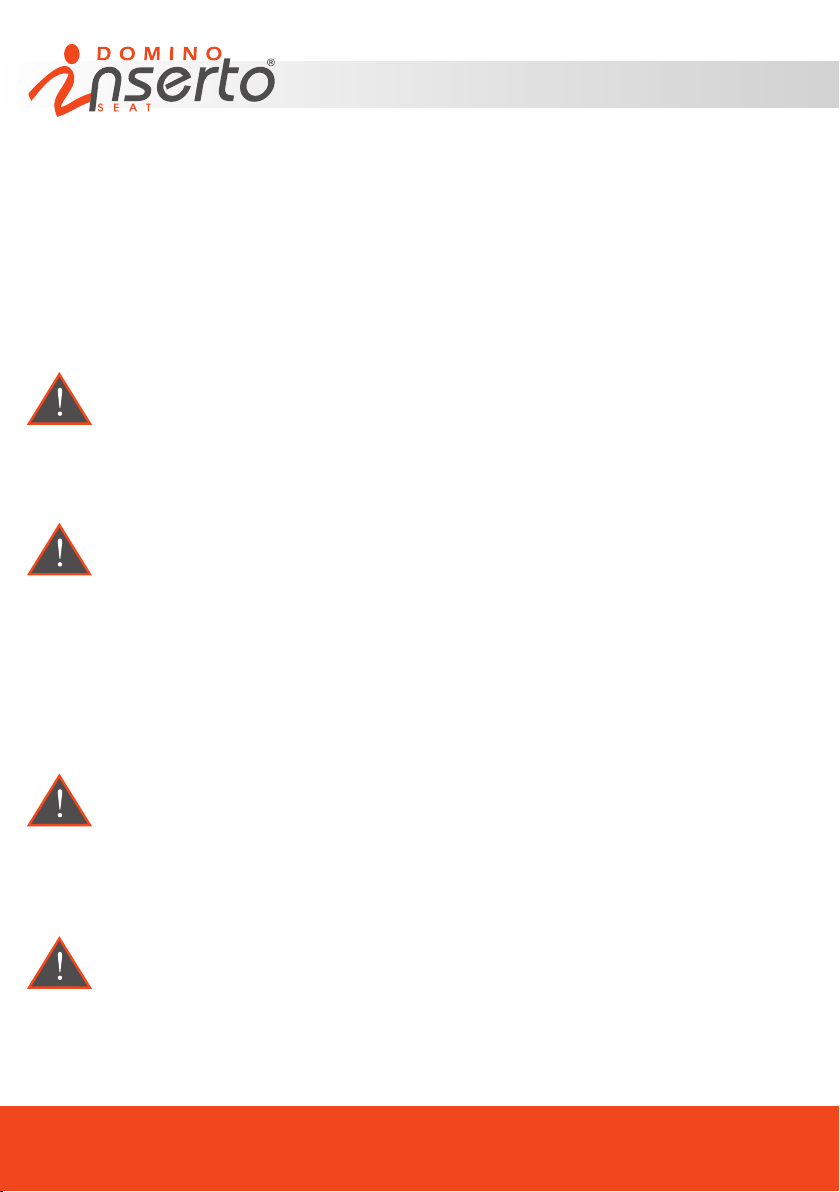

3) A cover, air-exchange and incontinent at the same time, made of three layers of different materials, latex

free, not ammable and at a low risk of skin irritation, commonly used in medical devices applications.

The pelvis positioning system Inserto Domino is recommended preferably, but not exhaustively, for users with

limited mobility, affected by severe deformities and having very high necessity of a postural containment, in

particular:

- Those who have leg length discrepancies, wind-swept, pelvic obliquity, pelvis rotation, anterior and posterior

pelvis tilt,adduction and abduction of the legs, of severe entities;

- Those who need to stabilise the ischium;

- Those who need trocantheric coccygeal-sacral suspension;

- Those having high risk to develop decubitus sores;

- Those who need to balance and contain legs/pelvis/rachis/ relationship system.

The pelvis positioning system Inserto Domino can be combined, by means of an adhesive gripping tape, to any

supporting base and/or wheelchair, provided that the structure will host the positioning system is solid enough

to safely support the user during the use.

Once the modications have been completed, such as removals, for the preparation and conguration

as per prescription of the seat individually customised to the perfect reconstruction of the anatomic

shape, the seat itself cannot be used by other users.

Page

PRODUCT TECHNICAL SHEET

01

www.versainserto.com

PRODUCT TECHNICAL SHEET

The Positioning System Inserto Seat Domino, in its design integrit and numerical and dimensional completeness

of the supplied components (structural kit, padding kit, cover) can be easily adapted to sizes/morphology/

deformities of the user. This kind of operations make the commissioning referable to a serial manufacturing

device.

Alternatively

The commissioning of the Positioning System Inserto Seat Domino, deprived or modied, even partially, of

its design integrity of numerical and dimensional completeness of the supplied components, built as per written

prescription of a professional operator in function of the anatomy/morphology/deformities of the user, through

the measurement detection and direct trials, can be referable to a custom-made device.

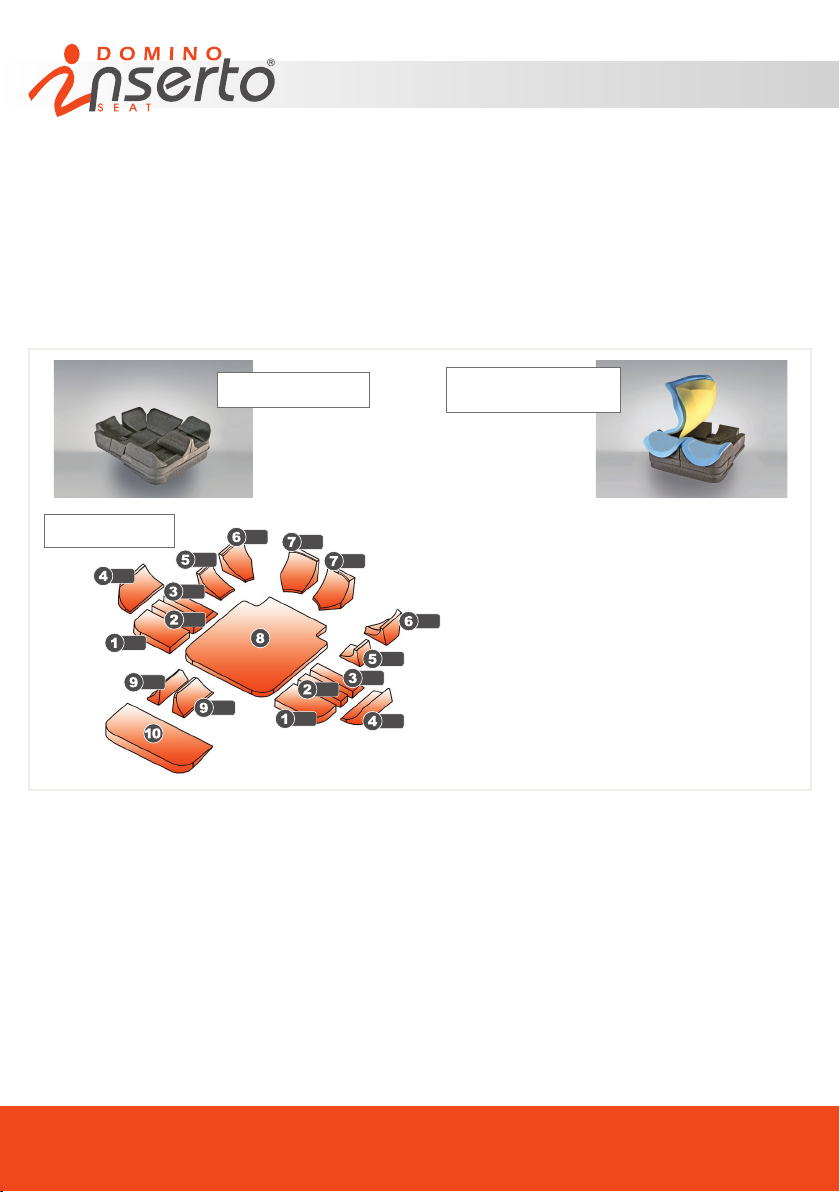

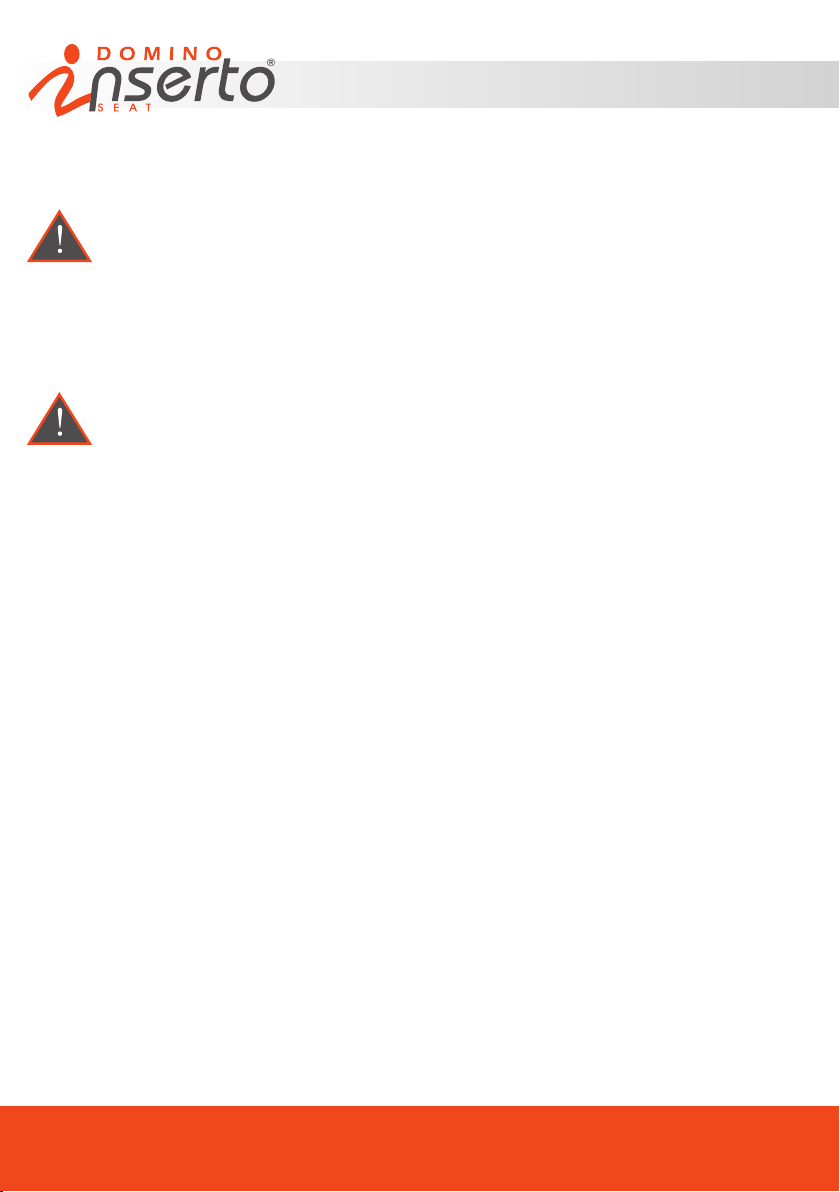

Pic.3 Pre-assembled Kit

+ padding Kit

01) Anterior insert for thighs position

02) Medial anterior insert for thighs position

03) Trapezoidal posterior insert for thighs position

04) Adductor insert

L

05) Medial hip guide insert

06) Pelvis guide insert

07) Buttock guide insert

08) Flat base of construction

09) Abductor insert

10) Leveling insert

Pic. 2 kit of inserts

R

R

R

Pic.1 Pre-assembled

structural kit

R

R

R

R

L

Inserto Domino

17 MODULAR CONFIGURABLE INSERTS

R

L

L

L

L

L

L

The structural kit of Inserto Domino is composed by a at base of construction and numerous inserts that can be

customised, shaped, modied as needed (Pic.1) and (Pic.2). Each element of the structural kit is supplied with

male/female hooks and loops tape that strongly x the inserts to the at base of construction. The preparation of

the pelvis positioning system shape, based on the prescription and the user’s anatomy and morphology, is done

through the detection of measurement and direct trials, therefore it has to be carried out as follows in order to

ensure a proper commissioning.

SUGGESTIONS RELATED TO SOME OPERATIONS

Positioning the gripping Tape

If it is necessary to replace or add the gripping hook and loops tape on one or more inserts of the structural kit,

please use the extra tape supplied in the packaging.

Page

PRODUCT TECHNICAL SHEET

02

www.versainserto.com

PRODUCT TECHNICAL SHEET

In order to do so: remove the adhesive lm and stick the tape rmly on the insert to attach. Therefore, check

for the correct placement. If it is correct remove the tape, taking care to heat the adhesive part for few seconds

by using an industrial hot hair dryer at temperature of around 100° (212°F), then reposition the tape denitely.

Be careful not to damage the materials during this operation

Modifying the Structural kit Inserts

The modications of reduction of the inserts by removal of material where necessary, will be implemented by

cutter. If it is necessary to reconstruct the modied component (where the removed material makes it possible)

use an industrial hot air dryer at a temperature of around 100 ° (212°F) to heat and weld together the two parts

to be recomposed.

Be careful not to damage the materials during this operation

1) Accurately detect the measurements of the user and of his wheelchair/mobility device;

2) Remove the cover;

3) Remove the padding;

4) Dispose the position thighs inserts (3,2,1) on the at base of construction (8) in order to match the distance

ischium RH/LH – popliteal cave RH/LH (-2,5 cm. -0.98”) with the length of the seat obtained by the their

combination for both left and right hand sides.The combination of the distribution and direction of the thighs

inserts may be different for the right hand side and the left hand side.

It should be noted that the function of the at base of construction (8) is to provide a supporting base between

the wheelchair / mobility device, as well as the primary structure of the construction kit on which to build or adapt

the positioning system by using, removing or modifying, as necessary and as required by the prescription, all

other inserts supplied with the construction kit.

INDICATIONS FOR THE LENGTH OF THE SEAT

It is possible to reach the desired seat length by operating on the at base of construction only (8) (see point a),

or on the at base of construction and consequently on the set of inserts supplied in the structural kit (see point

b), or on the inserts of the structural kit only (see point c).

a) Flat Base of construction: The at base of construction (8) has its own sizes accordingly to the size of the

positioning system chosen and have posterior notches of 5 cm.(1.96”) wide by 6 cm. (2.36”) deep.

Therefore it is possible to make it slide between the back rest tubes of the wheelchair /mobility device, once it

has been positioned on the cloth of the seat, in order to reduce its depth up to 6 cm. (2.36”).

If the length achieved is not enough and it is preferable to maintain the entire length of the at base or the user

has an irregular morphology and anthropometric measurements (i.e. leg length discrepancy), it is possible to

reduce the effective length of the at base (8) as needed, by removing the portion of exceeding material with a

cutter horizontally along the entire front or a part of it so as to make it asymmetrical.

b) Flat base of construction and consequently the set of inserts supplied:

Having carried out the above operation as necessary, it may be advisable to make a dimensional adjustment

of the depth measurement of the individual inserts supplied with the structural kit by removing the necessary

material using a cutter.If it is necessary to reduce the depth of the buttock guide inserts (7) remove only a

small part of material, horizontally along the posterior surface, in order to avoid affecting the pelvic contour. It is

Page

PRODUCT TECHNICAL SHEET

03

www.versainserto.com

PRODUCT TECHNICAL SHEET

suggested to keep the part of material removed, if not damaged, as occasionally, afterwards can be reused to

adapt the device to user’s changes.

Alternatively it can be suitable a placement of the inserts on the at base of construction (8) by removing the

exceeding inserts; alternatively both operations can be adopted.

If it is necessary to increase the useful length of the seat depth for one or both legs, one or both rows of thighs

position inserts (1,2,3) can be placed longitudinally along the at base of construction (8) and leave between

them the necessary distance in order to reach the desired total length. For this purpose, a measurement up to

2,5 cm. (0.98”) longer than the actual length measurement of the at base of construction can also be obtained.

This can be achieved by positioning longitudinally one or both the anterior thigh positioning inserts (1) on the

at base of construction, with their front portion out of it for a maximum of 2,5 cm. (0.98”) and the rear portion

connected to the surface of the at base by a hooked gripping tape.

c) Set of inserts supplied:

It may be appropriate to make a dimensional adjustment of the measurement of depth of the individual inserts

supplied with the structural kit by removing the necessary material using a cutter. If it is necessary to reduce

the depth of the buttock guide inserts (7) ) remove only a small part of material, horizontally along the posterior

surface, in order to avoid affecting the pelvic contour.It is suggested to keep the part of material removed if not

damaged by removal, occasionally, afterwards it may be reuse in order to adapt the device to the modications

made to the user.

Alternatively it can be suitable a placement of the inserts on the at base of construction (8) by removing the

exceeding inserts; alternatively both previous operation can be adopted. If it is necessary to increase the useful

length of the seat depth for one or both legs, one or both rows of thighs accommodation inserts (1,2,3) can be

placed longitudinally along the at base of construction (8) and leave between them the necessary distance in

order to reach the desired total length. For this purpose, a measurement up to 2.5 cm (0.98”) longer than the

actual length measurement of the at base of construction can also be obtained. What above can be achieved

by placing the anterior thighs positioning inserts (1) longitudinally along the at base with the anterior portion out

of it for a max. of 2,5 cm. (0.98”) and the posterior portion attached to the at base through a hooked gripping

tape.

Please be aware that any depth customisation of the kit must be made by considering the harmony

of the support and the compatibility with the wheelchair/mobility device with particular reference to

the variables to the height and inclination of the footplates, depth of the seat cloth, inclination of the

seating plan

5) Dispose the pelvis guide inserts (6) so as to match the width of the pelvis with the width of the seat obtained

by their combination. It is suggested to accomplish this operation by preparing the inserts (6) directly with the

user seated on the structural kit in order to better align the above inserts. During this operation make sure that

the distance between the pelvis guide inserts (6) is increased of 1,5 cm (0,59”) per side with respect to the width

of the user’s pelvis, in order to allow the perfect t when the padding is applied.

It should be noted that the function of the at base of construction (8) is to provide a supporting base between

the wheelchair / mobility device, as well as the primary structure of the construction kit on which to build or adapt

the positioning system by using, removing or modifying, as necessary and as required by the prescription, all

other inserts supplied with the construction kit.

Page

PRODUCT TECHNICAL SHEET

04

www.versainserto.com

PRODUCT TECHNICAL SHEET

INDICATIONS FOR THE WIDTH OF THE SEAT

It is possible to reach the desired seat width by operating only on the at base of construction (8) (see point a),

or on the at base of construction and consequently on the inserts of the structural kit (see point b), or on the

inserts of the structural kit only (see point c).

a) Flat base of construction: The at base of construction (8) has its own sizes accordingly to the size of the

positioning system chosen.

In order to insert the base on the cloth of the seat and reach the consequent compatibility with the width of the

wheelchair/mobility system, it is possible to remove a portion of material from the sides of the base up to total 2

cm. (0.78”) by using a cutter.

b) Flat base of construction and consequently the set of inserts supplied:

After having carried out the operation of point a) it may be necessary to make dimensional adjustment of the

width of the individual insert supplied with the structural kit, by removing the necessary material using a cutter.

It is suggested to remove a small portion of material from the outer edges (max. 1 cm. –0.39”) in order to avoid

affecting the concave design (4.5.6) and along the inner edges (9). Regarding the at inserts (1.2.3) perform

this operation along the longitudinal inner edges, for the buttock guide inserts (7) perform the operation along

the inner longitudinal edges.Alternatively it can be suitable the placement of the inserts on the at base of

construction (8) by removing the exceeding inserts; alternatively both previous operation can be adopted.It is

suggested to keep the part of material removed if not damaged by removal, occasionally, afterwards it may be

reused in order to adapt the device to the modications made to the user. If it is necessary to reduce the depth

of the buttock guide inserts (7), remove only a small portion of material in order to avoid affecting the concave

or convex curves. If it is necessary to increase the useful length with respect of all sizes dened for each model,

it is possible to protrude each insert of the structural kit up to 1 cm (0,39”) out of the at base of construction.

c) Set of inserts of the structural kit:

It also may be appropriate to operate a dimensional adjustment of the width of each insert of the structural kit

by removing the necessary material using a cutter. It is suggested to remove a small portion of material along

the outer edges (max. 1 cm. – 0.39”) in order to avoid affecting the concave or convex curves where present

(4.5.6) and along and along the inner edges (9).Regarding the at inserts (1.2.3) perform this operation along

the longitudinal inner edges, for the buttock guide inserts (7) perform the operation along the inner longitudinal

edges. If it is necessary to reduce the depth of the buttock guide inserts (7), remove only a small portion of

material horizontally, in order to avoid affecting the concave or convex curves. It is suggested to keep the part

of material removed if not damaged by removal, occasionally, afterwards it may be reused in order to adapt

the device to the modications made to the user. Alternatively it can be suitable the placement of the inserts on

the at base of construction (8) by removing the exceeding inserts; alternatively both previous operation can

be adopted. If it is necessary to increase the useful length with respect of all sizes dened for each model, it is

possible to protrude each insert of the structural kit up to 1 cm (0,39”) out of the at base of construction.

6) Place the other inserts as necessary

NOTE: The relation of the thrust, levelling and adhesion to the user’s morphology exerted by the

combined and harmonious use of each insert, enables the alignment and the postural compensation,

as well as the distribution of the body loads along all the sitting surface. Use any useful insert among

those supplied in order to achieve the compensation, support and posture correction and the

individual seat most suitable to match the anatomic shapes of the user.

PRODUCT TECHNICAL SHEET

Page

05

www.versainserto.com

PRODUCT TECHNICAL SHEET

7) Cover the structural kit with the padding by adjusting it as shown in Pic. 3.

8) Place the cover back onto the structure. There are elastic sides that can be securely positioned by pulling

the drawstring provided.

9) Once the pelvis positioning system has been assembled, have the user to be seated at least for one hour

and verify if the new seat is causing pressure redness on the skin. If this happens it is recommended to adopt

the most suitable interventions in accordance to the specics dened for the user by the professional operator

under his sole responsibility. On a contrary case, instead, proceed with the delivery of the product to the user.

10) It is advisable to keep documentary records of each operation carried out, as well as to provide the user with

any deprived/removed parts which can be useful for after delivery interventions and/or adjustments.

Before to use the product have the professional user to show the procedures for a correct commissioning and

maintenance.

It is strongly recommended to periodically check the skin of the user in order to verify any risk of

redness appearance.

11) When all operations of preparation of the kit to the shape and measures of the user have been accomplished

and the positioning system is ready to be delivered, it is possible to remove the excess of padding from the

edges by using a cutter. Take care to follow the direction of the cut as in the original design.

In relation to the modication, processing and / or adaptation operations carried out on the structural

kit and padding, the upper surface of the cover could result larger compared to the dimensions of the

seating conguration obtained. Take care to spread the surface well when the user is sitting, in order

to avoid wrinkles

2. Maintenance and cleaning

In order to avoid the development of infections, it is recommended to perform a careful cleaning every 2 weeks

and/or, if needed, check the pelvis positioning system in all its parts by avoiding malfunctions. Regarding the

cleaning of the padding, even if there is no direct contact with the skin, it is suggested to use a dump cloth or a

brush with natural bristles and warm water (max 60°C – 140°F), with the addition of a light gentle detergent, by

rubbing in a circular motion. Then rinse with water. Wipe out the excess of water from the padding by using a

dry cloth and dry away from heat sources. Do not expose the padding to the sun rays. Occasionally it can be

also wash in the washing machine, at max 30°C (86°F), by using a light detergent and centrifuge at a low spin.

The drying time is quite long; it is suggested to be equipped of an additional kit of padding.

The removable cover can be washed as it follows:

- Hand wash and then air dry;

- Washing machine (max temperature 60°C – 140°F) with the addition of a gentle detergent, bleach free, then

centrifuge at a low spin.

It is advisable to use a protective wrapping before inserting in the washing machine in order to avoid

any tearing of the lm provided in the cover. It is suggested to be equipped of an additional cover.

Page

PRODUCT TECHNICAL SHEET

06

www.versainserto.com

PRODUCT TECHNICAL SHEET

For additional information, please contact our technical-Sales Department at the following number:

+39 0831 777840

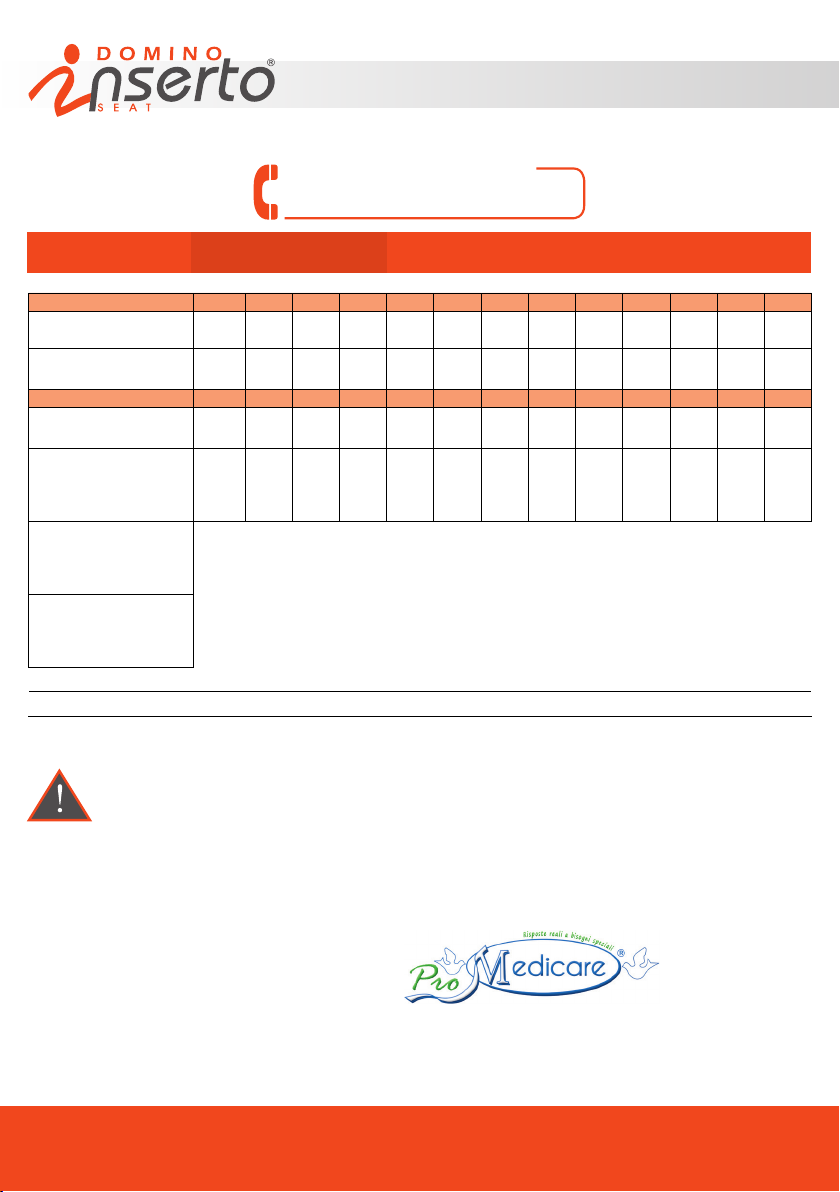

INSERTO DOMINO

SIZES TABLE

MODEL UUS USS US XXS XS XS1S XS1 S M M1S M1 L XL

Effective width (cm) 25 30 30 36 36 40 40 42 42 45 45 48 48

Max width achieved with

adaptation (cm)

Min. width achieved with

removal of material (cm)

Effective length (cm) 30 30 38 38 42 40 45 45 50 45 50 45 50

Max. length achieved

with adaptation (cm)

Min. length achieved with

adjustment through

seat notches and

removal inserts (cm)*

Min. and max. range of

anterior height of

at base of construction+

insert 1/2/3 (cm)**

Min. and max. range of

posterior height of at

base of construction +

insert 7 (cm)**

Weight of positioning system (min/max): 0,7 kg/2,8 kg

PAEDIATRIC ADULT

27 32 32 38 38 42 42 44 44 47 47 50 50

23 28 28 34 34 38 38 40 40 43 43 46 46

32,5 32,5 40,5 40,5 44,5 42,5 47,5 47,5 52,5 47,5 52,5 47,5 52,5

24 24 32 32 36 34 39 39 44 39 44 39 44

4/5,5 ** height referred to models UUS and XL

8,5/11,5 ** height referred to models UUS and XL

SIZES (cm.)

Max load (referred to model XL 48cm x 50cm): 135 kg

* possible and further reductions due to removal of material

Any operation of removal, preparation or adjustment for the specic user, on the basis of a prescription, have to

be performed by a professional operator and those interventions get the device customised. The professional

user has the charge and the responsibility to guarantee the efcacy and the performances of the device

Labeling

Below it is reported the description of the product as it is shown on the CE Label:

- The complete name of the device is: Seat VERSA INSERTO DOMINO size Xx

- The name of the product shown on the label is: VERSA INSERTO D. size Xx where D stays for Domino

MANUFACTURED BY:

COMPANY CERTIFIED WITH QUALITY MANAGEMENT SYSTEM ISO 9001 / EN ISO 13485 BY BUREAU VERITAS S.P.A.

Via Montagna Z.I. - Lotto 41 72023 Mesagne (BR) - ITALY

Tel. +(39) 0831 777840 - Fax. +(39) 0831 730739 - Email: sales@promedicare.it

www.versainserto.com - www.promedicare.eu

PRODUCT TECHNICAL SHEET

SCH.TEC.PRO.INS.SEA.DOM. EN Rev.5 - 04/2018

Page

07

Loading...

Loading...