Vermont Castings Radiance RADVTSCBM, Radiance RADVTSCBD, Radiance RADVTCBSB, Radiance RADVTBSSB, Radiance RADVTBDSB Installation And Operating Instructions Manual

...Page 1

RADVT Series Radiance® Direct Vent Gas Heater

S

Installation and Operating Instructions

Models: RADVTSCCB, RADVTSCBS, RADVTSCBD, RADVTSCBM,

RADVTCBSB, RADVTBSSB, RADVTBDSB, RADVTBMSB

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

• Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do

not use any phone in your building.

– Leave the building immediately.

– Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

– If you cannot reach your gas supplier,

call the re department.

• Installation and service must be performed

by a qualied installer, service agency or

the gas supplier.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this manual.

For assistance or additional information consult

a qualified installer, service agency or the

gas supplier.

This appliance may be installed in an aftermarket,*

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is for use only with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certied kit is used.

* Aftermarket: Completion of sale, not for purpose of resale, from

the manufacturer.

CERTIFIED

AFETY BARRIER

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this

appliance and shall be installed.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for

future reference.

20306759 0416 Rev. 5

Page 2

CONTENTS

Radiance® Direct Vent Gas Heater

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE.

Thank you and congratulations on your purchase of a Vermont Castings stove. IMPORTANT: Read all instructions and

warnings carefully before starting installation. Failure to follow these instructions may result in a possible re hazard

and will void the warranty.

Table of Contents

Important safety information ....................................... 3

Massachusetts Residents Only ......................................... 4

Pre-installation.............................................................. 5

Stove Dimensions ............................................................. 5

Installation Requirements .................................................. 6

Clearance Requirements................................................... 6

Parallel Installation ............................................................ 7

Corner Installation ............................................................. 7

Wall and Ceiling Clearances ............................................. 7

Hearth Requirements ....................................................... 7

Gas Specications............................................................. 8

Gas Inlet and Manifold Pressures ..................................... 8

High Elevations ................................................................. 8

Horizontal Termination ...................................................... 8

Vertical Termination ........................................................... 9

Restrictor Plate Adjustment

for Extended Pipe Runs .................................................... 9

Vent Termination Clearances .......................................... 10

General Venting Information - Termination Location ........11

Termination clearances. .................................................. 12

Assembly and installation ......................................... 13

Venting Requirements and Options................................. 13

Assembling the Stove ..................................................... 14

Install the Optional Fan - RADVT Model (Millivolt only) �� 15

Venting System Assembly ............................................... 16

Before You Start .............................................................. 16

Install the Vent Adapter Pipe ........................................... 17

Assemble Slip Sections ................................................... 18

Secure the Vent Sections ................................................ 18

Disassemble Vent Sections ............................................. 19

Horizontal Termination Cap ............................................. 19

Divert Roof Run-off .......................................................... 20

Vertical Side Wall Installation .......................................... 20

Vent Termination Below Grade ........................................ 21

Vertical Through-The-Roof Application/Installation ......... 22

Install Log Set.................................................................. 24

Install ON/OFF Switch - RADVT Model (Millivolt only) .... 26

Thermostat Connection (optional) ................................... 26

Signature Command® System (SC) ............................... 26

Junction Box Wiring......................................................... 27

Command Center Wall Installation .................................. 27

Wall Switch Installation ................................................... 27

Connect the Gas Supply Line.......................................... 28

Burner Information........................................................... 28

Signature Command Wiring Diagram.............................. 29

Install the Safety Barrier .................................................. 30

Install the Mesh and Grill ................................................. 30

Operating instructions ............................................... 31

Pilot and Burner Inspection ............................................. 31

Flame & Temperature Adjustment ................................... 31

Flame Characteristics...................................................... 31

Lighting and Operating Instructions................................. 32

Troubleshooting ............................................................... 33

Read before lighting ........................................................ 34

Signature command operating instructions ............ 36

Features .......................................................................... 36

Battery installation ........................................................... 36

System conguration/setup ............................................. 36

Operating instructions ............................................... 38

Turning on the stove ........................................................ 38

Command Center Operations ......................................... 38

Initialization and Setting up ............................................. 39

Safety Features ............................................................... 43

Troubleshooting ......................................................... 44

Fuel conversion .......................................................... 46

Cleaning and maintenance ........................................ 51

Annual System Inspection ............................................... 51

Logset and Burner / Cleaning and Inspection ................. 51

Care of Cast Iron ............................................................. 51

Cleaning the Glass .......................................................... 51

Gasket Replacement ....................................................... 52

Inspect the Vent System Annually ................................... 52

Check the Gas Flame Regularly ..................................... 52

Glass Replacement ......................................................... 52

Wiring diagrams ......................................................... 53

Replacement parts ..................................................... 55

Optional accessories ................................................. 58

Limited lifetime warranty .......................................... 59

22 20306759

Page 3

Radiance® Direct Vent Gas Heater

IMPORTANT SAFETY INFORMATION

The Radiance Direct Vent Room Heater, Model Nos. RADVTCBSB, RADVTBSSB, RADVTBDSB, RADVTBMSB, RADVTSCCB, RADVTSCBS, RADVTSCBD, RADVTSCBM, is a

vented gas appliance listed to the ANSI Standard Z21.88-2014

and CSA 2.33-2014 for Vented Room Heaters, and CSA 2.17M91, Gas-Fired Appliances For Use at High Altitudes.

The installation of the Radiance Direct Vent Room Heater must

conform with local codes, or in the absence of local codes, with

National Fuel Gas Code, ANSI Z223.1/NFPA 54 — latest edition

and CSA B-149.1 Installation Code. (EXCEPTION: Do not

derate this appliance for altitude. Maintain the manifold pressure

at 3.5 inches w.c. for Natural Gas and 10 inches w.c. for LP gas

at maximum input.)

This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other

gases unless a certied kit is used.

Installation and replacement of gas piping, gas utilization

equipment or accessories, and repair and servicing of equipment shall be performed only by a qualied agency, preferably NFI or WETT (Canada) certied. The term “qualied

agency" means any individual, rm, corporation, or company

that either in person or through a representative is engaged

in and is responsible for (a) installation or replacement of gas

piping, or (b), the connection, installation, repair, or servicing of equipment, who is experienced in such work, familiar

with all precautions required, and has complied with all the

requirements of the authority having jurisdiction.

The Radiance Direct Vent Room Heater should be inspected

before use and at least annually by a qualied service agency.

It is imperative that control compartments, burners, and

circulating air passageways of the appliance be kept clean.

The Radiance Direct Vent Room Heater and its individual shut-off

valve must be disconnected from the gas supply piping during

any pressure testing of that system at test pressures in excess

of 1/2 psig (3.5 kPa).

The Radiance Direct Vent Room Heater must be isolated from the

gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig.

An accessible tap is located above the pilot/On-Off knob for

checking the inlet pressure.

‘Direct Vent’ describes a sealed combustion system in which

incoming outside air for combustion and outgoing exhaust enter

and exit through two separate concentric passages within the

same sealed vent system. The system does not use room air

to support combustion. The Direct Vent system permits the gas

appliance to be vented directly to the outside atmosphere through

the side of the house or vertically through the roof. Conventional

venting systems (Natural Vent) take air from the room for combustion and vent the exhaust vertically through the roof to the

atmosphere.

This appliance is approved for bedroom installations in the U.S.

and Canada.

This appliance may be installed in an aftermarket* manufactured

(mobile) home, where not prohibited by state or local codes.

WARNING: Operation of this heater when not connected to a

properly installed and maintained venting system can result

in carbon monoxide (CO) poisoning and possible death.

The Radiance Direct Vent Room Heater, when installed, must

be electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code ANSI/

NFPA 70, (latest edition), or of the current Canadian Electrical

Code C22.1.

Due to high temperatures this appliance should be located

out of trafc and away from furniture and draperies.

WARNING: This appliance is hot while in operation. Keep

children, clothing, and furniture away. Contact may cause

burns or ignition of combustible materials.

Children and adults should be alerted to the hazards of high

surface temperatures and should stay away to avoid burns

or clothing ignition.

Young children should be carefully supervised when they

are in the same room as the appliance. Toddlers, young

children and others may be susceptible to accidental contact burns. A physical barrier is recommended if there are

at risk individuals in the house. To restrict access to a stove

or stove, install an adjustable safety gate to keep toddlers,

young children and other at risk individuals out of the room

and away from hot surfaces.

Clothing or other ammable materials should not be placed

on or near the appliance.

Any safety screen, glass or guard removed for servicing an

appliance must be replaced prior to operating the appliance.

The appliance area must be kept clear and free from combustible materials, gasoline, and other ammable vapors

and liquids.

The ow of combustion and ventilation air must not be

obstructed. The installation must include adequate accessibility and clearance for servicing and proper operation.

WARNING: Do not operate the Room Heater with the glass

panel removed, cracked or broken. Replacement of the panel

should be done by a licensed or qualied service person.

Do not use this appliance if any part has been under water.

Immediately call a qualied service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

Do not burn wood, trash or any other material for which this

appliance was not designed. This appliance is designed to

burn either natural gas or propane only.

This gas appliance must not be connected to a chimney ue

serving a separate solid-fuel burning appliance.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation.

Verify proper operation after servicing.

Aftermarket: Completion of sale, nor for purpose of resale,

*

from the manufacturer�

20306759

3

Page 4

IMPORTANT SAFETY INFORMATION

Radiance® Direct Vent Gas Heater

REQUIREMENTS FOR THE

COMMONWEALTH OF MASSACHUSETTS

All gas tting and installation of this heater shall only be

done by a licensed gas tter or licensed plumber.

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where

the side wall exhaust vent termination is less than seven

(7) feet above nished grade in the area of the venting,

including but not limited to decks and porches, the following

requirements shall be satised:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gas tter

shall observe that a hard wired carbon monoxide detector with an alarm is installed on each additional level of

the dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the services

of qualied licensed professionals for the installation of

hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery

back-up may be installed on the next adjacent oor level.

In the event that the requirements of this subdivision can

not be met at the time of completion of installation, the

owner shall have a period of thirty (30) days to comply with

the above requirements; provided, however, that during

said thirty (30) day period, a battery operated carbon monoxide detector with an alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFPA 720 and

ANSI/UL 2034 listed and IAS certied.

Signage

A metal or plastic identication plate shall be permanently mounted to the exterior of the building at a

minimum height of eight (8) feet above grade directly in

line with the exhaust vent terminal for the horizontally

vented gas fueled heating appliance or equipment. The

sign shall read, in print size no less than one-half (1/2)

inch in size, “GAS VENT DIRECTLY BELOW, KEEP

CLEAR OF ALL OBSTRUCTIONS".

Inspection

The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the installation unless, upon inspection, the inspector observes carbon

monoxide detectors and signage installed in accordance

with the provisions of 248 CMR 5.08(2)(a)1 through 4.

Exemptions

The following equipment is exempt from 248 CMR 5.08(2)

(a)1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented" in the most current edition

of NFPA 54 as adopted by the Board; and

• Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate

from the dwelling, building or structure used in whole or

in part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall hor-

izontally vented gas equipment provides a venting system

design or venting system components with the equipment,

the instructions provided by the manufacturer for installation

of the equipment and the venting system shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components; and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide

the parts for venting the ue gases, but identies “special

venting systems", the following requirements shall be sat-

ised by the manufacturer:

• The referenced “special venting system" instructions

shall be included with the appliance or equipment installation instructions; and

• The “special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a parts list and detailed installation

instructions.

A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists for venting

instructions, and/or all venting design instructions shall

remain with the appliance or equipment at the completion

of the installation.

Radiance Direct Vent

Certied to:

ANSI Z21.88-2014 / CSA 2.33-2014

Vented Gas Heaters

44 20306759

Proposition 65 Warning: Fuels used in gas, wood-burning

or oil red appliances, and the products of combustion of

such fuels, contain chemicals known to the State of California

to cause cancer, birth defects and other reproductive harm.

California Health & Safety Code Sec. 25249.6

Page 5

Radiance® Direct Vent Gas Heater

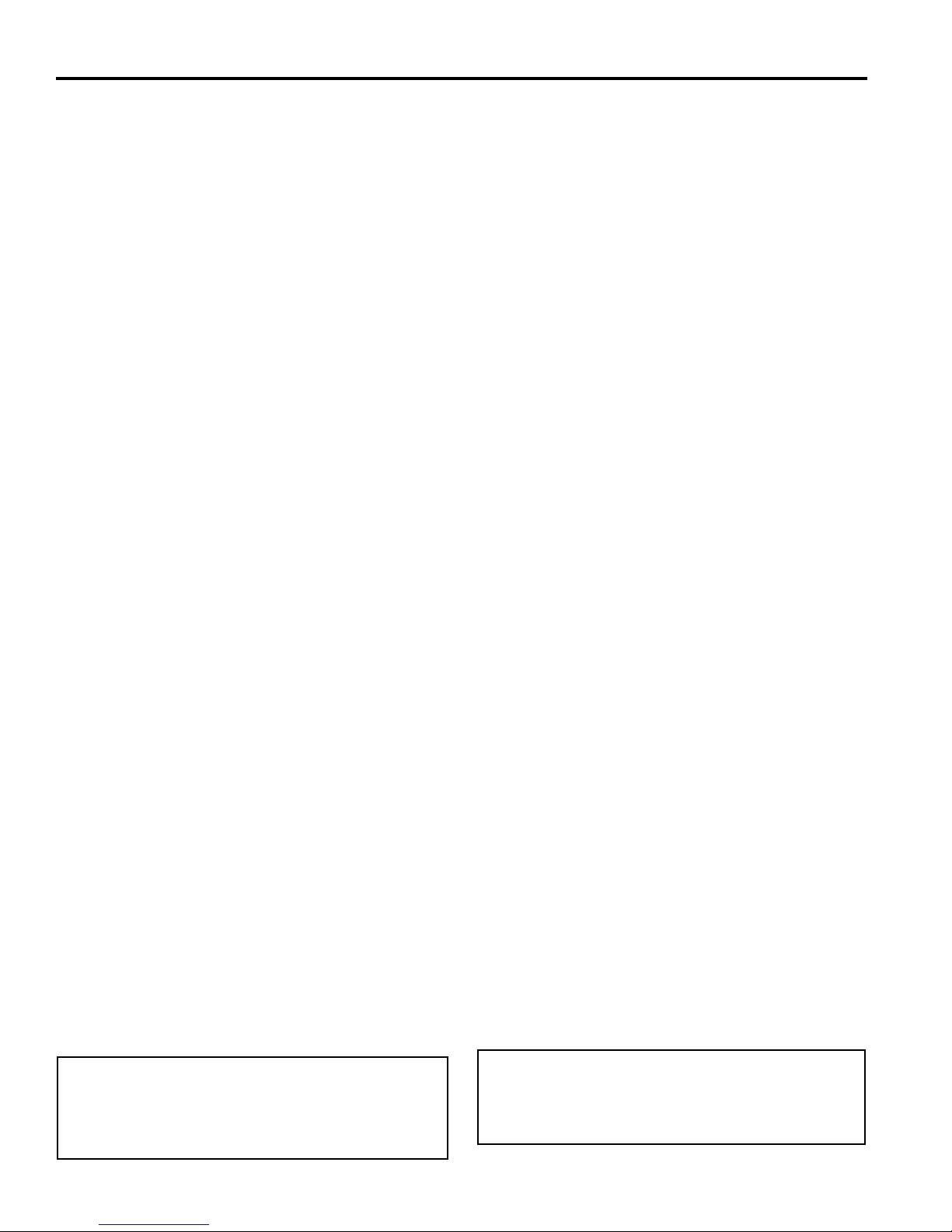

29-3/4"

(758 mm)

31"

(787 mm)

7" Outer Dia.

(178 mm)

Flue Collar

L

C

4-3/4"

(120 mm)

14-7/8"

(378 mm)

RADIANCE

28"

(711 mm)

5"

(127 mm)

18-1/4"

(464 mm)

Supply

Inlet

PRE-INSTALLATION

RADIANCE DIRECT VENT

Weight: Fully assembled; 350 lbs.

STOVE DIMENSIONS

Fig. 1 Radiance dimensions.

20306759

5

Page 6

A

B

E

C

D

PRE-INSTALLATION

INSTALLATION REQUIREMENTS

The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 - latest edition. (EXCEPTION: Do

not derate this appliance for altitude. Maintain the manifold pressure at 3.5" w.c. for Natural Gas, and 10" w.c. for

Propane).

In Canada, installation must be in accordance with the

current CSA B-149.1 Installation Codes and/or local codes.

The installation should be done by a qualied service

person who is familiar with the building codes and installation techniques appropriate for your area to accomplish

a safe and effective installation.

Your dealer or your local gas supplier will be able to refer

a qualied service person.

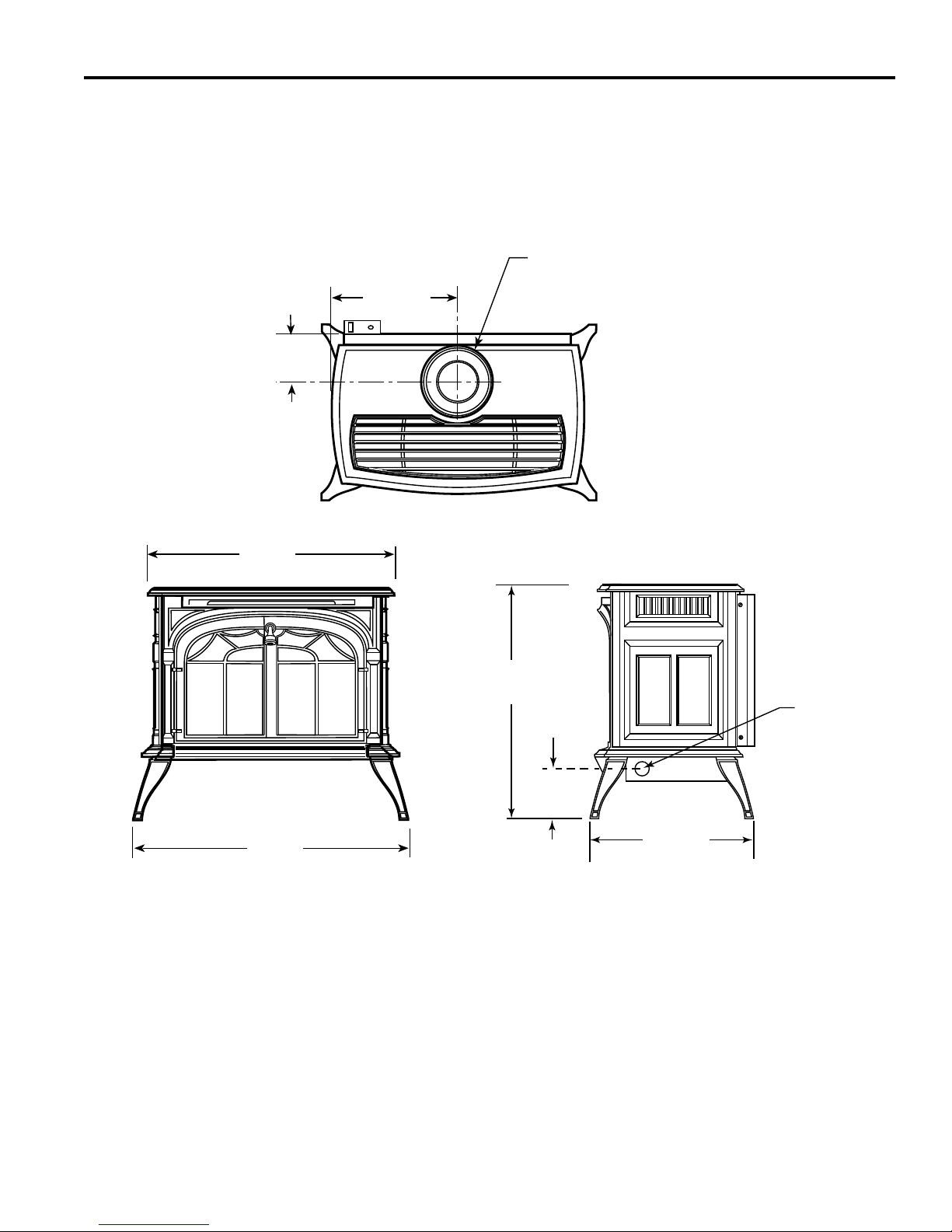

WARNING

Due to high temperatures, the heater should be located

out of trafc and away from furniture and draperies.

The surface of the Heater Is hot when it is in use. Young

children should be watched carefully when they are in

the same room when the Heater is in use, and they

should be taught to avoid the hot surface. Keep any

objects that can burn well away from the Heater, and

observe the recommended clearances that follow.

DANGER

Radiance® Direct Vent Gas Heater

Direct Vent System Only

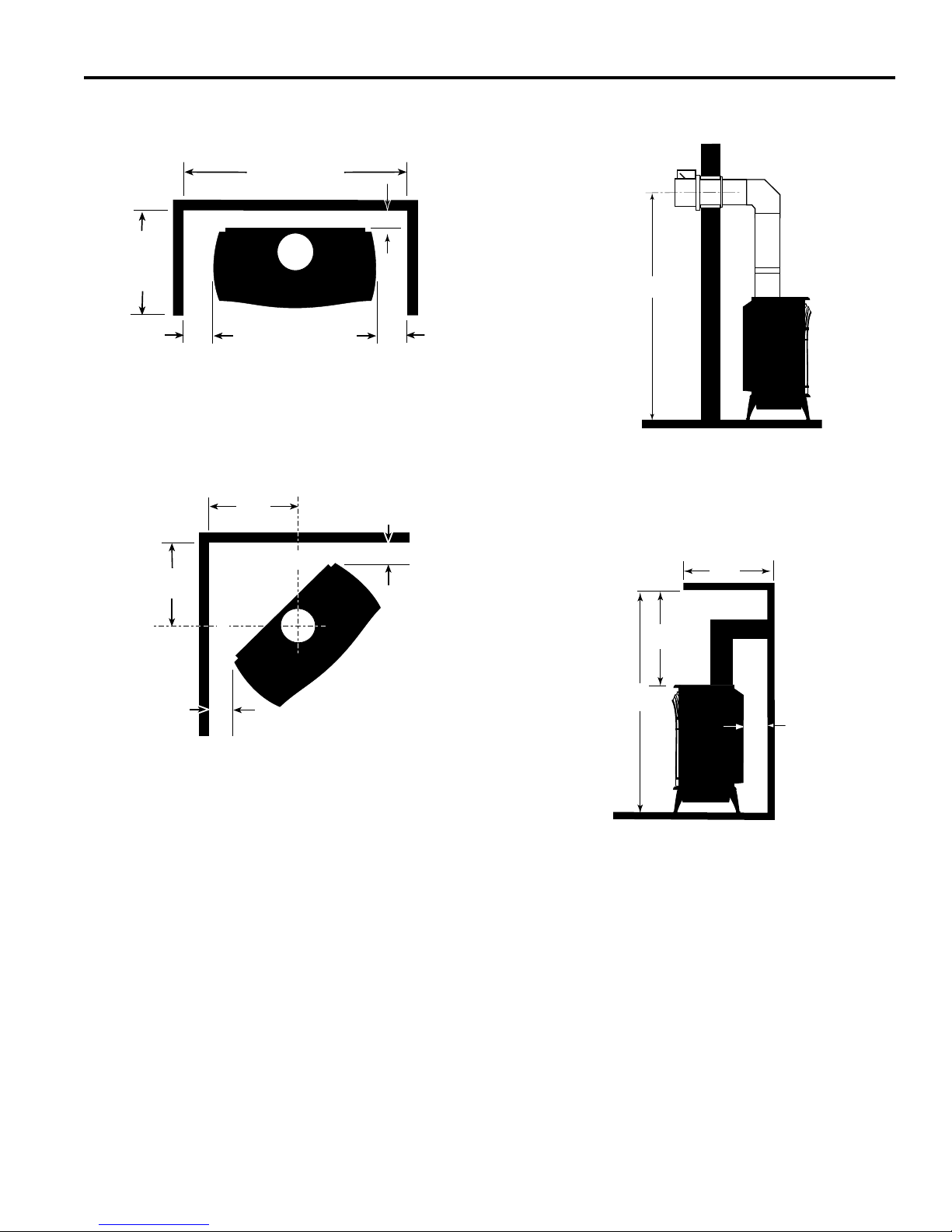

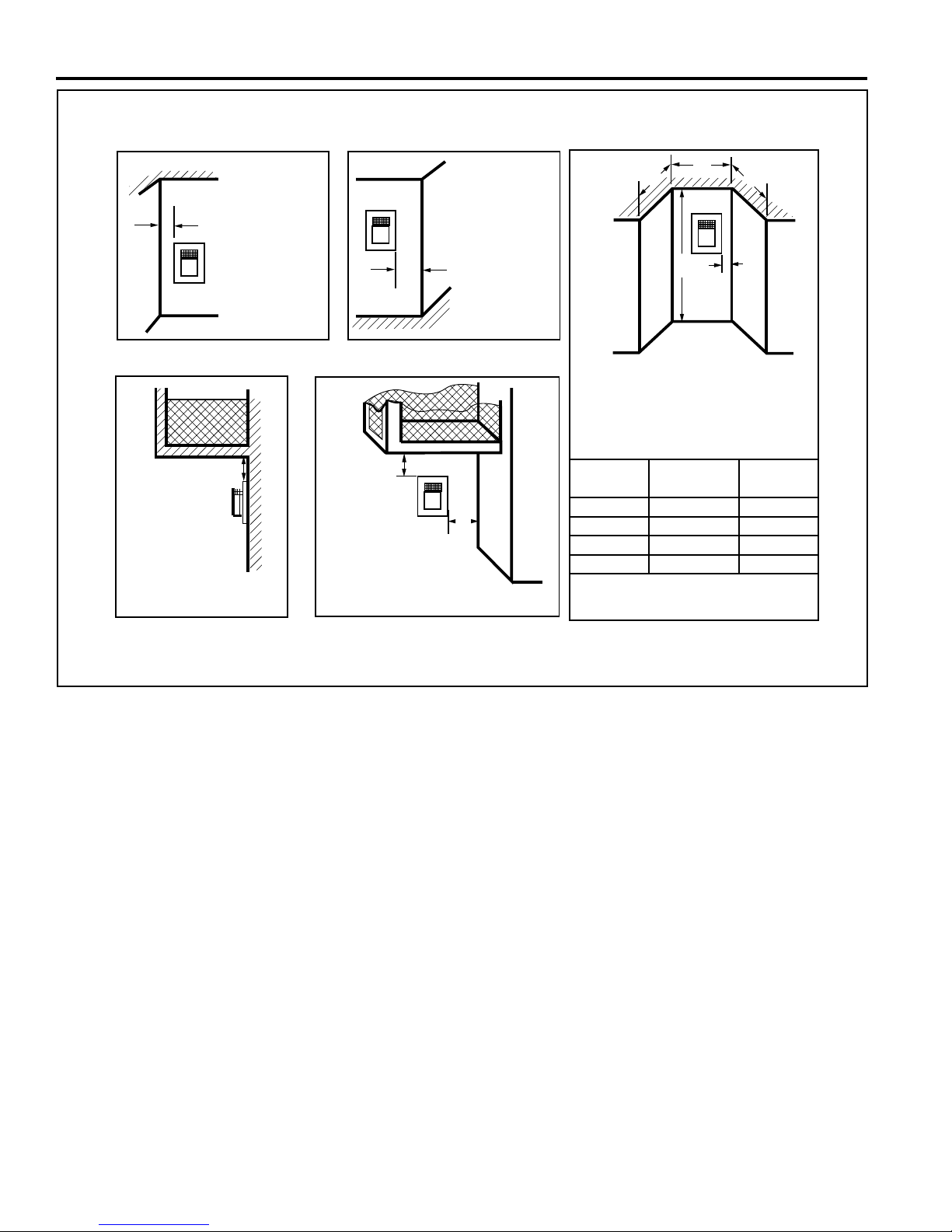

A. Flat on corner wall

B. Room Divider

C. Island

Fig. 2 Possible stove locations.

D. Cross Corner

E. Flat on wall

ST207a

CLEARANCE REQUIREMENTS

Minimum Clearances to Combustible Materials

Measure side clearances as shown in Figures 3, 4 and 5

from the outer edge of the cast iron stove top. Measure

rear clearances from the outermost surface of the steel

rear skirt.

The Radiance heater is approved for installation into an

alcove constructed of combustible materials to the dimensions and clearances shown on the next page.

The same clearances apply in a standard parallel installation.

HOT GLASS WILL

CAUSE BURNS.

WARNING

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this

appliance and shall be installed.

In choosing a location for the stove, consider:

• The location of outside walls;

• Where additional heat is needed:

• Where family members gather most often;

• The vent system requirements.

NOTE: We do not recommend the use of wallpaper

next to this stove. Over time, radiant heat may cause

the wallpaper to shrink, or may adversely affect the

binders in the wallpaper adhesive.

66 20306759

• Always maintain required clearances (air spaces) to

nearby combustibles to prevent re hazard. Do not

ll air spaces with insulation. All venting components

must maintain a 1" (25 mm) clearance to combustible materials. The gas appliance and vent system

must be vented directly to the outside of the building

and never be attached to a chimney serving a separate solid fuel or gas-burning appliance.

• Refer to the manufacturer’s instructions included

with the venting system for complete installation procedures.

Page 7

Radiance® Direct Vent Gas Heater

42" (1070mm)

Min. Alcove Width

48"

(1220mm)

Max. Alcove

Depth

6"

(150mm)

6"

(150mm)

4" (102mm)

18"

(457mm)

18"

(457mm)

6"

(150mm)

6"

(150mm)

C

L

C

L

A

A

C

D

B

PRE-INSTALLATION

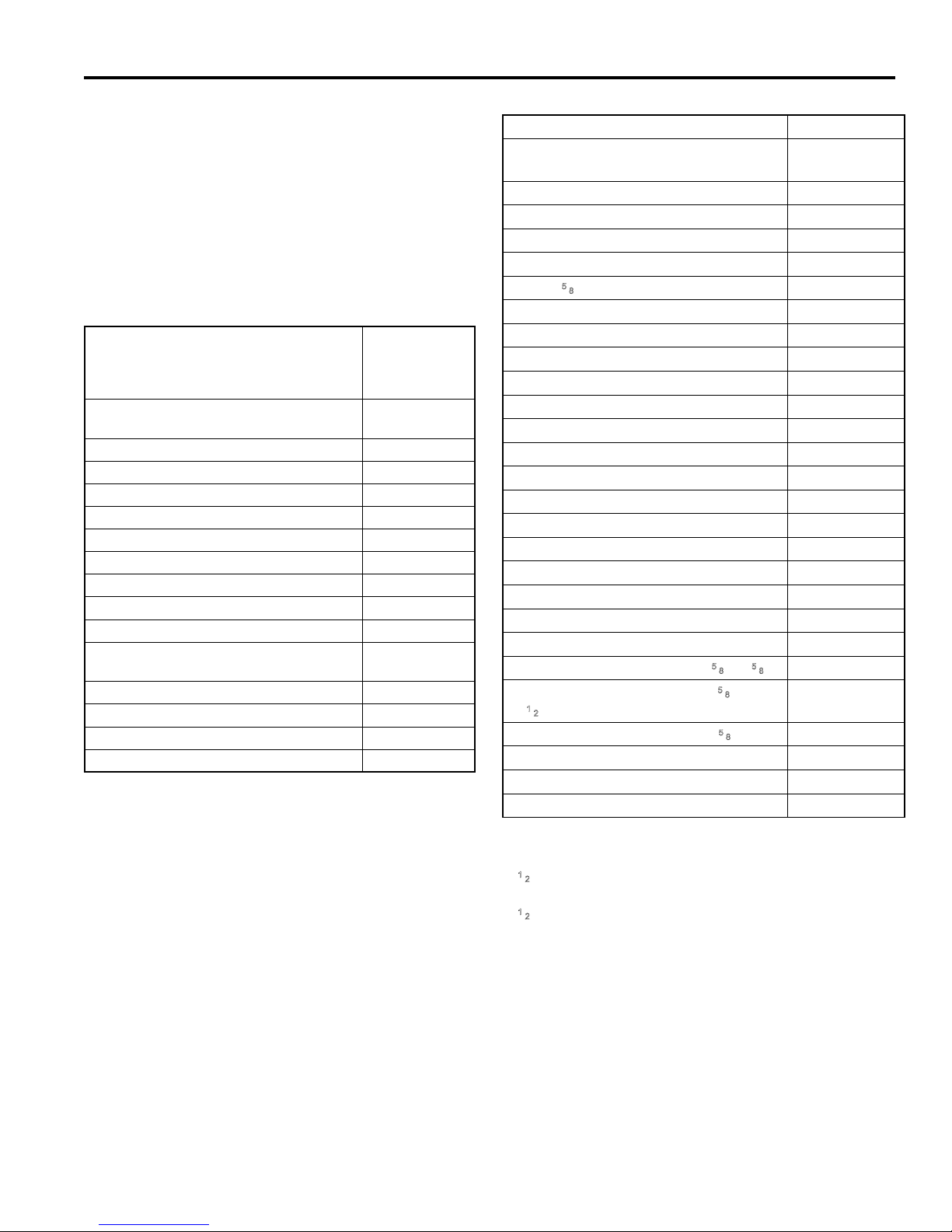

PARALLEL INSTALLATION

Minimum Clearance and Flue Centerline

ST130

Fig. 3 Parallel installation, minimum back and side clearances,

and ue centerlines.

CORNER INSTALLATION

Minimum Clearance and Flue Centerline

Wall Centerline from Floor

Direct Vent Only

ST131b

A

Effective Minimum

Centerline 57" (1448 mm) (HHT Pipe)

55" (1399 mm) (DuraVent Pipe)

Fig. 5 Minimum wall centerline.

WALL AND CEILING CLEARANCES

Fig. 4 Corner installation, minimum corner clearances and ue

centerline.

ST129

Direct Vent Only

A: Rear Wall 4" (102 mm)

B: Min. Clearance 44" (1118 mm)*

C: Min. Alcove Height 72" (1830 mm)*

D: Max. Alcove Depth 48" (1220 mm)

Sidewall Clearance 6" (150 mm)

*needed for installing DuraVent Minimum Vent Kit #2792 or

HHT Minimum Vent Kit #SLP-FSSK.

Fig. 6 Dimensions and clearances to ceiling or alcove.

ST101b

HEARTH REQUIREMENTS

The Radiance Heater must be installed on rigid ooring.

When the heater is installed directly on any combustible

surface other than wood ooring, a metal or wood panel

extending the full width and depth of the unit must be used

as the hearth. There are no other hearth requirements.

20306759

7

Page 8

20

19

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Vertical Run (in feet)

(Measured from the appliance flue collar to the top of the vent pipe.)

Horizontal Run (in feet)

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ST134b

Radiance

Horizontal

vent run

6/07

PRE-INSTALLATION

Radiance® Direct Vent Gas Heater

GAS SPECIFICATIONS

Max.

Input

Model Fuel Control

RADVT Nat.

RADVT LP

RADVTSC Nat.

RADVTSC LP

Millivolt

Manual

Millivolt

Manual

Signature

Command

Signature

Command

BTU/h

38,000 25,000

36,000 25,000

38,000 25,000

36,000 25,000

GAS INLET AND MANIFOLD PRESSURES

Natural Liquid Propane

Inlet Minimum 5.5" w.c. 11.0" w.c.

Inlet Maximum 14.0" w.c. 14.0" w.c.

Manifold Pressure 3.5" w.c. 10.0" w.c.

The installation of your Vermont Castings stove must

conform with local codes, or in the absence of local

codes, with the National Fuel Gas Code ANSI Z223.1/

NFPA 54 - latest edition, or CSA B149.1 Installation

code. (EXCEPTION: Do not derate this appliance

for altitude up to 2,000 (610 m) for natural gas and

4,500 feet (1,370 m) for LP Gas. Maintain the manifold pressure at 3.5" w.c. for Natural Gas and 10.0"

w.c. for LP Gas.

HIGH ELEVATIONS

Input ratings are shown in BTU per hour and are

certied without deration for elevations up to 2,000

feet (610 m) for natural gas and 4,500 feet (1,370 m)

for LP gas above sea level.

In the USA installations with elevations above 2,000

feet (610 m) for natural gas and 4,500 feet (1,370 m)

for LP gas must be in accordance with the current

ANSI Z223.1/NFPA 54 and/or local codes having

jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 2,000 feet (610 m) for natural gas

and 4,500 feet (1,370 m) for LP gas.

Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage.

Refer to this manual for correct installation and operational procedures. For assistance or additional infor-

mation consult a qualied installer, service agency, or

the gas supplier.

88 20306759

WARNING

Min. Input

BTU/h

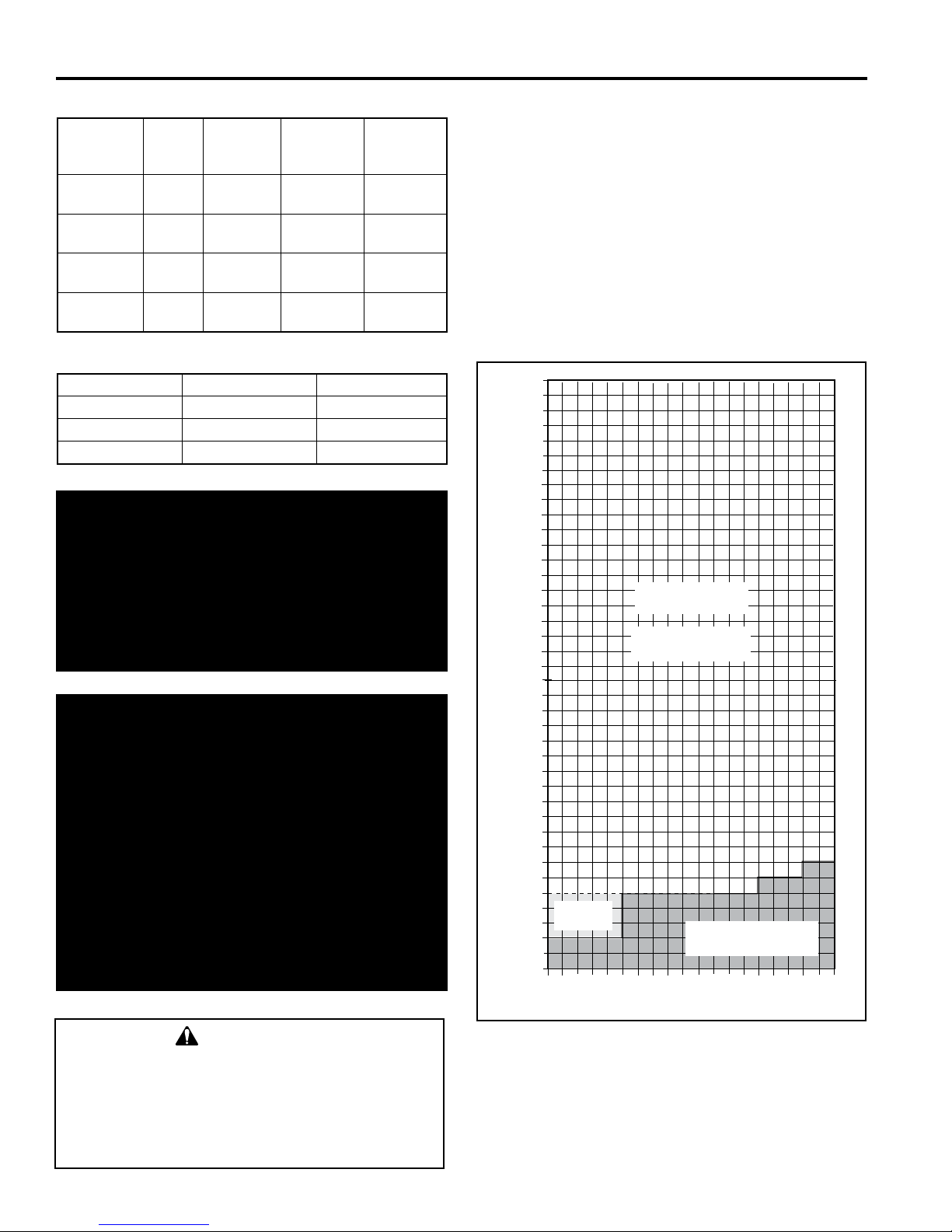

HORIZONTAL TERMINATION

The vent must rise vertically a minimum of 24" (610 mm)

off the top of the unit, before the rst elbow. The horizontal

run may extend up to 20’ (6m) and include a vertical rise

of up to 40’ (12 m). (Figure 7) Horizontal termination must

also meet the criteria shown in Figures 10 through 12.

• Approved vent systems must terminate above and including the heavy line in Figure 7.

• Two 45° elbows may be substituted for each single 90°

elbow.

• With a rise between 2’ - 5’, one 90° or two 45° elbows

may be used.

May use up to

three 90° Elbows

No Restrictor Plate

Required

One 90°

Elbow

Fig. 7 Horizontal vent termination window.

Unacceptable

Venting Conguration

ST134a

Page 9

Radiance® Direct Vent Gas Heater

20

19

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

20

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Vertical Run (in feet)

(Measure from the appliance flue collar to the top of the vent pipe.)

Horizontal Run (in feet)

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ST132a

FDV28

Vertical

vent run

12/3/99 djt

PRE-INSTALLATION

VERTICAL TERMINATION

A vertical vent system must terminate no less than 8’ (2.44

m) and no more than 40’ (12 m) above the appliance ue

collar. A restrictor plate (supplied) must be used, where

specied, in all vertically terminated vent systems. (Refer

to Figure 8) NOTE: The restrictor plate supplied with

the vertical termination should be discarded. Adjust the

restrictor plate according to recommendations in Figure

10. A vertically terminated vent system must also conform

to the following criteria:

• No more than three 90° elbows may be used.

• Two 45° elbows may be substituted for one 90° elbow.

No more than six 45° elbows may be used.

• Vent must rise a minimum of 2 feet (305 mm) before

offset is used.

• Termination height must conform to roof clearance as

specied in Figure 11.

All Vertical Ter-

minations in this

area Require use

of the Restrictor

Plate*

RESTRICTOR PLATE ADJUSTMENT

FOR EXTENDED PIPE RUNS

The Radiance stove is shipped with a restrictor plate in

the Parts Bag. Adjustments can be made by loosening the

adjustment screw to allow the restrictor plate to slide up or

down. (Figure 9) A guide for usage is shown in Figure 10.

NOTE: Some installations may require some adjustment

by the installer for optimum ame appearance. Optimum

ame appearance is a ame that is not subject to tall, dirty

yellow ames producing soot or ames lifting off of the

ember bed ports.

Restrictor Plate Adjustment

• Remove the screw in the back wall of the rebox.

• Install restrictor plate as shown in Figure 9 with cut out

on left side. Secure with adjustment screw.

• Measure from center of screw to top edge of diverter

(Figure 9) to adjust plate according to guidelines in

Figure 10.

• Tighten attachment screw.

• Install logs following log installation instructions.

Adjustment Screw

**No Restrictor

Plate

Fig. 8 Vertical vent termination window.

20306759

Vertical terminations

must be within this

area

Unacceptable

Venting Conguration

**

ST132a

Fig. 9 Loosen screw to adjust restrictor plate.

Examples for Extended Run/Restrictor Plate Settings

Vertical 20’

(6 m), 90°

elbow, out 8’

(2.4 m)

Vertical 11’

(3.4 m), 90°

elbow, out 2’

(610 mm)

Vertical 40’

(12 m)

Vertical 5’

(1.5 m), 90°

elbow, out 5’

(1.5 m)

Restrictor plate measurement from top of plate to

center of screw:

3

⁄4” (70 mm)

2

from center

of screw to

top edge of

plate

Figure 10

Plate down

to top of slot

Plate down

to top of slot

23⁄8” (60 mm)

from center

of screw to

top edge of

plate

ST917

9

Page 10

PRE-INSTALLATION

Radiance® Direct Vent Gas Heater

VENT TERMINATION CLEARANCES

When planning the installation, consider the location of the

vent terminal and clearances. Some of the most common

clearances to keep in mind are shown in Figure 11.

Important: All vent clearances must be maintained.

Check your vent termination clearances against Figures 11 and 12.

The vent should be placed so that people cannot be burned

by accidentally touching the vent surfaces when the stove

is operating.

The vent termination should be located where it cannot be

damaged by such things as automobile doors, lawn mowers

or snowblowers and it should be located away from areas

where it could become blocked by snow, etc.

Some considerations are:

• Obstructions or impediments to venting.

• Nearby combustible materials that could come into contact with combustion exhaust gases.

• Other nearby openings {within 12" (305 mm)} through

which exhaust gas could reenter the building.

• All vegetation within 3’ (76 mm) that may interfere with

the draft.

Other factors that inuence where the installation will be

sited include the location of outside walls, where additional

heat may be desired in the home, where the family members gather most regularly, and perhaps most importantly,

the distance limitations of the venting system.

IMPORTANT

The horizontal termination must not be recessed into

the exterior wall or siding.

Horizontal vent runs must be level toward the vent

termination.

Clearances around the vent termination must be

maintained.

For installations using DuraVent pipe, parallel installations with minimum wall clearance have restricted

access for connecting the Horizontal Vent Cap straps

to the vent pipe. See the maker’s instructions for recommended installation procedures.

Your stove is approved to be vented either through the side

wall, or vertical through the roof.

• HHT does not require any opening for inspection of vent

pipe.

• Only HHT SLP venting components or DuraVent vent-

ing components specically approved and labeled for

this stove may be used.

• Minimum clearances between vent pipes and combustible materials is one (1") inch (25 mm), except where

stated otherwise.

• Venting terminals shall not be recessed into a wall or

siding.

• Horizontal venting must be installed on a level plane

without an inclining or declining slope.

There must not be any obstruction such as bushes, garden

sheds, fences, decks or utility buildings within 24" from the

front of the termination hood.

Do not locate termination hood where excessive snow or

ice build up may occur. Be sure to check vent termination

area after snow falls, and clear to prevent accidental blockage of venting system. When using snow blowers, make

sure snow is not directed towards vent termination area.

LOCATION OF VENT TERMINATION

It is imperative the vent termination be located observing

the minimum clearances as shown in this manual.

1010 20306759

Page 11

Radiance® Direct Vent Gas Heater

V

X

X

X

D

E

B

B

B

C

B

M

B

A

J

K

F

L

VENT TERMINATION AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

H

I

Fixed

Closed

Operable

Operable

Fixed

Closed

B

INSIDE

CORNER DETAIL

A

G

CFM145a

V

V

V

V

V

V

V

V

N

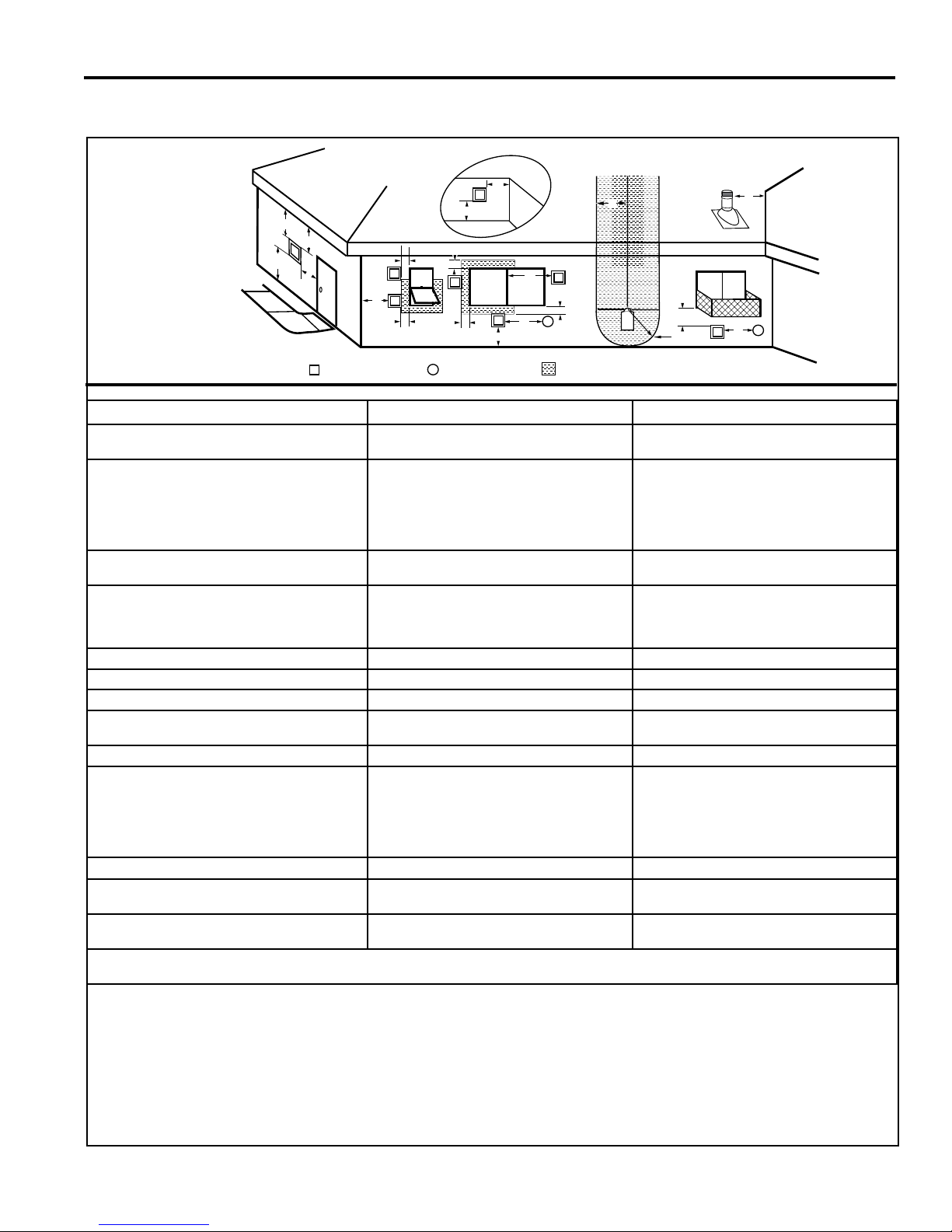

GENERAL VENTING INFORMATION - TERMINATION LOCATION

PRE-INSTALLATION

A = Clearance above grade, veranda, porch, deck

CANADIAN INSTALLATIONS

1

12" (30cm) 12" (30cm)

US INSTALLATIONS

2

or balcony

B = Clearance to window or door that may be

opened

C = Clearance to permanently closed window 12" (305mm) recommended to prevent window

D = Vertical clearance to ventilated soft located

6" (15cm) for appliances <10,000 BTU/h (3kW)

12" (30cm) for appliances >10,000 BTU/h (3kW)

and <100,000 BTU/h (30kW)

36" (91cm) for appliances >100,000 BTU/h

(30kW)

6" (15cm) for appliances <10,000 BTU/h (3kW)

9" (23cm) for appliances >10,000 BTU/h (3kW)

and <50,000 BTU/h (15kW)

12" (30cm) for appliances >50,000 BTU/h

(15kW)

12" (305mm) recommended to prevent window

condensation

condensation

18" (458mm) 18" (458mm)

above the terminal within a horizontal distance

of 2' (610 mm) from the center line of the

terminal

E = Clearance to unventilated soft 12" (305mm) 12" (305mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner see next page see next page

H = Clearance to each inside of center line

extended above meter/regulator assembly

3' (91cm) within a height of 15' (5m) above the

meter/regulator assembly

3' (91cm) within a height of 15' (5m) above the

meter/regulator assembly

I = Clearance to service regulator vent outlet 3' (91cm) 3' (91cm)

J = Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any

other appliance

6" (15cm) for appliances <10,000 BTU/h (3kW)

12" (30cm) for appliances >10,000 BTU/h (3kW)

and <100,000 BTU/h (30kW)

36" (91cm) for appliances >100,000 BTU/h

(30kW)

6" (15cm) for appliances <10,000 BTU/h (3kW)

9" (23cm) for appliances >10,000 BTU/h (3kW)

and <50,000 BTU/h (15kW)

12" (30cm) for appliances >50,000 BTU/h

(15kW)

K = Clearance to mechanical air supply inlet 6' (1.83m) 3' (91cm) above if within 10' (3m) horizontally

L = Clearance above paved sidewalk or paved

7' (2.13m)

†

7' (2.13m)

†

driveway located on public property

M = Clearance under veranda, porch, deck or

12" (30cm)

‡

12" (30cm)

‡

balcony

N = Clearance above a roof shall extend a minimum of 24” (610mm) above the highest point when it passes through the roof

surface, and any other obstruction within a horizontal distance of 18” (450mm).

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel

Gas Codes

† A vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings and

serves both dwellings

‡ Only permitted if veranda, porch, deck or balcony is fully open on a

minimum 2 sides beneath the oor.

Fig. 11 Vent termination clearances.

20306759

NOTE: 1. Local codes or regulations may require different

2. The special venting system used on Direct Vent

3. HHT assumes no responsibility for the improper

clearances.

Fireplaces are certied as part of the appliance, with

clearances tested and approved by the listing agency.

performance of the appliance when the venting system does

not meet these requirements.

11

Page 12

PRE-INSTALLATION

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

Inside Corner

G =

G

Combustible

6" (152 mm)

Noncombustible

V

2" (51 mm)

Outside Corner

V

F

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

Radiance® Direct Vent Gas Heater

Alcove Applications*

C

D

C

V

O

E

Balcony -

with no side wall

V

M =

Combustible &

Noncombustible

12" (305 mm)

*NOTE: Termination in an alcove space (spaces open only on one side and with an overhang) is permitted with the dimensions

specied for vinyl or non-vinyl siding and softs. 1. There must be a 3’ (914 mm) minimum between termination caps. 2. All mechanical air intakes within 10’ (1 m) of a termination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All gravity

air intakes within 3’ (914 mm) of a termination cap must be a minimum of 1’ (305 mm) below the termination cap.

Fig. 12

TERMINATION CLEARANCES.

Balcony -

with perpendicular side wall

E = Min. 2” (51 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O = 8’ (2.4 m) Min.

M

Combustible &

Noncombustible

M = 12" (305 mm)

P = 6” (152 mm)

M

V

P

No.

of Caps D

1 3’ (914 mm) 2 x D

2 6’ (1.8 m) 1 x D

3 9’ (2.7 m) 2/3 x D

4 12’ (3.7 m) 1/2 x D

D

= # of Termination caps x 3

Min.

C

= (2 / # termination caps) x D

Max.

C

Min.

Max.

Actual

Actual

Actual

Actual

Actual

584-15

1212 20306759

Page 13

Radiance® Direct Vent Gas Heater

ASSEMBLY AND INSTALLATION

VENTING REQUIREMENTS AND OPTIONS

Approved Vent System Components

The Radiance Heater must be vented to the outdoors

through an adjacent exterior wall or through the roof. The

venting system must be comprised of the appropriate listed

venting components specied on this page. These parts

are available from DuraVent Corporation or your Vermont

Castings Dealer.

See Figure 4 for dimensions relevant to the standard

minimum-vent kits.

HHT Components*

Free Standing Stove Kit w/adj.

Termination Cap, SLP24-BK, SLP6-BK,

SLP6A-BK, SLP90-BK, SLP-WT-BK &

CCSLP

Vertical Termination cap - High Wind

(includes storm collar)

Decorative Wall Thimble Cover SLP-WT-BK

Decorative ceiling restop - black SLP-DCF-BK

Cathedral ceiling support - black SLP-CCS-BK

4" (100mm) pipe length - black SLP4-BK

6" (150mm) pipe length - black SLP6-BK

12" Pipe length-black SLP12-BK

24" Pipe length-black SLP24-BK

36" (915mm) pipe length - black SLP36-BK

48" Pipe length-black SLP48-BK

3"–6" (75 - 150mm) telescoping pipe

extension - black

3"–12" telescoping pipe extension-black SLP12A-BK

45 degree elbow-black SLP45-BK

90 degree elbow-black SLP90-BK

Radiance, Stardance, Oxford SLP adapter CCSLP

*CCSLP adapter is required when using HHT components.

SLP-FSSK

SLP-TVHW

SLP6A-BK

DuraVent Components

Minimum Horizontal Vent Kit 2792

Starter Pipe Assembly (incl. inner &

2768*

outer sections)

90° Elbow, Blk. 46DVA-E90B*

45° Elbow, Gal. 46DVA-E45

6" Straight, Blk. 46DVA-06B*

9" Straight, Blk. 46DVA-09B

11" - 14

5

⁄8" Adjustable Straight Section 46DVA-08AB

12" Straight 46DVA-12

24" Straight 46DVA-24B*

36" Straight 46DVA-36B

48" Straight 46DVA-48

Horizontal Vent Cap 46DVA-HC*

Wall Plate 46DVA-DC

Vinyl Siding Shield 46DVA-VSS

Snorkel Termination - 14" 46DVA-SNK14

Snorkel Termination - 36" 46DVA-SNK30

Wall Strap 46DVA-WS

Cathedral Ceiling Support Box 46DVA-CS

Storm Collar 46DVA-SC

Firestop Spacer 46DVA-FS

Flashing 0/12 - 6/12 46DVA-F6

Flashing 6/12 - 12/12 46DVA-F12

Steel Chimney Conv. Kit A (6

Steel Chimney Conv. Kit B (6

5

⁄8" - 85⁄8") 46DVA-KCA

5

⁄8" -

46DVA-KCB

101⁄2")

Steel Chimney Conv. Kit C (6

5

⁄8" - 13") 46DVA-KCC

Masonry Chimney Conversion Kit 46DVA-KMC

Vertical Termination Cap (High Wind) 46DVA-VCH

Vertical Termination Cap (Low Prole) 46DVA-VC

*Included in Minimum Horizontal Vent Kit #2792

20306759

All DuraVent Straight vent pipe sections have a net length

1

⁄2" (37mm) less than the nominal dimension; i.e., a 6"

1

(152 mm) Straight pipe section has an effective length of

41⁄2" (115 mm).

13

Page 14

ASSEMBLY AND INSTALLATION

ASSEMBLING THE STOVE

Tools Required

• Phillips screwdriver (stub)

• Utility knife

• Metal drill bit: size 28 (.140"/3.5mm)

• Flat-blade screwdriver

• Power drill

• Reciprocating saw

• 9/16" wrench

Parts Bag Contents:

• Three (3) Vent Screws

• Two (2) Switch bracket screws

• Wood handle w/insert lifter (handle for operable door)

• Restrictor Plate

• 4" Starter pipe

• On-Off switch, housing, and wiring harness

• Three (3) Phillips round-head bolts, 1/4"- 20 x 1/2"

• One (1) Tube of Vent Gasket Cement

• Four (4) CS, Hex Hd 3/8-16 x 1 Gr 2-Z

• Four (4) Washer, Fl 3/8-Z

• LP Conversion Kit

• Homeowner’s Installation and Operating Manual

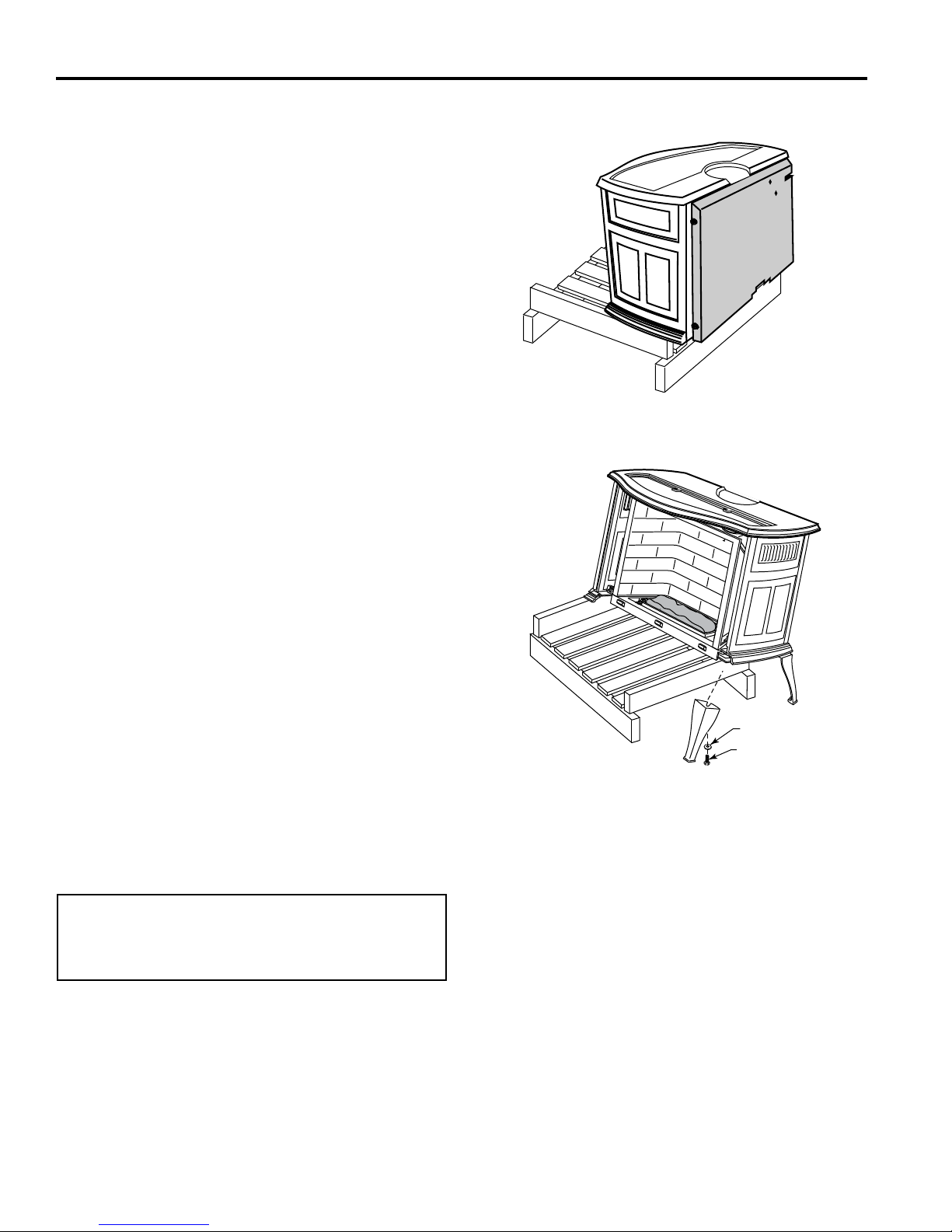

Unpack and Assemble Legs

The Radiance is shipped upright. Cut the shipping straps

before beginning assembly.

1. Slide stove to the rear of the pallet just far enough to

access rear leg holes. Make sure the stove does not

tip over backwards. (Figure 13)

2. Attach the rear legs using 3/8" hex head bolts and

at washer supplied. Tighten with a 9/16" wrench

or socket. Remove and discard the large slot-head

screws using the at-blade screwdriver.

3. Carefully tip the stove onto its rear legs. Adjust the

pallet to allow access to one of the front leg holes. Be

sure to leave the pallet under the stove to prevent the

stove from falling fully forward. (Figure 14)

CAUTION

To prevent valve tubing from being crushed or damaged,

do not rest valve or ignitor on wooden pallet.

Radiance® Direct Vent Gas Heater

ST720

Fig. 13 Slide stove back just far enough to access rear leg holes.

Washer

ST721

Fig. 14 Carefully tip stove onto back legs. Leave pallet under

stove to keep stove from falling fully forward.

4. Have your assistant attach one leg using the hardware described.

5. Move the pallet to allow access to the other front leg

hole. Attach remaining leg.

6. Remove pallet and allow stove to gently rest on all

four legs.

7. Adjust leg levelers to compensate for irregularities in

the hearth.

Hex Head Bolt

1414 20306759

NOTE: Verify the two relief doors (located on top of

the rebox) are properly seated on the gasket. The

doors should sit ush on the gasket, and should

lift easily from the seal around the opening.

Page 15

Radiance® Direct Vent Gas Heater

WARNING

This appliance is equipped with a three-prong (grounded)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong

from this plug.

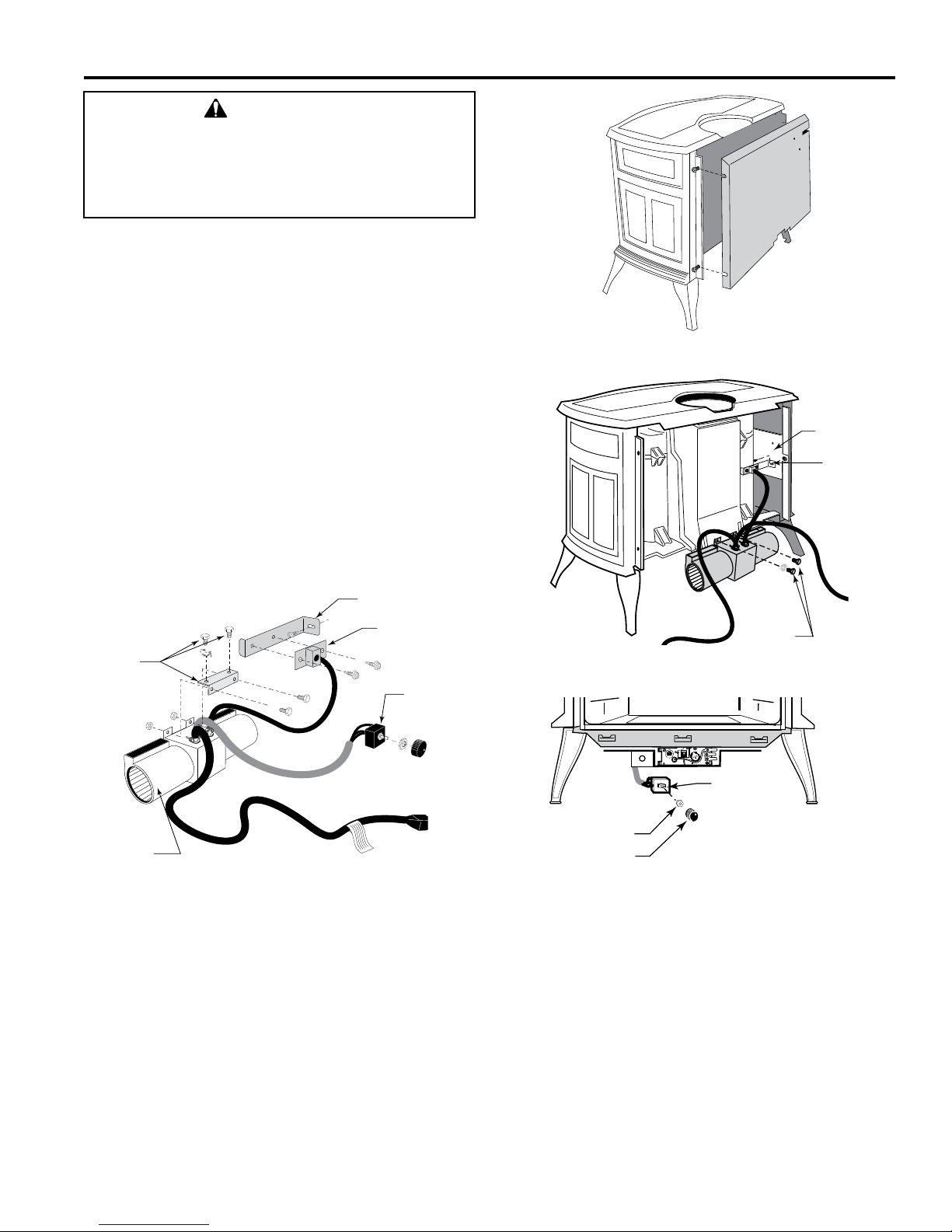

INSTALL THE OPTIONAL FAN - RADVT MODELS

(MILLIVOLT ONLY - SEE PAGE 27 FOR SC MODEL)

If you are installing the optional convection Fan Kit #2767

(FK26), continue here. It is easiest to install fan kit before

connecting gas line.

1. The fan kit includes a Blower Assembly and a Rheostat

Assembly, connected by a cable. (Fig. 15) The Blower

Assembly mounts to the bottom rear of the stove, and

the Rheostat mounts to the valve cover plate. The assembly includes a ‘snapstat’ which automatically turns

the fan On (or Off) above (or below) approximately

109°. The Rheostat also provides a range of fan speed

settings from Off (which overrides the snapstat function) to High. Unpack and inspect the Blower assem-

bly. Conrm that the fan spins freely.

ASSEMBLY AND INSTALLATION

ST147

Fig. 16 Remove rear shroud.

Side Shield

Snapstat

Snapstat

Bracket

Not

Used On

Radiance

Blower

Assembly

ST473a

Fig. 15 Fan kit components.

Snapstat/

Extension

Assembly

Rheostat

Assembly

2. Remove the rear shroud panel (Fig. 16) and fasten

the blower assembly to the rebox back with the two

bolts provided. (Fig. 17)

3. Attach the snapstat assembly to the snapstat bracket with two sheet-metal screws. Attach the snapstat

bracket to the side shield. (Fig. 17)

4. The rheostat control switch attaches to the left side

of the valve bracket at the front of the stove. (Fig. 18)

• Remove retaining nut from shaft of rheostat. (if preinstalled)

Bolts

Fig. 17 Attach blower assembly and snapstat.

Rheostat

Rheostat

Retaining Collar

Rheostat Knob

Fig. 18 Attach the fan rheostat.

ST149

ST347a

• Insert the rheostat through the hole in the back of the

left side of the valve bracket, aligning the locator pin

with the smaller hole in that bracket.

• Thread the retaining nut onto the shaft of the rheostat, tightening with a wrench. Do not overtighten.

• Attach the control knob to the rheostat shaft.

• Use the wire tie to secure the fan and rheostat wire

harnesses together.

20306759

15

Page 16

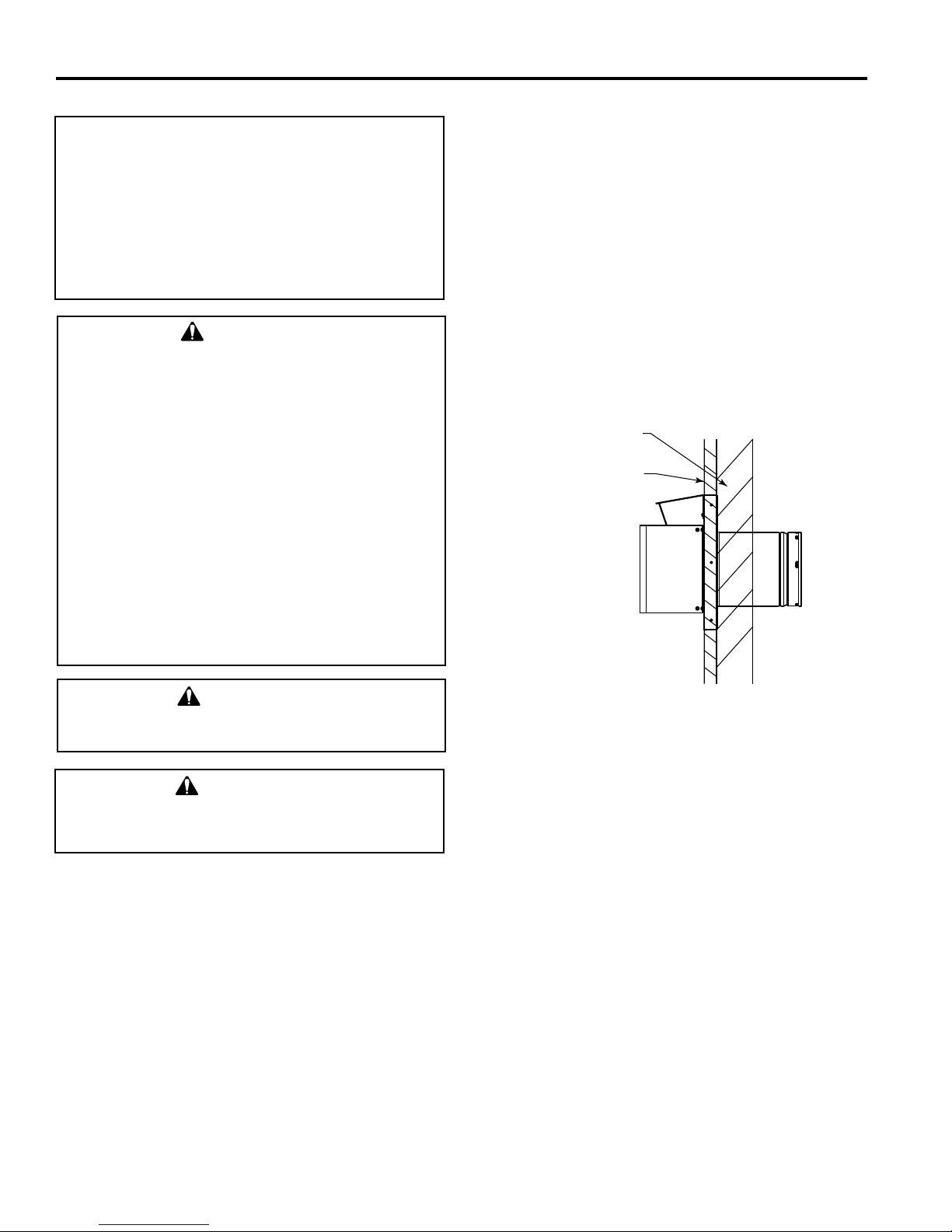

Outside Wall

Finishing Material

(Vinyl Siding, etc.)

ASSEMBLY AND INSTALLATION

Radiance® Direct Vent Gas Heater

VENTING SYSTEM ASSEMBLY

CAUTION

All HHT Direct Vent Stoves have been tested and

approved to ANSI/CSA Standards and will operate

safely when installed in accordance with this instruction

manual. Read all instructions before starting installation,

then follow these instructions carefully to maximize

stove performance and safety. Report damaged parts

to your dealer.

WARNING

Always maintain minimum clearances around vent

systems. Rear/Top Vent Vertical Side wall: Horizontal

sections of this vent system require a minimum of 3”

(76 mm) clearances to combustibles at the top of the

ue and 1” (25 mm) clearance at the sides and bottom

until the ue penetrates the outside wall. A minimum 1”

clearance all around the ue is acceptable at this point of

penetration. If vertical rise is 71⁄2 feet (2.3 m) or higher

when top venting, the clearance to combustibles is 1” on

all sides of the horizontal run. FOR VERTICAL RUNS

ONLY, maintain a 1” (25 mm) minimum clearance to all

sides. Do not pack the open air spaces around the stove

or ue with insulation or other materials. Any horizontal

run must have a 1/4” rise for every one (1) foot of run

towards the vent termination. Never run the vent level

or down.

• These models are approved to use HHT direct vent

pipe components and HHT termination kits, and DuraVent components. No other venting system components may be used.

• Horizontal runs must be supported every 3 feet (914

mm) using wall straps. Vertical runs must be supported

every 8 feet (2.4 m) using wall straps. Slip wall straps

loosely on to pipe. Attach straps to framing members

using nails or screws. Tighten nut/bolt to secure pipe.

• The stove and venting system should be inspected

before initial use and at least annually by a qualied

eld service person. Inspect the external vent cap on a

regular basis to make sure that no debris is interfering

with the airow. Inspect entire venting system to ensure

proper function.

Failure to follow these instructions may create a possible

re hazard and will void the warranty.

Any common venting of this gas appliance with other

gas appliances is not allowed.

Important Safety Information

The termination cap MUST be vented directly to the outside. The termination kit MUST NEVER be connected to

a chimney ue(s) servicing a separate solid-fuel burning

appliance or any other appliances.

• Termination cap MUST NOT be recessed into a wall

(see Figure 19).

• The installation must conform with local codes or in

the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (in the United States) or with the

current installation code CSA B149 (in Canada).

WARNING

WARNING

Fig. 19 Termination cap on wall

BEFORE YOU START

Plan your installation. Set the stove in place and survey how

to best vent the unit. Select the appropriate termination kit

and vent pipe for the installation. Read these instructions

and the stove Homeowner’s Manual before beginning

installation. After vent conguration has been decided,

begin attaching pipe to unit.

Items required for installation:

Tools:

Phillips screwdriver Hammer

Saw and/or saber saw Level

Measuring Tape Electric drill and bits

Pliers Square

Building Supplies:

Framing materials

Wall nishing materials

Caulking Material (noncombustible)

1616 20306759

Page 17

Radiance® Direct Vent Gas Heater

Align

Seams

Rotate

WARNING

Refer to pages 8 and 9 of this manual for the minimum

and maximum venting requirements of your stove and

for approved horizontal vent termination locations prior

to installation. Failure to do so may cause re hazard.

WARNING

Any horizontal run must have a 1/4” rise for every one

(1) foot of run towards the vent termination. Never allow

the vent pipe to run down. This could cause high tem-

peratures and may present a re hazard.

WARNING

Termination cap must be positioned so the embossed

arrow is pointed up.

General Information

The Radiance is approved for installation only with the vent

components listed on page 13. Follow the vent component

instructions exactly.

For U.S. installations: The venting system must conform

with local codes and/or the current National Fuel Gas Code,

ANSI Z223.1/NFPA 54.

For Canadian installations: The venting system must conform to the current CSA B149.1 installation code.

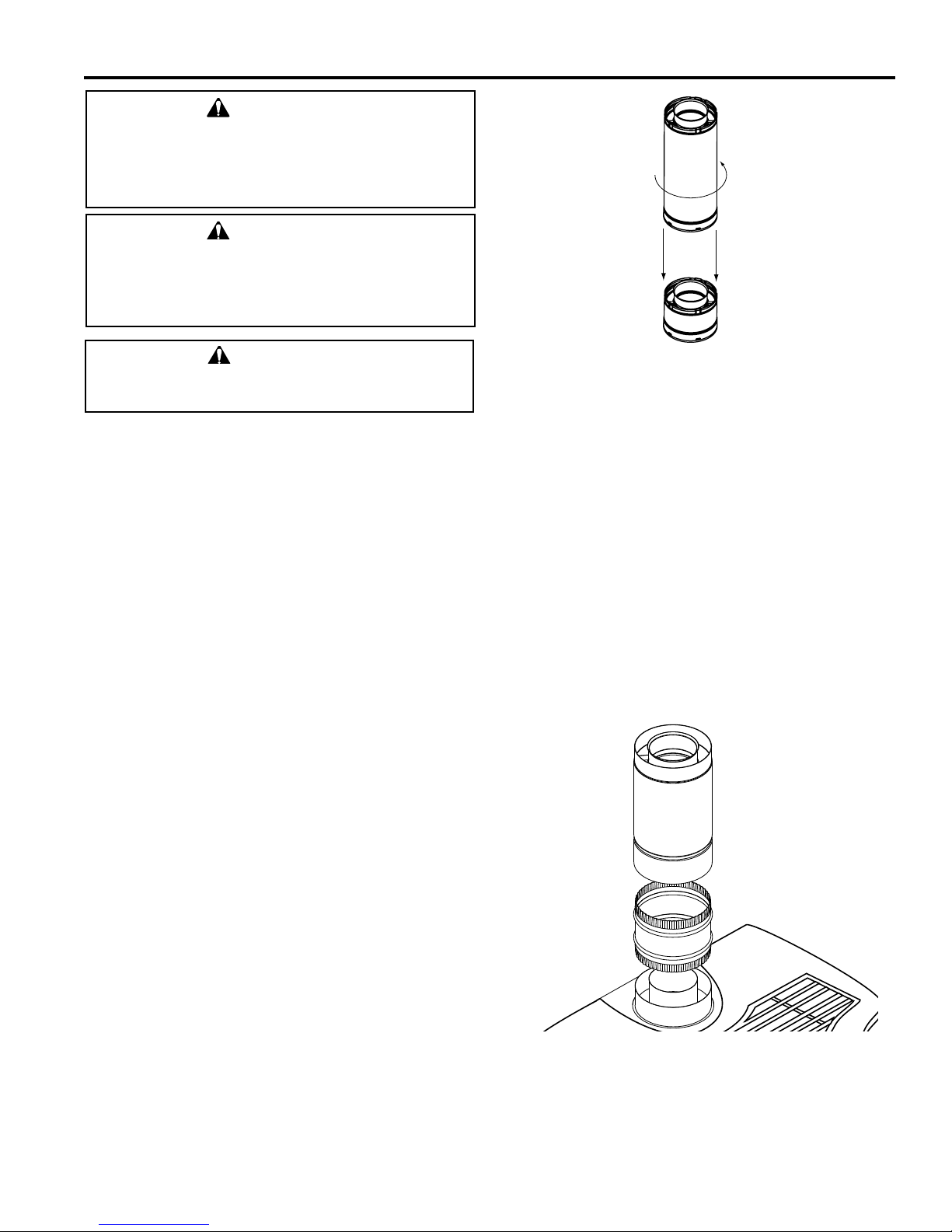

INSTALL THE VENT ADAPTER PIPE

(Vermont Castings SLP Vent Components)

1. Attach Inner Starter Pipe, (found in the Parts Bag), to

the next section of inner pipe.

2. Run a bead of sealant about 1/2" from the upper end

of the Inner starter pipe and join the two sections together.

3. Drill three pilot holes into the Inner Starter and secure

the assembly with three sheet metal screws. (Figure

20)

4. Dry t the Inner Pipe assembly to the stove for the

purpose of determining the center line of the pipe on

the wall.

5. Side Wall Terminations: Dry t the outer elbow with

the vertical outer vent and conrm the centerline

ASSEMBLY AND INSTALLATION

ST211

Fig. 20 Connect the inner starter with the next section of inner

vent pipe.

alignment with the wall thimble opening.

6. Attach the Inner Vent Assembly to the stove.

7. Place a 3⁄8" bead of millpack caulk around the inside

of the cast starter collar. Insert the 65⁄8" outer adapter into the cast outer starting collar and press down

rmly.

8. Install the CCSLP Outer Adapter Pipe.

9. Place a 3⁄8" bead of millpack caulk around the 4"

crimped end of the starter collar on the stove. Attach

the SLP pipe to the adapter, and secure by aligning

adapter and pipe seams, pressing down rmly until

pipe stops, and twisting to lock into place. (Figure 21)

20306759

ST648a

Fig. 21 Attach inner assembly to ue collar.

17

Page 18

ASSEMBLY AND INSTALLATION

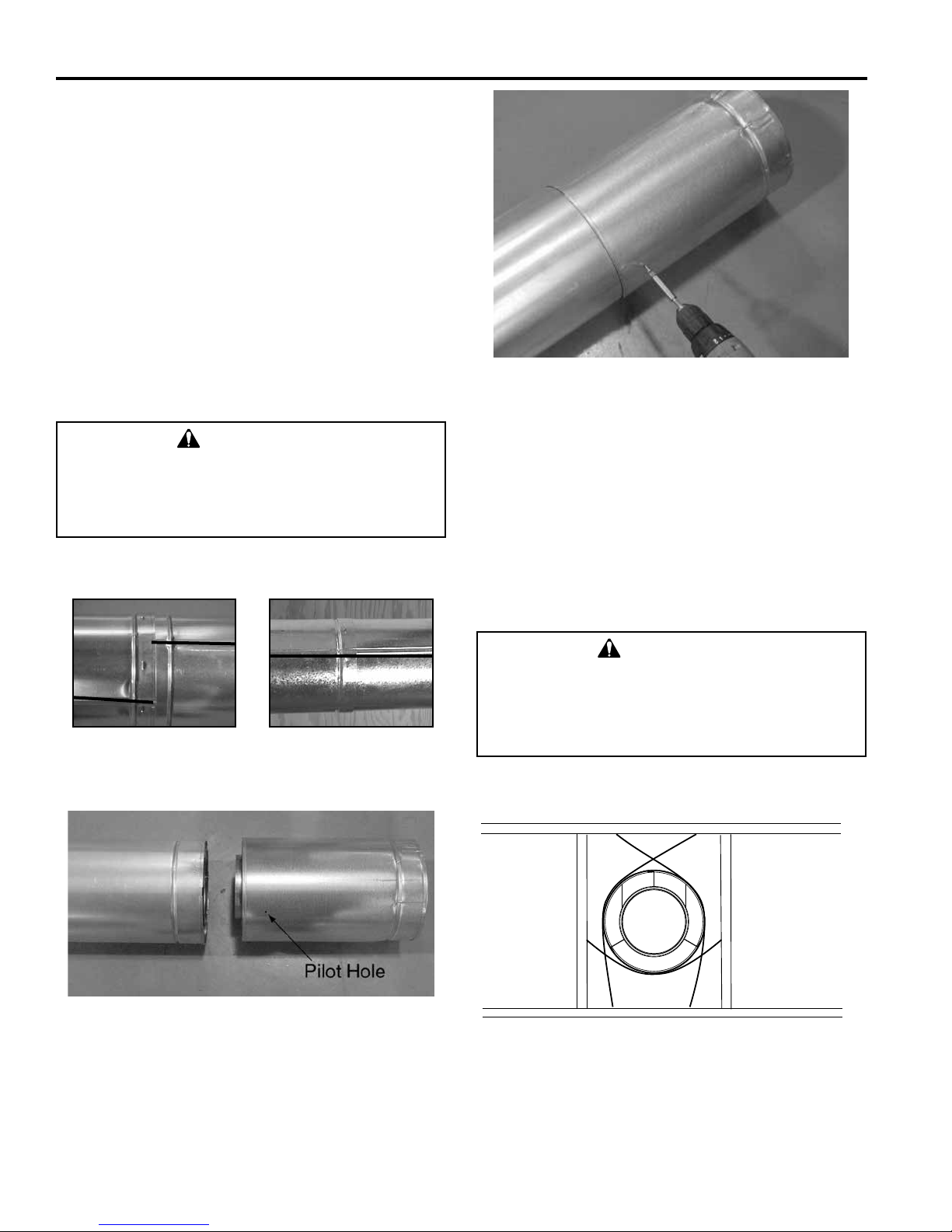

ASSEMBLE SLIP SECTIONS

The outer ue of the slip section should slide over the outer

ue of the pipe section and into (inner ue) the last pipe

section (see Figure 23).

Slide together to the desired length, making sure that a

11⁄2" outer ue overlap is maintained between the pipe

section and slip section.

The pipe and slip section need to be secured by driving

two 1/2 in. screws through the overlapping portions of the

outer ues using the pilot holes (see Figure 24).

This will secure the slip section to the desired length and

prevent it from separating. The slip section can then be

attached to the next pipe section.

If the slip section is too long, the inner and outer ues of

the slip section can be cut to the desired length.

WARNING

Risk of Fire/Explosion! DO NOT break seals on slip

sections. Use care when removing termination cap from

slip pipe. If slip section seals are broken during removal

of the termination cap, vent may leak.

Radiance® Direct Vent Gas Heater

Fig. 24 Screws into Slip Section

SECURE THE VENT SECTIONS

Vertical sections of SLP pipe must be supported every 8 ft.

The SLP restop includes tabs that may be used to secure

vertical sections.

The vent support or plumber’s strap (spaced 120° apart)

may be used to secure the vertical sections of pipe (see

Figure 25).

Horizontal sections of vent must be supported every 5 ft

with a vent support or plumber’s strap (see Figure 26).

CORRECT INCORRECT

Fig. 22 Make sure the seams are not aligned to prevent

unintentional disconnection.

Fig. 23 Slip Section Pilot Holes

WARNING

Risk of Fire/Explosion/Asphyxiation! Improper support

may allow vent to sag and separate. Use vent run

supports and connect vent sections per installation

instructions. DO NOT allow vent to sag below connection

point to appliance.

Fig. 25 Securing Vertical Pipe Sections

1818 20306759

Page 19

Radiance® Direct Vent Gas Heater

ASSEMBLY AND INSTALLATION

HORIZONTAL TERMINATION CAP

WARNING

Risk of Fire! The telescoping ue section of the termination cap MUST be used when connecting vent.

• 11⁄2” (38 mm) minimum overlap of vent and telescop-

ing ue section is required.

Failure to maintain overlap may cause overheating and

re.

Fig. 26 Securing Horizontal Pipe Sections

DISASSEMBLE VENT SECTIONS

To disassemble any two pieces of pipe, rotate either section

(Figure 27), so that the seams on both pipe sections are

aligned (Figure 28). They can then be carefully pulled apart.

Fig. 27 Rotate Seams for Disassembly

Note: For horizontal vent runs through a combustible wall and framing dimensions, refer to appliance

installation manual.

Install the Horizontal Termination Cap

Attach slip section of cap to last vent section. Maintain 11⁄2"

overlap between slip and vent sections.

Note: For installations using black pipe, slide the

decorative wall thimble over the last vent pipe

before connecting the termination to the pipe.

When this connection has been made, slide the

wall thimble up to the interior wall surface and

attach with screws provided.

Secure termination cap to exterior wall using provided

holes and fasteners.

Vent termination must not be recessed in the wall. Siding

may be brought to the edge of the cap base.

CAUTION

Risk of Burns! Local codes may require installation of a

termination guard to prevent anything or anyone from

touching the hot cap.

Fig. 28 Align and Disassemble Vent Sections

20306759

Flash and seal as appropriate for siding material at outside

edges of cap.

When installing a horizontal termination cap, follow the cap

location guidelines as prescribed by current ANSI Z223.1

and CAN/CGA-B149 installation codes.

19

Page 20

ASSEMBLY AND INSTALLATION

Radiance® Direct Vent Gas Heater

DIVERT ROOF RUN-OFF

HHT recommends, where excessive water run-off is

possible, use of one of the two options shown in Figure

29 to prevent water running off the roof and onto/into the

horizontal termination cap.

Install gutter

Vent Opening for Combustible Walls

9"

(244 mm)

9"

(244 mm)

Stove Hearth

Opening for Noncombustible Wall

7"

(190 mm)

Stove Hearth

Fig. 30 Locate Vent Opening on Wall

Framing Detail

2. Secure restop to the inside frame, center in the 9" x

9" vent opening.

3. Place stove into position. Measure the vertical height

(X) required from the base of the ue collars to the

center of the wall opening. Figure 31

Install L-shaped

diverter

Fig. 29 Locate Vent Opening on Wall

VERTICAL SIDE WALL INSTALLATION

NOTE: For all top vent vertical through-the-roof

installations, install the supplied ue restrictors

onto the top edge of the firebox flue adapter

according to the Vertical Side wall Installation Flue

Restrictor Chart.

1. Locate vent opening on the wall. It may be necessary

to rst position the stove and measure to obtain hole

location. Depending on whether the wall is combus-

tible or noncombustible, cut opening to size. Figure

30 (For combustible walls rst frame in opening.)

Combustible Walls: Cut a 9"H x 9"W (244 x 244 mm) hole

through the exterior wall and frame as shown. Figure 30

Noncombustible Walls: Hole opening must be 7" (178

mm) in diameter.

X

Fig. 31 Vertical Height Requirements

4. Using appropriate length of pipe section(s) attach to

stove by twisting collar.

5. Measure the horizontal length requirement including

a 2” (51 mm) overlap, i.e. from the elbow to the outside wall face plus 2” (51 mm) (or the distance required if installing a second 90° elbow). Figure 32

NOTE: When using ex vent, the opening will have

to be measured according to the 1/2” (13 mm) rise

in 12” (305 mm) vent run.

2020 20306759

NOTE: Always install vertical side wall horizontal

venting with a 1/4" rise for every 12" of run.

Page 21

Radiance® Direct Vent Gas Heater

ASSEMBLY AND INSTALLATION

6. Use appropriate length of pipe sections – telescopic

or xed – and install. The sections which go through

the wall are packaged with the starter kit, and can be

cut to suit if necessary.

5

7. Guide the vent terminations 4" and 6

⁄8" collars into

their respective vent pipes. Double check that the

vent pipes overlap the collars by 2" (51 mm). Secure

the termination to the wall with screws provided and

caulk around the wall plate to weatherproof. As an

alternative to screwing the termination directly to the

wall, you may also use expanding plugs or an approved exterior construction adhesive.

X

Fig. 32 Horizontal Length Requirement

FP1182

NOTE: Support horizontal pipes every 5' (152 cm)

with metal pipe straps.

VENT TERMINATION BELOW GRADE

Install Snorkel Kit #SLP-SNORK when it is not possible to

meet the required vent termination clearances of 12" (305

mm) above grade level. The snorkel kit will allow installation

depth of down to 7" (178 mm) below grade level. The seven

inches is measured from the center of the horizontal vent

pipe as it penetrates the wall. If the venting system is

installed below grade, a window well must be installed

with adequate and proper drainage. (Figure 35)

NOTE: Be sure to maintain side wall clearances

and vent run restrictions. Refer to Page 7, Figures

3, 4, 5, 6.

1. Establish the vent hole through the wall.

2. Remove soil to a depth of approximately 16" (406

mm) below the base of the snorkel. Install a window

well (not supplied). Rell the hole with 12" (305 mm)

of coarse gravel and maintain a clearance of at least

4" (102 mm) below the snorkel. (Figure 35)

3. Install the vent system as described on Pages 16-18.

4. Be sure to make a watertight joint around the vent

pipe joint at the inside and outside wall joints.

5. Apply high temperature sealant around the inner and

outer snorkel collars. Join the pipes and fasten the

snorkel termination to the wall with the screws provided.

6. Level the soil to maintain a 4" clearance below the

snorkel.

7. If the foundation is recessed, use extension brack-

ets (not supplied) to fasten the lower portion of the

snorkel. Fasten the brackets to the wall rst, and then

fasten to the snorkel with self-tapping #8 x 1/2" sheet

metal screws. Extend the vent pipes out as far as the

protruding wall face. (Figure 35)

Cutout On Vinyl

Termination Cap

Fig. 33 Horizontal Termination Cap on a Vinyl Siding Wall

20306759

Vinyl Siding Wall

Recessed Wall

Firestop

Sheet Metal

Screws and

Bracket

Wall Screws

and Anchors

Waterproof Seal

Around Pipe

ST219

Fig. 34 Use extension brackets to mount snorkel against

recessed wall.

Finishing

Collar

7" Pipe

Wall Plate

21

Page 22

RADIANCE

ASSEMBLY AND INSTALLATION

Radiance® Direct Vent Gas Heater

Wall Screws

and Anchors

Snorkel

Termination

Cap

4" Clearance

Gravel

Drain

Window Well

Fig. 35 Snorkel kit installation.

Waterproof Seal

Around Pipe

Firestop

list.)

• The maximum angular variation allowed in the system

is 270°. Figure 39

• For the minimum height of the vent above the highest

point of penetration through the roof refer to Figure 39�

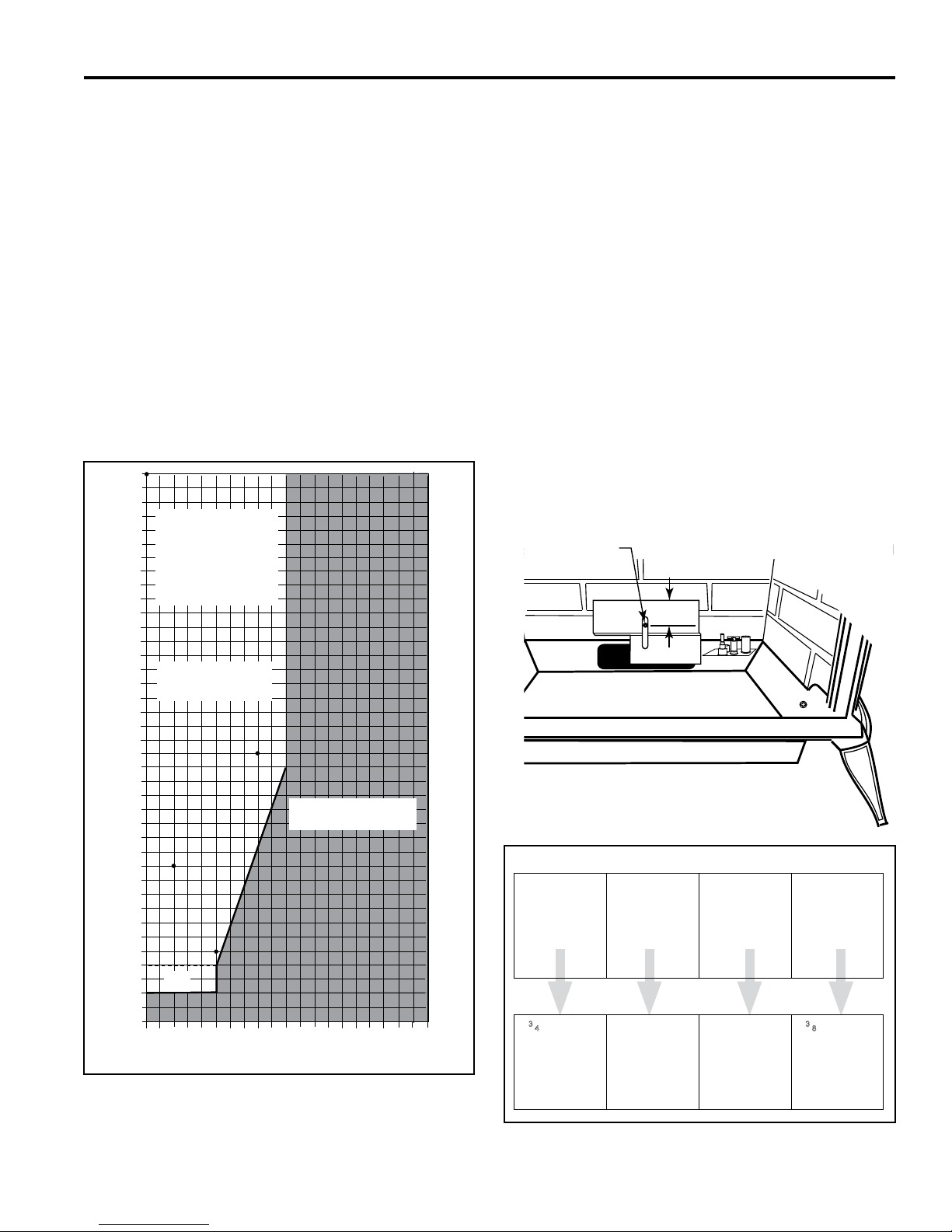

Vertical Through-the-Roof Installation

Flue Restrictor Setting Chart

Vertical Run Restrictor Setting

8-12 feet of pipe Medium restriction

(2.4 – 3.7 m) Figure 36

12-40 feet of pipe Maximum restriction

(3.7 – 12 m) Figure 37

ST653

VERTICAL THROUGH-THE-ROOF

APPLICATION/INSTALLATION

For all vertical through-the-roof installations, the supplied

ue restrictors must be installed. Install the ue restrictor

according to the settings shown in the Vertical Through-theRoof Installation Flue Restrictor Chart in order to balance

the airow in and out of the unit and to maintain proper

ame height.

This gas stove has been approved for:

• Vertical installations up to 40' (12 m) in height. Up to

a 10' (3 m) horizontal vent run can be installed within

the vent system using a maximum of two 90° elbows.

Figure 38

• Up to two 45° elbows may be used within the horizontal

run. For each 45° elbow used on the horizontal plane,

the maximum horizontal length must be reduced by

18" (450 mm).

Example: Maximum horizontal length:

No elbows = 10' (3 m)

1 x 45° elbow = 8.5' (2.6 m)

2 x 45° elbows = 7' (2.1 m)

• A minimum of an 8' (2.5 m) vertical rise is required.

(Figure 38)

• Two sets of 45° elbow offsets may be used within the

vertical sections. From 0 to a maximum of 8' (2.5 m) of

vent pipe can be used between elbows. Figure 38

• SLP-HVS supports offsets. This application will require

that you rst determine the roof pitch and use the appropriate starter kit. (Refer to Venting Components

FP3042

Fig. 36 Flue Restrictor Set at Medium Restriction

FP3043

Fig. 37 Flue Restrictor Set at Maximum Restriction

2222 20306759

Page 23

Radiance® Direct Vent Gas Heater

Horizontal

overhang

12

X

20 in.

(508 mm)

Lowest

Discharge

Opening

Termination

Cap

Roof Pitch

is X / 12

Vertical

wall

H (min.) - Minimum height

from roof to lowest

discharge opening.

24 in. min.

(610 mm)

Roof Pitch H (Min.) Ft. Roof Pitch H (Min.) Ft.

Storm Collar

Roof

Flashing

Storm Collar

Vertical Termination

24 in. min.

(610 mm)

Termination

Cap

ASSEMBLY AND INSTALLATION

Horizontal

overhang

20 in.

(508 mm)

Lowest

Discharge

Opening

Vertical

wall

Firestop

Spacer

Flashing

Offset

Support Collar

Storm Collar

Roof

Flashing

H (min.) - Minimum height

from roof to lowest

discharge opening.

Flat to 6/12 1.0* Over 11/12 to 12/12 4.0

Over 6/12 to 7/12 1.25* Over 12/12 to 14/12 5.0

Over 7/12 to 8/12 1.5* Over 14/12 to 16/12 6.0

Over 8/12 to 9/12 2.0* Over 16/12 to 18/12 7.0

Over 9/12 to 10/12 2.5 Over 18/12 to 20/12 7.5

Over 10/12 to 11/12 3.25 Over 20/12 to 21/12 8.0

* 3 ft. minimum in snow regions

X

12

Roof Pitch

is X / 12

Fig. 39 Minimum Height from Roof to Lowest Discharge Opening

Plate

Figure 38. Typical Vertical Venting Conguration

Ceiling Support CollarCeiling Support

Trim Plate

20306759

23

Page 24

ASSEMBLY AND INSTALLATION

INSTALL LOG SET

Before beginning log installation, remove stove front and

glass frame. Refer to Figures 40 and 41.

Note: Remove the safety barrier before you remove

the glass frame. To remove the barrier, simply lift

up and pull out until the tabs are clear of their

corresponding slots on the rebox. Then proceed

to remove the glass frame by following the steps

below.

Radiance® Direct Vent Gas Heater

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this

appliance and shall be installed.

Fig. 40 Remove the safety barrier and stove front.

Fig. 41 Release the latches to remove the glass frame.

ST139

ST141

2424 20306759

Page 25

Radiance® Direct Vent Gas Heater

ASSEMBLY AND INSTALLATION

Before installation, inspect ember bed burner for damage.

Do not use ember bed if damaged or cracked. Small, shallow surface cracks are acceptable.

1. Remove the logs from their packaging and inspect

each piece for damage. DO NOT INSTALL DAMAGED LOGS.

2. Install the rear log by placing it on the ember bed

toward the back of the rebox. (Figure 42) The log

should touch the back wall of the rebox. When the

log is in place, the two (2) notches on the bottom of

the log rest on the two (2) ribs on the back side of the

ember bed. (Figure 43)

Fig. 42 Rear Log

Ribs for Rear Log

Rear Log

LG488

Ember Bed

3. Install the front left and right logs (Figure 44) by placing them on the ribs shown in Figure 43. Make sure

the logs line up with the at spots on the ember bed

intended for location purposes. (Figure 43)

4. Install the left cross log by engaging the hole on the

bottom with the pin on the left side of the rear log. Set

front side of cross log on notch in ember bed. (Figure

45)

5. Install the right cross log by engaging the hole on the

bottom with the pin on the right side of the rear log.

Set front edge of cross log on ember bed as shown

in Figure 45.

LG489

Front Right Log

Front Left Log

Fig. 44 Front Logs

Rib Flat Spot for

Front Left Log

Fig. 43 Ribs for Logs

Rib and Flat Spot

for Front Right Log

LG487

Left Cross

Log

Front Left Log

Fig. 45 Completed Installation

Rear Log

Right

Cross Log

Front

Right Log

LG490

Ember Bed

20306759

25

Page 26

P

I

L

O

T

TPTH

TP

TH

ASSEMBLY AND INSTALLATION

Radiance® Direct Vent Gas Heater

INSTALL ON/OFF SWITCH - RADVT MODELS

The switch assembly parts are found in the parts bag.

1. Attach switch assembly to left rear side of stove

shroud (when facing shroud) using two screws and

existing holes in shroud. (Figure 46)

2. Run wires down back of stove, under bottom of rear

shroud to valve.

3. Attach wires to valve terminals. (Figure 47)

Switch Assembly

Screws

Fig. 46 Attach switch assembly to rear shroud.

Existing

Holes

ST315

SIGNATURE COMMAND® SYSTEM

General

RADVTSC models are equipped with the Signature Command control valve (Figure 48) which operates on 6 volts.

The A/C module plugs into the stove junction box A/C power

supply. Four (4) “AA” batteries are used for back up during

power outages.

The Signature Command System can also be operated

without A/C power. The system can run on four (4) “AA” batteries for approximately six (6) months under normal use.

A/C power must be used to power the A/C module and

blowers.

Pressure Inlet

Valve

SIT VALVE

Thermopile

ON/OFF Switch or

Millivolt Thermostat

Fig. 47 Install wiring to switch before connecting to valve.

Pressure Outlet

Fig. 48 Signature Command Valve

FP1622

FP1909a

Pilot Adjustment Screw

WARNING

THERMOSTAT OR WALL SWITCH

CONNECTION (OPTIONAL)

Use only a thermostat rated for 500 - 750 millivolts.

Check the table below for the appropriate gauge thermostat

wire to use for the length of lead required in your installation.

Thermostat

Wire / Gauge Maximum Run

18 20 feet

16 20 - 40 feet

14 up to 60 feet

1. Install the wall thermostat or switch in the desired

location and run the wires to the stove location. Terminate these leads with 1/4" female connectors.

2. Connect the thermostat wires to the valve. (Figure

2626 20306759

47)

Electrical connections should only be performed by a

qualied, licensed electrician. Main power must be off

when connecting to main electrical power supply or

performing service. All wiring shall be in compliance

with all local, city and state codes. The appliance, when

installed, must be electrically grounded in accordance

with local codes or in the absence of local codes, with the

National Electrical Code ANSI/NFPA 70 (latest edition)

and Canadian Electrical Code, CSA C22.1.

CAUTION

Label all wires before disconnecting when servicing

controls. Wiring errors can cause improper and dangerous operation.

Page 27

Radiance® Direct Vent Gas Heater

ASSEMBLY AND INSTALLATION

JUNCTION BOX WIRING

This should be done before framing the stove. Wire the

receptacle into an electrical circuit. Wire with minimum

60° C wire in accordance with prevailing codes.

Remove the external junction box cover by removing the

screw from the side of the outside rebox wall. Junction

box was installed at the factory.

The junction box cover has a factory installed “romex” style

strain relief connector. After connecting the wires, route

the wire leads through this connector. Refer to the wiring

diagram in Figure 49.

120V AC

60Hz

Factory Supplied

Not Supplied

Junction Box

Fig. 49 Junction Box Wiring Diagram

COMMAND CENTER WALL INSTALLATION

The command center may be mounted on the wall with

the use of the SCSWEK Kit (15ft. cable, junction box, wall

cover).

Mount the junction box provided at the desired location on the wall. Do not extend beyond the 15 ft.

wire cable provided. If a longer distance is required,

the 15 ft. may be extended up to 30 ft. maximum by

using two (2) SCSWEK cables plugged together.

Route the wire from junction box to lower control area