Page 1

Inner Top Replacement

Installation Instructions

Kit #0016

for the Dutchwest ExtraLarge Convection Heaters

General Information

The two-piece inner top kit for the Dutchwest ExtraLarge convection Heater fits 1990-93 units (model

2184, with two front doors) and 1993-97 units (model

2460, with a single front door).

The sides, front and inner back of the stove trap the inner top. Replacing the original style inner top requires a

complete rebuild of the stove. Once the new style inner

top is in place, if you need to replace the insert you can

do so by removing only the stove top.

Work in a clear, well-lighted area. If possible, work out

doors. If you must work indoors, use a drop cloth and

protect the surrounding area. Wear gloves, a dust mask

and protective eyewear.

Kit Contents:

• Inner top casting insert • Inner top insert

• Refractory insulator • 2 pieces of Interam gasket

• Refer to Figure 7 to identify parts.

Tools Required:

• Rubber mallet, or standard hammer and a block of

wood

• 7/16” open-end wrench

• 3/8” cold chisel, or old screwdriver

• Needle-nose pliers (for later units only)

• Wire brush, hand-held or rotary

• Stove cement and putty knife. The easiest way to apply cement is from a tube in a caulking gun. Otherwise, use a putty knife to apply cement from tube.

• Penetrating oil. Use Marvel Mystery Oil, Liquid

Wrench or similar; WD-40 is not strong enough for

this work.

• Automotive anti-seize compound

• Shop Vac with very good filter. Do not use a regular

household vacuum on soot - it is fine enough to pass

right through most common filters.

• Drop clot or tarp

-

Disassembly Procedure

1. Make sure the stove is completely cool before you

begin. Remove ashes and dispose of them properly.

An empty ashpan is a handy tray for hardware and

small parts.

2. Remove the probe thermometer from the stove

top. Some units have a small chrome sleeve on the

probe shaft; be sure to keep track of this if it is loose.

3. Lift off the front door(s) and the side door. You can

remove the doors by wiggling them back and forth,

and lifting at the same time.

4. Unfasten and remove the top. (Fig. 1) A bolt at each

corner holds the top to the rest of the stove body.

There is a gasketed seal between the stove top and

the rest of the body. Lift off the stove top and set it

aside, upside down. Check the gasket for compression or wear; replace if necessary.

Loosen

all four(4)

Bolts Before

Removal

Loosen, then

ST790

Fig. 1 Remove four (4) bolts to release the stove top.

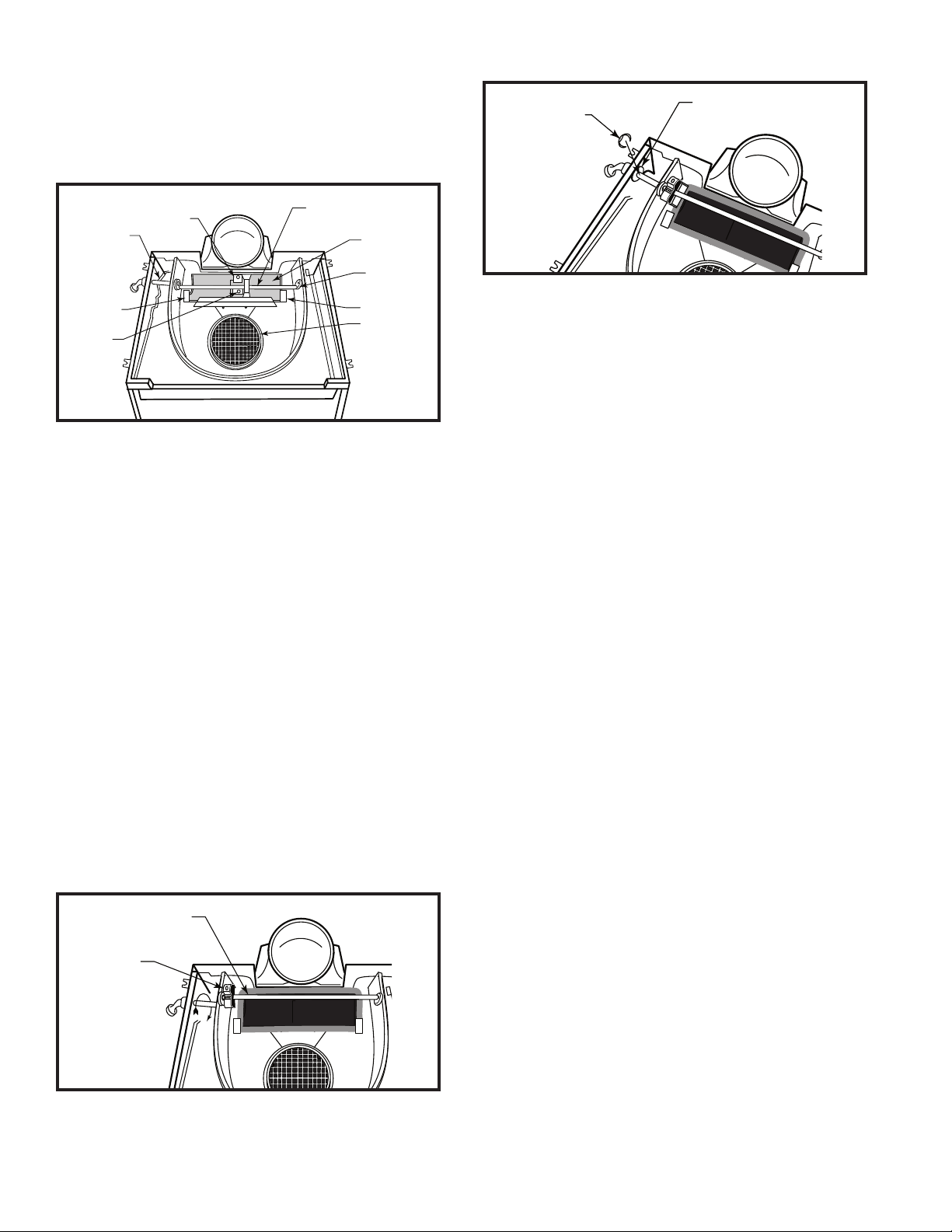

5. Lift out the decorative front brass bar, the refractory

insulator and the catalyst. (Figs. 2 and 3) Be careful

with the catalyst, as it is fragile. Place the insulator

in a sealed plastic bag pending disposal. Check the

combustor for major cracking or crumbling. Refer to

the stove manual for details on evaluating the catalyst.

From this point on, penetrating oil will help to release

hardware. Use automotive anti-seize compound

when you replace hardware, to ease future repairs.

Fig. 2 Remove the refractory insulator.

remove these

bolts

Refractory

Insulator

7001208 8/08 Rev. 3

Page 2

Remove the anchor bolt and nut joining the damper

to the damper adjuster; open the damper or reach

through the firebox to get at the nut. The rearward

bolt in the base of the adjuster is the adjusting bolt;

leave it in place. (Fig. 3)

C-Clip

Washer

Adjusting

Damper Rod

Steel Tab

Anchor

Bolt

Fig. 3 Catalyst, damper and associated parts.

Bolt

Damper Crank

Damper

Damper

Adjuster

Steel Tab

Catalyst

ST792

Remove the two bolts holding the steel tabs which

capture the pivoting ends of the damper, and remove

the damper. (Fig. 3)

Rotate the damper crank forward and flip the damp

er adjuster upside down. Slide the adjuster to the left

end of the crank. (Figs. 4 and 5)

Check the steel damper rod where it passes through

the left side of the stove. Early style rods have

threads where they pass through the left inner side

of the stove. Later units have a retaining clip in a

groove on the rod, just inside the left outer side. (Fig.

5)

For early units: use the stove door handle to turn the

damper rod and crank counterclockwise (as you

face the left end of the stove), till the rod unthreads

from its threaded hole. As you turn the rod and crank

through the high point of the arc, you will need to

maneuver the adjuster to clear the back plate of the

stove. When the threads on the rod clear the threaded hole, remove the rod and lift out the damper and

adjuster. Note that the illustrations show the later

style of handle, with a permanently-mounted base.

(Fig. 4 and 5)

Damper Crank

Damper

Adjuster

ST793

Fig. 4 For early units, unthread the damper rod from the

damper crank and the inner top’s inner wall.

ST794

Fig. 5 On later units, remove C-clip from damper rod.

For later units: remove the retaining clip from the steel

rod. Pull the rod out of the stove, then remove the

damper crank and the damper adjuster (Fig. 5)

5. Unfasten the stove front. There are nuts and wash

ers on threaded studs on the insides of the front/

sides joints; sometimes these are above the inner

top /front joints. Sometimes they are below this joint

(inside the firebox). There are two studs on each

side.

6. Break the cement seal around the stove front. From

inside the stove, tap outward along the seams

between the front and the stove sides, and between

the front and the inner top. Use either a rubber mallet or a hammer and a wooden block to cushion the

impact. Have a helper hold the top edge of the stove

front to keep it from falling when the cement seal

is completely broken. With the seal broken, lift the

front panel off the stove, and set it down flat, with

its outer side down; do not set it on its bottom edge,

as this can damage the ash door hinges. On stoves

with a single front door there is an air channel and

primary air valve fastened to the inside of the stove’s

front panel. Leave these in place on the stove front,

and be careful to avoid any impact on the air valve

handle.

7. Remove the right-hand side of the stove (as you

face the stove). Inside the firebox, use a wooden

prop to support the inner top. There is a nut and

washer on a threaded stud where the right side

meets the stove back; remove the nut and washer

and leave the stud in place. Tap outward, from inside

the firebox, to break the cement seal. With the seal

broken, pull the side away from the rest of the firebox, and set it down with its inner side up.

8. Now all that holds the inner top in place is the

wooden prop, and cement along its left and rear

edges. Grasp the inner top and wiggle it back and

forth while pulling toward yourself at the same time.

Watch that the supporting prop doesn’t fall out of

place. When the inner top comes loose, set it down

on a protected spot on the floor.

9. Remove the inner top channel cap by unbolting it

(from the underside of the inner top). You may need

2

Page 3

to tap it gently to release it from the inner top. Remove the steel air distributor by wiggling it out of its

socket in the inner top . (Fig. 7)

10. Use a cold chisel or old screwdriver to chip out the

old cement from joints on the right side, the front, the

top edge of the inner back and the inside of the left

side (including around the hole where the catalyst air

enters). Also remove cement from the upper edges

of the inner top channel cap, and from the forward

vertical edges of the panels that form the ashpit.

You do not need to get down to bare metal, but you

must clear a deep and continuous channel so there

is room for the new cement and a good tongue-andgroove joint.

Cement is a clay-based material; it dries and becomes

brittle. Pieces can have sharp edges, so be sure to

wear goggles. It is also dusty, so wear a dust mask or

respirator. If there was originally cement in the joint

between the stove’s right side and the outer back, you

should remove it but you need not replace it.

Reassembly Procedure

1. Do a ‘dry run’ of Step 2 - 6 to familiarize yourself with

them before applying cement.

2. You may notice a gap between the new inner top

and the new insert. There is a piece of ‘Interam’ gas

ket in this gap. Interam is a thin material resembling

felt; when it is first heated it expands greatly, to form

a flexible seal between cast iron parts. Any apparent

gaps will fill when the Interam expands under heat.

Apply cement to the upper edges of the inner top

channel cap. From the top, slide the air distributor

into its slot on the left side of the insert, and fasten

the inner top channel cap to the underside of the

new inner top with its original bolt. The channel cap

must capture and hold the air distributor.

Apply stove cement to the grooves on the left side,

where it supports the inner top, and on the top edge

of the inner back. Apply cement to the inside of the

left side, where the inner top channel cap abuts the

left side. Slip the inner top into position, using a prop

to support its right edge.

3. Apply cement to the grooves on the inside of the

stove’s right side, where it meets the inner top, inner

back and inner bottom of the stove. You do not need

to cement the joints between the right side and the

back or bottom of the stove, since these are not a

seal between the firebox and the room.

4. Put the right side into position, bottom edge first, and

secure it with a nut and washer on a threaded stud

where the side meets the outer back. Be sure the

side engages the inner firebox parts. Gentle pressure from a bar clamp will help ensure the right side

is fully mated against the inner parts.

5. Apply cement to the inside of the front panel, in the

seams where the panel meets the inner top, where

it meets the inner bottom, and where it meets the

stove sides. Also apply cement to the forward edges

of the two vertical walls around the ashpan.

6. Position the stove front on the stove. Lower the bottom edge of the panel into place first, in the channel

on the stove bottom, then swing the panel toward

the stove body. Be sure to avoid any pressure on

the ashdoor. The threaded studs on the inside of the

panel will pass through slots on the forward edges

of the stove sides. Fasten the front into position with

nuts and washers on the two threaded studs on

each side.

7. Install the damper crank and adjuster. Pass the

crank through the adjuster before you put its right

end into a hole in the catalyst chamber wall (the inner wall of the inner top).

8a. For early units: pass the steel damper rod through

the hole in the left side of the stove. Turn it clockwise (as seen facing the left side of the stove) until

its square end engages the square socket in the left

end of the iron damper crank. When the square end

engages the crank, turn both parts together, until

-

most of the threads on the rod engage the threads in

the inner top. While you spin the crank, the adjuster

should be upside down, and at the left end of the

crank.

8b. For later units: pass the steel damper rod through

the hole in the left side of the stove. Place the large

washer on the rod, inside the stove. Then slide the

square end of the rod through the catalyst chamber

wall and into the square socket on the left end of the

damper crank. When the parts are oriented properly,

both the handle and the crank should point downward.

Push the washer against the inside of the stove’s left

side, and use needle-nose pliers to put the retaining clip into the groove in the rod, to lock the rod in

place.

Damper Rod

Fig. 6 Install the damper rod and washer (later units).

Washer

Damper

Crank

ST795

3

Page 4

9. Turn the damper crank to its highest position and

install the damper, secure it at each end with a steel

tab held in place with a hex head bolt. (Fig. 3)

10. Join the damper adjuster to the damper with a hex

head bolt and a nut. The bolt passes through the forward hole in the base of the adjuster; the nut attaches to the bolt on the underside of the damper. Open

the damper or reach through the firebox to reach

the nut. Use the damper handle to test the damper

for smooth operation and adjust as needed; the

rearward bolt in the base of the adjuster regulates

the pressure on the damper. Loosen the forward

(anchor) bolt on the damper. Turn the adjusting bolt

clockwise to tighten the damper. However, do not

overtighten; the metal parts will expand under heat.

The damper should be snug, but not tight, when

the stove is cold. Use a piece of paper between

the damper and its gasket to gauge how tight the

damper is. When the damper is adjusted properly,

tighten the anchor bolt and its nut.

11.Put the catalytic combustor in place in the inner top

insert, with a piece of ‘Interam’ gasket around its bot

tom edge. (Fig. 7) Put the new refractory insulator in

place over the catalyst; note that its forward bottom

edge is slightly relieved in the center, to accommodate the new style insert. The original insulator is not

relieved.

12. Put the decorative brass bar in place in pockets at

the sides of the slot across the top edge of the front

panel.

13. Fasten the outer top into position with bolts and

washers at the corners of the top. The bolts should

be snug, but not tight; overtightening can bow the

top, leading to smoke leakage, and it can also snap

the extensions on the stove sides.

14. Remove any cement which has squeezed out from

any joints onto the outside of the stove. You do not

need to remove squeeze-out on the inside of the

stove.

15. Hand-turn a 1/4” drill bit, through the hole in the

outer top and through the new refractory insulator.

Avoid hitting the catalyst. Replace the probe thermometer, and its chromed sleeve if you took it out.

Do not simply punch the thermometer through the

insulator, this can break off a piece on the underside

of the insulator.

16. On Model 2184 (which has two front doors), make

sure the rocker grates can rotate freely. If they are

jammed, check the position of the loose grate frame

over them. If you need to move this frame, remove

the ‘grate back’ and the right inner half-wall (if so

equipped). Each of these panels mounts with two

hex head bolts. You will probably need penetrating

oil to loosen these bolts. With these two panels removed, prop the rear edge of the grate frame up out

of the way so you can properly position the rocker

grates. Be careful with your hands when you lower

the grate frame into position over the rocker grates.

Replace the grate back and right inner half-wall.

17. Replace the front door(s) and the side door; simply

slide their hinge pins into place on stubs on the front

and side panels. Do not strike them sharply with

any object. You may need to wiggle the doors back

and forth while pressing downward to seat the doors

properly.

18. Let the cement dry for at least 24 hours. When you

fire up the stove, treat it as a new one because of

the new cast iron parts; ‘cure’ it with four to six small

fires before you resume regular burning. Each fire

should be about 100° hotter and an hour longer than

the previous one. Use a surface thermometer on the

side door as your guide to firebox temperatures. The

-

probe thermometer in the stove top registers catalyst

temperatures, which are much higher than firebox

temperatures.

19. Discard the original inner top, baffle and refractory

insulator.

Top

Refractory

Insulator

Catalyst

‘Interam Gasket’

Inner Top

Inner Top

Channel

Cap

Inner Top Insert

Fig. 7 Inner top and associated parts.

Air Distributor

‘Interam Gasket’

ST796

MHSC

149 Cleveland Drive • Paris, Kentucky 40361

4

www.mhsc.com

Loading...

Loading...