Vermont Castings RADVT(CS)CBSB, RADVTCSBSSB, RADVTCSBDSB, RADVTCSBMSB, RADVTCBSB Installation And Operating Instructions Manual

...

RADVT Series Radiance® Direct Vent Gas Heater

S

Installation and Operating Instructions

Models: RADVT(CS)CBSB, RADVT(CS)BSSB, RADVT(CS)BDSB, RADVT(CS)BMSB

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

• Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do

not use any phone in your building.

– Leave the building immediately.

– Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

– If you cannot reach your gas supplier,

call the re department.

• Installation and service must be performed

by a qualied installer, service agency or

the gas supplier.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this manual.

For assistance or additional information consult

a qualified installer, service agency or the

gas supplier.

This appliance may be installed in an aftermarket,*

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is for use only with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certied kit is used.

* Aftermarket: Completion of sale, not for purpose of resale, from

the manufacturer.

CERTIFIED

AFETY BARRIER

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this

appliance and shall be installed.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for

future reference.

20306759 12/14 Rev. 1

Radiance® Direct Vent Gas Heater

Table of Contents

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE.

Thank you and congratulations on your purchase of a Vermont Castings stove.

IMPORTANT: Read all instructions and warnings carefully before starting installation. Failure to follow these instructions

may result in a possible re hazard and will void the warranty.

Installation & General Information .............................3

Massachusetts Residents Only ........................................4

Stove Dimensions ............................................................5

Installation Requirements .................................................6

Locating the Stove............................................................6

Clearance Requirements .................................................6

Parallel Installation ..........................................................7

Corner Installation ...........................................................7

Wall and Ceiling Clearances ...........................................7

Hearth Requirements ......................................................7

Gas Specications ...........................................................8

Gas Inlet and Manifold Pressures ...................................8

High Elevations ...............................................................8

Horizontal Termination .....................................................8

Vertical Termination .........................................................9

Restrictor Plate Adjustment for Extended Pipe Runs .......9

Vent Termination Clearances ........................................10

General Venting Information - Termination Location .....11

Termination Clearances .................................................12

Venting Requirements and Options ...............................13

Assembly Procedures ...............................................15

Tools Required ..............................................................15

Parts Bag Contents .......................................................15

Unpack and Assemble Legs ...........................................15

Install Optional Fan .......................................................16

Venting System Assembly - Direct Vent ........................17

Install Vent Adapter Pipe ...............................................17

Side Wall Termination Assembly ...................................18

Vent Termination Below Grade ......................................20

Vertical (Through the Roof) Vent Assembly ...................20

Selkirk Direct-Temp Metalbestos Direct Vent System ....21

Install Log Set.................................................................26

Connect Gas Supply Line ..............................................28

Burner Information .........................................................28

Install ON/OFF Switch ...................................................29

Thermostat Connection (Optional) ................................29

Receiver Installation - RADVTCS Series .......................29

Install the Safety Barrier .................................................30

Install the Mesh and Grille .............................................30

Operation ....................................................................31

Your First Fire ................................................................ 31

Pilot and Burner Inspection ...........................................31

Flame & Temperature Adjustment .................................31

Flame Characteristics ....................................................31

Lighting and Operating Instructions ...............................32

Troubleshooting - SIT NOVA 820 (RADVT Series) .......33

Instructions for RCSITEA ..............................................34

Troubleshooting RCSITEA .............................................38

Fuel Conversion Instructions .........................................39

Maintenance ...............................................................43

Annual System Inspection .............................................43

Logset and Burner/Cleaning and Inspection .................43

Care of Cast Iron ...........................................................43

Cleaning the Glass ........................................................43

Glass Replacement .......................................................44

Gasket Replacement .....................................................44

Inspect the Vent System Annually ................................. 44

Check the Gas Flame Regularly ...................................44

Wiring Diagrams ............................................................44

Replacement Parts ...................................................45

Optional Accessories ............................................... 49

Warranty ....................................................................51

22

20306759

Installation & Operating Instructions

The Radiance Direct Vent Room Heater, Model Nos. RADVTCB,

RADVTEB, RADVTBS, RADVTBD, RADVTBM, RADVTCSCB,

RADVTCSEB, RADVTCSBS, RADVTCSBD, RADVTCSBM, is

a vented gas appliance listed to the ANSI Standard Z21.88-2009

and CSA 2.33-2009 for Vented Room Heaters, and CSA 2.17M91, Gas-Fired Appliances For Use at High Altitudes.

The installation of the Radiance Direct Vent Room Heater must

conform with local codes, or in the absence of local codes, with

National Fuel Gas Code, ANSI Z223.1/NFPA 54 — latest edition

and CSA B-149.1 Installation Code. (EXCEPTION: Do not derate this appliance for altitude. Maintain the manifold pressure

at 3.5 inches w.c. for Natural Gas and 10 inches w.c. for LP gas

at maximum input.)

This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other

gases unless a certied kit is used.

Installation and replacement of gas piping, gas utilization

equipment or accessories, and repair and servicing of equipment shall be performed only by a qualied agency, preferably

NFI or WETT (Canada) certied. The term “qualied agency"

means any individual, rm, corporation, or company that

either in person or through a representative is engaged in

and is responsible for (a) installation or replacement of gas

piping, or (b), the connection, installation, repair, or servicing of equipment, who is experienced in such work, familiar

with all precautions required, and has complied with all the

requirements of the authority having jurisdiction.

The Radiance Direct Vent Room Heater should be inspected

before use and at least annually by a qualied service agency.

It is imperative that control compartments, burners, and circulating air passageways of the appliance be kept clean.

The Radiance Direct Vent Room Heater and its individual shut-off

valve must be disconnected from the gas supply piping during

any pressure testing of that system at test pressures in excess

of 1/2 psig (3.5 kPa).

The Radiance Direct Vent Room Heater must be isolated from the

gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig.

An accessible tap is located above the pilot/On-Off knob for

checking the inlet pressure.

‘Direct Vent’ describes a sealed combustion system in which incoming outside air for combustion and outgoing exhaust enter and

exit through two separate concentric passages within the same

sealed vent system. The system does not use room air to support

combustion. The Direct Vent system permits the gas appliance

to be vented directly to the outside atmosphere through the side

of the house or vertically through the roof. Conventional venting

systems (Natural Vent) take air from the room for combustion and

vent the exhaust vertically through the roof to the atmosphere.

This appliance is approved for bedroom installations in the U.S.

and Canada.

This appliance may be installed in an aftermarket* manufactured

(mobile) home, where not prohibited by state or local codes.

Radiance® Direct Vent Gas Heater

WARNING: Operation of this heater when not connected to a

properly installed and maintained venting system can result

in carbon monoxide (CO) poisoning and possible death.

The Radiance Direct Vent Room Heater, when installed, must

be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electrical Code

ANSI/NFPA 70, (latest edition), or of the current Canadian Electrical Code C22.1.

Due to high temperatures this appliance should be located

out of trafc and away from furniture and draperies.

WARNING: This appliance is hot while in operation. Keep

children, clothing, and furniture away. Contact may cause

burns or ignition of combustible materials.

Children and adults should be alerted to the hazards of high

surface temperatures and should stay away to avoid burns

or clothing ignition.

Young children should be carefully supervised when they

are in the same room as the appliance. Toddlers, young

children and others may be susceptible to accidental contact

burns. A physical barrier is recommended if there are at risk

individuals in the house. To restrict access to a replace

or stove, install an adjustable safety gate to keep toddlers,

young children and other at risk individuals out of the room

and away from hot surfaces.

Clothing or other ammable materials should not be placed

on or near the appliance.

Any safety screen, glass or guard removed for servicing an appliance must be replaced prior to operating the appliance.

The appliance area must be kept clear and free from combustible materials, gasoline, and other ammable vapors

and liquids.

The ow of combustion and ventilation air must not be obstructed. The installation must include adequate accessibility

and clearance for servicing and proper operation.

WARNING: Do not operate the Room Heater with the glass

panel removed, cracked or broken. Replacement of the panel

should be done by a licensed or qualied service person.

Do not use this appliance if any part has been under water.

Immediately call a qualied service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

Do not burn wood, trash or any other material for which this

appliance was not designed. This appliance is designed to

burn either natural gas or propane only.

This gas appliance must not be connected to a chimney ue

serving a separate solid-fuel burning appliance.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation.

Verify proper operation after servicing.

Aftermarket: Completion of sale, nor for purpose of resale,

*

from the manufacturer.

20306759

3

Radiance® Direct Vent Gas Heater

Installation & Operating Instructions

Requirements for the Commonwealth of

Massachusetts

All gas tting and installation of this heater shall only be

done by a licensed gas tter or licensed plumber.

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in whole

or in part for residential purposes, including those owned

or operated by the Commonwealth and where the side wall

exhaust vent termination is less than seven (7) feet above

nished grade in the area of the venting, including but not

limited to decks and porches, the following requirements

shall be satised:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gas tter

shall observe that a hard wired carbon monoxide detector

with an alarm is installed on each additional level of the

dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the services

of qualied licensed professionals for the installation of

hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery

back-up may be installed on the next adjacent oor level.

In the event that the requirements of this subdivision can not

be met at the time of completion of installation, the owner

shall have a period of thirty (30) days to comply with the

above requirements; provided, however, that during said

thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFPA 720 and

ANSI/UL 2034 listed and IAS certied.

Signage

A metal or plastic identication plate shall be permanently

mounted to the exterior of the building at a minimum height

of eight (8) feet above grade directly in line with the exhaust

vent terminal for the horizontally vented gas fueled heating

appliance or equipment. The sign shall read, in print size no

less than one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW, KEEP CLEAR OF ALL OBSTRUCTIONS".

Inspection

The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes

carbon monoxide detectors and signage installed in

accordance with the provisions of 248 CMR 5.08(2)(a)1

through 4.

Exemptions

The following equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented" in the most current edition

of NFPA 54 as adopted by the Board; and

• Product Approved side wall horizontally vented gas fueled

equipment installed in a room or structure separate from

the dwelling, building or structure used in whole or in

part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the manufacturer

for installation of the equipment and the venting system

shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components;

and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide

the parts for venting the ue gases, but identies “special

venting systems", the following requirements shall be

satised by the manufacturer:

• The referenced “special venting system" instructions

shall be included with the appliance or equipment

installation instructions; and

• The “special venting systems" shall be Product Approved

by the Board, and the instructions for that system shall

include a parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved

side wall horizontally vented gas fueled equipment, all

venting instructions, all parts lists for venting instructions,

and/or all venting design instructions shall remain with

the appliance or equipment at the completion of the

installation.

44

20306759

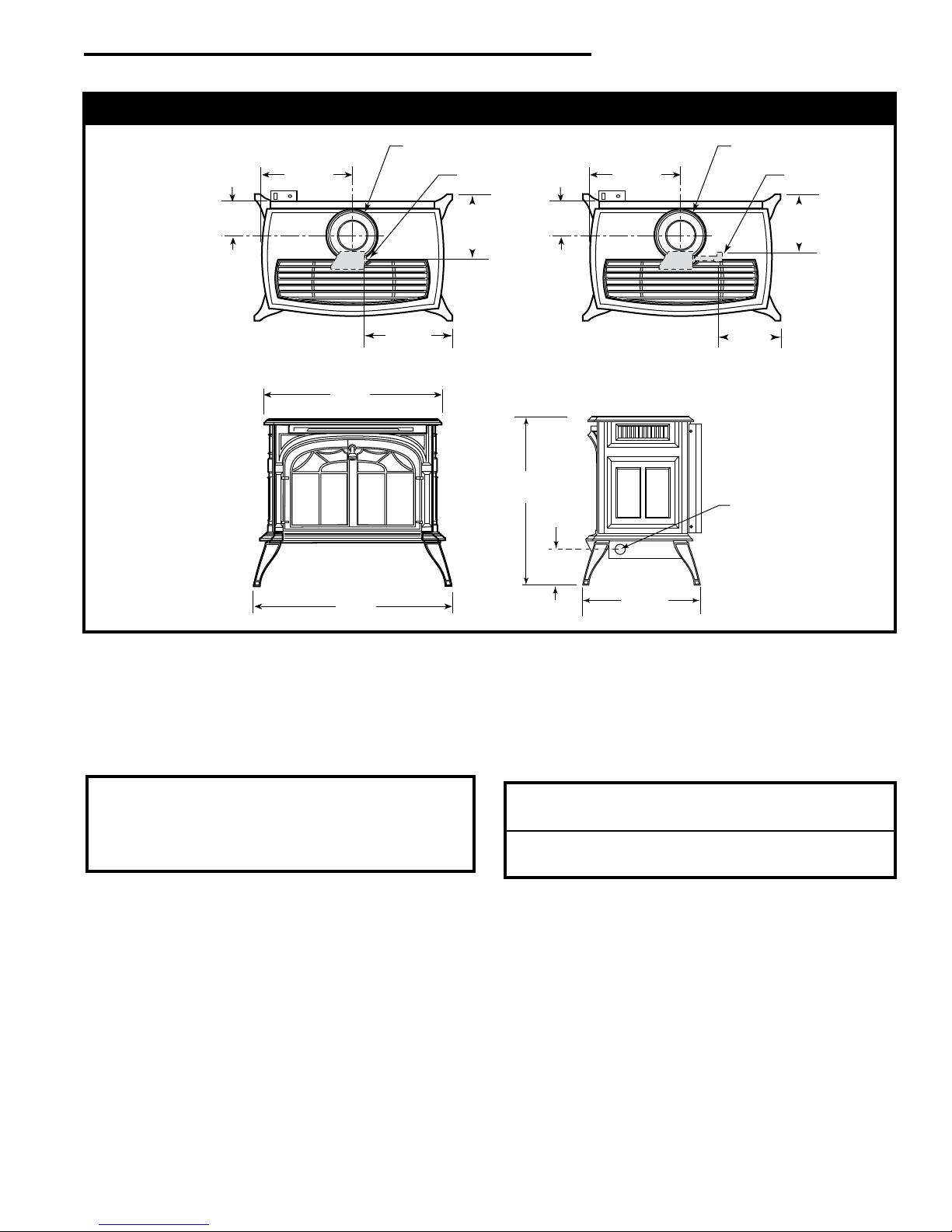

29³⁄₄"

(758 mm)

31"

(787 mm)

7" Outer Dia.

(178 mm)

Flue Collar

L

C

4³⁄₄"

(120 mm)

14⁷⁄₈"

(378 mm)

RADIANCE

28"

(711 mm)

5"

(127 mm)

18¹⁄₄"

(464 mm)

Supply

Inlet

9¹⁄₂"

(241 mm)

RADVT Models

7" Outer Dia.

(178 mm)

Flue Collar

L

C

4³⁄₄"

(120 mm)

14⁷⁄₈"

(378 mm)

8⁹⁄₁₆"

(218 mm)

RADVTC Models

Supply Inlet Supply Inlet

11”

(279 mm)

13³⁄₈”

(340 mm)

Radiance Direct Vent Stove Dimensions

See Page 7 for Flue Collar

Centerline Dimensions.

Radiance® Direct Vent Gas Heater

Fig. 1 Radiance dimensions.

Proposition 65 Warning: Fuels used in gas, woodburning or

oil red appliances, and the products of combustion of such

fuels, contain chemicals known to the State of California to

cause cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6

ANSI Z21.88-2009 / CSA 2.33-2009

Radiance Direct Vent

Certied to:

Vented Gas Fireplace Heaters

20306759

5

Radiance® Direct Vent Gas Heater

A

B

E

C

D

Installation Requirements

The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 - latest edition. (EXCEPTION: Do

not derate this appliance for altitude. Maintain the manifold pressure at 3.5" w.c. for Natural Gas, and 10" w.c. for

Propane).

In Canada, installation must be in accordance with the current CSA B-149.1 Installation Codes and/or local codes.

The installation should be done by a qualied service

person who is familiar with the building codes and

installation techniques appropriate for your area to

accomplish a safe and effective installation.

Your dealer or your local gas supplier will be able to

refer a qualied service person.

WARNING: Due to high temperatures, the HEATER

should be located out of trafc and away from

furniture and draperies.

The surface of the Heater Is hot when it is in

use. Young children should be watched carefully when

they are in the same room when the Heater is in use,

and they should be taught to avoid the hot surface.

Keep any objects that can burn well away from the

Heater, and observe the recommended clearances

that follow.

DANGER

HOT GLASS WILL

CAUSE BURNS.

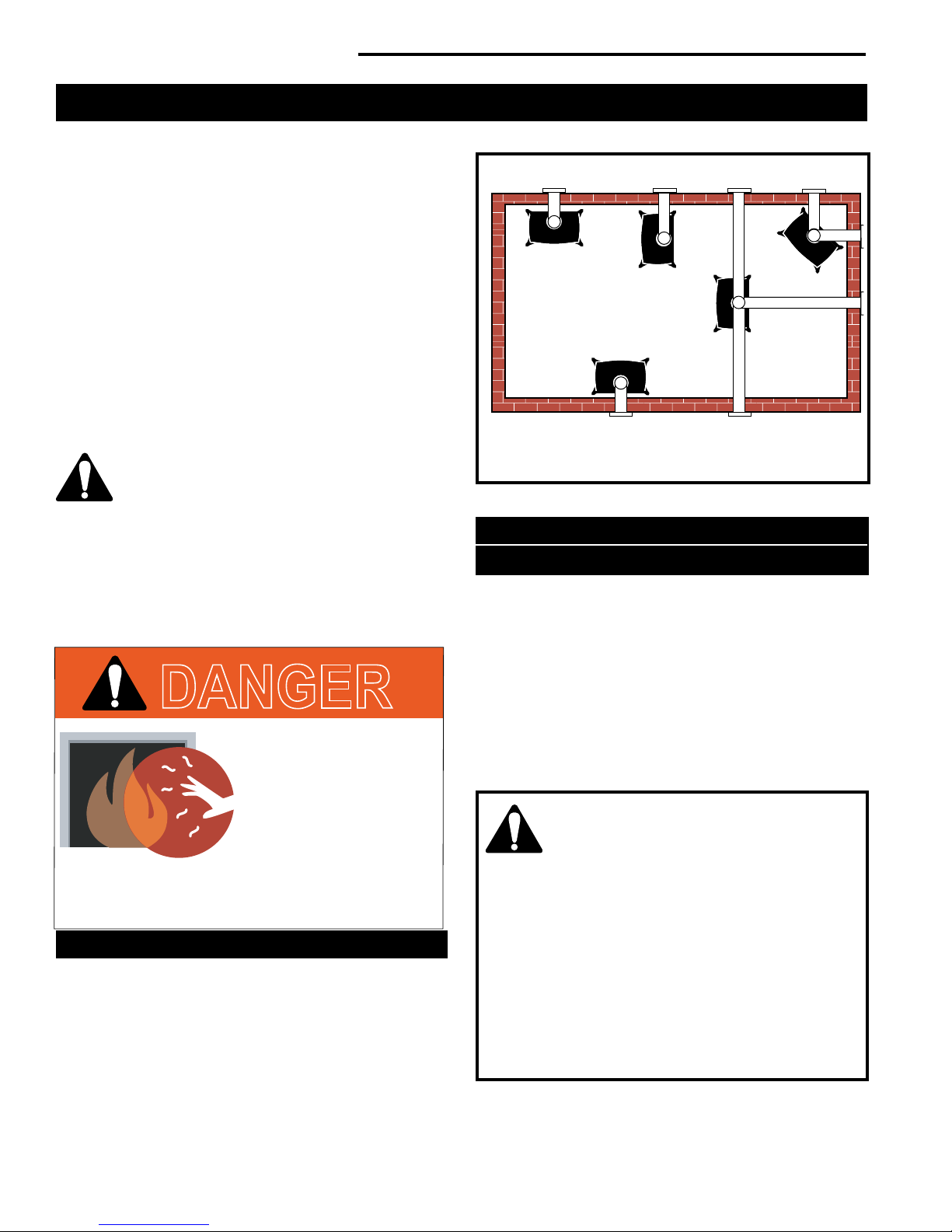

Direct Vent System Only

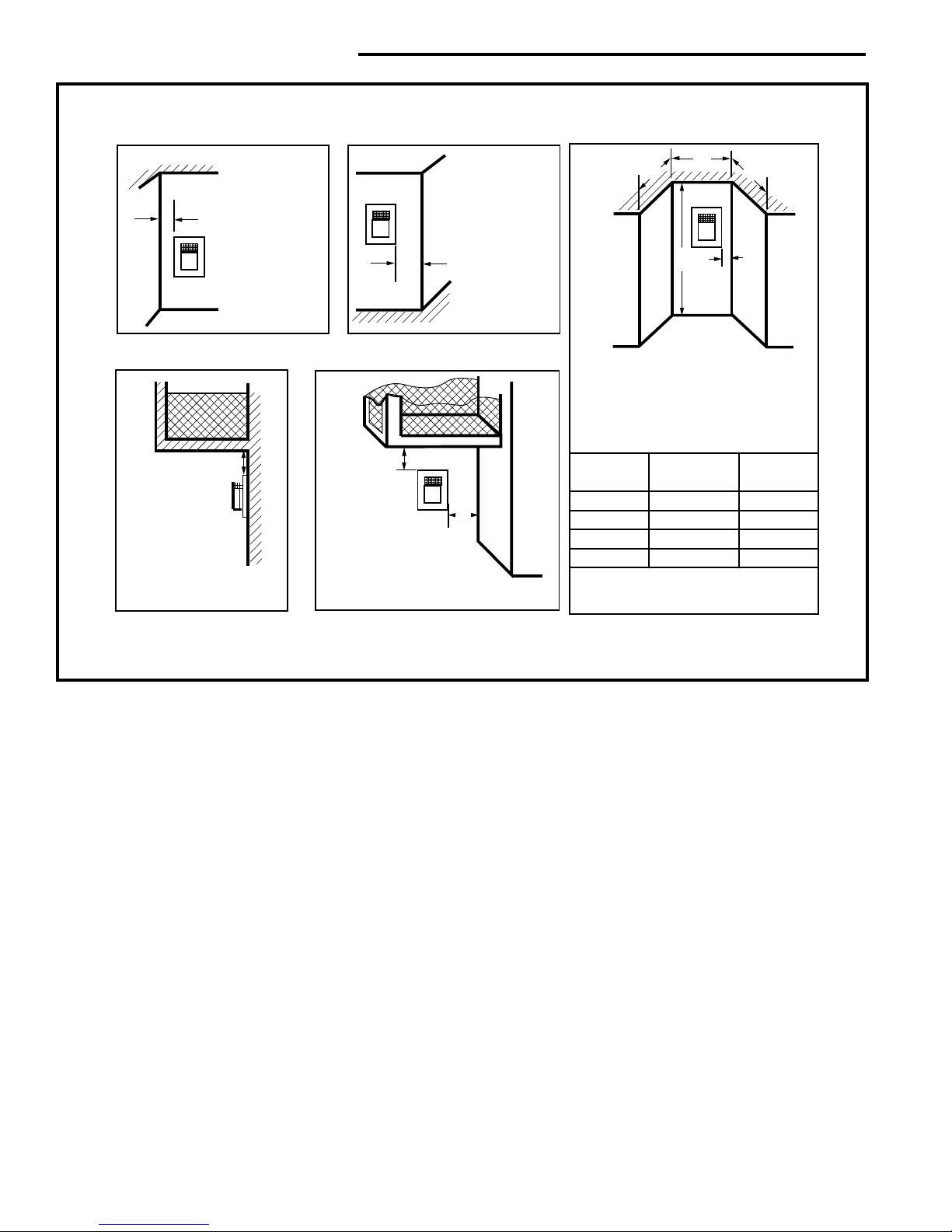

A. Flat on corner wall

B. Room Divider

C. Island

Fig. 2 Possible stove locations.

D. Cross Corner

E. Flat on wall

ST207a

Clearance Requirements

Minimum Clearances to Combustible Materials

Measure side clearances as shown in Figures 3, 4 and 5

from the outer edge of the cast iron stove top. Measure

rear clearances from the outermost surface of the steel

rear skirt.

The Radiance heater is approved for installation into an

alcove constructed of combustible materials to the dimensions and clearances shown on the next page.

The same clearances apply in a standard parallel installation.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this

appliance and shall be installed.

Locating The Stove

In choosing a location for the stove, consider:

• The location of outside walls;

• Where additional heat is needed:

• Where family members gather most often;

• The vent system requirements.

NOTE: We do not recommend the use of wallpaper next

to this stove. Over time, radiant heat may cause the wallpaper to shrink, or may adversely affect the binders in the

wallpaper adhesive.

66

WARNING:

• Always maintain required clearances (air

spaces) to nearby combustibles to prevent

re hazard. Do not ll air spaces with insu-

lation. All venting components must maintain a

1" (25 mm) clearance to combustible materials.

Maintain a 6" (150 mm) clearance when using

single wall pipe.

• The gas appliance and vent system must be vented

directly to the outside of the building and never

be attached to a chimney serving a separate solid

fuel or gas-burning appliance.

• Refer to the manufacturer’s instructions included

with the venting system for complete installation

procedures.

20306759

Radiance® Direct Vent Gas Heater

42" (1070mm)

Min. Alcove Width

48"

(1220mm)

Max. Alcove

Depth

6"

(150mm)

6"

(150mm)

4" (102mm)

18"

(457mm)

18"

(457mm)

6"

(150mm)

6"

(150mm)

C

L

C

L

A

A

C

D

B

Parallel Installation:

Minimum Clearance and Flue Centerline

ST130

Fig. 3 Parallel installation, minimum back and side clear-

ances, and ue centerlines.

Corner Installation:

Minimum Clearance and Flue Centerline

Wall Centerline from Floor

Direct Vent Only

A

Effective Minimum

Centerline 57" (1448 mm)

(Vermont Castings Group Pipe)

55" (1399 mm) (DuraVent Pipe)

Fig. 5 Minimum wall centerline.

Wall and Ceiling Clearances

ST131b

Fig. 4 Corner installation, minimum corner clearances and

ue centerline.

20306759

ST129

Direct Vent Only

A: Rear Wall 4" (102 mm)

B: Min. Clearance 44" (1118 mm)*

C: Min. Alcove Height 72" (1830 mm)*

D: Max. Alcove Depth 48" (1220 mm)

Sidewall Clearance 6" (150 mm)

* needed for installing DuraVent Minimum Vent Kit #2792 or

Vermont Castings Group Minimum Vent Kit #7TFSMSK.

ST101b

Fig. 6 Dimensions and clearances to ceiling or alcove.

Hearth Requirements

The Radiance Heater must be installed on rigid ooring.

When the heater is installed directly on any combustible

surface other than wood ooring, a metal or wood panel

extending the full width and depth of the unit must be used

as the hearth. There are no other hearth requirements.

7

Radiance® Direct Vent Gas Heater

20

19

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Vertical Run (in feet)

(Measured from the appliance flue collar to the top of the vent pipe.)

Horizontal Run (in feet)

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ST134b

Radiance

Horizontal

vent run

6/07

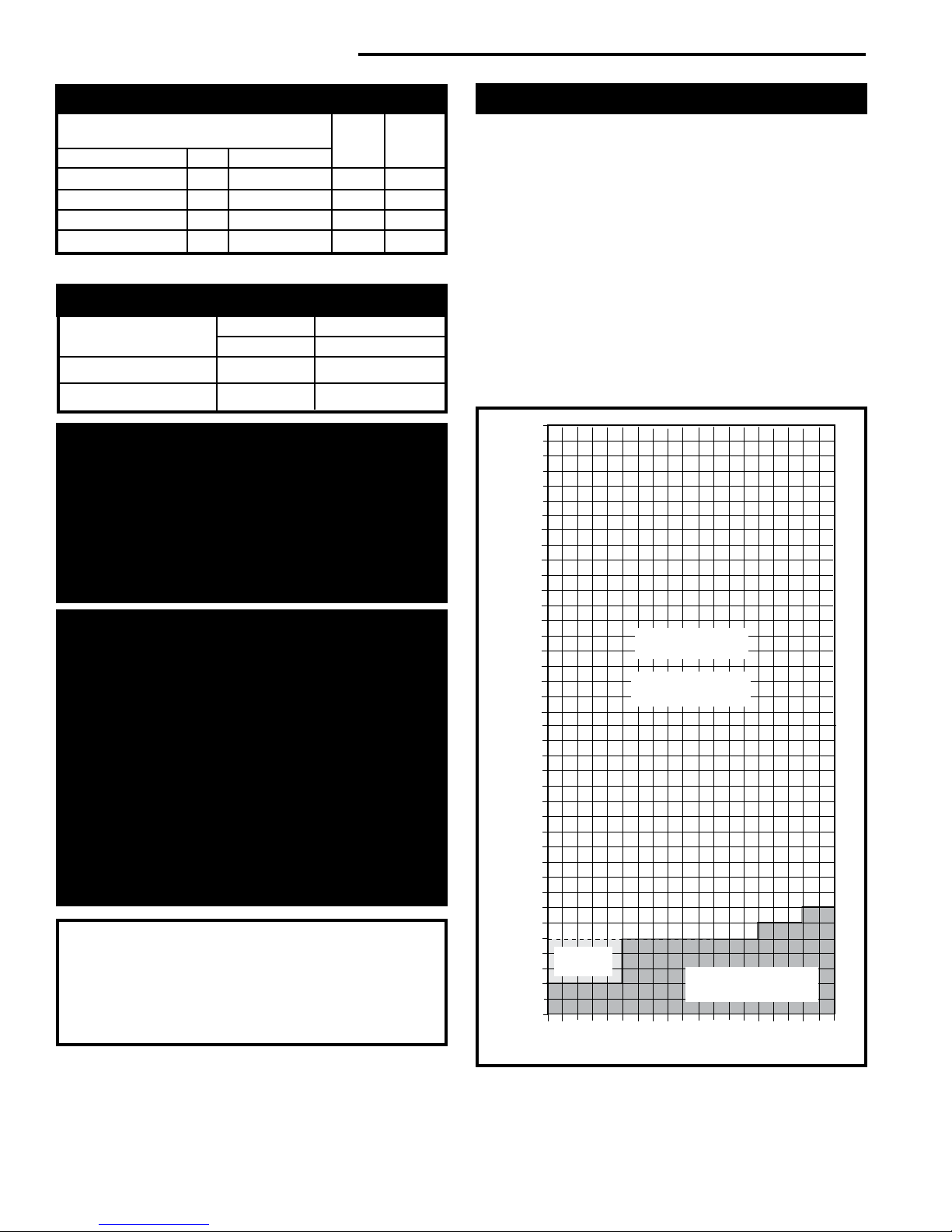

Gas Specications

Max. Min.

Input Input

Model Fuel Gas Control BTU/h BTU/h

RADVT Series Nat Millivolt Manual 38,000 25,000

RADVT Series Prop Millivolt Manual 36,000 25,000

RADVTCS Series Nat Millivolt Hi/Lo 38,000 25,000

RADVTCS Series Prop Millivolt Hi/Lo 36,000 25,000

Weight: Fully assembled; 350 lbs.

Gas Inlet and Manifold Pressures

Natural LP (Propane)

Inlet Minimum 5.5" w.c. 11.0" w.c.

Inlet Maximum 14.0" w.c. 14.0" w.c.

Manifold Pressure 3.5" w.c. 10" w.c.

The installation of your Vermont Castings stove must

conform with local codes, or in the absence of local

codes, with the National Fuel Gas Code ANSI Z223.1/

NFPA 54 - latest edition, or CSA B149.1 Installation code.

(EXCEPTION: Do not derate this appliance for altitude up

to 2,000 (610 m) for natural gas and 4,500 feet (1,370

m) for LP Gas. Maintain the manifold pressure at 3.5"

w.c. for Natural Gas and 10.0" w.c. for LP Gas.

Horizontal Termination

The vent must rise vertically a minimum of 24" (610 mm)

off the top of the unit, before the rst elbow. The horizontal

run may extend up to 20’ (6m) and include a vertical rise of

up to 40’ (12 m). (Fig. 7) Horizontal termination must also

meet the criteria shown in Figures 10 through 12.

• Approved vent systems must terminate above and including the heavy line in Figure 7.

• Two 45° elbows may be substituted for each single 90°

elbow.

• With a rise between 2’ - 5’, one 90° or two 45° elbows

may be used.

Input ratings are shown in BTU per hour and are

certied without deration for elevations up to 2,000

feet (610 m) for natural gas and 4,500 feet (1,370 m)

for LP gas above sea level.

In the USA installations with elevations above 2,000

feet (610 m) for natural gas and 4,500 feet (1,370 m)

for LP gas must be in accordance with the current

ANSI Z223.1/NFPA 54 and/or local codes having

jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 2,000 feet (610 m) for natual gas

and 4,500 feet (1,370 m) for LP gas.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. Refer to this manual for correct

installation and operational procedures. For assistance or additional information consult a qualied

installer, service agency, or the gas supplier.

88

High Elevations

May use up to

three 90° Elbows

No Restrictor Plate

Required

One 90°

Elbow

Unacceptable

Venting Conguration

Fig. 7 Horizontal vent termination window.

ST134a

20306759

Radiance® Direct Vent Gas Heater

20

19

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

20

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Vertical Run (in feet)

(Measure from the appliance flue collar to the top of the vent pipe.)

Horizontal Run (in feet)

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ST132a

FDV28

Vertical

vent run

12/3/99 djt

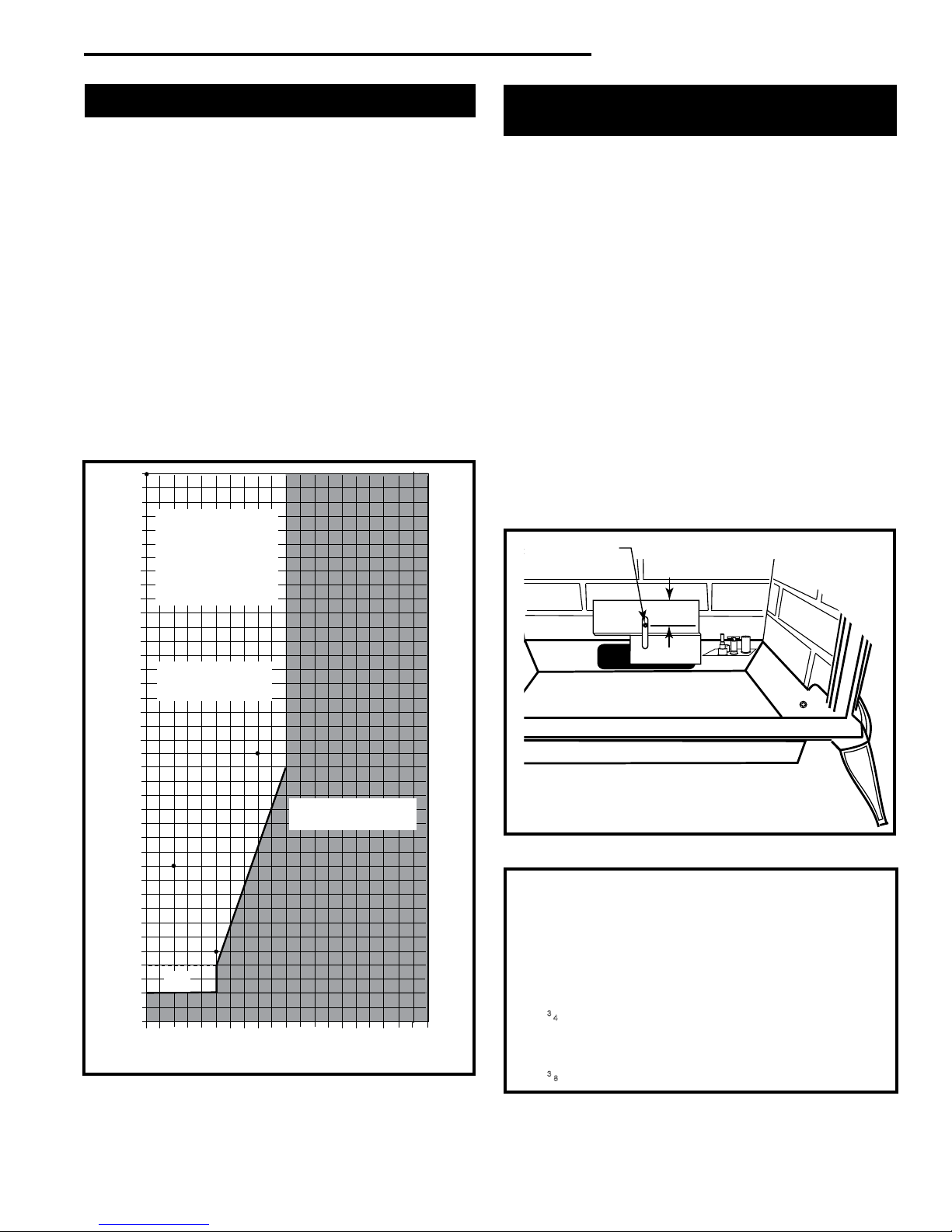

Vertical Termination

A vertical vent system must terminate no less than 8’ (2.44

m) and no more than 40’ (12 m) above the appliance ue

collar. A restrictor plate (supplied) must be used, where

specied, in all vertically terminated vent systems. (Refer

to Figure 8) NOTE: The restrictor plate supplied with

the vertical termination should be discarded. Adjust

the restrictor plate according to recommendations in

Figure 10. A vertically terminated vent system must also

conform to the following criteria:

• No more than three 90° elbows may be used.

• Two 45° elbows may be substituted for one 90° elbow.

No more than six 45° elbows may be used.

• Vent must rise a minimum of 2 feet (305 mm) before

offset is used.

• Termination height must conform to roof clearance as

specied in Figure 11.

All Vertical Ter-

minations in this

area Require use

of the Restrictor

Plate*

Restrictor Plate Adjustment

for Extended Pipe Runs

The Radiance stove is shipped with a restrictor plate in

the Parts Bag. Adjustments can be made by loosening the

adjustment screw to allow the restrictor plate to slide up or

down. (Fig. 9) A guide for usage is shown in Figure 10.

NOTE: Some installations may require some adjustment

by the installer for optimum ame appearance. Optimum

ame appearance is a ame that is not subject to tall, dirty

yellow ames producing soot or ames lifting off of the

ember bed ports.

Restrictor Plate Adjustment

1. Remove the screw in the back wall of the rebox.

2. Install restrictor plate as shown in Figure 9 with cut out

on left side. Secure with adjustment screw.

2. Measure from center of screw to top edge of diverter

(Fig. 9) to adjust plate according to guidelines in Figure 10.

3. Tighten attachment screw.

4. Install logs following log installation instructions.

Adjustment Screw

**No Restrictor

Plate

Fig. 8 Vertical vent termination window.

20306759

Vertical terminations

must be within this

area

Unacceptable

Venting Conguration

**

ST132a

ST917

Fig. 9 Loosen screw to adjust restrictor plate.

Examples for Extended Run/Restrictor Plate Settings

1. Vertical 20’ (6 m), 90° elbow, out 8’ (2.4 m)

2. Vertical 11’ (3.4 m), 90° elbow, out 2’ (610 mm)

3. Vertical 40’ (12 m)

4. Vertical 5’ (1.5 m), 90° elbow, out 5’ (1.5 m)

Restrictor plate measurement from top of plate to center of

screw:

3

⁄4" (70 mm) from center of screw to top edge of plate

1. 2

2. Plate down to top of slot

3. Plate down to top of slot

4. 23⁄8" (60 mm) from center of screw to top edge of plate

Figure 10

9

Radiance® Direct Vent Gas Heater

Vent Termination Clearances

When planning the installation, consider the location of the

vent terminal and clearances. Some of the most common

clearances to keep in mind are shown in Figure 11.

Important: All vent clearances must be maintained.

Check your vent termination clearances against Fig-

ures 11 through 13.

The vent should be placed so that people cannot be burned

by accidentally touching the vent surfaces when the stove

is operating.

The vent termination should be located where it cannot be

damaged by such things as automobile doors, lawn mowers

or snowblowers and it should be located away from areas

where it could become blocked by snow, etc.

Some considerations are:

• Obstructions or impediments to venting.

• Nearby combustible materials that could come into

contact with combustion exhaust gases.

• Other nearby openings {within 12" (305 mm)} through

which exhaust gas could reenter the building.

• All vegetation within 3’ (76 mm) that may interfere with

the draft.

Other factors that inuence where the installation will be

sited include the location of outside walls, where additional

heat may be desired in the home, where the family members gather most regularly, and perhaps most importantly,

the distance limitations of the venting system.

Your stove is approved to be vented either through the side

wall, or vertical through the roof.

• Vermont Castings Group does not require any open-

ing for inspection of vent pipe.

• Only Vermont Castings Group, DuraVent and Selkirk

Corporation venting components specically approved and

labelled for this stove may be used.

• Minimum clearances between vent pipes and combus-

tible materials is one (1") inch (25 mm), except where stated

otherwise.

• Venting terminals shall not be recessed into a wall or siding.

• Horizontal venting must be installed on a level plane without

an inclining or declining slope.

There must not be any obstruction such as bushes, garden

sheds, fences, decks or utility buildings within 24" from the

front of the termination hood.

Do not locate termination hood where excessive snow or ice

build up may occur. Be sure to check vent termination area

after snow falls, and clear to prevent accidental blockage

of venting system. When using snow blowers, make sure

snow is not directed towards vent termination area.

Location of Vent Termination

It is imperative the vent termination be located observing

the minimum clearances as shown on this page.

IMPORTANT

• The horizontal termination must not be recessed

into the exterior wall or siding.

• Horizontal vent runs must be level toward the vent

termination.

• Clearances around the vent termination must be

maintained.

• For installations using DuraVent pipe, parallel

installations with minimum wall clearance have

restricted access for connecting the Horizontal

Vent Cap straps to the vent pipe. See the maker’s

instructions for recommended installation procedures.

1010

20306759

Radiance® Direct Vent Gas Heater

V

X

X

X

D

E

B

B

B

C

B

M

B

A

J

K

F

L

VENT TERMINATION AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

H

I

Fixed

Closed

Operable

Operable

Fixed

Closed

B

INSIDE

CORNER DETAIL

A

G

CFM145a

V

V

V

V

V

V

V

V

N

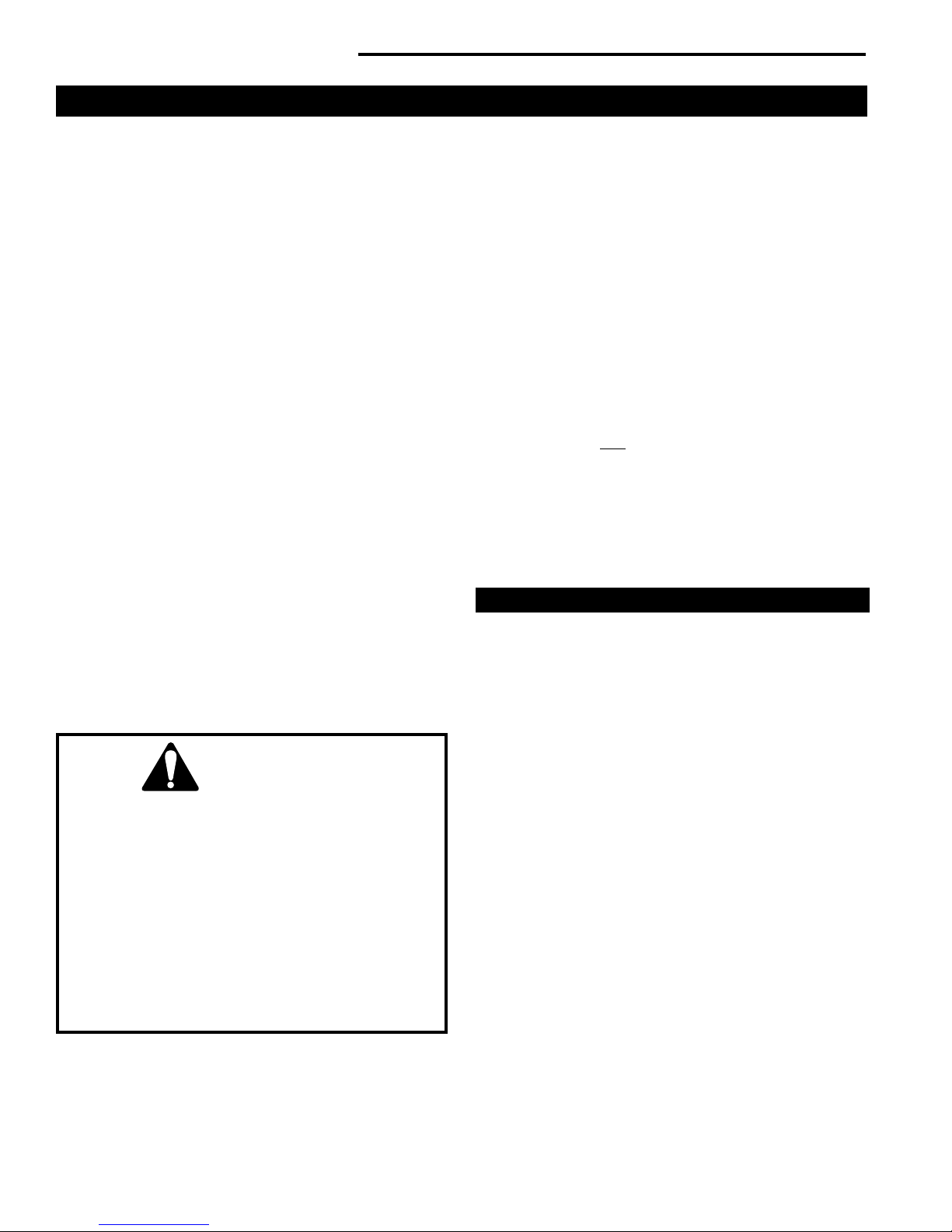

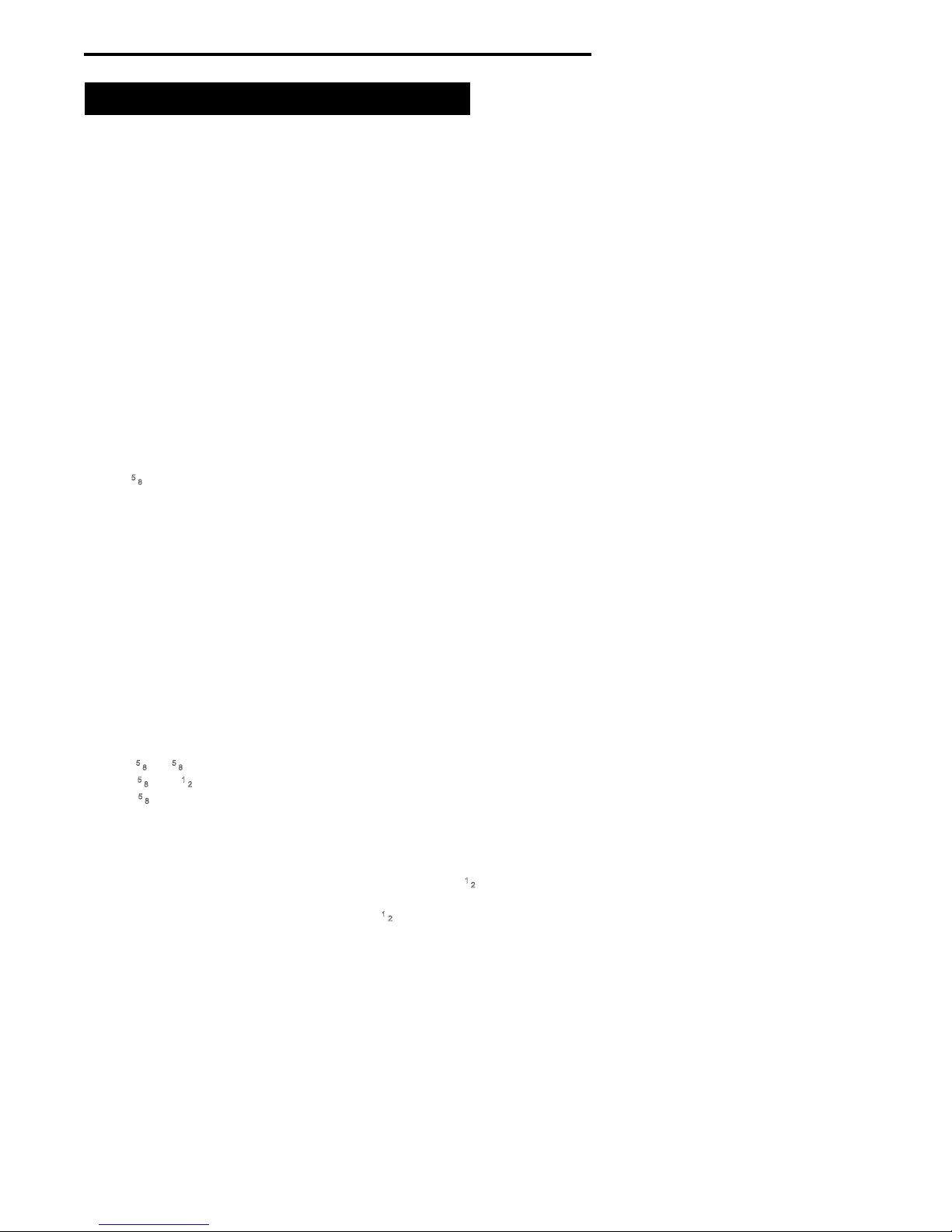

General Venting Information - Termination Location

Canadian Installations1 US Installations

A = Clearance above grade, veranda, porch, 12" (30 cm) 12" (30 cm)

deck, or balcony

B = Clearance to window or door that may be 6" (15 cm) for appliances 6" (15 cm) for appliances

opened < 10,000Btuh (3kW), 12" (30 cm) < 10,000 Btuh (3kW), 9"

for appliances > 10,000 Btuh (3kW) and (23 cm) for appliances > 10,000

< 100,000 Btuh (30kW), 36" (91 cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12" (30 cm) for

appliances > 50,000 Btuh (15kW)

C = Clearance to permanently closed window 12" (305 mm) recommended to 12" (305 mm) recommended to

prevent window condensation prevent window condensation

D = Vertical clearance to ventilated soft located

above the terminal within a horizontal 18" (458 mm) 18" (458 mm)

distance of 2’ (610mm) from the center

line of the terminal

E = Clearance to unventilated soft 12" (305 mm) 12" (305 mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner (see next page) see next page see next page

H = Clearance to each inside of center line 3’ (91 cm) within a height of 15’ (5 m) 3’ (91 cm) within a height of 15’

extended above meter/regulator assembly above the meter/regulator assembly (5 m) above the meter/regulator

assy

I = Clearance to service regulator vent outlet 3’ (91 cm) 3’ (91 cm)

J = Clearance to nonmechanical air supply inlet 6" (15 cm) for appliances < 10,000 6" (15 cm) for appliances

to building or the combustion air inlet to any Btuh (3kW), 12" (30 cm) for < 10,000 Btuh (3kW), 9"

other appliances appliances > 10,000 Btuh (3kW) and < (23 cm) for appliances > 10,000

100,000 Btuh (30kW), 36" (91 cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12" (30 cm) for

appliances > 50,000 Btuh (15kW)

K = Clearance to a mechanical air supply inlet 6’ (1.83 m) 3’ (91 cm) above if within 10’

(3 m) horizontally

L = Clearance above paved sidewalk or paved 7’ (2.13 m)† 7’ (2.13 m)†

driveway located on public property

M = Clearance under veranda, porch, deck or 12" (30 cm)** 12" (30 cm)**

balcony

N = Clearance to any other obstruction within a horizontal distance of 18" (450 mm).

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Codes

† A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings

** only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the oor:

NOTE: 1. Local codes or regulations may require different clearances.

2. The special venting system used on Direct Vent Stoves are certied as part of the appliance, with clearances tested and approved by the list-

ing agency.

3. Vermont Castings Group assumes no responsibility for the improper performance of the appliance when the venting system does

not meet these requirements.

Fig. 11 Vent termination clearances.

20306759

2

11

Radiance® Direct Vent Gas Heater

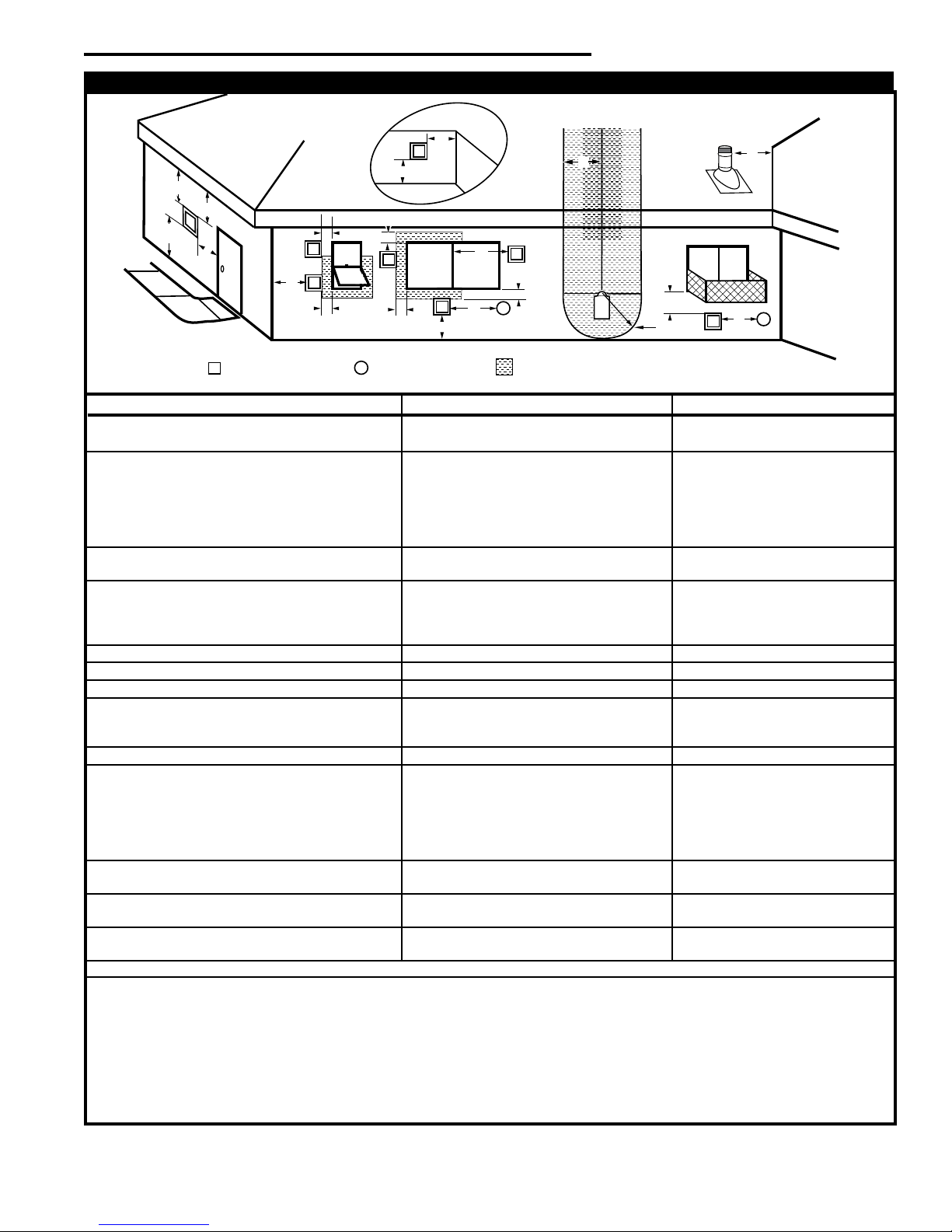

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

Inside Corner

G =

G

Combustible

6" (152 mm)

Noncombustible

V

2" (51 mm)

Outside Corner

V

F

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

Alcove Applications*

D

C

V

O

C

E

Balcony -

with no side wall

M

V

M =

Combustible &

Noncombustible

12" (305 mm)

*NOTE: Termination in an alcove space (spaces open only on one side and with an overhang) is permitted with the dimensions

specied for vinyl or non-vinyl siding and softs. 1. There must be a 3’ (914 mm) minimum between termination caps. 2. All mechanical air intakes within 10’ (1 m) of a termination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All gravity

air intakes within 3’ (914 mm) of a termination cap must be a minimum of 1’ (305 mm) below the termination cap.

Fig. 12 Termination clearances.

Balcony -

with perpendicular side wall

M

V

P

Combustible &

Noncombustible

M = 12" (305 mm)

P = 6” (152 mm)

E = Min. 2” (51 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O = 8’ (2.4 m) Min.

No.

of Caps D

1 3’ (914 mm) 2 x D

2 6’ (1.8 m) 1 x D

3 9’ (2.7 m) 2/3 x D

4 12’ (3.7 m) 1/2 x D

D

= # of Termination caps x 3

Min.

C

= (2 / # termination caps) x D

Max.

C

Min.

Max.

Actual

Actual

Actual

Actual

Actual

584-15

1212

20306759

Radiance® Direct Vent Gas Heater

Venting Requirements and Options

Approved Vent System Components

The Radiance Heater must be vented to the outdoors

through an adjacent exterior wall or through the roof. The

venting system must be comprised of the appropriate listed

venting components specied on this page. These parts are

available from DuraVent Corporation, Selkirk Corporation

or your Vermont Castings Dealer.

See Figure 4 for dimensions relevant to the standard minimum-vent kits.

DuraVent Components

www.duravent.com

Phone: 1-800-835-4429, Fax: 1-707-446-4740

Minimum Horizontal Vent Kit 2792

Starter Pipe Assembly (incl. inner & outer sections) 2768*

90° Elbow, Blk. 46DVA-E90B*

45° Elbow, Gal. 46DVA-E45

6" Straight, Blk. 46DVA-06B*

9" Straight, Blk. 46DVA-09B

11" - 145⁄8" Adjustable Straight Section 46DVA-08AB

12" Straight 46DVA-12

24" Straight 46DVA-24B*

36" Straight 46DVA-36B

48" Straight 46DVA-48

Horizontal Vent Cap 46DVA-HC*

Wall Plate 46DVA-DC

Vinyl Siding Shield 46DVA-VSS

Snorkel Termination - 14" 46DVA-SNK14

Snorkel Termination - 36" 46DVA-SNK30

Wall Strap 46DVA-WS

Cathedral Ceiling Support Box 46DVA-CS

Storm Collar 46DVA-SC

Firestop Spacer 46DVA-FS

Flashing 0/12 - 6/12 46DVA-F6

Flashing 6/12 - 12/12 46DVA-F12

Steel Chimney Conversion Kit

Kit A (65⁄8" - 85⁄8") 46DVA-KCA

Kit B (65⁄8" - 101⁄2") 46DVA-KCB

Kit C (65⁄8" - 13") 46DVA-KCC

Masonry Chimney Conversion Kit 46DVA-KMC

Vertical Termination Cap (High Wind) 46DVA-VCH

Vertical Termination Cap (Low Prole) 46DVA-VC

*Included in Minimum Horizontal Vent Kit #2792

All DuraVent Straight vent pipe sections have a net length 11⁄2"

(37mm) less than the nominal dimension; i.e., a 6" (152 mm)

Straight pipe section has an effective length of 41⁄2" (115 mm).

Selkirk Corporation Vent Components

www.selkirkcorp.com

1301 W. President George Bush Highway Ste. 330

Richardson, TX 75080

Phone: 1-800-992-8368, Fax: 1-877-393-4145

Appliance Adapter 4DT-AAV

90° Elbow, Blk. 4DT-EL90B

45° Elbow, Blk. 4DT-EL45B

6" Straight, Blk. 4DT-06B

9" Straight, Blk. 4DT-09B

4" - 10" Adjustable Straight Section, Blk. 4DT-AJ12

12" Straight, Blk. 4DT-12B

18" Straight, Blk. 4DT-18B

24" Straight, Blk. 4DT-24B

36" Straight, Blk. 4DT-36B

48" Straight, Blk. 4DT-48B

Horizontal Vent Cap 4DT-HC

Wall Plate 4DT-WT

Vinyl Siding Shield 4DT-VS

Snorkel Termination - 14" 4DT-ST14

Snorkel Termination - 36" 4DT-ST36

Wall Strap 4DT-WS/B

Cathedral Ceiling Support Box 4DT-CCS

Storm Collar 4DT-SC

Firestop Spacer 4DT-FS

Flashing 0/12 - 6/12 4DT-AF6

Flashing 6/12 - 12/12 4DT-AF12

Steel Chimney

Horizontal Kit A 4DT-HKA

Horizontal Kit B 4DT-HKB

Vertical Kit 4DT-VKC

Masonry Chimney Kit 4DT-MCK

Vertical Termination Cap 4DT-VC

20306759

13

Radiance® Direct Vent Gas Heater

Vermont Castings Group Vent Components

The following kits are available to meet the needs of most

installations. All pipe has a 7" outer diameter and includes

a 4" diameter inner section. A (CG) designation indicates

the part is nished in Charcoal Gray paint. Consult your

dealer about other vent parts that may be appropriate to

complete the installation.

Min. Through the Wall Vent Kit 7TFSSK

(1) 90-Degree Elbow (CG) (7537517)

(1) 24" Straight pipe (CG) (20001448)

(1) 24" - 42" Adjustable Straight Pipe (20006759)

(1) Side Wall Termination (06508)

(1) Firestop (50534)

(1) Zero-clearance sleeve (54623)

(1) Hardware package (20000160)

(1) Finishing plate (CG) (10000257)

(1) Finishing collar (CG) (56298)

(4) Charcoal Gray ue pipe rings (10001008)

Starter Kit for Below-Grade Termination 7TDVSKS

(1) Snorkel Termination (7TDVSNORK)

Vertical Termination Kit, 1/12-6/12 Pitch 7TDVSKVA

(1) Combination Horizontal Offset / Roof Support

(1) Vertical Termination

(1) Storm Collar

(1) 1/12-6/12 Flashing

(1) Finishing Plate (CG)

(1) Finishing Collar (CG)

(1) Polished Brass Flue Pipe Ring

(1) Hardware Package

Vertical Termination Kit, 7/12-12/12 Pitch 7TDVSKVB

(1) 7/12 - 12/12 Flashing

and all of the other Vertical Termination parts.

Vertical Termination, Flat Roof 7DVSKVF

(1) Flat Flashing

and all of the other Vertical Termination parts.

Twist Lock 12" Straight Pipe (CG) 7TFSDVP12

(1) 12" Non-adjustable Pipe

Twist Lock 12" - 18" Adjustable Pipe 7TFSDVP1218

(1) 12" - 18" Adjustable Pipe

Twist Lock 24" Straight Pipe (CG) 7TFSDVP24

(1) 24" Non-adjustable Pipe

Twist Lock 48" Straight Pipe (CG) 7TFSDVP48

(1) 48" Nonadjustable Pipe

Twist Lock 45-Degree Elbow (CG) 7TFSDVT45

for vertical offsets

(1) 45-degree Elbow

Combination Offset/Roof Support 7DVCS

Attic Insulation Shield 7DVAIS

7" Charcoal Gray Pipe Rings, (4) 7FSDRG

7" Polished Brass Pipe Rings (4) 7FSDRP

Wall Thimble 942G

1414

20306759

Radiance® Direct Vent Gas Heater

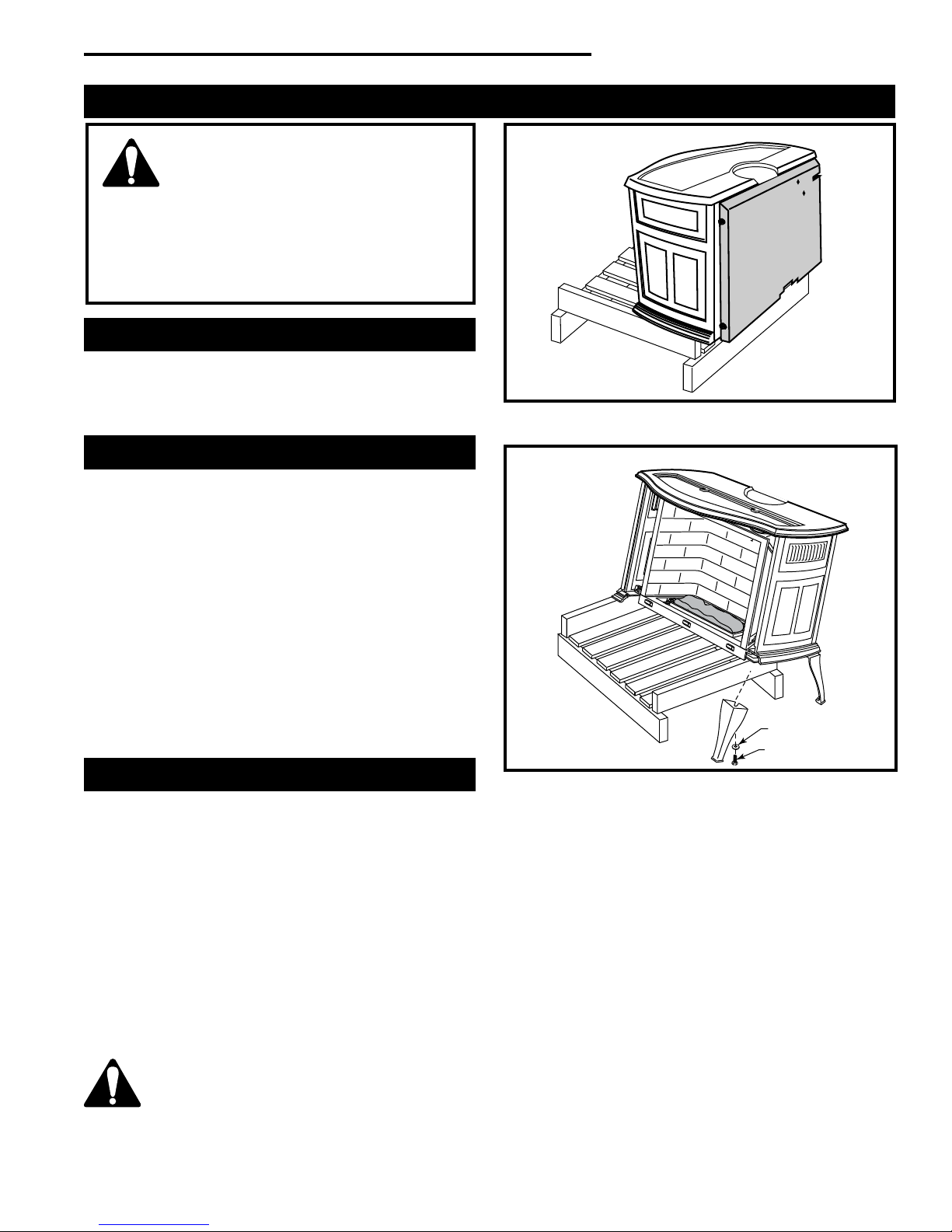

Assembly Procedures

Failure to position the parts in accor-

dance with these diagrams or failure to

use only parts specically approved for

use with this heater may result in property damage

or personal injury.

This heater and components are heavy. Have help

available for assembly.

WARNING

Tools Required

• Phillips screwdriver (stub) • power drill

• utility knife • reciprocating saw

• metal drill bit: size 28 (.140"/3.5mm) • 9/16" wrench

• Flat-blade screwdriver

Parts Bag Contents:

•

(3) Vent Screws

• (2) Switch bracket screws

• Wood handle w/insert lifter

(handle for operable door)

• Restrictor Plate

• 4" Starter pipe

• On-Off switch, housing, and wiring harness

(3) Phillips round-head bolts, 1/4"- 20 x 1/2"

• (1) Tube of Vent Gasket Cement

• (4) CS, Hex Hd 3/8-16 x 1 Gr 2-Z

• (4) Washer, Fl 3/8-Z

• Owner Registration Card

• Homeowner’s Installation and Operating Manual

Unpack and Assemble Legs

The Radiance is shipped upright. Cut the shipping straps

before beginning assembly.

1. Slide stove to the rear of the pallet just far enough to

access rear leg holes. Make sure the stove does not

tip over backwards. (Fig. 13)

2. Attach the rear legs using 3/8" hex head bolts and at

washer supplied. Tighten with a 9/16" wrench or socket.

Remove and discard the large slot-head screws using

the at-blade screwdriver.

3. Carefully tip the stove onto its rear legs. Adjust the pallet

to allow access to one of the front leg holes. Be sure

to leave the pallet under the stove to prevent the stove

from falling fully forward. (Fig. 14)

CAUTION: To prevent valve tubing from being

crushed or damaged, do not rest valve or ignitor

on wooden pallet.

ST720

Fig. 13 Slide stove back just far enough to access rear leg

holes.

Washer

ST721

Fig. 14 Carefully tip stove onto back legs. Leave pallet under

stove to keep stove from falling fully forward.

4. Have your assistant attach one leg using the hardware

described.

5. Move the pallet to allow access to the other front leg

hole. Attach remaining leg.

6. Remove pallet and allow stove to gently rest on all four

legs.

7. Adjust leg levelers to compensate for irregularities in

the hearth.

NOTE: Verify the two relief doors (located on top of the

rebox) are properly seated on the gasket. The doors

should sit ush on the gasket, and should lift easily

from the seal around the opening.

Hex Head Bolt

20306759

15

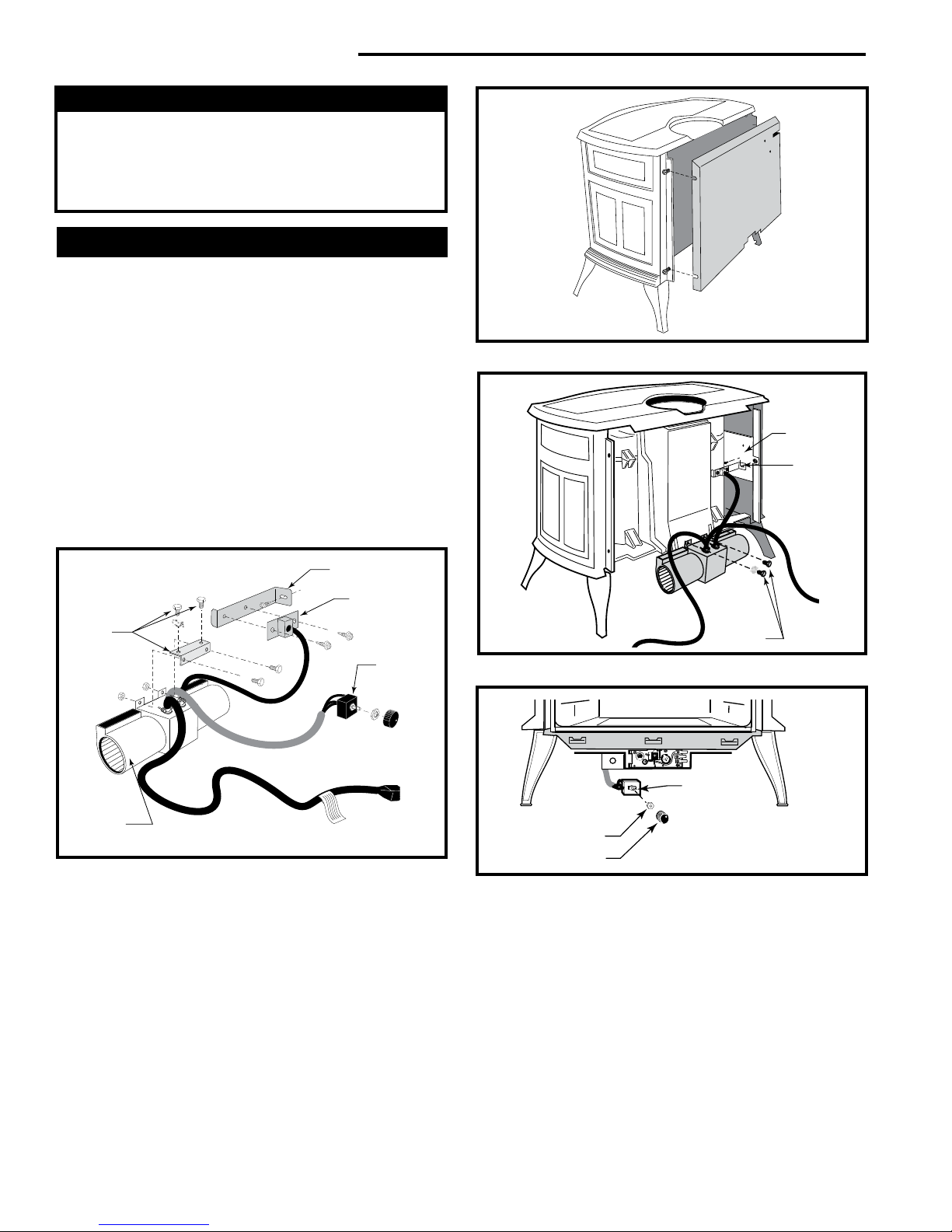

Radiance® Direct Vent Gas Heater

WARNING

This appliance is equipped with a three-prong

(grounded) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle. Do not

cut or remove the grounding prong from this plug.

Install the Optional Fan - RADVT Series

If you are installing the optional convection Fan Kit #2767

(FK26), continue here. It is easiest to install fan kit before

connecting gas line. If you are not installing a Fan Kit, go

to Page 17, Venting System Assembly.

1. The fan kit includes a Blower Assembly and a Rheostat

Assembly, connected by a cable. (Fig. 15) The Blower

Assembly mounts to the bottom rear of the stove, and

the Rheostat mounts to the valve coverplate. The assembly includes a ‘snapstat’ which automatically turns

the fan On (or Off) above (or below) approximately 109°.

The Rheostat also provides a range of fan speed settings from Off (which overrides the snapstat function) to

High. Unpack and inspect the Blower assembly. Conrm

that the fan spins freely.

ST147

Fig. 16 Remove rear shroud.

Side Shield

Snapstat

Snapstat

Bracket

Not

Used On

Radiance

Blower

Assembly

ST473a

Fig. 15 Fan kit components.

Snapstat/

Extension

Assembly

Rheostat

Assembly

2. Remove the rear shroud panel (Fig. 17) and fasten the

blower assembly to the rebox back with the two bolts

provided. (Fig. 17)

3. Attach the snapstat assembly to the snapstat bracket

with two sheet-metal screws. Attach the snapstat bracket

to the side shield. (Fig. 17)

4. The rheostat control switch attaches to the left side of

the valve bracket at the front of the stove. (Fig. 18)

• Remove retaining nut from shaft of rheostat. (if pre-

installed)

Bolts

Fig. 17 Attach blower assembly and snapstat.

Rheostat

Rheostat

Retaining Collar

Rheostat Knob

Fig. 18 Attach the fan rheostat.

• Insert the rheostat through the hole in the back of

the left side of the valve bracket, aligning the locator

pin with the smaller hole in that bracket.

• Thread the retaining nut onto the shaft of the rheo-

stat, tightening with a wrench. Do not overtighten.

• Attach the control knob to the rheostat shaft.

• Use the wire tie to secure the fan and rheostat wire

harnesses together.

ST149

ST347a

1616

20306759

Loading...

Loading...