Verona WALL HUNG GAS BOILER User Manual

A

INSTRUCTIONS

Riva HEAT ONLY

WALL HUNG GAS BOILER FOR

CENTRAL HEATING SUPPLY

Please Read Instructions Carefully

Save for Future Reference

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you can not reach your gas supplier call the fire department.

— Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Manufactured by:

Biasi S.p.A.

Verona, Italy

Quincy Hydronic Technologies, Inc.

80 Rochester AVE. Suite # 12

Distributed By:

Portsmouth, NH 03801

Phone: 603-334-6400

Fax: 603-334-6401

BOILER INSTALLATION, OPERATION

RIVA HEAT ONLY MANUAL - REV

RIVA HEAT ONLY MANUAL - REV A

2

Dear Customer:

Thank you for buying a Biasi Riva Heating Only Boiler System.

The Riva Heating Only is a high efficiency, non-condensing, wall mounted gas boiler

which provides central heat supply water.

We realize that it is not possible to answer all questions about the Riva boiler system in

this manual. Reading this installation manual does not make the reader an expert in all

aspects of installation and operation, and does not replace the need for a qualified,

licensed heating contractor. We urge you to contact your installing contractor or distributor

if you are in question about any aspect of your boiler's performance. Our main concern is

that you are satisfied with your boiler and its performance. We require that your contractor

complete efficiency tests using instruments.

The external controls and accessories listed in this manual (excluding those supplied

inside the boiler) are intended to serve as guidelines rather than specific

recommendations. We realize that other makes and models of such devices are available

and can be used as successfully as those we specify. The installing contractor is the best

judge of a system's specific requirements, as well as the local availability of certain makes

and models of controls and accessories. The preceding does not apply, however, to the

equipment that comes with every boiler, such as the overheat control and pressure relief

valves. The installation of the specific devices supplied with every boiler is

absolutely necessary to the safe operation of the boiler and protection of the

heating system.

All BIASI wall hung boilers are built in accordance with the ASME boiler and pressure

vessel code, and bear the "H" stamp. The Entire range of applications for the Riva boiler

has been tested to standard CSA 4.9 and is CSA compliant.

This Riva Heating Only boiler has a 2 year warranty, a copy of which is provided with the

boiler. Please be sure to return the warranty registration card as the warranty will be void

without your boiler's serial numbers (located on the ratings label affixed to the boiler), date

of installation and the name of your installer being on record in our files.

Thank you for purchasing our Riva Heating Only boiler. If you have questions or

comments, please don't hesitate to contact us immediately. Our goal is 100% customer

satisfaction.

QHT inc.

RIVA HEAT ONLY MANUAL - REV A

3

Table of Contents

Section Title Section Number Page Number

Warnings - 6-7

Important Information - 8

General Information 1 9

Technical Information (M130.30CR) 2 9-10

Parts List 3 11

Internal Piping and Parts List 4 12

Electric Diagrams 5 13

Installation Location 6 14

Exhaust Pipe Location 7 15

Mounting Bracket 8 16

Venting 9 17-20

Restrictor Sizing 9.1 17

Fitting the Flue System 9.2 17

Choice of Flue 9.3 18-20

Pipe Connections 10 21

Gas Pipe Connections 11 22

Electrical Connections/Wiring 12 23-25

Power Connection 12.1 23

Connection to the Electricity Supply 12.2 23

Room Thermostat Connection 12.3 24

Relay Panel Control Connection 12.4 24

Zone Valve Microswitch Connection 12.5 25

Circulator Sizing 13 26

Circ. Cap. as a Function of Flow Rate 13.1 26

Expansion Vessel 13.2 26

Piping 14 27-29

Primary-Secondary Piping 14.1 27

Primary-Secondary with Zone Valves 14.2 28

RIVA HEAT ONLY MANUAL - REV A

4

Table of Contents

Section Title Section Number Page Number

Manifold Piping with Zone Valves or Circ. 14.3 29

Commissioning 15 30-35

Initial Filling of the System 15.1 30

Lightning the Boiler 15.2 30

Checking the Gas Pres. at the Burner 15.3 31

Adjustment of the Gas Pressure 15.4 32

Checking the Ignition Device 15.5 32

Checking the Burner Ignition 15.6 33

Adjustment of the Useful c.h. Output 15.7 33

Labels Placement 15.8 34

Checking the Flue System and Comb. 15.9 35

Instructing the User 15.10 35

Gas Conversion 16 36

Annual Maintenance 17 37-38

Warnings 17.1 37

Dismantelling the External Panels 17.2 37

Emptying the C.h. System 17.3 37

Cleaning the Primary Heat Exch. 17.4 37

Checking the Pressuris. in C.h. Vess. 17.5 38

Cleanig the Burner 17.6 38

Checking the Flue 17.7 38

Visual Inspection of Appliance 17.8 38

Gas Pressures and Soundness 17.9 38

Installer Notes 18 39

RIVA HEAT ONLY MANUAL - REV A

5

W

Boiler is certified as an indoor appliance. Do not install boiler outdoors or locate where

it will be exposed to freezing temperatures.

— Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

— Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Caution: Do not store or use flammable materials, chemicals or flammable

liquids, especially gasoline, in the vicinity of this heating appliance.

WARNING: If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you can not reach your gas supplier call the fire department.

ARNING

DANGER

RIVA HEAT ONLY MANUAL - REV A

6

W

Any appliance that burns natural gas, propane gas, fuel oil, wood or coal is capable of

producing carbon monoxide (CO). Carbon Monoxide (CO) is a gas which is odorless,

colorless and tasteless but is very toxic. CO is lighter than air and thus may travel

throughout the building.

Symptoms of CO poisoning include the following:

The symptoms of CO poisoning are often confused with those of influenza, and the

highest incidence of poisoning occurs at the onset of cold weather or during flu season.

A victim may not experience any symptoms, only one symptom, or a few symptoms.

Suspect the presence of carbon monoxide if symptoms tend to disappear when

you leave your home.

The following signs may indicate the presence of carbon monoxide:

• Hot gasses from appliance, venting

system pipes or chimney, escaping into

the living space.

• Flames coming out around the appliance.

• Yellow colored flames in the appliance

If any of the symptoms of CO occur, or if any of the signs of carbon monoxide are

present, VACATE THE PREMISES IMMEDIATELY AND CONTACT A QUALIFIED

HEATING SERVICE COMPANY OR THE GAS COMPANY OR THE FIRE

DEPARTMENT.

ONLY QUALIFIED, LICENSED SERVICE CONTRACTORS SHOULD PERFORM

WORK ON YOUR BIASI RIVA HEAT ONLY BOILER.

BRIEF EXPOSURE TO HIGH CONCENTRATIONS OF CO, OR

PROLONGED EXPOSURE TO LESSER AMOUNTS OF CO MAY

RESULT IN CARBON MONOXIDE POISONING. EXPOSURE CAN BE

FATAL AND EXPOSURE TO HIGH CONCENTRATIONS MAY RESULT

IN THE SUDDEN ONSET OF SYMPTOMS INCLUDING

dizziness vision problems shortness of breath

headache loss of muscle control unclear thinking

nausea weakness unconsciousness

ARNING

UNCONSCIOUSNESS.

• Stale or smelly air.

• The presence of soot or carbon in or

around the appliance.

• Very high unexplained humidity inside

the building.

RIVA HEAT ONLY MANUAL - REV A

7

IMPORTANT INFORMATION

Please read this page carefully.

• ALL BOILERS MUST BE INSTALLED IN ACCORDANCE WITH NATIONAL,

STATE AND LOCAL PLUMBING, HEATING AND ELECTRICAL CODES AND

ORDINANCES, AS WELL AS THE REGULATIONS OF THE SERVING

ELECTRICAL, WATER AND GAS UTILITIES.

• All systems should be designed by competent contractors, and only persons

knowledgeable in the layout and installation of heating systems should

attempt the installation of any boiler. It is the responsibility of the installing

contractor to see that all controls are correctly installed and operating

properly when the installation is completed.

• This boiler is intended for use, only with propane or natural gas. All

flammable liquids (especially gasoline), chemicals, rags, paper, wood

scraps, debris, etc., should be kept away from the boiler at all times. Keep

the boiler area clean and free of all fire hazards.

• Please read the literature and warranties supplied by the manufacturers of

the various accessory equipment. This equipment is warranted by the

respective manufacturers, not by Quincy Hydronic Technologies, Inc. Each

piece of equipment must be installed and used according to the

recommendations of the manufacturer.

Codes and Regulations:

Installation of the boiler and related equipment must conform to national, state and

local regulating agencies and codes applicable to the installation of the equipment. In the

absence of local requirements, the following codes apply:

The above codes are available from:

National Fire Protection Association (NFPA)

Battery March Park

Quincy, Massachusetts, 02269

http://www.nfpa.org

A. ANSI/NFPA - #70 National Electric Code

B. ANSI/NFPA - #211 Chimneys and Vents

C. ANSI/NFPA - #Z223.1 National Fuel Gas Code

C. ANSI/NFPA - Domestic Gas Conversion Burner

D. CAN/CGA - B149 Installation Codes

E. ANSI/ASME - CSD-1

CSA International

8501 E. Pleasant Valley Road

Cleveland, OH 44134-5575

http://www.csa-international.org

RIVA HEAT ONLY MANUAL - REV A

8

1. General Information

The Riva Heat Only is a high efficiency, non-condensing, wall mounted gas boiler

which provides central heat. The boiler features a gas valve which modulates the energy

input from 44,000 BTU/h to 108,000 BTU/h. The boiler is shipped fully assembled with the

components listed on page 11. All units are pressure and combustion tested at the factory

prior to shipping.

Key Features:

• Wall mountable - saving valuable floor

space.

• Several flue options available

• Electronic spark ignition

• Safety flow switch - positioned on the

main circuit, which monitors the flow

and protects the main heat exchanger

from thermal shock should there be a

lack of water in the system.

• Frost protection - contains an integral

frost protection system to prevent frost

damage which can occur in areas

susceptible to very cold weather

conditions.

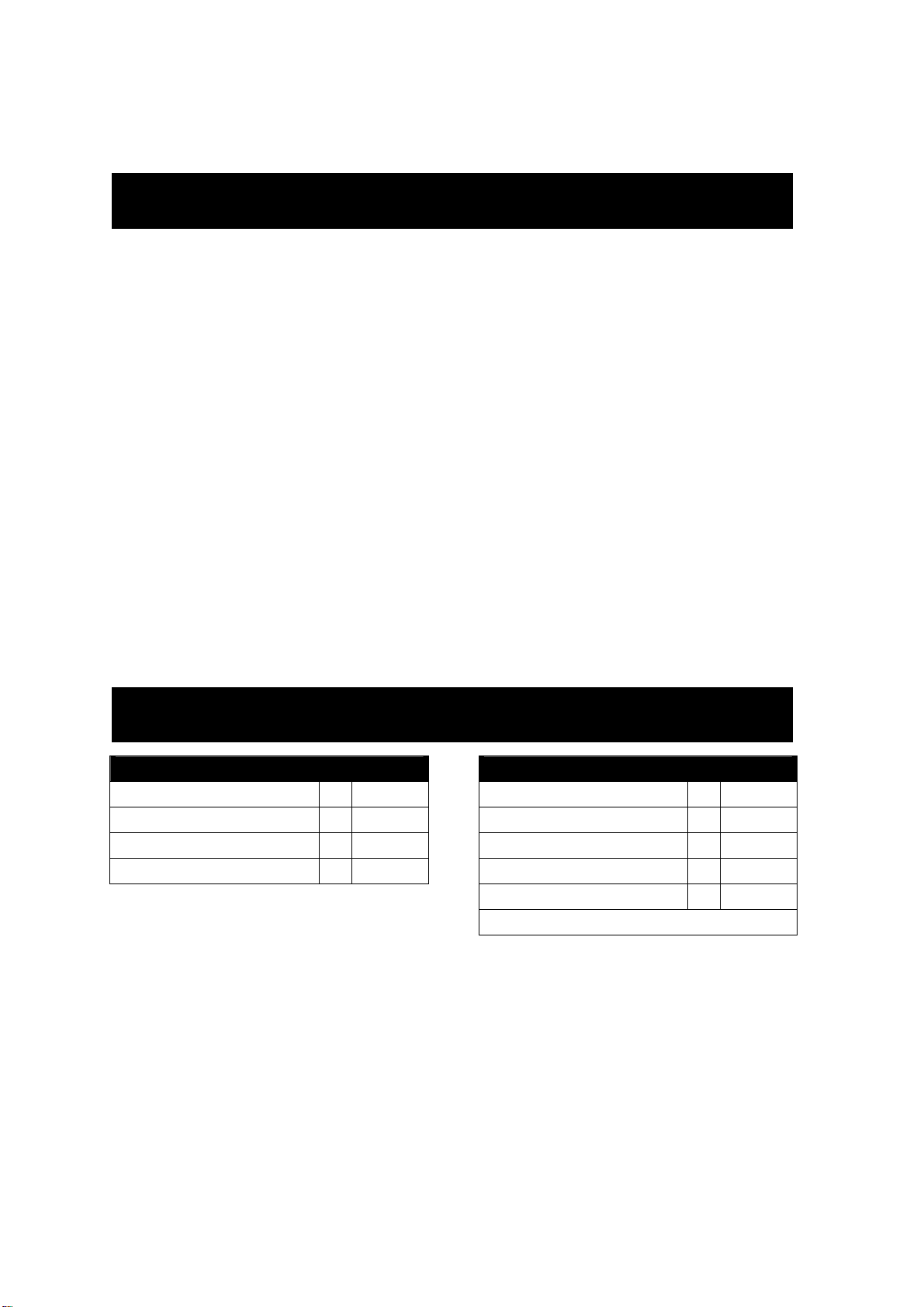

2. Technical Information (M130.30CR)

GENERAL

Height in

Width in

Depth in

Weight lb

27.7

15.7

12.8

79.4

• Boiler operation recognition system should the boiler not be used for

longer than 24 hours, it then performs

a controlled system test to ensuring

the motorized components within the

boiler do not become inoperable due

to lack of use.

• Gas valve modulation - the gas input

modulates based off central heating

temperature to within ± 2 ºF

• Diagnostic information system

equipped with three LED diagnostic

lights for quick error assessment.

CENTRAL HEATING

Maximum working temp. °F

Temp. Regulation range* °F

Maximum pressure psi

Minimum pressure psi

Max head loss (at 4.4 GPM) ft

*At the minimum useful output

185

100-176

30.0

4.35

10

RIVA HEAT ONLY MANUAL - REV A

9

2.Technical Information Cont.

ENERGY CAPACITY

Nominal heat input

(0/2000ft)

Nominal heat input

(2000/4500ft)

Minimum heat input MBH 49.5

Maximum useful output

(0/2000ft)

Maximum useful output

(2000/4500ft)

Minimum useful output MBH 37.0

MBH 122.8

MBH 116.7

MBH 100.7

MBH 95.9

INJECTORS No. Size

Natural 14 130

Propane 14 89

GAS FLOW RATE

Gas Min Max

Natural ft³/h 48.7 121.1

Propane lb/h 2.23 5.55

ELECTRICAL

Voltage V 120

GAS SUPPLY PRESSURE

Gas Normal Min Max

Natural inwc 7.0 3.5 10.5

Propane inwc 11.0 8.0 12.0

GAS PRESSURE AT BURNER

Gas Min Max Ignition

Natural inwc 0.8 5.3 2.4

Propane inwc 1.4 9.0 5.2

FLUE DESIGN

Minimum Venturi pressure inwc 0.64

Flue pipe diameter

Coaxial in

Twin split pipes in 3.25/3.25

Nominal heat flow rate

(0/2000ft)

Nominal heat flow rate

(2000/4500ft)

Min Exhaust temperature °F 262

Max Exhaust temperature °F 324

MBH 122.8

MBH 116.7

2.25/4

3.25/5

Frequency Hz 60

Current A < 1.6

Power consumption W 176

FLUE GAS FIGURES

Gas Min Max

CO2 2.5% 7.2%

O2 16.5% 8.1%

RIVA HEAT ONLY MANUAL - REV A

10

3. Parts List

Primary Components:

12

11

9

8

7

6

5

15

4

16

18

20

1 Pump

2 Pump vent plug

3 Automatic air purger valve

4 Modulation gas valve

5 Flame-detecting electrode

6 Ignition electrodes

7 Burner

8 Combustion chamber

9 Primary heat exchanger

10 Fan

11 Air pressure switch

12 Air switch pres. Test points

13 Safety thermostat

14 Modulation operator

15 Gas valve outlet pres. Test point

16 Gas valve inlet pres. Test point

10

19

3

14

1

2

13

26

17 Central heating expansion vessel

18 Central heating temp. Probe NTC

19 Central heating pressure relief valve

20 Primary circuit flow switch

21 Main circuit drain cock

22 By-pass valve

23 Venturi device

24 Flue outlet pipe

25 Air Intake Pipe

26 Control panel

27 Safety thermostat probe

28 Pressure reducing automatic fill valve

29 Backflow preventer

30 Gas supply line cock

31 Water supply inlet cock

RIVA HEAT ONLY MANUAL - REV A

11

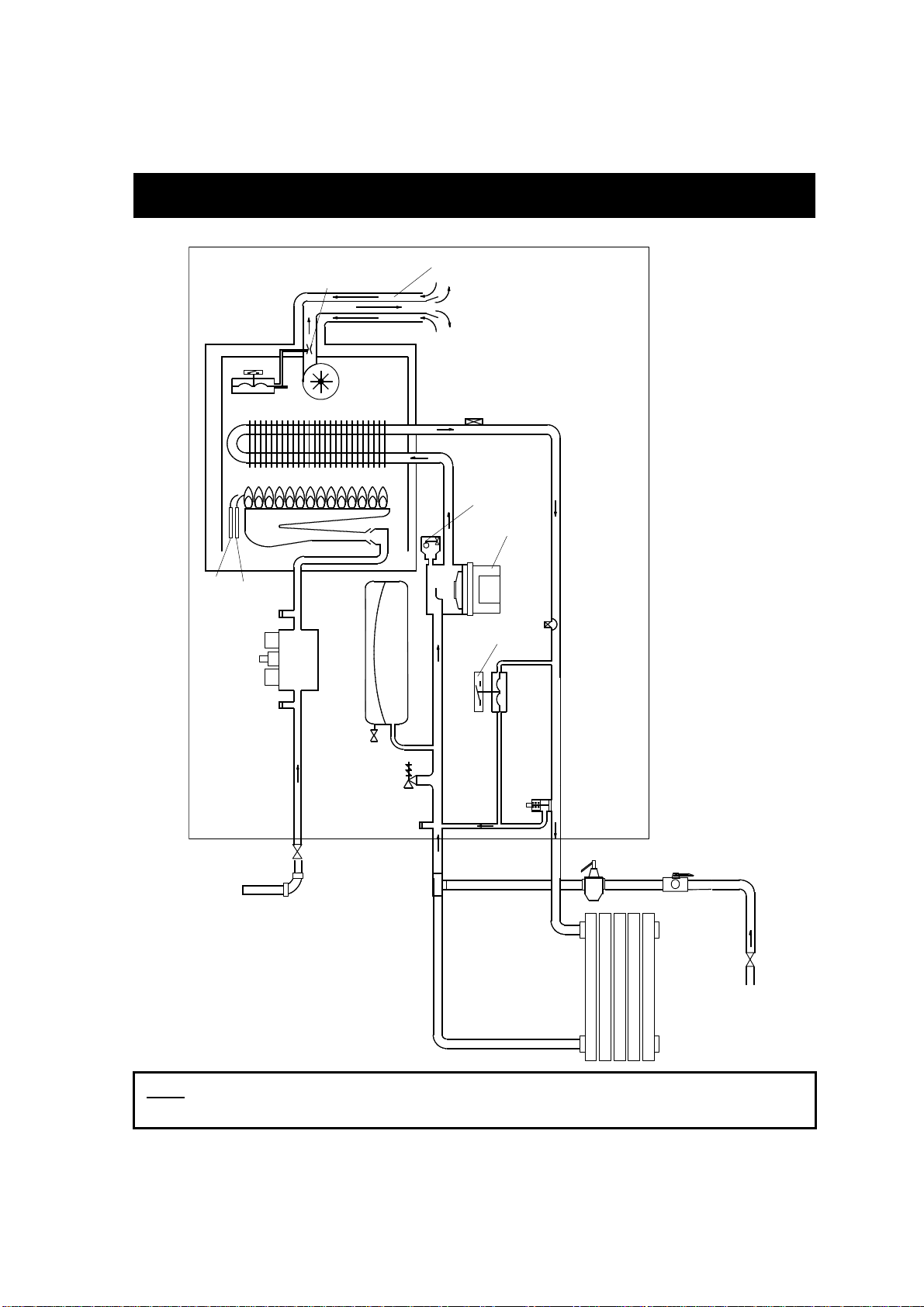

4. Internal Piping & Parts List

23

10

25

24

11

7

6

5

15

14

4

16

9

17

19

21

27

3

1

18

20

22

30

28

29

31

Note: Pressure Relief Valve (#19) should be piped to a drain or to the floor as lose as

possible to a drain.

RIVA HEAT ONLY MANUAL - REV A

12

Loading...

Loading...