Page 1

v/4

,s

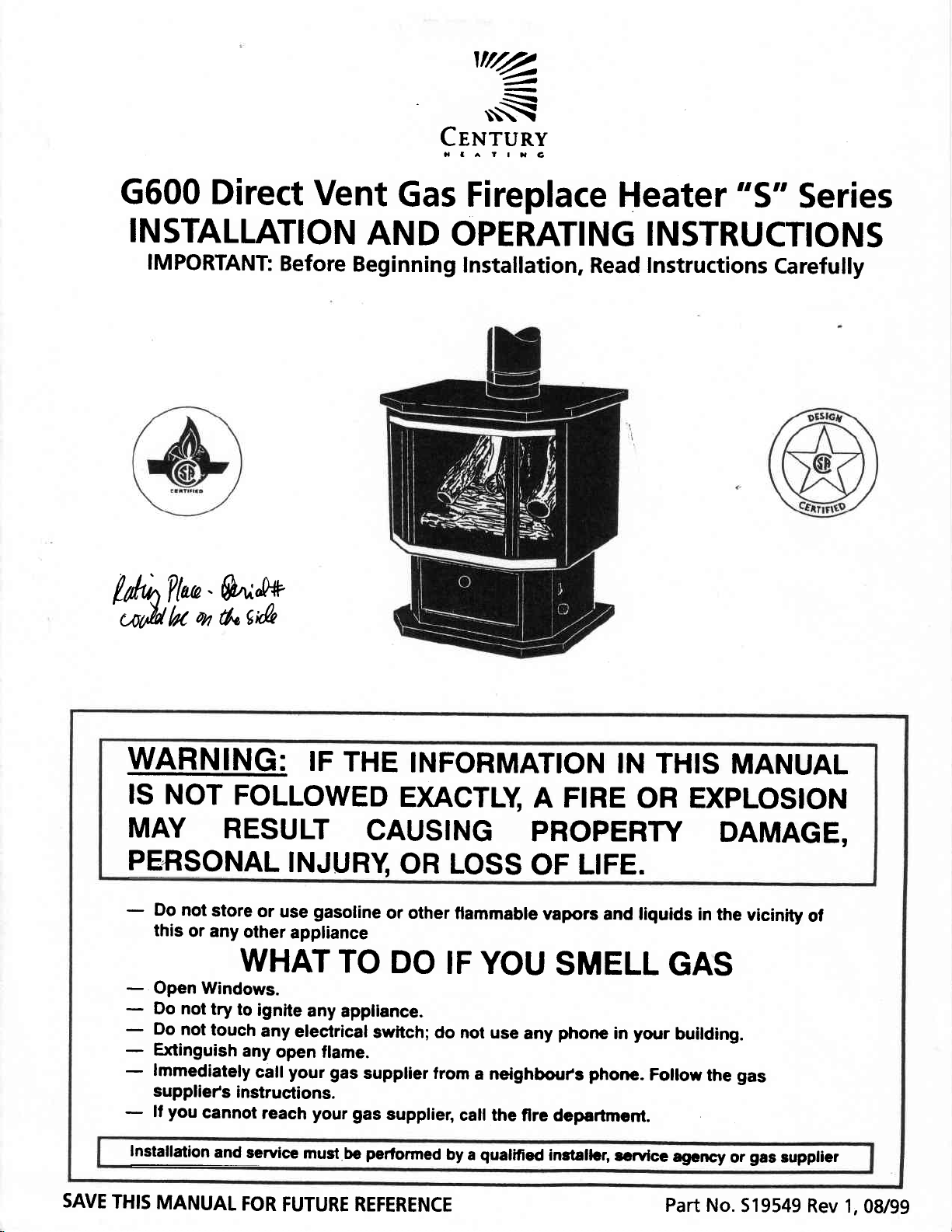

G600

INSTALLATION

lM PORTANT

ldrt^\lor

,nald

Direct

-

&^ep,

an

ta

6"

Before

silt

vent

AND

Beg

9rlrt

Gas

sy

Heater

OPERATING

inning

Installation,

Read

"s"

Instructions

Carefully

series

SAVE

WARNING:

IS NOT

MAY

FOLLOWED

RESULT

PERSONAL

-

Do

not

store or

this

or any

other

WHAT

-

Open

-

Do not

-

Do

-

Extinguish

-

lmmediately

supplie/s

-

ll

Installdion

THIS

Windows.

try

not

touch

you

cannot

and sewicc

MANUAL

to

ignite

any

any

call

instructions.

reach

FOR

IF

THE

INFORMATION

EXACTLY

CAUSING

TNJURY

gasoline

use

appliance

TO

any

appliance.

electrical

open flame.

your gas

your gas

must

be

FUTURE REFERENCE

OR LOSS

or other

DO

switch; do

supplier trom

supplier,

performed

IF

by a

A FIRE

PROPERTY

OF

flammable

yapors

YOU

not use

a neighbour.s

call the

any

flre department.

qualified

IN THIS

OR EXPLOSION

LIFE.

and liquids

SMELL

phone

ingtallcr,

your

in

phone.

scrvice

Follow

MANUAL

DAMAGE,

in

the

GAS

building.

the

agcncy

Part No.

or

vicinity

gas

gas

rupplier

519549

ol

Rev I

,0glgg

Page 2

CONTENTS

Description

lmportant

Installation

Instructions,

Clearances

Replacement

Glass Cleaning

Venting

Venting

Parts

Planning

Horizontal

Vertical

Cathedral

#1

List

Your

Installation

I nstallation

Termination

Ceiling

Installation

General

Page #

4

5

6

7

7

I

I

9

-

l\

it

10

10

11

13

16

19

20

For Your

Safety,

Lighting

To Turn

Off Gas To Appliance

Maintenance

Parts

Parts

Diagram

List

Fap,

Trouble

Shooting

Warranty

"WARNING:"

SERVICE

REFER

OR

TO

INFORMATION

GAS

SUPPLIER.

IMPROPER

MAINTENANCE

THIS

CONSULT

Before

Instruction

I nstructions

INSTALLATION,

CAN

MANUAL FOR

QUAL|FIED

Lighting

ADJUSTMENL

CAUSE INJURY

ASSISTANCE OR FOR

21

22

23

23

24

25

26,27

28,29

30

ALTERATION,

PROPERW DAMAGE.

ADDITIONAL

SERVTCE

OR

Page 3

-

Study these

Installation

Gas

Maintain

Code,

clearances

IMPORTANT

instructions carefully

conform to Local Codes,

must

ANSI 2223.1

(USA);

for servicing and

and

completely

Canadian

proper

INFORMATION

before

in

or,

the

absence

installation

operation. (See

installation.

must

fotlow

of Local

Clearance

Codes,

CAN/CGA-BI49-1

Section)

with

the Current

or 2

(latest

National

Edition).

Fuel

DANGER:

CARBON

The

rate

This

convert

WAR

IS FACTORY

DANGER:

SUPPLY

EXPLOSION.

MONOXIDE

maximum

is

21,000

heater is equipped

BTU/hr (Natural

heater

the

N ING:

EQUIPPED

CONTAINER

CAUTION:

ERRoRS

cAN cAUsE

"VERIF(

PROPER

oPERArtoN

POISONTNG.

gas

input

rate

with

controls

for

use

with another

coruvenTtNc

MAY LEAD TO

opERATtoN

WILL LEAD TO

LABEL

ALL wtREs

tMpRopER

OPERATION

oF THts AppLtANcE

is 28,000

Gas), 19,000

BTU/hr

and

orifices

type

BTU/hr

of

orratANcE

PERSONAL

oF THts

AppuANcE

GAS

LEAKS

pRtoR

AND

To

DANGERoUs

oN

(Natural

(propane/Lp).

for

gas.

FoR

INJURY

oN

AT

DtscoNNEcnoN

AFTER

GAsEs

Gas),

only

usE

Lp

THE

FoR

wHrcH

26,000

the

wrrH

OR DEATH.

cAs

BTU/hr

type

of

ANy

wrrHour

coNTRoL

wHEN

opERATtoN.

SERY'C'NG,.,

rr

rs Nor

(Propane/Lp).

gas

on the

cAs

orHER THAN

AN

AppRovED

WITH

A hossle|LmT

sERvrctNG

')

EourppED

rating

plate.

"o*rro...

MAy

LEAD

The

minimum

Do

not

THAT

REGUI-AToR

oF FIRE

gas

attempt

wHtcH

Ar rHE

oR

wrnrNc

To

input

to

rr

BROKEN.

PERSON.

DUE

FROM

ANY

APPLIANCE.

CHILDREN

SHOULD

YOUNG

APPLTANCF;'

DO

NOT

INSTALL.ATION

THE

SERVICE

:9YE

BURNERS

WARNTNG:

IT

IS

::5:i:91:llt-1ry-D

:5:Yj:5,-T?.Ll.9TL.oJFlAIrgN.

REPLACEMENT

To

HIGH

TEMPERATURES,

FUBNITURE

PARTS

APPLIANCE

IMPERATIVE

REMOVED

AND

ADULTS

BE

KEPT

CHILDREN

PLACE

CARPETTNG,

CLOTHING

AND

SHOULD

PERSON.

AND

CTRCULATING

ANY

CHANGE

TH

OF THE

AND

DRAPERIES.

FOR

SHOULD

AWAY

TO

SHOULD

OR

REPAIR

BE

MORE

BEDDING

FREQUENT

TO

CL_EAR.

PANEL

THE

AppLtANcE

SERVICING

BE

ALEHTED

AVOID

BE

SHOULD

THISAPPLIANCE

BURNS

CAREFULLY

OTHER

INSPECTED

MATERIAL,

AIR

FLAMMABLE

BE

PASSAGEWAYS

pnovloe

Heven

SHOULD

THE

APPLIANCE

TO

OR

CLOTHING

SUPERVISED

DONE

CLEANING

FoR

BY

A

BEFORE

MAY

ETC. IT

OF THE

OR

ITS

ADEoUATE

oBsrRucr

OF

THE

BE

DONE

sHouLD

MUST

THE

HAZARD

WHEN

MATEHIAL

OUALTFIED

USE

AND AT LEAST

BE REOUIRED

IS IMPERATIVE

CONTROLS

coMBusiloN

BY A

LICENSED

BE

LocATED

BE REPLACED

OF HIGH

IGNITION.

THEY ARE IN

ON OR NEAR THE APPLIANCE.

ANNUALLY

DUE

THAT

APPLIANCE

BE KEPT

CAN BE

DANGEROUS.

AND

OR

our

oF TRAFFIc

PRIOR

SURFACE

THE

TO

CONTROL

CLEAN.

vENilAnoN

;#;ffii';lHllilHH;

rHE

FRoNr

BUILDING.

opENrNG

oF rHE

OUALIFIED

eHffifrJ

TO

OPERATING

TEMPEFATURE

SAME

EXCESSTVE

ROOM

BY

A PROFESSIONAL

LINT

COMPARTMENTS,

AtR.

AppL|ANce

SERVICE

THE

AND

WITH THE

FROM

pRovtDE

on

Page 4

appliance;

The

in the

or,

National

when installed

absence

Electrical

I N

STALI-^ATION

must

be electrically

of local codes, with the current CSA C22-1

Code ANSI/NFPA

TGlatest

edition

I NSTR

connected

(USA).

UCTIONS

grounded in accordance

and

Canadian

Electrical

Code

local codes

with

(Canada)

or the

appliance

Keep

vapours.

Installation

local

the

with

gas

Turn

Do not

lmmediately

control

The

appliance and

during

KPa).

The

appliance must be

valve

p.s.i.g.(3.5

piping

Gas

Code ANSI

system

piping

and

codeS,

during any

with the National

current

supply

use this

call

system

pressure

any

..

KPa).

must be installed in accordance with local

2223.1

supply

systems

area clear and

provision

CAN/CGA

on and check for leaks.

appliance

qualified

a

and any

the heater

will

gas

its individual

testing of

isolated

pressure

(U.S.A.).

damage the controls used on this heater.

free from

for

combustion

Gas

Fuel

-

if

testing of

disconnect or

-

8149

part

any

service

control

shutoff

the

from the

(ln

Canada

1 or

has

technician to inspect the room

which has been under water.

gas

the

combustible

and ventilation air

Code,

2Installation Gode.

ANSI

DO NOT

been

valve must

supply

gas

gas

-

CAN/CGA.BI49-1

isolate

USE

under water.

piping

supply

supply

the heater from

materials,

2223.1

piping

-

OPEN FLAME.

be disconneaed;trom

system

piping

system

codes,

gasoline,

conform

must

latest edition

Use

appliance

pressures

test

at

system

or 2.) During

Do

by closing

at test

with the

or

piping

the

not use

other

and

local

with

-

in the United

and

soap

and

the

in excess

its individual

pressures

latest

edilion

pressure

syslem.

flexible

hose.

llammable

codes or,

States

water solution.

to replace

gas

supply

equal

testing

pressure

The

any

piping

112

oI

manual shut

to or

of the National Gas

ihe

of

liquids and

in

absence

in

or,

Canada,

parl

of

system

p.s.i.g.

less

than

gas piping

to test

used

of

the

(3.5

off

1/2

gas

Unions in

must

Gas

inches

The

Propane/LP

the

The

excessive

Include

servicing.

for

Use

bubbles

lmpoftant:

silicone.

resistant to the

be

piping

water

maximurn inlei

gas

must have a regulator which reduces the

control will not

a

gauge

test

a soap/water solution

which indicates

lines

must be

column

gases.

pressure.

manual shut-off

Include a drip leg

connection immediately

Atl references

should

action of

ol sufficient size to

for

natural

gas pressure

lf this heater is to

operate with

device and union

or a liquid

gas

to siliconing should

be of

gas

and a

leaks.

the

liquefied

or

to

lhe

gas

plugged

ground

be supplied

upstream ol

gas

joint

type. Compounds

petroleum gas.

provide

11 inches for Propane/LP

heater must not

line

118 inch NPT

leak detector to

a minimum

with

gas pressure

pressure

in the line

the

be adhered

exceed

gas (bottled

LP

directly from

the control

so

tapping

gas

supply

coat

to. Always use

used on

natural

10.5

to between

each

gas

gases

in the

for the

inches for

propane)

tank and may

the

or heater may

line.

connection

joint

threaded

pressure

purpose

naturalgas

the tank

11

and

The tapping must

to the

in

piping

the

600"F

ioints

the

al

of inpul

or bottle supplying

13 inches

leak

be

appliance.

system.

(316"C)

piping

gas

of

appliance of

adjustment.

and 13 inches for

water column.

gas

due

disconnected

be accessible

and

temperalure

high

4.5

to this

for

look lor

Page 5

'l:t

i;

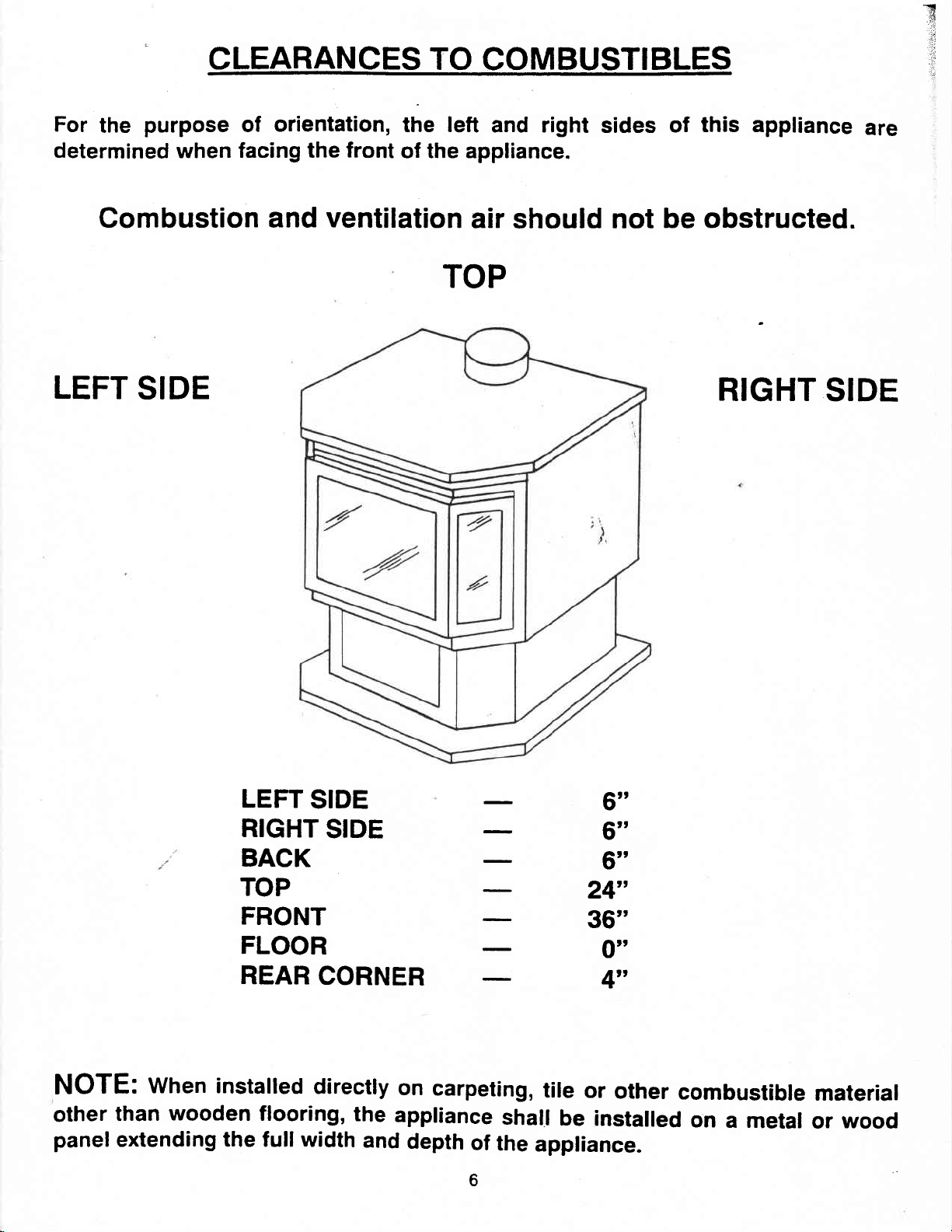

CLEARANCES

For

determined

LEFT

purpose

the

when

Combustion

SIDE

orientation,

of

facing the

ventilation

front

TO

the left

the appliance.

of

COMBUSTIBLES

and right

air

should

TOP

sides

of

not be

this appliance

obstructed.

RIGHT

SIDE

are

NOTE:

other

panel

than

extending

LEFT

SIDE

RIGHT

BACK

TOP

FRONT

FLOOR

REAR

When installed

wooden

flooring,

SIDE

CORNER

directly

on

the

appliance

and

depth

carpeting,

of

6

tile

shall

the

appliance.

6rt

6rt

6"

24"

36"

0"

4"

or

other

be

installed

combustible

on

a

metal

or

material

wood

Page 6

{

*'

3-,

I

5

a.

:

i

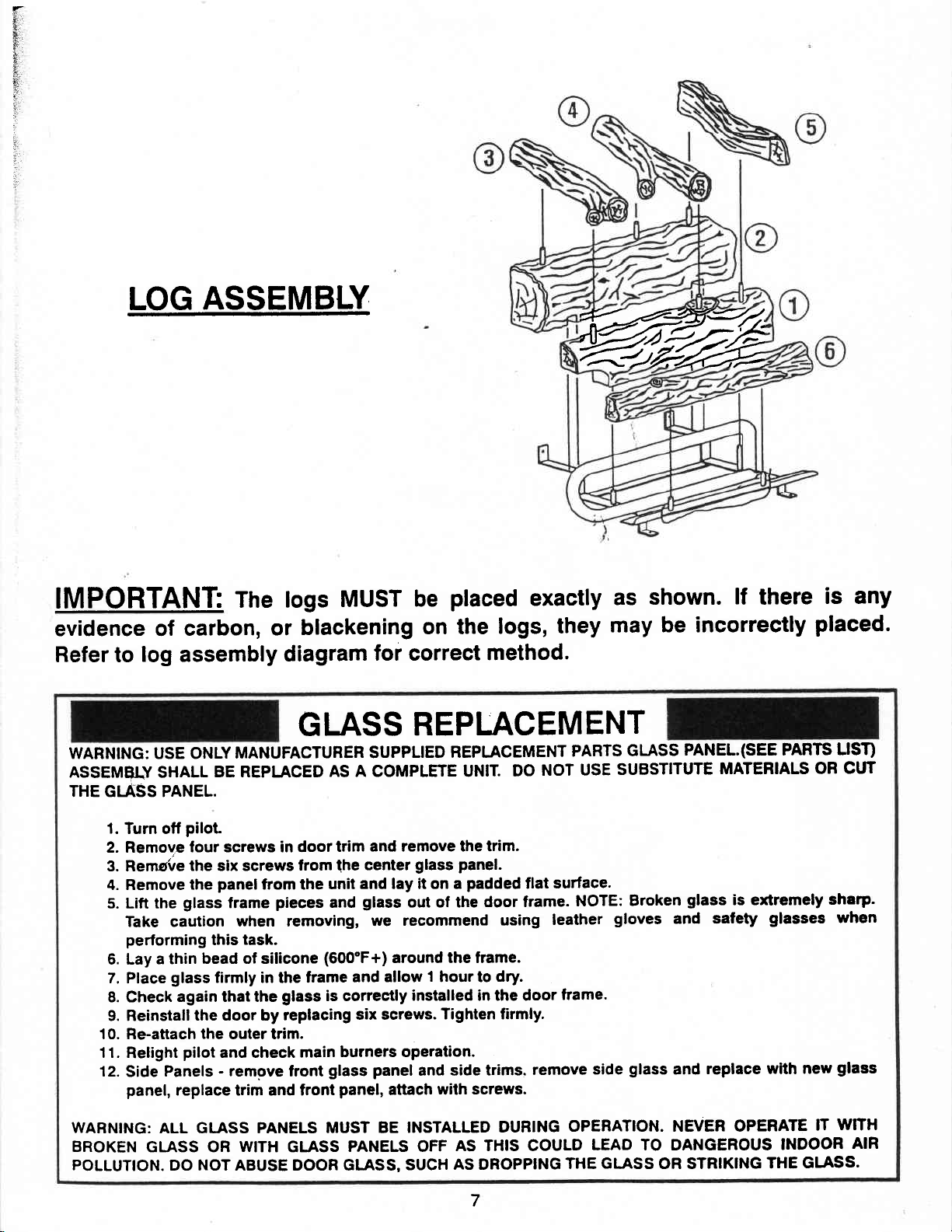

LOG

IMPORTANI

evidence of

Refer to

WARNING:

carbon,

log assembly

ONLY

SHALL

ASSEMBLY

fne logs

or

diagram

MUST

blackening

for correct

GLASS

MANUFACTURER

REPI-ACED

BE

SUPPLIED

AS A COMPLETE UNIT.

placed

be

on the

exactly

logs,

they

shown.

as

may

be incorrectly

method.

REPI-ACEMENT

REPLACEMENT

DO

PARTS

NOT USE

GLASS

SUBSTITUTE

PANEL.(SEE

lf

there

is any

placed.

MATERIALS OB

LIST)

CUT

1.

Turn off

2. Remove

3. Remdve

4. Remove the

5. Lift the

Take caution

performing

6. Lay

7.

8. Check

9. Reinstallthe

10. Re-attach

1 1.

12.

WARNTNG:

BROKEN

POLLUTION.

a thin

Place

Relight

Panels

Side

panel,

ALL GI.ASS PANELS

GLASS OR

pilot

and remove the trim.

four screws in door

the six screws

panel

from the

glass

frame

this

bead of silicone

glass

firmly in

again that the

door by replacing

lhe

outer trim.

pilot

and check

-

remove

replace trim and front

DO NOT ABUSE DOOR GLASS,

pieces

when removing,

task.

the

glass

WITH

G1ASS

trim

lrom

frame

main

front

center

the

and lay it on a

unit

glass

and

we

(600"F+)

is correctly

burners operation.

glass panet

panel,

MUST BE INSTALLED

around the frame.

allow t hour to

and

six screws.

attach

PANELS OFF

panel.

glass

padded

out of the

recommend using

installed in the door

Tighten firmly.

and side

screws.

wilh

AS THIS COULD

SUCH

AS DROPPING

7

flat

door frame.

dry.

trims.

remove

DURING

surface.

glass

NOTE:

leather

frame'

OPERATION. NEVER OPERATE

THE

Broken

gloves

side

LEAD TO DANGEROUS

GI-ASS

and salety

glass

and

OR STRIKING

is extremely

glasses

replace with

THE

sharp-

when

glass

new

WITH

lT

INDOOR

GI.ASS.

AIR

Page 7

GLASS

CLEANING

NOT

WARNING:

1.Turn

2.Remove

3.

WARNING:

.with

5.Feplace

e.Reiight

I

READ

INSTALLATIOT.I.

DAMAGE

DO

off

Pilot.

four

Remove

gt6ss surface

six

NOT

DO

a soft

door

pilot

VENTI

INSTRUCTIONS

ALL

LOSS

OR

CLEAN

screws

screws

USE

rag

and

by

and

in

ABRASIVES

paPer'towel

or

wipe

reversing

check

NG'l:,'J,flhT*Ii?,i,[B\OCEDU

FAILURE

LIFE.

OF

GLASS

door

in

center

off

main

TO

WHEN

trim

glass

ON

use

surface

until

the operation

burners

COMPLETELY

SO

DO

HOT'

remove'

and

panel

GLASS

regular

is dry'

operation'

AND

COULD

remove

and

SURFACE.

glass

remove

to

RESULT

cleaner,

door.

THOROUGHLY

IN

panel'

spray

BEFORE

SERIOUS

glass

the

RE

ATTEMPTING

INJURY

cleaner

on

I

PROPERTY

VENT

NOTE:

THE

PA|NTTocooRD|NATEw|THTHEEXTER|oRF|N|SH.

NOTE:

NOTE:

NOTE:

SEAL

(316'C)

BEFORE

stLtcoNE

ENSURE

PIPES

OPERATION

COULD

VENTING

REFER

AFTER

HIGH

CONNECTIONS.

ALL

OF

EVERY

JOINING

SEALANT

THAT ALL EXCESS

THESE PIPES ARE

AS

RESULT

TERMINAL

A

HAS

TO GRAPH

ANY

TEMPERATURE

THE CONNECTIONS

TIME

OF IMPROPERLY

IN

MAINTENANCE

A VENT

ELBOWS

(cE

SERIOUS

MAY

INCH

ONE

PAGE

ON

SILICONE

CONNECTION

AND

106/LOCT!TE

Rn/

SEALANT

VISIBLE

INSTALLED

INJURY

PAINTED

BE

CLEARANCE

(Ftc.1) FoR

11

REOUIRING

WITH

PIPES

ONCE

APPLY

IS CAREFULLY

PROPERTY

WITH

TO

MUST

HIGH

lS MADE-

81s8s)

RTV

INSTALLATION

THE

AND

DAMAGE

450"F

COMBUSTIBLES.

INSTALLATION

DISCONNECTION

BE

TEMPERATURE

BEAD

A

MAINTAINED

(232'C)

USED

OF

END

TO

CLEANED

LOSS

OR

HEAT

VARIABLES.

TO

SILICONE

HIGH

OF

OFF

IS COMPLETE.

VENTING

RESISTANT

VENTING'

OF

RE-SEAL

TEMPERATURE

ELBOW

THE

OF

OR

EXTERIOR

LIFE.

ALL

(6OO"F)

PIPE.

SYSTEM

Page 8

GLASS

CLEANING

NOT

WARNING:

1.Turn

2.Remove

3.

WARNING:

4.with

5.Feplace

e.Reiight

I

READ

INSTALLATIOT.I.

DAMAGE

DO

off

Pilot.

four

Remove

gt6ss surface

six

NOT

DO

a soft

door

pilot

VENTI

INSTRUCTIONS

ALL

LOSS

OR

CLEAN

screws

screws

USE

rag

and

by

and

in

ABRASIVES

paPer'towel

or

wipe

reversing

check

NG'l:,'J,flhT*Ii?,i,[B\OCEDU

FAILURE

LIFE.

OF

GLASS

door

in

center

off

main

TO

WHEN

trim

glass

ON

use

surface

until

the operation

burners

COMPLETELY

SO

DO

HOT'

remove'

and

panel

GLASS

regular

is

operation'

AND

COULD

remove

and

SURFACE.

glass

dry'

remove

to

RESULT

cleaner,

door.

THOROUGHLY

IN

panel'

spray

BEFORE

SERIOUS

glass

the

RE

ATTEMPTING

INJURY

cleaner

on

I

PROPERW

VENT

NOTE:

THE

PA|NTTocooRD|NATEw|THTHEEXTERIoRF|N|SH.

NOTE:

NOTE:

NOTE:

SEAL

(316'C)

BEFORE

stLtcoNE

ENSURE

PIPES

OPERATION

COULD

VENTING

REFER

AFTER

HIGH

CONNECTIONS.

ALL

OF

EVERY

JOINING

SEALANT

THAT ALL EXCESS

THESE PIPES ARE

AS

RESULT

TERMINAL

A

HAS

TO GRAPH

ANY

TEMPERATURE

THE CONNECTIONS

TIME

OF IMPROPERLY

IN

MAINTENANCE

A VENT

ELBOWS

(cE

SERIOUS

MAY

INCH

ONE

PAGE

ON

SILICONE

CONNECTION

AND

106/LOCT|TE

Rn/

SEALANT

VISIBLE

INSTALLED

INJURY

PAINTED

BE

CLEARANCE

(Ftc.1) FoR

11

REOUIRING

WITH

PIPES

ONCE

APPLY

IS CAREFULLY

PROPERTY

WITH

TO

MUST

HIGH

lS MADE-

81s8s)

RTV

INSTALLATION

THE

AND

DAMAGE

450"F

COMBUSTIBLES.

INSTALLATION

DISCONNECTION

BE

TEMPERATURE

BEAD

A

MAINTAINED

(232'C)

USED

OF

END

TO

CLEANED

LOSS

OR

HEAT

VARIABLES.

TO

SILICONE

HIGH

OF

OFF

IS COMPLETE.

VENTING

RESISTANT

VENTING'

OF

RE-SEAL

TEMPERATURE

ELBOW

THE

OF

OR

EXTERIOR

LIFE.

ALL

(6OO"F)

PIPE.

SYSTEM

Page 9

VENTING

INSTRUCTIONS

THESE

SYSTEM

IMPORTANT

STALIATI

I N

The

The

from

.Installation

.

Unauthorized

INSTRUCTIONS

USED

Century

warraniy

of the

any

WITH

Read all

follow

will void

for specific

may vary

PRECAUTIONS:

ON

Heating

will be voided,

following actaons.

of any

damaged

THE CENTURY

these

THE SIMPSON

APPLY

TO

HEATING

instructions

instructions

warranty.

the

venting

from one

is an engineered

and

serious

venting component.

of the

venting system.

carefully

may create

Be sure

clearance

and

appliance

product

fire,

G6OO.

before

to

to another.

starting

a

follow

combustible

to

that

health,

or

DURA.VENT

installation.

the

or

fire

these

has

other

other

been

safety

safety

installation

requirements,

designed

hazards

,i

DIRECT

Failure

hazard, and

instructions

and tested.

may

VENT

to

which

result

lnstallation

.lnstallation

Consult

of

other

your

any component

than

as

local building codes

Atways maintain

combustibles

insulation Be sure

requirements

combustible

requirements from decks,

inlets, and

instructions

gas

Ihe

outside of

separate

appliance

systems

part

instructed

to

between

surfaces.

public

and

appliance

the

sotid

must use it's own separate

prohibited.

are

not manufactured

by these

before

required clearances

prevent

to check these

local building codes.

and

building, and never

tuel or

instructions.

beginning

a tire

the

outer

Be sure to

windows,

walkways,

vent

gas-burning appliance.

hazard.

?S specified

system

approved

or

installation.

(air

Do

instructions

walls

check

be attached

of the

the

soffits,

must

vent

vent

Century

by

spaces)

fill air spaces

not

for minimum clearance

vent

termination

gas

regulatorS,

in these installation

vented directly

be

to a chimney seruing

This

system.

Heating.

to

pipe

and

direct

Common

nearby

nearby

clearance

supply

air

vent

to

with

the

a

gas

vent

:1:

:i,

E--

Page 10

r

SAFETY

PREcAUTIoNS

FoR

I

.Wear

.Exercise

.Be

The

installatiorr

decorative

concealed locations

the

ceiling

require

approved

gloves

aware of electrical

Simpson Dura-Vent

roofline.

support

vertical

Number

9088

9078

906

9068

904

9048

903

9038

902

9028

9118

945;"

9458

990

9908

and

safety

extreme

of both horizontal

black,

Decorative

for

use

caution

as well

boxes.

rise

with

Description

Pipe

6"

9"

Pipe

12" Pipe

12"

Pipe

24" Pipe

24"

Pipe

35" Pipe

36"

Pipe

48"

Pipe

48" Pipe

11"

to 14-518"

Adjustable,

45'Elbow

45'Elbow,

90"

Elbow

90'Elbow,

glasses

when

wiring locations

for

using

PARTS

Direct Vent

and vertical

galvanized

as

such

as

attics,

brass

Snorkel

on the

the

Length, Black

Length, Black

Length

Length, Black

Length

Length,

Length

Length,

Length

Length,

or

chrome

terminations

building

Gentury

Black

Black

Black

Pipe,

Black

Black

Black

Heating

protection.

ladders

in walls

LIST

System

finish.

or spaces

exterior.

otfers

The

trim

G000.

Number Description

940

941

943

g43S

gS3

gG3

g8B

g8l

982

984

gB3

950

or

roof

on

and ceilings.

tops.

#1

a complete

installations. Many items

galvanized pipe

where

kits

are available for

The components

corrosion is a factor,

available

are

,),

Round

Cathedral

Flashing,

Ffashing,

Snorkel

Snorkel Termination (1

Horizontal

Vertical

Vinyl

line

of component

and

fittings

for

both wall

applications

listed

Support

Ceiling

0/12

to

to 12112

Termination (36")

Square

Termination

Siding Standoff

are

offered

are used for

such

below

BoxA/Vall

Support

6/12

Termination

as above

thimbles and

which may

have been

Thimble

Roof

Roof

4")

parts

Box

Pitch

Pitch

for

in

STARTER

-90"

-Horizontal

-24"

-11"

KIT

Black

Black

-

14-5/8'Adjustabte

xA"

-

Horizontal

Elbow

Termination

Pipe

Wall

Thimbte

Cap

Black

Termination

pipe

10

Part

#971 Kit lnctudes:

Page 11

PLANNING

YOUR

":$h*G'*

INSTALLATION

VEFTICAL

TERMINATION

COLLAR

STORM

FIGURE

1

ROTJND

SUPPORT

8ox/wALlTHIMBLE

I

t

ptpF.

l.ENqrH

PIPE

I.ENGTH

CATHEDRAL

CEILING

suPPoFT 8OI

FIGURE

2

I

er

t:

ljrr

:l:

!::

Yt

5i

:+

€.,'

THERE

When

length

wall

horizontal"

vertical

the

and

applications,

the

ARE

11

2l

TWO

,'

Horizontal

Vertical

planning

of vent pipe

thickness.

type

installations,

ceiling,

allow

the

for

firestops

attic,

additional

BASTC

TYPES

Termination

Termination

your

Select

installations.

instattation,

for

your

the

particular

amount

To determine

measure

ceiling

sufficient

thickness,

vent height

are required

pipe

and elbows

OF DIRECT

(Fig.

(Fig.

1)

2)

it will

VENT SYSTEM

necessary to

be

requirements.

vertical rise desired for

of

length of

the

the distance from

the verticat

rise in an

above

at each floor

wiil be

11

required.

level.

INSTALLATION:

select

vent

the

apptiance

pipe

attic or

the roofline.

lf

an offset is

proper

the

to note the

"vertical

-

required

flue

second

For

outtet

story

two-story

needed in

to

for

-

to

Page 12

29

2A

27

26

25

24

23

NOTE:

tested

Unit

ol

vertical

to

30'

PiPe.

The Century

for

minimum

a

horizontal

This

includes

Heating

run.

thickness.

The maximum

vertical

rise.

has

wlth a maximum

rise

1'

stove

G600

clearances and

horizontal run

been tested

wall

is 6'

with 2'

1'

22

21

20

319

E

t

E18

g

';

17

e

5ts

ul

Hls

6tq

ff13

12

To vent

this

please refer

unit

to

within these

chart

figure 1.

dimensions

2CMN(IMUM

WAIITTIICKNESS

4'MINIMUM

wAtrTH|C|(NESS

6'MINIMUM

CI.EAFANCE

FTAMMABI.EWALI.

FROM

123456

TOTAL

Face of Erllrior Wrll

Oo

HORIZONTAL

The maximum

permitted per

side

The maximum

permitted

Vertical

On

allowed.

are

per

side wall

installations two

FIG.

FEET

Ercludlng Elboilr)

number

number

of 90 degree

wall installation is one

45 degree elbows

of

installation is one

(2)

1

elbows

(1).

(1).

45' elbows

is very

Since

system

it

maintain

combustion

exhaust

configurations

adhered

The

vertical

help

to.

graph

and horizontal side

determine the

to

allowable.

12

air intake

certain

apply

showing

important that

its balance

and the

limitations

and

must

the relationship

wall

various

venting

the

between

flue

to vent

as

strictly

be

between

venting will

vent

lengths

the

gas

Page 13

H ORIZONTAL I NSTALIATI

ON

Step

Step

1. Set

2.

NOTE:

1) Twist-lock

.

2')

lhe appliance in

Check

rafters are in

system

may

appliance.

Vent

special

the desired

elbows to the

seams

much out of view

located on

fittings,

the

by orienting

they match and slide

the male

sections

lock

one-quarter

fully locked.

be visible

pipe

examining

Horizontal

every

for

to determine if wall

the

is

attached. lf

want

pipe

male

one

or fittings.

three feet. Wall

this

to adjust

and fittings are designed

twist-lock cohnections. Assemble

combination

appliance

oriented

are designed

ends of adjacent

completely together, then

section clockwise

the inside of the

purpose.

towards the wall

as

procedure:

female

the

four

the

ends

turn, until the two

The

from the

runs of vent

(Fig.

female

They

way when

possible.

it's desired

studs

this is

the

Four

ends of

to slide straight

pipe

into four entry slots

5).

locking

outside, on the

may be located

must be

Straps are available

the case,

location

of black

adaptor with

pipes

indentations

Push the

approximately

female ends.

location.

or roof

the venting

you

of the

with

pipe

and

pipe

or floor, as

indentations,

pipes

and fittings,

sections

lugs will

supported

and

onto

pipe

twist-

not

black

so

on

are

by

5

;iFlG'

ru

l---l!-4

ITI

L^-/\)

FIG.6

\*-ffi

$

MALE

LUGS

LOCKING

Step

3.'With pipe

stove

minimum

mark

centre

with

shown

inch

the

penetrated

combustible

concrete,

acceptable.

into

the

wall

of

the

center-line

in

square

vent

will

attached to

it's

correct location,

clearances

for a 10-inch

the

square hole

Figure

a 7-inch

6. Cut and frame

hole in the

be terminated.

is constructed

material, i.e.

the

to combustibles

of the horizontal

diameter

stove, slide

insuring

square

should line

exterior wall

lf the wall

masonry block

hole. The

pipe,

the 10-

where

of

hole

the

and

up

as

being

non-

or

is

F

I

tJ

0

Page 14

NOTE:

1)

2l

3)

horizontal

The

towards

run

temperatures

cause

The

local

The

For

and

high

locaiion

nationat

and

terminal

vent

installations

36-inch

tall

procedures

Termination

drainage

must

must

Termination.

vent

of

run

termination.

the

of the

horizontal

building

shatl

requiring

Snorkel

used

as

be

provided to

be

not back

Do

must

be

Never

may

and

vent

codes,

recessed

be

not

vertical

a

ierminations

for standard

installed

below

fill around

have

level,

present

or

allow

the

the

termination

and

rise

must

are

not

a

into

the

on

available.

Horizontal

grade,

prevent

snorkeltermination'

the

1/4-inch

a

vent to

possibility

an

on

easily

be

wall or

siding.

exterior

Follow

rise

downward.

run

a

of

exterior

blocked

of the

the

Terminations.

(i.e. basement

water

FIG.7

from

entering

for every

1

This

fire'

must meet

wall

or obstructed.

Refer

building,

same

to Fig-

3.

1

installation

lf the Snorkel

applications),

lhe snorkel

of

foot

could

all

-inch

proper

Step

4. Position

'

NOTE:

1)

2l

horizontal

the

10'inch

the

centre

the

attach

wood

Vent

the

a bead

run

around

a seal

the

on

Insure

combustible

of

exterior

the

to

screws

provided. Before

Termination

of

it's outside

between

it

ient cap

that

ProPer

materials

non'hardening

and

should

(Fig.7)

The four

wood

be replaced

for stucco,

screws

with

brick,

concrete,

of siding.

,,For

'

buildings

Siding Standoff

with

(Part

installed between

exterior

Siding

wall.

Standoff

(Fig.

to

Termination. The

prevents

excessive

melting the vinyl siding

vent termination

with

hole,

the

square

wall

attaching

to the

edges, so

the

exterior

as

wall.

pointing

be

The arrow

clearances

maintained.

are

provided

or

other

fasteners

appropriate

vinyl siding,

950),

should

the vent cap

8) Attach

the

the Horizontal

Vinyl Siding

heat

from

material.

in

and

four

wall,

mastic

make

to

up.

to

should

types

Vinyl

a

be

the

and

Vinyl

Vent

Standoff

possibly

FIG.8

b-{

SCREWS

6

Step

Before connecting the

5.

vent

the black

over

pipe

the

the

to

decorative

pipe.

vent

horizontal

vent

termination,

wall thimble

run

slide

cover

14

of

VINYL SIDING

STANDOFF

Page 15

rE

''*l'

l_/_

ffi

rE

-]

*l-l-

I r-1

o

=

?

?

A

I

o

o

(,

!.3

€l

igtiiii$,i

o

UJ

E

=

IE

u,

c

o

z

.4

c,

E|C

tro

=\

E3

€3

=o

Eb

e=

-9 rE

s

s

F €E

z

=

TE

ul

ut

E

iiiggigiiii,

ul

I

3

lu

TE

itsE$;l=sssEsFs5

1

+{{

UJ

Y

=

a

4

o.

:)

o

a

igiit*Et

@

z

=

liglFgIggF*

UJ

z

u,

:

E

,|lT*

$3

t

;E

:

fF

E

; E6

-o

€ tro

o 3E

rE SE

9 :E

O

-r'l

'=

6e;

rE

!

85

be

'3^

=

i Eg

E

33

sE

G

$;:

gB

E

5;E

g.

iE

ggi

E

Ic=a

o;it c

c5g:

EJZ

Figure

-

Vent Terminal

3

15

E$rt

iglliiiiiigil

-crE+|,'

-CC|a

GOOG

sE$ia$s$gt$i$$E

{{3A,|l,1"

Locations

Page 16

Step

appliance

SliOe

6.

towards

vent

important that

the

the

pipe

wall,

into

the

the

the vent cap sufficient

resuft in a

minimum

inches. Secure

vent

the

attaching

extending

into the

siliconer'

sheet

the strips

remaining

back

towards

concealed

cover.

pipe

the

from

outer

vent

metal

to

portion

by the

(Fig.

9)

two sheet metal

connection.

screws

the

the

and vent

carefully

vent

cap

vent

pipe

assembly

inserting

assembly.

extend into

distance so as to

pipe

connection

the

and

the vent

overlap of

1-114

between

caP by

strips

vent

the

uiall of

provided

Pipe Section.

of the sheet metal

vent

cap assembly

the

Use

vent

pipe,

the two

to connect

Bend any

strip

cap, so it will

decorative wall thimble

the

lt is

WALL

THIMELE

STRAP

be

Step

7. Sliae the

wall

provided.

chrome

Step l.Check

clearance (air

passing

,'enclosures,

combustible

with

maximum

any

offset

venting

decorative

wall

surface and attach

Apply decorative

trim if

desired.

(Fig.

VERTICAL

these instatlation

spaces)

through

attic rafters,

surfaces. Do not

insulation.

vertical

maximum

must

graph.

Check

rise

horizontal

fall

within

(Fig.

instructions for required

ceilings, walls,

of the

t)

thimble

up

the

with screws

brass or

10)

to combustibles

other nearby

or

these

venting

pack

instructions

air spaces

system,

offset limitations.

parameters

the

of

FtG. 11

when

roofs,

for

and

Any

the

Step 2. Set the

plumb

a

of the

where

small hole

gas

appliance

bob

down from

appliance

flue

the vent will

at this

point.

in

it,s

desired location.Drop

the

ceiling

exit,

and

penetrate

Next,

position

the

to

mark the

location

the ceiling.

drop a

plumb

16

Drill

bob

a

Page 17

from

the

in

the

ceiling,

the vent

if

ceiling

framing

You

may

or to

cutting

offset,

loadbearing

roof

to the

penetrate

will

joists,

will

obstruct

wish

as

hole

and

mark

the

roof

the

relocate

to

shown in

members.

previously

the

spot where

roof.

Determine

rafters,

venting

or olher

system.

the appliance,

Fig. 13,

to

drilled

avoid

Step

3.

Step 4.

Step

5. Cut a

to

install

Thimble

square

hole

drilled

shown

Assemble

Pipe

and

the

Appliance

Round

the Round

in

hole in

in

Fig.

the desired

Elbows necessary

Support

and Elbow

twist-locked

hole

in

drill

hole

the

minimum

to

combustibles.

placed

hole

should

Supporr

a flat

in

12.

connections

position.

the roof

be

ceiling,

the ceiling,

Step

2. Frame

lengths

adaptor

Box. Insure

centred

in

the

roof

of

sufficient

requirements

cut

centred

the

to reach

up

through

that

are in

on

in

Step

size

for

BoxMatl

a 10-inch

on

the

hole

as

of Black

from

the

pipe

all

their

clearance

the

2. The

to

fully

small

meet

,\

,\

FlG. 14

Step

6.

NOTE:

1)

2l

Connect

through

lf

an

support

possible

a

hole.

offset

the

separation.

Whenever

less

restriction

section

of

is necessary

pipe

vent

wall

possible,

to the

use

flow

pipe

and

in

every

Straps

45"

of flue

extend

the

attic

3 feet,

to

are

Elbows

gases

17

up

to avoid

avoid

available

instead

excessive

for

of

and intake

obstructions,

stress

this purpose.

90' Elbows.

The

air.

it

is important

on

the

ElLows,

(Fig.

13)

45"

Elbow

to

and

offers

Page 18

Step 7.

flashing

the

Stip

protruding

base

roofing

overlaps

shown

least

combustibles

through

of the

nails.

the top

in Fig.

the

Flashing to

Insure the

minimum'

at

over the Pipe

the roof.

roofing material

edge of the

Verify

14.

that

the roofline.

Section(s)

Secure the

the roof

Flashing

you

with

have

as

at

clearance to

FtG. 15

DIM€NSION'H'

OETAINEO FROM

cAN/cGA-8l.9

oR ANSI

2223.1

OR

H

LOCAL

CODES

Step

Step

8.

9.

NOTE:

1)

2l' Any

Continue

height of

to

the

Vent Cap meets

Pipe

add

minimum building

Fig. 15. Note that

described

roof

pitches,

increased. In

nearby trees,

pitched

can result

ln these cases,

may

solve this

Twist lock

For

multi-story vertical

in

vent height

the

high wind

adioining

roofs, and other similar

in

poor

draft,

increasing

problem.

the Vent Cap.

Ceiling Firestop (Part

the

second floor,

floors. (Fig.

framed

to

dimensions,

.shown

in Fig. 12.

occupied

including

which

be

enclosed.

framed

closets

the vertical

and

construction

the

allowable

of

surfaces

of

instructions

clearance

the

vent

of the

the

required

16)

10-inch

in the same

sheetrocked

materials,

pipe,

and any

The opening

areas

above the first

and storage

passes

The

for

between

and

enclosure.

air

spaces

Sections

code

until

requirements

for steep

must be

conditions,

rooflines,

steep

factors

down-drafting.

or

the vent

height

installations,

963) is required

subsequent

should be

x 10-inch

inside

manner

floor,

spaces,

through,

enclosure

with

however

must

may be

standard

consult

the minimum

the outside

the combustible

Do not fill

with insulation.

the

the

a

at

as

any

FlG.,16

:\

,)

y'r

CLE^RANCE

I

INCH

CLEARANCE

1 INCH

18

Page 19

f

cATHEDRALcEtLtNG

INSTALLATIoN

f

Step 1.

Step 2.

'

Step

Step

3.

4.

rollow

Vertical

Using

line

and

.

and roof

locate

of the

Remove

as necessary

for

larger

Lower

in

the

Box

ceiling. (Fig.

both

level.

place

the roof

installation

Terminations.

plumb

the

of the

drill

the Support

roof

protrudes

vertically

Temporarily

through

venting

a small hole

at this

the drill

Cathedral

shingles or

than the

the

Support

until

sheathing.

Steps

bob,

system

through

point.

hole

and mark

Ceiling

other

to cut the

Box.

Support

Box

the

bottom

at least

17)

and

the inside

2 inches

Align

horizontally

tack the

1 and

mark

on the ceiling

From

Support Box.

roof

rectangular

Cut

the hole

Box

ouiline.

through

of

the Support

Support Box

walls

2 under

the centre-

the

ceiling

the

the

outline

covering

the hole

the

Support

below

with

and

roof,

hole

1lg

the

Box

a

in

into

PATTERN

BOX AS

ONTO ROOFLINE

OF SUPPORT

IT IS

PFOJECTED

Step

Step

5. Using

the top

fold

sheathing.

'ttre

mastic

Support

Box

combustible

Support

6.

Comptete

Installation

procedures

for

tin

the

roof,

and

Vertical

snips,

corners

resulting

run

around

Box,

Box.

cut

down

(Fig.

Terminations.

18)

a bead

the top

to make

the roof.

material

the

by

following

outlined

the Support

to

the roofline,

flaps

Carhedral

in

over the

Before

of non-hardening

edges

a

seal between

Clean

from

Steps 4

Box from

naiting

out

inside

the

through

19

and

rool

it

to

of

the

the

any

the

Ceiting

same

9

FlG. 18

E_

Page 20

GENERAL

MAINTENANCE

inspection

Conduct

Recommended

1. Check

2. Remove

3. Check

.

an

to

areas of

for corrosion.

extreme

replaced.

bird

forming in the

Continuous condensation can

fittings. lt may

elbows, and

weather.

nests,

cases,

the C"p,

or

for

evidences of excessive condensate,

the venting

of

inspect are as follows:

Venting

the

These will

holes. These

and shine a

other foreign material.

inner

be caused by having excessive

exterior

liner,

portions

System

appear as

and subsequently

which are

rust

components should

flashlight down

cause

of the system

spots

;i

corrosion

semiannually.

exposed to the

or

streaks, and

immediately

i

the Vent.

such as water

dripping out

of caps,

lateral runs,

being

Remove any

exposed

etements

in

be

droplets

joints.

at

pipe,

too many

and

to cold

4. Inspect

disturbed,

supports

)

...

joints,

and consequently loosened.

such as

to

Wall

verify

Straps,

that no Pipe

plumbers'tape

or

Sections

Also check

Fittings

or

for rigidity.

have been

mechanical

20

Page 21

IFOR

YOUR

SAFETY,

READ

BEFORE

LIGHTINGT

WARNING:

explosion

life.

A.

B.

may

This

pilot,

BEFORE

Be

than

lf

result,

appliance

follow

sure to

air and will

WHAT

Do

not

try to light

Do

not

your

Extinguish

lmmediately

Follow

lf

building

you

cannot

the

you

LIGHTING

do not

causing

these

smell neril to

settle on the floor.

TO DO

touch

any electrical

any

open flame.

your

call

gas

supplier's

reach

follow these instructions

property

piezo

instructions

smell all

ignition

around the appliance area for

the floor

IF YOU

the

appliance.

switch;

gas

supplier

instructions.

your

gas

supplier,

damage,

pilot

exactly.

because some

personal

light. When lighting

SMELL GAS

;

i

do'hot

from a

exactly,

injury

gas

is

heavier

use any

neighbour's

phone

phone.

a

fire or

or loss of

the

gas.

in

c.

Use

Never

dont

attempted

D..,

Do

lmmediately

and

control

only

try

not

to

WARNING:

explosion

life.

may result,

your

use

to repair it,

repair

use this

replace

which

you

tt

hand

tools. lf

call a

has

do

causing

push

to

the

knob will

call

a

may

any

result

appliance

qualified

part

been

not lollow

under

property

in

or turn

not

qualified

in

a fire

if

any

technician

of

the

water.

these instructions

21

service technician.

or

part

control system

damage,

the

push

explosion.

has been under

inspect

to

personal

gas

in or turn

controt

the appliance

and

exactly,

injury

knob.

by

hand,

Force

water.

any

gas

a

or

or

fire

loss

or

of

Page 22

1)

STOP! Read

LIGHTING

safety information.

the

INSTRUCTIONS

2l

Push

position.

knob

3) Wait five

Follow

next

4l Find

in

the

pushed

is

(5)

"B"

step.

pilot.

NOTE: Knob cannot be turned

5) Turn knob

gas

in slightly.

minutes

in the

gas

on

control

to clear out

safety information.

control

knob

Do not

slightly

force.

any

counter clockwise

and

from

gas.

you

lf

turn

you

lf

dont smell

clockttYise

"PILOT"

then

to

"OFF"

to

smell

"P|LOT".

g?s,

g?s,

to

unless

go

UOFF

STOP!

to the

*NOTE:

6) Push

pushing

by

iw'tor

pop

through

7) Turn

To

8)

9) To turn off

light

to

in

control

about

back

6.

lf

knob

your

lf

control

supplier.

the

gas

main

seryice

control

I"",],'j[ls3;,";HL:"o'ijTirlf,il;:':r;]:"oFF"

adjust

the

one

up.

does

pilot

knob

gas

flame

knob

spark

(1)

Pilot

not

technician

light

to

counter-clockwise

burner

to main

height

all the way

ignitor

minute

should

pop

wilt

"OFF"

only,

burner

after

remain

up

or

not

and

turn rocker

use

and hold in. lmmediately

button.

the

when

gas

stay

only,

to/Hi

the

Continue

pilot

lit. lf it

released,

supplier.

lit after

call

your

r-\

on/off

turn

to

On/Off

vatve.

on

to hotd

is lit. Release

goes

stop and

several

seryice

uONu.

switch

out,

to

switch to

light

the

control

knob

repeat

immediatety

tries,

technician

turn

,,oN,'.

',OFF,,.

the

and

it

steps 2

the

or

pilot

knob

will

call

gas

9as

22

Page 23

TO

TURN

OFF

GAS

TO APPLIANCE

1)

Push in

Do not force.

2l

Turn

gas

control knob

UOFFU

all

electrical

MAI

1) Periodical visual

to

conducted

control knob is in

ensure that

PROFER

PILOT

power.

'checks

"OFF"

the

FAT'E

slightly and

INSTRUCTION

of the

the flame

position.

pilot

tum cloclcwise

and

present

is

burner

except

'Soesn

BURNER

-

flames

when

FurrE

to

should

'OFF.

be

the value

At -r,' n r0

lV\f

0trr't'

\"nn;

t5\$w

Remove

2)

pailicles

All

3)

4)

s)

components

manufacturer.

Turn

Installation

person.

annually

compartments,

appliance

off

MORE FREQUENT

EXCESSIVE

the logs

from

all electrical

The

by

the

Write

and all repairs

apptiance

qualified

a

be

kept clean.

from the

grate

(see

burners

CLEANING

LINT

FROM

grate

and

burner

parts

Phone:

or

power

should

service

list) are available

Century

330 Humberline

Etobicoke,

Canada,

(416)

usA 1-800-836-1210

before

should

and

servicing.

be inspected before use

technician. lt

circulating air

MAY BE REQUIRED

CARPETING,

assembly

areas each

Heating

Ontario

MgW 1R5

7e8-2800

done

be

is imperative

BEDDING

and

year.

vacuum

directly

Drive

by a

passageways

qualified

any loose

through

and

that control

DUE TO

MATERIALS,

the

service

least

at

the

of

ETC.

Visually

6)

connections

7)

Using

connections,

inspect

annually.

a

soapy solution,

periodically

all vent

pipes

check all

for leaks.

23

for

corrosion,

gas

connections,

cracks

and

pilot

proper

line

Page 24

PARTS

DIAGRAM

"nt

\l

\AF,

tr

\l

E

24

Page 25

PARTS

LIST

NO. DESCRIPTION

KEY

1

1

2

3

4

5

6

8

9

10

11

12

13

13

14

15

16

17

17

18

19

20

21

21

22

23

24

26

27

28

29

BURNER

BURNER

GRATE

#8

x 112 PAN

LOG SET

FRONT

SIDE

GI-ASS

oRrFtcE

oRrFrcE

3/8 ADAPTOR

GAS

PIPE

3/8

VALVE

VALVE

3/8 ELBOW

THERMO

IGNITOR

P|LOT

PrLOr

THERMOPlLE

PILOT

PIEZO

..i

SWITCH

SWITCH

ROCKER

BENTTRIM

(NG)

(LP)

QUAD

TEK

GLASS ASSEMBLY

GLASS ASSEMBLY

CLIP

GI.ASS CLIPS

GLASS

FRAME

HANDLE

CATCH

(Ne)

(LP)

TUBE ASSEMBLY

TO

3/8 FLARE

(NG)

(LP)

COUPLE

WIRE

(NG)

(LP)

TUBE

IGNITOR

WIRE

WIRE

SWITCH

(GOLD

BAR

PLATED)

PART

941238

s41239

s41347

s11290

sl6215

s31216

s31217

s41319

s32461

sl3377

's11329

s11308

sl

s1 1 326

t

s11314

s32487

s11313

s11345

s11347

s11029

sl 1349

s14108

s11346

s11348

s14103

s11183

s14106

s14040

sl4039

sl4034

s32539

NO.

1325

G600lrGs

G600lts

1

1

17

1

1

2

1

2

1

1

1

'1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

G600PGS

G600PS

;

1

17

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

25

Page 26

fan installation

from carton.

1. Remove

2. Using

above.

Speed control

3.

and tighten

4.

Snap

Plug

5.

Electrical

This appliance

three-prong

proleclion

your

hazard and

directly

three-prong

not

Do

grounding

fan

four

screws

Be sure to

variable

in.

fan

WARNING

Grounding

is

equipped

(grounding)

against shock

should be

properly

inlo a

Jdceptacle.

or

cut

prong

from

provided attach

install

switch

is

until secure.

with

lor

the

control

a

speed

Insttuctions

plug

plugged

grounded

remove

plug.

this

instructions

fan to stove

rubber

to be

inserted

knob into

WIRTNG DTAGRAM

FAN

I1O

gromets

into

VOLT

LINE

shown

as

pedestal,

place.

(optiAnal

shown

as

above.

shown,

as

fan

kit

CAUTfOil

lo disconneclion when

conlrors.

cause

operation.'

'Veilty

serYicing.'

FAN MOTOR

t10V

6OHz

#S31

-'label

improper and

groper

all

Wiilng eftors

opcretion

1.5AMP

1921

wires

Prior

servicing

c.n

ctangerous

allel

Original

with wire

wiring that

having at least a 105'C

Key# Part

1 541225

2

S41059

3 514003

4

5

314005 Power

514009

is

Number

replaced musl be

temperature

replaced

rating.

Description Oty.

-

G300

Knob

-

G400

1

1

1

1

1

Fan

Case

Weld't

Motor Assy

Speed Control Switch

Cord

Speed Control

@@p

26

Page 27

F'G.

A

fan

1.

2.

3.

4.

5.

This

three-prong

your protectaon

hazard

directly

three-prong

Do

gfounctrng

Original

with

installation

Remove

using

above.

speed

and

Snap variable

Plug

Electrical

appliance is

and

into

nol

wire

fan

four

Be

control

tighten

fan

in'

WARNING

Grounding

(grounding)

shoutd

properly

a

rec,eptacle.

cu{'

or remove

prong

from

wiring

having

from

screws

sure

to

switch

until

speed

Instructions

equipped

ptug

against

ptugged

be

grounded

plug.

this

that

is

at least

instructions

cafton.

provided

install

is

secure.

control

with

a

tor

shock

the

replaced

a

IOS"C

attach

fan

to

rubber gromets

to be

temperature

knob

FAN

musl

wrBrNG

inserted

into

into

place.

DTAGRA^,

be

reptaced

rating.

(optionaf

stove

as shown

as

shown

pedestal,

above.

as

shown,

THENMOSTATIC

LIMITSWTCH

fan

CAUTI9N

to

contrors.

cause

oper.lion.'

'Verlly

se,vicing.'

kit

diEconneclion

lmproper

proper

FAN

1t0v

#Sgf

-'label

Wiring

MOTOR

60HZ

2ggl

wircs

senicing

anora

prior

crn

.fie?

alt

whcn

and dangercus

opa'rllon

|.'AMP

Key#

1

2

3

4

5

6

Part

Number

541225

541059

S14003

S14005

514009

S14060

Description

Fan

Case

Weld't

Motor

Assy

Speed

Power

Speed

Limit

Controlswitch

Cord

ControtKnob

Switch

Ory.

.l

1

1

l

l

1

@c

27

Page 28

TROUBLE

SHOOTING - G6OO

With proper

trouble-free

shown

and

below. This

the

corrective

SYMPTOM

l.

Spark

repeated

butlon.

ignilor

lriggering

installation

service. lf

you

guide

action to

will not light

of

and maintenance,

do

experience

will assist

be

a

taken.

your

qualified

POSSIBLE

after

red

A.

Defeclive

eleclrode).

B. Defective

electrode

electrode).

new

problem,

a

service

CAUSE

ignltor

pllot

at

(no

or

pllot

Fireplace

Gas

refer

person

at

spark

misafigned

(spark

at

)\

,t.

should

to the

in

trouble

diagnosis

the

CORRECTIVE

Check

1.

pilot;

and

electrode

connecled,

1.

using a match,

pllot

llghts,

lrigger lhe red

pllot

llghts,

mixture

lighting

period

will not

electrode

1/8

lf

iq-recommended.

inch

OK, replace

provide

shooting guide

problems

of

ACTION

for

spark

wire

replace

an improper

caused

and

light

and

lo have

at

lf

no

is

ignitor.

light

lurn

off

button again.

the improper

a

longer

-

check

-

pilot

a strong spark.

pllot.

years

electrode

spark and

pilot

should

of

properly

pilot.

tf

and

lf

gas/air

purge

pilot

ll

gap

at

be

Pilot

il.

carefully

inslructions.

will

not

stay

following

lil

after

lighting

C. No

D.

No L.P.

A.

Defective

B.

Defective

gas

or loW

in

tank.

thermocouple.

valve.

gas

pressure.

1.

Check remote

from

fireplace.

a valve

sometimes

the

lhan

fireplace

Low

a variety

bent line,

of

pressure.

lines.

plumber

1.

Check

be out

1.

Check

on thermocouple.

adiust

impingement

1.

Replace

serviceable).

near

main.

(1)

one

and

pressure

of

pipe

lf

or

L.P

of

fuel.

pilot

pilol

valve . (it

shut off

Usually

the fireplace

there is a valve

There

valve

main.

can

situations

too

narrow

or

even

Check for

none,

gas

supplier.

(Propane).

tlame.

for

maximum tlame

on

lherrnocouple.

there is

can be

between

be

caused

such as

diameter

low line

consult with

You

Must impinge

Clean

and

is not

valves

and

near

more

the

by

a

kinked

may

or

field

C.

Plugged

D.

Defectivethermopile.

burner orilice.

28

1.

Check

stoppage

1.

Replace

burner

and remove.

lhermopile.

orifice

for

Page 29

TROUBLE

SHOOTING

.

G6OO

lll.

Frequent

lV.

Pilot and

while

V.

Glass soots.

SYMPTOM

pilot

outage

maln

burner

being

in

operation.

probtem.

go

out

POSSIBLE

Pilot

blowlng

pllot

A.

Bad

Thermoplle.

B.

No

L.P. in tank.

c.

Bad

thermocouple.

A.

Flame

CAUSE

flame

may

(high),

safety

to drop

lmpingement

be too low or

causlng the

out.

on logs.

'),

CORRECTIVE

1.

Clean and

maximum

on

thermocouple.

1.

1.

1.

1.

Replace

Check

may

Replace

Adjusr

flame

lf

necessary.

L.P.

be

out of fuel.

lf necessary.

the log

does nol

ACTION

adlust

pllot

flame

(Propane)

implngement

set

so

lmpinge

flame lor

tank. You

that

the

on lt.

29

Page 30

MODEL

SERIAL

WARRANTY

KEEP

TH'S

INFORIIATION

WARRANTY

PURCHASED

seriat

warranty.

Always specify

right

to amend

our standard

written

DATE

modet and

these specifications

TWO

Warranty

This

State or

1.

2.

3.

4. To make claim under this

5.

Some States

damages,

Province.

The

manufacturer

and necessary

accessories)

of

date

This warranty

warranty covers

This

condition.

Century

original

quititieO

This warranty is etfective

changed,

been authorized

This

wear and tear or

proper

transportation

responsibility

the

from whom the appliance

the alleged defect

be d.elivered

The manufacturer

determination

in respect

'not

be

detect or a breach of this

gives you

will be

purchase

is extended

Warranty

Heating

factory

installer

repaired or treated

warranty

maintenance

liable for

so

does

of shipping,

Provinces

and

the

above limitation

specific

warrants

maintenance,

free from defects

while under originalownership

and

only

part(s)

witi

wno

replacement

in accordance

in writing by the

not apply

parts

of

any

that

defects caused

or

the owner.

provide proof

and

Heating at

shall,

at its

tabour

incidental,

numbers

at any

We make

when

no

communicating

without

time

wananty,

other

YEAR LIMITED

rights and

legal

to the original

your

new

in

only to the original

the cost of

MUST

provide

parts

only as

since shipment

to

fail

such other costs

warranty,

was

option,

The

warranty.

not

do

or exclusion

part(s)

be

original

voids this

with all

manufacturer.

or

purchased,

purchaser

or

consequential,

allow

local

to new

parts

become

purchase.

of

the address

repair or replace

transportation

the exclusion

you

consumer/purchaser

gas

appliance

materials and

retail

required

obtained

codes

gas

from the