Page 1

Centripetal Force

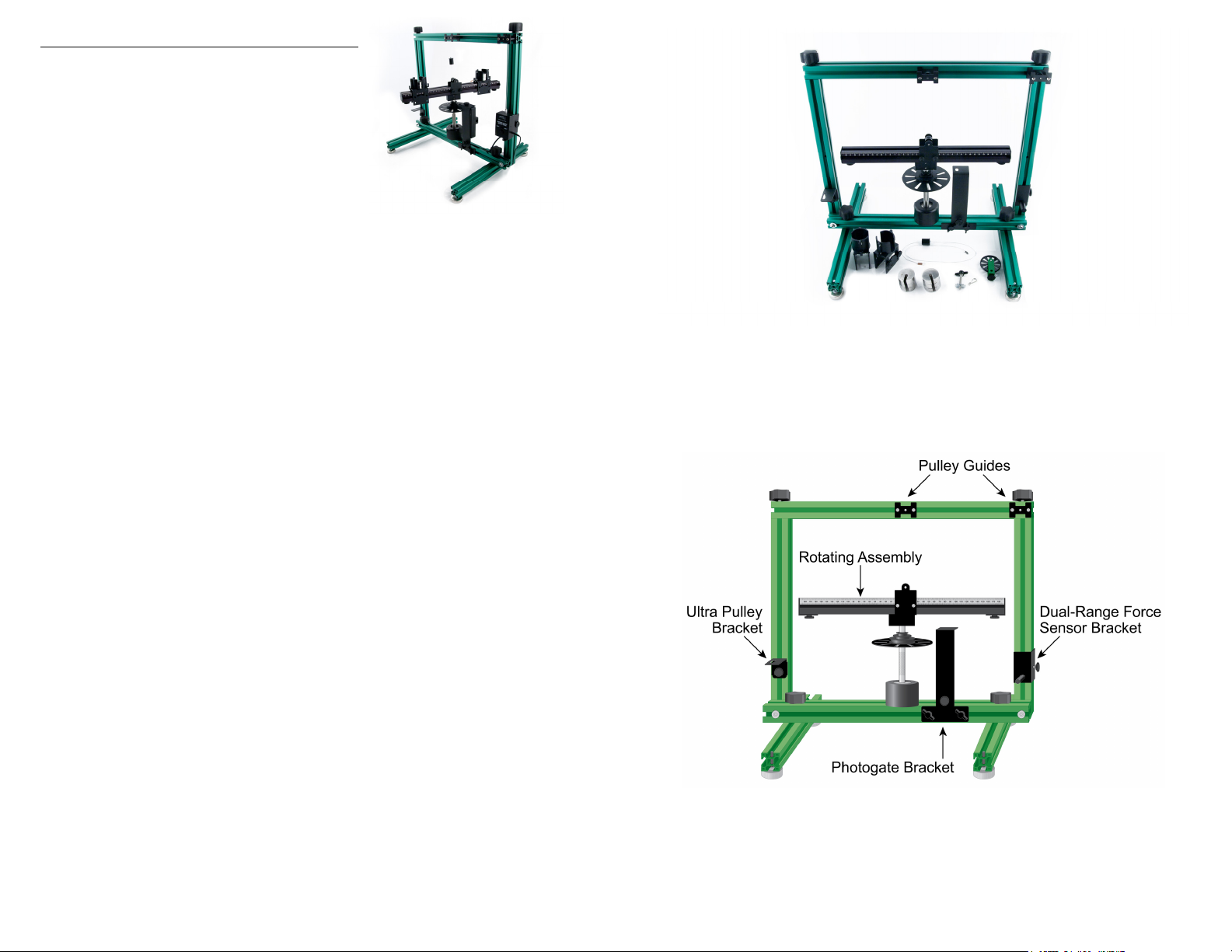

Apparatus

(Order Code CFA)

The Centripetal Force Apparatus (CFA) facilitates

the study of circular motion. It allows students to

easily and accurately see the relationship between

centripetal force, tangential velocity (or angular

velocity), radius and mass. The traditional method, i.e., twirling a rubber stopper in a

horizontal circle, is instructional in that students can have kinesthetic understanding

of the relationships. For example, they can feel the change in the force as the radius

changes. The CFA allows students to make direct measurements of the variables and

to obtain excellent quantitative data.

With this equipment, students are able to investigate relationships between

Centripetal force and the mass of the accelerating object

Centripetal force and the radius of the motion

Centripetal force and the tangential velocity of the accelerating object

Centripetal force and the angular velocity of the accelerating object

Angular acceleration, torque and moment of inertia

What is included with the Centripetal Force Apparatus?

Rectangular Frame

Support Legs (2)

Rotating Assembly consisting of Rotational Shaft, Encoder Wheel, 3-Step Pulley,

Rotating Beam, Bearing Housing

Sliding Carriage to hold the test masses

Counterbalance Carriage to balance the rotating beam

Swivel Assembly (connects Sliding Carriage to a Dual-Range Force Sensor)

Ultra Pulley

Ultra Pulley Bracket (preinstalled on Assembly)

Photogate Bracket with 1/4 x 20 mounting screw (preinstalled on Assembly)

Dual-Range Force Sensor Bracket (preinstalled on Assembly)

50 g masses (4)

100 g masses (4)

Hook (attaches a Wireless Dynamic Sensor System (WDSS) to the Sliding

Carriage)

WDSS Mounting Screw and T Nut to secure a WDSS

A Closer Look at the Components

Rectangular Frame

The frame supports the Rotating Assembly and it accommodates a variety of

sensors. Two Pulley Guides on the top of the frame allow a Dual-Range Force

Sensor to be connected to a carriage that slides along the Rotating Beam.

2

Page 2

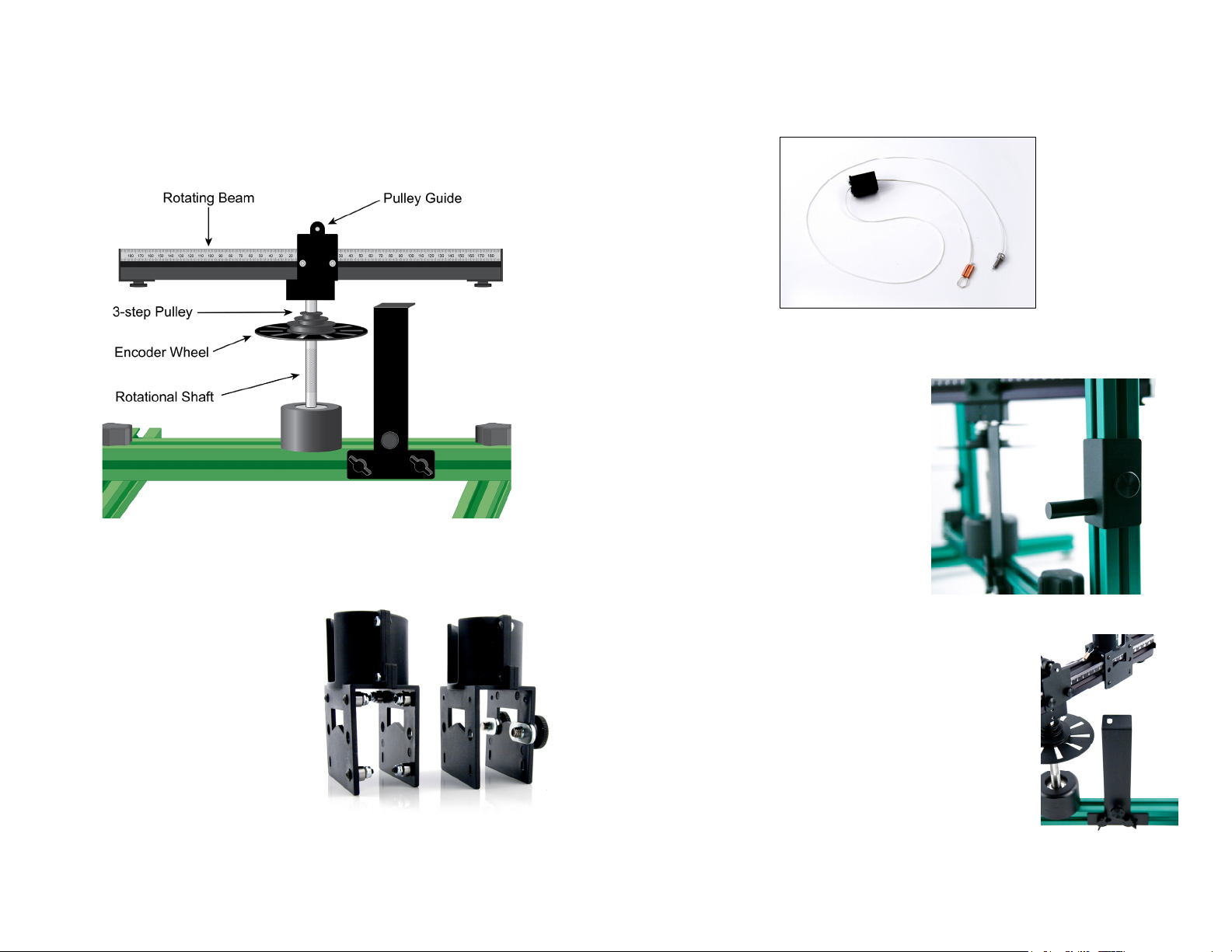

Rotating Assembly

The Rotating Assembly consists of a Rotating Beam, Rotational Shaft, Bearing

Housing, Encoder Wheel, and 3-Step Pulley. Carriages are placed on the Rotating

Beam. A string can be attached to the 3-Step Pulley to apply a torque to the

Rotational Shaft.

In the middle of the Rotating Beam, you’ll find a Pulley Guide. A string from a

Dual-Range Force Sensor threaded through this pulley can be used to attach the

force sensor to the Sliding Carriage.

Carriages

Two carriages ride on the Rotating Beam during data collection. A Sliding Carriage

(shown at left) has low friction bearings that allow it to slide along the beam during

the experiment. The Sliding Carriage

is attached to a force sensor (e.g., a

Dual-Range Force Sensor or Wireless

Dynamic Sensor System). A

Counterbalance Carriage (shown at

right) is secured to the other side of

the beam using screws and T-nuts. As

the beam rotates, the force sensor

measures the centripetal force on the

Sliding Carriage. A separate sensor

(i.e., a Vernier Photogate) measures

the angular position and angular

velocity.

Swivel Assembly

The Swivel Assembly consists of two strings and a swivel. The assembly is used to

connect the Sliding Carriage to a Dual-Range Force Sensor. A small screw on one

end of the assembly connects to the end of the force sensor. The other end of the

Swivel Assembly contains a loop that slides over a hook on the Sliding Carriage.

Swivel Assembly

Dual-Range Force Sensor Bracket

This bracket is attached to the right side

of the frame. Slide the Dual-Range Force

Sensor onto the post and use the plastic

1/4 x 20 screw that ships with the force

sensor to secure the sensor to the bracket.

A screw on the right side of the bracket

allows the bracket to move up and down,

which enables a change in the radius of

motion of the Sliding Carriage when

attached via the Swivel Assembly.

Photogate Bracket

This bracket, located on the bottom of the frame, allows

you to attach a Vernier Photogate to the frame. A

1/4 x 20 screw is stored in the bottom of the bracket.

3

4

Page 3

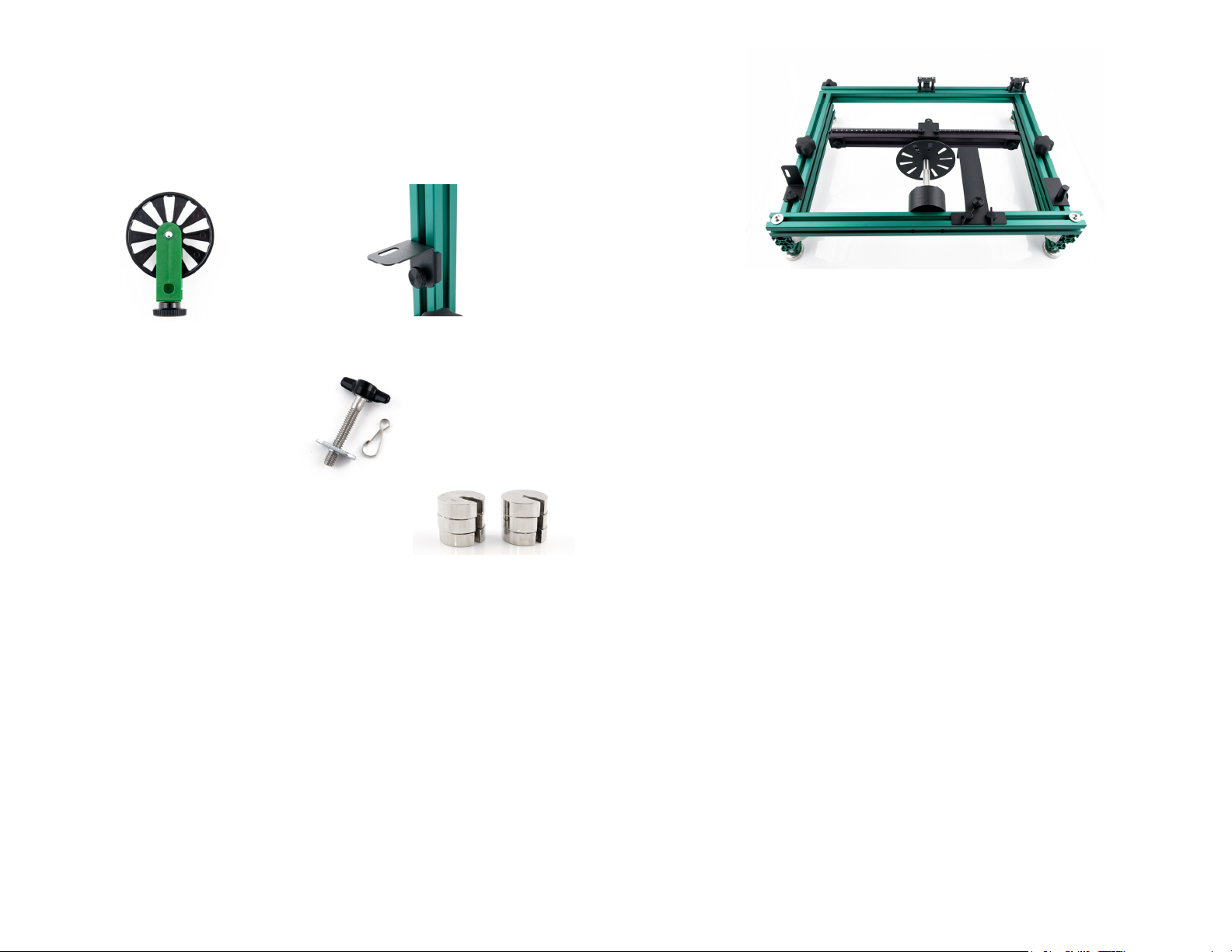

Ultra Pulley and Pulley Bracket

The Ultra Pulley and Pulley Bracket allow a torque to be applied to the Rotational

Shaft. Secure the Ultra Pulley to the bracket using the included 1/4 x 20 screw.

Attach one end of a string to the 3-Step Pulley mounted on the Rotational Shaft.

Attach a small mass to the other end of the string. Run the string over the Ultra

Pulley and allow it to fall to apply a torque to the Rotational Shaft.

Ultra Pulley Ultra Pulley Bracket

WDSS Screw and Clip

The WDSS Screw allows you to attach the WDSS to

the rotating beam. The Clip connects the WDSS to the hook

on the Sliding Carriage.

Masses

Four 50 g masses and four 100 g masses are included in

the apparatus. They slip into the carriages to allow you

to vary the masses of the carriages.

Assembly and Storage of the Frame and Support Legs

The apparatus is shipped flat, and it can be stored flat when not in use. The Rotating

Assembly and Rectangular Frame come completely assembled. The brackets for the

Dual-Range Force Sensor, Vernier Photogate, and Vernier Ultra Pulley are also

preinstalled. The Support Legs are stored on the sides of the frame. Remove the

knob of the knob screw that holds each leg and use the knob screw to attach each

Support Leg to the bottom of the frame, then replace the knob and tighten. Reverse

this procedure to store the equipment.

Rectangular Frame stored flat. Support legs attached to

the underside of the side vertical frame members.

Leveling the Apparatus

Follow these steps to level the apparatus.

1. Secure the Counterbalance Carriage to the outer end of the Rotating Beam.

2. Place three of the Masses in the carriage.

3. Use a flathead screw driver to lower each foot on the CFA footer to its lowest

height.

4. Give the Rotating Beam a very slow spin and watch its motion. The beam will

tend to settle to its lowest point. Confirm the location of lowest point by spinning

the beam a couple more times.

5. Raise the lowest end or side of the apparatus by increasing the height of the

nearby footer or footers.

6. Repeat Steps 4 and 5 until the beam spins without returning to a consistently low

spot.

Attaching the Carriages to the Rotating Beam

It is important to attach the carriages in the proper orientation on the Rotating Beam.

The beam is not symmetric about the Pulley Guide located near the middle of the

beam. With the ruled side of the rotating beam facing you, the Sliding Carriage goes

on the right and the Counterbalance Carriage goes on the left.

5

6

Page 4

Counterbalance Carriage on left. Sliding Carriage on right.

To attach the carriages, remove the end pieces on the

Rotating Beam. As you look at the ruled side of the

Rotating Beam, you will attach the Sliding Carriage to

the right side as follows:

1. Note the sets of bearings upon which the carriage

slides. Two sets of bearings appear on the top of the

carriage and one set appears on the bottom.

2. As you slide the Sliding Carriage on the beam, orient

the carriage so that the end of the carriage with the

single bottom set of bearings slides on first. (See on

next page.) If you orient the carriage the other way, your carriage will not be able

to reach its maximum radius (~16 cm) on the beam.

3. Slide the Counterbalance Carriage on the other side of the beam.

Attaching the Sliding Carriage to the Rotating Beam

Using Sensors with the Apparatus

While investigating centripetal force with this apparatus, students use sensors to

measure force and angular velocity. Our recommendation is to use the Dual-Range

Force Sensor to measure force and the Vernier Photogate to measure angular speed.

The Vernier Wireless Dynamic Sensor System can also be used to measure force.

The following describes how to connect each sensor to the apparatus.

Attaching a Dual-Range Force Sensor to the Frame

A Dual-Range Force Sensor attaches to the right-hand vertical side of the apparatus.

Follow these assembly instructions.

1. In normal use, a hook or a bumper is attached to the end of the Dual-Range Force

Sensor. Remove the hook or bumper if it is attached.

2. Two pulleys are attached to the top of the frame. With the pulleys facing you,

attach the Dual-Range Force Sensor to the Force Sensor Bracket on the right side.

3. Thread the screw end of the Swivel Assembly over the middle pulley on the top

of the frame, then thread the screw end through the pulley on the right side of the

frame.

4. Attach the screw end of the Swivel Assembly to the force sensor, as shown

below.

5. Thread the loop end of the Swivel Assembly under the Pulley Guide near the

middle of the beam and attach the loop end to the Sliding Carriage, as shown in

the larger photo on page 7. The Sliding Carriage should be on the right side of the

Rotating Beam with the ruled side of the beam facing you.

7

8

Page 5

Dual-Range Force Sensor attached to frame, and with screw end of Swivel Assembly

attached. Vertical adjustment screw on the right.

Attaching a Photogate

A photogate can be attached to the Vernier Photogate

Bracket, which is positioned next to the Encoder mounted on

the Rotating Shaft. Follow these assembly instructions:

1. Locate the Photogate Bracket on the lower horizontal

piece of the frame.

2. Secure the photogate into the stand with the

1/4 x 20 mounting screw. In this position the photogate

beam will be interrupted by the Encoder Wheel.

Attaching a Wireless Dynamic Sensor System (WDSS)

The WDSS can be used instead of the Dual-Range Force Sensor, and attaches to the

horizontal rotating beam. Follow these assembly instructions:

1. On the middle of the Rotating Beam, you’ll find a Pulley Guide used when the

Swivel Assembly is connected to the Dual-Range Force Sensor. Loosen the wing

nuts on the pulley and remove them from the beam.

2. Attach the Sliding Carriage to the Rotating Beam if it is not already attached.

3. Remove the end piece and the Counterbalance Carriage if it is mounted on the

Rotating Beam.

4. Attach the WDSS mounting screw and T-nut to the WDSS, slide the WDSS onto

the Rotating Beam so that the hook end is adjacent to the Sliding Carriage.

5. Attach the small end of the WDSS clip to the hook end of the WDSS.

6. Clip the other end of the WDSS clip to the Sliding Carriage.

7. Move the Sliding Carriage to the desired radius. Pull the WDSS tight and secure

it to the beam with its mounting screw.

Removable Pulley Guide on Rotating Beam

Note: The beam is not perfectly balanced when using a WDSS, because the

Counterbalance Carriage cannot be placed directly opposite the Sliding Carriage.

The shaft and bearing are sufficiently rigid such that a small imbalance will not

affect results.

WDSS attached to beam and Sliding Carriage

Data-Collection Interface and Software Compatibility

Data collection with the CFA is possible with the following combinations of

interfaces and software.

Logger Pro 3 Use this computer program with LabQuest

LabQuest Mini, and LabPro

LabQuest App Use this program with LabQuest 2 or original LabQuest, when

LabQuest 2 or original LabQuest is used as a standalone device.

DataQuest App Use this application with TI-Nspire™ Technology and the

TI-Nspire™ Lab Cradle.

LabVIEW™ National Instruments LabVIEW™ software is a graphical

programming language sold by National Instruments. It is used with SensorDAQ

and the sensors that are compatible with the CFA. Contact Vernier for more

information concerning compatibility.

®

.

®

2, LabQuest,

9

10

Page 6

Data-Collection Overview and Software Setup

Sensors used with the CFA provide a reading of the force required to keep the

Sliding Carriage in position (the centripetal force) and the angular speed of the

rotating beam. Data can be collected from both sensors simultaneously, but the

software data-collection mode choices will depend on your goals and the particular

sensors chosen.

In order to discuss common data-collection modes used with this apparatus, let us

first examine a few experiments for context.

Experiments fall into two broad classes: exploration of centripetal force relations

2

(F=mv

/r, where v is the tangential velocity, or F=mr

velocity) and moment of inertia experiments. We will concentrate here on centripetal

force.

Although the v

2

/r relationship is commonly encountered first in a physics

curriculum, the basic sensor measurement is angular speed. As a result, any software

configuration that reports tangential velocity will be more complex to implement,

because the student must provide the additional radius information in order for the

software to calculate tangential velocity from angular velocity (v=

recommend the use of angular velocity for analysis with this apparatus.

Another data-collection subtlety is the behavior of photogate-based data collection

compared to time-based data collection. Most often with sensors, data collection is

time-based, where the sensor value is recorded at uniform time intervals, such as

every 0.02 seconds, or 50 times per second. Photogate data collection, in contrast, is

a record of times at which the gate state changes. These times will not be at regular

time intervals.

If force data are taken whenever the photogate records a transition (known as

Digital Events mode in Logger Pro), data will not be uniformly spaced. For most

analyses, unevenly spaced points will not matter. If force data are collected at

uniform time intervals, either the force or velocity data will have to be interpolated

in order to create a graph of force vs. velocity or velocity

Different combinations of sensors and interfaces will determine how data are best

collected. The Photogate always yields event times, even if other data collection is in

time-based mode. The WDSS and the Dual-Range Force Sensor can be used in

either time- or event-based data collection on LabQuest, but on Logger Pro the

WDSS must be used in time-based data collection.

The following sections give setup suggestions for a single experiment, centripetal

force vs. velocity (or velocity

2

), using various sensor combinations, interfaces, and

either the angular velocity or the much simpler tangential velocity approach. We

suggest that you begin with one of our Logger Pro experiment files available in the

Probes and Sensors folder in Logger Pro version 3.8.5.1 and later.

2

, where ω is the angular

r). We

2

.

Angular Velocity – Logger Pro 3 with Dual-Range Force Sensor

and Vernier Photogate

Open the file

CFA-DFS-Photogate-angular.cmbl.

This file is set up for a Dual-Range

Force Sensor and a Vernier Photogate.

The file contains the setup and a few

calculated columns that allow for easy

data collection. The data-collection

mode is time-based, which means that

the force readings will be taken at a

50 Hz rate, and the photogate readings

will happen as the Encoder Wheel

rotates. As a result, the force readings

are blank when there is a velocity

reading, and vice versa. This prevents

direct graphing of these columns, until

a simple calculation is done to provide

interpolated force values between the

regularly-spaced values.

The column labeled “Force” contains the raw sensor values. The calculated column

“Force Interpolated,” or “F-i” for short, fills in the missing values. To see how we

defined the column, hover your mouse over the F-i column header in the data table

to see the definition. Any graphs between force and velocity must use the

F-i column.

The photogate is used to collect motion data of the object, where the “Distance”

column increments by a fixed amount for each block-to-block pair sensed by the

gate. Since the Encoder Wheel has ten slots, the increment is set to 0.628, with units

of radians, or 2π/10. The velocity (ω) column then has units of radians/second.

The file also contains a calculated column called “angular velocity

This column is helpful in the data analysis, since a graph of F vs. ω

proportionality of slope mr, given that F=mr

2

.

Connect an interface, Vernier Photogate, and Dual-Range Force Sensor, and reopen

the file CFA-DFS-Photogate-angular.cmbl. Place equal masses on the Sliding

Carriage and Counterbalance Carriage. Adjust the location of the force sensor so that

the Sliding Carriage will move in a circle of about a 10 cm radius, and set the

Counterbalance Carriage to a similar radius.

The current force reading is shown in the Logger Pro live readout. Spin the beam so

that the force reaches a reading of more than 5 N. This is most easily done by

spinning the shaft between the thumb and fingers. Start data collection.

Observe the Force-Interpolated vs. Time graph, and then display Force-Interpolated

vs. Angular Velocity. Also create and analyze a graph of Force-Interpolated vs.

Angular Velocity

2

.

2

,” or ω2 for short.

2

is a direct

11

12

Page 7

Your graphs show how centripetal force varies with angular velocity. Now take

additional data with other masses and other radii.

Angular Velocity – LabQuest App with Dual-Range Force Sensor

and Vernier Photogate

Data collection with the Dual-Range Force Sensor and Vernier Photogate is

simplified because the LabQuest App automatically calculates the interpolated force.

To find the angular velocity, you must configure the photogate motion timing mode

with the angular position information, detailed below.

1. Start the LabQuest App and let it auto-ID the sensors.

2. On the Meter tab of the LabQuest App, tap Mode.

3. Tap User Defined.

4. Enter 1/10 of the angular position change for each slot, or 2π/10, as the User

Defined value. You will not need to adjust this value each time you change the

radius, since the angular velocity is independent of radius.

5. On this screen, choose the option to end the data collection with the Stop button.

6. Tap OK.

Collect data and examine the graphs. For further analysis, change one of your graphs

to display Force vs. Velocity or Force vs. Velocity

2

.

Tangential Velocity – Logger Pro 3 with Dual-Range Force

Sensor and Vernier Photogate

If desired, you can add calculations to the Logger Pro file to determine the tangential

velocity, and use that quantity instead of angular velocity for graphs. We show you

how to add these calculations in the file CFA-DFS-Photogate-tangential.cmbl. This

file is set up for Dual-Range Force Sensor and a Vernier Photogate, and provides

several calculated columns.

The first is the same interpolated force column as in the example above.

The second calculation is needed to determine tangential velocity, since the

tangential velocity of the rotating mass is a function of its radius of motion, using

v=

r. The photogate is set up as before to collect motion data, and the “Tangential

Velocity” column is used to find the product of the angular velocity and the current

radius. The file contains a User Parameter called “Radius.” The student must set the

parameter to match the radius of motion for each run. Take note that if the parameter

is changed for a later run, all columns depending on this parameter will be updated.

This includes stored runs, therefore, altering the radius may upset previous

calculations, including curve fits.

After taking data as before, observe the Force-Interpolated vs. Time graph, and then

display Force-Interpolated vs. Tangential Velocity. Also create and analyze a graph

of Force-Interpolated vs. Velocity

Your graphs show how centripetal force varies with tangential velocity. Now take

additional data with other masses and other radii. The slope of the line for the

velocity

F=mv

2

graph will be proportional to mass, and inversely proportional to radius, per

2

/r.

2

.

Tangential Velocity – LabQuest App with Dual-Range Force

Sensor and Vernier Photogate

Data collection with the Dual-Range Force Sensor and Vernier Photogate is

simplified because the LabQuest App automatically calculates the interpolated force.

To find the tangential velocity, you must configure the photogate motion timing

mode with the circumference information, detailed below.

1. Start the LabQuest App and let it auto-ID the sensors.

2. On the Meter tab of the LabQuest App, tap Mode.

3. Tap User Defined.

4. Enter 1/10 of the circumference of the mass path, or 2πr/10, as the User Defined

value. You will need to adjust this value each time you change the radius.

5. On this screen, choose the option to end the data collection with the Stop button.

6. Tap OK.

Collect data and examine the graphs. For further analysis, change one of your graphs

to display Force vs. Velocity or Force vs. Velocity

2

.

Logger Pro 3 with Wireless Dynamic Sensor System (WDSS)

Start Logger Pro software and establish a Bluetooth connection to the device as

described in the WDSS manual.

If you want to use a photogate to collect position and tangential velocity data, use

one of these Logger Pro files.

a. The file CFA-WDSS-Photogate.cmbl, which is part of the file collection on the

CFA web page.

b. The Vernier lab manual Advanced Physics with Vernier – Mechanics contains an

experiment called “12A Centripetal Acceleration” that uses the CFA to

investigation circular motion. The book also contains a Logger Pro file called

“12A Centripetal Acceleration.cmbl” that you can use. The file can be found in

the folder called “Supplemental Materials” on the CD that accompanies the book.

Collect data and change the Force-Interpolated vs. Time to display

Force-Interpolated vs. Velocity. Also create and analyze a graph of Force-

Interpolated vs. Velocity

Collect data and examine the graphs. For further analysis, change one of your graphs

to display Force vs. Angular Velocity (ω). The file contains a calculated column

called Angular Velocity

Velocity

2

(ω2).

2

.

2

(ω2). Create and analyze the graph of Force vs. Angular

13

14

Page 8

LabQuest with Wireless Dynamic Sensor System (WDSS)

Start LabQuest App, let it auto-ID the photogate. Establish a Bluetooth connection to

the WDSS.

When using a photogate, you will need to set the position increment in photogate

motion timing to either 1/10 of the circumference (for tangential velocity) or 2π/10

(for angular velocity).

1. On the Meter tab of the LabQuest App, tap Mode.

2. Tap User Defined.

3. Enter the desired position increment as the User Defined value.

4. On this screen, choose the option to end the data collection with the Stop button.

5. Tap OK.

Collect force data with the WDSS and examine the graphs. For further analysis,

change one of your graphs to display Force vs. Velocity or Force vs. Velocity

2

.

Sample Data from the CFA

The following are summaries of experiments that you can perform with the

Centripetal Force Apparatus.

Centripetal Force with a Spin

To illustrate the capability of the CFA, here is a quick experiment using a different

perspective than is often used. Quite often, centripetal force is investigated using the

equation F=mv

r = radius of motion; however, a comparable equation is F=mr

angular velocity of the mass. This suggests an experiment that lets you explore a

variety of speeds with one run and with a very simple graphical result. If you simply

spin the beam by hand and let it slow down over 30 or 40 seconds, you will have

force as a function of angular speed. A graph of force vs. the square of the angular

speed is a direct proportionality, where the slope represents the product of the mass

and radius, since F=(mr)

The graph below shows two combinations of mass and radius. In each case, the slope

is the product of the mass and radius, and the functional relationship is

proportionality. A Vernier Photogate and Dual-Range Force Sensor were used, since

those will be most commonly available.

2

/r, where F = centripetal force, m = mass, v = tangential velocity, and

2

.

2

where ω is the

Centripetal Force with a Spin – a Detailed Look

The Vernier lab manual Advanced Physics with Vernier – Mechanics has an

excellent experiment that investigates F=mv

experiment is similar to the one mentioned above in that the students spin the

Rotating Beam and collect data as it slows down. A graph of F vs. v

2

/r in a guided inquiry fashion. The

2

shows a linear

relationship. They then vary the mass and determine that the F is directly

proportional to m. Next they compare runs with different radii and see that the force

is inversely proportional to the radius. The lab called “12A Centripetal Acceleration”

is also posted on our web site at www.vernier.com/accessories/cfa/

Moment of Inertia

You can also measure moments of inertia with the CFA. A beginning experiment is

to determine the moment of inertia of the entire rotating assembly. This

measurement is done by hanging a mass over the Ultra Pulley (which can be

attached to the side of the frame) and using a string to attach the mass to the 3-Step

Pulley on the Rotating Assembly. Allow the mass to fall, which applies a torque to

the system. Use a Vernier Photogate to measure the angular acceleration of the

system and then calculate the moment of inertia.

Attach the carriages to the beam and repeat the above experiment to determine the

moment inertia of this system and then determine the moment of inertia of the

carriages idealized as point masses.

Specifications

Encoder Wheel 10 spokes

15

Diameters of Pulleys on 3-Step Pulley on

20 mm, 29 mm, 48 mm

Rotational Shaft

16

Page 9

Other Products for Use with this Kit

Dual-Range Force Sensor (DFS-BTA)

This low-cost force sensor has two ranges: –10 to +10 N and –50 to +50 N. It can be

easily mounted on a ring stand or dynamics cart, or used as a replacement for a

spring scale. Use it to study friction, simple harmonic motion, impact in collisions,

or centripetal force.

Vernier Photogate (VPG-BTD)

Photogates can be used to study free fall, rolling objects, air track collisions,

pendula, etc. This photogate can be easily mounted on a ring stand.

Wireless Dynamic Sensor System (WDSS)

The Wireless Dynamics Sensor System combines a 3-axis accelerometer, altimeter,

and force sensor into one unit that communicates wirelessly with your computer

using Bluetooth

logger.

®

wireless technology. You can also use it as a standalone data

Warranty

Vernier warrants this product to be free from defects in materials and workmanship

for a period of five years from the date of shipment to the customer. This warranty

does not cover damage to the product caused by abuse or improper use.

17

18

Page 10

19

Vernier Software & Technology

13979 S.W. Millikan Way Beaverton, OR 97005-2886

Toll Free (888) 837-6437 (503) 277-2299 FAX (503) 277-2440

Revised 1/7/2015

Logger Pro, LabPro, LabQuest, and Vernier and caliper design are our registered trademarks. All other marks not owned

by us that appear herein are the property of their respective owners, who may or may not be affiliated with, connected to,

or sponsored by us.

Printed on recycled paper.

info@vernier.com www.vernier.com

20

Loading...

Loading...