Page 1

Installation Instructions

Installation and service of this

appliance should be performed by

qualied personnel. CFM suggests

Models: MO18M, MO24M

Majestic Burner/Hearth and Log Kits

For Natural Gas Use Only

Intended for use in all CFM Corporation factory built replaces

Check with your local building code agency before you begin installation to ensure compliance with local codes, including

the need for permits and follow-up inspections. If you encounter any problems regarding code approvals, or if you need

clarication of any of the instructions contained here, contact the Technical Services Dept.,

CAUTION

DO NOT DISCARD THIS MANUAL

•

• Im porta nt operating

a n d m a i n t e n a n c e

instructions included.

•

Rea d , understa n d

an d fo ll ow th es e

instructions for safe

i ns ta ll at io n a n d

operation.

Leave this manual with

party responsible for

use and operation.

NFI certified or factory-trained

professionals, or techni c i a n s

supervised by an

NFI certied professional.

WARNING

If the information in these instructions is not followed exactly, a

re may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other am

mable vapors and liquids in the vicinity of

this or any other appliance.

• What to do if you smell gas:

- Do

not try to light any appliance.

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

- If you cannot reach your gas supplier, call

the re department.

• Installation and service must be performed

by a qualied installer, service agency, or

the gas supplier.

-

WARNING

HOT! DO NOT TOUCH.

SEVERE BURNS MAY RESULT.

CLOTHING IGNITION MAY RESULT.

Glass and other surfaces are hot during

operation and cool down.

• Keep children away.

• CAREFULLY SUPERVISE children in same room as

appliance.

• Alert chil d r e n and adult s to haza r d s of hi gh

temperatures.

• Keep cl o t h i n g , fu r n i t u r e , dr a p e r i es an d other

combustibles away.

In the Commonwealth of Massachusetts:

• This appliance must be installed by a licensed plumber

or gas tter.

• The chimney ue damper, when used with gas logs, will

be welded open or completely removed.

• A CO detector shall be installed in the room where the

appliance is installed.

20012914 7/05 Rev. 0

1

Page 2

Read this manual before installing or operating this appliance.

Please retain this owner’s manual for future reference.

Congratulations

Congratulations on selecting a CFM gas log set—an elegant

and clean alternative to burning wood. The CFM gas log set

you have selected is designed to provide the utmost in safe-

ty, reliability, and efciency.

As the owner of this new gas log set, you’ll want to read

and carefully follow all of the instructions contained in this

owner’s manual. Pay special attention to all cautions and

warnings.

This owner’s manual should be retained for future reference.

We suggest you keep it with your other important documents

and product manuals.

The information contained in this owner’s manual, unless

noted otherwise, applies to all models and gas control systems.

Your new gas log set will give you years of durable use and

trouble-free enjoyment.

Listing Label Information/Location

The model information regarding your specic gas log set can be found on the rating plate.

CFM Majestic

Decorative Gas Logs MODEL NUMBER

SERIAL NUMBER

INPUT RATING

Complies with RGA2-72

NOTE: TO BE USED IN A WOOD-BURNING FIRE PLACE

ONLY. KEEP DAMPER WIDE OPEN WHEN IN USE.

FOR YOUR SAFETY

Do not store or use gasoline or other ammable vapors

and liquids in the vicinity of this or any other appliance

GAS TYPE

MANIFOLD PRESS. In water column

Manufacture: CFM Corporation - Decatur, GA 30035

20012914 7/05 Rev. 0

2

Page 3

Table of Contents

1 Listing and Code Approvals

A. Appliance Certication . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Table 1

2 Getting Started

A. Size of Firebox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B. Negative Pressure

C. Tools and Supplies Needed

D. Inspect the Appliance and Components

E.

3 Appliance Preparation

A. Gas Supply Connection . . . . . . . . . . . . . . . . . . . . . . . . 7

B. Convert to Left Side Gas Piping

C. Gas Pressure

4 Installation Instructions

A. Install the Damper Stop . . . . . . . . . . . . . . . . . . . . . . . .9

B. Install the Burner/Pan Assembly

C. Install the Grate

D. Place Sand and Rockwool

E. Install the Logs

F. Adjust the Burner Flame

G. Inspect the Venting System

5 Operating Instructions

A. Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. Glass Doors

C. Important Safeguards

6 Maintaining and Servicing the Appliance

A. Servicing Your Appliance . . . . . . . . . . . . . . . . . . . . . .14

B. Cleaning Your Appliance

C. Annual Inspection

D. Troubleshooting

7 Reference Materials

A. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . .15

B. Owner Registration/Warranty . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

. . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . 5

Components of the Gas Hearth Kit . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

20012914 7/05 Rev. 0

3

Page 4

Listing and Code Approvals

1

A. Appliance Certication

The Gas Log Hearth Kits have been tested and listed in the

U.S. in accordance with ANSI Z21.84-2003 (Gas Log Set).

They have been listed by OMNI Test Labs for installation and

operation in the United States and Canada as described in

these Installation and Operating Instructions. All components

are UL, OMNI or CSA safety certied.

Check with your local building code agency prior to installing

this appliance to ensure compliance with local codes,

including the need for permits and follow-up inspections. In

the absence of local codes, comply with the National Fuel

Gas Code, ANSI Z223.1-Latest Edition in the U.S. If any

assistance is required during installation, please contact

your local dealer.

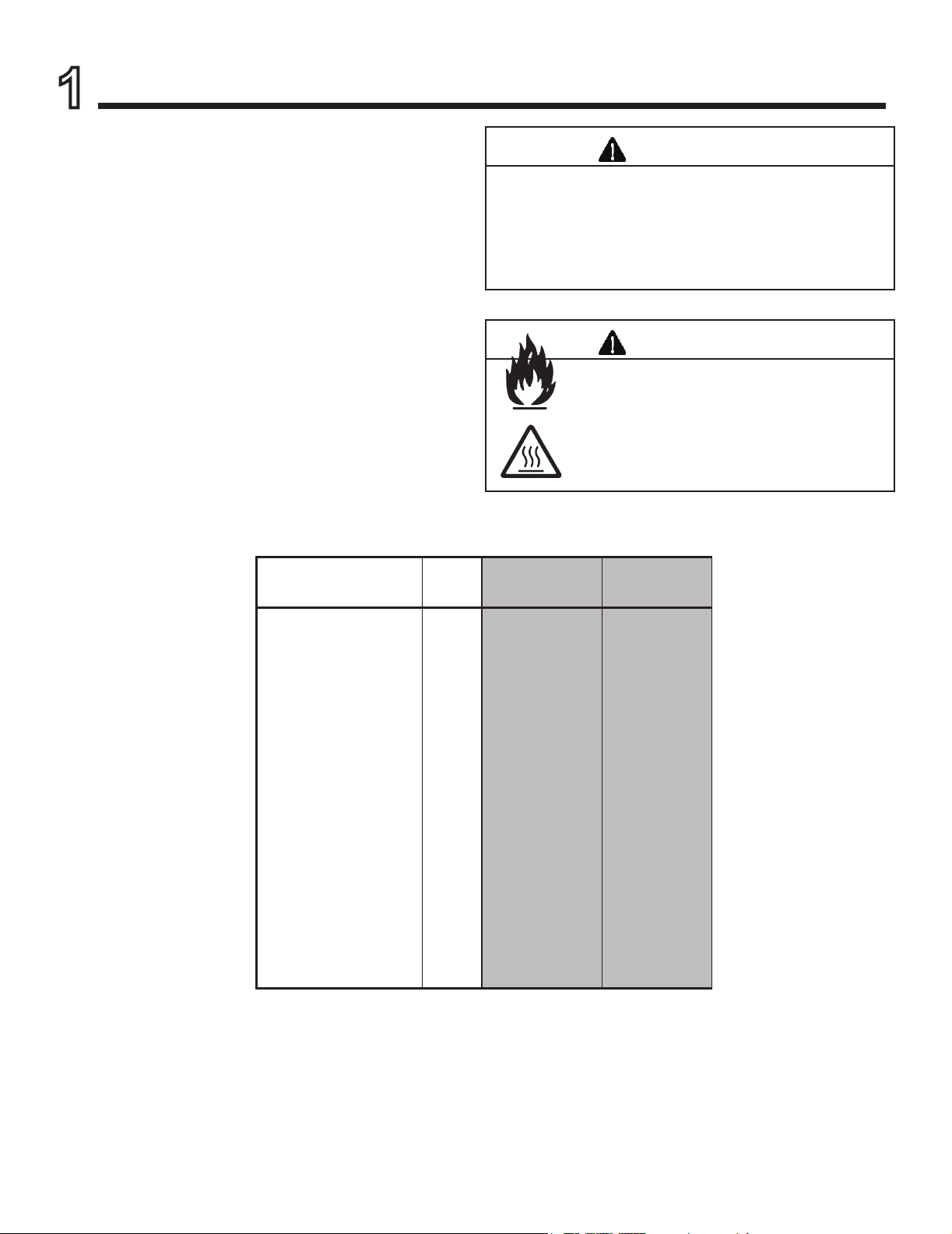

B. Table 1

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage.

Refer to the owner’s information manual provided with

this appliance. For assistance or additional information

consult a qualied installer, service agency or the gas

supplier.

WARNING

Fire Risk

Exhaust Fumes Risk

• Do NOT use this appliance as a “vent-free

heater.

The ue must be permanently open. Refer

to Table 1.

Product 18” 24”

Inlet BTU Nat. 67,000 68,000

Max. Inlet Pressure

IN. WC / KPa

Min. Inlet Pressure IN.

WC / KPa

Orice Size

In.

Minimum Fireplace

Opening Size

In. / cm

Min. Vent Opening in

Square In. / cm

These Hearth/Log Kits are for use with all CFM Factory built replaces.

Nat. 10.0 / .052 10 / .052

Nat. 3.5 / .018 3.5 / .018

Nat. (#28) (#26)

Front 33 38

Rear 20 26

Depth 15 15

Height 21 21

39 / 251.6 48 / 309.7

20012914 7/05 Rev. 0

4

Page 5

Getting Started

2

A. Size of Firebox

See Table 1 in Section 1.B.

CAUTION

B. Negative Pressure

Negative pressure results from the imbalance of air avail-

able for the replace to operate properly. Causes for this

imbalance include:

• Exhaust fans (kitchen, bath, etc.).

• Range hoods.

• Combustion air requirements for furnaces, water heaters

and other combustion appliances.

• Clothes dryers.

• Loc a ti on of re tu r n- a ir ve nt s to fu rn a ce or ai r

conditioning.

• Imbalances of the HVAC air handling system.

• Upper level air leaks: recessed lighting, attic hatch

opening, duct leaks.

C. Tools and Supplies Needed

Tools and supplies normally required for installation:

Pliers

Phillips screwdriver

Tape measure

Crescent wrenches

Gas shutoff valve

Non-corrosive leak check solution

3/4 in. wrench, 7/16 in. wrench

Sharp Edges

• We a r protective gloves

and safety glasses during

installation.

WARNING

Asphyxiation Risk

This appliance produces carbon monoxide

(CO).

• The free opening areas (in square inches)

of the chimney damper as shown in the

tables must be met.

• User must make sure damper is locked

open.

• The installer is responsible to ensure

proper ventilation of ue gases before

appliance is used.

Fire needs to draft properly fo r sa f e

operation.

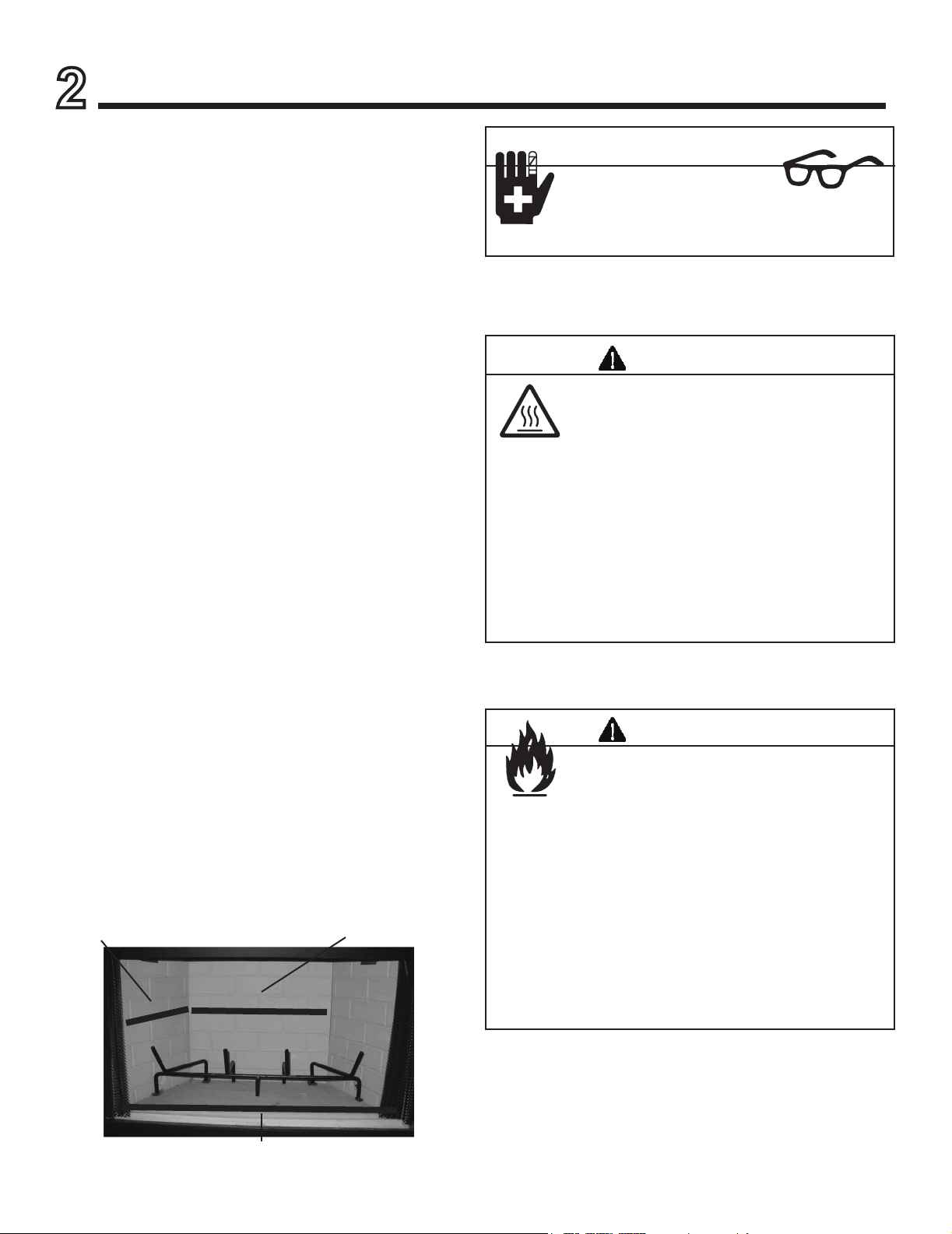

D. Inspect the Appliance and Components

• Remove the contents from the carton. Attached to the

burner are tags identifying the manufacturer name, serial

number, model number (including gas log size), BTU

ratings, gas type, etc.

• Review the attached tags before proceeding. Ensure

that all minimum replace dimension requirements are

achieved using Table 1 in Section 1.B. Ensure the gas

type provided in the replace coincide with the gas type

marked on the tag.

Rear dimensionDepth dimension

Front dimension

20012914 7/05 Rev. 0

WARNING

CFM disclaims any responsibility for, and

the warranty will be voided by, the following

actions:

• Installation and use of any damaged appliance or

vent system component.

• Modication of the appliance or vent system.

• Installation other than as instructed by CFM•

Improper positioning of the gas logs or the glass

door.

• Installation and/or use of any component part not

approved by CFM.

Any such action may cause a re hazard.

5

Page 6

WARNING

Inspect appliance and components for

damage. Damaged parts may impair safe

operation.

• Do NOT install damaged components.

• Do NOT install incomplete components.

• Do NOT install substitute components.

Report damaged parts to dealer.

E. Components of the Gas Hearth and Log Kit

The Burner/Hearth Kit consists of the following:

• Burner/Pan Assembly

• Grate Assembly

• Glowing Embers

• Sand

• Lava Rock

• Damper Stop

• Aluminum Tubing Assembly

• Brass Elbow Connector

• Brass Orice & Cap

. Log Set

WARNING

Keep appliance dry.

• Mold or r u s t may cau s e

odors.

• Water may damage controls.

WARNING

Do NOT use this appliance if any part has been under

water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

WARNING

Shock Risk

Fire Risk

Use ONLY optional accessories approved

for this appliance.

• Using non-listed accessories voids

warranty.

• Using non-listed accessories may result

in a safety hazard.

• Only CFM approved accessories may be

used safely.

20012914 7/05 Rev. 0

6

Page 7

Appliance Preparation

3

Note: Have the gas supply line installed in accordance

with local building codes, if any. If not, follow ANSI 223.1.

Installation should be done by a qualied installer approved

and/or licensed as required by the locality. (In the Common-

wealth of Massachusetts installation must be performed by

a licensed plumber or gas tter.)

A. Gas Supply Connection

Ensure ttings are of the appropriate size and type on the

gas line connection. If the tubing has to be cut to length be

sure to use the proper cutting and aring tool. Also, be careful not to crimp the tubing while bending. If the tubing becomes crimped, do not use for installation.

Certied joint compound or Teon tape must be used on all

threaded male connections to ensure a tight seal.

WARNING

Fire Risk

Explosion Risk

Verify inlet pressures.

• Hi g h pr es su re may ca us e ov er fi re

condition.

• Low pressure may cause explosion.

Install regulator upstream of valve if line

pressure is greater than 1/2 psig.

B. Convert to Left Side Gas Piping

• Remove the brass elbow from the right side.

• Remove the cap from the left side.

Note: Prior to installing the ttings, use Teon tape or joint

compound on the male threads.

WARNING

Gas Leak Risk

• Support control when attaching pipe to

prevent bending gas line.

WARNING

Fire Risk

Explosion Risk

Personal Injury Risk

An explosion could occur if a connection is

made directly to an unregulated propane (LP)

tank.

Note: An individual manual shutoff valve (not supplied) is

required when installing this appliance. Check local codes

for location of shut off valve.

Note: A listed (and Commonwealth of Massachusetts

approved) 1/2 in. (13 mm) T-handle manual shut-off valve

and exible gas connector are connected to the 1/2 in.

(13 mm) control valve inlet.

• If substituting for these components, please consult

local codes for compliance.

• Replace the cap on the opposite end of the burner tube.

• Install the brass elbow on the left side of the burner.

WARNING

Fire Risk

Explosion Risk

• Gas build-up during line purge may

ignite.

• Purge should be performed by qualied

technician.

• Ensure adequate ventilation.

• Ensure there are no ignition sources such

as sparks or open ames.

20012914 7/05 Rev. 0

7

Page 8

C. Gas Pressure

Proper input pressures are required for optimum appliance

performance. Gas line sizing requirements need to be made

following NFPA54 and CSA B-149..

WARNING

Fire Risk

Explosion Risk

High pressure will damage valve.

• Disconnect gas supply piping BEFORE

pressure testing gas line at test pressures

above 1/2 psig.

• Close the manual shutoff valve BEFORE

pressure testing gas line at test pressures

equal to or less than 1/2 psig.

WARNING

CHECK FOR GAS LEAKS

Fire Risk

Explosion Risk

Asphyxiation Risk

• Check all ttings and connections.

• Do not use open ame.

• After the gas line installation is complete,

all connections must be tightened and

checked for leaks with a commercially

available, non-corrosive leak check

solution. Be sure to rinse off all leak check

solution following testing.

Fittings and connections may have loosened

during shipping and handling.

High Altitude Derate

In the USA, input BTU shall be derated 4% (one orice size)

per 1000 feet for altitudes above 2000 feet. In Canada, input

BTU shall be derated 10% (two orice sizes) at altitudes

from 2000-4500 feet.

• Gas Supply Pressure: Minimum inlet gas supply pressure

must be 3.5 in. W.C. for the purpose of input adjustment.

Maximum inlet gas pressure must not exceed 10.0 in. W.C.

The gas line supplying the appliance must be sufcient

size to furnish the appropriate supply pressure to the

appliance while operating in the “High” setting.

• Gas Line Pressure Test: Perform pressure test according

to state and local code (if pressure exceeds 1/2 in. psi [3.5

kPa]) before appliance is connected. Be sure to release

air pressure from the gas line before connection is made

to the appliance.

• Gas Leak Test: Make sure the gas connections are tight.

Turn on the gas and coat each joint with a non-corrosive

gas leak check solution. Always check for gas leaks with a

mild soap and water solution applied with a brush no larger

than 1” (25mm). Never apply soap and water solution with

a spray bottle. Air bubbles will form indicating any leaks.

DO NOT USE A FLAME OR ANY TYPE OF IGNITION

SOURCE TO CHECK FOR LEAKS. All leaks must be

corrected before proceeding with installation.

• The appliance must only be installed in a solid-fuel burning

replace with the ue damper clamped open. The replace

must be constructed of non-combustible material.

• The minimum permanent free opening (in square inches)

that must be provided by the replace chimney or damper

to vent the ue gases is provided in Table 1. If the free

opening is smaller than the specied area, do not use this

appliance.

• The damper must be removed or xed in a manner in

which will secure it open. Some jurisdictions require the

damper to be removed or permanently welded fully open.

Check with state and local codes.

• Be sure that the chimney is completely unobstructed to

ensure proper ventilation of ue gases including carbon

monoxide (CO). CO (a poisonous gas) is tasteless,

odorless, colorless and undetectable without proper

equipment.

20012914 7/05 Rev. 0

8

Page 9

Installation Instructions

4

A. Damper Stop:

For Use With All Other Fireplaces

For Use with BR, BC, SR, SC, TF and TL Series CFM

Corporation Fireplaces

This Damper Stop is designed to work on all CFM Corporation BR, BC, SR, TF and TL series replaces. For all other

replaces, refer to note bellow.

When installing a decorative gas appliance in a replace,

some local codes require this Damper Stop to be used so

the Damper will not close completely. To install the Damper

Stop:

The Damper Locking Bracket is already installed on all BR,

BC, SR, TF and TL replaces. Locate the Damper Locking

Bracket on the left side of the replace’s Combustion Dome.

(Fig. 1)

With the Damper open, align the two slots on either side

of the cut-out on the Damper Stop with the two small holes

on the angled portion of the Damper Locking Bracket. Attach the Damper Stop with the Screws provided, as shown

in Figure 2.

NOTE: Some of the early replace units may not have the holes in

the end of the Damper Locking Bracket. If this is the case, use the

Damper Stop as a template to drill two (2) 1/8” holes in the Damper

Locking Bracket to mount the Damper Stop.

The Damper Clamp provided keeps your damper from accidentally closing during operation of your set. This Damper Clamp must be installed onto your Damper at all times.

NOTE: The damper clamp is designed to hold the damper

plate open 3 inches. However, the damper must be fully

open when the log set is in operation.

Install the Damper Clamp onto the edge of the damper plate.

Attach by securing the bolt provided to the damper plate with

an adjustable wrench. (Fig. 3)

If the Damper Clamp does not t, drill a ¼” hole onto the

damper plate and install an anchor bolt with a nut, at a 90 degree angle, so that the damper plate will remain fully open.

The proper nished installation of the Damper Clamp is

shown in Figure 4. If the bolt fails to block the damper in

an open position, the damper should be removed from the

chimney.

To check your vent for proper drafting: Light a tightly rolled

newspaper on one end and place it at the inside front edge

of the replace. Observe the smoke and be sure the vent

is properly drawing it up the chimney. If the smoke is drawn

back into the room, extinguish the ame and remove any obstruction until proper venting is achieved. If that fails, check

with a qualied chimney sweep.

Damper Locking Bracket

Figure 1

Damper Locking Bracket

DamperPlate

DamperPlate

Damper Clamp

Figure 3

Figure 2

Damper Stop

20012914 7/05 Rev. 0

Figure 4

9

Page 10

B. Install the Burner/Pan Assembly

The burner/pan assembly is shipped ready for right-hand

gas connection. See Section 3.B. for left-hand connection.

• Remove the existing cap or gas jet assembly from the

gas stub in your replace. Clean the threads using a wire

brush or steel wool. Apply Teon tape or pipe dope to the

steel tting and attach the provided brass adapter to the

stub.

• Place the burner/pan assembly in the replace. The pan

should be centered both front to back and side to side.

• Bend the provided gas connector to facilitate its installation

between the burner and the gas stub.

• Attach one end of the gas connector to the brass elbow

or safety pilot tting. Attach the other end to the brass

adapter at the gas tube.

C. Grate

• The grate, supplied with the rebox will be centered within

the rebox. Refer to Figure 4.2.

D. Place Sand and Rockwool

• Pour the sand into the burner pan. Sand should follow the

slope of pan, covering it and the burner tube completely.

• Allow the sand to spill out the front of the pan and over

the sides onto the replace oor.

• Lightly place dime-sized pieces of rockwool evenly on top

of the sand.

• The gas burns at the point of the least resistance. In case

of an uneven ame pattern it may be necessary to adjust

the materials in the pans (using an object such as a long

screwdriver) to achieve the desired effect.

WARNING

Explosion Risk

• Follow rockwool placement instructions

in this manual.

• Replace rockwool material annually.

Improperly placed rockwool interferes with

proper burner operation.

Figure 4.2 Center Grate Over Burner Pan

Note: For best results, do not pack down the rock wool.

The placement of rock wool can have an effect on ame

pattern and may need to be adjusted to achieve a desired

appearance.

10

20012914 7/05 Rev. 0

Page 11

E. Install the Logs F. Adjust the Burner Flame

• The burner ame can be adjusted at the manual shutoff

WARNING

Fire Risk

Explosion Risk

Personal Injury Risk

Failure to position the parts in accordance

with the diagrams provided with the log

pa ckages or fail ure to use onl y parts

approved with this appliance may result in

property damage or personal injury.

• Install the logs using the installation instructions included

with them.

• Light the burner as outlined in the operating section. Allow

the ame pattern to stabilize. If you are satised with the

ame pattern go to the next step. If you want more or less

ame around the front log, turn off the gas and move the

burner pan backward or forward.

• Once you are satised, turn on the gas and go on to the

next step.

• Arrange the top logs as shown in your log set up

instructions. Light the burner as outlined in the operating

instructions and allow the ame to stabilize.

• Spread the lava rock around the outside of the burner

pan on the oor of the replace. If possible, cover the gas

connector with the cinders.

MO18 MO24

valve beside the replace to obtain the desired ame

appearance.

• The flame color will stabilize after ten minutes of

operation.

G. Inspect the Venting System

The replace venting system is designed and constructed to

develop a positive ow adequate to remove ue gases to the

outside atmosphere. See replace installation instructions.

A spillage test must be made before the installed

appliance is left with the consumer

• Close all doors and windows in the home.

• Light the log set.

• After three minutes, test with a smoke match, smoke

candle, stick incense or cigarette one inch below the top of

the opening (lintel) moving across the full width. If spillage

(smoke drawn into the room) occurs, it will most likely be

near the top, outside corners.

Possible Cures if Spilling Occurs

• The damper should be fully open.

• The replace opening needs to be reduced by adding a

drop panel across the top under the lintel.

• The air supply from outdoors needs to be increased. Open

the outside air kit if the appliance is so equipped, or crack

open a door or window.

• If necessary, seek expert advice. Do not operate this

appliance.

Cleaning

• Periodic examination and cleaning of the venting system

of the replace should be done before initial use and at

least annually by a qualied agency.

Step 1

Step 3

Step 1

Step 2Step 2

WARNING

Fire Risk

Explosion Risk

Inspect external vent cap regularly.

• Ensure no debris blocks cap.

• Combustible materials blocking cap may

ignite.

• Restrict e d air flow aff ects burner

operation.

Step 3

20012914 7/05 Rev. 0

11

Page 12

Operating Instructions

5

A. Lighting Instructions

12

20012914 7/05 Rev. 0

Page 13

B. Glass Doors

If your replace is equipped with glass doors:

• Glass doors should be in fully open poisition when

appliance is operating.

• Operating in the closed position will block the radiant heat

output and may cause incomplete combustion of the gas

and increase overheating of the system.

WARNING

Fire Risk

Explosion Risk

Do not close the glass doors during appliance

operation.

• Could cause incomplete combustion of

the gas.

• Glass doors may be closed when the hearth kit is not being

used.

C. Important Safeguards

• Other Fuels

- Although your gas log set is very realistic in appearance,

it is not a real woodburning re and must not be used

for burning any fuel other than natural gas.

- To avoid irreparable damage to the appliance and/or

personal injury, wood, matches, paper, garbage or any

other material must not be placed or thrown on top of

the logs.

• Appliance Safety

- To avoid personal injury, do not touch hot surfaces

when the appliance is operating.

- Always ensure that the replace screen is closed when

the appliance is operating.

- Close supervision is necessary when the appliance is

being used near children.

• Do not remove any of the attached metal plates, which

contain important safety and operating information.

• Keep the appliance area clear and free of all combustible

materials, gasoline and other ammable vapors and

liquids.

WARNING

Do NOT use this appliance if any part has been under

water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

•

A qualied service technician must perform installation

and repair. The appliance should be inspected and cleaned

annually by a qualied service technician. More frequent

cleaning may be required due to excessive lint, dust, pet

hair, etc. It is imperative that the control compartments,

burners and air passageways are unobstructed during

operation.

- Review proper placement of logs, rockwool, lava rock

and sand.

- Ensure there are no gas leaks.

- Ensure the ow of combustion and ventilation air is not

obstructed (front grilles and vent caps).

• Before installing into a solid fuel burning replace, the

chimney and rebox should be inspected and cleaned to

remove soot, creosote, ashes, paint, bird nests etc.

• Annual examination of the chimney must be performed

by a qualied agency to ensure proper ventilation of ue

gases created by this appliance.

• Have the chimney and adjacent structure inspected

and cleaned by qualied professionals. Hearth & Home

Technologies recommends that NFI certied professionals,

or technicians under the direction of certied professionals,

conduct a minimum of an NFPA 211 Level 2 inspection

of the chimney.

• Replace component parts of the chimney and replace as

specied by the professionals.

• Ensure all joints are properly engaged and the chimmney

is properly secured.

• Do not allow fans to blow directly into the replace. Avoid

any drafts that alter burner ame pattern.

• Do not use a blower insert, heat exchanger insert or other

accessories not approved for use with this appliance.

Solid fuels shall not be burned in a replace where a

decorative appliance is installed.

• If glass doors are present, the glass doors must be fully

opened while appliance is in operation.

WARNING

Fire Risk

High Temperatures

Keep combustible household items away

from appliance.

Do NOT obstruct combustion and ventilation

air.

• Do NOT place combustible items on top

of or in front of appliance.

• Keep furniture, draperies away from

appliance.

20012914 7/05 Rev. 0

13

Page 14

Maintaining and Servicing the Appliance

6

A. Servicing Your Appliance

WARNING

Risk of injury or property damage

Before servicing:

• Turn off gas.

• Turn off electricity to appliance.

• Disable remote control, if one is present.

• Ensure appliance is completely cooled.

After Servicing:

• Replace any screen or barrier that was removed.

• Reseal and reinstall any venting removed for

servicing.

• Repair and replacement work should be done by a

qualied service technician.

• Always shut off the gas supply and make sure the appliance

is cool before beginning any service operation.

• Always check for gas leaks after servicing.

• Always check for proper venting.

C. Annual Inspection

WARNING

Annual inspection by qualified technician

recommended.

Check:

• Condition of doors, surrounds and fronts.

• Obstructions of combustion and ventilation

air.

• Condition of logs.

• Condition of rebox.

• Gas connections and ttings.

• Obstructions of termination cap.

Clean:

• Glass.

• Logs.

• Burner, burner ports.

Risk of:

• Fire

• Delayed ignition or explosion

• Exposure to combustion fumes

• Odors

B. Cleaning Your Appliance

Your gas logs require little care. Keep the burner assembly,

logs and burner area surrounding the logs clean by

vacuuming or brushing with a dry paint brush at least twice

a year.

• The logs become fragile after burning. Take care in

handling.

• Always turn off the gas before cleaning. For relighting,

refer to lighting instructions located in Section 5.A. of these

instructions.

• Always keep the appliance clear and free from combustible

materials, gasoline, and other ammable vapors and

liquids.

• Never obstruct the ow of combustion and ventilation air.

Keep the front of the appliance clear of all obstacles and

materials.

• Leave clearance of at least 36 in. from the front of the

replace.

• The air shutter should not be blocked.

CAUTION

• Logs can get very hot. Handle only when they are

cool.

D. Troubleshooting

With proper installation and maintenance, your new

decorative gas appliance should provide years of trouble-

free service. If you do experience a problem, refer to the

troubleshooting guide below. This guide will assist you or a

qualied service technician in the diagnosis of problems and

the corrective action to be taken.

Symptoms Possible Causes Corrective Action

1. A match will

not light the

main burner;

no gas to the

main burner

A. Main gas shutoff

valve is closed

B. There is air in the

gas line.

C. No gas supply to

the appliance.

D. A blockage is

preventing gas ow.

1. Make sure the shutoff

valve located on the

incoming gas line is

open.

1. Bleed air from the gas

line; wait ve minutes

and attempt to relight

the main burner.

1. Check the plumbing to

ensure the appliance

has been hooked up

to the gas supply line.

1. Inspect the burner

orice for obstruction.

Call a qualied

service technician.

14

20012914 7/05 Rev. 0

Page 15

Reference Materials

7

A. Replacement Parts

Replacement Parts

Exploded Parts Diagram

1 - Burner Pan Assembly

CFM HeartH Kits

Connection Hardware

2 - Grate Assembly

3 - Hearth Kit Assembly

Connector Tube

Connection Hardware

Orice

20012914 7/05 Rev. 0

15

Page 16

Service Parts

Service Parts List

Description of Part MO18M MO24M Qty.

Damper Stop Assy 4304045 4304045 1

Burner Pan Assy 20013012 20013013 1

Orce 20013017 20013018 1

Connector Tube 20013023 20013023 1

Sand 4310006 4310006 1

Lava Rock 4310010 4310010 1

Glowing Embers 4310001 4310001 1

Damper Stop for BR/BC, SR/SC, TF/TL only 3030176 3030176 1

Damper Stop Screws 7521901 7521901 2

CFM HeartH Kits

Description of Log Parts MO18M MO24M Qty.

Log 1 20013043 20013048 1

Log 2 20013044 20013049 1

Log 3 20013045 20013050

Log 4 20013046 20013051 1

Log 5 20013047 20013052 1

Log 1

Log 2

Log 2

Log 1

Log 4Log 3

Log 4Log 3

1

16

Log 5

Log 5

20012914 7/05 Rev. 0

Page 17

B. Optional Components

Safety Pilot Burner/Hearth Kits

20013010 Hearth ember burner for 18 in. hearth kits

20013011

Remote Ready Burner/Hearth Kits

20013019 Hearth ember burner for 18 in. hearth kits

20013020

20013021

20013022

20013025

Hearth ember burner for 24 in. hearth kits

Hearth ember burner for 24 in. hearth kits

on/off remote control

Wall switch (on/off only)

Switch in Log

20012914 7/05 Rev. 0

17

Page 18

B. Owner Registration/Warranty

Please complete and return your owner registration card to ensure proper warranty coverage. If you wish to communicate

with the factory, write to

LIMITED ONE YEAR WARRANTY

For CFM Corporation Decorative Gas Appliances

CFM Corporation extends the warranties specied in paragraphs A and B below with respect to its Vermont Castings

Decorative Appliances (the “Gas Appliance”), including CFM

Corporation supplied accessories and components referred

to in those paragraphs, subject to the following conditions and

limitations:

(1) These warranteis extended only the the Gas Appliance installed in the continental United States, including Alaska, and

Canada; only if and so long as the accordance with the installation and operating instructions furnished therewith; and only

if and so long as Gas Appliance is not removed from its original

installation.

(2) These warranties are limited to only the component parts

manufactured and supplied by CFM Corporation. The use of

components manufactured by others with the Gas Appliance

(except for a listed Type B venting system and dened in the installation instructions) could create serious safety hazard, may

result in the denial of certication by recognized national safety

agencies, and could be in violation of local building codes.

(3) The Gas Appliance must be operated at all times in accordance with the operating instruction furnished therewith. The

Gas Appliance is designed to burn either natural or propane

gas only. Burning conventional replace fuels such as wood,

coal, or any other solid fuel will cause damag to the Gas Ap-

pliance, will produce excessive temperatures and will result in

re hazard.

(4) These warranties are limited to repair, replacement or furnishing a replacement for sale, as specied in Paragraphs A

and B, for a part found to CFM Corporation satisfaction, after

examination, to be defective in materials or workmanship under

normal conditions, use and service.

(5) All obligations with respect to these warranties may be fully

discharged by CFM Corporation refunding the wholesale price

of a defective part.

(6) Except as otherwise expressly specied in Paragraphs A

and B. NONE OF THESE WARRANTIES COVER AND CFM

CORPORATION SHALL NOT BE RESPONSIBLE FOR, ANY

CONSTRUCTION, INSTALLATION, LABOR, TRANSPORTATION OR OTHER COSTS OR EXPENSES ARISING FROM

A DEFECTIVE PART, ITS REPAIR OR REPLACEMENT OR

OTHERWISE, NOR SHALL CFM CORPORATION IN ANY

EVENT BE RESPONSIBLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, EXCEPT TO THE EXTENT PROVIDED BY LAW. THERE ARE NO IMPLIED WARRANTIES WITH RESPECT TO THE GAS APPLIANCE, ITS

COMPONENTS AND ACCESSORIES (INCLUDING IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), ALL OF WHICH ARE HEREBY EXPRESSLY INCLUDED.

IN NO EVENT SHALL ANY IMPLIED WARRANTY PRESCRIBED BY LAW (NOTWITHSTANDING THE FOREGOING

EXPRESS EXCLUSION) REMAIN IN EFFECT AFTER EXPIRATIONS OF WARRANTIES SET FORTH IN PARAGRAPHS

A AND B.

A. Gas Appliances, electrical and manual components,

glass panels, all sealants or adhesives and optional acces-

sories (exclusive of CFM Corporation supplied decorative logs

which are covered by a separate warranty under paragraph B

below):

Within one year from the date of manufacture of the gas ap

pliance, CFM Corporation will repair, or replace (at our option) a

defective part without charge.

B. Cement or ceramic ber log components:

Within one year from the date of manuracture of the gas ap

pliance, CFM Corporation will replace a defective part without

charge. Within one year from the date of manufacture of the

gas appliance, CFM Corporation will provide a replacement for

a defective part to the homeowner, but assumes no liability for

incurred labor cost.

The foregoing warranties gives you specic legal rights and

you may also have other rights which vary from state to state.

Some states do not allow limitations on how long an implied

warranty may last, so the limitation specied above on the du-

ration of any implied warranty prescribed by law may not apply

to you. Similarly, some states do not permit the exclusion or

limitation of incidental or consequential damages, so the above

exclusion of such damages may not apply to you.

In order to obtain performance of any of the above warranty

obligations, write to the CFM Corporation at this address:

CFM Corporation

410 Admiral Blvd.

Mississauga, Ontario Canada L5T 2 N6

Attention: Manager of Warranty Services

Since local building requirements may vary greatly through

out the country, users of CFM Coproation products should de-

termine in advance whether there are any building code restric-

tions on the use of a specied product. CFM CORPORATION

MAKES NO REPRESENTATION OR WARRANTY REGARDING, AND SHALL NOT BE RESPONSIBLE FOR, ANY BUILDING CODE COMPLIANCE. The foregoing warranties give you

specic legal rights and you may also have other rights which

vary from state to state.

-

-

-

18

20012914 7/05 Rev. 0

Loading...

Loading...