Vermont Castings RFSDV22, RFSDV32, RFSDV42 Homeowner's Installation And Operating Manual

INSTALLER/ CONSUMER

SAFETY INFORMATION

PLEASE READ THIS MANUAL

BEFORE INSTALLING AND

USING APPLIANCE

WARNING!

IF THE INFORMATION IN

THIS MANUAL IS NOT

FOLLOWED EXACTLY, A FIRE

OR EXPLOSION MAY RESULT

CAUSING PROPERTY

DAMAGE, PERSONAL INJURY

OR LOSS OF LIFE.

Freestanding

Direct Vent Fireplaces

Models: RFSDV22,

FOR YOUR SAFETY

Installation and service must

be performed by a qualified

installer, service agency or the

gas supplier.

WHAT TO DO IF YOU SMELL

GAS:

• Do not try to light any

appliance.

• Do not touch any electric

switch; do not use any phone

in your building.

• Immediately call your gas

supplier from your neighbor's

phone. Follow the gas

suppliers instructions.

• If you cannot reach your gas

supplier call the fire

department.

DO NOT STORE

OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY

OF THIS OR ANY OTHER

APPLIANCE.

RFSDV32, RFSDV42

Homeowner’s Installation and

Operating Manual

I

S

G

E

N

D

C

E

D

R

E

I

T

I

F

CFM Specialty Home Products

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

CERTIFIED

INSTALLER: DO NOT DISCARD THIS MANUAL - LEAVE FOR HOMEOWNER

10001028 7/04 Rev. 2

RFSDV22/32/42 Freestanding Direct Vent Fireplace

Table of Contents

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE.

Thank you and congratulations on your purchase of a CFM Specialty Home Products fireplace

IMPORTANT: Read all instructions and warnings carefully before starting installation. Failure to follow these instruc-

tions may result in a possible fire hazard and will void the warranty.

Installation Instructions

Important Curing/Burn Information.....................................................................................3

Locating the Fireplace........................................................................................................3

Fireplace Dimensions.........................................................................................................4

Clearance to Combustibles ................................................................................................5

Gas Specifications .............................................................................................................5

Gas Inlet & Manifold Pressures..........................................................................................5

High Elevations ..................................................................................................................5

Preparation.........................................................................................................................5

Gas Line Installation...........................................................................................................5

Installation of Remote Switch for RN/RP gas valve ...........................................................6

General Venting Information

General Venting Information - Termination Location .........................................................7

Termination Clearances .....................................................................................................8

General Information on Assembling Vent Pipes ................................................................8

Twist Lock Pipes ................................................................................................................8

How to use the Vent Graph................................................................................................9

Vertical Sidewall Applications ............................................................................................9

Vertical Sidewall Installation.............................................................................................11

Below Grade Installations (Snorkel).................................................................................12

Vertical Through-the-Roof Applications & Installation......................................................13

Twist Lock Venting Components......................................................................................15

Operating Instructions

Glass Information .............................................................................................................16

Louvre Removal ...............................................................................................................16

Trim Removal...................................................................................................................16

Glass Removal.................................................................................................................16

Glass Cleaning.................................................................................................................17

Installation of Logs & Burner Lava Rock Material ............................................................17

Ceramic Refractory ..........................................................................................................18

Flame Adjustment ............................................................................................................18

Temperature Adjustment..................................................................................................18

Flame Characteristics ......................................................................................................19

Lighting Instructions .........................................................................................................20

Troubleshooting ...............................................................................................................21

Maintenance ............................................................................................................................24

Replacement ............................................................................................................................25

Accessories ............................................................................................................................28

Mobile Home Instructions ...........................................................................................................29

Warranty ............................................................................................................................30

2

10001028

RFSDV22/32/42 Freestanding Direct Vent Fireplace

Installation and Operating Instructions

This gas fireplace should be installed by a qualified installer in

accordance with local building codes and with current CSAB149.1 Installation codes for Gas Burning Fireplaces and

Equipment and CAN/CSA Z 240.4 Canada.

FOR U.S.A Installations follow local codes and/or the current

National Fuel Gas Code. ANSI Z223.1/NFPA 54.

FOR SAFE INSTALLATION AND OPERATION PLEASE NOTE

THE FOLLOWING:

1 . This fireplace gives off high temperatures and should be

located out of high traffic areas and away from furniture

and draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this fireplace and should stay

away to avoid burns or ignition of clothing.

3. Children should be carefully supervised when they are in

the same room as your fireplace.

4. Under no circumstances should this fireplace be

modified.Parts removed for servicing should be replaced

prior to operating the fireplace again.

5. Installation and any repairs to this fireplace should be

carried out by a qualified service person. A professional

service person should be contacted to inspect this fireplace

annually.Make it a practice to have all of your gas fireplaces checked annually. More frequent cleaning may be

required due to excess lint and dust from carpeting,

bedding material, etc.

6. Control compartments, burners and air passages in this

fireplace should be kept clean and free of dust and lint.

Make sure that the gas valve and pilot light are turned off

before you attempt to clean this fireplace.

7, The venting system(chimney) of this fireplace should be

checked at least once a year and if needed your venting

system should be cleaned.

8. Keep the area around your fireplace clear of combustible

materials, gasoline and other flammable vapour and

liquids. This fireplace should not be used as a drying rack

for clothing,nor should Christmas stockings or decorations

be hung in the area of it.

9. Under no circumstances should any solid fuels

(wood,coal,paper or cardboard etc.)be used in this fireplace.

10.The flow of combustion and ventilation air must not be

obstructed in any way.

11.When the fireplace is installed directly on carpeting, vinyl

tile or any combustible material other than wood, the

fireplace must be installed on a metal or wood panel

extending the full width and depth of the fireplace.

12.This fireplace requires adequate ventilation and

combustion air to operate properly.

13.This fireplace must not be connected to a chimney flue

serving a separate solid fuel burning fireplace.

IMPORTANT:

PLEASE REVIEW THE FOLLOWING CAREFULLY

Remove any plastic from trim parts before turning

the fireplace ON.

It is normal for fireplaces fabricated of steel to give

off some expansion and/or contraction noises during

the start up or cool down cycle. Similar noises are

found with your furnace heat exchanger or car

engine. It is not unusual for your gas fireplace to

give off some odor the first time it is burned. This is

due to the curing of the paint and any undetected oil

from the manufacturing process.

Please ensure that your room is well ventilated -

open all windows.

It is recommended that you burn your fireplace for a

least six (6) hours the first time you use it. If optional

fan kit has been installed, place fan in the "OFF"

position during this time.

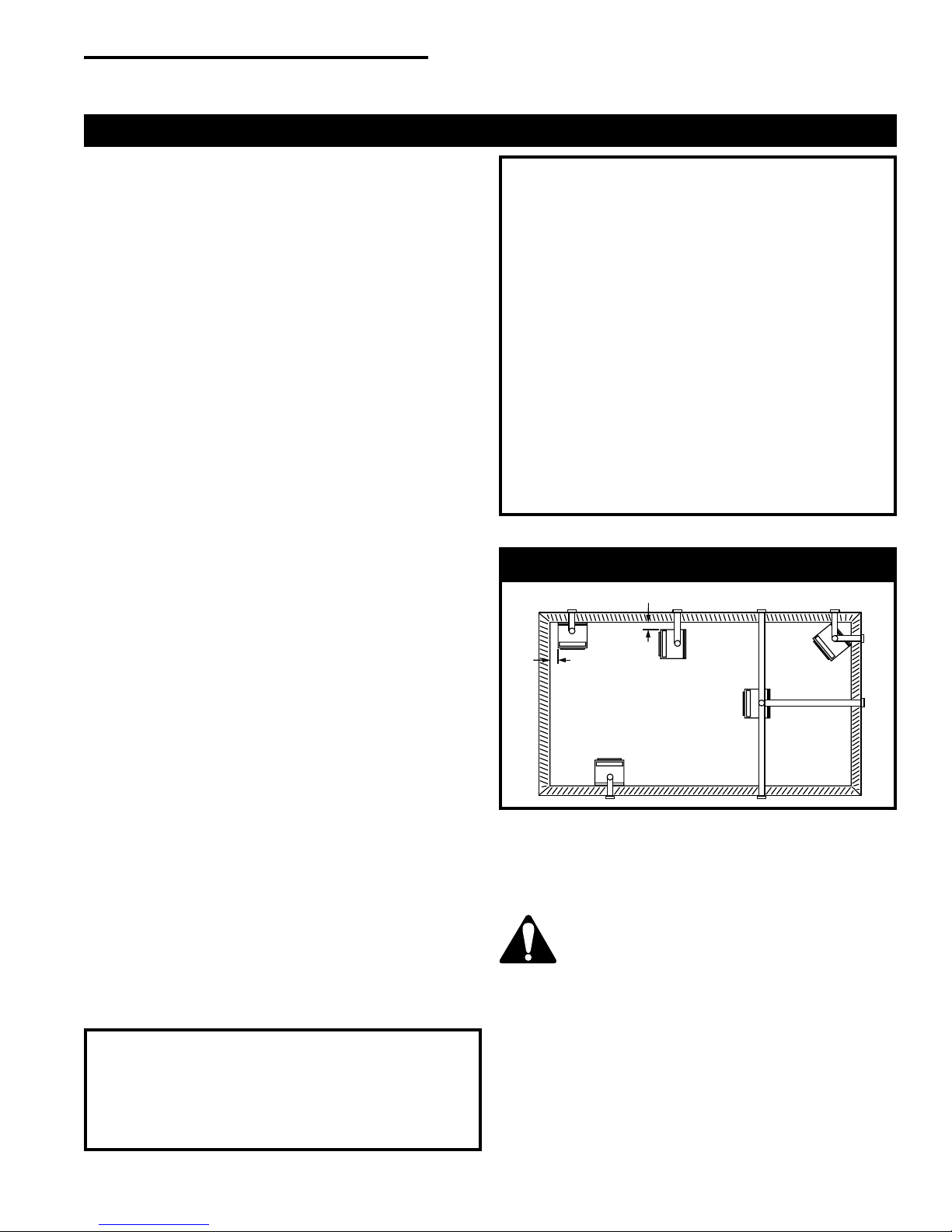

Locating the Fireplace

12 in. (305mm)

A

12 in.

(305mm)

B

C

E

Fig. 1 Locating gas fireplace.

A) *Flat on wall corner B) *Room divider

C) Island D) Cross corner

E) Flat on wall

* A & B must maintain a 12" (305mm) clearance between the wall and

side glass of fireplace.

There is a minimum vertical rise required for the venting

which varies depending on the application. The maximum

horizontal run also has restrictions. Become familiar with

the venting instructions starting on page 7, before starting

the installation.

D

Proposition 65 Warning: Fuels used in gas,

woodburning or oil fired appliances, and the products

of combustion of such fuels, contain chemicals known

to the State of California to cause cancer, birth defects

and other reproductive harm.

California Health & Safety Code Sec. 25249.6

10001028

3

RFSDV22/32/42 Freestanding Direct Vent Fireplace

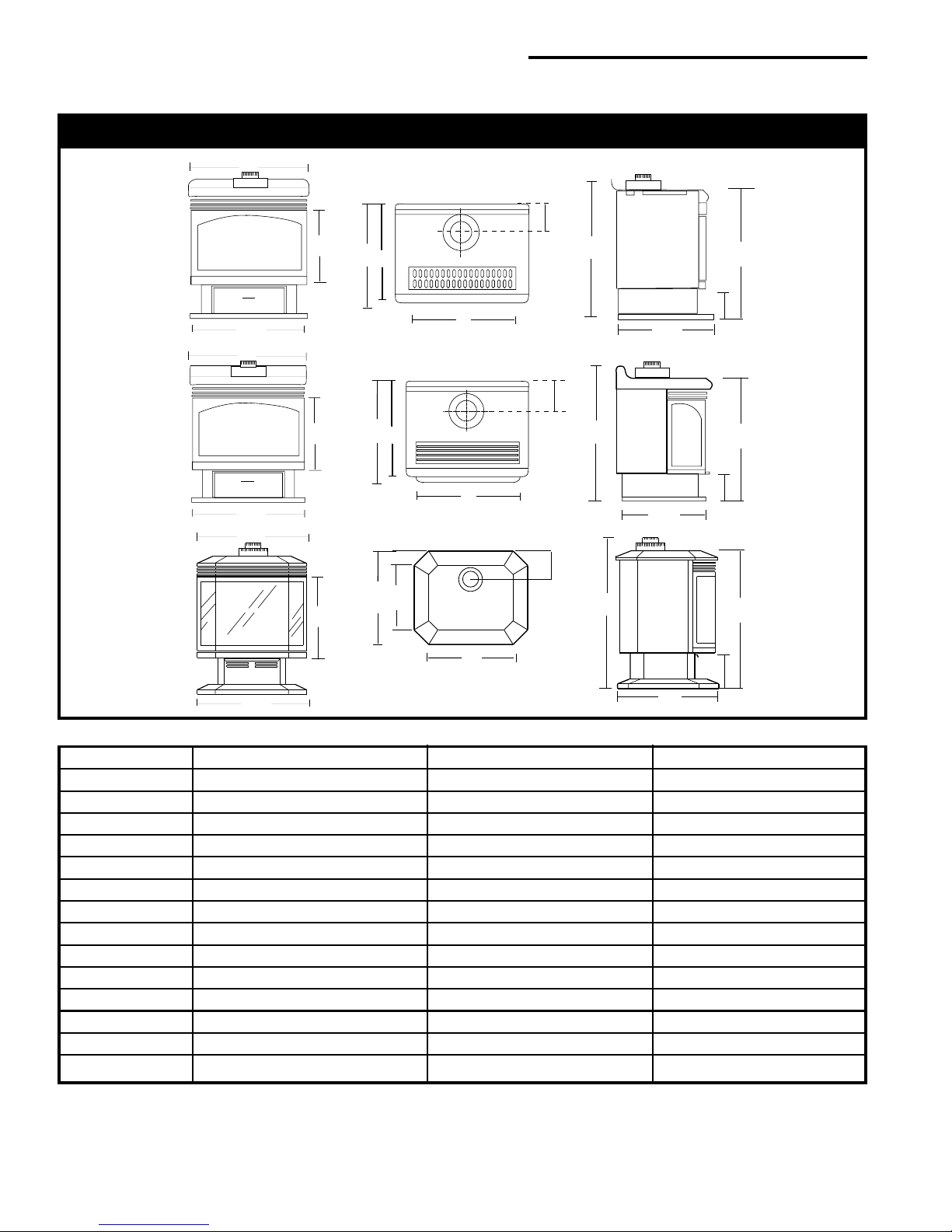

Fireplace Dimensions

A

K

C

D

E

B

A

C

B

A

C

D

E

D

M

F

RFSDV22

F

RFSDV32

N

RFSDV42

B

G

H

K

G

H

K

L

H

I

J

I

J

I

J

Fig. 2 Fireplace specifications.

Ref. RFSDV22 RFSDV32 RFSDV42

A 26" (660mm) 25" (635mm) 28¹⁄₄" (717mm)

B 26" (660mm) 24¹⁄₈" (613mm) 28¹⁄₄" (717mm)

C15¹⁄₄" (387mm) 16" (406mm) 17⁷⁄₈" (454mm)

D19¹⁄₄" (488mm) 20" (508mm) 22³⁄₄" (578mm)

E18⁵⁄₈" (473mm) 19" (483mm) -- --

F 21" (533mm) 21" (533mm) -- -G31¹⁄₂" (800mm) 31³⁄₄" (806mm) -- --

H17³⁄₄" (451mm) 17³⁄₄" (451mm) 22³⁄₄" (578mm)

I29⁵⁄₈" (752mm) 29⁵⁄₈" (752mm) 33⁵⁄₈" (854mm)

J9⁵⁄₈" (244mm) 9" (229mm) 10⁵⁄₈" (270mm)

K6¹⁄₂" (165mm) 6¹⁄₂" (165mm) 7" (178mm)

L-------- 36³⁄₈" (924mm)

M-------- 14³⁄₁₆" (360mm)

N-------- 17³⁄₈" (441mm)

4

10001028

RFSDV22/32/42 Freestanding Direct Vent Fireplace

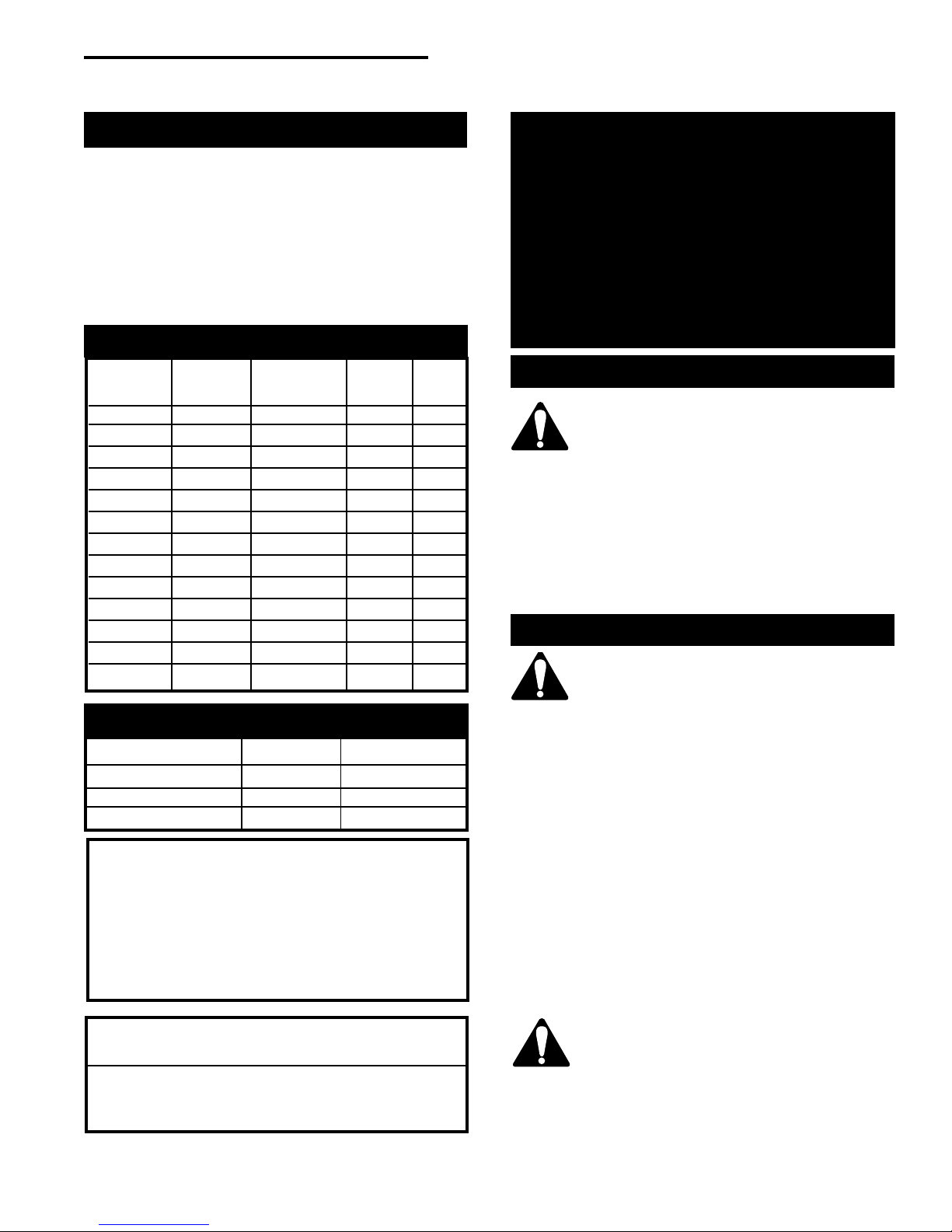

Clearance to Combustibles

Adequate clearances as listed below must be

maintained for servicing and proper operation:

Back ...............................................................0" (0mm)

Side .......................................................... 12" (305mm)

Floor ............................................................... 0" (0mm)

Top ........................................................... 36" (914mm)

Corner ....................................0" to Back Edges (0mm)

Vent Pipe......................................................1" (25mm)

Gas Specifications

Max. Min.

Input Input

Model Fuel Gas Control B.T.U.H B.T.U.H.

RFSDV22RN Natural Gas Millivolt Hi/Lo 30,000 21,000

RFSDV22RP Propane Gas Millivolt Hi/Lo 30,000 22,500

RFSDV22TN Natural Gas Thermostatic 30,000 21,000

RFSDV22TP Propane Gas Thermostatic 30,000 22,500

RFSDV32RN Natural Gas Millivolt Hi/Lo 30,000 21,000

RFSDV32RP Propane Gas Millivolt Hi/Lo 30,000 22,500

RFSDV32TN Natural Gas Thermostatic 30,000 21,000

RFSDV32TP Propane Gas Thermostatic 30,000 22,500

RFSDV32RMH Nat/Prop Millivolt Hi/Lo 30,000 N/A

RFSDV42RN Natural Gas Millivolt Hi/Lo 40,000 28,000

RFSDV42RP Propane Gas Millivolt Hi/Lo 37,000 27,750

RFSDV42TN Natural Gas Thermostatic 40,000 28,000

RFSDV42TP Propane Gas Thermostatic 37,000 27,750

Gas Inlet and Manifold Pressures

Natural LP (Propane)

Inlet Minimum 4.5" w.c. 11.0" w.c.

Inlet Maximum 14.0" w.c. 14.0" w.c.

Manifold Pressure 3.5" w.c. 10.0" w.c.

This appliance may be installed in an aftermarket

permanently located, manufactured (mobile) home,

where not prohibited by local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a

certified kit is available and used.

RFSDV22 / RFSDV32 / RFSDV42

Certified To

ANSI.Z21.88-2002 / CSA 2.33-2002

Vented Gas Fireplace Heaters

High Elevations

Input ratings are shown in BTU per hour and

are certified without deration for elevations up

to 4,500 ft. (1,370 m) above sea level. For

elevations above 4,500 ft. (1,370 m) in USA,

installations must be in accordance with the

current ANSI Z223.1 and/ or local codes having

jurisdiction.

In Canada, please consult provincial and/ or

local authorities having jurisdiction for

installations at elevations above 4,500 ft.

(1,370 m).

Preparation

The use of wall paper adjacent to this

fireplace is not recommended, as the

high temperatures given off by this

fireplace may adversely effect the binders

in the adhesive used to apply the wallpaper.

Before beginning, remove the glass door from the

fireplace. Also check to make sure there is no hidden

damage to the fireplace. Take a minute and plan out

the gas, vent and electrical supply. See Glass Removal

Section.

Gas Line Installation

When purging gas line, the front glass

must be removed.

The gas pipeline can be brought in through the rear of

the fireplace as well as the bottom. Knockouts are

provided on the bottom behind the valve to allow for

the gas pipe installation and testing of any gas connection. It is most convenient to bring the gas line in

from the rear right side of the valve, as this allows

fan installation or removal without disconnecting

the gas line.

The gas line connection can be made with properly

tinned 3/8" copper tubing, 3/8" rigid pipe or an

approved flex connector. Since some

municipalities have some additional local codes, it

is always best to consult your local authority and

the CSA- B149.1 installation code.

For U.S. Installations consult the current National

Fuel Gas Code, ANSI Z223.1.

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to

provide a 1/8" test point up stream of the control.

10001028

5

RFSDV22/32/42 Freestanding Direct Vent Fireplace

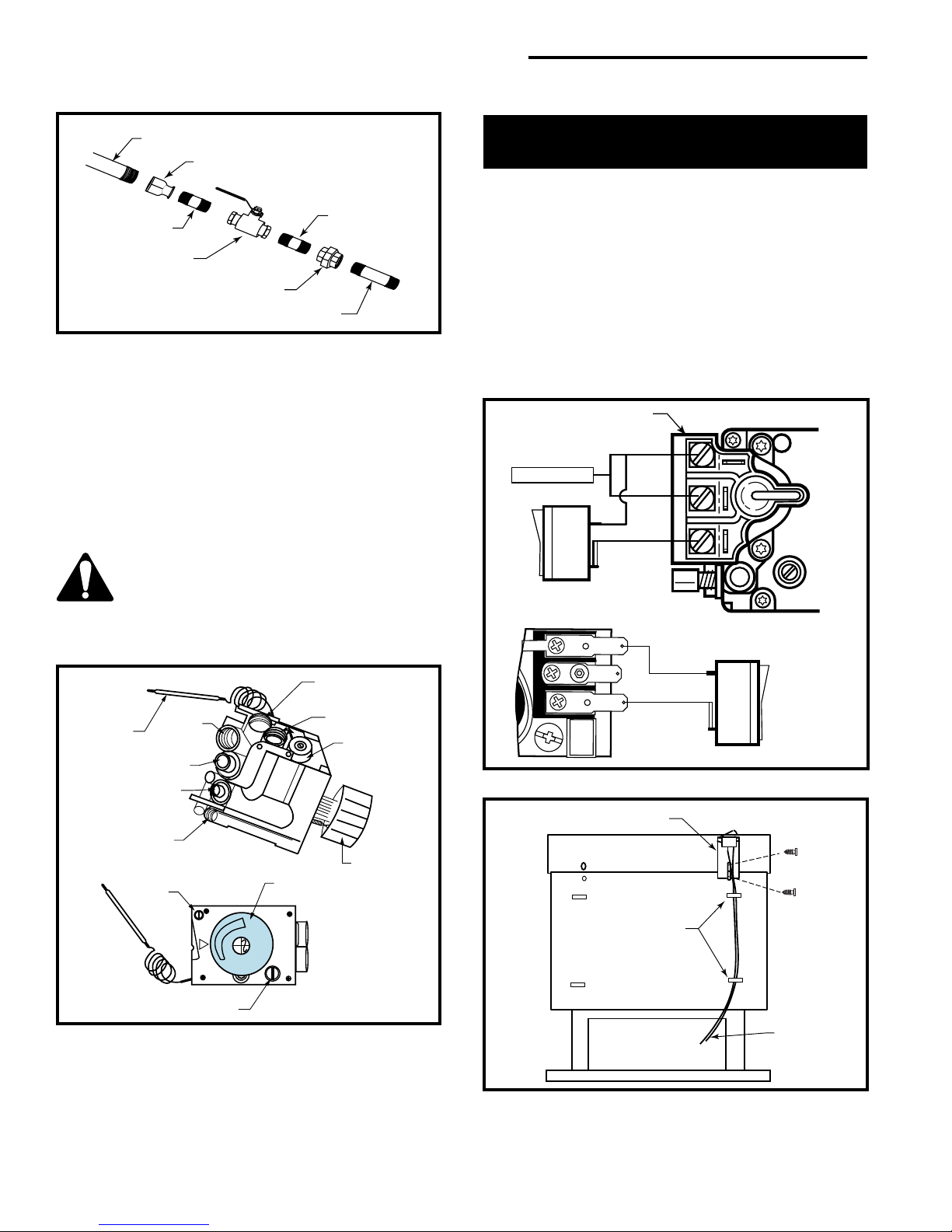

1/2" Gas Supply

1/2" x 3/8" Reducer

3/8" Nipple

3/8" x 3/8" Shut Off

Valve

3/8" Union

3/8" Nipple

3/8" Nipple

CFM106

Fig. 3 Typical gas line installation.

When using copper or flex connector use only approved fittings. Always provide a union when using

back iron pipe so that gas line can be easily disconnected for burner or fan servicing. (Fig. 3) Refer to gas

specification chart for pressure details and ratings.

The fireplace valve must not be subjected to any test

pressures exceeding 1/2 psi. Isolate or disconnect this

or any other gas appliance control from the gas line

when pressure testing.

Do not use this fireplace if any part of

this fireplace has been under water.

Immediately call a qualified service

technician to inspect the heater and to

replace any part control which has been

under water.

Manifold Gas

Outlet

Brass Plug

Control Knob

Pressure

Regulator

Control Knob

Thermostat

Bulb

Gas Inlet

Thermocouple

Inlet

Pilot Tube Entry

Pilot Adjustment

Screw

Brass

Plug

Installation of Remote

Switch for RN/RP Gas Valve

Install on/off switch assembly on either the rear right or

left side of the Fireplace.

1. Remove the screw at the back of the cabinet top

either on the left or the right side of the fireplace.

2. Position switch assembly onto the back of the

fireplace, then fasten two screws as shown in Figure

6.

3. Attach wiring under the clips on the rear casing (Fig.

6) and install wiring through the rear opening of the

fireplace before connecting to the valve as shown in

Figure 5.

SIT Valve

THTP

Thermopile

TH

TP

TPTH

Fig. 5 On/Off switch or millivolt thermostat.

ON/OFF Switch Assembly

TP

TH

P

I

L

T

O

Screw

(Through

existing

hole)

FP382a

FP1218a

I

H

it

OFF

PILOT

LO

Minimum Rate Screw

(Nonadjustable)

Fig. 4 On fireplaces equipped with Eurosit 630 gas valves

there are brass plugs in two of the holes. These plugs are

not to be removed. The gas inlet hole has a plastic cap in it.

Remove the plastic cap and connect your gas supply line at

this point.

6

HV118

Clips

Wiring for

Milli-Volt

Gas Valves

FP1331

Fig. 6 Secure wiring under clips on the rear casing.

10001028

RFSDV22/32/42 Freestanding Direct Vent Fireplace

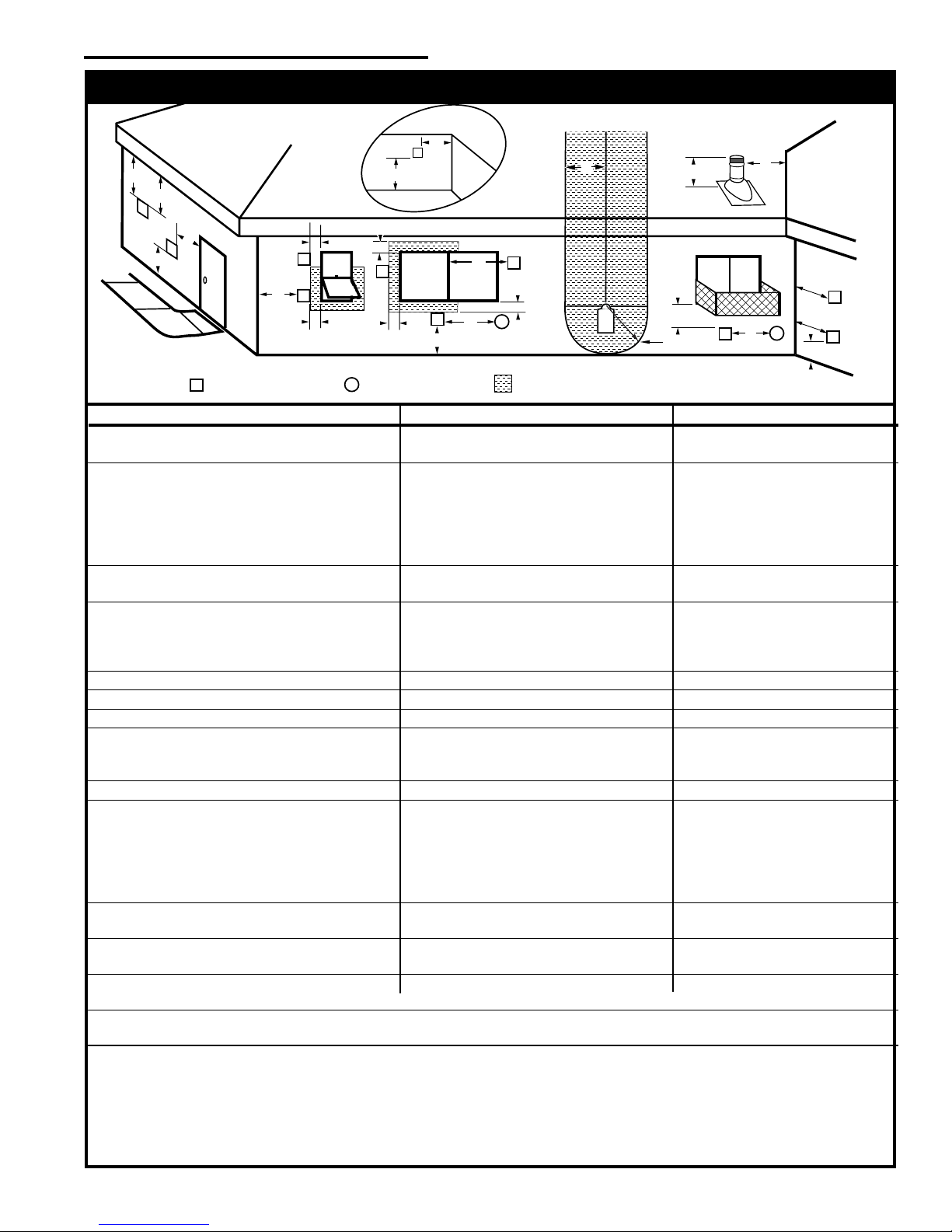

General Venting Information - Termination Location

INSIDE

CORNER DETAIL

G

V

D

E

V

A

H

N

N

CFM145a

B

V

L

VENT TERMINATION AIR SUPPLY INLET

V

C

Fixed

Fixed

V

Closed

Closed

F

Operable

V

B

B

V

Operable

B

X

B

Fixed

Closed

V

A

V

B

X

J

AREA WHERE TERMINAL IS NOT PERMITTED

Canadian Installations

G

V

M

I

1

K

V

US Installations

G

X

V

A

2

A = Clearance above grade, veranda, porch, 12” (30cm) 12” (30cm)

deck, or balcony

B = Clearance to window or door that may be 6” (15cm) for appliances 6” (15cm) for appliances

opened < 10,000Btuh (3kW), 12” (30cm) < 10,000 Btuh (3kW), 9”

for appliances > 10,000 Btuh (3kW) and (23cm) for appliances > 10,000

< 100,000 Btuh (30kW), 36” (91cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30cm) for

appliances > 50,000 Btuh (15kW)

C = Clearance to permanently closed window 12” (305mm) recommended to 12” (305mm) recommended to

prevent window condensation prevent window condensation

D = Vertical clearance to ventilated soffit located

above the terminal within a horizontal 18” (458mm) 18” (458mm)

distance of 2 feet (610mm) from the center

line of the terminal

E = Clearance to unventilated soffit 12” (305mm) 12” (305mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner (see next page) see next page see next page

H = Clearance to each inside of center line 3’ (914mm) within a height of 15’ (4.6m) 3’ (914mm) within a height of 15’

extended above meter/regulator assembly above the meter/regulator assembly (4.6m) above the meter/regulator

assy

I = Clearance to service regulator vent outlet 3’ (914mm) 3’ (914mm)

J = Clearance to nonmechanical air supply inlet 6” (15cm) for appliances < 10,000 6” (15cm) for appliances

to building or the combustion air inlet to any Btuh (3kW), 12” (30cm) for < 10,000 Btuh (3kW), 9”

other appliances appliances > 10,000 Btuh (3kW) and < (23cm) for appliances > 10,000

100,000 Btuh (30kW), 36” (91cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30cm) for

appliances > 50,000 Btuh (15kW)

K = Clearance to a mechanical air supply inlet 6’ (1.83m) 3’ (91cm) above if within 10’

(3m) horizontally

L = Clearance above paved sidewalk or paved 7’ (2.13m)† 7’ (2.13m)†

driveway located on public property

M = Clearance under veranda, porch, deck or 12” (30cm)‡ 12” (30cm)‡

balcony

N = Clearance above a roof shall extend a minimum of 24” (610mm) above the highest point when it passes through the roof

surface, and any other obstruction within a horizontal distance of 18” (450mm).

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Codes

† A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and

serves both dwellings

‡ only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the floor:

NOTE: 1. Local codes or regulations may require different clearances.

2. The special venting system used on Direct Vent Fireplaces are certified as part of the appliance, with clearances tested and

approved by the listing agency.

10001028

7

RFSDV22/32/42 Freestanding Direct Vent Fireplace

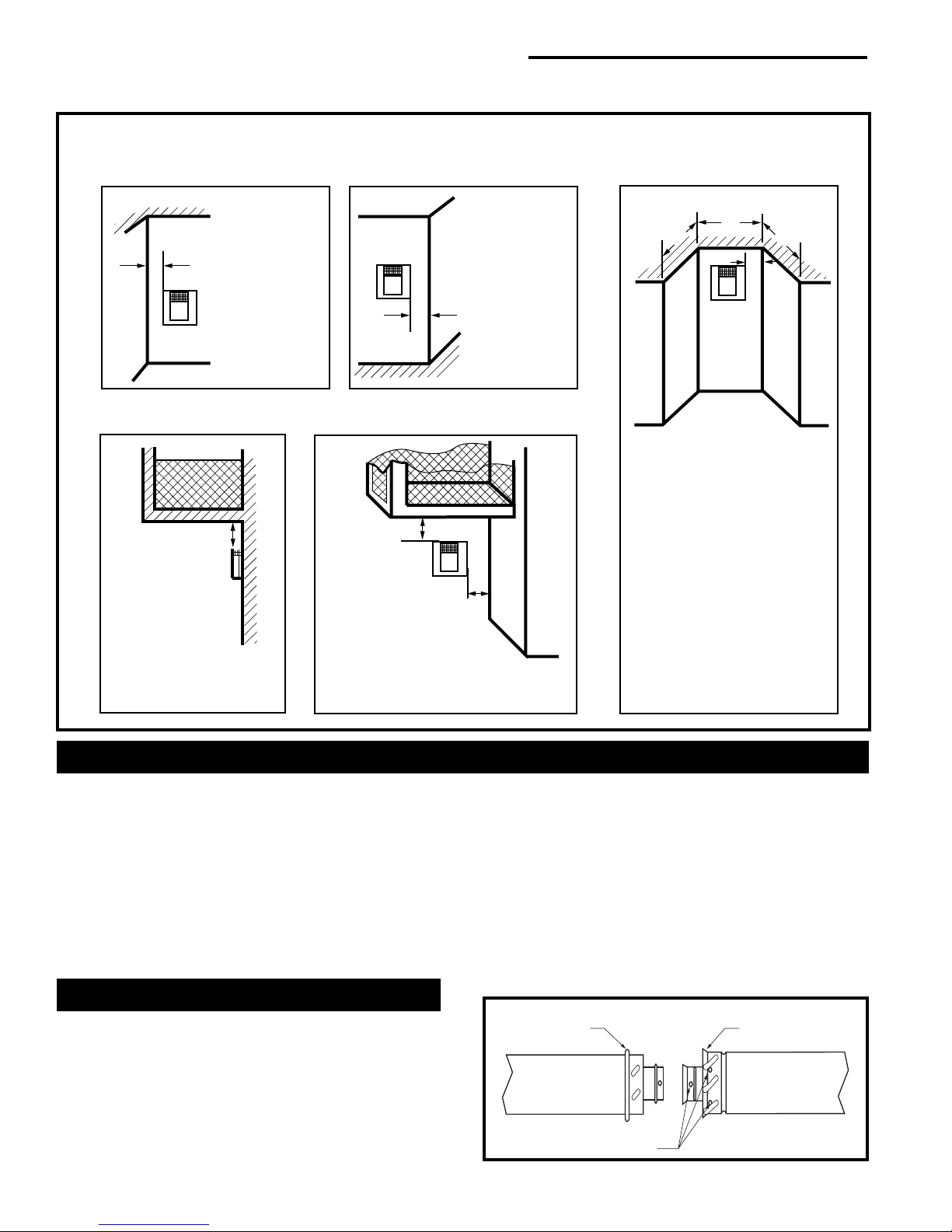

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

Inside Corner

Outside Corner

Recessed Location

A

V

Balcony with no side wall

G =

Combustible &

Noncombustible

12"(305mm)

A =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

G

V

B =

Combustible

6"(152mm)

V

Noncombustible

2"(50mm)

B

Balcony with perpendicular side wall

H

V

Combustible &

Noncombustible

H = 24"(610mm)

J = 20"(508mm)

J

D

C

C

E

V

C = Maximum depth of 48"

(1219mm) for recessed

location.

D = Minimum width for back wall

of a recessed location.

Combustible 38"(965mm)

Noncombustible 24"(610mm)

E = Clearance from corner in

recessed location.

Combustible 6"(152mm)

Noncombustible 2"(50mm)

584-15

General Information Assembling Vent Pipes

Canadian Installations:

The venting system must be installed in accordance

with the current CSA-B149.1 installation code.

U.S.A. Installations:

The venting system must conform with local codes

and/or the current National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

Only venting components manufactured by CFM

Corporation may be used.IST LOCK

Twist Lock PIpes

When using CFM Corporation twist lock pipe it is not

necessary to use sealant at the twist lock joints.

The only areas of the venting that need to be sealed

with high temperature silicone sealant are the collars

on the fireplace and termination, and the sliding joint of

any telescopic vent pipes used in the system.

8

To join the twist lock pipes together, simply align the

beads of the male end with the grooves of the female

end, then while bringing the pipes together, twist the

pipe until the flange on the female end contacts the

external flange on the male end.

It is recommended that you secure the joints with 3

sheet metal screws, however this is not mandatory with

twist lock pipe.

To make it easier to assemble the joints we suggest

putting a lubricant (Vaseline or similar) on the male end

of the twist lock pipe.

Male End

Screw Holes

Fig. 7 Twist-lock pipe joints.

Female End

TWL100

10001028

RFSDV22/32/42 Freestanding Direct Vent Fireplace

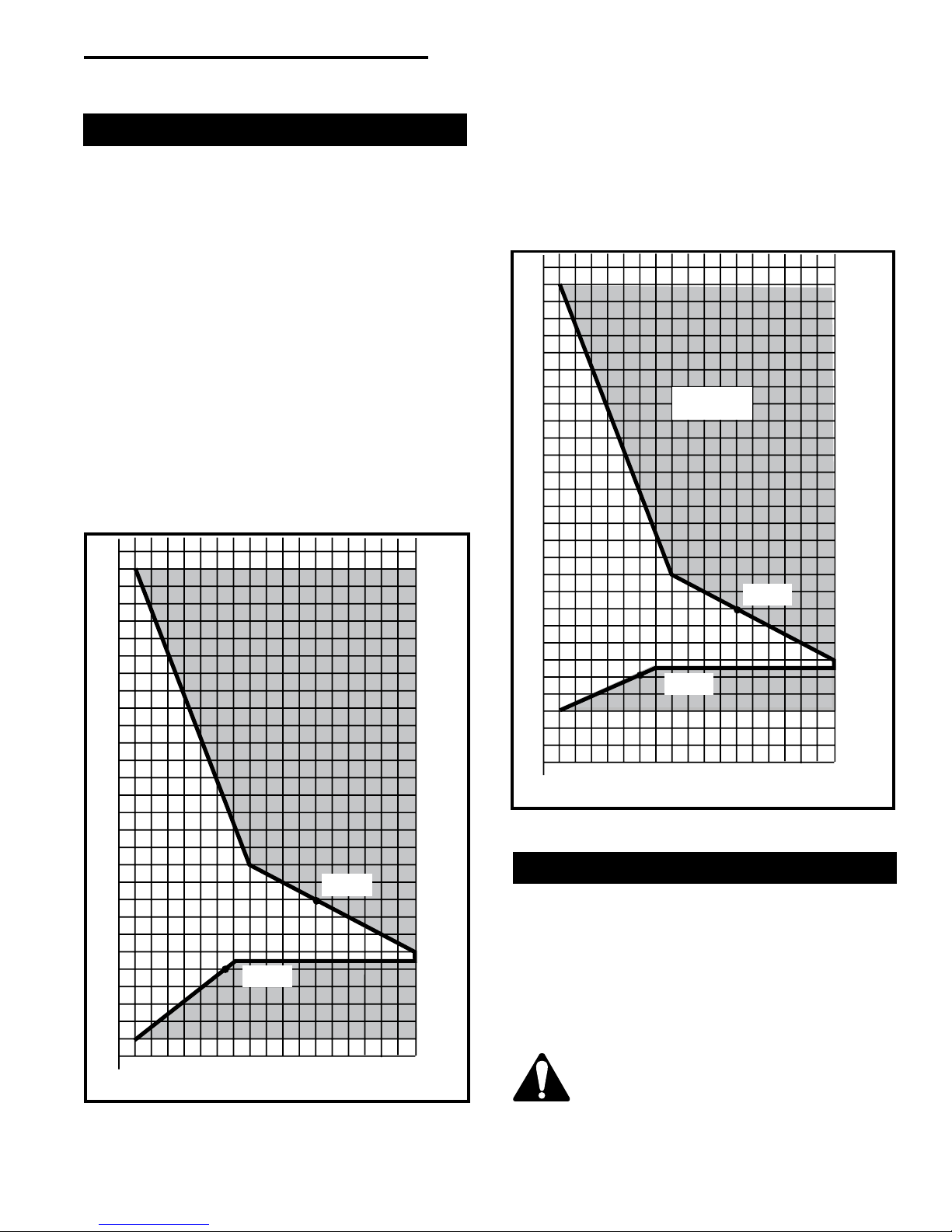

How to Use the Vent Graph

1. Determine the height of the centre of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph (Fig. 8 or 9),

locate the point it intersects with the slanted graph

line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the fireplace in accordance with same.

EXAMPLE A:

If the vertical dimension from the floor of the fireplace

is 11' (335cm) the horizontal run to the face of the

outer wall must not exceed 14' (427cm).

EXAMPLE B:

If the vertical dimension from the floor of the fireplace

is 7' (214cm), the horizontal run to the face of the outer

wall must not exceed 8.5' (259cm).

For RFSDV22 & RFSDV32

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

eg: B

eg: A

Horizontal Dimension

Fig. 8 Sidewall venting graph for use with RFSDV22/32.

Vertical Dimension from the Floor of the Fireplace to the

Center of the Horizontal Vent Pipe

EXAMPLE C: (only RFSDV42)

If the vertical dimension from the floor of the fireplace is

7' (214mm), the horizontal run to the face of the outer

wall must not exceed 8' (244cm).

Refer to Page 12 for venting requirements for

snorkels.

For RFSDV42

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

RFSDV42

ONL Y

eg: A

eg: C

Vertical Dimension from the Floor of the Fireplace

to the Center of the Horizontal Vent Pipe

Horizontal Dimension

Fig. 9 Sidewall venting graph for use with RFSDV42 only.

Vertical Sidewall Applications

Since it is very important that the venting system

maintain its balance between the combustion air

intake and the flue gas exhaust, certain limitations

as to vent configurations apply and must be

strictly adhered to.

The graph showing the relationship between vertical

and horizontal side wall venting will help to determine

the various lengths allowable. (Fig. 8 or 9)

Minimum clearance between vent pipes

and combustible materials is 1" (25mm)

on top, bottom and sides unless otherwise noted.

10001028

9

Loading...

Loading...