Vermont Castings Pinnacle PDV20 Series, PDV20 2997, PDV20 4065-4067, PDV20 4069-4072, PDV20 4075-4077 Homeowner's Installation & Operating Manual

...

INSTALLER / CONSUMER

CERT IF IED

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

SAFETY INFORMATION

PLEASE READ THIS MANUAL

BEFORE INSTALLING AND USING

APPLIANCE.

WARNING!

IF THE INFORMATION IN THIS

MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

— Do not store or use gasoline

or other flammable vapors and

liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL

GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from your neighbor’s phone. Follow

the gas supplier’s instructions.

Pinnacle & Stardance

Direct Vent, Rear Vent

Gas Heater

Models:

SDVR: 3920-3936, 3960-3976

PDV20: 2995, 2997, 4065-4067,

4069-4072, 4075-4077, 4080-4083

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas

supplier.

This appliance may be installed in an

after market permanently located

manufactured (mobile) home where not

prohibited by local codes.

This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases unless a certified kit is

used.

Homeowner’s Installation

and Operating Manual

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

20007066 10/06 Rev. 8

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

Table of Contents

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE.

Thank you and congratulations on your purchase of a Vermont Castings stove.

IMPORTANT: Read all instructions and warnings carefully before starting installation. Failure to follow these

instructions may result in a possible fire hazard and will void the warranty.

Installation & Stove Dimensions ................................................................................................................4

Operating Clearance Requirements .....................................................................................................5

Instructions Minimum Clearances, Parallel Installation, Corner Installation ............................................5

Minimum Clearances, Alcove Installation .............................................................................

Mantel Clearances ...............................................................................................................

Hearth Requirements ...........................................................................................................

Gas Specifications

Gas Inlet and Manifold Pressures ........................................................................................

High Elevations ....................................................................................................................

Horizontal Termination ..........................................................................................................

Vertical Termination ..............................................................................................................

Vent Termination Clearances ...............................................................................................

General Venting Information - Termination Location ..........................................................

Termination Clearances .....................................................................................................11

Vent Components ...............................................................................................................

Installation Install Optional FK28 Fan Kit .............................................................................................

Venting System Assembly - Direct Vent .............................................................................

Rear Vent ...........................................................................................................................

Through Side Wall / Vent Termination Below Grade ..........................................................

Side Wall Termination Assembly ........................................................................................

Vent Termination Below Grade ...........................................................................................

Vertical (Through the Roof) Vent Assembly .......................................................................

Vertical Through Existing Chimney ....................................................................................

Fireplace Vent Termination Clearances ..............................................................................

Fireplace Installation Requirements ...................................................................................

Connect Gas Supply Line ..................................................................................................

Burner Information

Complete the Assembly .....................................................................................................

Install ON/OFF Switch (R Models Only) .............................................................................

Install the Front Plate .........................................................................................................

Thermostat Connection ......................................................................................................

Install the Log Set ..............................................................................................................

Operation Operable Doors ..................................................................................................................

Your First Fire .....................................................................................................................

Pilot and Burner Inspection ................................................................................................

Flame & Temperature Adjustment ......................................................................................

Flame Characteristics .........................................................................................................

Lighting and Operating Instructions ...................................................................................

Troubleshooting ..................................................................................................................

Instructions for RF Comfort Control Valve ..........................................................................

Fuel Conversion Instructions ..............................................................................................

Maintenance Annual System Inspection ..................................................................................................

Logset and Burner Cleaning ..............................................................................................

Care of Cast Iron ................................................................................................................

Cleaning the Glass .............................................................................................................

Glass Replacement ............................................................................................................

Gasket Replacement ..........................................................................................................

Inspect the Vent System Annually ......................................................................................

Check the Gas Flame Regularly ........................................................................................

Stove Disassembly .............................................................................................................

Wiring Diagrams .................................................................................................................

Replacement Parts

Optional Accessories

Warranty

Energuide ...........................................................................................................................................48

...........................................................................................................................................47

..........................................................................................................................................40

......................................................................................................................................43

................................................................................................................6

..............................................................................................................23

6

6

6

6

7

7

8

8

10

12

13

14

14

15

16

17

18

19

19

21

23

23

23

24

24

25

26

26

26

26

26

28

29

30

33

37

37

37

37

37

38

38

38

39

39

2

20007066

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

Installation & Operating Instructions

The Pinnacle (PDV20) and Stardance (SDVR) Direct

Vent Room Heater, Model Nos. 3920, 3926, 3930, 3936,

3960, 3966, 3970, 3976, 4065, 4070, 4075, 4080, are

vented gas appliance listed to ANSI Standard Z21.88b2002 and CSA-2.33b-2002 for Vented Room Heaters,

and CSA 2.17-M91, Gas-Fired Appliances For Use at High

Altitudes.

The installation of the PDV20 and SDVR Direct Vent

Room Heaters must conform with local codes, or in the

absence of local codes, with National Fuel Gas Code,

ANSI Z223.1/NFPA 54 — latest edition and CSA B-149.1

(EXCEPTION: Do not derate this appliance for altitude.

Maintain the manifold pressure at 3.5” w.c. for Natural Gas

and 10” w.c. for LP gas at maximum input.) Refer to Page

37 (RF only).

This appliance is only for use with the type of gas indi

cated on the rating plate. This appliance is not convertible

for use with other gases unless a certified kit is used.

Installation and replacement of gas piping, gas

utilization equipment or accessories, and repair and

servicing of equipment shall be performed only by a

qualified agency. The term “qualified agency” means

any individual, firm, corporation, or company that either

in person or through a representative is engaged in

and is responsible for (a) installation or replacement

of gas piping, or (b), the connection, installation, repair,

or servicing of equipment, who is experienced in such

work, familiar with all precautions required, and has

complied with all the requirements of the authority

having jurisdiction.

The PDV20 and SDVR Direct Vent Room Heaters

should be inspected before use and at least annually by

a qualified service agency. It is imperative that control

compartments, burners, and circulating air passage

ways of the appliance be kept clean.

The PDV20 and SDVR Direct Vent Room Heaters and

the individual shut-off valve must be disconnected from the

gas supply piping during any pressure testing of that system

at test pressures in excess of 1/2 psig (3.5 kPa).

The PDV20 and SDVR Direct Vent Room Heaters must

be isolated from the gas supply piping system by closing the

individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to

or less than 1/2 psig.

An accessible tap is located above the pilot/on-off knob

for checking the inlet pressure.

‘Direct Vent’ describes a sealed combustion system in

which incoming outside air for combustion and outgoing

exhaust enter and exit through two separate concentric

passages within the same sealed vent system. The system

does not use room air to support combustion. The Direct

Vent system permits the gas appliance to be vented directly

to the outside atmosphere through the side of the house or

vertically through the roof.

This appliance is approved for bedroom installations in

the U.S. and Canada.

This appliance may be installed in an aftermarket*

manufactured (mobile) home, where not prohibited by state

or local codes.

20007066

WARNING: Operation of this heater when not connected to a properly installed and maintained venting

system can result in carbon monoxide (CO) poisoning

and possible death.

The PDV20 and SDVR Direct Vent Room Heater, when

installed, must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the Na

tional Electrical Code ANSI/NFPA 70, (latest edition), or of

the current Canadian Electrical Code C22.1.

Due to high temperatures this appliance should

be located out of traffic and away from furniture and

draperies.

WARNING: This appliance is hot while in operation.

Keep children, clothing, and furniture away. Contact may

cause burns or ignition of combustible materials.

-

Children and adults should be alerted to the hazards

of high surface temperatures and should stay away to

avoid burns or clothing ignition. Young children should

be carefully supervised when they are in the same room

as the appliance.

Clothing or other flammable materials should not be

placed on or near the appliance.

Any safety screen, glass or guard removed for servic

ing an appliance must be replaced prior to operating

the appliance.

The appliance area must be kept clear and free from

combustible materials, gasoline, and other flammable

vapors and liquids.

The flow of combustion and ventilation air must not

be obstructed. The installation must include adequate

accessibility and clearance for servicing and proper

operation.

WARNING: Do not operate the Room Heater with the

-

glass panel removed, cracked or broken. Replacement

of the panel should be done by a licensed or qualified

service person.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

Do not burn wood, trash or any other material for

which this appliance was not designed. This appliance is

designed to burn either natural gas or propane only.

This gas appliance must not be connected to a

chimney flue serving a separate solid-fuel burning

appliance.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

and dangerous operation.

Verify proper operation after servicing.

Proposition 65 Warning: Fuels used in gas, woodburn

ing or oil fired appliances, and the products of combustion

of such fuels, contain chemicals known to the State of

California to cause cancer, birth defects and other repro

ductive harm.

California Health & Safety Code Sec. 25249.6

* Aftermarket: Completion of sale, nor for purpose of resale,

from the manufacturer.

-

-

-

-

3

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

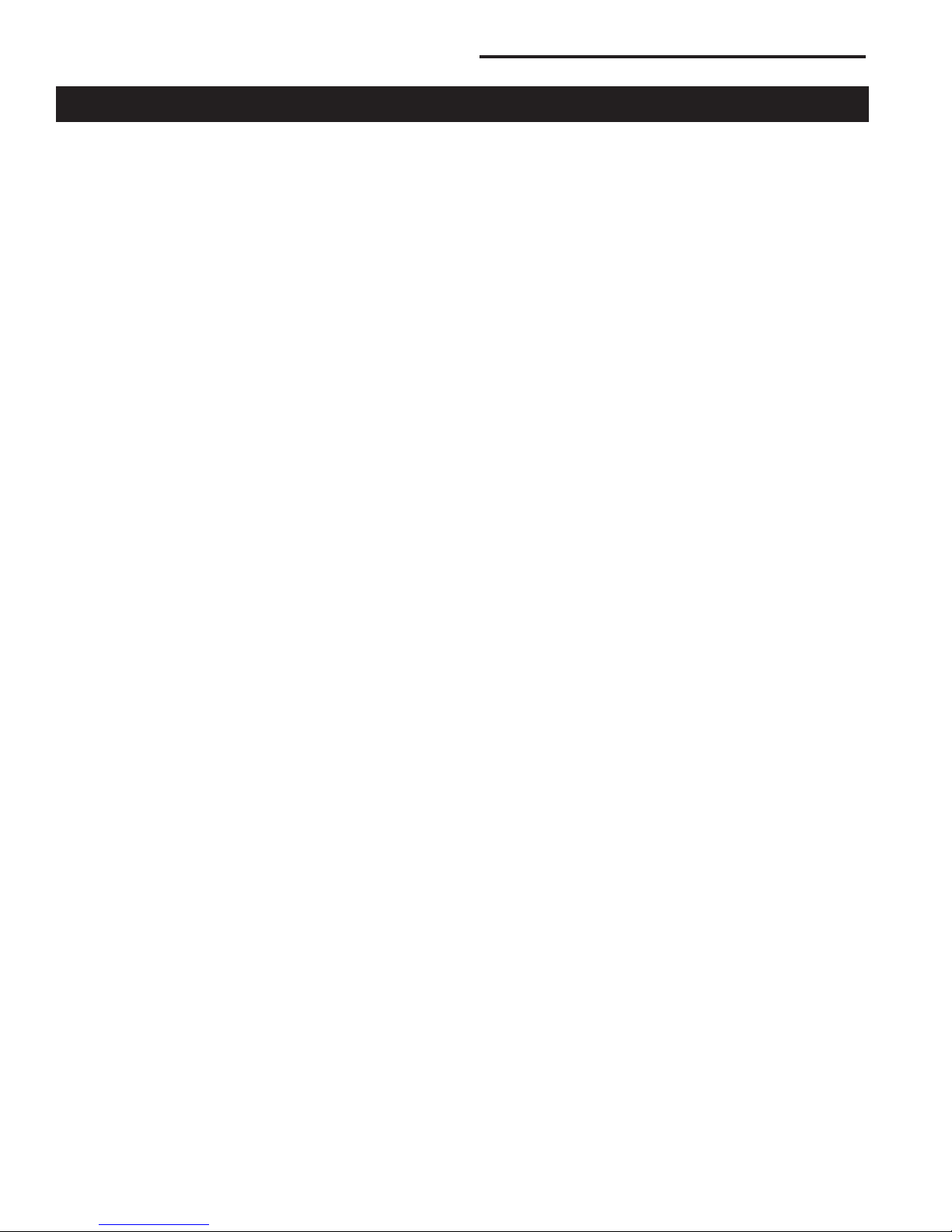

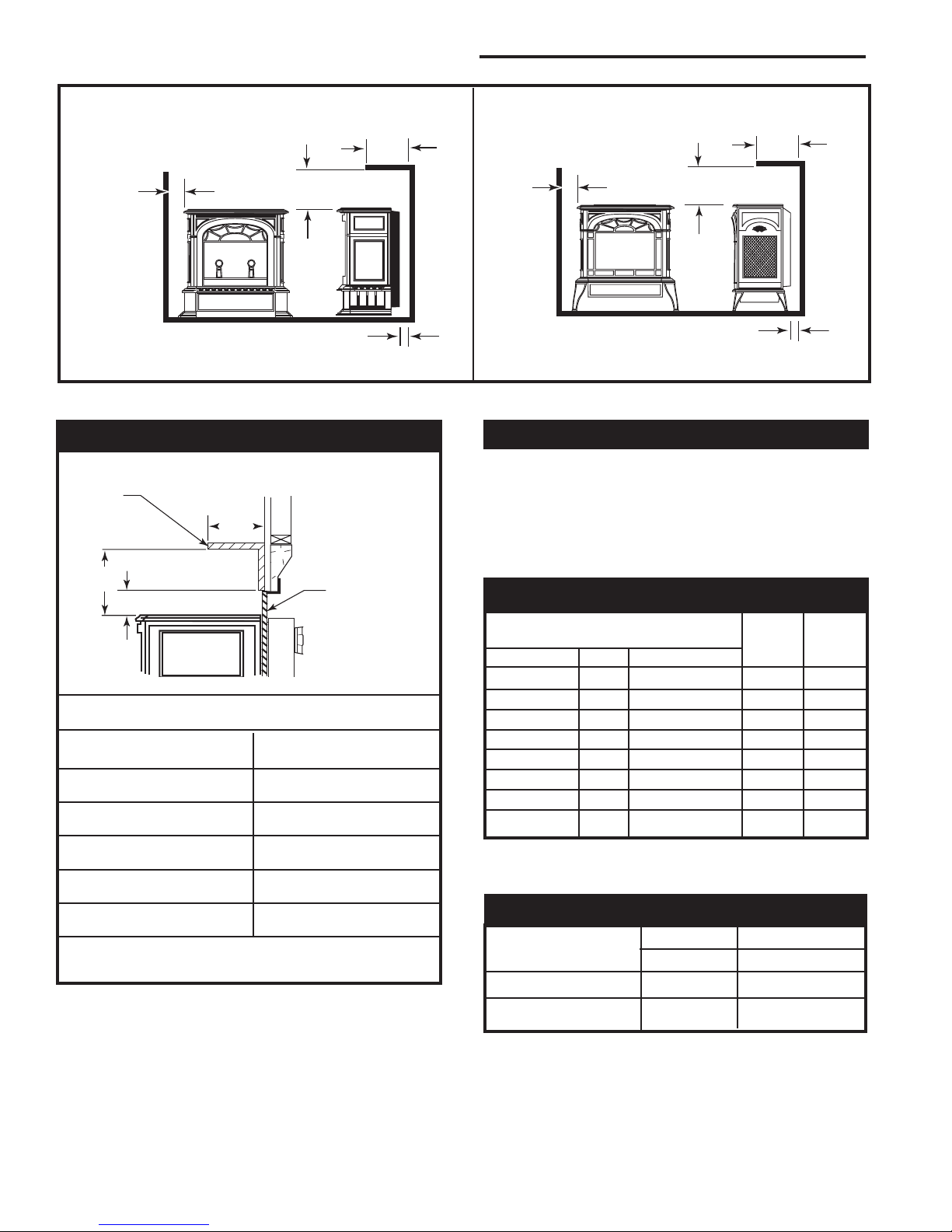

16³⁄₈"

(400mm)

26¹⁄₂"

(673mm)

25¹⁄₄"

(641mm)

22³⁄₈"

(568mm)

24

³⁄₈"

(619mm)

17"

(432mm)

5"

(140mm)

9"

(229 mm)

C

L

Valve

Inlet

26"

(680 mm)

25"

(635 mm)

14"

(356 mm)

3"

(76 mm)

C

L

Valve Inlet

24"

(610 mm)

26"

(660 mm)

Stove Dimensions - Pinnacle Direct Vent Gas Heater

Flue Transition Connector

(For fireplace installation

only)

Fig. 1 PDV20 dimensions.

Stove Dimensions - Stardance Direct Vent Gas Heater

3457

Fig. 2 SDVR dimensions.

4

3457

20007066

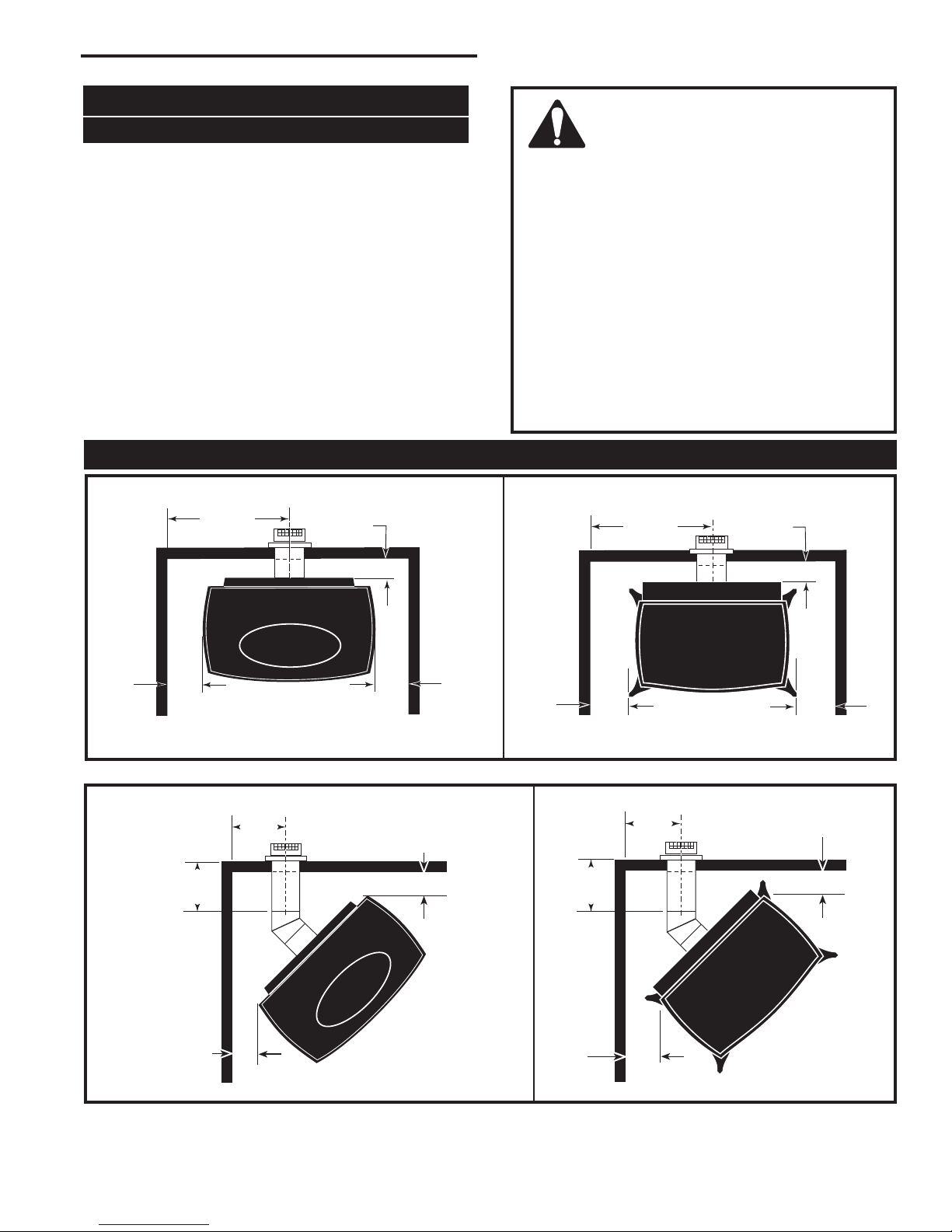

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

C

L

"

(476mm)

2"

(64mm)

6"

(150mm)

6"

(150mm)

C

L

18"

(476mm)

2"

(63mm)

2" (50mm)

2"

(50mm)

7¹⁄₂"

(190mm)

Max. Vent

Length

20" (508mm)

Max. Vent

Length

20" (508mm)

7¹⁄₂"

(190mm)

2" (50mm)

2"

(50mm)

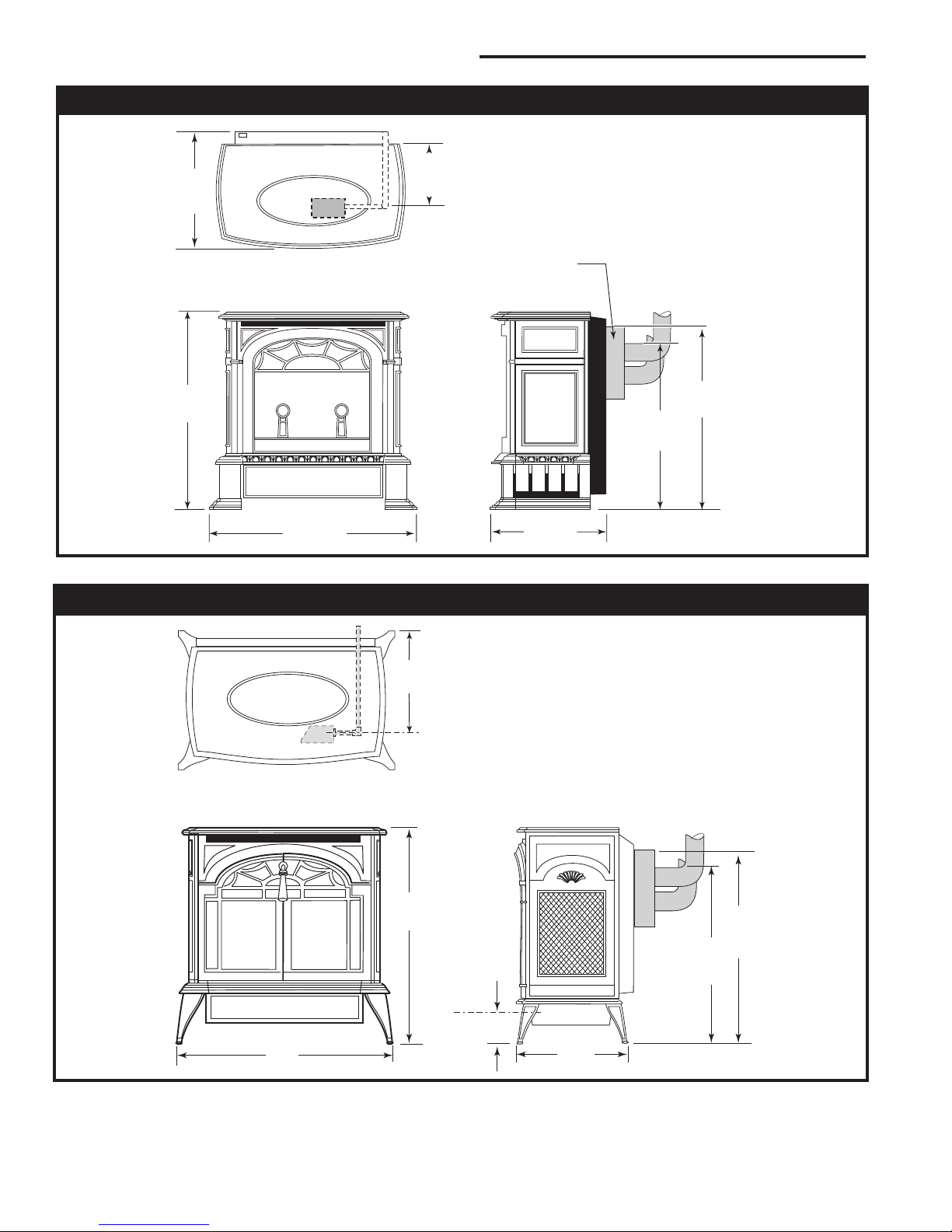

Clearance Requirements

Minimum Clearances to Combustible Materials

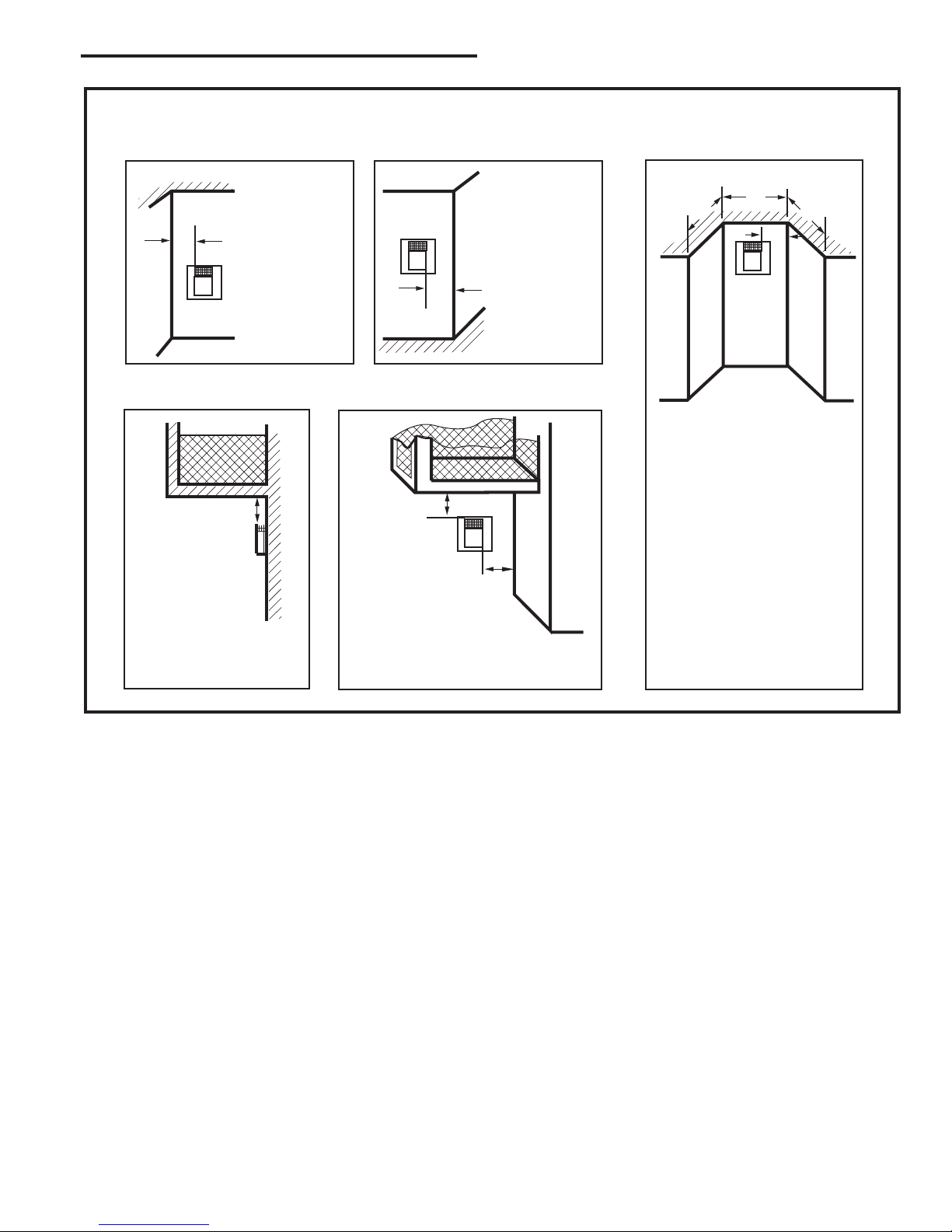

Measure side clearances as shown in Figures 3, 4 and

5 from the outer edge of the cast iron stove top. Measure rear clearances from the outermost surface of the

steel rear skirt.

The PDV20 and SDVR heaters are approved for installation into an alcove constructed of combustible materials to the dimensions and clearances shown on the

next page.

The same clearances apply in a standard parallel installation.

Minimum Clearances

Parallel Installation

WARNING:

• Always maintain required clearances

(air spaces) to nearby combustibles

to prevent fire hazard. Do not fill air spaces

with insulation. All venting components must

maintain a 1” (25mm) clearance to combustible materials. Maintain a 6” (152mm) clearance when using single wall pipe. Maintain a

2” (51mm) clearance on top and 1” (25 mm) on

sides and bottom when venting straight off the

rear.

• The gas appliance and vent system must be

vented directly to the outside of the building

and never be attached to a chimney serving a

separate solid fuel or gas-burning appliance.

• Refer to the manufacturer’s instructions included with the venting system for complete

installation procedures.

PDV20

ST128c

Fig. 3 Parallel installation minimum clearances and flue centerline.

Corner Installation

PDV20

Fig. 4 Corner installation minimum clearances.

20007066

SDVR

ST128a

SDVR

ST129a

5

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

9"

(230mm)

Max. Mantel

Width

See

Fig. 6

6"

(150mm)

Sidewall/

Tr

im

2¹⁄₂"

(63mm)

Rear Wall

9"

(230mm)

Max. Mantel

Width

See

Fig. 6

6"

(150mm)

Sidewall/

Tr

im

2¹⁄₂"

(63mm)

Rear Wall

A

B

3" (75mm) Min.

Alcove Installation

ST381

Fig. 5 Alcove installation.

PDV20

Mantel Clearances

Combustible

Mantel or Trim

Materials

Noncombustible

Materials

PDV20 and SDVR

A (Max.) B (Min.)

9” 10

(230 mm) (270 mm)

7

(190 mm) (230 mm)

6” 7

(152 mm) (190 mm)

4

(114 mm) (152 mm)

3” 4

(76 mm) (114 mm)

1¹⁄₂” 3”

(38 mm) (76 mm)

A = Depth of Mantel and/or Top Trim

B = Height from Top of Heater

Fig. 6 Mantel / top trim clearances.

¹⁄₂” 9”

¹⁄₂” 6”

¹⁄₂”

¹⁄₂”

¹⁄₂”

ST382

SDVR

ST381a

Hearth Requirements

The PDV20 and SDVR Heaters must be installed on

rigid flooring. When the heater is installed directly on

any combustible surface other than wood flooring, a

metal or wood panel extending the full width and depth

of the unit must be used as the hearth. There are no

other hearth requirements.

Gas Specifications

Max. Min.

Input Input

Model Fuel Gas Control BTU/h BTU/h

PDV20RN Nat Millivolt 21,000 15,500

PDV20RP Prop Millivolt 21,000 16,500

PDV20RFN Nat Comfort Control 21,000 15,500

PDV20RFP Prop Comfort Control 21,000 16,500

SDVRRN Nat Millivolt 21,000 15,500

SDVRRP Prop Millivolt 21,000 16,500

SDVRRFN Nat Comfort Control 21,000 15,500

SDVRRFP Prop Comfort Control 21,000 16,500

Weight: Fully assembled 350 lbs.

Gas Inlet and Manifold Pressures

Natural LP (Propane)

Inlet Minimum 5.5” w.c. 11.0” w.c.

Inlet Maximum 14.0” w.c. 14.0” w.c.

Manifold Pressure 3.5” w.c. 10” w.c.

6

20007066

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

20

19

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Vertical Run (in feet)

Measured after the first elbow. (Transition elbow)

Horizontal Run (in feet)

21

22

23

24

25

26

27

28

29

30

ST134a

FDV28

Horizontal

vent run

12/3/99 djt

areas modified

1/11/00 djt

Pinnacle / Stardance

Direct Vent / Rear Vent

Certified to:

ANSI Z21.88-2005 / CSA Z2.33-2005

Vented Gas Fireplace Heaters

The installation must conform with local codes or, in

the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 - latest edition. (EXCEPTION: Do not derate this appliance for altitude. Maintain the manifold pressure at 3.5” w.c. for Natural Gas

and 10” w.c. for Propane.)

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1/NFPA 54 and/or local codes

having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

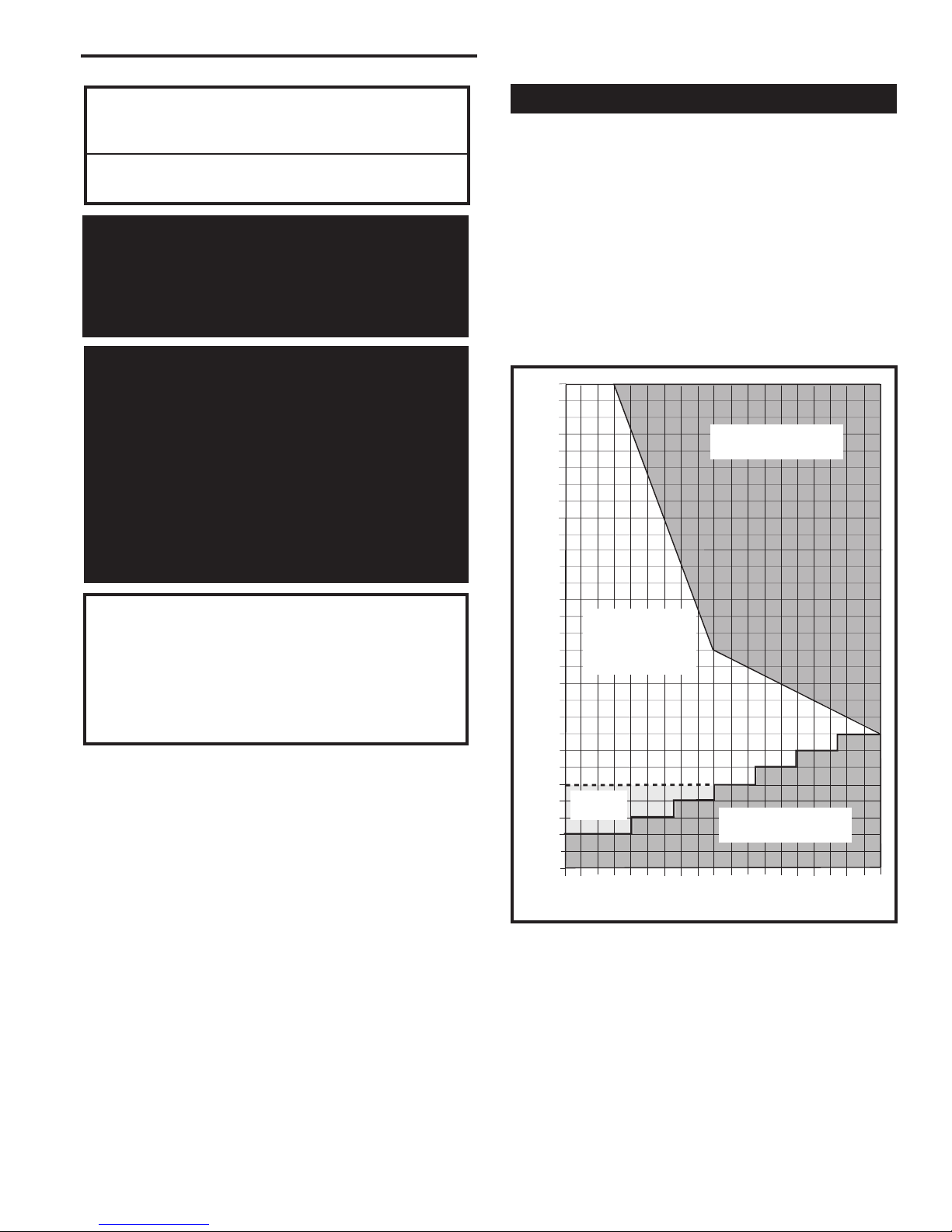

Horizontal Termination

The vent must rise vertically a minimum of 24” (610mm)

after the first elbow directly off the back of the unit,

before the next elbow. The horizontal run may extend

up to 20’ (6m) and include a vertical rise of up to 40’

(12m). (Fig. 7) Horizontal termination must also meet

the criteria shown in Figures 9 and 10.

• Approved vent systems must terminate above and

including the heavy line in Figure 7.

• Two 45° elbows may be substituted for each single

90˚ elbow.

• With a rise between 2’ - 5’, one 90° or two 45° elbows may be used (Excluding the first elbow directly

off the back of the unit.

Unacceptable

Venting Configuration

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage. Refer

to this manual for correct installation and

operational procedures. For assistance or

additional information consult a qualified

installer, service agency, or the gas supplier.

20007066

May use up to

three 90° Elbows

(Excluding elbow

directly off back

of unit.)

One 90°

Elbow*

Unacceptable

Venting Configuration

Fig. 7 Horizontal vent termination window.

* Not the transition elbow.

ST134f

7

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

20

19

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

20

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Vertical Run (in feet)

(Measured after the first elbow. (Transition elbow)

Horizontal Run (in feet)

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ST132f

Pinstar

Ve

rtical

vent run

10/9/00 djt

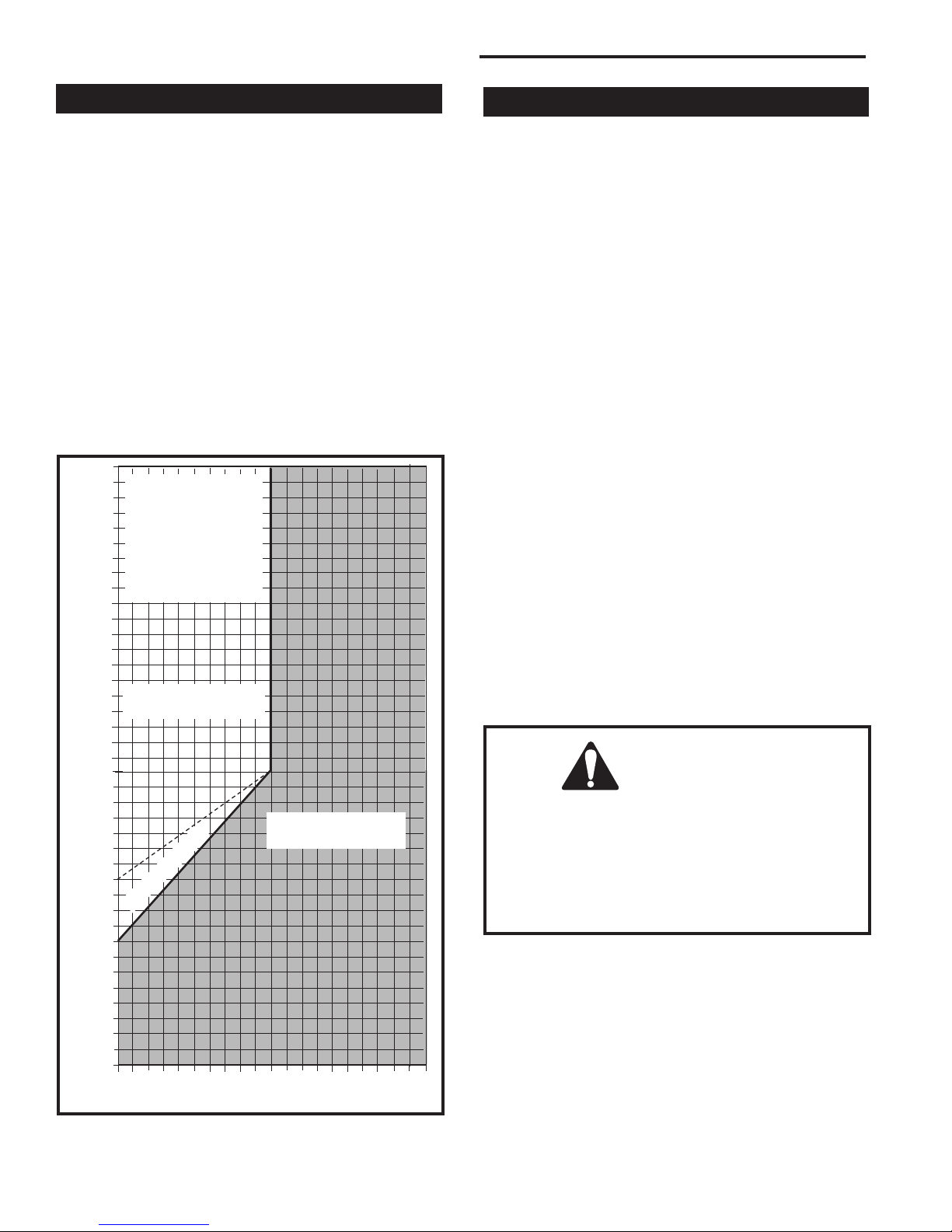

Vertical Termination

A vertical vent system must terminate no less than 8’

(2.44m) and no more than 40’ (12m) above the appliance flue collar. A 2¹⁄₄" restrictor plate (supplied) must

be used (where specified) in all vertically terminated

vent systems. NOTE: The restrictor plate supplied

with the vertical termination should be discarded.

Install restrictor plate supplied with stove directly at

stove outlet. A vertically terminated vent system must

also conform to the following criteria:

• No more than three 90° elbows may be used. 90°

elbow off back must be transition elbow.

• Two 45° elbows may be substituted for one 90°

elbow. No more than six elbows may be used.

• Vent must rise a minimum of 2 feet before offset is

used.

• Termination height must conform to roof clearance

as specified in Figure 9.

All Vertical Terminations in this

area Require

use of the 2¹⁄₄”

Restrictor Plate*

Fig. 8 Vertical vent termination window.

8

Vertical terminations

must be within this area

No Restrictor Plate

Unacceptable

Venting Configuration

Vent Termination Clearances

When planning the installation, consider the location

of the vent terminal and clearances. Some of the most

common clearances to keep in mind are shown in

Figure 9.

Important: All vent clearances must be maintained.

Check your vent termination clearances against

Figures 9 and 10 .

The vent should be placed so that people cannot be

burned by accidentally touching the vent surfaces when

the stove is operating.

The vent termination should be located where it cannot

be damaged by such things as automobile doors, lawn

mowers or snowblowers and it should be located away

from areas where it could become blocked by snow,

etc.

Some considerations are:

• Obstructions or impediments to venting.

• Nearby combustible materials that could come into

contact with combustion exhaust gases.

• Other nearby openings {within 9” (230mm)} through

which exhaust gas could reenter the building.

• All vegetation within 3’ (914mm) that may interfere

with the draft.

Other factors that influence where the installation will

be sited include the location of outside walls, where

additional heat may be desired in the home, where the

family members gather most regularly, and perhaps

most importantly, the distance limitations of the venting

system.

IMPORTANT

• The horizontal termination must not be recessed

into the exterior wall or siding.

• Horizontal vent runs must be level toward the

vent termination.

• Clearances around the vent termination must be

maintained.

ST132f

20007066

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

Vent Termination Clearances

Your stove is approved to be vented either through the

side wall, or vertical through the roof.

• CFM Corporation does not require any opening

for inspection of vent pipe.

• Only CFM Corporation venting components

specifically approved and labelled for this stove

may be used.

• Minimum clearances between vent pipes and

combustible materials is one (1”) inch (25mm),

except where stated otherwise.

• Venting terminals shall not be recessed into a wall

or siding.

• Horizontal venting must be installed on a level plane

without an inclining or declining slope.

There must not be any obstruction such as bushes, garden sheds, fences, decks or utility buildings within 24”

from the front of the termination hood.

Do not locate termination hood where excessive snow

or ice build up may occur. Be sure to check vent termination area after snow falls, and clear to prevent accidental blockage of venting system. When using snow

blowers, make sure snow is not directed towards vent

termination area.

Location of Vent Termination

It is imperative the vent termination be located observing the minimum clearances as shown in Figure 9.

20007066

9

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

V

V

V

V

V

V

V

X

X

X

D

E

B

B

B

C

B

M

B

A

J

K

F

L

VENT TERMINATION AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

H

I

Fixed

Closed

Fixed

Closed

Operabl

e

Operable

Fixed

Closed

V

B

INSIDE

CORNER DETAIL

V

A

G

V

N

N

V

V

G

G

A

CFM145a

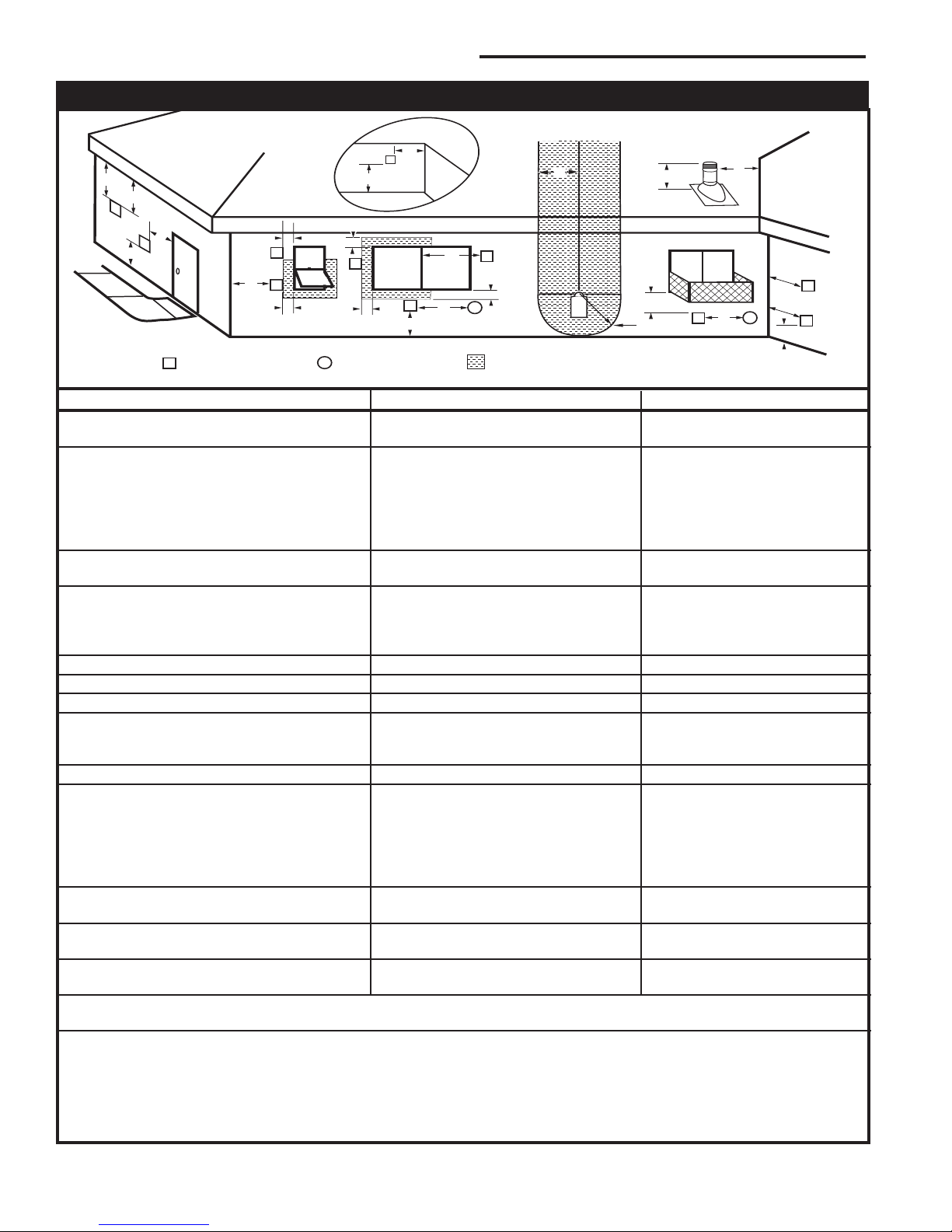

General Venting Information - Termination Location

Canadian Installations1 US Installations

A = Clearance above grade, veranda, porch, 12” (30cm) 12” (30cm)

deck, or balcony

B = Clearance to window or door that may be 6” (15cm) for appliances 6” (15cm) for appliances

opened < 10,000Btuh (3kW), 12” (30cm) < 10,000 Btuh (3kW), 9”

for appliances > 10,000 Btuh (3kW) and (23cm) for appliances > 10,000

< 100,000 Btuh (30kW), 36” (91cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30cm) for

appliances > 50,000 Btuh (15kW)

C = Clearance to permanently closed window 12” (305mm) recommended to 12” (305mm) recommended to

prevent window condensation prevent window condensation

D = Vertical clearance to ventilated soffit located

above the terminal within a horizontal 18” (458mm) 18” (458mm)

distance of 2’ (610mm) from the center

line of the terminal

E = Clearance to unventilated soffit 12” (305mm) 12” (305mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner (see next page) see next page see next page

H = Clearance to each inside of center line 3’ (91cm) within a height of 15’ (5m) 3’ (91cm) within a height of 15’

extended above meter/regulator assembly above the meter/regulator assembly (5m)above the meter/regulator

assy

I = Clearance to service regulator vent outlet 3’ (91cm) 3’ (91cm)

J = Clearance to nonmechanical air supply inlet 6” (15cm) for appliances < 10,000 6” (15cm) for appliances

to building or the combustion air inlet to any Btuh (3kW), 12” (30cm) for < 10,000 Btuh (3kW), 9”

other appliances appliances > 10,000 Btuh (3kW) and < (23cm) for appliances > 10,000

100,000 Btuh (30kW), 36” (91cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30cm) for

appliances > 50,000 Btuh (15kW)

K = Clearance to a mechanical air supply inlet 6’ (1.83m) 3’ (91cm) above if within 10’

(3m) horizontally

L = Clearance above paved sidewalk or paved 7’ (2.13m)† 7’ (2.13m)†

driveway located on public property

M = Clearance under veranda, porch, deck or 12” (30cm)‡ 12” (30cm)‡

balcony

N = Clearance above a roof shall extend a minimum of 24” (610mm) above the highest point when it passes through the roof

surface, and any other obstruction within a horizontal distance of 18” (450mm).

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Codes

† A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both

dwellings

‡ only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the floor:

NOTE: 1. Local codes or regulations may require different clearances.

2. The special venting system used on Direct Vent Stoves are certified as part of the appliance, with clearances tested and approved by the

listing agency.

10

Fig. 9 Vent termination clearances.

20007066

2

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

A =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

B =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

A

Balcony -

with no side wall

G =

Combustible &

Noncombustible

12"(305mm)

G

Balcony -

with perpendicular side wall

H = 24"(610mm)

J = 20"(508mm)

H

J

B

Recessed Location

C = Maximum depth of 48"

(1219mm) for recessed

location.

D = Minimum width for back wall

of a recessed location.

Combustible 38"(965mm)

Noncombustible 24"(610mm)

E = Clearance from corner in

recessed location.

Combustible 6"(152mm)

Noncombustible 2"(50mm)

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

Fig. 10 Termination clearances.

20007066

584-15

11

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

Vent Components

The following kits are available to meet the needs of most

installations. All pipe has a 7” outer diameter and includes a

4” diameter inner section. A (CG) designation indicates the

part is finished in Charcoal Gray paint. Consult your dealer

about other vent parts that may be appropriate to complete

the installation.

CFM Corporation Vent Components

Rear Vent Kit 7TFSRSK

(1) 20” Starter pipe (CG) for through wall installation

(1) Side Wall Termination

(1) Finishing Collar (CG)

(1) Firestop

(1)Zero Clearance Sleeve

(1) Wall plate (CG)

(1) Hardware Package

Min. Through the Wall Vent Kit 7TFSSK

(1) 90-Degree Elbow (CG)

(1) 24” Straight pipe (CG)

(1) 24” - 42” Adjustable Straight Pipe

(1) Side Wall Termination

(1) Firestop

(1) Zero-clearance sleeve

(1) Hardware package

(1) Finishing plate (CG)

(1) Finishing collar (CG)

(4) Charcoal Gray flue pipe rings

Starter Kit for

Below-Grade Installation 7TFSDVSKS

(1) Snorkel Termination (7TDVSNORK)

Vertical Termination Kit, 1/12-6/12 Pitch

7TDVSKVA

(1) Combination Horizontal Offset / Roof Support

(1) Vertical Termination

(1) Storm Collar

(1) 1/12-6/12 Flashing

(1) Finishing Plate (CG)

(1) Finishing Collar (CG)

(1) Polished Brass Flue Pipe Ring

(1) Hardware Package

Vertical Termination Kit, 7/12-12/12 Pitch

7TDVSKVB

(1) 7/12 - 12/12 Flashing

and all of the other Vertical Termination parts.

Vertical Termination, Flat Roof 7DVSKVF

(1) Flat Flashing

and all of the other Vertical Termination parts.

Twist Lock 12” Straight Pipe (CG) 7TFSDVP12

(1) 12” Non-adjustable Pipe

Twist Lock 12”-18” Straight Pipe (CG)

(1) 12” - 18” Adjustable Pipe

7TFSDVP1218

Twist Lock 24” Straight Pipe (CG) 7TFSDVP24

(1) 24” Non-adjustable Pipe

Twist Lock 48” Straight Pipe (CG) 7TFSDVP48

(1) 48” Nonadjustable Pipe

Twist Lock 45-Degree Elbow (CG) 7TFSDVT45

for vertical offsets

(1) 45-degree Elbow

Combination Offset/Roof Support 7DVCS

Attic Insulation Shield 7DVAIS

7” Charcoal Gray Pipe Rings, (4) 7FSDRG

7” Polished Brass Pipe Rings (4) 7FSDRP

Use the following approved CFM/Majestic vent components for fireplace installations vented through a

masonry chimney:

7TFSCSK Transition Connector

HEDV25 25-foot flex connector

(two 25 foot sections)

HEDV35 35-foot flex connector

(two 35 foot sections)

HEDV32T812 Vent termination for 8 x 12” flue

HEDV32T1212 Vent termination for 12 x 12” flue

HEDVT Round termination

12

20007066

Unpack the Stove

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

Installation

The stove is shipped fully assembled on its back. Unpack the stove and carefully set it upright.

CAUTION

Porcelain enamelled surfaces are fragile. Handle

porcelain enamelled castings tenderly. Familiarize

yourself with the assembly steps before you begin

and proceed with deliberation and care. If possible,

have assistance available.

Place enamelled castings on a soft, cushioned surface until you are ready to assemble.

Avoid contact between the castings and other hard

surfaces or objects.

NOTE: Verify the two relief doors (located on top of

the firebox) are properly seated on the gasket. The

doors sit flush on the gasket, and should lift easily

from the seal around the opening.

If you are not installing a fan, proceed to the appropriate vent assembly section.

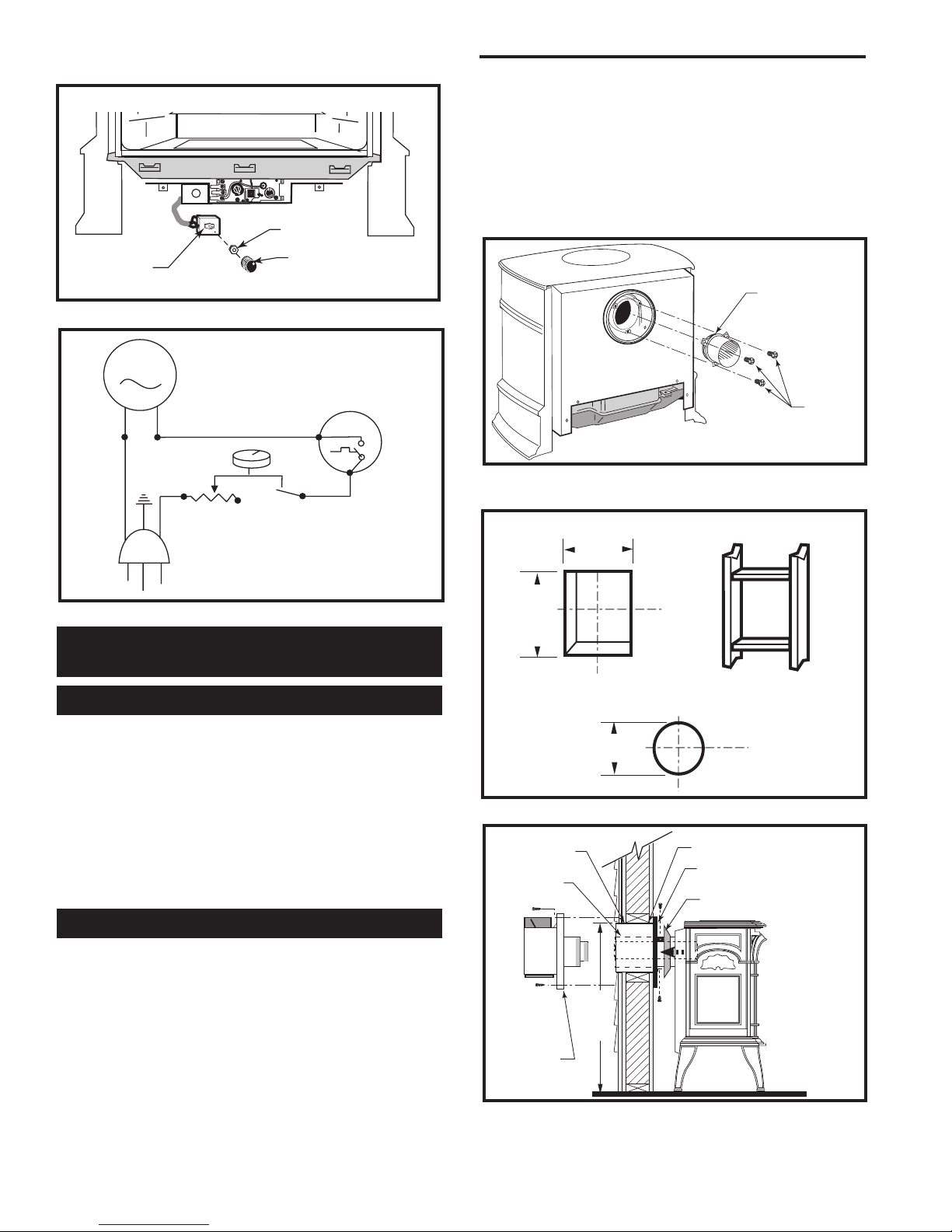

Install Optional Fan Kit #2960/FK28

Fan Kit Contents:

• #10 x 1/2” phillips screws, 6

• Control Knob

• Retainer Collar

• Snapstat • Snapstat Bracket

• Blower Assembly w/ Rheostat Control

NOTE: The Rheostat Assembly and the Snapstat Assembly are not used on RF Models.

For RF Models only: Follow Step 3, then run the

spliced female leads to the front of the stove and attach

to PC board of RF valve. Then follow Step 5.

1. Attach the Snapstat to the Bracket using two #10 x

1/2” phillips sheet metal screws as shown in Figure

12.

2. Locate and remove the 1/4-20 x 3/8” hex head bolt

installed in the hole in the right rear ledge of the

firebox. (Fig. 11) Use that bolt to secure the Snapstat

Bracket to the firebox. The mounting hole is slotted

to allow you to adjust the bracket so that its head

makes contact with the firebox surface. (Fig. 11)

3. Attach the Fan to the firebox by engaging the up

per flange of the fan skirt under the lower edge of

the Shroud and secure the skirt with the four screws

provided with the kit. (Figs. 12, 13)

-

1/4-20 x 3/8”

Hex Head Bolt

Bracket

Snapstat

FK101a

Fig. 11 Snapstat assembly and installation.

Upper

Flange

Fig. 12 The upper flange of the fan skirt should be located

behind the lower edge of the shroud.

Fig. 13 Correct position of fan skirt installation.

1/2” Sheet

Metal Screws

ST240

ST241

4. The rheostat control switch attaches to the left side of

the valve bracket at the front of the stove. (Fig. 14)

• Insert the switch box shaft through the hole in the

back of the right side of the valve bracket, aligning

the locator pin with the smaller hole in that bracket.

• Attach the retaining nut to the switch control shaft

to secure it to the plate.

• Attach the Control Knob to the rheostat shaft.

• Use the wire tie to secure the fan and rheostat

wire harnesses together.

20007066

13

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

27³⁄₈"

(695mm)

to Top of

Opening

9³⁄₈"

(240mm)

10³⁄₈"

(265mm)

7¹⁄₂" Dia.

(190mm)

MOTOR

SNAPSTAT

ON/OFF

RHEOSTAT

WHT

WHT

BLK

BLK

BLK

GRN

BLK

Retaining Nut

centerline. It may be necessary to first position the

stove and measure to find the hole location. Depending on whether the wall is made of combustible

materials, cut the opening to the size shown in Figure 17. Combustible wall openings must be framed

as shown in Figure 17.

3. Measure the wall thickness and cut the wall sleeve

sections to proper length (MAXIMUM 12”). Assemble

Rheostat

Rheostat Knob

FK104

Fig. 14 Attach rheostat to bracket.

Blower Wiring Diagram

Fan Assembly

No. 000-2960 / FK28

WARNING:

DISCONNECT

ELECTRICAL SUPPLY

BEFORE SERVICING

Fig. 15 Blower wiring diagram.

Venting System Assembly -

Direct Vent

General Information

The PDV20 and SDVR are approved for installation

only with the vent components listed on Page 13. Follow the vent component instructions exactly. These instructions apply to both the PDV20 and the SDVR shell.

Sealant

Phillips

Screws

ST396a

Fig. 16 Apply sealant to the starter pipe, and fasten to stove

with Phillips screws.

Vent Opening - Combustible Wall

Framing Detail

Vent Opening -Noncombustible Wall

VO584-100

For U.S. installations: The venting system must conform with local codes and/or the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54

For Canadian installations: The venting system must

conform to the current CSA B149.1 installation code.

Rear Vent

Use Rear Vent Kit 7TFSRSK for an installation where

the heater is parallel to the wall and the vent system

extends straight back through that wall.

1. Attach Inner Starter Pipe, (found in with the logset),

to the stove.

• Run a bead of sealant beneath the pipe bead and

attach to the stove using three 1/4-20 x 3/8” phillips

screws provided in the parts bag. (Fig. 16)

2. Locate the vent opening on the wall. Refer to Figures 17, 18 & 19 to determine the top of the opening

14

Fig. 17 Locate vent opening.

9³⁄₈” W x 10³⁄₈” H

Wall Opening

Wall Sleeve

- Seal Around

Seal

Around

Terminal

ST400

Firestop

Ventilated Wall Plate

- Open End Down

Finishing Collar

Fig. 18 SDVR with Rear Vent Kit 7TFSRSK installation.

20007066

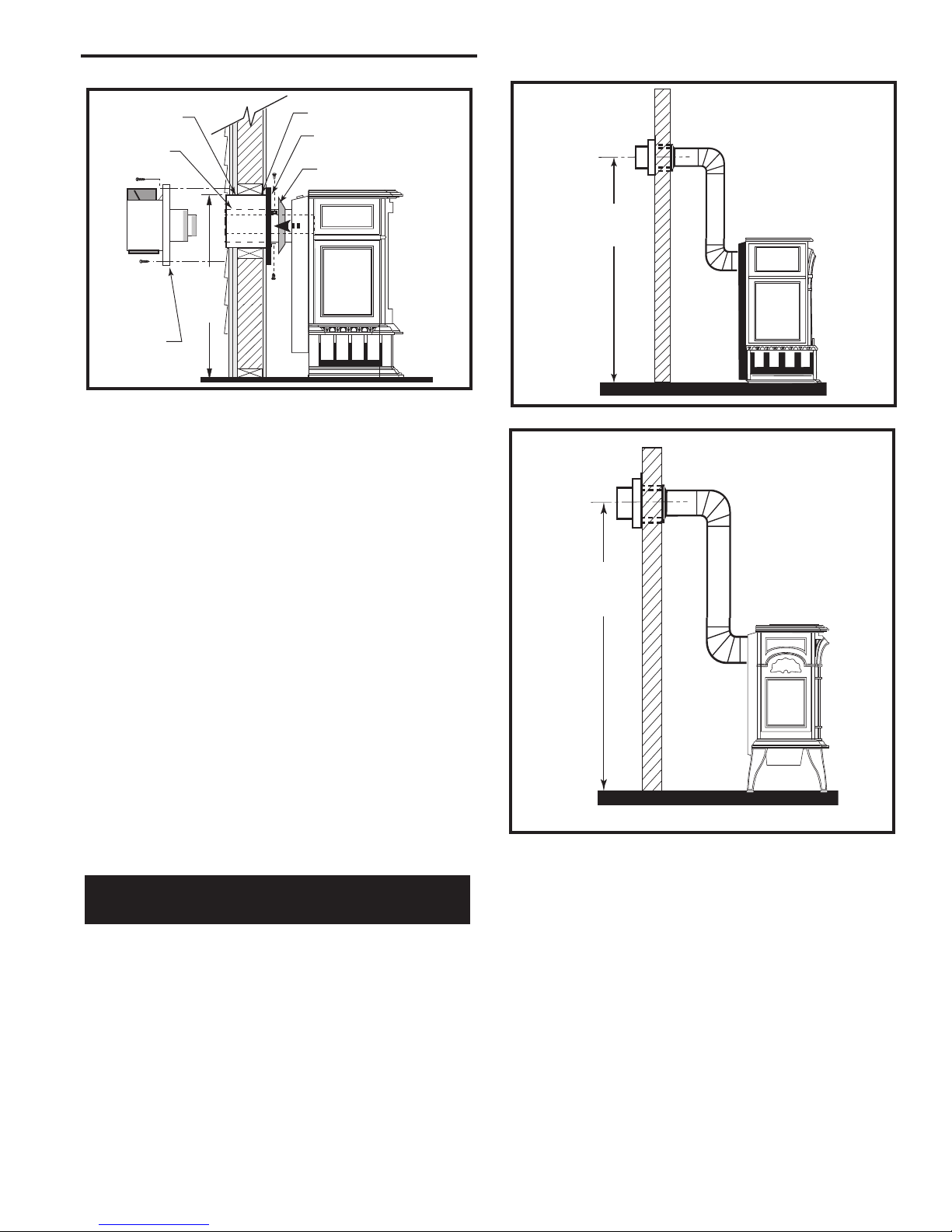

Pinnacle & Stardance Direct Vent - Rear Vent Gas Heaters

25³⁄₄"

(654mm)

to Top of

Opening

59¹⁄₄"

(1505mm)

61"

(1549mm)

9³⁄₈” W x 10³⁄₈” H

Wall Opening

Wall Sleeve

- Seal Around

Seal

Around

Terminal

ST400

Fig. 19 PDV20 with Rear Vent Kit 7TFSRSK installation.

Firestop

Ventilated Wall Plate

- Open End Down

Finishing Collar

the sleeve with the #8 sheet metal screws supplied.

Attach the firestop plate to the sleeve end with the

holes. (Fig. 25) NOTE: The wall sleeve is required in

combustible walls only.

4. Install the Wall Firestop/Sleeve assembly into the

wall cutout and fasten the firestop to the wall cutout

framing members. (Figs. 18, 19)

5. Measure, and cut if necessary, the appropriate

length of pipe section needed to make the connection through the wall.

6. Slip the wall plate and trim collar over the interior

end of the horizontal pipe and install into the wall

sleeve. Seal the joint inside the wall plate if needed

to keep cold air from being drawn into the home.

7. Connect the pipe to the inner collar. Fasten the wall

plate to the pipe with three sheet metal screws. Slide

the trim collar up against the wall plate to cover the

screws. (Figs. 18, 19)

8. Install the vent terminal. (Figs. 18, 19) Guide the

inner and outer vent termination collars into the adjacent pipes. Double check that the vent pipes overlap

the collars by 2”. Fasten the termination to the wall

with the screws provided, and caulk the joint with

weatherproof sealant.

Through Side Wall /

Vent Termination Below Grade

Refer to Figures 20 & 21 for minimum centerline of wall

opening.

1. Attach Inner Starter Pipe, (found in with the logset),

to the stove.

• Run a bead of sealant beneath the pipe bead and

attach to the stove using three 1/4-20 x 3/8” phillips

screws provided in the parts bag. (Fig. 22)

2. Dry fit the inner and outer pipe of the first elbow

directly to the starter pipe.

20007066

ST131c

Fig. 20 Minimum wall thimble centerline.

ST131b

Fig. 21 Minimum wall thimble centerline.

3. Dry fit the Inner pipe assembly to the stove for the

purpose of determining the center line of the pipe on

the wall.

• Side Wall Terminations: Dry fit the outer elbow

with the vertical outer vent and confirm the centerline

alignment with the wall thimble opening.

4. Attach the elbow to the starter pipe.

• Run a bead of sealant about 1/2” from end of the

starter pipe and attach the assembly to the stove

using three 1/4-20 x 3/8” Phillips screws provided in

the parts bag. (Fig. 22)

15

Loading...

Loading...