Vermont Casting WOOD STOVE User Manual

OWNERS MANUAL

CFM Corporation

HIGH EFFICIENCY

AIR TIGHT WOOD STOVE

SAFETY NOTICE

IF THIS WOOD BURNING APPLIANCE IS NOT PROPERLY

INSTALLED, A HOUSE FIRE MAY RESULT.

FOR YOUR SAFETY, FOLLOW THE INSTALLATION

DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT

RESTRICTIONS AND INSTALLATION INSPECTION

REQUIREMENTS IN YOUR AREA.

THIS UNIT IS NOT MOBILE HOME APPROVED.

made in

CANADA

6" FLUE REQUIRED

SAVE THIS MANUAL FOR FUTURE REFERENCE

CAUTION

After reading these instructions, if you have any doubt about your ability to complete your installation in a

professional like manner you should obtain the services of an installer versed in all aspects as to the

correct and safe installation.

Do not use temporary makeshift compromises during installation.

BEFORE INSTALLATION OF YOUR APPLIANCE

1. HOT WHILE IN OPERA TION. KEEP CHILDREN, CLOTHING AND FURNITURE A WAY . CONTACT

MAY CAUSE SKIN BURNS.

2. DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS.

3. Check with the building inspector’s office for compliance with local codes; a permit may be required.

4. This appliance requires a masonry or prefabricated chimney listed to ULC S629 (Canada) and Ul103ht

(U.S.) Sized correctly .

5. A 6" (152mm) diameter flue is required for proper performance.

6. Always connect this unit to a chimney and NEVER vent to another room or inside a building.

7. DO NOT connect to any duct work to which another appliance is connected such as a furnace.

8. DO NOT connect this unit to a chimney flue serving another appliance.

9. DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE.

10. The connector pipe and chimney should be inspected periodically and cleaned if necessary .

1 1. Remember the clearance distances when you place furniture or other objects within the area. DO

NOT store wood, flammable liquids or other combustible materials too close to the unit.

12. Contact your local municipal or provincial fire authority for information on how to handle a chimney fire.

Have a clearly understood plan to handle a chimney fire. In the event of a chimney fire, turn air control

to closed position and CALL THE FIRE DEPARTMENT.

13. DO NOT tamper with combustion air control beyond normal adjustment.

14. Once the required draw is obtained, operate only with doors closed and open doors slowly when refueling. (This will reduce or eliminate smoke from entering the room).

15. DO NOT install these units in a mobile home or trailer . These units are NOT mobile home approved.

3

OPERATION

WHY THE CORRECT FLUE SIZE IS IMPORTANT - 6"

Draft is the force which moves air from the appliance up through the chimney . The amount of draft in your

chimney depends on the length of the chimney , local geography , nearby obstructions, and other factors.

T oo much draft may cause excessive temperatures in the appliance. An uncontrolled burn or a glowing

red part or chimney connector indicates excessive draft. Inadequate draft may cause back puffing into

the room and “plugging” of the chimney and/or cause the appliance to leak smoke into the room through

appliance and chimney connector joints.

T oday’s solid fuel appliances are much more efficient than in the past. The units are designed to give you

controlled combustion, as well as maximum heat transfer, using less fuel to do so.

The design of your new appliance is such that the exhaust “smoke” is now at lower temperatures than in

the past, therefore requiring proper chimney size to give adequate draft. If your chimney is too large, the

heating appliance will have a difficult time to raise the “chimney flue” temperature to give adequate draft,

therefore causing a smoke back up, poor burn, or both.

Should you experience such a problem call in a local chimney expert.

With the door closed, the rate of burning is regulated by the amount of air allowed to enter the unit through

the air control. With experience you will be able to set the control for heat and burning time desired.

Attempts to achieve higher output rates that exceed heater design specifications can result in permanent

damage to the heater. The recommended wood load is level with the top of the firebricks. Overloading

may prevent sufficient air entering the heater to properly fuel the fire.

Do not tamper with combustion air control beyond the normal adjustment capacity .

Operate this heater only with the door closed.

ALWAYS PROVIDE A SOURCE OF FRESH AIR INTO THE ROOM WHERE THE UNIT IS

INSTALLED. FAILURE TO DO SO MAY RESULT IN AIR STARVATION OF OTHER FUEL

BURNING APPLIANCES AND THE POSSIBLE DEVELOPMENT OF HAZARDOUS

CONDITIONS.

THIS HEA TER IS EXTREMEL Y HOT WHILE IN OPERA TION. SERIOUS BURNS CAN RESUL T

FROM CONTACT. CAUTION SHOULD BE OBSERVED ESPECIALLY WHEN CHILDREN ARE

PRESENT .

OPTIONAL BLOWER: MODEL S31105

120 VOLTS, 60Hz, 0.75 AMPS, 2900 RPM

DANGER: RISK OF ELECTRIC SHOCK. DISCONNECT POWER BEFORE SERVICING UNIT .

IMPORT ANT: FOR OPTIMUM HEA TER PERFORMANCE A T “LOW” BURN RA TE, OPERATE THE F AN A T LOW SPEED.

4

INSTALLATION

1. Remove all parts from inside the stove body .

2. Select the proper location for the stove. These appliances must not be installed any closer than the

minimum clearance to combustible materials shown in Figure A (on diagram sheet). The stove must be

installed on a non combustible surface as shown in Figure A (on diagram sheet).

FAILURE TO FOLLOW THE MINIMUM CLEARANCE REQUIREMENTS MAY RESULT IN AN

UNSAFE INSTALLATION.

3. If non combustible materials have been installed on the walls, obtain the minimum clearances from

either the manufacturer of these materials or the local building inspectors office.

4. Install the refractory bricks (see Figure B on diagram sheet).

5. Install the stovepipe INSIDE the flue collar on the top of the stove between the stove and chimney .

6. DO NOT use a grate to elevate the fire.

STOVE PIPE

1. A clearance of 18 inches (457mm) between the stovepipe and combustible materials may be required.

Check with authorities having jurisdiction in your area.

2. All pipe sections must be connected with the male end (crimped end) toward the stove.

3. Fasten the stove pipe to the flue collar by the use of three sheet metal screws. Do the same at each

additional joint to make the entire installation rigid.

4. Maintain the required diameter flue for the entire installation.

5. If you are connecting the stove to an old masonry flue, be sure to have it inspected for cracks and

general condition. Resizing with a stainless steel liner may be required.

6. It is recommended that no more than two 90 degree bends be used in the stovepipe installation. More

than two 90 degree bends may decrease the amount of draw and possibly cause smoke spillage.

7. A damper is not required in this installation. Remove damper plate in the chimney or secure in the

OPEN position.

8. Single wall flue pipe assemblies must not exceed 10 feet (3 metres) in overall length.

5

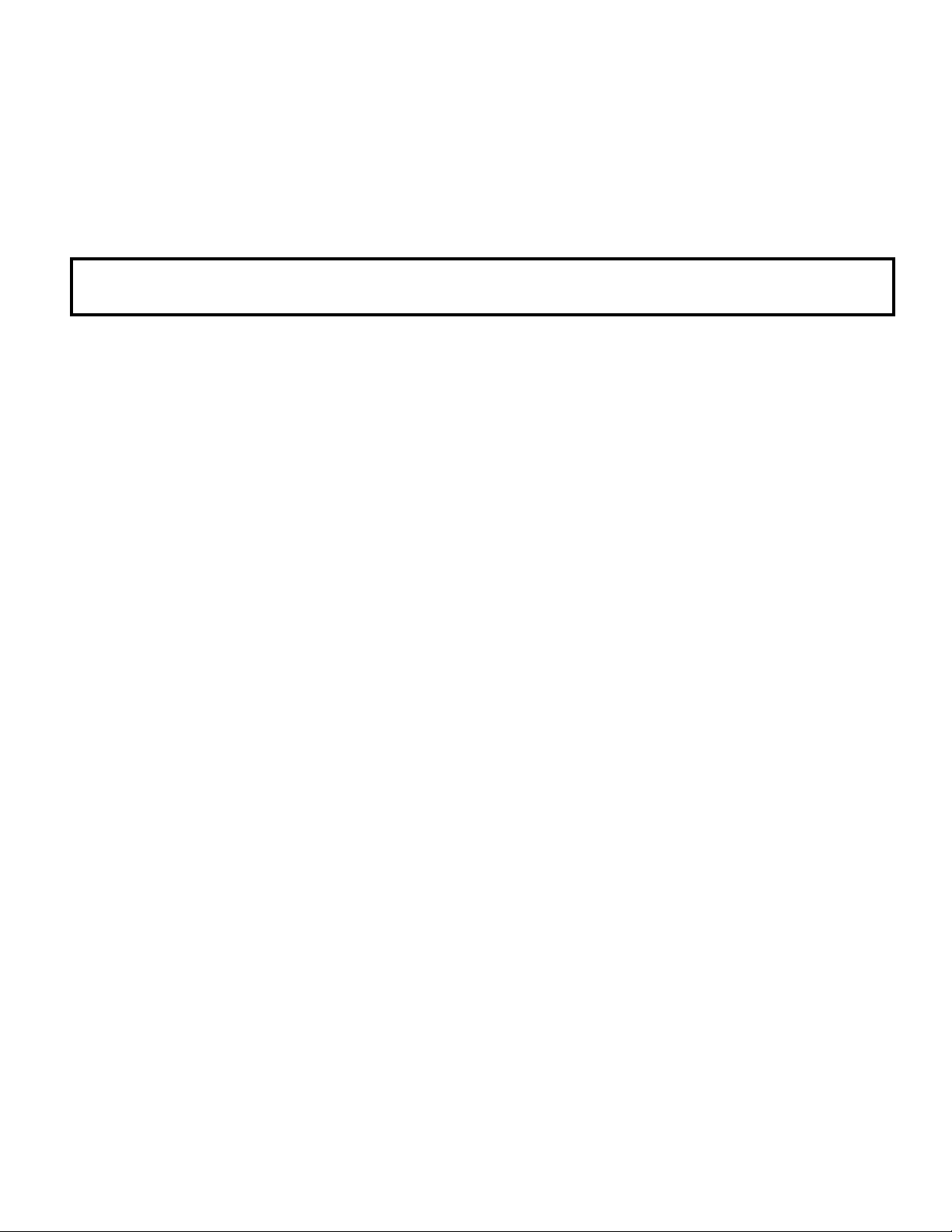

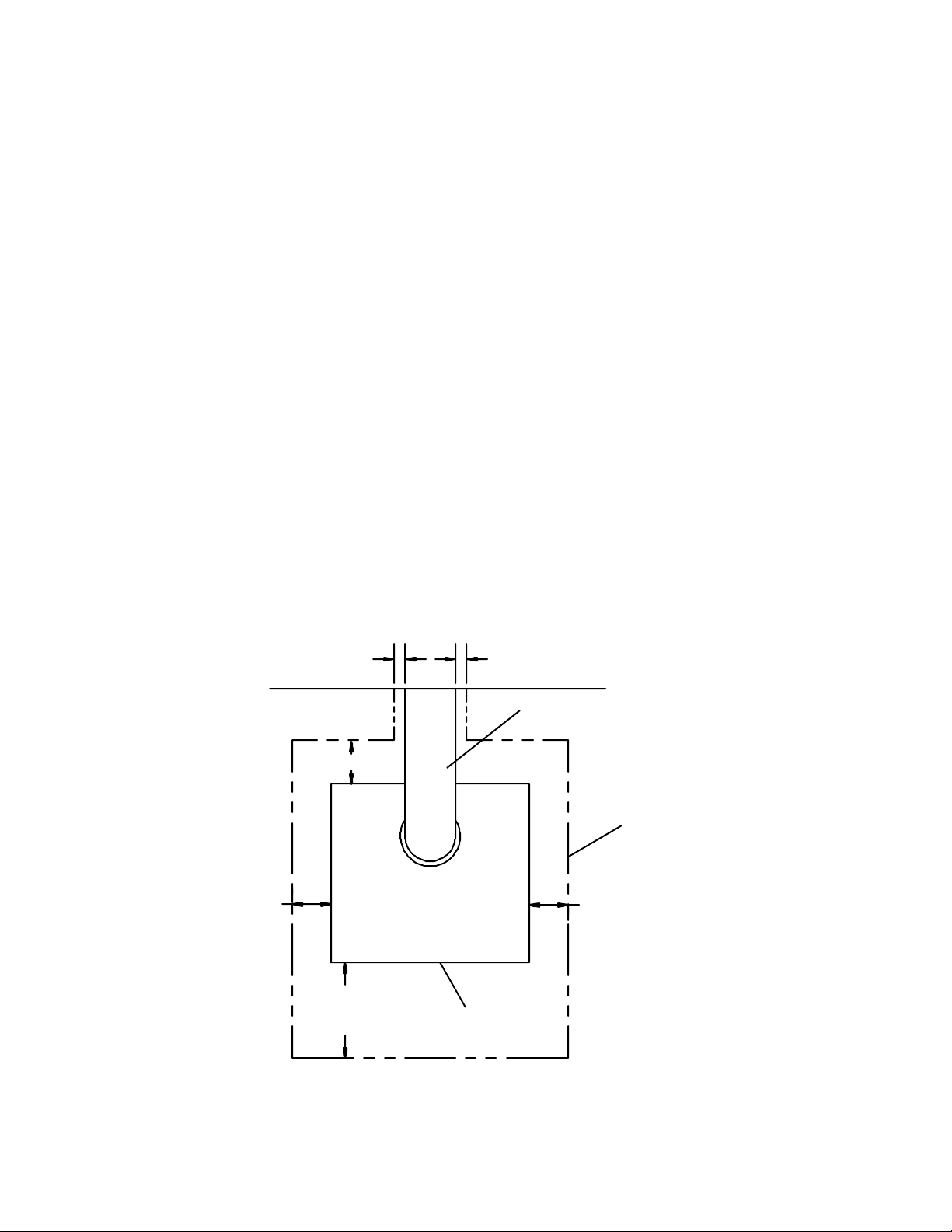

Floor Protector

Installation on a Concrete Floor

An appliance mounted on a concrete floor does not require floor protection.

Carpeting and any other combustible material shall not cover the Floor Protector .

If a combustible surface is applied to the concrete floor, a clearance must be maintained equivalent to the

area reserved for the floor protector. See diagram below .

Installation on a Combustible Floor

If the appliance is to be installed on a combustible floor or a combustible floor covering, it must be installed

on a 3/8”(10mm) thick non-combustible millboard floor protector or durable equivalent. The pad must be

installed beneath the appliance extending 18”(457mm)in Canada, 16”(406mm) in the U.S. on any side

equipped with a door, and 8”(203mm) on all other sides. In the U.S. the pad must cover any horizontal

chimney connector runs and extend 2”(51mm) beyond each side.

A grouted ceramic floor-tile surface installed per local building code is considered a durable equivalent.

2” (51mm) 2” (51mm)

Wall Line

Chimney Connector

8” (203mm)

Floor Protector

8” (203mm)

8” (203mm)

*18” (457mm)

**16” (406mm)

* CANADA

** UNITED ST A TES

Door Side of

Appliance

6

Loading...

Loading...