Page 1

VECTIM365

VECTIM304

Page 2

Page 3

Table of Contents

Page

Special Warnings ..............................................................

Product Dimensions and Cutout Requirements.............

Important Preparation Suggestions .....................................

Cooktop Installation..........................................................

Electrical Connections....................................................

General information...........................................................

3-Wire branch circuit ......................................................... 1

4-Wire branch circuit ......................................................... 1

IMPORTANT: Save these instructions for the local electrical inspector use.

INSTALLER: Please leave this manual with owner for future reference.

OWNER: Please keep this manual for future reference.

Pay attention to these symbols present in this

manual

You can be killed or seriously injured if you don't

IMMEDIATELY follow instructions.

DANGER

Proper installation is your responsibility. Have a

qualified technician install this cooktop.

Please read all instructions before using this appliance

WARNING

Special Warnings

Important:

Observe all governing codes and ordinances.

Write down the model and serial numbers before

installing the cook top. Both numbers are on the

serial rating plate located on bottom of cooktop

box.

Before Starting Installation

WARNING

It is the customer's responsibility to contact a

qualified electrical installer. To assure that the

electrical installation is Adequate and in

conformity with national electrical code:

ANSI/NFPA 70-latest edition** or CSA standards

C22.1-94, Canadian Electrical Code, part No.0M91 - latest edition*** and all local codes and

ordinances.

Installation Manual

ENGLISH

WARNING

This is the safety alert symbol. This symbol

alerts you to potential hazards that can kill or

hurt you and others.

You can be killed or seriously injured if you

don't follow these instructions.

READ AND SAVE THESE INSTRUCTIONS.

To installer:

Leave these instructions with the appliance.

To customer:

Retain these instructions for future reference.

WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result in

personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

Copies of the standards listed may be obtained from:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd. Cleveland,

OH 44131-5575

To eliminate the risk of burns by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If he

cabinet storage is to be provided, the risk can be

reduced by installing a range hood that projects

horizontally a minimum of 5" (12,7 cm) beyond the

bottom of cabinet.

3

Page 4

Installation Manual

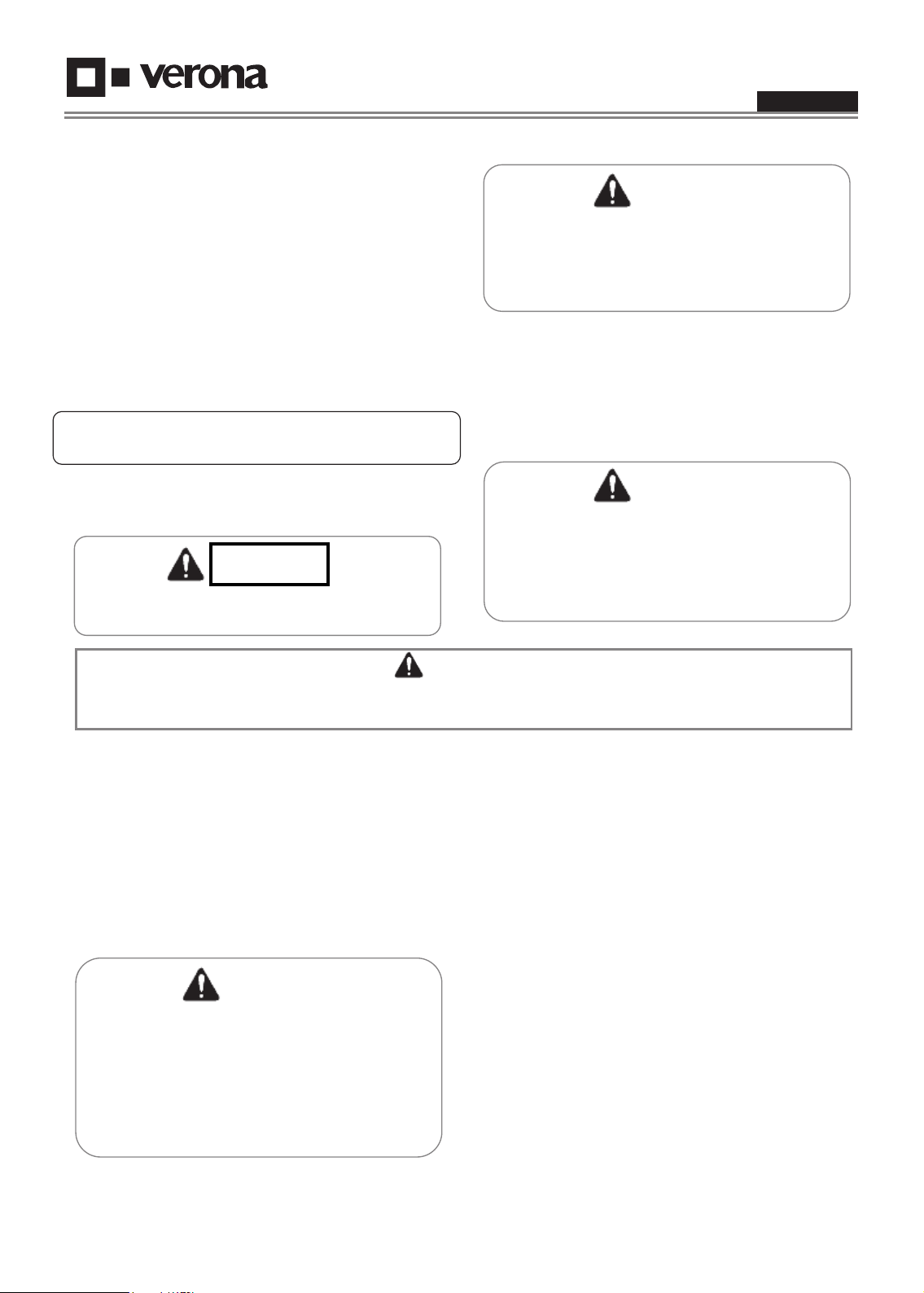

30” 3/8 (77,1cm)

3” 1/8 (8cm)

ENGLISH

�

30’’

21” 3/16 (53,8cm)

36’’

Figure 1.

1” (2,5cm)

1” (2,5cm)

36” 3/16 (91,9cm)

2” 7/8 (7,4)

2” 7/8 (7,4)

1/4” (0,6cm)

21” 3/16 (53,8cm)

1/4” (0,6cm)

3”1/8 (8cm)

Figure �.

4

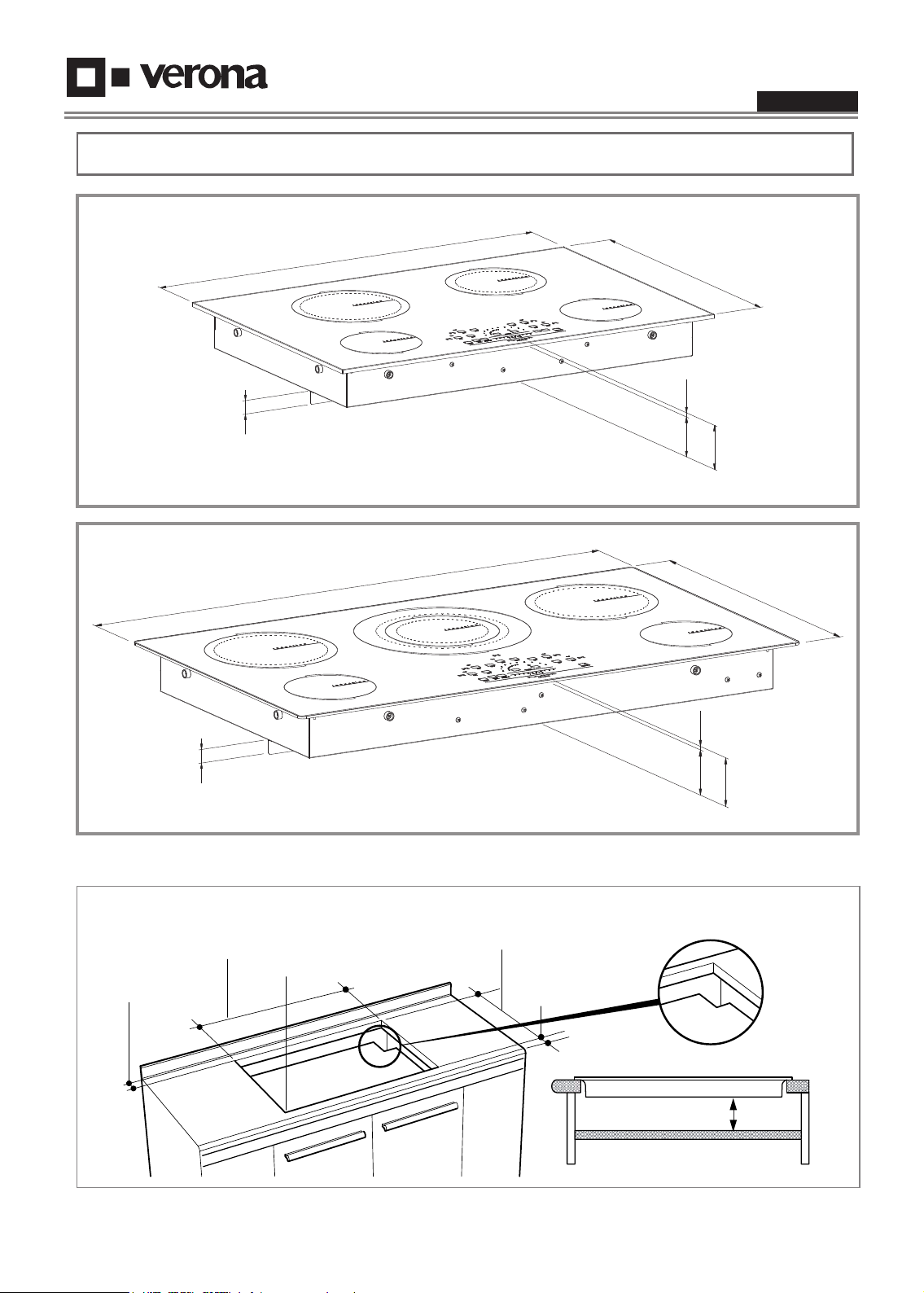

CUTOUT DIMENSION

LENGTH OFF CUT

SEE NOTE

A

1-1/2” (3.8CM)

MIN CLEARANCE

LENGTH OFF CUT

B

FROM EDGE OF CUTOUT

R

AND FRONT EDGE OF

COUNTERTOP

2-1/2” (6.5 cm)

1-1/4” (3,2 cm) Canadian

2-1/4” (5,7cm) US

SLOT FOR

CABLE

ROUTING

3-1/2” (9 cm)

2-1/2” (6.5 cm)

Page 5

Installation Manual

ENGLISH

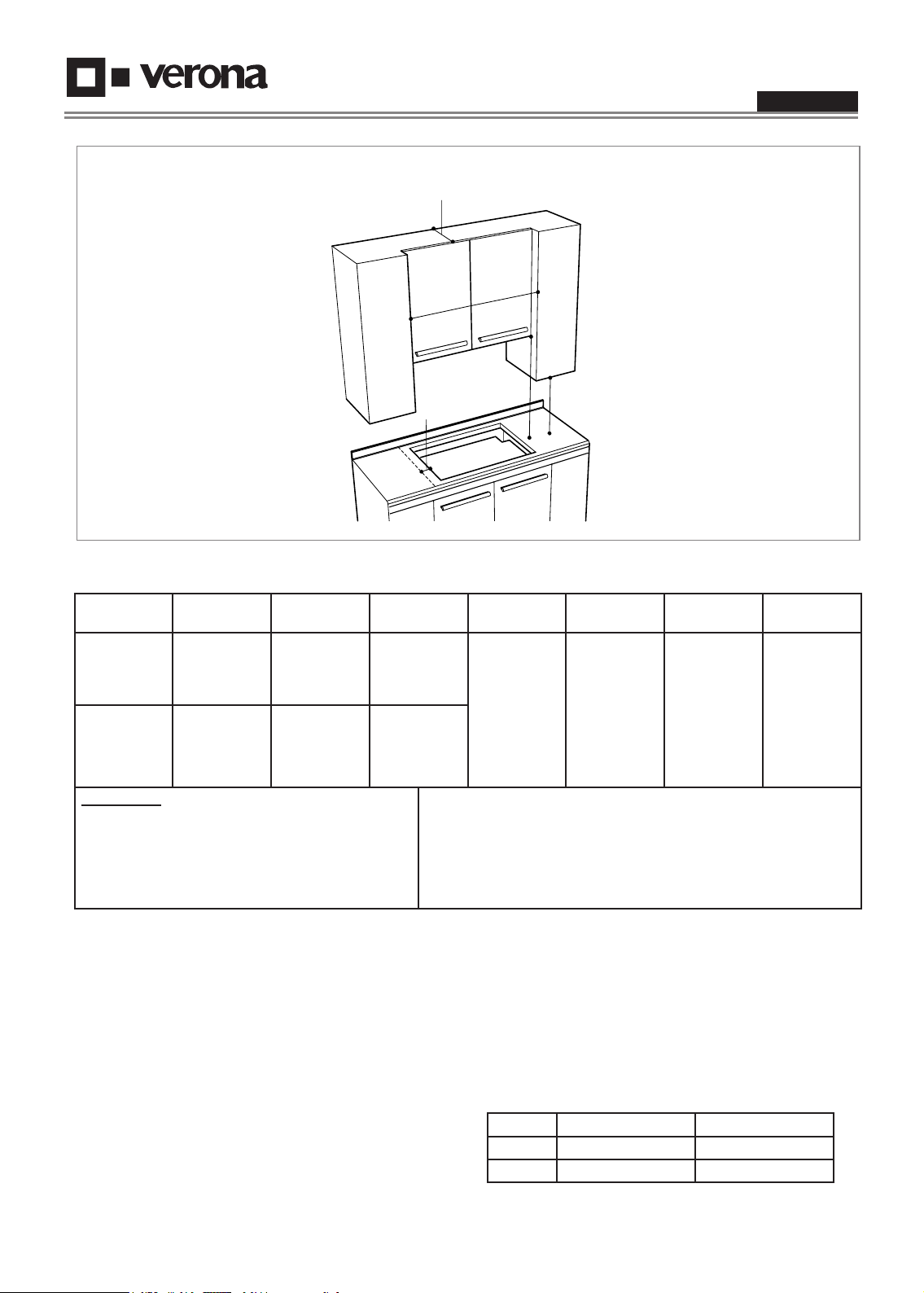

CUTOUT REQUIREMENTS

G

WALL COVERING CABINETS,

AND COUNTERTOP MUST

WITHSTAND HEAT UP TO 93° C (200° F)

C

E

F

D

Figure 3. Cutout dimensions and requirements

CUTOUT

WIDTH

30”

(76.2cm)

36”

(91.4cm)

IMPORTANT

Under the cooktop it is necessary to install a partition,

as shown in gure 2-3.

A B C D E F G

28-11/16”

(72.9 cm)

28- 15/16”

(73.5 cm)

34-1/16”

(86.5 cm)

34- 5/16”

(87.2 cm)

19-1/4”

(49.0 cm)

19-5/8”

(49.8 cm)

19-1/4”

(49.0 cm)

19-5/8”

(49.8 cm)

30”

(76.2 cm) min

36”

(91.4 cm) min

* NOTE

24” (61 cm) min. clearance if bottom of wood or metal cabinets is

protected by not less than 1/4“ (0.6 cm) ame retardant millboard

covered with no less than No. 28 MSG sheet steel 0.015” (0.04 cm)

stainless steel, or 0.024” (0.06 cm) aluminum or 0.020” (0.05cm)

copper. 30”(76.2 cm) min. clearance between top of cooking platform

and bottom of unprotected wood or metal cabinet

Important Preparation Suggestions

1. Chamfer all exposed edges of decorative laminate

to prevent damage from chipping.

2. Radius corners of cutout and file to Insure

smooth edges and prevent corner cracking.

Recommend 1/4“or 3/8“diameter drill In each

corner.

3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking

of the countertop laminate.

18” (45.7 cm)

min

Height from

countertop

to nearest

cabinet on

either side of

unit

30” (76.2 cm)

min.

(see note*)

Clearance

from

countertop to

unprotected

overhead

surface

2” (5 cm) min

Clearance

from cutout to

side wall on

the left and

right of the

unit

13” (33 cm)

Depth of

unprotected

overhead

cabinets

This cooktop has been designed with wide

tolerances of cut-out to cover possible

replacement with other brands. We recommend to

that you consider the minimum dimension of cutout size In the case of new Installation.

Some cut out sizes for possible replacements:

Dim. Inches cm

• 30” 28-15/16” x 19-5/8” 73,5 x 49,8

• 36” 34-5/16” x 19-5/8” 87,2 x 49,8

5

Page 6

BURNER BOX

TABLE CLOTH

Cooktop Installation

WARNING

Excessive Weight Hazard

Use two or more people to move and install

cooktop.

Failure to do so can result in back or other injury.

Cut Hazard

Beware of sharp edges. Use the polystyrene ends

when carrying the product. Failure to use caution

could result in minor injury or cuts.

Always consult the countertop manufacturer for

specific instructions.

Ensure the countertop is square and level and

ensure no structural members interfere with space

requirements.

Prepare the cut-out according to the instructions

(see cut-out dimensions).

Make sure the wall coverings, countertop and

cabinets around the cooktop can withstand heat

(up to 200 °F / 93 °C).

Installation Manual

ENGLISH

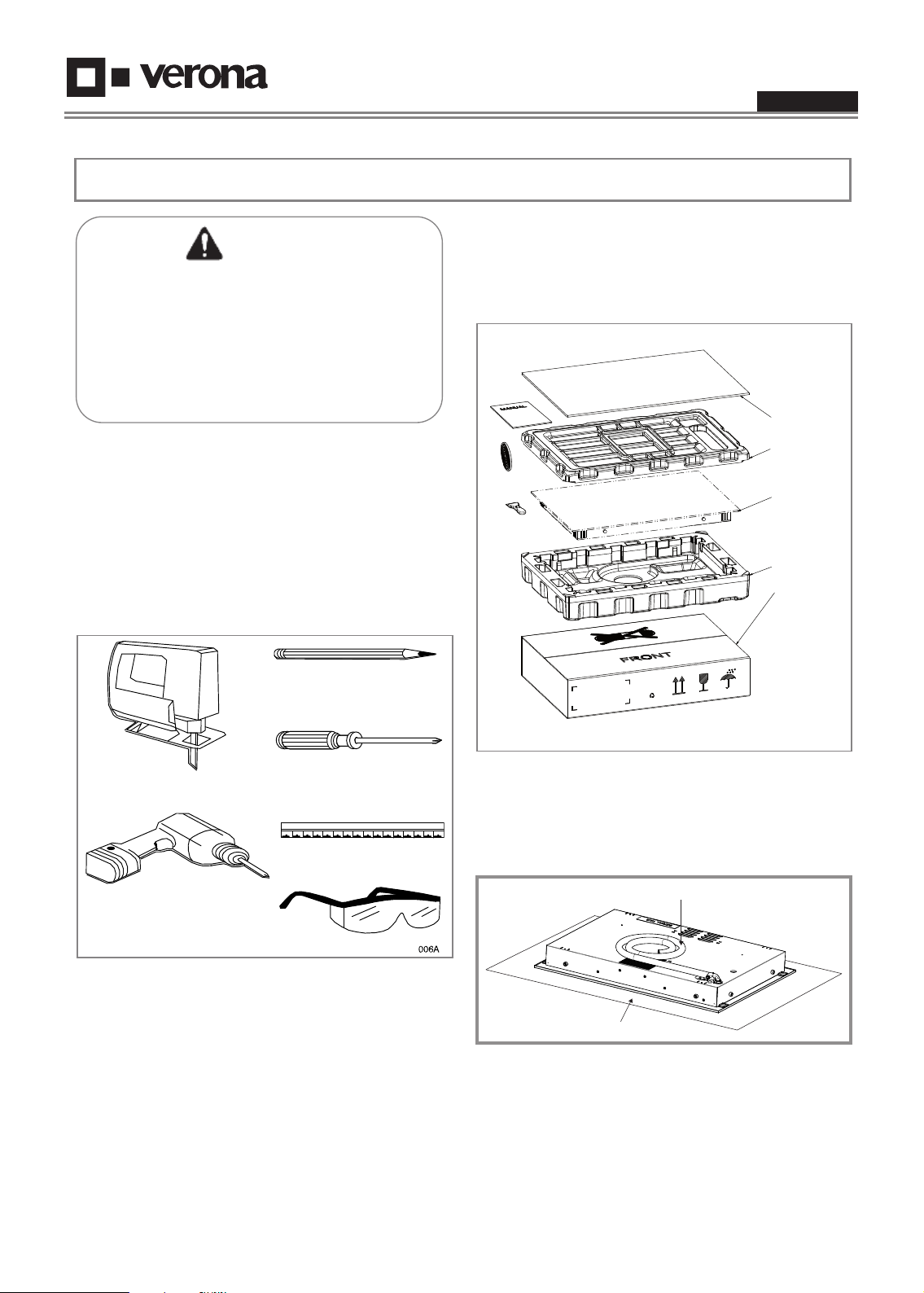

Step 1

Remove packaging materials and literature package

from the cooktop before beginning installation.

Remove Installation Manual from literature pack and

read them carefully before you begin.

MANUAL

TOP-CARDBOARD

TOP PACKAGING

GASKET

SCRAPER

COOKTOP

BOTTOM PACKAGING

CARDBOARD

Figure 4. Tools you will need

6

Figure 5. Parts

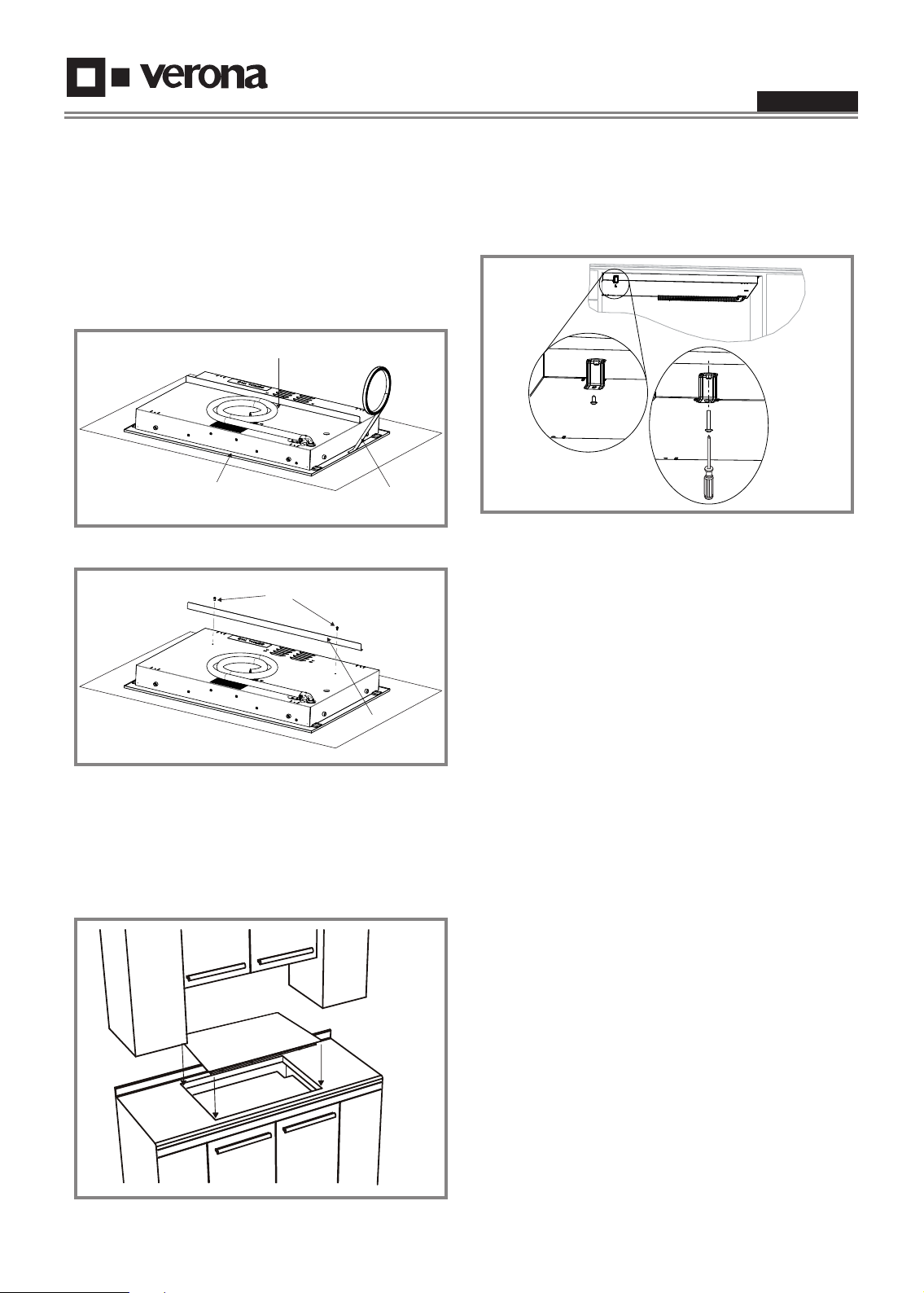

Step 2

Place a towel or table cloth onto the counter top. Lay

the cooktop upside down onto the protected surface.

Figure 6.

Page 7

Installation Manual

BURNER BOX

SEAL

SCREWS

ENGLISH

Step 3

A foam tape is provided to seal the cooktop edges to the

countertop. Apply tape approximately 1/16” (1.5 mm)

from the glass edge to the underside of the cooktop

glass. Use tape around the entire glass perimeter. Cut

off excess where tape ends butt.

Remove the two screws from burner box, then place

the bafe as showed below xing it by the screws

removed previously.

COOKTOP GLASS

FOAM TAPE

Figure 7.

Step 5

Four clamp brackets are provided to clamp the cooktop

to the countertop. Tighten screws just enough to hold

brackets in place when cooktop is put into cutout.

Tighten screws securely.

Figure 9.

BAFFLE

Figure 7b.

Step 4

Insert the cooktop centered into the cutout opening.

Make sure the front edge of the counter top is parallel

to the cooktop. Make nal check that all required

clearances are met.

Figure 8.

7

Page 8

Installation Manual

ENGLISH

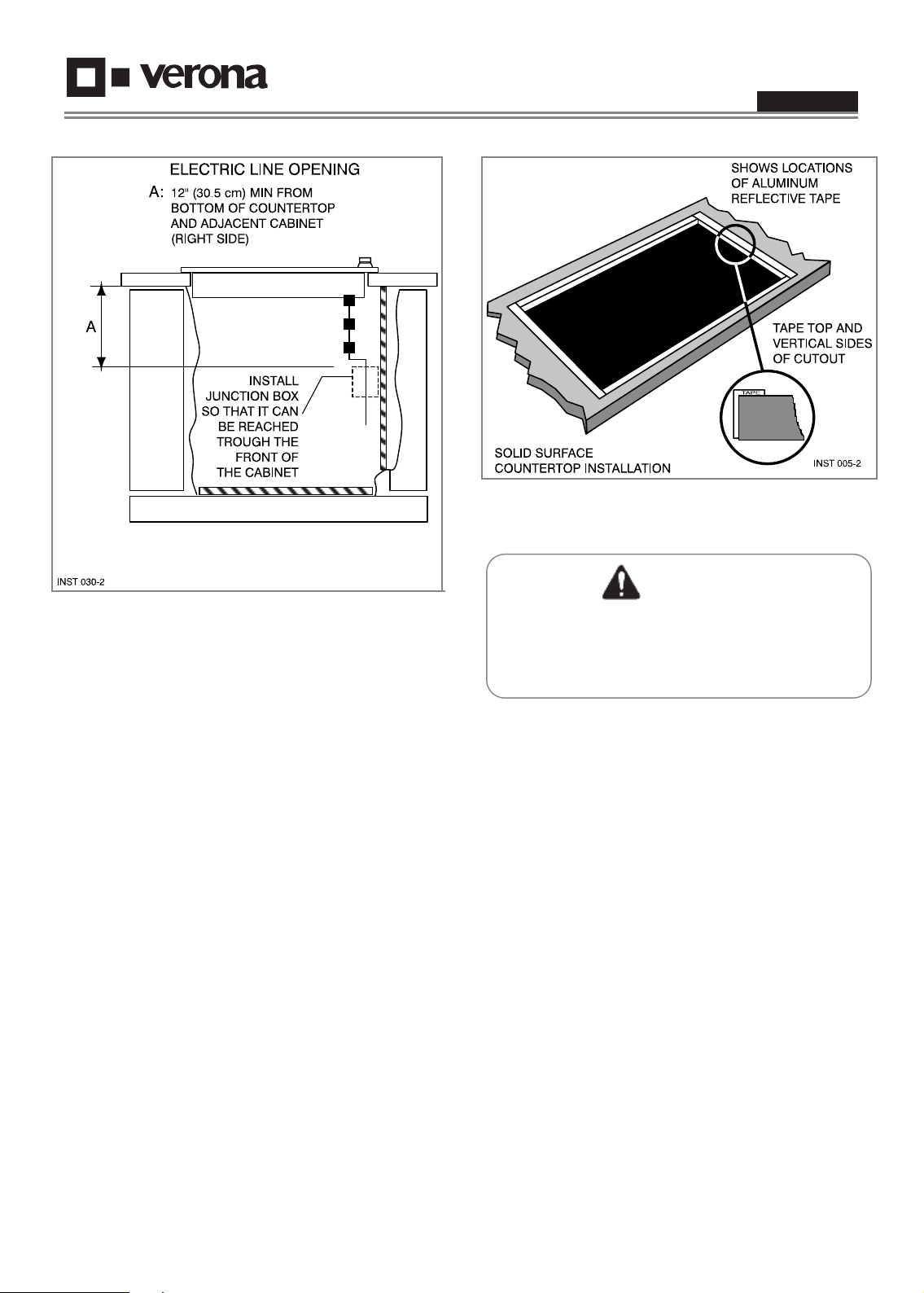

Figure 1.

Figure 1.

WARNING

THE CONDUIT IS 3 FEET LONG

The junction box, must be located where it will

allow considerable slack in the conduit for

serviceability.

Important:

For solid surface material installations such as

Surel™ and Corian

manufacturer. Apply heat reflective tape such as

Scotch® Aluminum Foil Tape #425 or #427

around the cutout so that it folds over on the top

and sides.

Do not wrap the tape underneath the cooktop.

Be sure the tape extends beyond the outermost

flange of the cooktop. All corners should be

covered with tape.

®

, consult with solid surface

8

Page 9

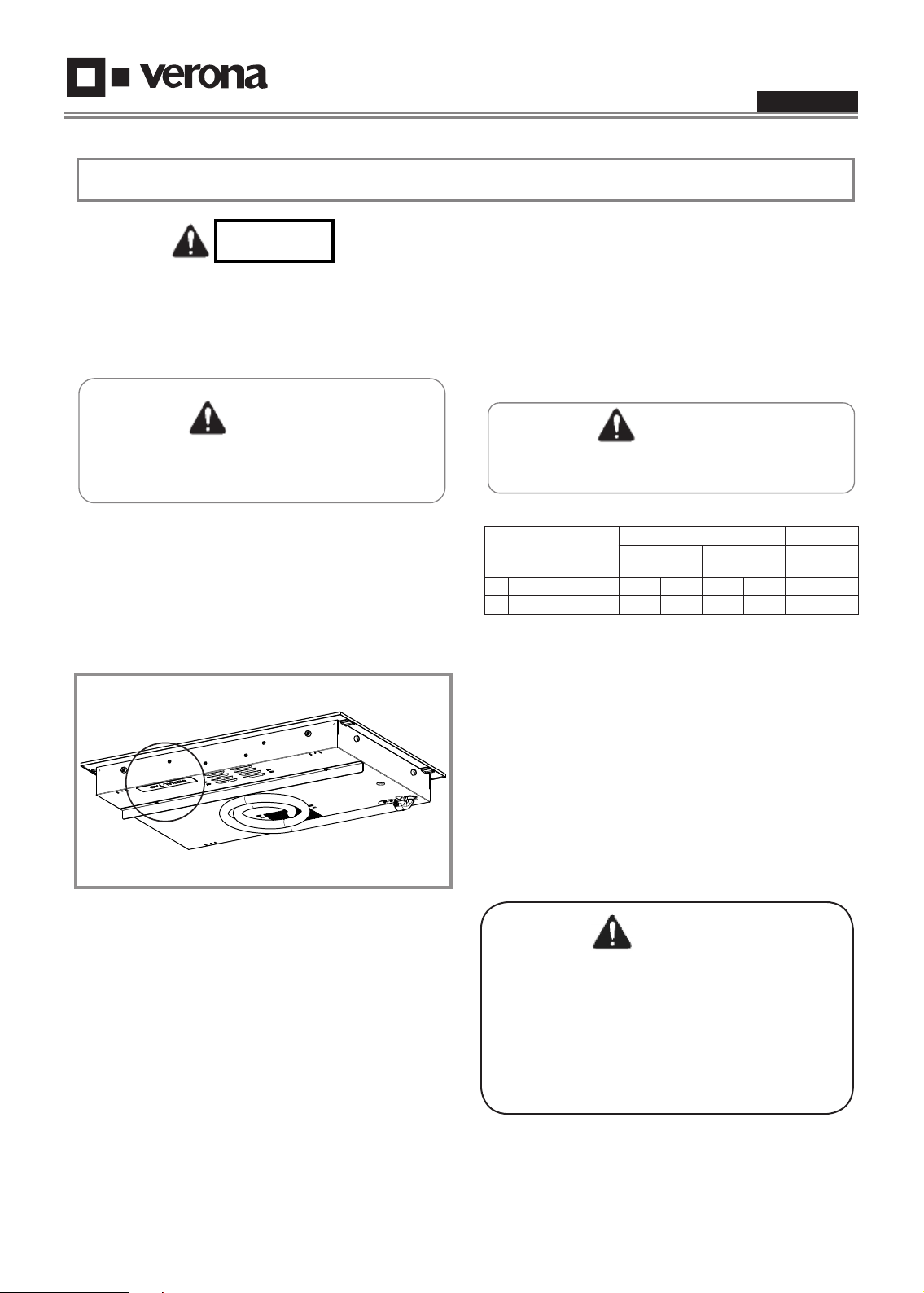

Electrical Connections

DANGER

Disconnect power before servicing the product.

Failure to do so could result in death or

electrical shock.

General information

Installation Manual

ENGLISH

The flexible conduit (supplied) 3 feet long (100 cm)

located at the right rear of the cooktop bottom box

should be connected directly to junction box. Do not

cut the conduit. A U.L - or CSA - listed conduit

connector must be provided at each end of the power

supply cable (at the cooktop and at the junction box.)

A time delay fuse or circuit breaker is recommended.

Do not ground to a gas pipe. Do not have a fuse in the

grounding or neutral circuit.

Fuse both supply (phase) lines.

WARNING

The models may be powered at 240V or

208V.

This cooktop does not require a neutral connection. If

the cooktop is to be completely enclosed in a cabinet,

feed the cooktop cable through the opening in the

cabinet. Make the electrical connection following the

appropriate steps for your installation.

Your cooktop must be connected to the proper

electrical voltage and frequency as specified in the

table on the right.

WARNING

Improper connection of aluminum house wiring to

the copper leads can result in a serious problem.

Model

30”

VECTIM304

36”

VECTIM365

National Fire Protection Association

Batter/march Park Quincy, Massachusetts 02269

A three-wire, single phase, 240 Volt 60 cycle electrical

system (properly circuit protected to meet Local

Codes of NFPA No.70) must be provided. Unit must

be properly grounded in accordance with local wiring

code. The chart below recommends the minimum

circuit protector and wire size if the appliance is the

only unit on the circuit. If smaller sizes of wire are

used, the unit efficiency will be reduced and a fire

hazard may be created. It is advisable that the

electrical wiring and hookup be accomplished by a

competent electrician.

Power Supply

240 V 60 Hz 208 V 60 Hz

7,2kW 30A 6,2kW 29,8A 812T40IP

10,8kW 45A 9,7kW 46.6A 812V50IQ

Approval

code

Figure 12. Location of serial tag

Connect with copper wire only

If the house has aluminum wiring, follow the

procedure below:

1. Connect the aluminum wiring to the copper wire

by using special connectors designed and

Underwriters Laboratories-listed for joining copper

to aluminum. Follow the electrical connector

manufacturer's recommended procedure.

2. Aluminum/copper connection must conform with

local codes and industry- accepted wiring

practices.

WARNING

This touch control works using optical light sensing

technology. When rst connecting electrically or

after a power failure, any direct strong light over the

sensor area may affect the touch control functionality.

When powering on the unit make sure that no strong

light is shining direct over the touch control zone,

it can compromise the start-up sensor calibration

resulting in an unresponsive touch control.

9

Page 10

Recommended Minimum

kW Rating on

serial plate

0-4.8

20 12

4.9-6.9

30 10

7.0-9.9

40 8

10.0-11.9

12.0-14.9

Be sure your appliance is properly installed and

grounded by a qualified technician. Ask your

dealer to recommend a qualified technician or an

authorized repair service. This cooktop does not

require a neutral connection. If the cooktop Is to

be completely enclosed In a cabinet, feed the

cooktop cable through the opening in the cabinet.

Make the electrical connection following the

appropriate steps for your installation.

This appliance is manufactured with a green ground

wire connected to the cooktop chassis. After making

sure that the power has been turned off, connect the

flexible conduit from the cooktop to the junction box

using a U.L. listed conduit connector. Figures 13 and

14 and the instructions provided below present the

most common way of connecting the cooktops. Your

local codes and ordinances, of course, take

precedence over these instructions. Complete

electrical connections according to local codes and

ordinances

Risk of Electric Shock, frame grounded to

neutral of appliance through a link.

Grounding through the neutral conductor is prohibited

for new branch-circuit installations (1996 NEC);

mobile homes; and recreational vehicles, or in an area

where local codes prohibit grounding through the

neutral conductor.

50 8

60 6

Circuit protection

in amperes

DANGER

Wire size

(AWG)

3-Wire branch circuit

Where local codes allow the connection of ground

wire from the cooktop to the branch circuit neutral wire

(gray or white colored wire) proceed as follows (see

figure 13).

1. If local codes permit, connect the green GROUND

wire from the cooktop to the branch circuit neutral

wire (gray or white colored wire).

2. Connect the red and black leads from the cooktop

to the corresponding leads in the junction box.

Installation Manual

ENGLISH

Figure 1.

4-Wire branch circuit

Refer to figure 14:

1. Connect the green ground wire from the cooktop

to the ground wire in the junction box (bare or

green colored wire).

2. Connect the red and black leads from the cooktop

to the corresponding leads in the junction box.

3. Connect the white wire from the cooktop to the

neutral (gray or white) wire in the junction box.

4. Terminate and insulate the neutral (gray or white

colored wire) in the junction box.

Figure 1.

10

Page 11

Manuel d’Installation

FRANÇAIS

Tables des matieres

Page

Avertissement Spéciaux................................................. 1

Dimensions du Produit et Découpe............................... 1

Conseils importants de préparation................................... 1�

Installation de la Table de Cuisson ...............................

Connexions Electriques .................................................

Informations générales......................................................

Connexion à 3 fils..............................................................

Connexion à 4 fils..............................................................

IMPORTANT: Gardez ces instructions pour une utilization

d’inspection électrique locale

INSTALLATEUR: Veuillez laisser ce manuel au propriétaire

pour de futures références.

PROPRIETAIRE: Veuillez garder ce manuel pour de futures références.

Veuillez prêter attention à ces symboles que vous

rencontrerez dans ce manuel

Si vous ne suivez pas IMMEDIATEMENT ces instructions, vous courez le risque de mourir ou

d’être sérieusement blessé.

DANGER

Veuillez lire les instructions avant toute utilisation

AVERTISSEMENT

Avertissement Spéciaux

Il est de votre responsabilité d’installer l’appareil correctement. Confiez l’installation de cette table de

cuisson à un technicien qualifié.

Important:

Respecter les règlements et ordonnances en vi-

gueur.

Avant d’installer la table de cuisson, veuillez no-

ter les numéros de modèle et de série. Ces deux

numéros se trouvent sur la plaquette signalétique

située en dessous de la caisse de la table de

cuisson.

Avant de Procéder à l’Installation

AVERTISSEMENT

Ce symbole signifie que la sécurité est en

danger. Il signale les risques potentiels qui

peuvent entraîner la mort ou des blessures à

l’opérateur ou aux autres.

Si vous ne suivez pas ces instructions à la let-

tre, vous courez le risque de mourir ou d’être

sérieusement blessé.

BIEN LIRE CES INSTRUCTIONS ET LES CONSERVER.

À l’installateur:

Laissez ces instructions avec l’appareil.

Au client:

Gardez ces instructions comme référence future.

AVERTISSEMENT

La non-observation des instructions conte-

nues dans ce manuel peut entraîner la mort

ou des blessures sérieuses du fait d’un incendie ou d’une explosion.

Ne pas stocker ou utiliser de l’essence ou

d’autres liquides inflammables à proximité de

cet appareil ou de tout autre appareil électroménager.

Copies des normes mentionnées ci-dessus peuvent être obtenues:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd. Cleveland,

OH 44131-5575

Pour éviter le risque de brûlures en touchant les surfaces chauffées, l’espace de stockage du meuble au

dessus des unités de surface doit être évité. Si le

meuble de stockage est fourni, le risque peut être réduit en installant une hotte qui projète horizontalement un minimum de 5" (12,7 cm) sous le dessous

du meuble.

AVERTISSEMENT

La responsabilité revient au client de contacter un

électricien installateur qualifié. Veuillez vous assurer que l’installation électrique est adéquate et

conforme à la réglementation électrique nationale

: ANSI/NFPA 70 -dernière édition ** ou normes

CSA C22.1-94, réglementation électrique canadienne, partie No.0-M91 – dernière édition *** et

tous les règlements et ordonnances locaux.

11

Page 12

Manuel d’Installation

30” 3/8 (77,1cm)

3” 1/8 (8cm)

FRANÇAIS

�

�

30’’

21” 3/16 (53,8cm)

1” (2,5cm)

36’’

1” (2,5cm)

Figure 1.

DIMENSION DE LA DÉCOUPE

LONGUEUR DE DÉCOUPE

VOIR NOTE

A

1-1/2” (3.8CM)

ESPACE MINIMUM

R

36” 3/16 (91,9cm)

LONGUEUR DE DÉCOUPE

B

DU BORD DE LA DÉCOUPE

AU BORD ANTÉRIEUR DU

PLAN DE TRAVAIL

2-1/2” (6.5 cm)

2” 7/8 (7,4)

2” 7/8 (7,4)

1/4” (0,6cm)

21” 3/16 (53,8cm)

1/4” (0,6cm)

3”1/8 (8cm)

SLOT POUR

CABLES

3-1/2” (9 cm)

2-1/2” (6.5 cm)

12

1-1/4” (3,2 cm) Canada

2-1/4” (5,7cm) US

Figure 2.

Page 13

DISPOSITIONS POUR LA DÉCOUPE

G

F

Manuel d’Installation

FRANÇAIS

LES REVETEMENTS DES MEUBLES ET LE

PLAN DE TRAVAIL DOIVENT RESISTER A

UNE CHALEUR DE 93° C (200° F)

C

E

D

Figure 3. Dimensions pour la découpe

DÉCOUPE

LARGEUR

30”

(76.2cm)

36”

(91.4cm)

IMPORTANT

En dessous de la table de cuisson, il est nécessaire

d’installer une cloison, comme indiqué sur la gure

2-3.

A B C D E F G

28-11/16”

(72.9 cm)

28- 15/16”

(73.5 cm)

34-1/16”

(86.5 cm)

34- 5/16”

(87.2 cm)

19-1/4”

(49.0 cm)

19-5/8”

(49.8 cm)

19-1/4”

(49.0 cm)

19-5/8”

(49.8 cm)

30”

(76.2 cm) min

36”

(91.4 cm) min

* NOTE

24” (61 cm) espace min. si le bas des meubles en bois ou en métal est

protégée par au moins 1/4“ (0,6 cm) de carton-reliure ignifuge avec

une tôle d’acier inoxydable No. 28 MSG d’au moins 0.015” (0,04 cm),

ou d’aluminium 0.024” (0,06 cm) ou de cuivre 0.020” (0,05cm). 30”

(76,2 cm) d’espace min. entre le haut de la plate-forme de cuisson et

le bas du meuble non-protégé en bois ou métal.

Conseils importants de préparation

1. Biseautez tous les bords exposés du contre-plaqué

décoratif pour empêcher qu’ils ne s’écaillent.

2. Arrondissez les quatre coins de la découpe et

limez le pourtour pour que les bords soient lisses et que les coins ne se fissurent pas. Utilisez une mèche de 1/4‘’ ou 3/8’’ pour percer les

trous à chaque angle.

3. Si les bords ne sont pas lisses, l’intérieur des coins

n’est pas arrondi et l’encastrement a été forcé, il

est possible que le contre-plaqué du plan de travail

se fendille.

18” (45.7 cm)

min

Hauteur min.

du plan de

travail au

meuble le

plus près des

deux cotés de

l’appareil

30” (76.2 cm)

min.

(voir note*)

Du plan de

travail à la

surface non

protégée à la

verticale

2” (5 cm) min

Espace min.

de la

découpe à la

paroi latérale

sur la gauche

et la droite de

l’appareil

13” (33 cm)

Profondeur

des meubles

non

protégées à

la verticale

Cette table de cuissons a été conçue avec de

grande tolérance de découpe pour couvrir le replacement possible avec d’autres marques.

Quelques découpes pour des remplacements

possibles:

Dim. Inches cm

• 30” 28-15/16” x 19-5/8” 73,5 x 49,8

• 36” 34-5/16” x 19-5/8” 87,2 x 49,8

13

Page 14

CAISSON DES FOYERS

Installation de la Table de Cuisson

AVERTISSEMENT

Risque du fait du poids excessif

Soyez à deux personnes ou plus pour porter et

installer la table de cuisson. Sinon, vous risquez

de vous blesser au dos ou de subir d’autres blessures.

Risque de coupure

Méfiez-vous des bords tranchants et des extrémités du polystyrène lorsque vous portez le produit.

Sinon, vous risquez de vous couper ou de vous

faire légèrement mal.

Toujours consulter le fabricant du plan de travail

pour les instructions spécifiques.

Bien vérifier que le plan de travail est carré et à

niveau et assurez-vous qu’aucun élément de

structure n’interfère avec les exigences d’espace.

Préparez la découpe selon les instructions (voir

dimensions découpe).

Bien vérifier que les éléments suspendus, le

plan de travail et les meubles autour de la table

de cuisson résistent à la chaleur (jusqu’à 200 °F /

93 °C).

Manuel d’Installation

FRANÇAIS

Étape 1

Enlevez les matériaux d’emballage et les manuels

d’explication de la table de cuisson avant de commencer l’installation.

Retirez les Instructions d’installation du manuel et lisez-les soigneusement avant de commencer.

MANUEL

PANNEAU CARTON

SUPÉRIEUR

EMBALLAGE DU HAUT

RACLOIR À

LAME DE RASOIR

JOINT

TABLE DE CUISSON

EMBALLAGE DU BAS

CARTON

Figure 4. Les outils dont vous aurez besoin

14

Figure 5. Piéces

Étape 2

Placez un torchon ou une serviette sur le plan de travail. Posez la table de cuisson du haut vers le bas

dans la surface protégée.

SERVIETTE

Figure 6.

Page 15

Étape 3

CAISSON DES FOYERS

ÈTANCHE

VIS

Un ruban adhésif est fourni pour assurer l’étanchéité

entre les bords de la table de cuisson et les angles du

plan de travail. Appliquez le ruban à environ 1/16”(1,5

mm) des angles en verre au dos du verre de la table de

cuisson. Utilisez un ruban tout autour du périmètre du

verre. Coupez le ruban en trop.

Enlever les deux vis du boîtier mélangeur, puis placer

la cloison protectrice comme on le montre ci-dessous

en rexant les deux vis.

VERRE DE LA TABLE DE CUISSON

RUBAN ADHÈSIF

Figure 7.

Manuel d’Installation

FRANÇAIS

Figure 8.

Étape 5

Quatre supports de xation sont fournis pour accrocher

la table de cuisson au plan de travail. Serrez les vis

juste assez pour tenir en place les xations lorsque la

table de cuisson est mise dans la découpe. Serrez bien

les vis.

DÉFLECTEUR

Figure 7b.

Étape 4

Insérez la table de cuisson centre de l’ouverture de la

découpe. Vériez que le bord avant du plan de travail

est parallèle à la table de cuisson. Faites la dernière

vérication que vous avez laissé tous les espaces

nécessaires.

Figure 9.

15

Page 16

Manuel d’Installation

FRANÇAIS

Figure 1.

Figure 1.

AVERTISSEMENT

LE CONDUIT A UNE LONGUEUR DE 3 PIEDS

la boîte de jonction, doit être dans un endroit qui

permette que le conduit pour l’entretien ait suffisamment de jeu.

Important:

Pour les installations de matériau solide comme le

Surei™ et le Corian

surface solide. Appliquez du ruban thermoréfléchissant comme le Scotch

aluminium #425 ou #427 autour de la découpe de

sorte qu’il déborde et se replie sur le dessus et

les côtés.

N’enveloppez pas le ruban en-dessous de la ta-

ble de cuisson. Vérifiez bien que le ruban aille audelà du rebord le plus externe de la table de cuisson. Tous les angles doivent être recouverts par

du ruban.

®

, consultez le fabricant de

®

feuille de ruban

16

Page 17

Connexions Electriques

DANGER

Débranchez l’électricité avant de mettre en

service le produit. Sinon, vous risquez de vous

tuer ou de vous électrocuter.

Informations générales

AVERTISSEMENT

Les modèles peuvent être actionnés

à 240V ou à 208V.

Cette table de cuisson n’exige pas de branchement

neutre. Si la table de cuisson doit être complètement

fermée dans un meuble, alimentez le câble de la table

de cuisson à travers l’ouverture du meuble. Faites les

branchements électriques selon les étapes appropriées pour votre installation. Votre table de cuisson

doit être connecté au voltage électrique correct et au

fréquence spécifié à droite.

Figure 12. Numéro de série

Manuel d’Installation

FRANÇAIS

Le conduit flexible conduit (fourni) de 3 pieds (100 cm)

situé à l’arrière à droite sous le caisson de la table de

cuisson doit être connecté directement à la boîte de

jonction. Ne coupez pas le conduit. Un raccord de

conduit U.L - ou CSA- listed doit être posé à chaque

extrémité du câble d’alimentation électrique (à la table

de cuisson et à la boîte de jonction.) Un dispositif de

surcharge ou un disjoncteur est recommandé.

Ne le branchez pas à un tuyau à gaz. Ne placez de

fusible dans le branchement ou de circuit neutre.

Raccordez les deux lignes d’alimentation (phase).

AVERTISSEMENT

Une connexion incorrecte de l’installation électrique en aluminium au cuivre peut entraîner des

problèmes graves.

Modèle

30”

VECTIM304

36”

VECTIM365

National Fire Protection Association

Batter/march Park Quincy, Massachusetts 02269

Il faut avoir une prise à trois fils, courant monophasé,

système électrique de 240 volt 60 cycles (circuit protégé correctement pour être conforme aux codes locaux de NFPA No.70). L’appareil doit être correctement branché selon le code de câblage local. Le tableau ci-dessous recommande le protecteur de circuit minimum et la taille de câble minimum si l’appareil

est le seul sur le circuit. Si des tailles de câble plus

petites sont utilisées, l’efficacité de l’appareil sera réduite et un risque d’incendie est possible. Il est

conseillé que le câblage électrique et le branchement

soit mis en place par un électricien compétent.

Alimentation électrique requise

240 V 60 Hz 208 V 60 Hz

7,2kW 30A 6,2kW 29,8A 812T40IP

10,8kW 45A 9,7kW 46.6A 812V50IQ

Approval

code

Connexion uniquement avec un câble en cuivre

Si la maison est pourvue d’un câblage aluminium, suivez la procédure suivante:

1. Raccordez le câblage aluminium au câble en cuivre en utilisant des raccords spéciaux conçus et

venant de Underwriters Laboratories-listed pour

joindre le cuivre à l’aluminium. Suivez les instructions recommandées du fabricant des raccords

électriques.

2. La connexion aluminium/cuivre doit être conforme

aux codes locaux et industriels acceptés pour les

câblages.

ATTENTION

Cette commande par efeurement fonctionne selon la

technologie du captage optique de la lumière.

Lors du premier branchement électrique ou après une

coupure de courant, toute lumière forte atteignant

directement la surface du capteur peut affecter le

fonctionnement de la commande par efeurement.

Au moment de la mise sous tension de l’unité, veiller à ce

qu’aucune lumière forte n’atteigne directement la surface

de commande par efeurement, parce que cela risque de

compromettre le calibrage du capteur de démarrage et

d’insensibiliser la commande.

17

Page 18

Minimum recommandé

Caractéristiques des

kW sur plaques de

série

0-4.8

20 12

4.9-6.9

30 10

7.0-9.9

40 8

10.0-11.9

12.0-14.9

Assurez-vous que votre installation est correctement installée et branchée par un technicien qualifié.

Demandez à votre revendeur un technicien qualifié

ou un service de réparation agréé. Cette table de

cuisson n’exige pas de connexion neutre. Si la table

de cuisson doit être complètement enfermée dans

un meuble, posez le câble de la table de cuisson à

travers l’ouverture du meuble. Faites les branchements électriques en suivant les étapes appropriées

pour votre installation.

Cet appareil est fabriqué avec un conducteur de terre

vert connecté au châssis du table de cuisson. Après

vous être assurer qu’il n’y a plus de courant, branchez

le conduit flexible depuis le table de cuisson jusqu’au

boîtier de raccordement en utilisant un connecteur de

conduit U.L. listed. Les figures 13 et 14 et les instructions fournies présentant la manière la plus commune

de brancher un table de cuisson. Vos codes locaux et

règlements sont évidemment prioritaires sur ces instructions.

Effectuez les connexions électriques conformément

aux codes locaux et les règlements.

Risque d’électrocution, cadre à la masse à une

position neutre d’un appareil par une liaison.

Mettre à la masse par un conducteur neutre est interdit

pour les nouvelles installations de circuit électrique (1996

NEC); les mobile homes; et les véhicules de parc, ou

dans les régions où les codes locaux interdisent de

brancher à la masse à travers un conducteur neutre.

50 8

60 6

Protection de

circuit en am-

DANGER

pères

Taille de

câble

(AWG)

Connexion à 3 fils

Où les codes locaux (voir figure 13) permettent la

connexion du conducteur de terre du four au fil neutre

du circuit de branchement (fil gris ou coloré blanc):

1. Si les codes locaux le permettent, connectez le

conducteur de terre vert du table de cuisson et le

fil neutre du circuit de branchement (fil gris ou co-

loré blanc).

2. Connectez les broches de raccordement du table

de cuisson aux broches de raccordement correspondantes dans le boîtier de jonction.

Manuel d’Installation

FRANÇAIS

Figure 13.

Connexion à 4 fils

1. Connectez (voir figure 14) le conducteur de terre vert

du table de cuisson au conducteur de terre dans le

boîtier de jonction (câble nu ou coloré vert).

2. Connectez les broches de raccordement rouge et

noir du table de cuisson aux broches de raccordement correspondantes dans le boîtier de raccordement.

3. Connectez le câble vert du table de cuisson du câble neutre (gris ou blanc) dans le boîtier de raccordement.

4. Raccordez et isolez le câble neutre (gris ou blanc)

à la boîte de jonction.

Figure 14.

18

Page 19

Manual de Instalación

ESPAÑOL

Tabela de Contenido

Pagina

Advertencias Especiales ................................................

Dimensiones del Producto y de Encastre..................... 2

Importantes Consejos de Preparación ..............................

Instalación de la Placa de Cocción................................

Conexiones Eléctricas....................................................

Informaciones generales ...................................................

Circuito de conexión de 3 hilos .........................................

Circuito de conexión de 4 hilos .........................................

IMPORTANTE: Guarde estas instrucciones para el uso del

inspector eléctrico local.

INST ALADOR : Por favor, deje este manual a propietario para

futuras consultas.

PROPIETARIO: Por favor, conserve este manual para futuras consultas.

Preste la debida atención a los siguientes símbolos que encontrará en el manual.

Si no sigue estas instrucciones de forma INMEDIATA, puede correr peligro de muerte o de resultar gravemente herido.

PELIGRO

Efectuar una instalación adecuada es responsabilidad suya. Asegúrese de que el electrodoméstico es

instalado por un técnico cualificado.

Importante:

Por favor, lea todas las instrucciones antes de utilizar este aparato

Advertencias Especiales

ADVERTENCIAS

Cumpla todas las normativas y ordenanzas vi-

gentes aplicables.

Anote el número de serie y de modelo de la pla-

ca de cocción antes de instalarla. Ambos números se encuentran en la placa de serie de la base

del electrodoméstico.

Antes de comenzar la instalación

ADVERTENCIA

Contactar con un instalador eléctrico cualificado

es responsabilidad suya. Debe asegurarse de

que la instalación eléctrica es adecuada y conforme con el código eléctrico nacional, ANSI/NFPA 70 (última edición **) o con las normativas C22. 1-94, o con el Código eléctrico canadiense (Canadian Electrical Code),

sección 0-M91 (última edición ***) y con todos los

códigos y ordenanzas locales.

ADVERTENCIA

Este es el símbolo de los avisos relacionados

con la seguridad: alerta sobre potenciales peligros que pueden derivar en muerte o daños

a las personas.

Si no sigue estas instrucciones, puede correr

peligro de muerte o de resultar gravemente

herido.

LEA Y CONSERVE ESTAS INSTRUCCIONES

Instalador:

Deje las instrucciones con el electrodoméstico.

Cliente:

Conserve las instrucciones como referencia futura.

ADVERTENCIA

La inobservancia de las indicaciones recogi-

das en este manual puede derivar en muerte

o en daños a las personas.

No almacene ni utilice gasolina u otros vapo-

res o líquidos inflamables cerca de este ni

otro electrodoméstico.

Puede obtener copias de las normas citadas en:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd. Cleveland,

OH 44131-5575

Para prevenir el riesgo de incendios por recalentamiento de superficies, es aconsejable evitar la colocación de armarios sobre la placa de cocción. Si

desea colocar un armario sobre la placa, puede reducir el riesgo instalando una campana extractora

que se superponga al armario (al menos 12,7 cm) y

lo proteja.

19

Page 20

Manual de Instalación

30” 3/8 (77,1cm)

3” 1/8 (8cm)

�

�

ESPAÑOL

30’’

21” 3/16 (53,8cm)

1” (2,5cm)

2” 7/8 (7,4)

36’’

36” 3/16 (91,9cm)

1/4” (0,6cm)

21” 3/16 (53,8cm)

1” (2,5cm)

Figura 1.

DIMENSIONES DEL HUECO DE ENCASTRE

LONGUITUD DEL CORTE

VER NOTA

A

1-1/2” (3.8CM)

ESPACIO MINIMO

R

LONGUITUD DEL CORTE

B

DESDE EL BORDE DEL

CORTE AL BORDE FRONTAL

DE LA ENCIMINERA

2-1/2” (6.5 cm)

2” 7/8 (7,4)

1-1/4” (3,2 cm) Canada

2-1/4” (5,7cm) US

1/4” (0,6cm)

3”1/8 (8cm)

SLOT PARA

CABLE

3-1/2” (9 cm)

2-1/2” (6.5 cm)

Figura 2.

20

Page 21

REQUISITOS DEL HEUCO DE ENCASTRE

G

F

Manual de Instalación

ESPAÑOL

LOS ARMARIOS DE LA PARED Y LA

ENCIMERA DEBEN PODER SOPORTAR

TEMPERATURAS DE HASTA 93° C (200° F)

C

E

D

Figura 3. Dimensiones de encastre

ANCHO

DEL CORTE

30”

(76.2cm)

36”

(91.4cm)

IMPORTANTE

Es necesario instalar bajo la encimera un panel

de separación, como se muestra en la gura 2-3.

A B C D E F G

28-11/16”

(72.9 cm)

28- 15/16”

(73.5 cm)

34-1/16”

(86.5 cm)

34- 5/16”

(87.2 cm)

19-1/4”

(49.0 cm)

19-5/8”

(49.8 cm)

19-1/4”

(49.0 cm)

19-5/8”

(49.8 cm)

30”

(76.2 cm) min

36”

(91.4 cm) min

* NOTE

La distancia mínima podrá ser de 61 cm. si la base de madera o metal

del armario está protegida como mínimo por 0,6 cm de cartón grueso

resistente al fuego cubierto por una lámina de acero inoxidable de 28

MSG (mín. 0.04 cm), o de aluminio (0.06 cm) o de cobre (0.05 cm). Si

la base del armario es de madera o metal sin protección, la distancia

entre esta y la encimera será de 76,2 cm.

Importantes Consejos de Preparación

1. Bisele todos los bordes expuestos de laminado decorativo para evitar que se astille.

2. Redondee las esquinas recortadas y líjelas: los

bordes deben quedar suaves para evitar que se

resquebrajen las esquinas. Se recomienda utilizar un taladro con una broca de diámetro de

1/4 o 3/8 en cada esquina.

3. Los bordes ásperos, las esquinas interiores que no

han sido redondeadas y forzar el acoplamiento de

la placa pueden contribuir a resquebrajar el laminado de la encimera.

18” (45.7 cm)

min

Distancia

mínima

desde la

encimera

hasta la base

del armario

más cercano

en ambos

lados de la

placa

30” (76.2 cm)

min.

(ver nota*)

Espacio

mínimo

desde la

encimera

hasta una

supercie no

protegida

2” (5 cm) min

Espacio

mínimo

desde el

corte en

los lados

izquierdo y

derecho de la

placa

13” (33 cm)

Fondo de

los armarios

superiores no

protegidos

Esta placa de cocción ha sido diseñada para

adaptarse a unas dimensiones de encastre estándar que permitan sustituirla con placas de otras

marcas. Recomendamos que considere la dimensión mínima de encastre en caso de efectuar una

nueva instalación. Algunas dimensiones de encastre para una eventual sustitución:

Dim. Inches cm

• 30” 28-15/16” x 19-5/8” 73,5 x 49,8

• 36” 34-5/16” x 19-5/8” 87,2 x 49,8

21

Page 22

CAJA DE LA PLACA

MANTEL

Instalación de la Placa de Cocción

ADVERTENCIA

Peso excesivo

La placa de cocción debe ser transportada e instalada por dos o más personas. Si lo hiciera una sola

persona, podría sufrir daños y lesiones en la espalda o en otras partes.

Peligro de corte

Tenga cuidado con los bordes afilados. Utilice los

complementos de poliestireno para trasladar el producto. Si no se presta atención, las personas que

lleven a cabo la instalación podrían resultar heridas.

Consulte siempre con el fabricante de la encimera

que le dará instrucciones específicas.

Asegúrese de que la encimera está bien equilibrada

y de que ningún elemento interfiera o limite las condiciones de espacio.

Prepare los cortes de la encimera de acuerdo con

las instrucciones (vea “Dimensiones de encastre”).

Asegúrese de que el revestimiento de la pared, la

encimera y los armarios que rodeen la placa de

cocción sean resistentes al calor (hasta 200 °F / 93

°C).

Manual de Instalación

ESPAÑOL

Paso 1

Retire el embalaje y separe los manuales de instrucciones antes de comenzar la instalación.

Lea atentamente el manual de instalación antes de

comenzar.

MANUAL

CARTÓN SUPERIOR

EMBALAJE SUPERIOR

JUNTA

PLACA DE COCCIÓN

RASCADOR

EMBALAJE INFERIOR

CARTON

Figura 4. Herramientas necesarias

22

Figura 5. Piezas

Paso 2

Coloque una toalla o un mantel sobre la encimera.

Apoye la placa de cocción boca abajo sobre la superficie protegida.

Figura 6.

Page 23

Manual de Instalación

CAJA DE LA PLACA

CINTA SELLADORA

TORNILLOS

ESPAÑOL

Paso 3

En el embalaje encontrará una cinta de espuma que

sirve para sellar el perímetro de la placa de cocción.

Aplique la cinta en la parte trasera de la placa de

cocción, en todo el perímetro, aproximadamente a

1,5 mm del borde de cristal. Recorte los extremos

sobrantes.

Sacar los dos tornillos de la cámara de combustión

y luego colocar la placa de protección, tal como se

muestra a continuación, y jarla con los dos tornillos.

CRISTAL DE LA PLACA

Figura 7.

Paso 5

En el embalaje encontrará también cuatro grapas de

jación. Apriete los tornillos solo lo necesario para

mantenerlos en su posición mientras coloca la placa

en el hueco. Apriete los tornillos hasta que queden bien

asegurados.

Figura 9.

DEFLECTOR

Figura 7b.

Paso 4

Inserte la placa de cocción bien centrada en el hueco

de encastre. Asegúrese de que el borde frontal de la

encimera esté paralelo a la placa. Compruebe que

una vez instalada, la placa respeta las distancias de

seguridad.

Figura 8.

23

Page 24

Figura 1.

Manual de Instalación

ESPAÑOL

Figura 1.

ADVERTENCIA

EL CONDUCTO TIENE 100 CM DE LONGITUD

Para garantizar un buen mantenimiento del conducto, este no debe estar tirante: la ubicación de

la caja de empalme debe darle una cierta holgura.

Importante:

Para efectuar instalaciones en encimeras con su-

perficie sólida (como Surei™ y Corian

con el fabricante de la encimera. Aplique cintas

adhesivas de gran resistencia al calor, como la

cinta de Aluminio Scotch

del hueco, de forma que se doble sobre la encimera y los laterales.

No pegue la cinta por debajo de la placa de coc-

ción. asegúrese de que la cinta se extiende más

allá del borde exterior de la placa de cocción. Todas las esquinas deben estar recubiertas con cinta.

®

425 o 427, alrededor

®

), consulte

24

Page 25

Conexiones Eléctricas

PELIGRO

Desconecte la electricidad antes de instalar el

producto. Si no lo hace, podría correr peligro

de muerte o de sufrir una descarga eléctrica.

Informaciones generales

ADVERTENCIA

Los modelos se pueden accionar

en 240V o 208V.

Esta placa de cocción no requiere conexión del neutro. Si va a colocar la placa en un armario, asegúrese

de que en él hay una abertura para pasar el cable de

alimentación. Efectúe la conexión eléctrica siguiendo

los pasos adecuados para su instalación.

La placa debe estar conectada al voltaje y la frecuencia adecuados, tal y como se indica a la derecha.

Manual de Instalación

ESPAÑOL

El conducto flexible (suministrado con el producto) de

100 cm de longitud que se encuentra en la parte trasera derecha de la caja de la placa, debe conectarse

directamente a la caja de empalme. No corte el conducto. Debe conectar un conector aprobado por UL o

CSA en cada extremo del cable de alimentación (en

la placa y la caja de empalme). Es recomendable instalar también un fusible de acción retardada o un diferencial. No utilice como toma de tierra una tubería de

gas. No conecte la toma de tierra o el circuito neutro

cerca de un fusible. Instale fusibles en las dos líneas

(fases) de alimentación.

ADVERTENCIA

Una conexión inadecuada del cableado de aluminio al cableado de cobre puede provocar graves

problemas.

Alimentación

240 V 60 Hz 208 V 60 Hz

7,2kW 30A 6,2kW 29,8A 812T40IP

10,8kW 45A 9,7kW 46.6A 812V50IQ

Approval

code

30”

36”

Modelo

VECTIM304

VECTIM365

Figura 12. Locacion numero di serie

Utilice únicamente cableado de cobre

Si su vivienda tiene cableado de aluminio, siga este

procedimiento:

1. Conecte el cable de aluminio al cable de cobre

utilizando los conectores específicos diseñados y

garantizados por Underwriters Laboratories (UL)

para conectar cobre y aluminio. Siga el procedimiento recomendado por el fabricante del conector eléctrico.

2. La conexión aluminio-cobre debe estar conforme

con los códigos locales y con las prácticas industriales aprobadas.

National Fire Protection Association

Batter/march Park Quincy, Massachusetts 02269

Debe instalarse un sistema eléctrico de tres cables,

una fase, 240 voltios y 60 ciclos, debidamente protegido conforme al código local de la NFPA n.º 70. La

unidad debe conectarse adecuadamente a una toma

de tierra de acuerdo con los códigos locales. La tabla

que encontrará a continuación recoge las recomendaciones mínimas de protección del circuito y el calibre del cableado si el electrodoméstico es la única

unidad del circuito. Si utiliza un calibre de cableado

menor, la eficiencia de la unidad se vería reducida y

podría provocar un riesgo de incendio.

Es recomendable que la conexión del cableado y del

electrodoméstico sean efectuadas por un electricista

cualificado.

ATENCIÓN

Este control táctil funciona según la tecnología del sensor

óptico de la luz.

Durante la primera conexión eléctrica o después de

un corte de energía, cualquier luz intensa que llegue

directamente hasta la supercie del sensor puede modicar

el funcionamiento del control táctil.

Cuando se enciende la unidad, es necesario asegurarse

de que ninguna luz intensa llegue directamente hasta la

supercie del control táctil, ya que podría comprometer la

calibración del sensor de puesta en marcha e insensibilizar

el control.

25

Page 26

Mínimos recomendados

Potencia (kW)

placa de serie

0-4.8

20 12

4.9-6.9

30 10

7.0-9.9

40 8

10.0-11.9

12.0-14.9

50 8

60 6

Protección del

circuito en ampe-

re

Calibre del

cable (AWG)

Asegúrese de que un técnico cualificado instale y

conecte a tierra correctamente su aparato. Consulte con su vendedor para que le recomiende un

técnico cualificado o un servicio de mantenimiento autorizado. Esta placa de cocción no requiere

conexión del neutro. Si va a colocar la placa en un

armario, asegúrese de que en él hay una abertura

para pasar el cable de alimentación. Efectúe la

conexión eléctrica siguiendo los pasos adecuados para su instalación.

Este aparato está fabricado con un hilo verde de tierra

conectado al bastidor de la placa de cocción. Después

de haberse asegurado de que la corriente está desconectada, conecte el conducto flexible desde la placa de

cocción hasta la caja de empalme usando un conector

de conducto que figure en la lista U L. Las figuras 13 y

14 que aparecen debajo muestran las maneras más comunes para conectar la placa de cocción. Las disposiciones y las normas locales de su zona, por su puesto,

tienen precedencia con respecto a estas instrucciones.

Complete las conexiones eléctricas en conformidad con

las normas y disposiciones locales.

PELIGRO

Riesgo de electrocución, marco conectado

a tierra al neutro del aparato por medio de un

enlace.

La puesta a tierra por medio de un conductor neutro

está prohibida para las instalaciones de nuevos circuitos de conexión (1996 NEC); casas móviles, vehículos recreativos, o en áreas en donde las normas locales prohíben la conexión a tierra mediante un conductor de neutro.

Circuito de conexión de 3 hilos

Tome como referencia la figura 13, en la que las normas locales permiten conectar el hilo de toma de tierra desde la placa de cocción hasta el hilo de neutro

del circuito (hilos de color gris o blanco):

1. Si las normas locales lo permiten, conecte el cable cable lo verde de tierra desde la placa de cocción y el cable de neutro del circuito de conexión

(hilos de color gris o blanco).

2. Conecte los conductores rojo y negro desde la

placa de cocción hasta los conductores correspondientes en la caja d empalme.

Manual de Instalación

ESPAÑOL

Figura 13.

Circuito de conexión de 4 hilos

Tome como referencia la figura 14.

1. Conecte el cable verde de tierra desde la placa de

cocción al cable de tierra en la caja de empalmes

(cable de color carne o verde).

2. Conecte los conectores rojo y negro desde el placa de cocción hasta los conectores correspondientes en la caja de empalme.

3. Conecte el cable blanco desde la placa de cocción al cable de neutro (gris o blanco) en la caja

de empalme.

4. Conecte y aísle el cable neutro (gris o blanco) a la

caja de empalme.

Figura 14.

26

Page 27

Page 28

EuroChef USA, Inc.

41 Mercedes Way - Suite 25

Edgewood, NY 11717

Phone (866) 844-6566 09VR6630 ed 10-13

Loading...

Loading...