Vermont Castings 36CFDV, 42CFDV, 33CFDV(N/P)(V/I)SB, 36CFDV(N/P)(V/I)SB, 42CFDV(N/P)(V/I)SB Installation And Operating Instructions Manual

...

CFDV Series Direct Vent Gas Fireplace

Installation and Operating Instructions

Models: 36CFDV, 42CFDV

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

• Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do

not use any phone in your building.

– Leave the building immediately.

– Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

– If you cannot reach your gas supplier,

call the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency or

the gas supplier.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this manual.

For assistance or additional information consult

a qualified installer, service agency or the

gas supplier.

This appliance may be installed in an aftermarket,*

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is for use only with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certifi ed kit is used.

* Aftermarket: Completion of sale, not for purpose of resale, from

the manufacturer.

INSTALLER: Leave this manual with the appliance.

DANGER

DO NOT TOUCH GLASS

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

CONSUMER: Retain this manual for

future reference.

HOT GLASS WILL

CAUSE BURNS.

UNTIL COOLED.

20305832 8/14 Rev. 3

CFDV Series Gas Fireplace

CONTENTS

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS

BEFORE USING APPLIANCE.

Thank you and congratulations on your purchase of a Vermont Castings Group fi replace.

IMPORTANT: Read all instructions and warnings carefully before starting installation.

Failure to follow these instructions fully may result in a possible fi re hazard and will void the warranty.

Important Safety Information ................................................3

Code Approval ........................................................................4

Product Features ....................................................................5

Product Specifi cations ....................................................... 6

Fireplace Controls ............................................................. 6

Gas Specifi cations & Orifi ce Sizes .................................... 6

Gas Pressures................................................................... 6

High Elevations ................................................................. 6

Cold Climate Insulation ..................................................... 6

Fireplace & Framing Dimensions ......................................7

Pre-Installation Information ................................................... 6

Before Y ou Start ................................................................6

Items Required for Installation........................................... 6

Fireplace Framing ............................................................6

Fireplace Location ............................................................. 8

Clearances .............................................................................. 8

Clearances to Combustibles ............................................. 8

Mantel Clearances ............................................................ 8

Fireplace Installation .............................................................. 9

Secure Fireplace to Floor or Framing................................ 9

Finishing Material ..............................................................9

Venting Installation Information ..........................................10

Optional Top V ent Application .......................................... 10

Installation Precautions ................................................... 12

General Venting .............................................................. 12

Termination Location ................................................13

Termination Clearances ...........................................14

Assembling Vent Pipe .....................................................14

Flex Vent Pipe ................................................................. 14

Twist Lock Pipe ...............................................................15

Rear Vent Installation Only .............................................. 15

How to Use the Vent Graph............................................. 16

Vent Pipe Clearances ...................................................... 17

Rear Wall Vent Applications ........................................... 18

Rear Wall Vent Installation—Twist Lock Pipe .................. 18

Rear Wall Vent Installation—Flex Vent Pipe ................... 18

Top Vent Side Wall Application ........................................ 19

Vertical Side Wall Applications ........................................ 21

Vertical Side Wall Installaion—Twist Lock Pipe ............... 21

Vertical Side Wall Installation—Flex Vent Pipe ............... 22

Below Grade Installation .................................................23

Vertical Through-the-Roof Application ............................. 24

Vertical Through-the-Roof Installation ............................. 25

Fireplace Installation ............................................................ 27

Check Gas Type ..............................................................27

Installation Items Needed ................................................ 27

Gas Pipe Installation ....................................................... 28

Check Gas Pressure – Millivolt ....................................... 29

Electrical Installation – Millivolt .......................................... 29

Electrical Wiring ............................................................... 29

Remote Wall Mounted Switch ......................................... 30

Remote Wall Switch ........................................................30

Optional DC Remote Systems ........................................ 30

Optional Fan/Blower System BLOT ................................31

Optional Fan/Blower System FK12 .................................31

Operating Instructions – Millivolt ........................................32

For Your Safety Read Before Lighting ............................. 32

What To Do If You Smell Gas .......................................... 32

Lighting Pilot for the First Time ........................................32

Lighting Pilot .................................................................... 33

Lighting Burner ................................................................ 34

To Turn Off Gas ............................................................... 34

Check Gas Pressure – IPI .................................................... 35

Electrical Installation – IPI ................................................... 35

Electrical Wiring ............................................................... 35

Junction Box Wiring......................................................... 36

Wall Switch Installation .................................................... 36

IPI System Wiring Diagram .............................................37

Operating Instructions – IPI .................................................38

For Your Safety Read Before Lighting .............................38

What To Do If You Smell Gas .......................................... 38

Operating Instructions ..................................................... 39

To Turn Off Gas ............................................................... 39

Operation and Indications—EcoLogic Control System ... 40

Final Installation ................................................................... 41

Glass Frame Removal..................................................... 41

Pilot Flame ...................................................................... 42

Burner Flame................................................................... 42

Installing Porcelain Liner Kit ............................................ 42

Installing Brick Liner Kit ................................................... 43

Rockwool Placement .......................................................43

Adjustable Baffl e .............................................................44

Log Placement ................................................................44

Lava Rock and Ember Placement ................................... 45

Fireglass and Stone Placement ...................................... 46

Cleaning and Maintenance .................................................. 47

Burner, Pilot and Control Compartment .......................... 47

Burner.............................................................................. 47

Vent System .................................................................... 47

Glass Door ......................................................................47

Logs................................................................................. 47

Rock Wool ...................................................................... 47

Troubleshooting ...................................................................48

Millivolt Standing Pilot Ignition ......................................... 48

IPI System .......................................................................49

All Control/Pilot Systems ................................................. 50

Optional Accessories ........................................................... 50

Replacement Parts ............................................................... 51

Firebox Components ....................................................... 51

Logs................................................................................. 52

Standing Pilot – Millivolt Control ...................................... 53

IPI System .......................................................................54

Venting Components ............................................................ 55

Massachusetts Requirements ............................................. 58

Limited Lifetime Warranty Policy ........................................ 59

Effi ciency Ratings ................................................................60

2

20305832

IMPORTANT SAFETY INFORMATION

CFDV Series Gas Fireplace

INSTALLER

Please leave these instructions with the appliance.

OWNER

Please retain these instructions for future reference

.

• Read this owner’s manual carefully and

completely before trying to assemble, operate,

or service this fi replace.

• Any change to this fi replace or its controls can

be dangerous.

• Improper installation or use of this fi replace

can cause serious injury or death from fi re,

WARNING

burns, explosions, electrical shock and carbon

monoxide poisoning.

This fi replace is a vented product. This fi replace must be

properly installed by a qualifi ed service person. The glass

door must be properly seated and sealed. If this unit is not

properly installed by a qualifi ed service person with glass

door properly seated and sealed, combustion leakage can

occur.

CARBON MONOXIDE POISONING: Early signs of carbon

monoxide poisoning are similar to the fl u with headaches,

dizziness and/or nausea. If you have these signs, the fi re-

place may not have been installed properly. Get fresh air

at once! Have the fi replace inspected and serviced by a

qualifi ed service person. Some people are more affected

by carbon monoxide than others. These include pregnant

women, people with heart or lung disease or anemia,

those under the infl uence of alcohol, and those at high

altitudes.

Propane/LP gas and natural gas are both odorless. An

odor-making agent is added to each of these gases. The

odor helps you detect a gas leak. However, the odor added

to these gases can fade. Gas may be present even though

no odor exists.

Make certain you read and understand all warnings. Keep

this manual for reference. It is your guide to safe and proper

operation of this fi replace.

1. Installation and repair should be done by a qualifi ed

service person. The appliance should be inspected

before use and at least annually by a professional

service person. More frequent cleaning may be

required due to excessive lint from carpeting,

bedding material, et cetera. It is imperative that

control compartments, burners and circulating air

passageways of the appliance be kept clean.

2. This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases unless a certifi ed

kit is used.

3. For propane/LP fi replace, do not place propane/LP

supply tank(s) inside any structure. Locate propane/LP

supply tank(s) outdoors. T o prevent performance problems, do not use propane/LP fuel tank of less than 100

lbs. capacity.

4. If you smell gas:

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building .

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

5. Never install the fi replace:

• In a recreational vehicle

• Where curtains, furniture, clothing, or other fl am-

mable objects are less than 36" from the front, top,

or sides of the fi replace

• In high traffi c areas

• In windy or drafty areas

6. Due to high temperatures, the appliance should be

located out of traffi c and away from furniture and

draperies.

7. This fi replace reaches high temperatures. Children

and adults should be alerted to the hazards of high

surface temperature and should stay away to avoid

burns or clothing ignition. Fireplace will remain hot

for a time after shutdown. Allow surfaces to cool before

touching.

8. Young children should be carefully supervised

when they are in the same room as the appliance.

Toddlers, young children and others may be susceptible to accidental contact burns. A physical

barrier is recommended if there are at risk individuals in the house. To restrict access to a fi replace

or stove, install an adjustable safety gate to keep

toddlers, young children and other at risk individuals out of the room and away from hot surfaces.

9. Clothing or other fl ammable material should not be

placed on or near the appliance.

10. When the appliance is installed directly on carpeting,

tile or other combustible material other than wood fl oor-

ing, you must set appliance on a metal or wood panel

or hearth pad extending the full width and depth of the

appliance.

1 1. Do not modify fi replace under any circumstances. Any

parts removed for servicing must be replaced prior to

operating fi replace.

12. Turn fi replace off and let cool before servicing, install-

ing, or repairing. Only a qualifi ed service person should

install, service, or repair the fi replace. Have burner

system inspected annually by a qualified service

person.

20305832

3

CFDV Series Gas Fireplace

IMPORTANT SAFETY INFORMATION

13. You must keep control compartments, burners, and

circulating air passages clean. More frequent cleaning

may be needed due to excessive lint and dust. Turn of f

the gas valve and pilot light before cleaning fi replace.

14. Have venting system inspected annually by a qualifi ed service person. If needed, have venting system

cleaned or repaired. Refer to Cleaning and Mainte-

nance, Page 47.

15. Keep the area around your fi replace clear of combus-

tible materials, gasoline, and other fl ammable vapor

and liquids. Do not run fi replace where these are used

or stored. Do not place items such as clothing or decorations on or around fi replace.

16. Do not use this fi replace to cook food or burn paper or

other objects.

17. Never place anything on top of fi replace.

18. Do not use any solid fuels (wood, coal, paper, cardboard, etc.) in this fi replace. Use only the gas type

indicated on rating plate.

19. This appliance, when installed, must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFP A 70, or the Canadian Electrical Code,

CSA C22.1.

20. Do not obstruct the fl ow of combustion and ventilation

air in any way. Provide adequate clearances around

air openings into the combustion chamber along with

adequate accessibility clearance for servicing and

proper operation.

21. Do not use fi replace if any part has been under water.

Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which as been

under water.

22. Do not operate fi replace if any log is broken.

23. Do not use a blower insert, heat exchanger insert, or

any other accessory not approved for use with this

fi replace.

24. Do not operate appliance with the glass front

removed, cracked, or broken. Replacement of the

glass should be done by a licensed qualifi ed ser-

vice person.

CODE APPROV AL

Direct Vent type appliances draw all combustion air from

outside of the dwelling through the vent pipe.

These appliances have been tested by CSA and found to

comply with the established standards for DIRECT VENT

GAS FIREPLACE HEATERS in the USA and Canada as

follows:

LISTED VENTED GAS FIREPLACE HEATER

TESTED TO:

ANSI Z21.88a-2012/CSA 2.33a-2012 STANDARDS

The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the National Gas and Propane

Installation Code, CSA B149.1.

A manufactured home (USA only) or mobile home OEM

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280,

or when such a standard is not applicable, the Standard for

Manufactured Home Installations, ANSI/NCSBCS A225.1,

or Standard for Gas Equipped Recreational Vehicles and

Mobile Housing, CSA Z240.4.

IMPORTANT:

PLEASE READ THE FOLLOWING

CAREFULLY

It is normal for fi replaces fabricated of steel

to give off some expansion and/or contraction

noises during the start up or cool down cycle.

Similar noises are found with your furnace heat

exchanger or car engine.

IMPORTANT:

PLEASE READ THE FOLLOWING

CAREFULLY

It is not unusual for gas fi replace to give off some

odor the fi rst time it is burned. This is due to the

manufacturing process.

Please ensure that your room is well ventilated

during burn off — open all windows.

It is recommended that you burn your fi replace

for at least ten (10) hours the fi rst time you use it.

Place the fan switch in the “OFF” position during

this time.

4

Never connect unit to private (non-utility)

gas wells. This gas is commonly known

as wellhead gas.

WARNING

20305832

PRODUCT FEATURES

CFDV Series Gas Fireplace

PRODUCT SPECIFICATIONS

• This appliance has been certifi ed for use with either

natural or propane gas. See appropriate data plates.

• This appliance is not for use with solid fuels.

• The appliance is approved for bedroom or bedsitting

room installations.

• The appliance must be installed in accordance with local

codes if any. If none exist use the current installation

code. ANSI Z223.1/NFPA 54 in the USA, CSA B149 in

Canada.

• This appliance is mobile home approved.

• The appliance must be properly connected to a venting

system.

• The appliance is not approved for closet installations.

• This appliance is approved to be vented using V ermont

Castings Group Twist-Lock Direct Vent components.

The classifi cation “noncombustible material” includes, but

is not limited to stone, brick and mortar. Noncombustibles

are safe to overlay the black-painted metal face (including

radiant plates) and do not pose a fi re hazard. Do not allow

any noncombustible fi nish material to extend past or inter-

fere with fi replace opening.

The classifi cation “combustible material” includes, but is not

limited to plywood, drywall and particle board. Combustible

materials may contact the sides, bottom or back of fi rebox.

Do not overlay the black painted face with combustible

materials.

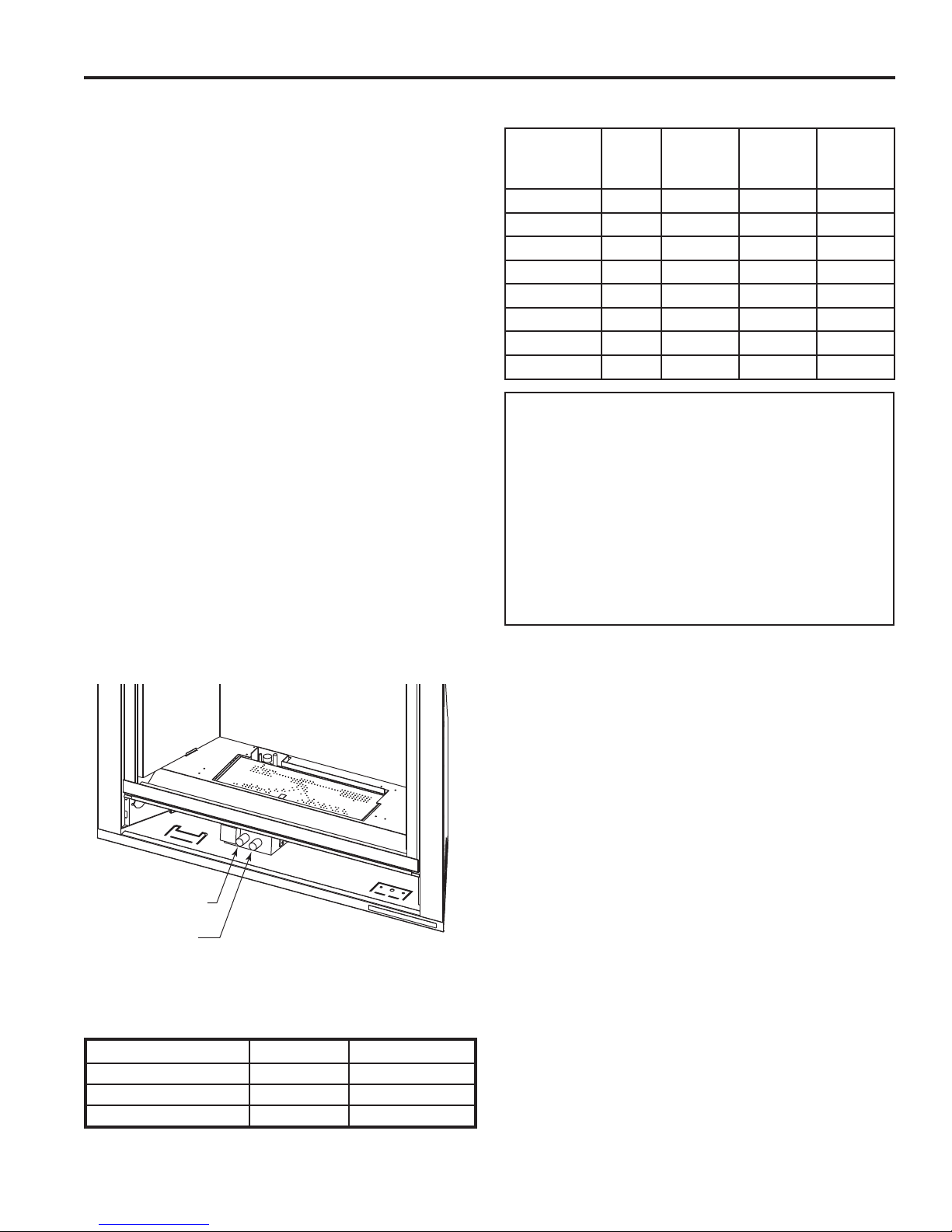

GAS SPECIFICATIONS & ORIFICE SIZE

MAX

INPUT

MODEL FUEL

36CFDVNV NAT. 21,000 15,000 #44

36CFDVPV LP 21,000 17,500 #54

36CFDVNI NAT. 21,000 15,000 #44

36CFDVPI LP 21,000 17,500 #54

42CFDVNV NAT. 24,000 16,500 2.35mm

42CFDVPV LP 24,000 17,500 1.45mm

42CFDVNI NAT. 24,000 16,500 2.35mm

42CFDVPI LP 24,000 17,500 1.45mm

BTU/H

MIN.

INPUT

BTU/H

ORIFICE

SIZE

HIGH ELEVATIONS

Input ratings are shown in BTU per hour and are certifi ed

without derating for elevations up to 4,500 feet (1,370

m) above sea level.

For elevations above 4,500 feet (1,370 m) in USA,

installations must be in accordance with the current

ANSI Z223.1/NFPA 54 and/or local codes having jurisdiction.

In Canada, please consult provincial and/or local authorities having jurisdiction for installations at elevations

above 4,500 feet (1,370 m).

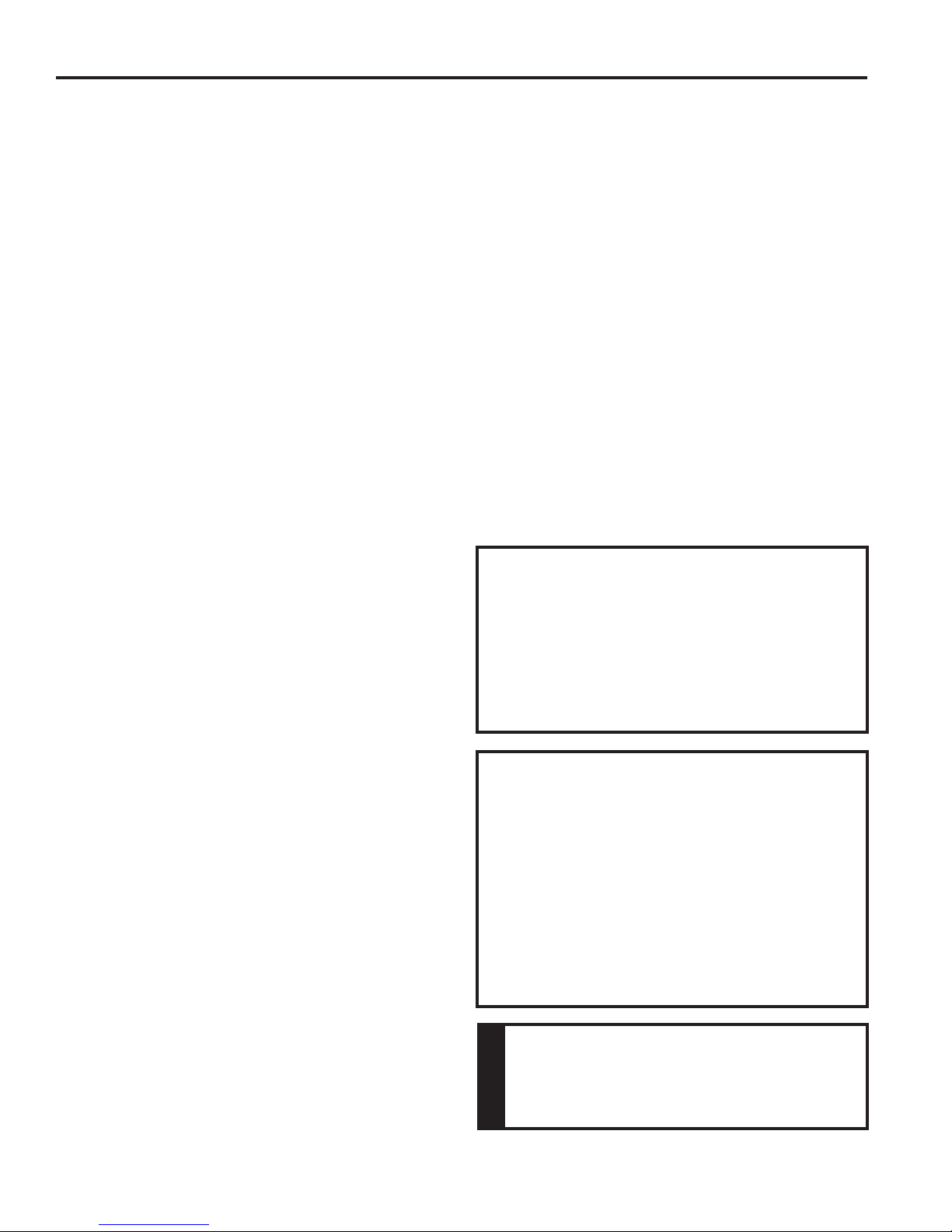

FIREPLACE CONTROLS

Hi/Lo Knob

Off/Pilot/On Knob

Figure 1 –

CFDV Fireplace Controls – Millivolt

FP3011

GAS PRESSURES

Natural Propane (LP)

Inlet Minimum 5.5" w.c. 11.0" w.c.

Inlet Maximum 14.0" w.c. 14.0" w.c.

Manifold Pressure 3.5" w.c. 10.0" w.c.

COLD CLIMATE OPTION (IPI Models Only)

NOTE: If you live in a cold climate, seal all cracks around

your appliance, and wherever cold air could enter the room,

with noncombustible material. It is especially important to

insulate the outside chase cavity between the studs and

under the fl oor on which the appliance rests, if the fl oor is

above ground level.

Your fi replace is equipped with an intermittent pilot ignition

(IPI) control. An IPI control with a standing pilot option provides the dual benefi t of an economical and environmentally

responsible product and one which lights easily even in

the coldest climates. When in intermittent pilot mode (as

it comes from the factory), your pilot remains unlit until

needed, saving you fuel. Standing pilot mode, by comparison, is characterized by a continuously burning pilot.

The benefi t of a pilot which lights only when needed is fuel

savings. However, with no pilot burning in your fi replace,

units operating in colder climates may experience delayed

start up or lock out. Because colder air is heavier than

milder air and there is no pilot burning to maintain a warm

stable temperature in your fi rebox, establishing a draft to

aid ignition becomes diffi cult. This is perfectly normal but

can be somewhat frustrating.

T o remedy this issue, your fi replace has been designed with

a cold climate pilot option, which, when active, maintains

a warmer temperature inside your fi rebox to make ignition

20305832

5

CFDV Series Gas Fireplace

PRE-INSTALLATION INFORMATION

faster and more effi cient. Operating your appliance in cold

climate (aka standing) pilot mode will prohibit the need for

multiple ignition attempts and will prevent the system from

delaying start up or locking out.

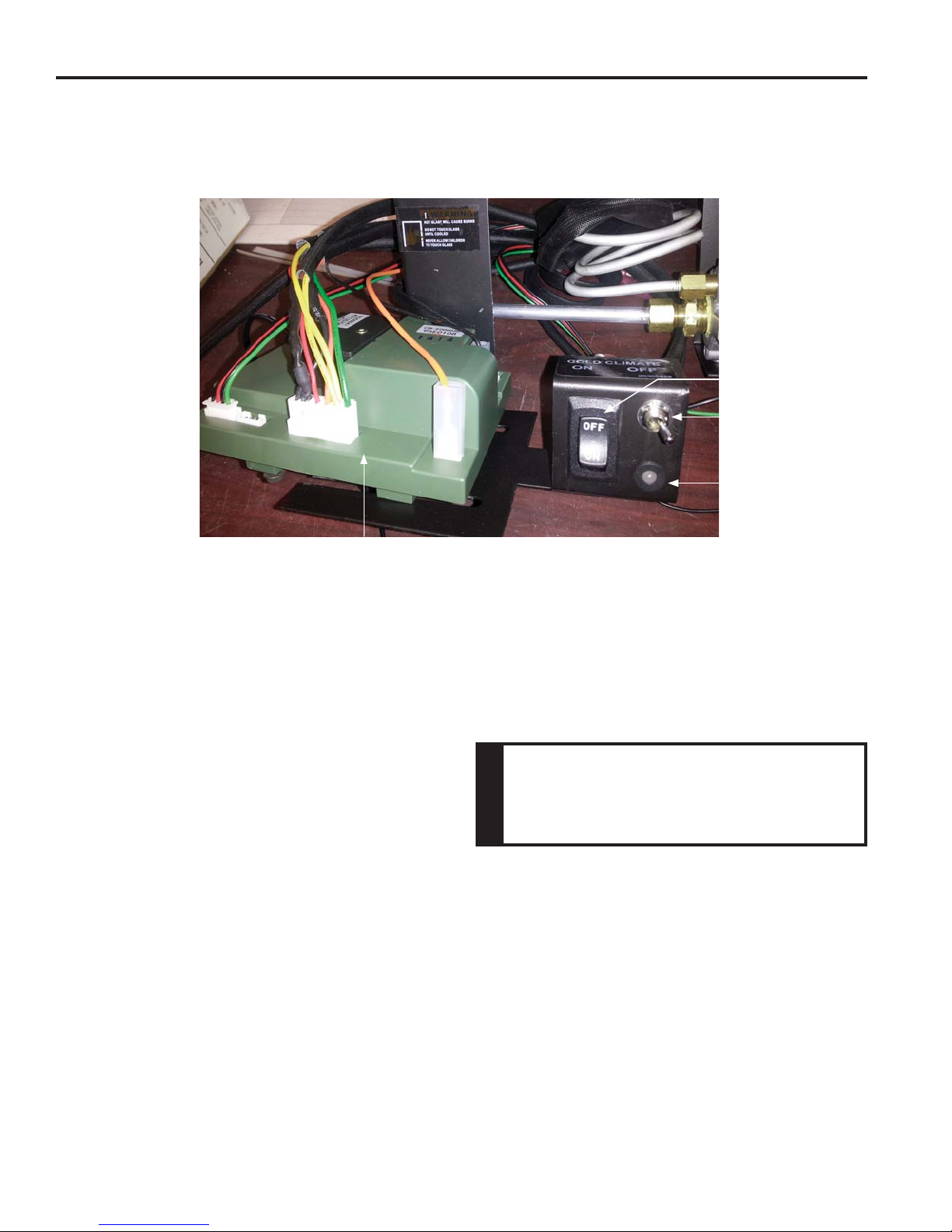

Control Board

Figure 2 –

CFDV Fireplace Controls–IPI (featuring Cold Climate option)

To activate the cold climate option, simply move the cold

climate toggle switch located on the right side of the black

control center to the “On” (left) position. (Figure 2) Y ou can

operate your appliance in this mode regardless of whether

you are using a remote control, wall switch or thermostat.

Master Switch

Cold Climate Switch

LED indicator

BEFORE YOU ST ART

Read this homeowner manual thoroughly and follow all

instructions carefully. Inspect all contents for shipping

damage and immediately inform your dealer if any damage

is found. Do not install any unit with damaged, incomplete,

or substitute parts. Check your packing list to verify that

all listed parts have been received. You should have the

following:

• Fireplace (Firebox and Burner System)

• Log Set

• Rock Wool

• Volcanic Rock

ITEMS REQUIRED FOR INSTALLATION

Tools and Building Supplies:

• Phillips Screwdriver

• Hammer

• Pliers

• Square

• Level

• Tee Joint

• Pipe Wrench

• Saw and/or saber saw

• Measuring Tape

• Electric Drill and Bits

• Framing Materials

• Wall Finishing Materials

• Caulking Material (Noncombustible)

• Fireplace Surround Material (Noncombustible)

• Piping Complying with Local Codes

• Pipe Sealant Approved for use with Propane/LPG

(Resistant to Sulfur Compounds)

Do not fill spaces around firebox with

insulation or other materials. This could

cause a fi re.

WARNING

FIREPLACE FRAMING

Firebox framing can be built before or after the appliance

is set in place. Construct fi rebox framing following Figure

3 (page 6) for specifi c installation requirements and for

fi rebox dimensions. The framing headers may rest on the

top of the fi rebox standoffs. Do not bring headers below

top of standoffs.

The fi rebox may be installed directly on a combustible fl oor

or raised on a platform of an appropriate height. When

the fi rebox is installed directly on carpeting, tile, or other

combustible material, other than wood fl ooring, the fi rebox

shall be installed on a metal or wood panel extending the

full width and depth of the enclosure.

6

20305832

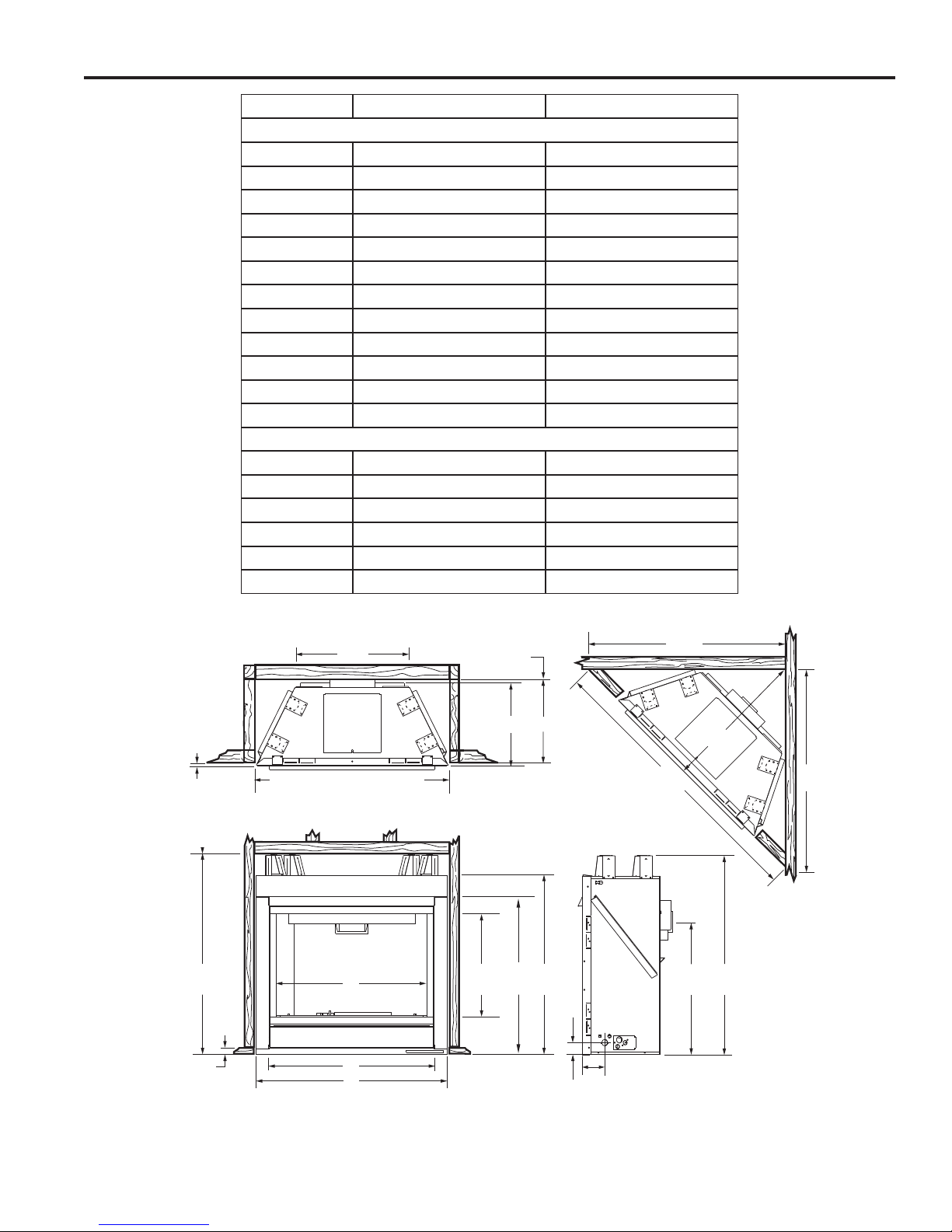

PRE-INSTALLATION INFORMATION

REFERENCE 36CFDV 42CFDV

FIREPLACE DIMENSIONS

A 37" (940 mm) 41" (1042 mm)

B38

C34

D29

E19

F15

G22

H25

I 32" (813 mm) 36" (914 mm)

J2

K4

L30

FRAMING DIMENSIONS

M54

N38

O 28" (711 mm) 301⁄4" (768 mm)

P15

Q37

R38

1

⁄2" (978 mm) 381⁄2" (978 mm)

3

⁄4" (883 mm) 343⁄4" (883 mm)

1

⁄8" (740 mm) 331⁄8" (841 mm)

7

⁄8" (505 mm) 197⁄8"(505 mm)

7

⁄8" (430 mm) 157⁄8" (430 mm)

1

⁄8" (562 mm) 261⁄2" (673 mm)

5

⁄8" (657 mm) 255⁄8" (657 mm)

1

⁄4" (57 mm) 21⁄4" (57 mm)

3

⁄8" (111 mm) 43⁄8" (111 mm)

1

⁄2" (775 mm) 301⁄2" (775 mm)

1

⁄2" (1384 mm) 575⁄8" (1464 mm)

1

⁄2" (978 mm) 403⁄4" (1035 mm)

5

⁄8" (397 mm) 155⁄8" (397 mm)

1

⁄2" (946 mm) 411⁄2" (1054 mm)

3

⁄4" (978 mm) 383⁄4" (978 mm)

CFDV Series Gas Fireplace

1/2" (13 mm)

or 5/8" (16 mm)

Minimum Rough

Opening

Height

15/16"

(24 mm)

G

Minimum Rough Opening Width

Q

D

I

A

Minimum Rough

Opening

Depth

F

P

LB

CRE

J

K

N

O

M

C

L

H

N

Figure 3 –

CFDV Series Fireplace Dimensions

20305832

7

CFDV Series Gas Fireplace

CLEARANCES

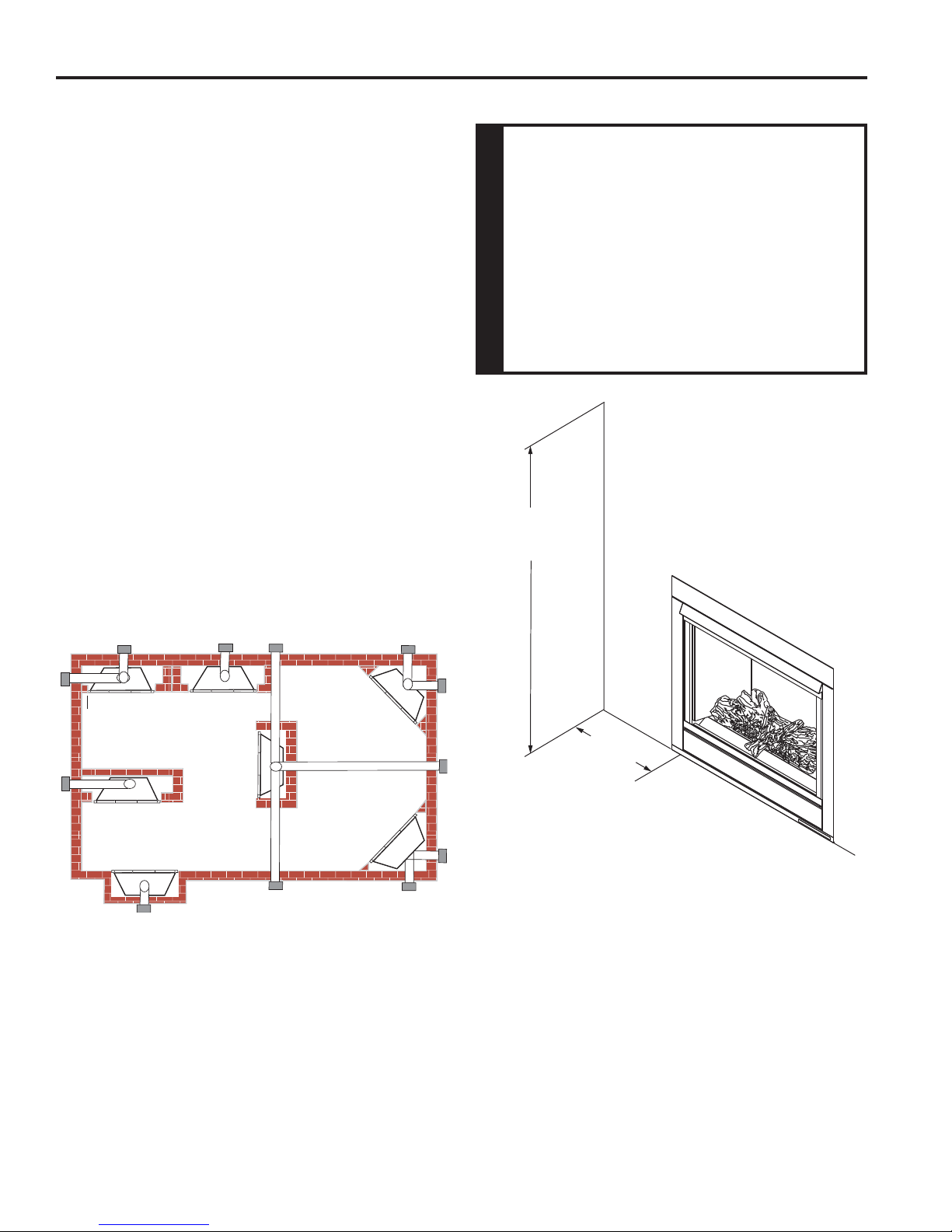

FIREPLACE LOCATION

Plan for the installation of your appliance. This includes

determining where the unit is to be installed, the vent confi guration to be used, framing and fi nishing details, and

whether any optional accessories (i.e. blower, wall switch,

or remote control) are desired. Consult your local building

code agency to ensure compliance with local codes, including permits and inspections.

The following factors should be taken into consideration:

• Clearance to side-wall, ceiling, woodwork, and windows.

Minimum clearances to combustibles must be main-

tained.

• This fi replace may be installed along a wall, across a

corner, or use an exterior chase. Refer to Figure 4 for

suggested locations.

• Location should be out of high traffi c areas and away

from furniture and draperies due to heat from appliance.

• Never obstruct the front opening of the fi replace.

• Do not install in the vicinity where gasoline or other

fl ammable liquids may be stored.

• Vent pipe routing. See Venting section found in this

manual for allowable venting confi gurations.

• These units can be installed in a bedroom. See National

Fuel Gas Code ANSI Z233.1/NFPA 54 — (current

edition), the Uniform Mechanical Code — (current edition), and Local Building Codes for specifi c installation

requirements.

CLEARANCES TO COMBUSTIBLES

Follow these instructions carefully to

ensure safe installation. Failure to follow

in struc tions exactly can create a fire

hazard.

The appliance cannot be installed on a

carpet, tile or other combustible material

other than wood fl ooring. If installed on

WARNING

carpet or vinyl flooring, the appliance

shall be installed on a metal, wood or

noncombustible material panel ex tend ing

full width and depth of the appliance.

Ceiling

72"

(1828 mm)

Minimum

Side Wall

E

Y

D

F

A Flat on Wall

B Cross Corner

C Island**

** Island (C) and room divider (D) installation is possible as long as the

horizontal portion of vent system (X) does not exceed 20' (6 m).

* When you install your fi replace in (D) room divider or (E) fl at on wall

corner positions (Y), a minimum of 6" (102 mm) clearance must be

maintained from perpendicular wall and front of fi replace.

Figure 4 –

Locating Gas Fireplace

A

C

D Room Divider*

E Flat on Wall Corner*

F Chase Installation

B

B

6"

(152 mm)

Minimum

Figure 5 –

Ceiling and Side Wall Clearances

FP3012

MANTEL CLEARANCES

NOTE: The combustible area above the facing must not

protrude more than 3/4" (19 mm) from the facing. If it

does, it is considered a mantel and must meet the mantel

requirements listed in this manual.

8

20305832

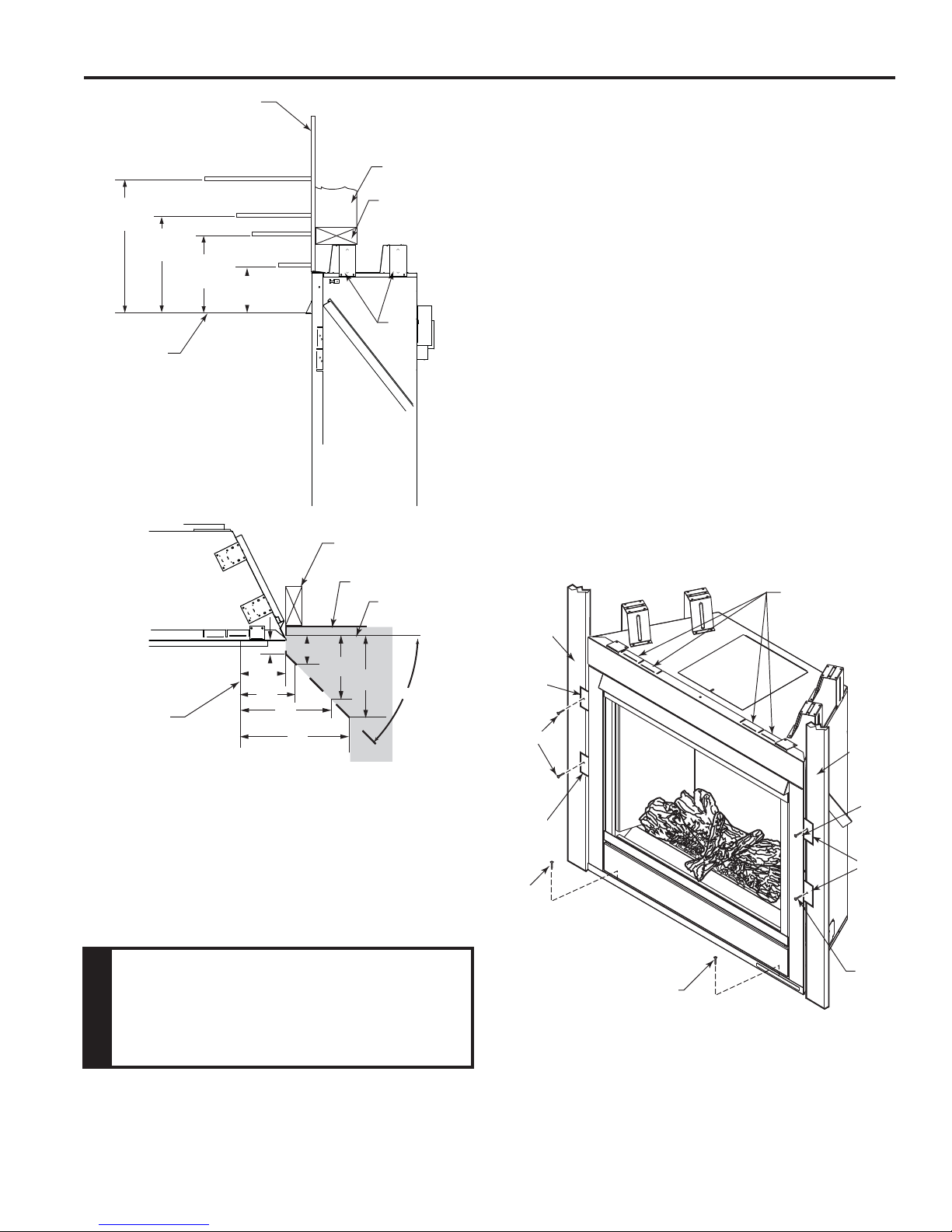

FIREPLACE INSTALLATION

CFDV Series Gas Fireplace

12”

(305 mm)

11”

(279 mm)

Top of Heat

Exhaust Vent

Side View

Side of Fireplace

Opening

Finish Wall

12” (305 mm)

10”

(254 mm)

8” (203 mm)

(152 mm)

6”

256O”

(64 mm)

8” (203 mm)

1"

256O”

3"

5"

156O”

6"

Stud

356O”

Stud

Header

Wall

Combustible

Material Area

456O”

Standoffs

FP3000

45°

SECURE FIREPLACE TO FLOOR OR

FRAMING

The fi replace must be secured to the fl oor and/or to framing

studs as shown in Figure 7. Use two (2) wood screws or

masonry/concrete screws to secure fi replace to the fl oor.

Use four (4) screws to attach fi replace to framing. The side

nailing fl anges are 1⁄2" or 5⁄8" to accommodate different wall

thickness.

FINISHING MATERIAL

NOTE: Any wiring (i.e. remote control, wall switch, and

optional fan) must be done prior to fi nal fi nishing to avoid

costly reconstruction.

Only noncombustible materials (i.e. brick, tile, slate, steel,

or other materials with a UL fi re rating of Zero) may be

used to cover the black surface of the appliance. A 300°F

minimum adhesive may be used to attach facing materials

to the black surface. If joints between the fi nished wall

and the fi replace surround are sealed, a 300°F minimum

sealant material (General Electric RTV103 or equivalent)

must be used.

Finished Wall

Support Tabs

(Do Not Use for

Framing or Header)

Framing

Nailing

Flange

Screws

Framing

Front View

Figure 6 –

Mantel Clearances

Never obstruct or modify the air inlet.

This may create a fi re hazard.

WARNING

20305832

FP3013

Nailing

Flange

Screw

Screw

Figure 7 –

Securing Fireplace to Floor and Framing Studs

Screw

Nailing

Flange

Screw

9

CFDV Series Gas Fireplace

VENTING INSTALLATION

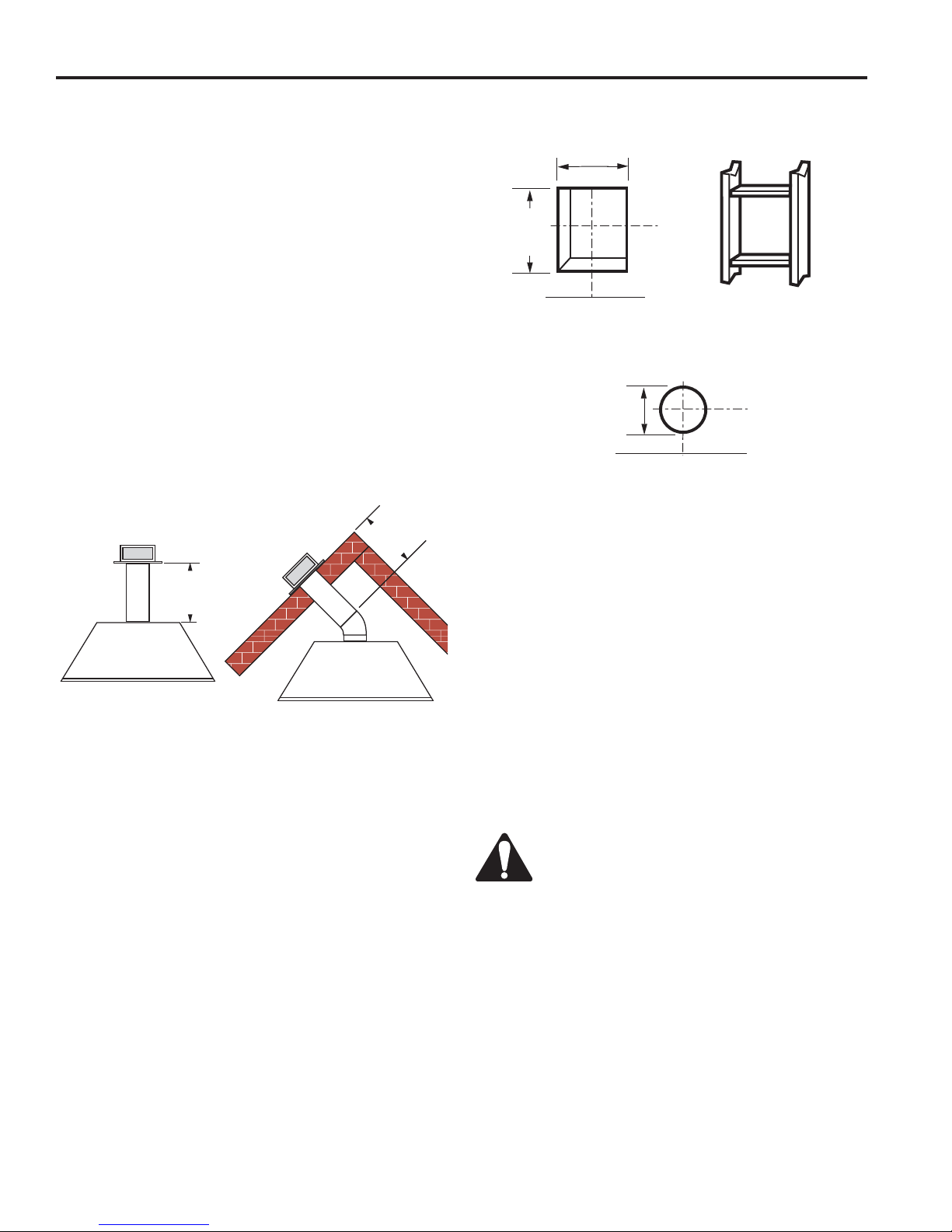

OPTIONAL TOP VENT APPLICATION

The appliance is shipped as a rear vent unit. If the installation layout requires the unit to be a top vent confi guration

the appliance can be converted by following the steps

below.

When removing and refi tting the plates be sure the associ-

ated gaskets are undamaged and refi tted as required.

1. Remove the rear plate by removing one (1) screw . Set

aside. Figure 8

Screw

Rear Plate

3. Remove the plate with the 4" collar and gasket by removing four (4) screws. Set aside. Figure 10

4. Remove the top plate located on top of the unit by removing one (1) screw. Set aside. Figure 10

Top Plate

Remove

Screw

Remove

Screws

4" Collar

Remove

Screws

FP3023

FP3021

Figure 8 –

Remove Rear Plate

2. Remove the plate with the 7" collar and gasket by removing eight (8) screws. Set aside. Figure 9

Remove

Screws

7" Collar

Remove

Screws

FP3022

Figure 10 –

Remove 4" Collar and Gasket and Top Plate

5. Remove one (1) screw to remove the inner top plate

located on top directly beneath the plate just removed.

Break away the 7" circle using a screwdriver and reinstall. Figure 11

Inner Top Plate

FP3025

Remove Circle

Figure 9 –

Remove 7" Collar and Gasket

10

FP3024

Figure 11 –

Remove Circle Section from Inner Top Plate

20305832

VENTING INSTALLATION

CFDV Series Gas Fireplace

6. Remove the large square plate and gasket by removing

the eight (8) screws. Set aside. Figure 12

Remove

Screws

Large Square

Plate

FP3026

8. Install the plate and plates with collars removed in Steps

1-3 in reverse order onto the top of the unit. Install the

top plate and large and small plates in reverse order

into back of unit. Figure 14.

FP3028

Figure 12 –

Remove Large Square Plate and Gasket

7. Remove the small square plate and gasket by removing

four (4) screws. Set aside. Figure 13

Remove Screws

Small

Square

Plate

FP3027

Figure 14 –

Completed Top Vent Conversion

Figure 13 –

Remove Small Square Plate and Gasket

20305832

11

CFDV Series Gas Fireplace

VENTING INSTALLATION

Read all instructions completely and

thoroughly before attempting installation.

Failure to do so could result in serious injury ,

property damage or loss of life. Operation

of improperly installed and maintained

WARNING

venting system could result in serious injury ,

property damage or loss of life.

This fireplace must be vented to the

outside. The venting system must NEVER

be attached to a chimney serving a separate

solid fuel burning appliance. Each gas

appliance must use a separate vent system.

WARNING

Do not use common vent systems.

Do not pack the open air spaces with

insulation or other materials. This could

cause high temperatures and may present

a fi re hazard.

WARNING

Failure to follow these instructions will

void the warranty.

NOTICE

INSTALLATION PRECAUTIONS

Consult local building codes before beginning the

installation. The installer must make sure to select the

proper vent system for installation. Before installing vent

kit, the installer must read this fi replace manual and vent

kit instructions.

Only a qualifi ed installer/service person should install vent-

ing system. The installer must follow these safety rules:

• Wear gloves and safety glasses for protection.

• Use extreme caution when using ladders or when on

rooftops.

• Be aware of electrical wiring locations in walls and

ceilings.

The following actions will void the warranty on your venting system:

GENERAL VENTING

Your fi replace is approved to be vented either through the

side wall, or vertical through the roof.

• Only Vermont Castings Group venting components

specifi cally approved and labeled for this fi replace

may be used.

• Flexible UL1777 listed venting may be used in any vent-

ing application where rigid direct vent components can

be used. All restrictions, clearances and allowances that

pertain to the rigid piping apply to the fl exible venting.

Flex kits may not be modifi ed. Flex kits may be added to

the end of a vent run made of rigid vent sections using

pipe manufacturer's approved fl ex to pipe adapters. This

may occur only if doing so does not violate any of the

venting length, height, routing, horizontal to vertical ratio

requirements or clearance considerations detailed in this

manual.

• Venting terminals shall not be recessed into a wall or sid-

ing.

• Select the amount of vertical rise desired. All horizontal

run of venting must have 1/4" rise for every 12" (305 mm)

of run towards the termination below 71/2 feet of vertical

rise. With 71/2 feet (2.3 m) or more vertical rise off top of

fi replace, the horizontal run may run level. NEVER run

vent piping downward.

• Horizontal venting which incorporates the twist lock pipe

must be installed on a level plane without an inclining or

declining slope.

• Horizontal venting which incorporates the use of fl ex

venting shall have an inclining slope from the unit of 1"

(25 mm) per 24" (610 mm).

There must not be any obstruction such as bushes, garden sheds, fences, decks or utility buildings within 24"

(610 mm) from the front of the termination hood.

Do not locate termination hood where excessive snow or

ice build up may occur. Be sure to check vent termination area after snow falls, and clear to prevent accidental

blockage of venting system. When using snow blowers,

make sure snow is not directed towards vent termination

area.

Location of Vent Termination

It is imperative the vent termination be located observing

the minimum clearances as shown on following page.

• Installation of any damaged venting component.

• Unauthorized modifi cation of the venting system.

• Installation of any component part not manufactured

or approved by Vermont Castings Group.

• Installation other than permitted by these instruc-

tions.

12

20305832

VENTING INSTALLATION

V

X

X

X

D

E

B

B

B

C

B

M

B

A

J

K

F

L

VENT TERMINATION AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

H

I

Fixed

Closed

Operable

Operable

Fixed

Closed

B

INSIDE

CORNER DETAIL

A

G

CFM145a

V

V

V

V

V

V

V

V

TERMINATION LOCATION

Figure 15 –

Termination Locations

CFDV Series Gas Fireplace

A = Clearance above grade, veranda, porch,

CANADIAN INSTALLATIONS

1

12" (30cm) 12" (30cm)

US INSTALLATIONS

2

deck or balcony

B = Clearance to window or door that may be

opened

C = Clearance to permanently closed window 12" (305mm) recommended to prevent

D = Vertical clearance to ventilated soffi t

6" (15cm) for appliances <10,000 BTU/h

(3kW)

12" (30cm) for appliances >10,000 BTU/h

(3kW) and <100,000 BTU/h (30kW)

36" (91cm) for appliances >100,000 BTU/h

(30kW)

6" (15cm) for appliances <10,000 BTU/h

(3kW)

9" (23cm) for appliances >10,000 BTU/h

(3kW) and <50,000 BTU/h (15kW)

12" (30cm) for appliances >50,000 BTU/h

(15kW)

12" (305mm) recommended to prevent

window condensation

window condensation

18" (458mm) 18" (458mm)

located above the terminal within a horizontal distance of 2' (610 mm) from the

center line of the terminal

E = Clearance to unventilated soffi t 12" (305mm) 12" (305mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner see next page see next page

H = Clearance to each inside of center line

extended above meter/regulator assembly

3' (91cm) within a height of 15' (5m) above

the meter/regulator assembly

3' (91cm) within a height of 15' (5m) above

the meter/regulator assembly

I = Clearance to service regulator vent outlet 3' (91cm) 3' (91cm)

J = Clearance to non-mechanical air supply

inlet to building or the combustion air inlet

to any other appliance

6" (15cm) for appliances <10,000 BTU/h

(3kW)

12" (30cm) for appliances >10,000 BTU/h

(3kW) and <100,000 BTU/h (30kW)

36" (91cm) for appliances >100,000 BTU/h

(30kW)

6" (15cm) for appliances <10,000 BTU/h

(3kW)

9" (23cm) for appliances >10,000 BTU/h

(3kW) and <50,000 BTU/h (15kW)

12" (30cm) for appliances >50,000 BTU/h

(15kW)

K = Clearance to mechanical air supply inlet 6' (1.83m) 3' (91cm) above if within 10' (3m) horizontally

L = Clearance above paved sidewalk or

7' (2.13m)

†

7' (2.13m)

†

paved driveway located on public property

M = Clearance under veranda, porch, deck or

12" (30cm)

‡

12" (30cm)

‡

balcony

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel

Gas Codes

† A vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings and

serves both dwellings

‡ Only permitted if veranda, porch, deck or balcony is fully open on a

minimum 2 sides beneath the fl oor.

20305832

NOTE: 1. Local codes or regulations may require different

2. The special venting system used on Direct Vent

3. Vermont Castings Group assumes no responsibility for

clearances.

Fireplaces are certifi ed as part of the appliance, with

clearances tested and approved by the listing agency.

the improper performance of the appliance when the venting

system does not meet these requirements.

13

CFDV Series Gas Fireplace

TERMINATION CLEARANCES

Termination clearances for buildings with combustible and non-combustible exteriors.

VENTING INSTALLATION

Inside Corner

G =

G

Balcony -

with no side wall

Combustible

6" (152 mm)

Noncombustible

V

2" (51 mm)

M

V

M =

Combustible &

Noncombustible

12" (305 mm)

*NOTE: Termination in an alcove space (spaces open only on one side

and with an overhang) is permitted with the dimensions specifi ed for

vinyl or non-vinyl siding and soffi ts. 1. There must be a 3' (914 mm) min-

imum between termination caps. 2. All mechanical air intakes within 10'

Outside Corner

V

F

Balcony -

with perpendicular side wall

M

Combustible &

Noncombustible

M = 12" (305 mm)

P = 6” (152 mm)

Figure 16 –

Termination Clearances

ASSEMBLING VENT PIPE

Only venting components manufactured or approved by

Vermont Castings Group may be used in Direct Vent systems.

USA Installations

The venting system must conform to local codes and/or

the current National Fuel Code ANSI Z223.1/NFPA 54.

Canadian Installations

The venting system must be installed in accordance with

the current CSA-B149.1 installation code.

Alcove Applications*

D

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

C

O

C

V

E

E = Min. 2” (51 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O = 8’ (2.4 m) Min.

No. of

V

P

(1 m) of a termination cap must be a minimum of 3' (914 mm) below the

termination cap. 3. All gravity air intakes within 3' (914 mm) of a termination cap must be a minimum of 1' (305 mm) below the termination cap.

Caps DMIN.CMAX.

1 3' (914 mm) 2 x D

2 6' (1.8 m) 1 x DACTUAL

3 9' (2.7 m) 2/3 x DACTUAL

4 12' (3.7 m) 1/2 x DACTUAL

DMin. = Number of Termination caps x 3

CMax. = (2 / Number termination caps) x DActual

ACTUAL

• Tighten fl ex clamp to fl ex pipe so it is tight to collar and

cannot slip off.

• Apply a tug to be sure the vent will not slip off the col-

lars.

• Repeat process with 7" fl ex vent pipe. The same pro-

cedure must be performed on the vent side.

584-15

FLEX VENT PIPE

Secure fl ex vent pipe in place with a hose clamp (provid-

ed).

• Be sure the fl ex pipe overlaps at least 1" (25 mm) onto

the collars of the fi replace and termination. If the ter-

mination has an internal bead, be sure to overlap and

secure 1" (25 mm) past the bead.

14

Figure 17 –

Secure Flex Vent Pipe with Hose Clamps.

Hose Clamp

FP2290

20305832

VENTING INSTALLATION

CFDV Series Gas Fireplace

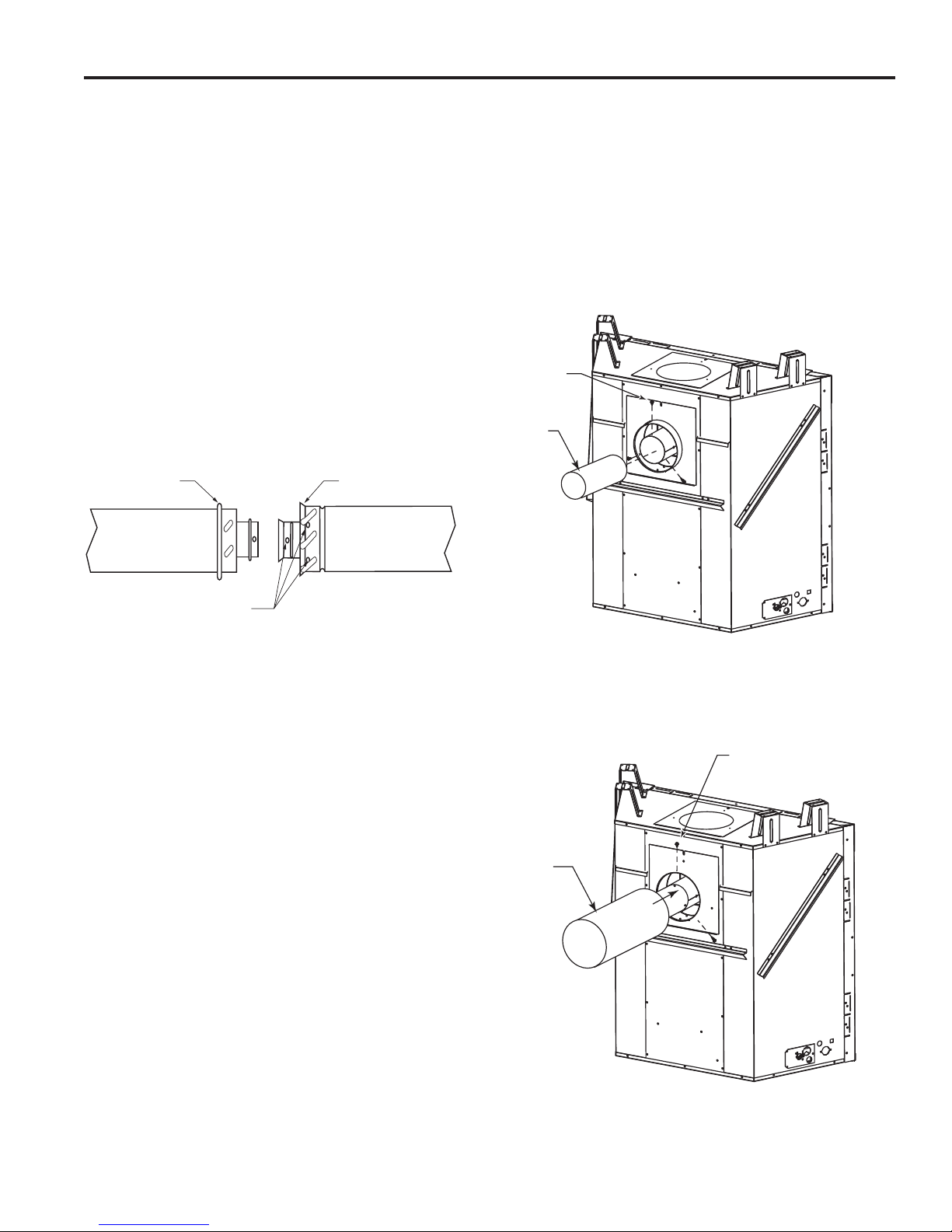

TWIST LOCK PIPE

When using twist lock pipe it is not necessary to use sealant on the joints.

To join twist lock pipes together, simply align the beads of

the male end with the grooves of the female end, twisting

the pipe until the fl ange on the female end contacts exter-

nal fl ange on the male end. It is recommended that you

secure the joints with three (3) sheet metal screws, however, this is not mandatory with twist lock pipe. Figure 18

NOTE: Sealant is not required to assemble fi replace

venting. Do not use silicone sealant at the inner fl ue

exhaust connections.

To make it easier to assembly the joints, we suggest putting a lubricant (V aseline or similar) on the male end of the

twist lock pipe prior to assembly.

Male End

Female End

REAR VENT INSTALLATION ONLY

Install the 4" (102 mm) inner vent pipe to the appliance

inner collar and secure with three (3) stainless steel sheet

metal screws. Figure 19. Install the 7" (178 mm) outer

vent pipe to the appliance outer collar. Secure pipe to the

rear cover plate using the tabs and three (3) sheet metal

screws. Figure 20. If a 45° or 90° elbow is being used, at-

tach the elbow to the appliance in the same manner then

attach the venting to the elbow.

Sheet Metal

Screws

4" Inner

Pipe

Screw Holes

Figure 18 –

Twist-lock Pipe Joints

TWL100

Figure 19 –

Install 4" Inner Vent Pipe

7" Outer

Pipe

FP3001a

Sheet Metal Screw

20305832

FP3031

Figure 20 –

Install 7" Outer Vent Pipe

15

CFDV Series Gas Fireplace

VENTING INSTALLATION

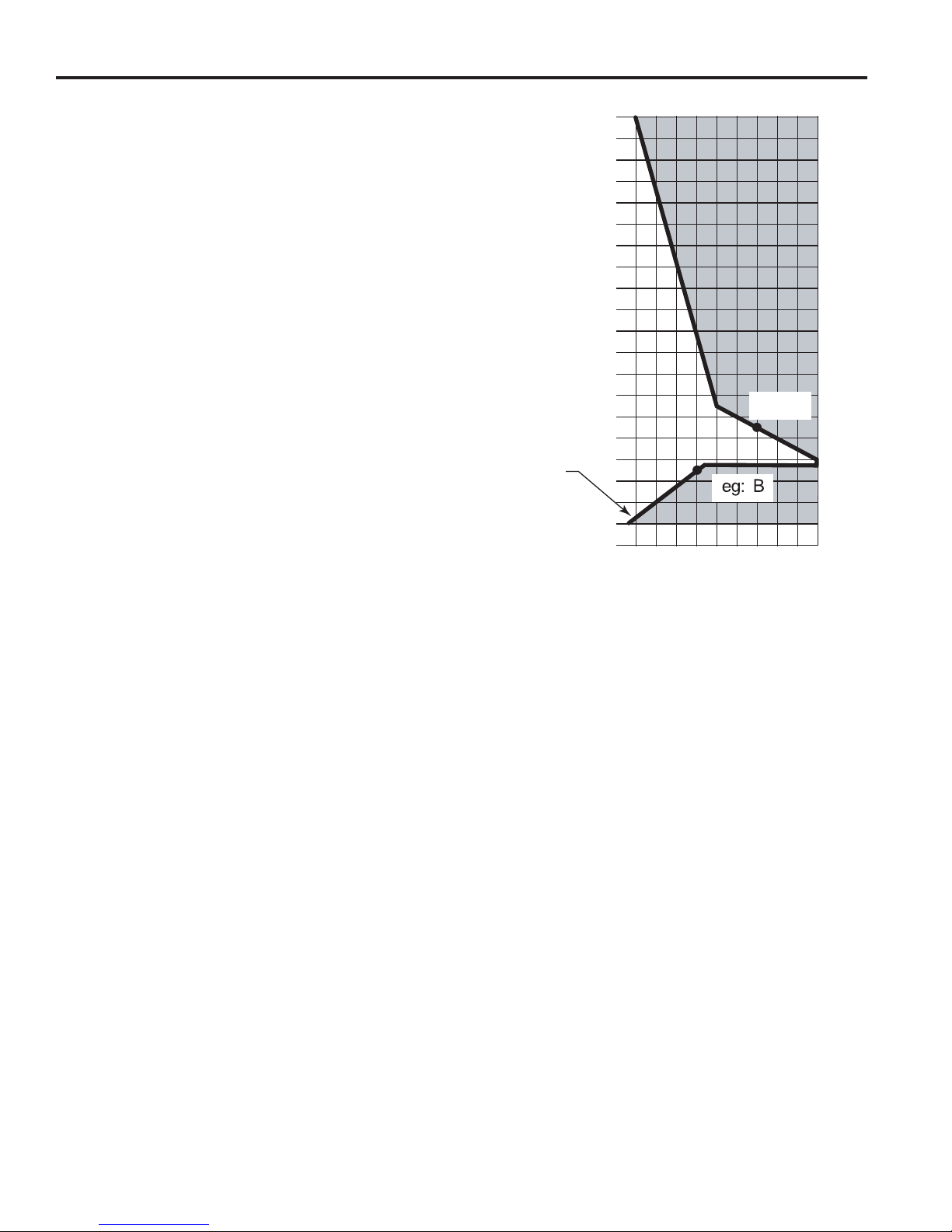

HOW TO USE THE VENT GRAPH

The Vent Graph should be read in conjunction with the

following vent installation instructions to determine the relationship between the vertical and horizontal dimensions

of the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Side wall Vent Graph, Figure 21, locate the point intersecting with the slanted graph line.

2. From the point of this intersection, draw a vertical line

to the bottom of the graph.

3. Select the indicated dimension, and position the fi re-

place in accordance with same.

EXAMPLE A:

If the vertical dimension from the fl oor of the unit is 1 1' (3.4

m) the horizontal run to the face of the outer wall must not

exceed 14' (4.3 m).

EXAMPLE B:

If the vertical dimension from the fl oor of the unit is 7' (2.1

m), the horizontal run to the face of the outer wall must not

exceed 8' (2.4 m).

Refer to Page 23 for snorkel requirements.

40

38

36

34

32

30

28

26

24

22

20

18

the Horizontal Vent Pipe

16

14

12

eg: A

10

Vertical Dimension from the Floor of Unit to the Center of

X

8

6

4

2

2 4 6 8 10 12 14 16 18 20

Horizontal Dimension From the Outside of Termination to

the Back of the Fireplace

X = 22" minimum for 33" Model

X = 251⁄4" minimum for 36" Models

(Floor to center of horizontal pipe)

Figure 21 –

Side Wall Venting Graph

16

20305832

VENTING INSTALLATION

VENT PIPE CLEARANCES

CFDV Series Gas Fireplace

A Minimum of 3" (76 mm)

Clearance to the Top Is

Required Along Horizontal

Length until Flue Pipe

Penetrates Outside Wall.

A Minimum 1" (25

mm) Clearance

to Combustibles

Permitted All Around

Flue at Outside Wall

1"

3"

1"

1"

A Minimum of 3" (76

mm) Clearance to the

Top Is Required Along

Horizontal Length until

Flue Pipe Penetrates

Outside Wall.

3"

A Minimum 1" (25

mm) Clearance

to Combustibles

Permitted All Around

Flue at Outside Wall

1"

1"

1"

Rear Vent

Figure 22 –

Combustible Clearances for Vent Pipe

FP3017

Rear Wall Vent: Horizontal sections of this

vent system require a minimum of 3" (76

mm) clearances to combustibles at the top

of the fl ue and 1" (25 mm) clearance at the

sides and bottom until the fl ue penetrates

the outside wall. A minimum 1" clearance

WARNING

all around the fl ue is acceptable at this point

of penetration.

Top Vent

FP3018

Rear/T op V ent Vertical Side wall: Horizontal

sections of this vent system require a

minimum of 3" (76 mm) clearances to

combustibles at the top of the fl ue and 1"

(25 mm) clearance at the sides and bottom

until the fl ue penetrates the outside wall. A

minimum 1" clearance all around the fl ue

WARNING

is acceptable at this point of penetration. If

vertical rise is 71/2 feet (2.3 m) or higher when

top venting, the clearance to combustibles

is 1" on all sides of the horizontal run.

All vertical sections of this vent system

require a minimum of 1" (25 mm) clearance

to combustibles on all sides of the pipe.

WARNING

20305832

17

CFDV Series Gas Fireplace

VENTING INSTALLATION

REAR WALL VENT APPLICATIONS

When installed as a rear vent unit this appliance may be

vented directly to a termination located on the rear wall

behind the appliance.

• Only Vermont Castings Group approved venting com-

ponents are approved to be used in these applications

(Refer to ‘Venting Components’ listed for different installation requirements).

• The maximum horizontal distance between the rear of

the appliance (or end of the transition elbow in a corner application) and the outside face of the rear wall is

20" (508 mm). Figure 23

• Only one 45° elbow is allowed in these installations.

• Minimum clearances between vent pipe and combus-

tible materials are as follows:

Top – 3" (76 mm), except at outside wall 1" (25 mm)

Sides – 1" (25 mm)

Bottom – 1" (25 mm)

Rear Vent Top View

20”

(508 mm)

Max.

Figure 23 –

Rear Vent Application, No Elbows

20”

(508 mm)

Max.

FP3002

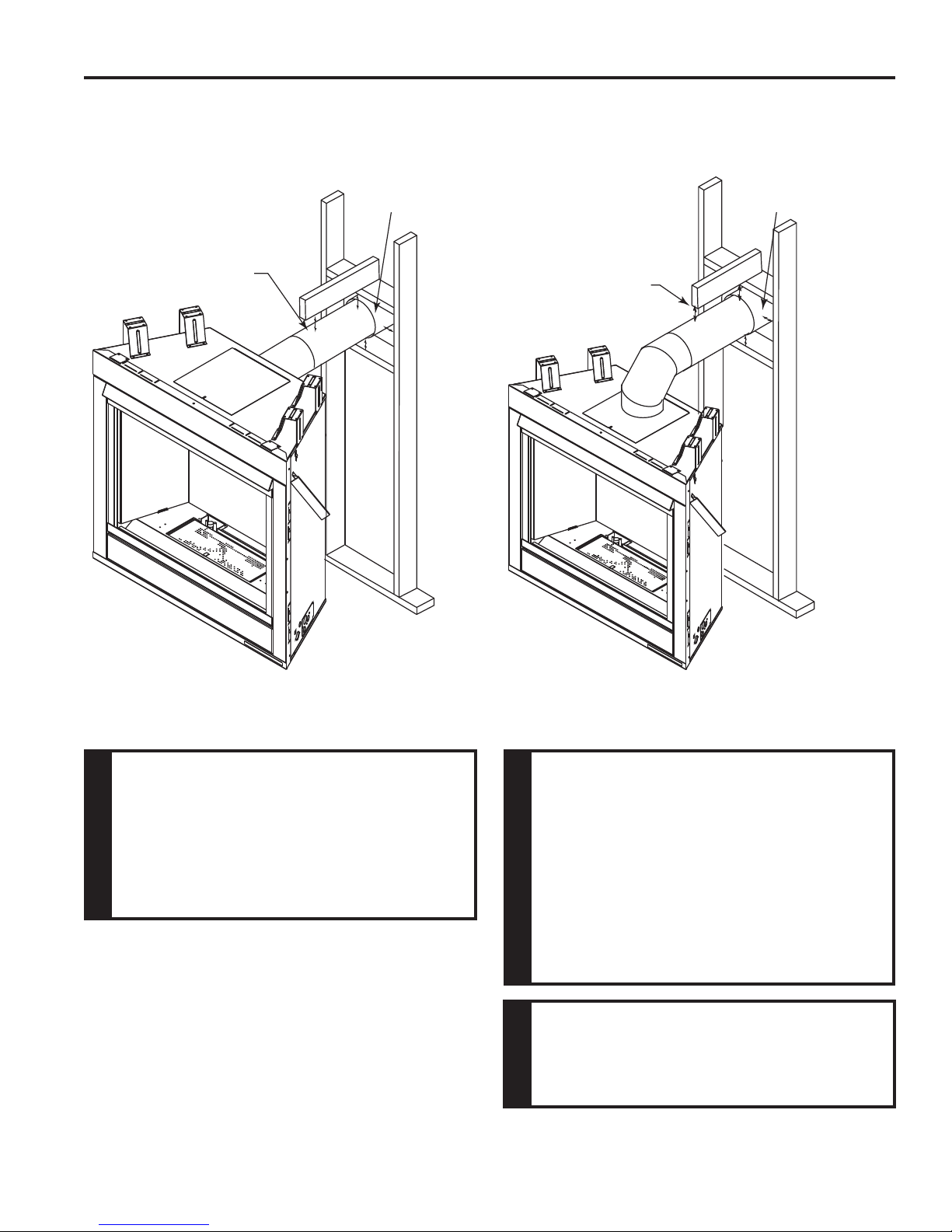

REAR WALL VENT INSTALLATION – TWIST

LOCK PIPE

Step 1

Locate and cut the vent opening in the wall.

For combustible walls fi rst frame in opening. Figure 24

NOTE: When using fl ex vent, the opening will have to be

measured according to the 1" (25 mm) rise in 24" (610

mm) vertical run.

Combustible Walls: Cut a 95⁄8" H x 95⁄8" W (244 x 244

mm) hole through the exterior wall and frame as shown.

Figure 24

Noncombustible Walls: Hole opening should be 71⁄2"

(191 mm) diameter.

Vent Opening for Combustible Walls

95⁄8"

(244 mm) Min.

95⁄8"

(244 mm)

Min.

Fireplace Hearth

Opening for Noncombustible Wall

71⁄2"

(190 mm)

Figure 24 –

Locate vent opening on wall

Fireplace Hearth

Framing Detail

FP2293

Step 2

Secure fi restop to the inside frame, center in the 95⁄8" x

95⁄8" vent opening.

Step 3

Measure the horizontal length requirement for the venting

including a 2" (51 mm) overlap, i.e. from the elbow to the

outside wall face plus 2" (51 mm). Figure 25

Step 4

Install the 4" (102 mm) vent to the appliance collar and

secure with 3 sheet metal screws. Install the 7" (178 mm)

vent pipe to the appliance collar and secure with 3 sheet

metal screws. It is not necessary to seal this connection.

If a 45° elbow is being used attach the elbow to the appliance in the same manner then attach the venting to the

elbow.

It is critical that there is no downward slope

away from the appliance when connecting

the vent or elbow.

Step 5

Guide the venting through the vent hole as you place the

appliance in its installed position. Guide the 4" (102 mm)

and 7" (178 mm) collar of the vent termination into the

outer ends of the venting. Do not force the termination. If

the vent pipes do not align with the termination, remove

and realign the venting at the appliance fl ue collars. Fig-

ure 25. Attach the termination to the wall as outlined in the

instruction sheet supplied with the termination.

18

20305832

Loading...

Loading...