Page 1

STR/CVR Series

Woodburning Fireplace

Homeowner's Installation

and Operating Manual

For Models:

STR33

STR36

For use in U.S./Canada

Underwriter's Laboratories

Report No. MH6018

STR42

CVR36

CVR42

DO NOT DISCARD THIS MANUAL: Retain for future use.

7412961 3/06 Rev. 15

Page 2

STR/CVR Series Woodburning Fireplaces

Safety Information

PLEASE READ THIS MANUAL BEFORE INSTALLING AND USING FIREPLACE.

IMPORTANT:

Read all instructions and warnings carefully before starting installation. Failure to

follow these instructions may result in a possible fire hazard and will void the warranty.

Description

The STR/CVR Series fireplaces are multi-side solid fuel,

woodburning fireplaces. These are radiant models only

and include a preinstalled outside air kit.

Precautions

Majestic Fireplaces and component parts have been

highly tested and will operate safely when installed in

accordance with instructions provided in this manual.

Carefully read and understand all instructions before

beginning installation.

If you notice any damage to fireplace or component parts,

immediately report damage to your Majestic Fireplaces

dealer.

Only use CFM Corporation components or the warranty

will be voided and a fire hazard may be created.

CFM Corporation warranty will be voided by and CFM

Corporation disclaims any responsibility for the following

actions:

• Installation of any damaged fireplace or chim-

ney component;

Do not install a solid fuel burning insert or other

products not specified for use with this fireplace.

Proposition 65 Warning: Fuels used in gas, wood-

burning or oil fired appliances, and the products of

combustion of such fuels, contain chemicals known to

the State of California to cause cancer, birth defects

and other reproductive harm.

California Health & Safety Code Sec. 25249.6

WARNING: Check with your electronics manufacturer before installing a television or other electronic

device above this fireplace.D

Drafts

The fireplace should not be located in areas that create

drafts (ie: frequently opened doors and central heating air

inlets/outlets) that hamper the normal flow of air into the

fire.

Gas Logs

If you plan to install a gas log, the gas line should be

installed before framing the fireplace. The gas line must

be installed by a certified gas line installer.

• Modification of fireplace, chimney assembly or

any component parts thereof; (except for chase

flashings as detailed in the Chimney Top installation instructions).

• Installation other than as instructed by CFM

Corporation; or

• Installation and/or use of any component part

not manufactured or approved by CFM Corporation in combination or assembly with a Majestic Fireplaces fireplace system, notwithstanding

any independent testing laboratory or other

third party approval of such component parts

or accessory.

Any such action may possibly cause a fire hazard.

Consult local building codes to ensure that you are in

compliance before installing the fireplace.

Fireplaces must be vented to the out-of-doors.

Do not obstruct or modify air inlets/outlets in any

manner.

Do not install combustible materials on any of the

black fireplace surround.

Burn only solid wood fuel or gas logs.

Units: EC20R0, FC20R0, GC20R0, FD20R0, GD20R0

Safety Information . . . . . . . . . . . . . . . . . . 2

Specifications and Framing

Parts Identification

Chimney Requirements . . . . . . . . . . . . . 6

Planning Information . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Replacement Parts . . . . . . . . . . . . . . . . 20

Accessories . . . . . . . . . . . . . . . . . . . . . 22

STR33 / STR36 / STR42

CVR36 / CVR42

Listed

UL 127 / ULC-S610

Standard for Factory Built Fireplaces

Table of Contents

. . . . . . . . . . 3

. . . . . . . . . . . . . . . . . 4

2

7412961

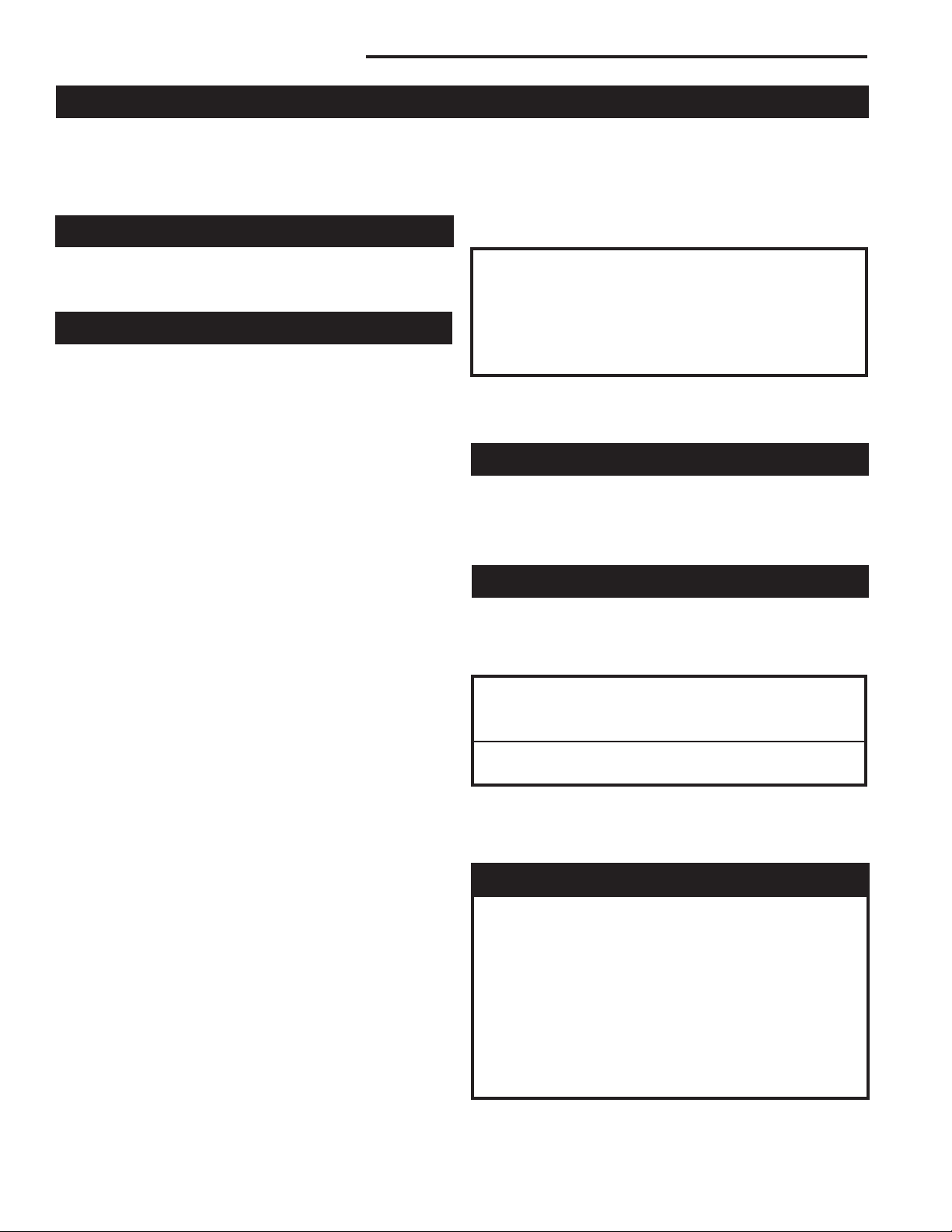

Page 3

STR/CVR Series Woodburning Fireplaces

12"

9"

A

D

E

36"

21"

37"

7"

7"

Gas Line Access

Outside

Air

14"

12"

C

12"

G

F

B

J

24" Total

Unit Width

Framing Width

Will be 24" Minus

2 x (Drywall Thickness)

18"

STR33 STR36 STR42

A 33" 36" 42"

838mm 914mm 1067mm

B 37" 40" 46"

940mm 1016mm 1168mm

C 18" 20" 23"

470mm 508mm 584mm

D 49" 49" 53"

1267mm 1267mm 1368mm

E 52" 52" 56"

1340mm 1340mm 1442mm

F 11" 11" 13"

279mm 279mm 343mm

G 8" 8" 11"

203mm 203mm 279mm

J 26" 29 " 35"

680mm 741mm 894mm

"

"

B

A

D

E

36"

"

37"

"

"

Gas Line

Access

" Total

Unit Width

"

G

F

C

Outside

Air

"

"

J

Framing Width

Will be 24"

2 x (Drywall Thickness)

18"

CVR36 CVR42

A 36" 42"

914 mm 1067 mm

B 40" 46"

1016 mm 1168 mm

C 20" 23"

508 mm 584 mm

D 49" 53"

1267 mm 1368 mm

E 52" 56"

1340 mm 1442 mm

F 11" 13"

280 mm 340 mm

G 8" 11"

203 mm 280 mm

J 29" 35"

741 mm 895 mm

STR Series Woodburning Fireplace

Fig. 1 STR Series specifications and framing.

Fig. 2 CVR Series specifications and framing.

7412961

CVR Series Woodburning Fireplace

3

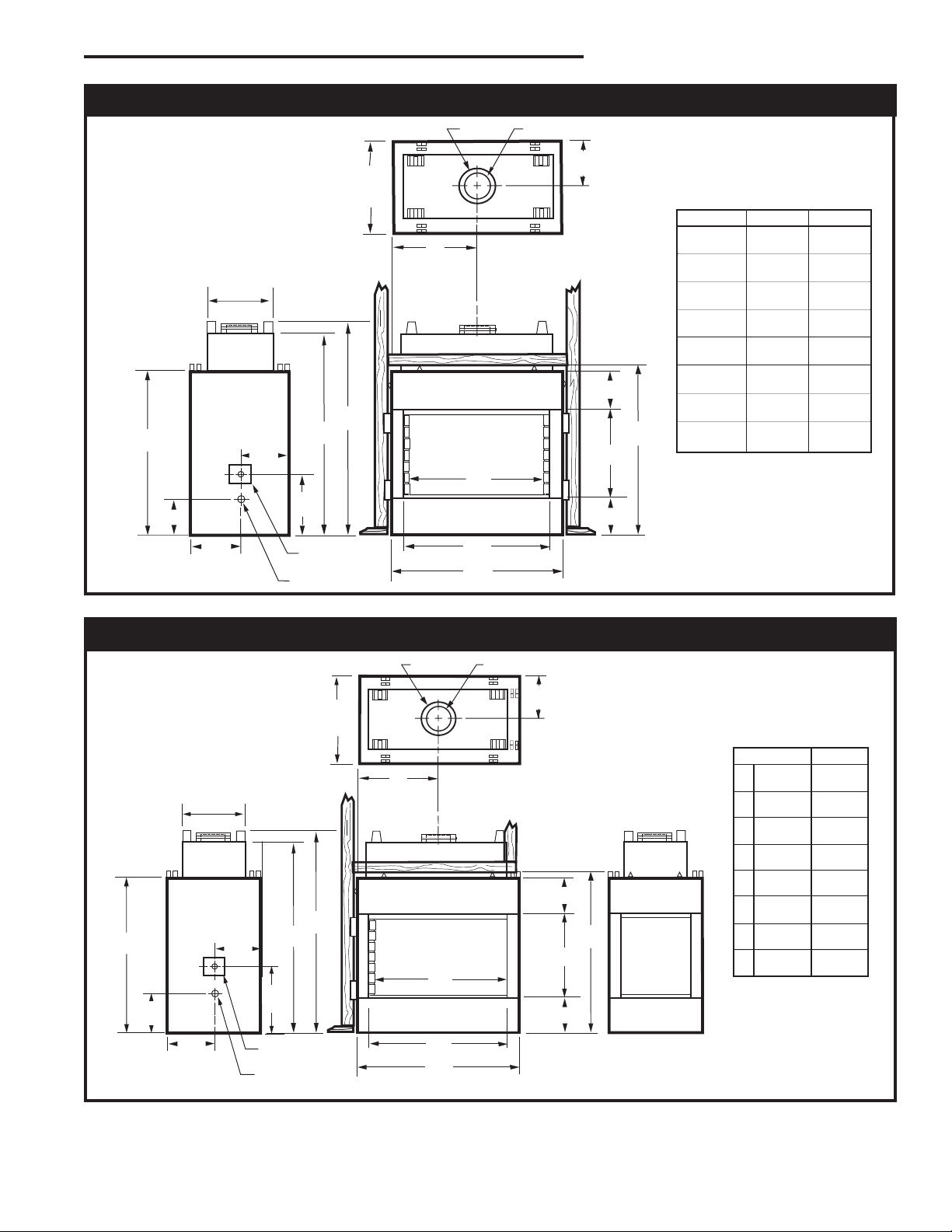

Page 4

STR/CVR Series Woodburning Fireplaces

STR Fireplace

CVR Fireplace

Gas Line

Access

Outer

Dome

Outside Air Access

Ledge

Brackets

Header

Standoffs

Flue Damper

Control

(Inside)

Flue

Damper

Flue

Collar

Outer Collar

Screen

Gas Line

Knock-out

(Both Sides)

Brick liner on

Sides and Hearth

Air Inlet

Hearth

Wood Grate

Firebox

Metal Safety Strips,

shown not in place

(1, 2, or 3 Pieces)

Outside Air

Control

Outer

Dome

A

B

STR/CVR Series Woodburning Fireplace

Fig. 3 STR/CVR Parts Identification.

Front/Back Width Side Width

A B

STR33 26" 17¹⁄₈"

(660 mm) (435 mm)

STR/CVR36 29" 17¹⁄₈"

(737 mm) (435 mm)

STR/CVR42 35" 17

(889 mm) (435 mm)

Fig. 3a Hearth dimensions.

FP1545

¹⁄₈"

FP701

4

7412961

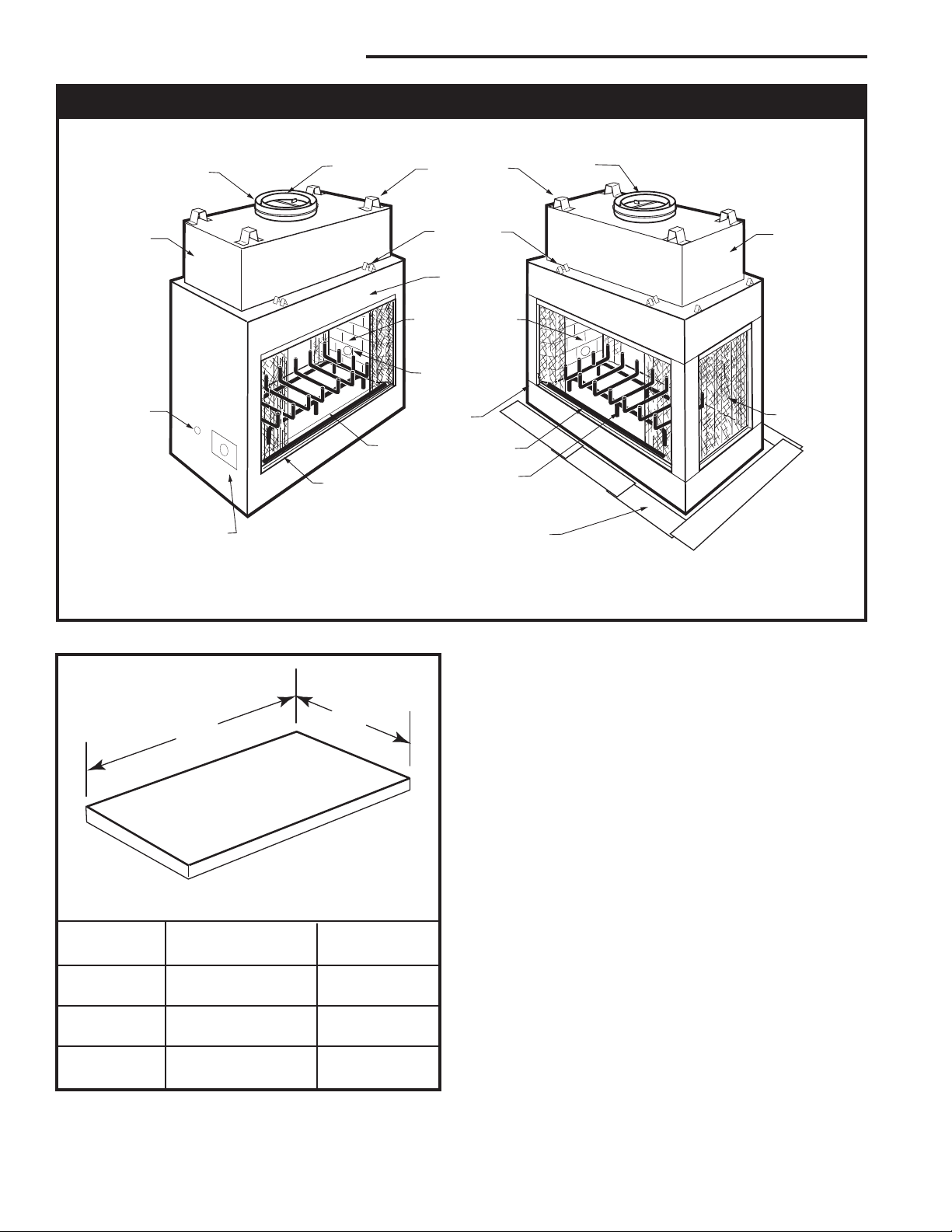

Page 5

Chase Installation

Insulation methods shown are optional

for cold climate, not a requirement for

unit operation.

Batt Insulation

(cut out around

firestop)

STR/CVR Series Woodburning Fireplaces

Termination Cap

Storm Collar

Pan Flashing

Firestop

Ceiling Level

Outer Dome

Refer to Figures 21

and 26 for clearance

information.

Ledge Brackets

Nailing Flange

Gas Access

(both sides)

Outside Air Cover Plate

Draftstop

Finish Wall

Surround

Screen

Grate

Firebox

Fig. 4 Fireplace and chase parts identification.

7412961

Outside Air

Control

FP704

5

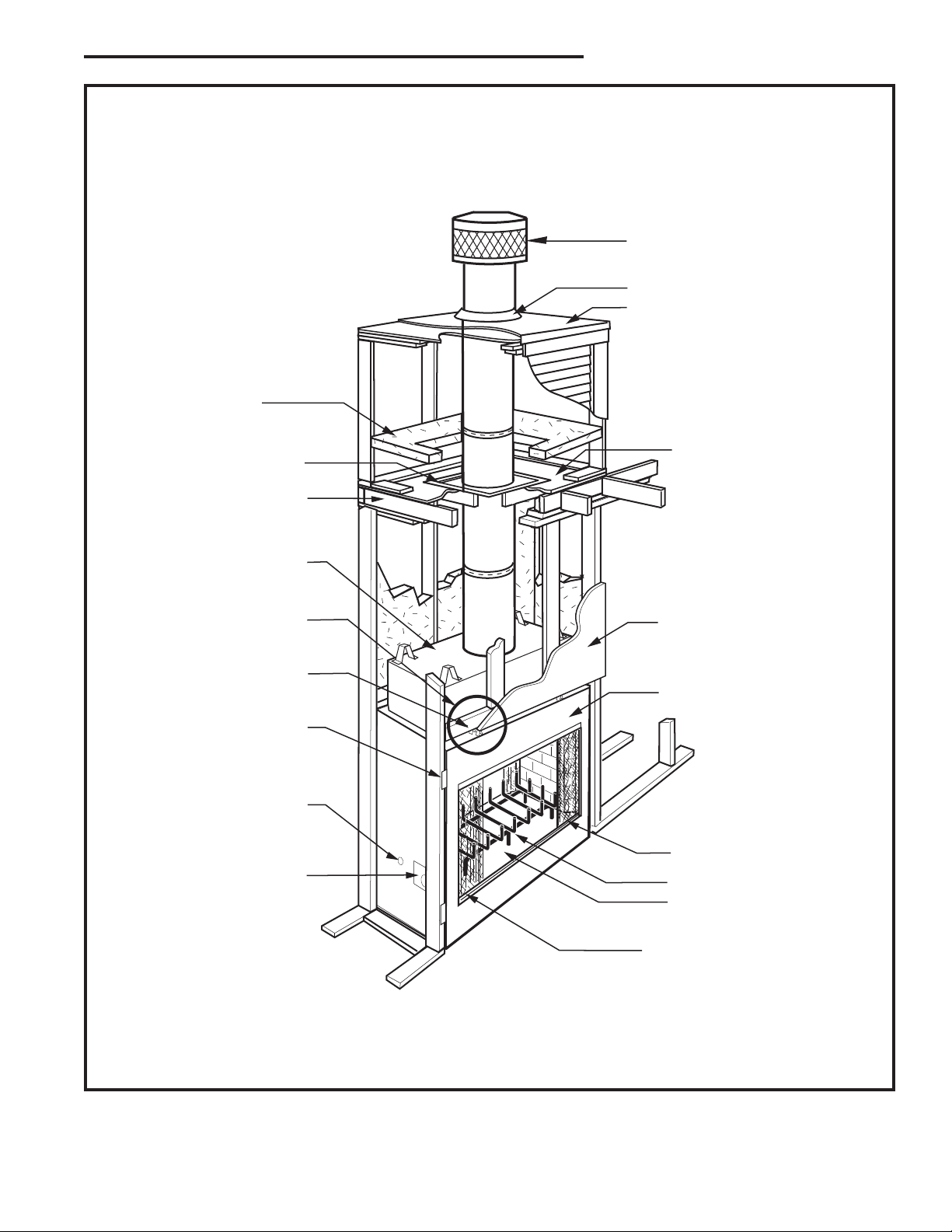

Page 6

STR/CVR Series Woodburning Fireplaces

OFFSET

RISE

D

RISE

B

G

H

B

OFFSET

C

E

6 FT.

G

H

A

HEARTH

FLOOR

CHIMNEY

SECTION

CHIMNEY FLUE EXIT

ELBOW

30˚

OFFSET

ELBOW

30˚

OFFSET

ELBOW

30˚

RETURN

ELBOW

30˚

RETURN

ELBOW

SKCS8

SUPPORT

Example 1 Example 2 Example 3

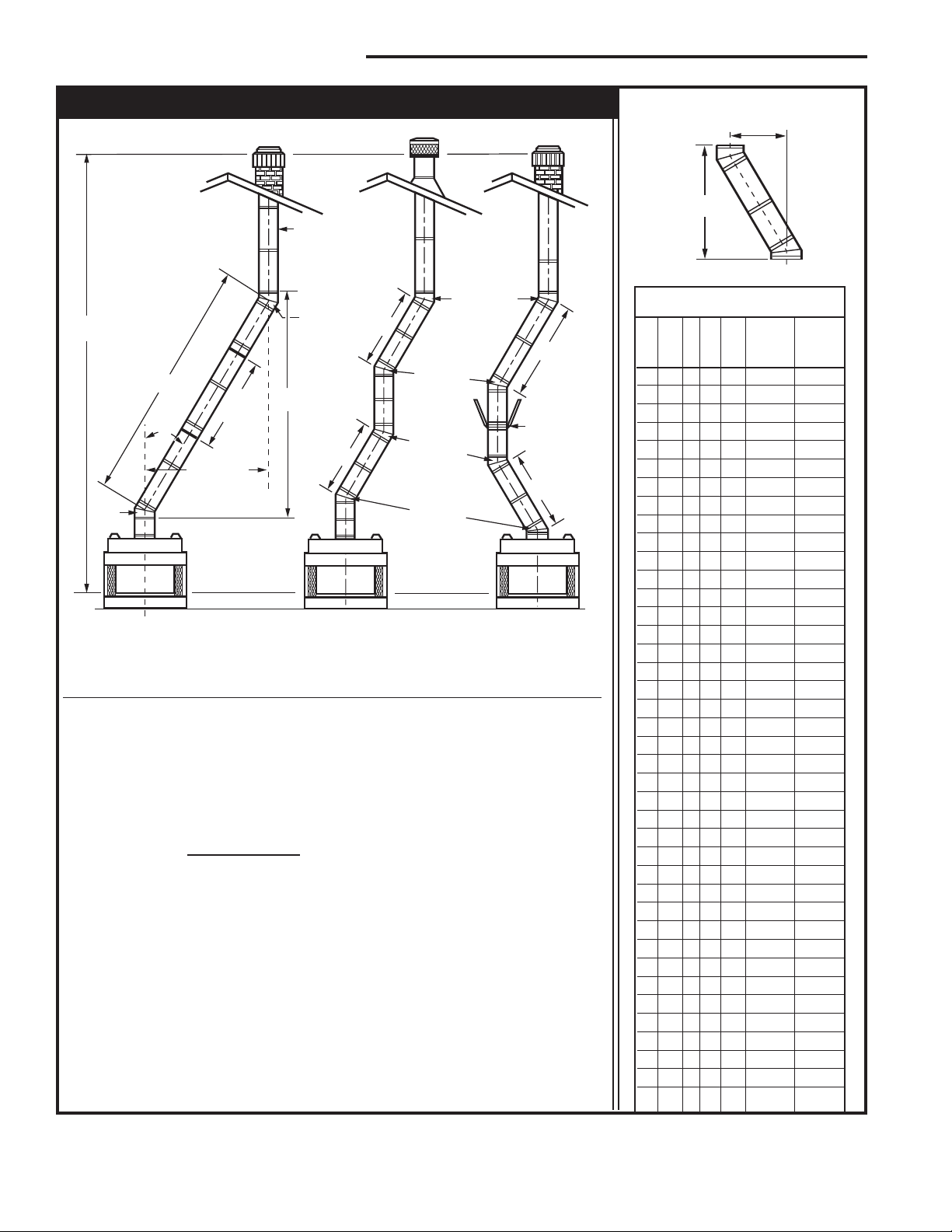

Chimney Requirements - Offset Installations

FP282

30˚ Elbow Offsets

Notes: G + H cannot exceed 20 feet.

Air Space Clearances:

SK8 (2-wall) = 1¹⁄₂" , and 11CF (2-wall) = 2"

Illustration Key

The following safety rules apply to

offset installations (letters correspond

with illustration above):

A. Height of the chimney is measured

from the hearth to the chimney exit.

Maximum: 90'0"

Minimum:

Without Elbows 15'6"

With 2 Elbows* 17'6"

With 4 Elbows* 21' 0"

B. Do not use more than 4 elbows per

chimney.

Attach the straps of the return (top)

elbow to a structural framing member.

The offset (first) elbow of any pair does

not have straps.

* In Canada, two (2) SK845 are allowed.

Fig. 5 Chimney system requirements.

6

CVR / STR Series

C. The chimney cannot be more than 30˚

(45˚ in Canada) from the vertical plane in

any installation*.

D. The maximum length of the angled run

of the total chimney system is 20 feet. (G

plus H cannot exceed 20 feet.)

E. A chimney support (Models TCS8A or

11CS) is required every 6 feet of angled

run of chimney. Chimney supports are re

quired for every 30 feet and 60 feet (SK8

& CF11 pipe) of vertical chimney height

above the hearth.

Determine the offset distance of your

chimney arrangement from the centerline

of the fireplace to the centerline of the

chimney where it is to pass through the

first ceiling.

NOTE: This offset distance may not be

your full offset distance. See Examples 2

and 3.

FP720

1'

3' 4'

1¹⁄₂'

0 0 0 0 0 3" 11"

1 0 0 0 0 8

0 1 0 0 0 11

2 0 0 0 0 13

1 1 0 0 0 16

0 0 1 0 0 20

2 1 0 0 0 21

0 0 0 1 0 26

0 1 1 0 0 28

1 0 0 1 0 31

0 1 0 1 0 34

0 0 2 0 0 37

1 1 0 1 1 41

0 0 1 1 1 45" 83

0 1 2 0 1 47

0 0 0 2 1 51" 94"

0 1 1 1 1 53

0 0 3 0 1 56

0 1 0 2 1 59

0 0 2 1 1 62

0 1 3 0 1 64

0 0 1 2 1 68

0 1 2 1 1 70

0 0 0 3 1 74

0 1 1 2 2 78" 140

0 0 3 1 2 81" 146"

0 1 0 3 2 84" 151

0 0 2 2 2 87" 156

0 1 3 1 2 89

0 0 1 3 2 93" 166

0 1 2 2 2 95

0 0 0 4 2 99

0 1 1 3 2 101

0 0 3 2 2 104

0 1 0 4 2 107

0 0 2 3 2 110

0 1 3 2 3 114" 203

0 0 1 4 3 117

0 1 2 3 3 120" 213

0 0 0 5 3 123

Chimney

Offset

Support

¹⁄₄" 20"

¹⁄₄" 25¹⁄₄"

¹⁄₂" 29¹⁄₄"

¹⁄₂" 34¹⁄₄"

¹⁄₄" 40³⁄₄"

³⁄₄" 43¹⁄₂"

¹⁄₄" 51¹⁄₄"

¹⁄₂" 55¹⁄₄"

¹⁄₂" 60¹⁄₄”

¹⁄₂" 65¹⁄₂"

¹⁄₂" 70³⁄₄"

¹⁄₂" 77³⁄₄"

¹⁄₄" 87¹⁄₂"

¹⁄₄" 98"

¹⁄₄" 103¹⁄₄"

¹⁄₄" 108¹⁄₂"

¹⁄₄" 113¹⁄₂"

¹⁄₂" 117¹⁄₂"

¹⁄₄" 124"

¹⁄₂" 128"

¹⁄₄" 134¹⁄₂"

¹⁄₄" 160¹⁄₄"

¹⁄₄" 170³⁄₄"

¹⁄₄" 177³⁄₄"

¹⁄₄" 181³⁄₄"

¹⁄₄" 186¹⁄₄"

¹⁄₄" 191¹⁄₂"

¹⁄₄" 196³⁄₄"

³⁄₄" 209³⁄₄"

³⁄₄" 220"

Rise

³⁄₄"

³⁄₄"

¹⁄₄"

¹⁄₂"

³⁄₄"

¹⁄₄"

¹⁄₂"

7412961

Page 7

STR/CVR Series Woodburning Fireplaces

L

1

L

1

L

T

MODEL SK &

MODEL 11 CF

2 WALL CHIMNEY

TOTAL

LENGTH

(L

T

)

INSTALLED

LENGTH

(L

1

)

SK81 / 11CF1

SK818 / 11CF18

SK83 / 11CF3

SK84 / 11CF4

"

"

"

"

"

"

"

"

2' Min.

2' Min.

3'

Min.

0 To 10'

3'

Min.

0 To 10'

Reference

Point

Planning Information

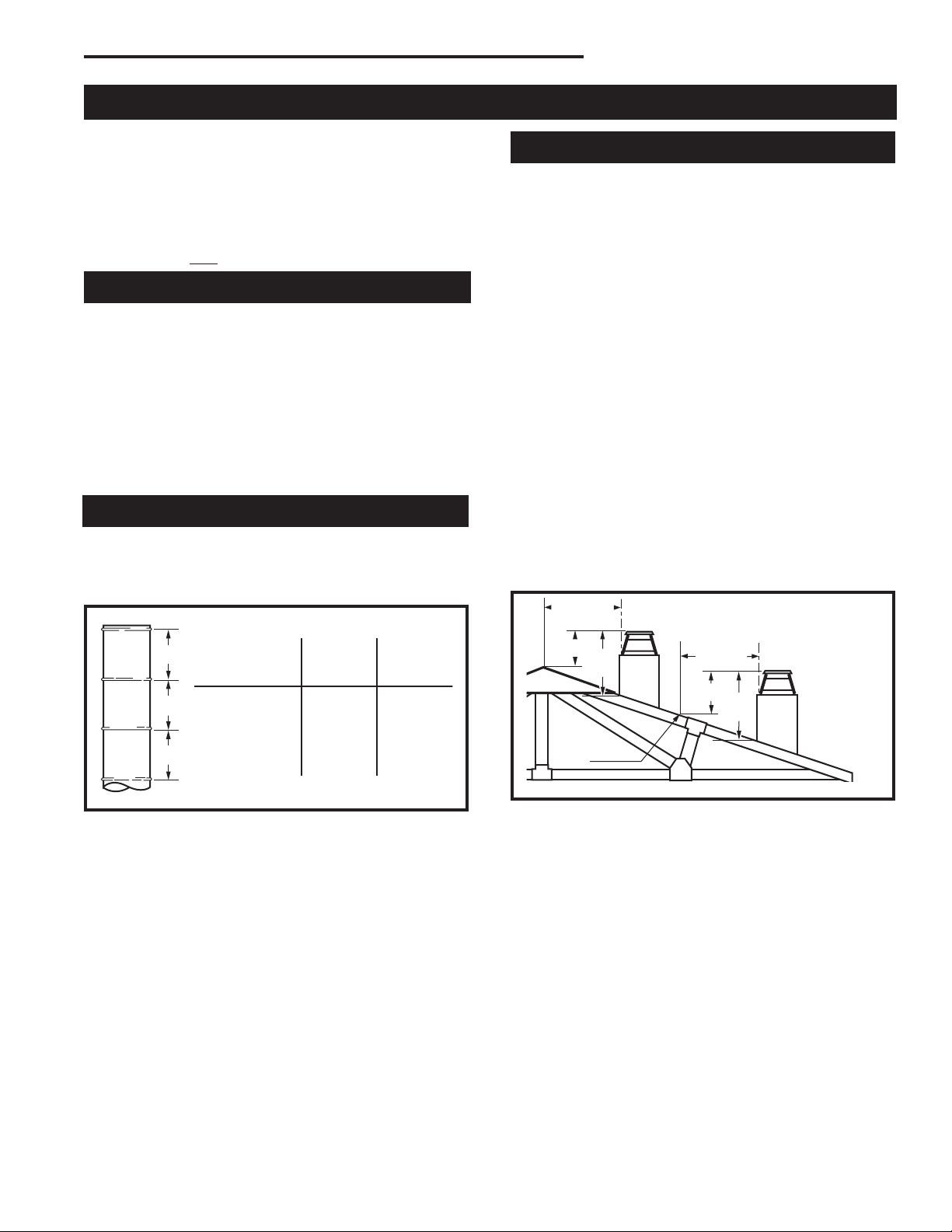

Preplanning an installation is very important to ensure

safety and to save time and money. An installer must

predetermine where a fireplace will be set and how the

chimney system will be run.

NOTE: STR33/36 and CVR36 models use CFM Corporation SK8 (2-wall) chimney systems. STR/CVR42

Fireplaces use only model 11CF chimney system.

Mounting the Fireplace

A fireplace may only be mounted on the following surfaces:

1. A flat combustible surface.

2. A raised wooden platform.

3. A concrete block or other solid object placed beneath

each of the four (4) corners of the fireplace.

The fireplace must be spaced 1/2" (13mm) from a combustible back wall and 1/2" (13mm) from a combustible

side wall or support. (Page 14, Fig. 20)

Planning the Chimney Run

Determine how the chimney will be run, length of run

and chimney components required to complete the

job. (Fig. 6) Never install a chimney below minimum

heights.

The Ten Foot Rule

Major U.S. building codes specify a minimum chimney

height above the roof top. The “Ten Foot Rule” is a fire

safety rule and not a draft rule. To ensure proper draft,

it is recommended that you always meet or exceed the

“Ten Foot Rule,” especially when installing a termination

on a high pitch roof. (Fig. 7)

The key points of the "Ten Foot Rule" are:

1. If the horizontal distance from the chimney to the

peak of the roof is 10' (3m) or less, the top of the

chimney must be at least 2' (610mm) above the peak

of the roof, but never less than 3' (914mm) in height

above the highest point where it passes through the

roof.

2. If a horizontal distance from the chimney to the peak

of the roof is more than 10' (3m), a chimney height

reference point is established on the surface of the

roof a distance of 10' (3m) from the chimney in a

horizontal plane. The top of the chimney must be

at least 2' (610mm) above the reference point, but

never less than 3' (914mm) in height above the highest point where it passes through the roof.

FP705

Fig. 6 Installed lengths of chimney sections.

In planning a chimney system, it is important to know:

1. The height of a chimney is measured from the

hearth to the exit point on the termination.

2. A chimney cannot be offset more than 30° from a

vertical plane.

3. A chimney may run straight up or it may be neces

-

sary to offset it to avoid obstructions.

4. The maximum length of an angled run (total chimney

system) is 20' (6m).

5. No more than 2 offsets (4 total 30˚ elbows in U.S./or

2 total 45° elbows in Canada) per fireplace may be

used.

6. A guy wire stabilizer is required for chimneys extend

ing more than 6' (1.8m) above a roof line.

7412961

AC246

Fig. 7 Ten Foot Rule illustration.

-

7

Page 8

STR/CVR Series Woodburning Fireplaces

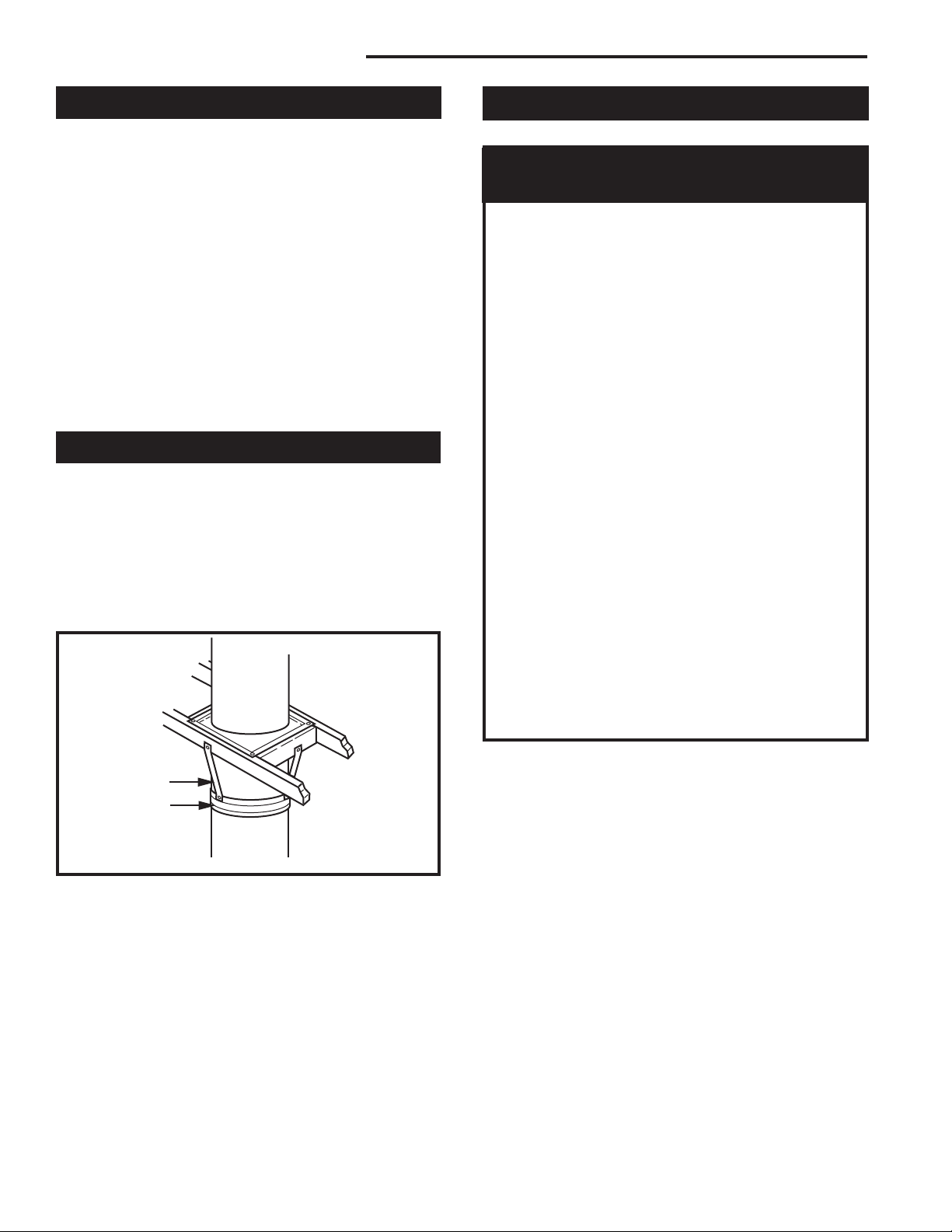

Chimney Supports

The chimney system is supported by the fireplace for

vertical chimney heights less than 20' (6m) above the

hearth. Chimney supports are required if the vertical

height exceeds 20' (6m). Locate chimney supports

at ceiling holes or other structural framing at 20' (6m)

heights. Spacing between chimney supports must not

exceed 20' (6m). Use Chimney Support Model SKCS8

for SK8 chimney, and Model 11CS for 11CF chimney.

(NOTE: the chimney support can not be mounted

directly to the fireplace.) Support provided by elbow

straps fulfills the support requirement only if they are

spaced as previously described. (A chimney support is

2¹⁄₂" (64mm) long when installed.)

Angled chimney runs require a support every 6' (1.8m)

in addition to the elbow straps. Chimney supports are

used for this function. (Fig. 9)

Chase Installation

A chase is a vertical box-like structure which encloses

the fireplace and/or chimney. Chases are typically built

on the outside of the house with fireplace opening cut

into the outer wall of a room. (Page 5, Fig. 4)

If you need help in determining fireplace location or how

the chimney system should be run, contact your Majestic dealer for assistance.

Installation

Insulating Fireplace Enclosure for Cold

Climates

If you live in a cold climate, it is not required but

highly recommended that you insulate fireplace

enclosure to eliminate cold air penetration as much

as possible.

Insulate base of fireplace with a non-combustible

insulation rated for a minimum of 300°F. Insulating

is very important for outside wall installations over

a concrete slab. If fireplace is installed on a platform,

insulation should be placed on top of the platform

before fireplace is set. (Fig. 9)

When a fireplace is installed in a chase or on a

outside wall, enclosure should be treated like any

outside wall in a home. Insulation should be installed

on the inside wall as well as the outside wall(s). In

a chase, it is also a good idea to install a firestop at

the first ceiling level above the fireplace and enclose

the chase with sheeting material. Insulation may

then be installed above sheeting material to assure

the space around the fireplace is totally protected.

(Fig. 4)

When installing the chimney, DO NOT caulk between outer pipe and firestop. It is vital that some air

be allowed to flow through this very thin gap.

CAUTION: WHEN INSTALLING A FIREPLACE

IN AN INSULATED ENCLOSURE, BE SURE ALL

REQUIRED AIR SPACES ARE MAINTAINED. (Page

14, Fig. 20)

Chimney Support Strap

SKCS8

Fig. 8 Chimney support installation

8

FP284

7412961

Page 9

STR/CVR Series Woodburning Fireplaces

Framing

Framing can be constructed before or after the fireplace

is set in place, however, most installers build the frame

before setting the fireplace.

Frame fireplace with 2 x 4 lumber or heavier materials. Refer to framing dimensions in Figures 1, 2, 3 or 4

for basic fireplace specifications. Headers and support

studs must be turned on end as illustrated on Page 5,

Figure 4.

NOTE: Framing should be positioned to accommodate

wall covering and fireplace facing material. Maintain

1/2" (13mm) air space between the outer dome and

any combustible framing materials that may be supported by the ledge brackets. Refer to Figures 20

and 26 for details.

Hard, Flat

Surface

Chimney Set-up

Since you have already preplanned the chimney run,

you should know exactly how the installation is to

be accomplished — how much pipe is required, the

number of elbows, if any, and type of termination to be

used.

CAUTION: REPORT TO YOUR DEALERS ANY

PARTS DAMAGED IN SHIPMENT, SPECIFICALLY

CHECK THE END CONNECTION OF CHIMNEY SECTIONS AND ELBOWS.

NOTE: STR33/36 and CVR36 models use CFM Corporation SK8 (2-wall) chimney systems. STR/CVR42

Fireplaces use only model 11CF chimney system.

Straight-Up Chimney Installation

To locate the centerline of the flue put the fireplace in

final position and place a plumb bob from the ceiling to

the center of the fireplace flue collar. Mark this spot on

the ceiling. Draw a line through that mark to either side

of the firebox and indicate dimension X to locate the

side wall framing. (Fig. 10) Be sure to observe clearance requirements for side and parallel combustible

walls as noted in Page 16, Figure 23.

Insulation

Plateform

Fig. 9 Insulating between platform and fireplace.

FP706

Offset Installation

In order to clear an obstruction, it may be necessary

to offset chimney from vertical. This is accomplished

by using CFM Corporation elbows. Use the 30° Offset

Elbow table on Page 6 to determine proper offset and

parts required.

Each offset requires two (2) elbows. The second elbow

is equipped with support straps. It is very important to

install the second elbow in each offset as close to the

ceiling or support as possible so that the elbow straps

can be secured to framing members to help support the

weight of the chimney.

Determine offset distance of your chimney arrangement

from centerline of fireplace to centerline of chimney

where it is to pass through ceiling.

Locate center point of the chimney on ceiling as though

a straight up chimney arrangement is to be used.

Measure your offset dimension from the chimney center

point on the ceiling.

7412961

9

Page 10

STR/CVR Series Woodburning Fireplaces

X

STR 33: 19" (483mm)

STR36 / CVR36: 20/" 521mm)

STR42 / CVR42: 23/" (597mm)

MODEL X =

A/B

A/B

A "SK8" Series framing = 14" X 14" (368 x 368mm)

B 11CF framing = 17" X 17" (445 x 445mm)

Actual Centerpoint

Chimney

Centerline

Side of

STR/CVR

Plumb Line

Plumb Bob

Imaginary

Centerpoint

Framing the Ceiling Hole

Frame the ceiling chimney hole as shown in Figure

12. It is good practice to use framing lumber that is the

same size as the ceiling joists; this is a requirement at

attic level.

The following table gives firestop spacer model numbers:

Angle of Chimney at Ceiling

Size of Chimney Vertical 30°

8" Flue SKFS2A SKFS6A

"SK" Series 14

(368mm x 368mm) (368mm x 648mm)

FS2A FS6A

11" CF 2-Wall 17

(445mm x 445mm) (454mm x 753mm)

Fig. 11 Ceiling chimney hole sizes necessary for installing

firestop spacer.

The inside dimension of the frame must be the same

as the hole size selected from Figure 12 in order to

provide the required air space (1¹/₂" (38mm)with SK8,

2" (51mm) with Model 11CF) between the outside

diameter of the chimney and the edges of the framed

ceiling hole.

¹⁄₂" x 14¹⁄₂" 14¹⁄₂" x 25¹⁄₂"

¹⁄₂" x 17¹⁄₂" 17⁷⁄₈" x 29⁵⁄₈"

FP707

Fig. 10 Locate centerline of chimney with plumb line.

Ceiling Chimney Hole/

Possible Obstructions

The size of the hole in ceiling will vary with the angle at

which the chimney passes through ceiling.

Drive a nail up through ceiling at marked chimney center point. Go to floor above and see where hole will be

cut. Check to see where existing ceiling joists and other

possible obstructions are located...i.e. wiring, plumbing

etc... If necessary, re-position chimney and/or fireplace

to avoid obstructions.

Cutting the Hole

Cover fireplace collar opening and cut proper sized

chimney hole in chimney. The SK8 pipe allows you to

run pipe through a typical 16” on center joist without

cutting joists.

10

Existing

Ceiling

Joists

New Framing

Members

Fig. 12 Typical frame for ceiling chimney hole.

Chimney Hole

FP551A

7412961

Page 11

Positioning, Safety Strips,

Metal Safety

Strips

(1, 2 or 3 pieces)

" (13mm)

Min. Overlap

"

(38mm)

"Z"

Safety

Strip

FirePlace

PlatForm

Hearth Ext.

(not supplied)

Model STR

CLOSED

OPEN

Securing the Fireplace

Slide fireplace into position.

Lift the fireplace front slightly and slide the metal safety

strips under front bottom edge about 1¹⁄₂" (38mm), allowing the remainder to extend in front of firebox. Overlap strips at least 1/2" (13mm) to provide a positive joint.

(Flat safety strips are packed with fireplace.) (Fig. 13)

Safety strips are used to ensure that any combustible

materials in front of the fireplace are protected even

though a noncombustible hearth extension is required.

If fireplace is to be elevated above the floor, a “Z”

shaped metal safety strip must be fabricated and used

to protect combustible surfaces in front of the fireplace.

This “Z” shaped safety strip is not provided but must be

fabricated of metal with each horizontal leg at least 1¹⁄₂"

(38mm) wide and equal in length to the metals strips

provided with the fireplace.

NOTE: Safety strips are not required over non-combustible floors where all supports at the base of the

fireplace are noncombustible.

Eight (8) nailing flanges are supplied with the fireplace

(found on the fireplace hearth). To level the box and

secure it firmly in place, remove the nailing flanges from

the hearth and install at the sides of the fireplace as

shown in Figure 14.

Outside Air Kit

An outside air kit damper is installed in all STR/CVR

Series Fireplaces. If desired, or if local codes mandate

the use of an air kit, then an AK-MST is required to

complete the installation (from air kit to the outdoors). If

the outside air kit is to be used, the AK-MST Air Termination Kit MUST be installed BEFORE the fireplace

is enclosed. Refer to the AK-MST instructions for field

installation. The outside air kit control is located in the

lower left hand side of the fireplace behind the screen

panel. (Fig. 15) To operate, simply lift up to close or

push down to open .

STR/CVR Series Woodburning Fireplaces

FP708

Fig. 13 Safety strip installation.

Standoffs

Side-Nailing

Flanges

FP709

Fig. 14 Fasten fireplace in position.

7412961

FP710

Fig. 15 Outside air operation.

11

Page 12

STR/CVR Series Woodburning Fireplaces

UP

Lance

Hem

Pipe Rim

Pipe

Rim

Installing the Chimney System

Start by attaching the first chimney section to the collar

on top of the fireplace.

Install the pipe as pictured in Figure 16. When you

get a good lock, you will hear the pipe clearly snap

together. Once sections are snap-locked in place, it is

extremely difficult to get them apart. Make sure the

pipe is firmly snapped and locked together as each

pipe section is mounted.

When installing elbows, only outer pipe will snaplock. Middle pipes simply slide into position. Be sure

to always attach straps on upper elbow to a structural

framing member. (Fig. 17)

Continue installing the pipe as required until pipe is

installed up through the ceiling. At this point, you must

install a firestop spacer. Refer to Figure 18 for appropriate spacer orientation.

Installing the Firestop Spacer

in the Ceiling Hole

A firestop spacer is used to keep pipe spaced properly

and required for safety.

Nail the firestop spacer (at each corner) to the framing

members of the ceiling hole. NOTE: A firestop spacer

is not required at the roof.

Hole sizes listed in Figure 12 for angled firestop spacers provide minimum required air space to chimney

pipe for ceiling thickness up to 8" (203mm). When

combined thickness of ceiling material, ceiling joists

and flooring material exceeds 8" (203mm), adjustments

must be made in framing to assure that minimum air

spaces to chimney are maintained.

Proper Firestop Spacer Installation

Figure 18 shows different installation procedures for

both an area that is an attic and an area that is not an

attic.

If the area above the ceiling is not an attic, position the firestop spacer

with the flange on the ceiling side and the angled

portion extending up into

the hole.

If the area above the

ceiling is an attic, position

the firestop spacer with

the flange on the top of

the framed hole and the

angled portion extending

down into the hole.

Fig. 18 Installing firestop spacer.

Attic Installation

FP593

Pipe Section

Fig. 16 Install pipe, listening for the snap-lock to fasten.

Elbow Strap

Angled Strap

FP270/271

Fig. 17 Attach straps to a structural framing member.

Ceiling Installation

Nails (4)

Firestop

Spacer

Joist

Support Structure

Elbow Strap

(must be tight)

Ceiling

Hole Framing

Angle Firestop

Chimney Support

Strap

(must be tight)

Joist

Firestop

Spacer

Nails (4)

FP711

12

7412961

Page 13

Firestop spacers are not available for nor are they required on vertical walls.

DO NOT put any sealant around the area where the

outer pipe slides through the firestop spacer. If you

seal this area, it may cause a fire hazard.

Canadian Requirements

for Insulation Shield

In Canada, an attic insulation shield is required to prevent attic insulation from contacting the chimney section. Framing dimensions for the chimney hole should

measure 14¹⁄₂" x 14¹⁄₂" (368 x 368mm)(SK8). (An attic

shield MUST be installed on top of attic joists (above

the floor level). Refer to Figure 19.

Install the attic insulation shield with the flanges on its

base extending down into the framing hole. Nail each

corner of attic insulation shield to the framing members

of the ceiling hole using 8d nails. Attic shields are not

required at the roof.

Continue Installing Pipe to Complete Run

Continue attaching pipe sections to complete system

to next level always being careful that the pipe is firmly

snapped locked in place before proceeding to next pipe

section.

Chimney Supports

If chimney supports are required, they are installed the

same as elbows. Nail chimney support straps to adjacent structural framing, as shown on Figure 8, Page

8. Bend straps as necessary and make sure they are

secure so they will support the weight of the chimney.

A chimney support is 2¹⁄₂" (64mm) long when installed.

Consider this dimension when determining how many

straight chimney sections are needed.

NOTE: Chimney supports are generally used in long

runs in a chase installation. A chimney support can-

not be mounted directly to the fireplace.

Additional Ceilings

If you encounter additional ceilings, repeat same steps

required for first ceiling installation. Refer to firestop

illustration on Page 12, Figure 18.

Penetrating the Roof

Run pipe to roofline. Since chimney system must be

vented to the out-of-doors, you must use an approved

termination.

If a chase is used, refer to the installation manual provided with the termination cap.

STR/CVR Series Woodburning Fireplaces

Attic Insulation Shield

Nails

(4 required)

Attic Joist

Base

Ceiling

Model 11CF chimney is not approved

for use in Canada.

Fig. 19 Attic shield installlation (Canadian requirement).

Flanges

FP263

Locate Chimney Centerpoint on Roof

Use same procedure detailed in locating centerpoint of

the flue system.

Drive a nail up through roof at the centerpoint. This will

determine center point on outside of the roof.

Cut and Frame Roof Hole

Size of roof hole varies with the type of chimney termination installed. Refer to installation instructions provided with the chimney termination to find correct size

of roof hole.

NOTE: The air space dimensions in this manual

that pertain to model 11CF chimney pipe have been

changed from 2" to 1" (51 - 25mm) clearance for first

joist space only. This change only applies to Majestic Fireplaces models STR42 and CVR42 fireplaces.

Because of framing concerns these models, and only

these models, have been tested and approved at the

reduced clearance. In all other cases the minimum air

space referred to on the UL label on the 11CF pipe

must be maintained. A special firestop is shipped with

these units that will maintain the 1" (25mm) clearance

at the first joist. The chimney hole size for this firestop

will be 15¹⁄₂" (394mm). Refer to Figure 18 for ceiling

joist installation instructions.

There must be an air space (1¹⁄₂" (38mm) with SK8 and

1" (25mm) with 11CF) between outermost portion of

chimney sections and any adjacent combustible surfaces. (Fig. 20) (Combustible surfaces include burnable

materials such as: ceiling members, joists, flooring,

combustible insulation and roof structures.)

7412961

13

Page 14

STR/CVR Series Woodburning Fireplaces

Front View

Side View

Standoff

Combustible framing material MUST NOT

penetrate AIR SPACE (shaded areas).

Air Space Clearances

Only noncombustible

material may be applied

as facing to the black

fireplace surround.

Wall

Shield

Hearth

Extension

0" Clearance

to Floor

Firestop

OUTER

DOME

" (13mm)

Air Space

to Sides

" (13mm) air space

to sides

1" (38mm)

1"

(51mm)

Maintain

" (13mm)

air space

to sides

WARNING: DO NOT PACK REQUIRED AIR SPACES

WITH INSULATION OR OTHER MATERIALS.

Mark an outline of the roof hole around the center of the

point nail. NOTE: Hole dimensions given in the chimney top installation instructions are horizontal dimensions; therefore, the hole size must be marked on the

roof accordingly.

Cover the opening of the installed chimney so debris

cannot get into the system.

Cut and frame the hole. It is good practice to use framing lumber that is the same size as the rafters. Install

the frame securely because the chimney top and flashing anchored to the frame must be able to withstand

heavy winds.

Install Remainder of Chimney Sections

Since you have already preplanned the height of your

termination according to the Ten Foot Rule, continue to

install pipe to the predetermined height.

Check the chimney top installation instructions for

details on how high above the roof top the chimney sections (all pipes) should extend.

Installing Top Housing or Termination

Follow the installation instructions provided with the

chimney termination you have selected.

Installing Chimney In a Chase

Refer to Page 5, Figure 4 for an illustration of a typical

chase installation.

CAUTION: Treatment of firestop spacers and construction of chase may vary with type of building. These

instructions are not a substitute for local building codes.

You must check your local building codes to determine

specific requirements for your city or state. NOTE:

Other building materials may be required in addition to

Firestop Spacers.

CAUTION: All joints between the finished wall and the

fireplace surround (top/sides) must be sealed with noncombustible material to prevent cold air leakage into the

room. Only noncombustible material may be applied

to the facing of the fireplace surround. (Black painted

area) (Fig. 20)

Finish the wall with material of your choice. Do not

install a combustible mantel shelf less than 12"

(305mm) above the front opening. Do not install a

mantel face plate less than 6" (159mm) from top of

fireplace opening. (Fig. 21) If a combustible mate-

Finishing

Finish Wall

FP717

Fig. 20 Minimum clearances to combustibles.

rial is used below a flat mantel shelf, consult your local

building codes for minimum clearance from top of fireplace opening to bottom of mantel shelf.

NOTE: No side wall protection is required for fireplaces

installed at 45° to two (2) side walls (corner installation).

Adjacent combustible side walls that are within 16"

(406mm) (STR33/36 and CVR36) and 20" (508mm)

(STR42 and CVR42) of fireplace opening must be protected with CFM Corporation Wall Shield Model SP40

or a specifically built wall shield described in Figure 20

& 24.

Often a decorative surround or vertical portion of the

mantel is desired. If this is constructed of any combustible material, it must be within the safe zone indicated

in Figure 24.

14

7412961

Page 15

STR/CVR Series Woodburning Fireplaces

1"

Ref.

Combustible materials are

permitted within a shaded area

shown in Figure 23, titled

Minimum Wall Clearances.

*

* *

"

1/2"

*

12"

(305mm)

Min.

12"

(305mm)

Max.

1/2"

12"

(305mm)

Min.

12"

(305mm)

Max.

6'

(159mm)

Min.

Mantel Clearance No Noncombustible Facing Material

Combustible

Mantel and Trim

* Minimum width from top of surround to bottom of screen rail

Finished Wall

Standoff

2 x 4 Stud

Noncombustible Mate-

rial

Header

Ledge Bracket

Fireplace

Front

Fireplace Opening

Combustible

Mantel and Trim

Fireplace

Front

Mantel Clearance with Noncombustible Facing Material

Finished Wall

Standoff

2 x 4 Stud

Noncombustible Material

Header

Ledge Bracket

Noncombustible Facing Material

Fireplace

Front

Fireplace Opening

2 x 4 Stud

Finished Wall

Must be sealed with

noncombustible material

FP721

Fig. 21 Fireplace surround flush with finished wall.

*12" (305mm) from top of fireplace opening.

** 6" (159mm) from top of fireplace opening.

(Noncombustible material must separate the

black face surround of the fireplace and any

combustible mantel material)

Fig. 22 Combustible mantel clearances.

Face Plate

MA81

7412961

15

Page 16

STR/CVR Series Woodburning Fireplaces

A

A

B

B

C

CC

D

Side Wall Protection

All joints (top, bottom and sides) where wall or decorative facing material meets fireplace surround must

be completely sealed with a noncombustible material.

(Figs. 20 and 24)

The special wall shield design described in Figure 20 is

an alternate method of adding protection to side walls

and can be used in place of the SP40 with the same

wall clearances specified for the SP40. Rt must =1.85

minimum.

Minimum Dimensions to Side Walls

(for on-site contruction)

Model STR33 STR36 STR42 CVR36 CVR42

Parallel Side Wall A 44" 44" 44" 44" 44"

to Movable Doors (1118mm) (1118mm) (1118mm) (1118mm) (1118mm)

Perpendicular B 16" 16" 20" 16" 20"

Side Wall to Firebox Opening (406mm) (406mm) (508mm) (406mm) (508mm)

Air Space to Sides C 1/2" 1/2" 1/2" 1/2" 1/2"

or Back of Unit (13mm) (13mm) (13mm) (13mm) (13mm)

End Panel Parallel D -- -- -- 36" 36"

to End of Unit (914mm) (914mm)

Examples of wall shield insulation:

1. Manville - CERAFORM 126, K=.27,

1/2 inches thick

2. CFM Corporation - EH2416, K = .458,

1 inch thick required.

Perpendicular Side Wall

Parallel Side Wall

STR Series

Fig. 23 Minimum firebox dimensions from combustible materials.

Parallel Side Wall

Perpendicular Side Wall

CVR Series

FP723

16

7412961

Page 17

STR/CVR Series Woodburning Fireplaces

Minimum Wall Clearances

WITH

Noncombustible

Surround Facing

WITHOUT

Noncombustible

Surround Facing

Minimum Hearth Extension Dimensions

(for On-Site Construction)

G

H

G

J

Seal cracks

between the

fireplace

and hearth

extension with

noncombustible

material

Safety strips

must overlap

" minimum

May install

noncombustible

decorative

covering

OR .018" min.

sheet metal

Fireplace

Hearth

Combustible

Floor

Minimum

Insulation

Value "R"

4" MIN.

Firebox

Opening

A - Min. clearance

to combustible

perpendicular wall

B - Min. clearance

to combustible

perpendicular wall when

using noncombustible wall shield*

Side

Wall

Side

Wall

F**

C**

E

E

D

4" BRICK

(Example material)

Combustible material permitted within shaded area.

*

Noncombustible wall shield requires 1" CFM Corporation

EH2416 insulation (minimum R Value = 1.85) between

decorative noncombustible rigid covering and combustible wall.

Minimum height and width is 40" x 40".

**

Dimension/degree of angle will vary depending on thickness

of noncombustible surround facing.

G

H

G

J

CVR

STR

4"

Shaded area starts

1/2" away from

edge of unit

A B C D E F G H J K

STR33/36 CVR36 16" 12" 48° 41° 18" 14" 8" 16" 48" 24"

(406mm) (305mm) (457mm) (356mm) (203mm) (406mm) (1219mm) (610mm)

STR42 CVR42 20" 12" 42° 35° 18" 14' 12" 20" 61¹⁄₂" 24"

(508mm) (305mm) (457mm) (356mm) (305mm) (508mm) (1562mm) (610mm)

FP714

Fig. 24 Combustible side wall protection and hearth extension dimensions.

Hearth Installation

A hearth extension is required to protect a combustible

floor in front of the fireplace. Refer to Figure 24 for minimum dimensions and mounting detail.

Note: Hearth Extension must not cover the air inlet

opening of a fireplace.

The hearth extension described in Figure 24 must be a

durable noncombustible material with a minimum (total)

Rt value of 1.09; refer to Figure 25 for examples. The

overall height (above a combustible floor), depth and

width must be as indicated, with the extension centered

to the fireplace opening.

The top of the insulation material must be covered with

a noncombustible decorative covering or a piece of

.018” minimum sheet metal, to protect hearth extension

material. (Fig. 24)

Secure the hearth extension to the floor to prevent

shifting, using trim molding or other similar means at

three (3) outer edges. Seal crack between the fireplace

hearth and hearth extension with a noncombustible

material. (Figs. 24 and 26)

7412961

WARNING: HEARTH EXTENSION MUST BE INSTALLED IN ACCORDANCE WITH FIGURES 24 AND

25.

Alternate noncombustible materials may be used

providing the (total) thermal resistance (Rt value) of the

alternate material employed is greater than or equal to

R = 1.09. Thermal resistance (R) or thermal conductivity

(K), may be obtained from manufacturer of the material.

Factors are related by the formula K = 1/R.

T = given thickness

R = thermal resistance for a given thickness (T)

K = thermal conductivity

Noncombustible material with a lower R value may

be used, provided thickness of material is sufficiently

greater to maintain an equivalent (total) thermal resistance (Rt).

17

Page 18

STR/CVR Series Woodburning Fireplaces

COMMON MATERIALS AND FACTORS

MATERIAL K*

R

MINIMUM

THICKNESS

EH2416

Common Brick

0.458

5.0

1.09 0.50 in.**

0.10 5.46 in.**

R Value is for inch.

* Units of K = BTU/SQ FT/HR/˚F/IN

** Thickness of Listed Material

Wall Covering

Noncombustible

Decorative

Facing

Noncombustible

Decorative

Covering

Seal all cracks

between fireplace

surround and wall

materials with

noncombustible

material.

Seal crack

between fireplace

and hearth extension

with noncombustible

material.

2x4" Header -

Do not notch at

standoffs.

2x4"

Stud

Safety Strips Must be overlapped

" minimum.

Hearth Extension

Insulation

Side View

NOTE: /"

air space

between

Outer Dome

and

combustible

materials

/"

/"

Outer Dome

2”

(51 mm)

2”

(51 mm

)

Maximum

14”

(356 mm)

Maximum

10”

(254 mm)

A

A

Minimum

33”

(838 mm)

Minimum

36” (914 mm)

6”

(152 mm)

Minimum

Example of Determining Hearth Extension

Equivalents

To determine the thickness required for any new material:

NEW K of new material (per inch) thickness

required =

thickness K of listed material (per inch) material

Example for Common Brick

X of listed

Seal Cracks Between Fireplace and Hearth

Extension with Noncombustible Material

Noncombustible

Material 7¹⁄₂"

Max. Thickness

Combustible

Floor

Lower Surround

Noncombustible

Material

Fireplace

Hearth

T (new) = 5.0 / 0.458 x 0.50 in. = 5.46 in. (new required

thickness).

Fig. 25 Hearth extension material factors.

Fig. 26 Finish wall treatments and gap sealing.

18

FP533AD

FP719

1/4" Min. Thickness

Minimum Insulation

FP1170

Value R-0.94

Majestic Safety

Strips Must be

Overlapped 1/2"

Min.

Fig. 27 Hearth extension dimensions.

Recessed Installation - STR33/36, CVR36 Only

Noncombustible

Material

(if desired)

Insulation

with Minimum

R Value

of 2.75

Hearth Extension

Minimum .030 Thick Stainless Steel Plate

Insulation with Minimum R

Value of 2.75

Minimum .030

Thick Stainless

Steel Plate

Hearth

Extension

FP1608

View A

NOTE: If noncombustible material is not used between the

stainless steel plate and fireplace opening, the steel must

be attached to the front of the unit a minimum of four (4)

places on each piece with sheet metal screws no longer

than 1/2".

NOTE: The size of the insulation and stainless steel

plate must be within limits stated above and covers all

combustible framing material.

Fig. 28 Recessed installation.

7412961

Page 19

STR/CVR Series Woodburning Fireplaces

1"

Installing Line for Gas Logs

Majestic Fireplaces are designed to accept a 1/2"

(13 mm) gas line for installation of an approved gas appliance. (CFM Corporation manufactures a wide variety

of gas logs for use in Majestic fireplaces.)

Be sure to have the appliance installed in accordance

with building codes.

Gas connection may enter from either left or right side

of the fireplace.

Locate appropriate gas line in the outer casing of fireplace and remove insulation from gas line tube. (Fig. 29)

From inside the fireplace, locate the knockout on the

firebrick -- be sure you are on the appropriate or "gas

line" side of the fireplace. Using a flat bladed screwdriver or small chisel and hammer, carefully tap around

the knockout until it loosens and falls out.

Install 1/2" (13 mm) certified gas pipe through opening.

After gas pipe installation is complete, use insulation

that was removed from gas line tube to repack space

around the pipe. Material should be inserted from

outside of the fireplace and packed tightly to totally seal

between the pipe and tube.

NOTE: Gas pipe should not come in contact with

any wood structures until it has reached a point at

least 1" (25 mm) away from fireplace side.

Note: Local codes may require removal of flue damper

when installing any type of gas appliance in a fireplace.

NOTE: When installing an ANSI Z21.11.2 ventless appliance, the fninshing material used for the mantel must

be rated at 250°F or greater.

BTU input of a gas appliance installed in fireplace

should be rated less than 100,000 BTU/Hr.

Gas pipe installation is intended for connection to a

decorative gas appliance only when (1.) incorporating

an automatic shutoff device and (2.) complying with the

Standard for Decorative Gas Appliances for Installation

in Vented Fireplaces (ANSI Z21.60) or CSA draft requirements for Gas-Fired Log Lighters for Woodburning

Fireplaces (Draft No. 4, August 1993).

Decorative gas appliance should be installed in accordance with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 (latest edition).

Fireplace Top View

Hole in

Outer

Casing

Gas Line

Tube

Hole in

Outer Casing

Fig. 29 Gas line access.

CAUTION: WHEN USING DECORATIVE

GAS APPLIANCE, FLUE DAMPER MUST

BE SET IN FULLY OPEN POSITION. IF YOU

HAVE GLASS DOORS ON THE FIREPLACE,

THEY MUST ALSO BE FULLY OPENED.

WARNING: DO NOT OPERATE AN

UNVENTED GAS LOG SET IN THIS FIREPLACE WITH THE CHIMNEY REMOVED.

WARNING: WHEN INSTALLING AN

UNVENTED GAS LOG SET, THE CFM

CORPORATION MODEL AH3244BK OR

AH3244PB 4" ADJUSTABLE HOOD MUST

BE USED.

Supply Line

Repack Insulation

Ceramic

Knockout

(Both Sides

on STR)

FP716

7412961

If installing an unvented gas log set, refer to statement below:

Only unvented gas log sets which have been found to comply

with the Standard for Unvented Room Heaters, ANSI Z21.11.2,

are to be installed in this fireplace.

19

Page 20

STR/CVR Series Woodburning Fireplaces

5a

1, 2, 3

4a

6

7

a

b

c

d

8

9

10

11

5b

4b

e

12

13

14

961

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

CVR36/42 SERIES

Ref. Description CVR36 CVR42

1. Flue Damper RP102 RP161

2. Damper Actuator 7548170 7548169

3. Damper Handle Push Nut 7512903 7512903

4a. Screen Rod Assembly - Side (two per fireplace) 3030126 3032112

4b. Screen Rod Assembly - End 7554342 7554342

5a. Screen Assembly - Side (four per fireplace) 7554338 7554340

5b. Screen Assembly - End 7554340 7554340

6. Screen Pulls (four per fireplace) 5584139 5584139

7a. Firebrick - Hearth 3102103 3101105

7b. Firebrick - Side Ash Lip (two per fireplace) 3102102 3101103

7c. Firebrick - End Ash Lip 3101104 3101104

7d. Firebrick - Side 3079147 3079147

7e. Firebrick - Side Filler (two per fireplace) 3079148 3079148

8. Top Brick Retainers (two per fireplace) 3079130 3079130

9. Cable Clips (twelve per fireplace) 7512135 7512135

10. End Panel (Glass and Extrusion) 3080145 3080145

11. Tempered Glass (two per fireplace) 20000399 20000399

12. Nailing Flange (four per fireplace) 5069164 5069164

13. Basket Grate 2056100 2058100

14. O.S.A. Assy. 20003212 20003212

20

7412961

Page 21

STR/CVR Series Woodburning Fireplaces

5

1, 2, 3

4

6

7

a

b

c

d

8

9

10

11

12

961

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

STR33/36/42 SERIES

Ref. Description STR33 STR36 STR42

1. Flue Damper RP102 RP102 RP161

2. Damper Handle 7548170 7548170 7548169

3. Damper Handle Push Nut 7512903 7512903 7512903

4. Screen Rod Assembly (two per fireplace) 3049122 3030126 3032112

5. Screen Assembly (four per fireplace) 7554338 7554338 7554340

6. Screen Pulls (four per fireplace) 5584139 5584139 5584139

7a. Firebrick - Hearth 3100103 3102103 3101105

7b. Firebrick - Side Ashlip (two per fireplace) 3100102 3102102 3101103

7c. Firebrick - Side (two per fireplace) 3079147 9079147 3079147

7d. Side Filler (four per fireplace) 3079148 3079148 3079148

8. Top Brick Retainers (four per fireplace) 3079130 3079130 3079130

9. Cable Clips (eight per fireplace) 7512135 7512135 7512135

10. Nailing Flange (eight per fireplace) 5069164 5069164 5069164

11. Basket Grate 2056100 2056100 2058100

12. O.S.A. Assy. 20003212 20003212 20003212

7412961

21

Page 22

STR/CVR Series Woodburning Fireplaces

Accessories

The following accessories for this appliance are available from your local Majestic Fireplaces distributor. Should you

need additional information beyond what your distributor can furnish, contact: CFM Corporation, 2695 Meadowvale

Blvd., Mississauga, Ontario, Canada L5N 8A3, Attn: Technical Services.

CAUTION: This fireplace and chimney assembly is a highly engineered system, and, as such, must be oper

ated only with CFM Corporation approved components. If you use an unapproved component to make any

modifications, you may create a possible fire hazard and will void the CFM Corporation warranty. In addition,

such action may void the coverage provided by the owner’s insurance.

Model NumberDescriptionAccessory

-

Glass Door Bi-Fold door set Brushed Brass finish 33GDKBB - STR33

36GDKBB - STR36, CVR36

42GDKBB - STR42, CVR42

Black finish 33GDKBK - STR33

36GDKBK - STR36

42GDKBK - STR42

Polished Brass finish 33GDKDP - STR33

36GDKDP - STR36

42GDKDP - STR42

Pewter finish 33GDKS - STR33

36GDKS - STR36, CVR 36

42GDKS - STR42, CVR42

Outside Air Termination Completes connection from air kit to

out-of-doors AK-MST

Hearth Extension Insulation Provides hearth extension floor

protection EH2416

Basket Grate Holds firewood in firebox RBG36ST (33" & 36" models)

RBG42ST (42" models)

Hearth Patch Compound Patch cracks in hearth HPC-1

22

Contact your Majestic Fireplaces distributor or dealer for finishing

Marble and Mantels, available in a wide selection of styles.

7412961

Page 23

U.S.

STR/CVR Series Woodburning Fireplaces

Chimney Components

DescriptionComponent

Round Top Termination Round termination to be used with SK8 chimney RLTSK8

system. (Flashing not included.)

Round Top Termination Round termination to be used with 11CF chimney RLTCF11

system. (Flashing not included.)

Long Round Top Round top to be used with a chase installation RLTSK8L

Termination utilizing SK8 chimneysystem.

Long Round Top Round top to be used with a chase installation RLTCF11L

Termination utilizing 11CF chimney system.

Knock-down Shroud - Black pyramid knock-down shroud used for PKDSBL

Pyramid chase installations with any RLT round top

termination. Gives appearance of a pyramid cap.

Knock-down Shroud - Black square knock-down shroud used for SKDSBL

Square chase installations with any RLT round top

termination. Gives appearance of a square cap. Adaptor required

Square Termination Top housing with simulated brick pattern. T20B

(Red, Tan or Black) Proper adapter must be

used. Includes flashing.

Adapter Required adapters for T20B top housing. CF8CA (SK8)

8CA

Housing Extensions Extends Square Termination on steep pitched roofs. 202036

Flashing Metal finishing required around Contemporary 8-6-12 with 8" flue:

Termination to prevent rain leakage. 0-6/12 pitch

8-12-12 with 8" flue:

6/12-12/12 pitch

Square Termination Top housing of simulated brick pattern T20B

available in red, tan or white. Appropriate

adapter required. Flashing included.

SK8 Pipe used to build 8" SK8 flue systems. SK81 (1' Long)

Chimney Sections SK818 (1

SK83 (3' Long)

SK84 (4' Long)

11CF Chimney Sections Pipe used to build 11" (11CF) flue systems. 11CF1 (1' Long)

11CF18 (1

11CF3 (3' Long)

11CF4 (4' Long)

Chimney Elbows Elbow used to create an offset in a SK830 / 2 (SK8)

chimney system. Only 30˚ elbows available. 11CF30 / 2 (11CF)

Packaged 2 per carton (offset and return).

Model Number

(11CF)

¹⁄₂' Long)

¹⁄₂' Long)

7412961

23

Page 24

STR/CVR Series Woodburning Fireplaces

U.S. Chimney Components, cont'd.

DescriptionComponent

Model Number

Firestop Required at each floor level of chimney SKFS2A — SK8

installation. (Plus attic on multi-story installation.) (8" straight flue)

SKFS6A — SK8

(8" 30˚ inclined flue)

FS2A (Model 11CF)

(straight flue)

FS6A (Model 11CF)

(30˚ inclined flue)

Chimney Support Used to support chimney for each of: 20' vertical SKCS8 - SK8

height and 6' of angled chimney run. 11CS - 11CF

Canada

Component

Attic Insulation Shield Used to prevent insulation from coming in AIS-SK - SK8

contact with the chimney system.

SK8 Chimney Sections Used to build chimney systems exposed above SK818CAN (1¹⁄₂') SK8

roof. SK84CAN (4') SK8

45˚ Chimney Elbows Provides 45˚ offset and return. FOR CANADIAN SK845/2

INSTALLATIONS ONLY. For use with

SK8 chimney only. (Maximum use of 2, or 1pair.)

Model NumberDescription

24

7412961

Page 25

STR/CVR Series Woodburning Fireplaces

7412961

25

Page 26

STR/CVR Series Woodburning Fireplaces

26

7412961

Page 27

STR/CVR Series Woodburning Fireplaces

LIMITED WARRANTY & 30 YEAR PROTECTION PLAN

For MAJESTIC FIREPLACES® PRE-ENGINEERED Fireplace Systems

CFM Corporation warrants its MAJESTIC FIREPLACES®

Pre-Engineered Fireplace (“Fireplace”) and the CFM Corporation supplied firegrate, glass doors, outside air system, fan motor, and liners to be free from defects in material or workman

ship, as follows:

A. Fireplace and Chimney Components: (exclusive of CFM

Corporation-supplied firegrate, glass doors, outside air sys

tem, fan motor, and liners all of which are covered by separate

warranties under paragraphs B through D below): At its option

for a period of thirty (30) years from the date the Fireplace is

installed, CFM Corporation will;

(1) For a period of five (5) years from the date the Fireplace

is installed, CFM Corporation, at its option, will repair or replace

any defective part without charge.

(2) Thereafter, through the 10th year after the date the

Fireplace is installed, if replacement parts are available, CFM

Corporation will provide a replacement for any defective part

without charge for the part itself. The consumer must pay for

everything else other than the part.

(3) Thereafter, through the 30th year after the date the

Fireplace is installed, if replacement parts are available,CFM

Corporation will provide a replacement for any defective part

at a cost to the consumer of CFM Corporation then current list

price, FOB CFM Corporation factory.

B. Firegrate, Glass Doors, Outside Air System:

For a period of 90 days from the date the Fireplace is

installed CFM Corporation, at its option, will provide a replacement for any defective part, without charge for the part itself,

FOB CFM Corporation factory, (The consumer must pay for

everything else other than the part.).

C. Fan Motor:

(1) For a period of one (1) year from the date the Fireplace is

installed, CFM Corporation, at its option, will repair or replace

any defective part without charge.

(2) Thereafter, through the 30th year after the date the Fire

place is installed CFM Corporation, at its option, if replacement

parts are available, will provide a replacement for any defective

part at a cost to the consumer of CFM Corporation then current

list price, FOB CFM Corporation factory.

D. Liners (Refractory or Metal):

(1) For a period of two (2) years from the date the Fireplace

is installed, CFM Corporation, at its option, will repair or replace

any defective part without charge.

(2) Thereafter, through the 30th year after the date the Fireplace is installed CFM Corporation, if replacement parts are

available, will provide a replacement for any defective part at a

cost to the consumer of CFM Corporation then current list price,

FOB CFM Corporation factory.

This warranty is subject to the following conditions and limitations:

(1) This warranty is extended only to a Fireplace installed in

the continental United States, the state of Alaska and Canada;

only if and so long as the Fireplace is installed according to

the installation instructions furnished with the Fireplace, and

-

-

-

operated at all times under normal conditions, use and service

according to the operative instructions furnished with the Fireplace, and only if and so long as the Fireplace is not removed

from its original installation.

(2) This warranty is non-transferrable, and is made to the

original owner, provided that the purchase was made through

an authorized supplier of the Company.

(3) The sole and exclusive remedies for breach of any war

ranties hereunder shall be for the repair, replacement or provi

sion of a replacement part at CFM Corporation then current list

price, FOB CFM Corporation factory, for any defective part as

specified in paragraphs A through D.

(4)CFM Corporation shall not be liable for damage from any

smoking of a MAJESTIC FIREPLACES Pre-Engineered Fireplace System related to environmental geographic conditions

(such as, for example, nearby structures or roof peaks, trees,

hills, or mountains), inadequate ventilation, or negative air

pressure in the place where the Fireplace system is installed,

related to any mechanical system (such as, for example, furnaces, fans, air conditioners, clothes dryers, etc.)

(5) Except as otherwise expressly specified in paragraphs

A through D, NONE OF THESE WARRANTIES COVER, AND

CFM CORPORATION SHALL NOT BE RESPONSIBLE FOR,

ANY CONSTRUCTION, INSTALLATION, LABOR, TRANSPORTATION OR OTHER COSTS OR EXPENSES ARISING

FROM A DEFECTIVE PART, ITS REPAIR OR REPLACEMENT

OR OTHERWISE, NOR SHALL CFM CORPORATION IN ANY

EVENT BE RESPONSIBLE FOR ANY INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES EXCEPT TO THE EXTENT

REQUIRED BY LAW. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you.

NO IMPLIED WARRANTIES, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, SHALL REMAIN IN EFFECT AFTER

THE EXPIRATION OF THE WARRANTIES SET FORTH IN

PARAGRAPHS A THROUGH D. Some states do not allow limitations on how long an implied warranty lasts, so this limitation

may not apply to you.

In order to obtain performance of any of the above warranty

obligations write to CFM Corporation at this address:

CFM Corporation

2695 Meadowvale Blvd.

Mississauga, Ontario, Canada L5N 8A3

Attention: Director of Warranty Services

Since local building requirements may vary greatly throughout the country, users of CFM Corporation products should

determine in advance whether there are any building code

restrictions on the use of a specific product.

TION MAKES NO REPRESENTATION OR WARRANTY REGARDING, AND SHALL NOT BE RESPONSIBLE FOR, ANY

BUILDING CODE COMPLIANCE.

The foregoing warranties give you specific legal rights and

you may also have other rights which vary from state to state.

CFM CORPORA-

-

-

7412961

27

Page 28

CFM Corporation

2695 Meadowvale Blvd. • Mississauga, Ontario, Canada L5N 8A3

800-668-5323 • www.cfmcorp.com

Loading...

Loading...