Page 1

Vernier Dynamics

NOTE: Vernier products are designed for educational use. Our products are not

designed nor recommended for any industrial, medical, or commercial process such

as life support, patient diagnosis, control of a manufacturing process, or industrial

testing of any kind.

System

(Order Code VDS)

The Vernier Dynamics System consists of a 1.2 m

track, two carts, and related accessories. The system

is designed for use in physics and physical science

courses for motion and energy experiments. An optional Optics Expansion Kit

(Order code OEK) converts the track to an optics bench. An optional Track to Track

Coupler (Order code T2T-VDS) joins two tracks together. Some typical experiments

done with the system include

Motion under zero acceleration

Motion under constant acceleration with the ramp inclined

Inelastic collisions using the included hook and pile tabs

Elastic collisions using the included magnetic bumpers

The Vernier Dynamics System is designed for use with many data-collection tools,

such as the Vernier Motion Detector, Go! Motion, Vernier Photogates, and the

Vernier LabPro

computers, LabQuest App for LabQuest

EasyData

What is included with the Vernier Dynamics System?

The Vernier Dynamics System is shipped in two boxes. The long box contains the

track and feet, while the other box contains the remaining parts.

Long box marked TRACK

Track

Double foot stand (2)

Box marked VDS-KIT

Standard Cart with two magnets and foam plugs for included end caps and

Plunger Cart with two magnets and foam plugs for included end caps, hook

Rod clamp

Adjustable end stop with two magnets and foam plugs for included end caps

Photogate brackets (two)

Motion Detector bracket

Mass

Accessory mounting hardware

Hex wrench

®

interface. Appropriate software includes Logger Pro® for

®

for calculators, and DataQuest™ with TI-Nspire™ Technology.

hook and pile tabs

and pile tabs

®

2 and LabQuest®, DataMate and Vernier

Carts

The Vernier Dynamics Carts are supplied with

magnets and hook and pile tabs. You may choose to

install either or both on your carts. Since the magnets

may interfere with certain experiments using force

sensors on the carts, only install the magnets if you

need them.

The magnets are useful in studying collisions with

the magnets positioned so that they are the same

polarity on both sides and on both carts. This way the carts will repel one another,

and you can arrange a collision in which the carts never actually touch. The collision

will be very nearly elastic, unlike a collision using a spring or any kind of contact.

To install magnets so that carts will repel one another, as well as the adjustable end

stop, use the following procedure.

1. Remove the teardrop from the cart end or the end stop.

2. Insert the silver magnet (supplied with the cart) into the teardrop, oriented so that

the outside of the teardrop will attract the south-pointing end of a compass

needle.

3. Insert a foam plug (supplied with the cart) into the teardrop.

4. Reinsert the tear drop into the cart end or the end stop, and fasten the screw.

If you like, test by holding the compass near the cart or stop, in the same position as

an approaching cart, and verify that the south-pointing end of the compass is

attracted to the cart.

Carts come with magnets, foam plugs, teardrop inserts, and a hex key to remove and

replace the screw holding the teardrop to the cart end. A magnetic compass is not

included.

The magnets can be removed at any time by reversing this process. Store the

magnets away from computers.

To study totally inelastic collisions, place hook and pile tabs on top of the

teardrop-shaped plugs. Looking at the end of the cart, place a hook pad on the

left-hand plug, and a pile tab on the right-hand side. Center the pad on the round part

of the plug. This way any cart with hook and pile tabs will stick to any other. Hook

and pile equipped carts will stick together, creating a totally inelastic collision.

One cart includes a spring-loaded plunger for collisions. To use the plunger,

simultaneously press the horizontal button above the plunger and press the plunger

in until it locks. To release, press on the pin from the top of the cart. The plunger

force can be adjusted. To adjust the plunger release force, rotate the plunger while it

is extended.

2

Page 2

Both the plunger and simple carts have a mass of 500 g. Adding accessories will

change the mass.

Photogate Bracket

Photogate brackets are attached to the side of the

track. With the nut loosely on the T-handled bolt,

slide the nut into the side channel of the track.

Attach the photogate using the supplied wing bolt

in the long slot. Adjust the gate height so the beam

intercepts the desired portion of the target.

Adjustable End Stop

The adjustable end stop slides into the end of

the track. Adjust the position as desired. Insert

magnets in the end stop if desired.

Motion Detector Bracket

Any Vernier Motion Detector with a hinged head can be attached to the supplied

Motion Detector Bracket. The Motion Detector Bracket has a pin to locate the

Motion Detector on the bracket. There is a knob, nut and bolt to attach the bracket to

the track underside, and a threaded hole at the end near the pin. To assemble, place

the Motion Detector with the back

end over the pin of the bracket. Insert

the screw through the slot into the

threaded insert on the detector with

the hinge toward the track, and

tighten. Insert the bracket into the slot

in the underside of the track as shown

in the photo. When the Motion

Detector is not attached to the

bracket, its mounting screw can be

stored in the threaded hole near the

pin.

Newer Vernier Motion Detectors (green or black case with

adjustable sensitivity) can be placed so that the sensor is 15 cm

from the end of the track. The carts can then be detected

properly all the way to the end. The track mode is appropriate

for the dynamics system.

Rod Clamp

The rod clamp is used to support the track with a

user-supplied ring stand. Insert the rod clamp nut

into the side of the track. Adjust the height as

desired.

Mounting Hardware

The supplied mounting hardware is used to

attach devices to the cart, such as a force

sensor, accelerometer, or mass. To attach a

Wireless Dynamics Sensor System (WDSS)

use the hardware supplied with that device.

The hex-head bolts may be attached to any

point along the slots in the cart, but the head

must be inserted in the flare region of the

slots. Tighten the threaded barrels on the

bolts.

Double Foot Stand

The double foot stand slides into the end of the

track, with the nut in the center slot of the track

underside. Adjust the height as desired. Install

the stands before attaching the motion detector

bracket.

3

4

Page 3

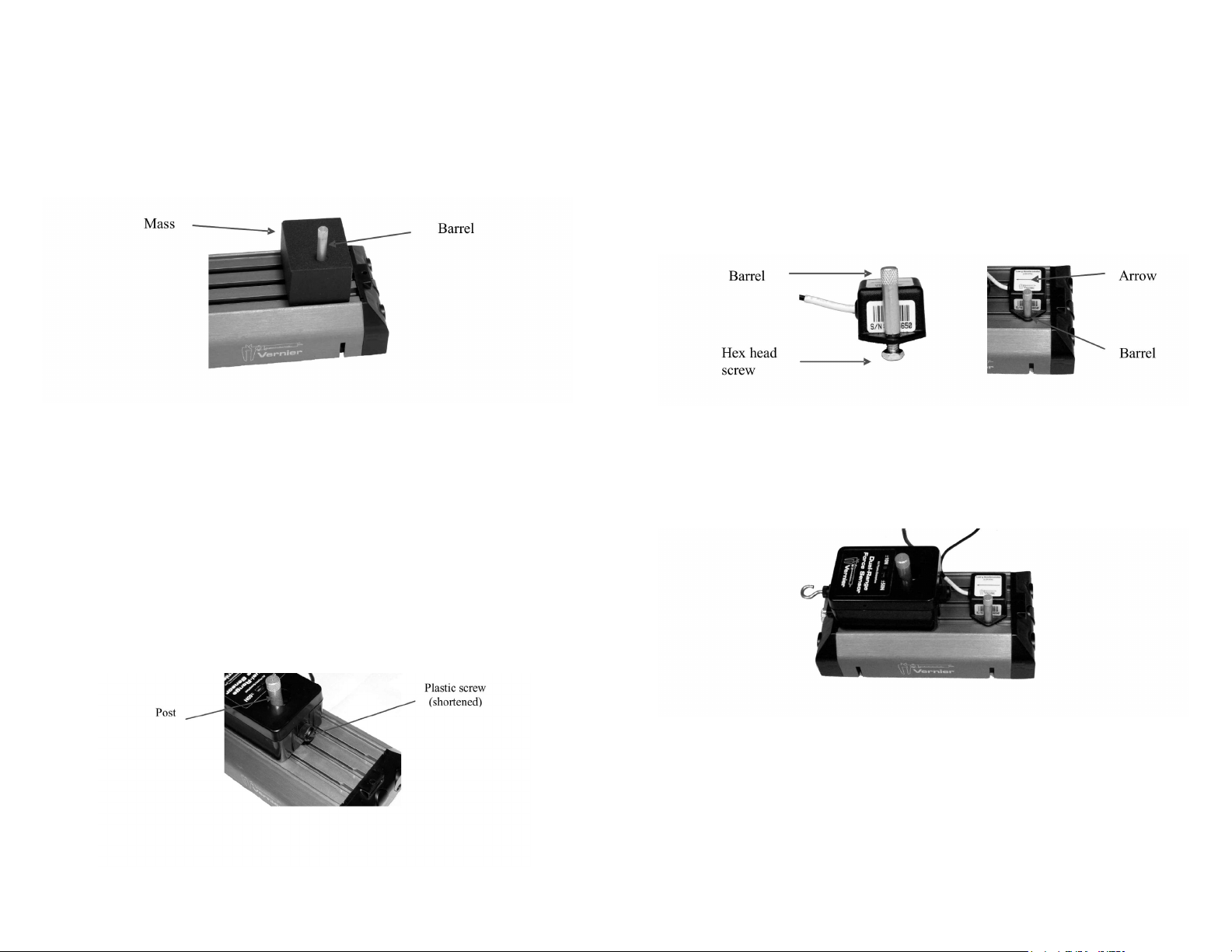

The Additional Mass (MASS)

The 500 g mass is used to double the mass of the cart.

1. Insert the hex head of the #10-32 x 1-3/4” screw into either of the side slots on

the cart from the flared end.

2. Fit the mass over the screw and position the mass and screw as required on the

cart.

3. Screw the small barrel onto the projecting end of the #10-32 x 1-3/4” screw and

tighten to secure the mass.

The following examples show various sensors attached to the Vernier

Dynamics Cart. Sensors are not included with the Vernier Dynamics

System.

Attach the Dual-Range Force Sensor (DFS)

1. Insert the hex head of the screw on the bottom of the post into the center slot of

the cart at the flare. The flats of the hex head should be parallel to the slot and the

washer should be above the slot to avoid marring the cart with the metal post.

2, Slide the post to the desired position on the cart and lightly tighten in place with

the knurled end of the post.

3. Place the DFS on the cart with the post through its central hole. Reposition the

post if necessary, and tighten. Tighten the plastic screw on the end of the sensor

to secure the DFS in place.

The Low-g Accelerometer (LGA)

The LGA is attached to one of the side slots of the cart using the #10-32 x 3/8” hex

head screw and the small threaded barrel. The LGA is attached on one side only to

maintain the correct orientation of the sensor.

1. Insert the #10-32 x 3/8” hex head screw into one of the mounting holes of the

LGA from the bottom and screw on the barrel a few turns, leaving at least half of

the screw threads exposed for fitting into the slot.

2. Use the arrow printed on the sensor to decide which of the cart side slots to use so

that the sensor is oriented in the desired direction.

3. Slide the head of the screw into the chosen slot from the flared end, position the

sensor as required, and tighten the small barrel to secure it to the cart.

DFS and LGA in Combination

The DFS (Dual-Range Force Sensor) and LGA (Low-g Accelerometer) can be

combined using the same procedures.

As long as the DFS is positioned so that the attachment to be used is facing in the

required direction, the order of attachment is not critical.

5

6

Page 4

MASS and DFS

Attach the DFS first, since the plastic screw on the DFS becomes inaccessible when

the MASS is attached.

The DFS must be attached at the opposite end of the cart from the slot flares if you

want to be able to remove the mass without removing the DFS.

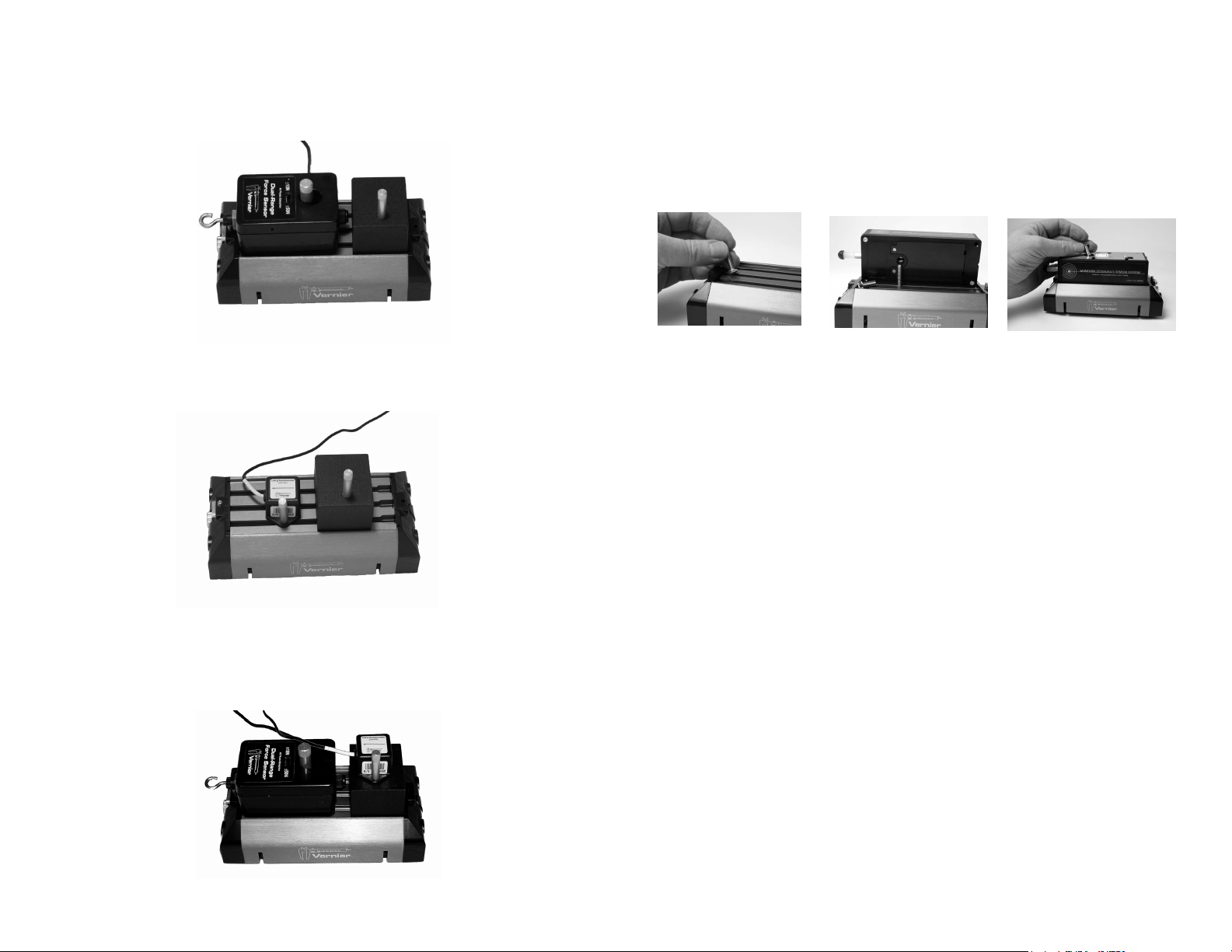

Wireless Dynamics Sensor System

Mounting on a Vernier Dynamics Cart

For connection to a Vernier Dynamics cart use a 5/8" × 10-24 binding barrel and a

hex-head bolt (1" × 10-24). First place the bolt head in the middle slot of the top of

the Vernier dynamics cart. Then lower the WDSS on top of the cart and insert the

binding barrel in the large hole of the WDSS. The bolt threads into the binding

barrel. Tighten the binding barrel. The process is shown in the series of photos

below:

MASS and LGA

For this combination, the order of attachment is not critical:

MASS, DFS, and LGA

This is a similar case to the MASS and DFS, where the DFS must be attached first.

There is sufficient room on the new MASS bolt to piggyback the LGA on top of the

mass before attaching the small barrel.

Hints for Using VDS

Don’t install the magnets unless you know you want to use them. They will

interfere if you perform an experiment with a force sensor riding on the cart, since

the force sensor will then not read the total force acting on the cart.

The magnets can be hard to pull apart if they stick together before installation;

slide them across one another to separate.

The conventional arrangement for magnets to have the cart ends attract the S end

of a compass needle. The key thing is that all magnets repel, so if you use the

opposite convention everywhere, no harm is done.

The magnets are designed for fairly gentle collisions. If the cart is moving too

quickly, the magnetic forces may cause the cart to jump off the track to the side.

If this happens, use a lower initial velocity for the cart.

Keep the track clean; if it is very dusty the carts will not roll smoothly.

Use lower speeds and lower inclines than you might initially choose; the physics

is the same and students will have more time to observe what is happening.

Attach the track feet, sliding at least one in about 30 cm before inserting the

Motion Detector bracket.

Study the Motion Detector bracket photo carefully and note that the bracket is

attached to the underside of the track. A common error is to attach the bracket to

the top slot on the track.

Some Dual Range Force Sensors come with a plastic bolt that is too long to allow

simultaneous attachment of the DFS with a MASS. If your bolt is long, use a wire

cutter to remove a few threads at a time.

7

8

Page 5

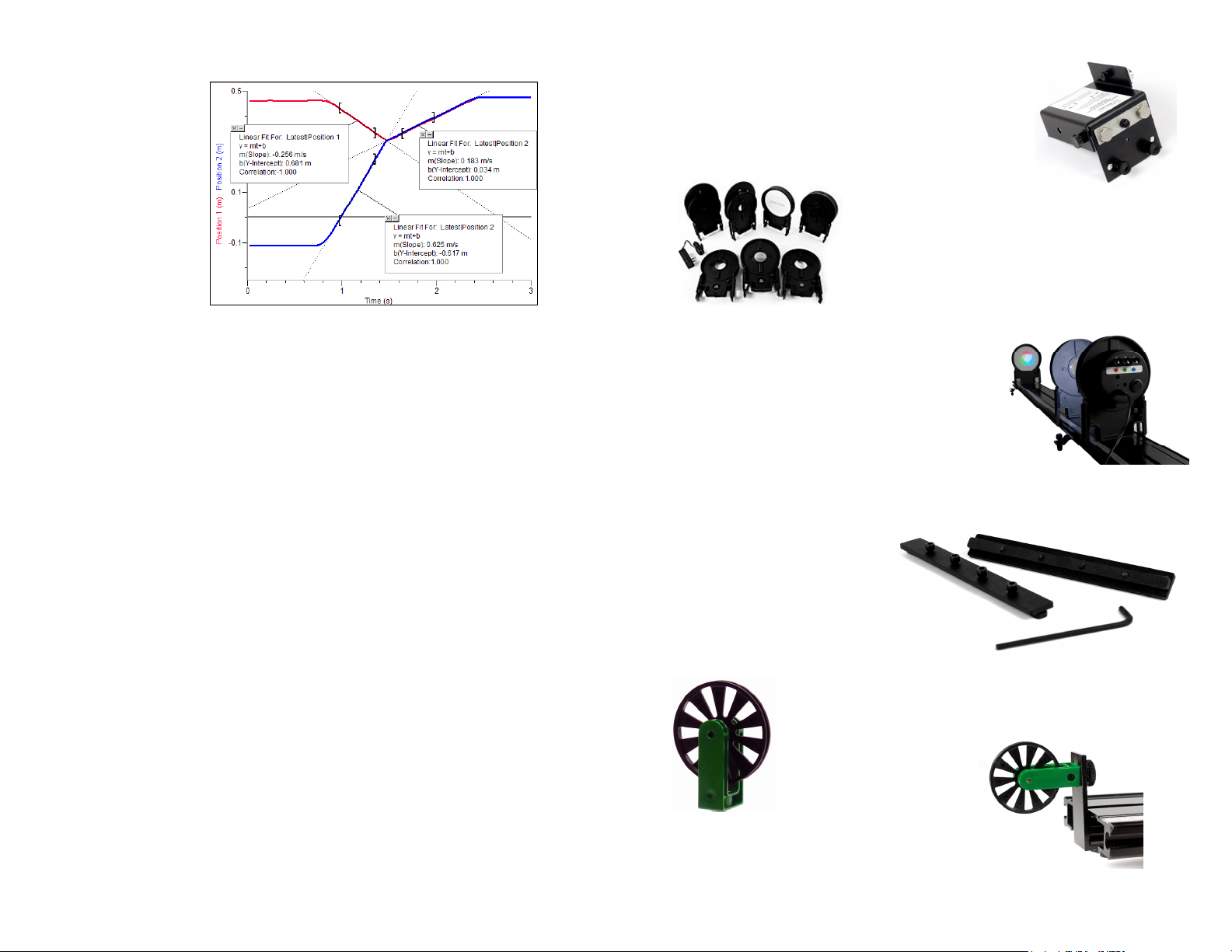

Sample Experiment

An example of a typical experiment done with the Vernier Dynamics system is a two

cart, inelastic collision

for studying momentum

conservation.

This experiment takes

two motion detectors,

since both carts are in

motion. A Motion

Detector is placed just a

few centimeters from

each end. For this

experiment, in

Logger Pro the

direction of one detector

was reversed, and then

both detectors are zeroed with the carts stuck together near the middle of the track.

This places the origin of the common coordinate system near the middle, and the two

readings will then be the same when the carts are in contact.

The Vernier carts had the hook and pile tabs in place to create a completely inelastic

collision. After starting data collection, the carts were rolled toward one another,

with one cart moving a bit faster than the other. On collision, the hook and pile tabs

held the carts together as they roll on.

Note several features of the graph:

Before the collision, the carts are moving with constant velocities of opposite

sign, since they are moving toward one another.

The carts move as a unit after the collision with a common, constant velocity.

Both carts are very nearly 0.500 kg; the total momentum before the collision is then

0.184 kg m/s. Afterward, the momentum is 0.183 kg m/s.

Suggested Accessories

Dynamics Track Adapter (DTA-DFS). The DTA is used

to attach a Dual Range Force Sensor to a track in

several different positions. Magnetic bumpers for the

DFS are included.

Optics Expansion Kit

(OEK). The Vernier Optics Expansion Kit extends

the Vernier Dynamics System for use in optics

experiments.

Color Mixer (CM-OEK). The Vernier Color Mixer

Kit consists of a three-color LED illuminator with

power supply, a lens, and a double-sided screen.

Experiments in additive and subtractive color

mixing can be easily and conveniently carried out

using this kit. The intensity of the red, blue and

green LEDs can be smoothly controlled from the

light source.

Additional Track (TRACK). Add another track to your system.

Track-to-Track Coupler

(T2T-VDS). The Track-toTrack Coupler rigidly connects

two tracks for larger

experiments and

demonstrations.

Ultra Pulley (SPA). The pulley can be attached to the end of a

track using the Pulley Bracket to make a half-Atwood machine.

Pulley Bracket (PB-SPA).

The pulley bracket allows

easy attachment of an Ultra

Pulley to the end of a

Vernier track. Compatible

with a photogate bracket for measuring

motion using the pulley.

9

10

Page 6

The Cart Friction Pad (PAD-VDS) is a variable friction mechanism for use with

the Vernier Standard Cart and Plunger Cart. It can be used on any flat surface or, for

best results, with the Vernier Dynamics System to study the effects of friction.

The two-speed Dynamics Cart Fan (FAN-VDS) magnetically attaches to the

Vernier Standard Cart and Plunger Cart. It can be used on any flat surface or, for

best results, with the Vernier Dynamics System to study motion, force, and

momentum

Warranty

Vernier warrants this product to be free from defects in materials and workmanship

for a period of five years from the date of shipment to the customer. This warranty

does not cover damage to the product caused by abuse or improper use.

Vernier Software & Technology

13979 S.W. Millikan Way Beaverton, OR 97005-2886

Toll Free (888) 837-6437 (503) 277-2299 FAX (503) 277-2440

Rev. 7/16/12

Logger Pro, Logger Lite, Vernier LabQuest 2, Vernier LabQuest, Vernier LabPro, Go!

marks shown are our registered trademarks in the United States. TI-Nspire, CBL 2, TI-GRAPH LINK, and TI Connect

are trademarks of Texas Instruments.

All other marks not owned by us that appear herein are the property of their respective owners, who may or may not be

affiliated with, connected to, or sponsored by us.

Printed on recycled paper.

11

info@vernier.com www.vernier.com

Link, Vernier EasyLink and other

12

Loading...

Loading...