Page 1

OWNERS

MANUAL

GENTURY

VENTED

GAS

WARNING:

not

result causing

or loss

-

Do not

ftammable

vicinity

-WHAT

.

.

.

.

.

G400

FIREPLAGE

the

lf

life

store

of

TO

try

not

touch

not

not

cannot

the

exactly,

property

vapors

this

DO

to

use

instructions.

fire

followed

of

Do

Do

Do

lmmediately

neighbor's

a

supplier's

ydu

lf

call

HEATING

information

fire

a

use

or

or any

IF

light

any electrical

phone

any

your

call

Phone.

reach

dePartment.

in this

or explosion

damage,

gasoline

liquids

and

other

YOU

aPPliance.

any

in

gas

Follow

your

manual

personal iniury

or

in

appliance-

SMELL

switch.

your

gjas

building.

supplier

the

supplier,

is

may

other

the

GAS

from

gas

HEATER

-

INSTALLATION

MUST

A

QUALIFIED

SERVICE

THE

"WARNTNG:"

MAINTENANCE OqN CNUSE

tNFoRMATtox

ADDITIONAL

OR GAS

made

CANADA

labriqu6

au CANAOA

SUPPLIER.

in

IMPROPER

unuuAL

INFORMATION

|NSTALUTTON,

pRovtDED

AND

PERFORMED

BE

SERVIGE

INSTALLER,

AGENCY

GAS

NJURY

CONSTJLT A QIJALIFIED

NOTES:

MUST

iHEnpplnNcE

OFF.

SUPPLIER

ADJTJSTMENT

OR PROPERTY

wtrH

THIS IS A SEALED

ALWAYS

ANY

SAVE

THts

BE INSTALLED

wlTH

LEAKAGE MAY

THIS

OR

DAMAGE.

AppLtANcE

INSTALLER,

APPLIANCE

BROKEN

CAUSE

MAI'IUAL

BV

ALTERNION,

REFER

Ass/srAwcE

FoR

SERVICE

AND

DURING

GLASS

F()R

OPERATION.

wlTH

OR

DANGEROUS

FUTURE

SERV,CE

THE

TO

GLASS

THE

NEVER

GLASS

THE

POLLUTION.

AIR

OR

OWNER'S

FoR

oR

AGENCV

RETAINER

OPERATE

RETAINER

REFERET'ICE

Part No.

519402

Rev.3 08/99

PRINTED

IN CANAOA

Page 2

,rrr2

S

CENTURY

HEATING

INSTALLATION

PLEAilEREADTHTIMANUALBEF1RETNiTALLINGAND|JStNGYoUnyENTEDGAS

FIREPLACE

FOR

Do

otner

in the

appliance.

FOR

lf

1.

2.

3.

-

YOUB

store

not

flammable

vlcinitY

YOUR

you

smell

not

Do

nol

Do

nqt

do

tMIuiEDnrELY

cAC

phone.

instructions.

iit6u

4.

the

cail

AND

HEATER

SAFETY

or

of

gas:

to

try

touch

any

use

SuPPLIER

Follow

cannol

dePartment.

lire

OPERATION

gasoline

use

or

and

any

vaPorc

this

SAFETY

applianc.e'.

any

light

electrical

any

phone in

CALL

lrom

gas

the

reach

suPPlier's

your

switcn;

the

YOqR

neighbor's

gas

INSTHUCTIONS

or

liquids

other

buildlng'

supplier'

HIGH

TO

DUE

APPLIANCE

THE

UOCITEO

NWNV

DRAPERIES.

NOT

DO

oinen

ON

OT.T

ciiruoneN

AtEtrTED

B-E

iiloH

oF

NTIO

IVbrO

IGNITION.

OUT

FROM

PLACE

FLAMMABLE

NEAR

AND

suRFAcE

STTOULD

BURNS

TEMPERATURES'

SHOULD

TRAFFIC

OF

FURNITURE

CLOTHING

BE

AND

AND

OR

MATERI4L

APPLIANCE.

THE

ADULTS

THE

TO

sHo-uLD

HAZARDS-

TEMPERATURE

STAY

OR

AWAY

CLOTHING

TO

.

WARNING:

IMPROPER

MATNTENANCE

MANUAL

tNsTALLEn,

INSTALLATION,

CAUSE

cAN

AsstsrANcE

FoR

seiv'ibe'-leEnrcv

#from$S*r.'oNscA'Frql!:Y-.gElgLF-ss1st$fl1*x1'?Irifl b'ft

FoLLow

To

WILL

VOID

PTEASE

rHEsE

THE

RETAIN

rNsrRucrro'r'rs

WARRANTY.

IH'S

ADJUSTMENT,

llJgiv-bc

ql

lpq'.i.iolli $r^*MlilitN

THE

oR

laM

MANITAL

FOR

AUTERATION'

pnopEryrv'oni,rnce-

SUPPLIER'

GAS

nesur-frN;

FIJTITRE

REFERENCE'

SERVICE

coNsuLr

FilisreLE

OR

!FfER

F.RE

rHrs

ro

QUALTFIED

A

HAZARD

AND

-_.=*<4!:q|I

Page 3

1 (800) 668-5323

Monday to Friday, 9am to 5pm Eastern Standard time

Page 4

ffinsandguide|inesinthismanua|.Fai|ureto|o||owtheseinstructions

exactly

may

resuliifri?i

"i

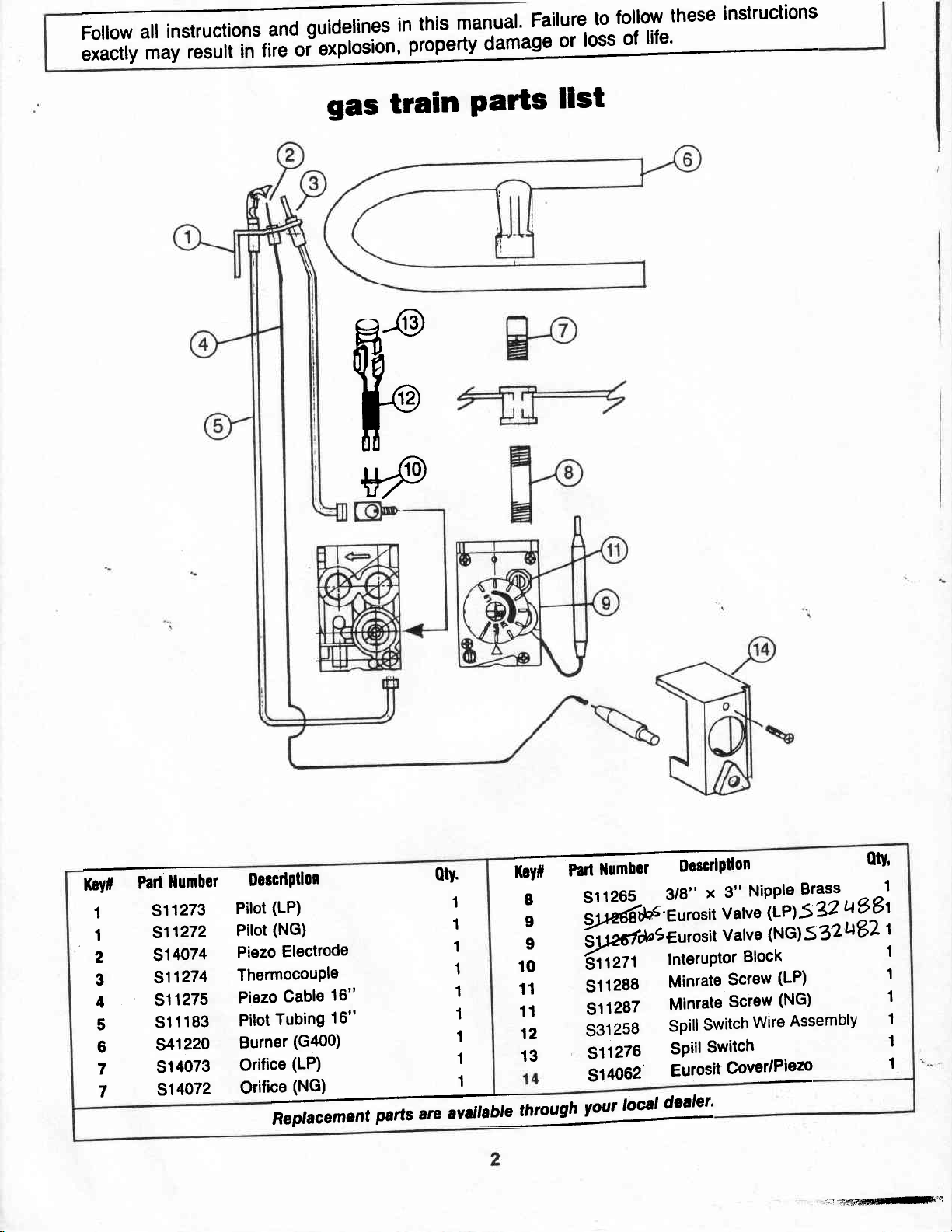

gas train

F

VP

Parts

list

K.Vt

1

1

2

3

4

5

6

7

7

ttttfi

P.tt

S11273

511272

514074

511274

511275

511183

S41220

S14073

514072

DercrlPtlon

(LP)

Pilot

(NG)

Pilot

Electrode

Piezo

ThermocouPle

Cable

Piezo

Tubing

Pilot

Burner

Orifice

Orifice

ReplacemeHt

16"

16"

(G4OO)

(LP)

(NG)

parts

","

0tY'

1

1

1

1

1

1

1

"*t''"

ffisdptlon

8

;

S11265,

Z)iaw

; {tiJ*"eurosit

to

11

11

12

1

1

13

"""t^

{rtr,

511288

511287

s31258

s11276

S14062

""''t*'

3/8"

l'l'o'it

varve'(LP)s

Valve

InteruPtor

Minrate

Minrate

spill

:l1l^:_T:: a,rPiano I

Eurosit

Block

Screw

Screw

switch

CIYIP|"*

wire

NiPPle

3"

x

Brass

?2

(NG)532t182

(LP)

(NG)

Assembly

ri.r.iiffrdltflFi.:

1

u98t

1

1

1

1

1

otv'

Page 5

manual

control

wlth

pressure

regulator

6

I

,/A

(r.i

PILOT BUHNER

TECHNTCAL

Inlets

Outlets

Maximum

Working

Thermostat

Calibration

Max.

Min.

Pilot

(2)

(2)

Temperature

Regulated

Regulated

Flow

SPEC|FICAT|ONS

Working

Range

Temperature (oF)

Capacily

Capacity-

Rate

-

Weight

(')

Based

on 1,000

A=

B=

Q=

Pressure

(oF)

fF)--

BTU/Ff

:0.64

Filter

Manual

Flame

shut-off

Failure

(EUROS|T

55oF to IOOoF

100oF

,

N.G.

2.5 Ft./hr. at

s.g.gas

at 1.00"W.C.

Device

VALVE)

3/8 NPT

3/8 NPT

32oF

at

Hl Knob

4q,000

1o,ooo

0.S" Pressure

pressure

Female

Female

1/2

PSIG

to 175oF

(Standard)

position

BTU/hr.(')

BTU/hr.

'1.2lb.

drop.

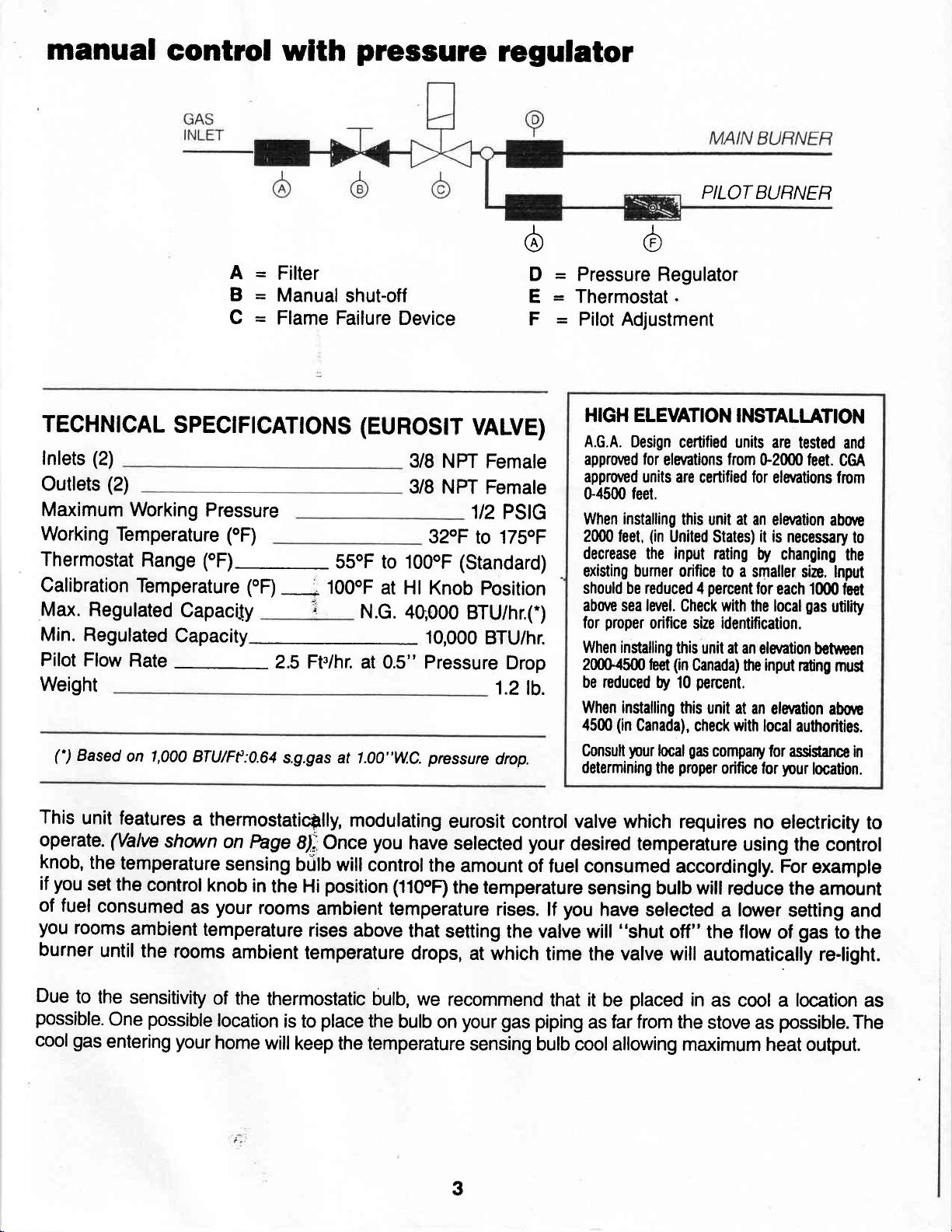

D = Pressure Regulator

E = Thermostat.

F = Pilot Adjustment

HIGH ELEVATION

Drop

A.G.A. Oesign

approved

approved

G4500 feet.

When installing

feet,

2000

decrease the input

existing burner

should be reduced

aborc

sea

proper

for

When installing

2000-4500leet

be reduced

When installing

(in

45fi)

your

Consuh

determining

certified

for

elaations

unils are

this unit at an

(in

United

orifice t0 a smaller

4

la/el.

Check with

orifice size identification.

this unit at

(in

Canada)

percent.

by 10

this unit at

Canada),

local

proper

the

check with

gas

INSTALLANON

units are

from

0-2000 feet.

certified

lor

elaations from

elention

it is

States)

nting by

percent

for

local

the

an elaation

input

$e

an elantion

local authorities.

company lor

orifice lor

changing

each 1ffi0leel

your

tested and

CM

above

necessary

size. lnput

nting

asigance in

to

the

gas

utility

betneen

mug

abon

location.

This

unit

operate.

knob,

you

if

of fuel

you

burner

Due

possible.

coolgas

(Valve

the

set

consumed

rooms

until

to

the

One

entering

features

temperature

the

ambient

a thermostaticilly,

shovrn

on

sensing

control

knob

as

your

temperature

the rooms

sensitivity

possible

your

of the

location

home

modulating

hge

SI; Once

O0tO

in

the Hi

rooms

will controlthe

position

ambient temperature

rises above

ambient

temperature

thermostatic bulb, we

place

is to

will keep

temperature

the

you

(110'R

the

bulb

eurosit control

have

selected

amount

the temperature

rises.

that

setting the valve

drops,

at which

recommend

your gas piping

on

sensing bulb cool allowing

3

valve which requires

your

desired temperature

of fuel consumed

accordingly. For

sensing butb

you

lf

have

will

selected a lower

"shut

off" the flow

time the valve will

placed

it

that

be

far from

as

the stove

no

electricity

using

the control

example

will reduce

the amount

setting

gas

of

to

and

the

automatically re-light.

in

as

cool a

location

possible.The

as

maximum heat output.

to

as

Page 6

---\

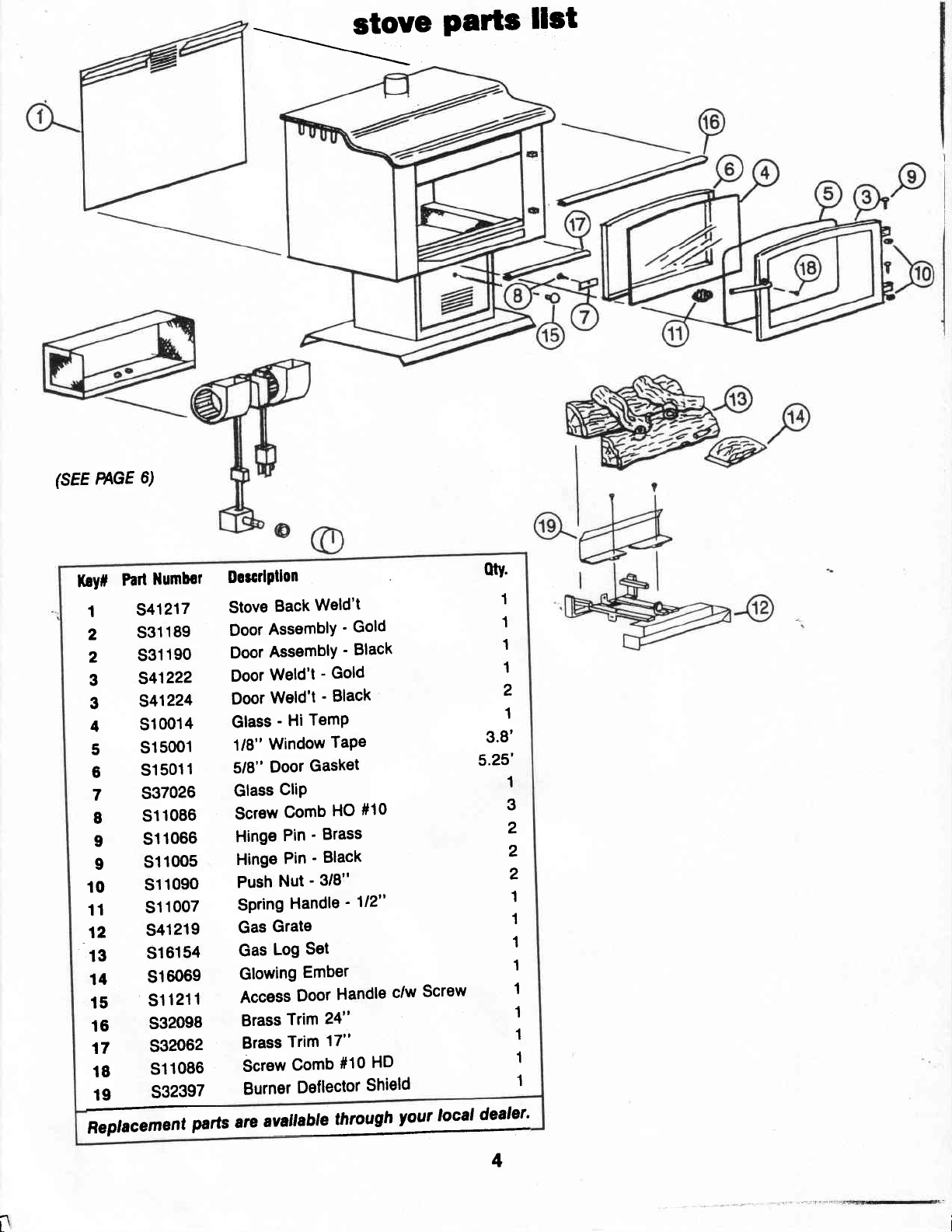

stove

Parts

llst

(sEE PAGE

Part

Koy#

I

2

10

11

S41217

S31189

2

3

3

4

12

13

14

S31190

5

6

7

I

I

9

15

16

17

18

19

Replacement

6)

llumbcr

541222

541224

S1OO14

S15001

S15011

S37026

S11086

S11066

S110O5

S11O9O

S11007

S41219

S16154

516069

S11211

S32098

532062

S11086

S32397

parts

Dorcdptlon

Weld't

Stove

Back

AssemblY

Door

AssemblY

Door

Weld't'

Door

DoorWeld't'

Glass'Hi

1/8"

5/8"

Glass

Screw

Hinge

Hinge

Push

SPring

Gas

Gas

Glowing

Access

Brass

Brass

Screw

Burner

arc

TemP

Window

Gasket

Door

GliP

Comb

Pin'

Pin'

Nut'3/8"

Handle

Grate

Set

Log

Ember

Door

Trim

Trim

Comb

Deflector

avattable

'

Gold

'

Black

Gold

Black

TaPe

#10

HO

Brass

Black

'112"

Handle

24"

17"

#10

through

c/w

HD

Shield

lour

Screw

local

otv.

1

1

1

1

2

1

3.8'

5.25'

1

3

2

2

2

1

1

1

1

1

1

1

1

1

dealer'

11

t\

4

Page 7

ANY

SAFETY

REPLACED

PRIOR

SCREEN

OR

TO

OPERATING

GUARD

REMOVED

THE

FOR

SERVICING

APPLIANCE.

AN

APPLIANCE

MUST

BE

''WARNING''

CRACKED

LICENSED

YOUNG

SAME

door

REMOVE

BE

set

CHILDREN

ROOM

lock

SURE

assembly

DO

NOT

OPERATE

OR BROKEN.

OR

QUALIFIED

SHOULD

AS

THE

APPLIANCE.

screw

DOOR

TO

LOCK

REPLACE

THE

APPLIANCE

REPLACEMENT

SERVICE

BE

SCREW

AFTER

BEFORE

SERVTCING

PERSON.

CAREFULLY

WITH

OFTHE

SUPERVISED

ATTEMPTING

TO

AVOID

THE

GLASS

TO

ACCIDENTAL

GLASS FRONT

SHOUT

WHEN

OPEN DOOR.

D BE DONE

THEY AHE

OPENING

-8.>C/:

REMOVED,

BY

A

IN

THE

OF DOOR.

mlneral

Remove

suppfied.

S4".

log

HUTION:

UNDER

"TOO

USE

RE-INSTALL

BEFORE

UUT,ON;

OF BURNEN

, rszlr,r.rwc

a handfulof

Break

Loosely

tray

grate

of

BURNER

ilUCH"

ONLY IN

OPERATING

and

DO

EIVSURE

wool

placement

mineralwoolfrom

pieces

into

evenly

as

shorn

NOI

PACK

DO

WOOL.

LOCATION

DOOR

'GA"TES

LOCK

FRONT

wooL.

roughly

place

wool

above.

WOOL

NOT

USE

SPECIFIED.

SCREW

UNIT.

PORT/ION

AFIER

bag

314',

x

in front

Page 8

FIG.

A

-a

-------->

fan

1.

2.

'

lnstallatlon

Remove

Using

Be

Speed

3.

and

Snap

4.

Plug

5.

Elcblcrl

This appliance

throeprong

protsction

your

hazard

directly

threeprong

not cut

Do

prong

ding

fan

four

to

sure

control

tighten

variable

in.

fan

illlxo

w

Goundl4

b €quiPPed

(grcunding)

should

and

a

inlo

Pfoporly

receBeclo.

or tamwe

lrom this

from

screws

install

switch

secure.

until

speed

Inrtucllonr

wilh

Plug

againsl

shock

be

Plugged

grounded

groun'

the

Plug'

instructlons

carton.

provided

rubber

is

control

a

for

attach

gromets as

inserted

be

to

knob

fan.to

shown

into

FAN

LINE

1lOV

stove

as

above'

pedestal, as

into

place'

W|/NING

D/,AGNAM

(ipttonal

shown

above'

shown,

fan

VARIABLE

CONTROL

klt

CAUIfOX

to

Drlor

tcnlcttrg

ciure

c.n

d.ngarous

"WrW

canlclng;'

W.

G.

B.

#S3rr92l

"bbcl

-

dlrconnrcllon

conlrolf.

oPenllon."

NoPat

FAN

11OV

SPEED

tll

ffirltry

lmProPcr

oPe/lllton

MOTOR

60Hz

wlnt

whcn

ormn

tnd

.lLl

1.5

AMP

l(cy#

1

2

3

4

5

llumbor

Parl

541225

S41059

S14003

S140OS

S140Og

Ducrlpllon

Case

Fan

AssY

Motor

SPeed

Power

Speed

Control

Cord

Control

Weld't'G40O

-

G300

Switch

Knob

0ty'

1

1

1

1

1

@

6

@-"

Page 9

CIOTHING

NEAR

OR

OTHER

THE APPLIANCE.

installation

GAS

Manifold Pressure

Minimum Inlet Pressure'

Maximum lnlet

Fl'U Input

Input

BTU

gas

Make

2.

l) Black iron

ll) A corrugated

in

length)

lll)

Copper

table to the authority

gas

Turn

OPEN FLAME.

For correct

ASSEMBLY.

lnstallation and

tion air must

local

of

Z,223|l - latest

Canada, with

Code.

codes,

Pressure

(Max.)

Rating

(Min.)

Rating

'For

purpose

connection

pipe

metal

. .

or

pipe

or tubing

supply

on and

Use soap and

positioning

provision

conlorm

with

edition - in

the

current CAN/CGA

FLAMMABLE

instructions

SPECIFICATIONS

llatural

ot lnput

to

the

or malleable

connector

.

(internally

having

check for leaks. DO NOf

of logs

for

with local

the National

the

Gas

3.5" W.C.

5.0" w.c.

10.5"

W.C.

30,000

23,500

Mustment.

valve

assembly

iron fittings or . .

(not

to exceed 2

tinned)

jurisdiction.

water solution.

grate,

on the

combustion

codes o[ in absence

Fuel Gas Code, ANSI

United States

-

Bl49.lnstallation

MATER'AIS

Propane/LP

10.0" w.c.

WC.

11.0"

13.0" W.C.

26,000

23,500

with:

.

feet

if

accep-

USE

refer to

and

SET

ventila-

or, in

SHOULD NOT

Keep operating area

materials,

vapours.

The appliance and

disconnected from the

any

excess

8.

The

ing

by

ing

any

at test

9.

A 1/8" inch

gauge

upstream

gas

A

llue

DUE

TO HIGH TEMPERATURES,

SHOULD

AWAY

The

appliance,

connected

codes or, in

current

the National

gasoline,

pressure

1/2

of

appliance

closing its individual

pressure

pressure

N.Hl-.

connection

of the

appliance must

serving

FROM FURNITURE

C9{ C22-1

a soparate

BE LOCATED OUT

and

the absence

Electrical

BE PLACED

and

clear

and other

individual

its

gas

supply

system at test

testing

when installed

grounded

of the

psig (3.5

musl be

testing

equalto

gas

kPa.)

isolated

of the

less than

or

plugged

supply connection

Canadian

code ANSI/NFPA

tapping,

must be

not be connected

solid

AND DBAPERIES.

in accordance

local

of

Electric C'ode

manual

OR

O'V

free lrom combustible

llammable

shut off

piping

from the

shut

gas

supply

accessible for

provided

fuel burning appliance.

THE APPLIANCE

OF TRAFFIC AND

must

be

codes,

liquids

valve

system during

pressures

gas

supply

otf

piping

psig

112

immediately

to the appliance.

to

electrically

with local

with

(Canada)

TGlatest

and

must be

pip

valve

dur-

systom

(35

kPa.).

test

a chimney

the

or

edition

in

CH'LDREN

TEMPENNURE

CLEARANCE

Ceiling

Sides

Front

Back

please

It

is

normalfor your

This

Please

IT

BE

ADEOI'ATE

SERI/ICE

DIRECT

Height

of Stove

note

is

due

to the curing

ensure

IS

IMPEBATIVE

KEPT

that

CLEAN

CLEARANCES

AND PROPER

VENT

AND ADULTS

AND

SHOUTD

TO

COMBUSTIBLES

Century

your

THAT

AND

TERi'INATION

Heating fireplace

paint

of the

room is wellventllatqd

THE CONTROL

CLEAR.

AROUND AIR OPENINGS

OPERATTON. NEVER

SHOUTD

Minimum = 24"

Minimum

Minimum = 36"

Minimum

and

PROVTDE FOR

THE EXTERIOR

ON

BE ALERTED

AWAY TO

STAY

=

=

any undetected

COMPARITUENT

TO

AVOID

DO NOT

lhe fieater

8"

9"

give

to

-

OBSTRUCT THE

otf some odour the first tlme

open

atlwindows.

ADEOUATE

OF THE

whlch

from

oll

BURNER, AND CTRCULATING AIB PASSAGE

COMBUSTION

AND

BUILDING.

THE HATARDS OF HIGH SURFACE

BUR'VS

been under

qualtfled

control

OR CI.OTHING

lfits heater

USE

water. lmmedlately call a

serylce

and

system and

technlclan to

to replace any

any

has been under

it is burned.

the manufacturing

AND VENTILATION AIR.

ADEOUATE ACCESSIBILITY

FRONT

OPENING OF THE

process.

'G'V'T'O'V.

lf any

paft

inspect

part

gas

control

waten

CLEARANCE

APPLTANCE OR

has

of the

WAYS

PROVIDE

FOR

THE

7

Page 10

temperature

(#1

The thermostat

see berow

range

drawing)

caribrated

is

and

set

at

factory'

the

(55-110"F)

gas

Maximum

the

Minimum

the

This

rate

This

flow

knob

knob

(#4 see

flow

(#4 see

rate

flow

screw).

screw

flow

rate

is

(#3

rate

pressure

pressure

tnret

turns

3

2 or

Oulet

pressure can

WARN'NG;

SCREWs

can

and

AFTER

cLOcKwGi

checked

be

can

below

can

berow

determined

see

drawing)

be checked

drawing)

by

below

drawing)

readings

checked

be

placing tubing

then

be checled

TAKING

rrnnrLY

cooling

by

counter

by

counter

o.E.M.

the

must

turning

by

[he

in

PRESSURE

TO

clockwise

cooling

crockwise

at

be

captured

gauge

to

same

RESEAL.

Adiushent

Pilot

thermostat

the

the

to

thermostatic

the

$;rt

design

the

driven

over

manner

READINGS,

Screw

rt"i"

fully

screw

test

NOT

DO

above

below

bulb

position'

Hl

below

bulb

rtopping

"no

seiwitfr

and

assure

down

point'

to

(#6 see

BE

OVER

drawing

using

SURE_I9JIJRN

captured

ToROUE'

temperature

room

temperature

room

when

a

proper

you hear

pre-drilled

below)

screw

CAPTURED

screw

flow'

counter

(#7)'

turning

and

turning

and

"snap"'

the

(minimum

clockwise

Minimun

Regulalor

Pressure

WARN'NG;

FLow,

cAs

H,i

8ffi

GAS

THE

ANy

rooLs

THE

CONTROL

Rate Screw

i

Iemperalure

rHE

r'rt=*ii

Sensing

CONTROL

ptLor

"'*'

KNOB

DURTNG

Bulb

AN

HAS

BURNER

HH;

E

i,il

DESIGNED

IS

rHrs

opERAiiNG.

INTERLOCK

crnHor

iil\c

BE

Ei

N

TO

DAMAG'6-ftrloes

Pressure

0ullel

Pornt

Test

Plessure

lnlel

Poinl

Iesl

DEVICE;

RELri

e e

io

BE-OPERATED

AFTER

rli,r^::t^ Tlt^T*t:3:::i

''

e

n

r

e

s

BY

MAY

SHUTTING

p

p

rox.

(

a

D

HAND'

DO

RESULT

OFF

t-

:

.:::' I .

ilOT

sERlous

lN

ALL

to'

USE

Page 11

yentlng

Instaltailon

guldeflnes

PROPER

IS

AN

IMPORTANT

APPLIANCE

IF

YOU

ATTEMPT

GAS

APPLIANCES,

flsted

A

designed,

combustion,

burning

,"_"1!,9T?l_oy

rng

warm

lype

gas

listed

and

fuel

atr

space.

and reduce

B

lllsted

Irfgl"

and

!1q

mrnrmum

obstruction

fla!

the

.of the.

Gas

beginning

Gas

Vent

vents.

rools

are

roof

and

bu.itdi

Vent.

extending

height

wirhin

requiredr6

at

ng

INSTALLATION

SAFETY

PERFOFMANCE

ARE

NOT

QUALIFIED,

INSTALLATIONS

PIPTNG

vents

vent

is

a

instalted

excess

gas.

metal

doubte

wail

This

air.spac-e

heat

vent

B.O

instailation

size

conform

of

at

3m

least

60O

or

adjolnin

factory

exctusively

airi

vents,

construction

transferred

or

through pitcnJi

lea.st

(10').

exireno

mm

g

made

and

diiution

me

both

instalfa$on

G]€aterf

be

sure

to

building

g0O

g,

cas

venti-dxrenoing

"tliili

(2')

frigfrerinan

Oujrainglvitfrin'gm

OF

GAS

VENTING

AND

CONCERN.

DO

NOT

Oi

NCPNIRS

OR

VENTING.

and

listed

toi

iemoving p.Oj"tJoi

air

reiutting

moslcommon

enclosing

helps

to

niarOy

that

coJe

i*f,

(2')

6db',rn

the

an

keep-flue

cbmbusiibles.

overail

requiremen-tr.

."n

higher

iz,)

any

O,i

tr

OF

system

tro;

type

iniufat_

gases

height

exrend

than

any

ihiiugf,

aooie

portion

oi

if,"

of

a

TYPICAL

and

Awey

Out

EnClosure

Gas Vent

"B''

VENT

Keep

Eleclricit

Buitdrnq

From

Gis

The

Ol

Reeurrcd

Wall

Length

25 mm

fl'l

Clearance

Combustrbtcs

IT{STALLATION

wires

Insutalron

Vcnt

rnd

Art

Sorc:

Fo

F

rrgglgp

Spacer

suDport Ptata

Where

8pace3,

cortact

l1re Taung- 9Qual

tnrough

alnglc

Sltuate

be

malortoad

tmportant

n9l

I}1,_rl"^,.app[ance

carpeung,.ille

than

es

wldth

thc

Gas

lt

should

and

whtch

or

two-hmily

the

Inctatted

Gas

beqtng

to

posslbte

as

wood

f toortng,

on

a

metat

and

depth

vent

be

damage.

to

the

Vent

ln

wtrhour

cutilnj

partrtroni'oi;;i#;.

locete

or

the

to

the

other

ttra

or wood

of

the

cxtonds

cncloseO

through

to

iod

Enclosurr,"afli

grcater

or

Gas.%nt

dwelllngr.

the

atructure

base

heailng

is

Instailed

combusilble

than

pasc--

i"t.6;;iltr,

of

the

appltance.

materlal

ippr[nce;;jil"

panel

extendlng

ippflance.

accegslble

pereonal

"froufd

thc

ftoore

-xcept

so that

lt

ptates

I te

Gas

Vent

dtrecili

bther

Instath

the

hare

In

can

or

atso

as

on

full

Thls

appllance

syst?m

deslgned

ventlng

THIS

APPLIANCE

A

CHIMNEY

FUEL

BURNING

Use

only

above

Consult

the conect

than

the

necessary

ls

equlpped

to

of

combustion

MUST

FI.UE

SERYING

APPLIANCE

vents

the

labelled

roofllne.

Authorlty

Gas

\tentiilametJr.

yent

wlth

protect

products.

NOT

BE

A

'.FOR

havlng

diameter.

furlsdlcilon

eroic

Adtustable

agalnst

CONNECTED

SEPARATE

EXTERIOR

a

sahty

;t;i

Length

contrcl

lmproper

SOLID

USE',

lo

setect

a

targer

TO

',:j

.ii

il

1

.rj

lrl

:!l

i'i{

iii

Ilr

ti,

!i

fj

Ji:i

li

I

I

I

i

,

Page 12

venting

installation

guldellnes

WARN'NG!

Installations

procedures

iools

and

Installations

peron

io the

to the

Installer,

should

required for the

testing

made

risk of injury

installatlon

be

only

instruments,

be unqualiiied

or

but also to

persons

llisted

qualilied

and

by

ol

who

made

Installation

persons

electrlcat

shock

being

B.O

Yentl

the

have athleved

can

serued

persons

Product'

result

whlch

by

continued

CHECKING

gas

Complete

and

adiusting

lighting

couple

lighted

a

of the

ing(s).

flame toward

ilamg

lmproper

escape

will

be

-l

I

I

I

i

The dratt

same

tion

all

vent connections.

the

the main

ol

minutss

match

gralt

draft

of the

oI Ing

Proper

lowaro

cause

pulled

venting

or

or

venting,

or sPillage

match

into

the

hood

atmosphiiic

Inlet

air

who

equipped

arc

who

Proper.certificatlon

hazards

In

be

can

equlpment.

the

VENT

piping, electrical,

appliance(s)

burner(s),

forwarm'up.

under

iust

into

lnto

hood

lllJu(J

willdraw

the

InGt

indicated

burned

of

flicker

to

draft

must

relief

lElrer

sublectlng

serious

or

CAPACITY

After

and

a

allow

Hold

rim

the

op€n-

vPerr-

the

u'

hood.

rr|",t

draft

ulalt

bY

gas'

go

or

hood

be

smoke

out.

vent

if the

lfrstalled

pressure

aPPllance.

the

to

famillar

are

wlth the safety

wlth the

licensing.

of

unqualified

the

fatal not only

even

-: .,'

.(

../ |

.r'

is

zone

|

| Y

il .. *'oI Ine

ll

V'

a cigarette

from

drawing

to

as

so

the

as

proper

..

\

-.

\

k)-.

-\ -

T

\

will also

properly'

in the

be

combus'

.\

)

\

When

your vent

iemperature

clearances

ed.

jurisdiction in

venting

venting

PiPe

rating.

must

Consult

through

through

have

must

Manulacturer's

be

also

authoritY

the

your

area

wall.

side

a side

wall

the

ProPer

maintain'

having

regarding

10

il

{xi

Page 13

WARNING!

Installations

procedures

tools

and

Installations

person

to

the

instafler,

testing

to

the

required

made

venting

should

risk

only

for

instruments,

be

of

lnirty

but

also

installation

be

made

the

installation

and

unqualified

or

electrical

persons

to

qualified

by

of

who

have

persons

shock

being

guidelines

persons

product,

the

achieved proper

can

result

which

served

in-hazards

can

by

the

who

are familiar

who

are

equipped

certificaiion

sublecting

be

serious

equipment.

with

with

of

the

or evin

the

salety

proper

the

licensing.

unqualified

latat

not

only

chimneys

o

Complete

clearance

Consult

area

applicalions.

A

complete

persons

o

Appliances

masonry

feet

vent

connector

.

Oversized

listed

r

Cleanout

familiarity

to

combustibles

the

authorlty

regarding

chimney

should

using

or factory-built

in

length

for

connector

has

chirnneyd

relining

systems.

access

relining

Suitability

determined.

Condition,

relined

a

No

a

Joints

manufacturer's

and

size,

must

be

substitution

and

connectors

with

chimney

and

having

masonry

inspection

performed.

be

B

vent

connectors

chimney

every

inch

of connector

has

a maximum

maximum

may

7-112

should

be relined

be required.

systems

approval

height,

determined.

instructions.

of relining

termination

of

components

should

condition,

other

lactors

jurisdiction

chimney

made

by

to vent

should

4-ll?tdot

foot

be

not

diameter (3

length;

length).

with

materials

of

the

chimney

should

made

according

height,

is

venting

qualified

exceed

bppropriate

be

size,

essential.

your

in

into

1-1/2

inch

inch

5

should

be

to

be

made.

to

a

installation

STRAIGHT

INSTALLATION

INTO

CHIMNEY

installation

TYPICAL

STRAIGHT

INSTALLATION

MASONRY

gitt"ffiii"y

Liner)

I

l,

;i

ri

Consult

area

applications.

OPERATION

AND

COULD

PROPERTY,

F- rr

rollow

result

the

authority

regarding

OF

MAINTAINED

RESULT

DAMAGE

Instructions

all

in

fire

or

having

listed

lurlsdiction

chimney

IMPROPERLY

VENTING

IN

SERIOUS

OR

LOSS

guidelines

and

explosion,

property

your

in

liner

venting

INSTALLED

SYSTEM

INJURY,

OF LIFE.

in this

damage

manual.

or

Failure

loss

of life.

to follow

these

instructions

exactly may

Page 14

ErrttrNvs

flltrlN

I

INSTr|UGTIONS

Periodic

1.

lo ensure that the

valve control knob

All component

3.

manufacturer. Write

visual checks

flame

is

GAS

CONTROL

parts

Century Heating

Humberline Drive,

330

Ontario, Canada, MgW 1R5

1-800-836-1210 United States

1-416-798-2800 Canada

pilot

of the

is

in

the

are available directly

phone.

or

Etobicoke

should

present

"OFF"

be

excgpt

position.

TYPICAL

AURNER

Line

Watts

through

conducted

when the

-

FLAME

(A)

AND CARRY

the

Periodically

2.

vacuum

and

burner areas.

PATTERN SHOWING

DOWN POFTS

installation

qualified

inspected

quititiea

control

passageway's of

ireque-nt

lint from

sivd

5. Disconnect

remove

any

and

service

before

service

compartments,

clianing

all

logs

the

particles

loose

(B)

carpeting,

power

VIEW

repairs

all

person. The

and

use

person. lt is

burners

appliance

the

be

may

to unit

from the

from the

PILOT

OF

FROM

should

appliance

least

at

and

be

required

bedding

before

grate

assembly

grate

FLAME

ABOVE

be done

should

annually

imperative

circulatin-g

clean.

kgpJ

due.to

material

servicing'

etc.

and

by a

be

by a

that

air

More

exces'

WARiltNG:

DO

COMBUSTIBLE

inspection

-

Pilot and main

-

Check

-

Venting should

cleaning

(Dlsconnect

1. Remove

2. Using

3. Cleai

using

4. Re-install

and clean

of

all

burner

vacuum, clean

a

burner

small wire

a

burner

NOr ADJUST

MATERIALS,

burner

be

flames

main

the

checked

burner

main

power

hold down

parts

using

or

and

gas

and

bottom

vacuum

paperclip. Ensure

burner

THE GAS

GASOLINE

should

be

once

year

once

a

burner

supply

screws

of

deflector

to fhe unit).

and

firebox

any

and

and

ORIFICE.

KEEP.AREA

AND OTHER

checked

year.

a

assure

to

and

remove

and

particals

that all

put

visually

proper

orifice

burner and

orifice.

that may

parts

logs in their

CLEAR

FLAMMABLE

each

VAPOURS

month.

functioning.

burner

be

are free

proper

deflector

lodged

debris.

from

location.

AND

ports

in

FREE

AND

shield.

to

are

FROM

LIQUIDS.

removed

be

12

Page 15

IF

YOU

MAY

This

lighting

b.

BEFORE

area for

because

on the floor.

WHAT

o

Do

r

Do not

phone

r

lmmediately

neighbour's

Follow

o

you

lf

fire

DO

NOT

RESULT

appliance

the

LIGHTING

gas.

some

TO

not try

touch

in

the

cannot reach

department.

CAUSING

has

pilot,

follow

Be

sure

gas

OO IF

your

YOU

to light

any

building.

call

phone.

gas

supplier's

F('r| V('U]|

BEAD BEFORE

FOLLOW

piezo

a

these

smellatlaround

to

smell next

is

heavier

SMELL

any

appliance.

electrical

your gas

your

THESE

PROPERIY

ignition

instructions

than air

GAS

switch;

supplier

instructions.

gas

supplier, call

INSTRUCTIONS

DAMAGE,

pilot.

When

exacily.

the

apptiance

to the floor

will

and

do not use

from

setile

a

SAFETY

LIGHTING

WARNING:

PERSONAL

d.

any

the

EXACTLY

Use only

control

push

qualified

a

repair

Do

under

technician

any

which

your

knob. Never use tools. lf

in

or turn

service

may result

not

use

water.

to inspect the appliance

part

of the control system

has

been under

A FIRE

EXPLOSION

OR

INJURY OR LOSS

hand to

by hand,

this appliance if

lmmediately call a

push

in

or turn

the

don't try to

technician. Force

in

a fire

or explosion.

part

any

qualified

and any

water.

OF LIFE.

the

knob will

repair

it,

or

attempted

has

service

and

to replace

gas

control

gas

not

call

been

-

1.

STOP!

2. Push

in

Wait

five

then

smell

information.

Read

tfre

gas

control knob

"OFF".

lo

(5)

minutes

gas,

you

lf

LIGHTING

safety information.

slightly and

to

clear

out any

STOP! Follow

don't smell

"8"

gas, go

TNSTRUCIIONS

turn clockwise

gas.

in

to next

you

lf

the saiety

step.

4.

5.

6.

pilot.

Find

Turn

knob

"PILOT".

to

Push

in

lmmediately

hold

the

after

the

back

up. Pilot

repeat

r

lf knob

immediately

supplier.

.

lf the

the

service

r

Disconect

gas

Turn

"ON".

to

gas

on

control knob

control knob in for

pilot

steps

does not

pilot

gas

control

technician or

control knob

control counter-clockwise

all the way

light the

is lit. Release

5 through

call

will not stay lit

all

pilot

should remain

pop

your

knob

power

-

r-

and hold

with ignitor,

approx.

knob

lit. lf it

L

when released,

up

service

to

gas

source

counter-clockwise

technician

after

several tries,

"OFF"

supplier.

to the

in.

Continue

(2)

minutes

it

and

and

unit,

will

goes

stop

call

r-.

or

to

pop

out,

and

gas

turn

your

-TO

1.

Push

/-:r

in

gas

to

control

knob

"OFF".

TUI|N

slightly

Do

not force.

('FF

and turn

GAS

clockwise

T(,APPLIANGE-

Page 16

-

T}Io)UBLE

SHOOTTNG.

G4OO

proper

With

tree

dervice.

guide

will assiit a

action

l. Spark

repeated triggerlng

after

red

button.

instailation

to be taken.

SYMPTOM

tgnitor

you

lf

do

qualiiied

will not light

and

maintenance,

experience a

servic'e

A.

of

at

B.

electrode

electrode).

your

problem,

persion

POSSIBLE

Defective

electrode).

Delective

at

gas

No

c.

new Gas

to the

refer

the diagnosis

in

CAUSE

(no

lgnitor

pilot

pitot (spark

low

or

spark

misaligned

or

at

pressure.

gas

'

Fireplace

trouble

should

shooting-

of

-

'

provide

guide

problems

CORRECTIVE

1. Check

pilot;

and

is

wire

replace

Using

1.

lights,

button

red

imProPer

an

caused

a

and

recommended.

light'check

and

Pilot'

a strong

have

OK,

lf

check

1.

fireplace.

lrom

valve

sometimes

main.

the

(1)

one

main'

and

shown

and

for

if no

properly connecled,

ignitor.

match,

a

otf

turn

again.

gas/air

imProPer

the

longer

rePlace

near

should

remote

the

there

There

valve

Purge

gap

between

yeaq

of troubl+

below. This

correctlve

the

ACTION

at electrode

spark

and electrode

spark

pilot'

light

pilot-and

pilot

lf

mixture

lighting

Period

lf

sPark'

Pilot'

Usually

firePlace

will

Pilot

electrode

at

be 1/8

shut

valve near

is a

be

can

the

there

pilot

lf

trigger the

lights,

is

not

inch

to

off valves

is

a

and

more than

fireplace

will not

Pilot

ll.

caretully

Instructions.

following lighting

stay

lit after

L.P. in tank.

No

D.

A. Defective

B Defective

Plugged burner

C.

valve.

thermocouple.

orifice.

pressure

Low

2.

variety

a

bent

pipe

Check

consult

supplier.

1.

be out

1.

on

adjust

impingement

1. Replace

field

1. Check

page

of situatlons

narrow

too

line,

low

even

or

lor kinked

with

Plumber

Check

Check

thermocouPle.

L.P.

fuel.

of

pilot

pilot

for

on

valve

serviceable).

burner

remove.

and

be caused

can

as a

such

diameter

line

Pressure.

lf none,

lines.

gas

or

(ProPane)

flame'

Clean

maximum

thermocouPle'

-

You

Must

and

(lt is not

orilice

imPinge

llame

tor stoP'

bY

of

maY

or

14

Page 17

- TFOUBLE

SHOOTING

-

G4('('-

sYlrPTOm

lll. Frequent

problem.

lV.

Pilot

and

out white

belng in

pilot

maln

operation.

outage

burner

go

POSSTBLE

A.

Pilot

flame

blowing

safety

A.

has

temperature.

B. NO

C. Bad

(high),

to drop

High

limit

reached

L.P. in

thermocouple.

may

causing

out.

switch

it's

maximum

tank.

GAUSE

be

too low or

the

is

defective

pitot

or

CORBECT.IVE

1.

Clean

for maximum flame

on thermocouple.

1. Allow

lighting instructions.

2. lf 1.

ignition, check high limit

Place

limit

pilot,

the

defective. Do

until

replaced,

safety feature.

light

the wires

the connectors

1.

Check L.P

You may

1. Replace if

and

to

unit

above does not

jumper

switch.

the high limit

with

wires across

you

ll

your

high

not

as

this is an

lf the

jumper

may

be

be out

necessary.

AGTTON

adjust

are bad.

(Propane)

pilot

impingement

cool. Then

can

re-ignite

limit

use fireplace

switch is

important

unit

wires

in

defective

of fuel.

flame

repeat

allow for

switch.

high

switch

does

not

place,

or

tank.

is

V.

Glass

....

Vl.

Flame

otl burner.

soots.

burns

blue

and lifts

A. Flame

B. lmproper

Minwool

C.

burner

grille.

A. Insufficient

supplied.

impingement

venturi

around

or blocking

oxygen

on logs.

setting,

base

of

bottom

being

lront

1. Adjust

flame

1. Adjust

base

1.

lnspect

It is imperative

placed

be

burner

passage

1.

Check to

minwool has

placed

blocking

the log

does not impinge

the

air shutter

the

of

burner.

the base

around

in

or

bottom

way,

make

not

at the

burner base

botlom front

set

so that

ol the

NO

that

the

base

front

sure

been improperly

grille.

the

on

if.

the

al

burner.

material

of the

grille

that the

or

air

15

Page 18

\'ENTTNG

TROUBLE

Pl|OBLEMS

SHOOTING

Most

venting

vent

sizing, improper

air supply. A

problem

.

Using a

system

tions.

r

Checking

manufacturer's

input,

r

Examining

faults

damaged vent

o

Making

obstructed.

lf these

of the

attention to

discussed below.

problem,

FLUE GAS

problems

preliminary

might

draft meets

and venting

procedures

include:

draft

meter

the vent

the

such

sure vent

as disconnected

troubleshooting

common

SPILLAGE

are

caused

installation,

to

determine

manufacturer's

sizing according

specifications,

configuration.

entire

sections.

venting system

and air openings

do not reveal

venting

or

check

may

incorrect

by

inadequate

for a

the source

field

venting

if

specifica-

to

appliance

for

joints

problems

or

not

are

include

Venting

Loose

Mashed-in

caps can

Examine and

Obsfructions

Small animals

the vent

foreign objects

obstructions

Lateral

Lengthy

resistance

to cause

also

pitched

the

Elbows

Too many elbows

of flow and may

90 degree turns

sized venting

cause

system.

Condltion

joints

be a

appliance

can

vent

restrict

replace

or

draft

or

may

and

(L)

Run

horizontal

to flow

spillage.

problem; lateral

114" rise

to

problems

affect

sections

birds

hood

clean oPenings.

and

The

per

the

result

can

system.

and

and

draft

and damaged

flow and

needed.

as

get

may

outlet.

obstruct

non-vertical

or

may

foot

vent.

cause

be tolerated

necessitate

air

reduce

pitch

of

runs should

horizontal

of

excessive

in spillage.

More

cause

cause

into and

Dust, lint,

inlets. Remove

lateral runs

than

spillage.

vent

spillage.

block

and

runs

cause

draft enough

can

run

from

restriction

Usually, two

properly

in a

two may-

changing the

be

-

Spillage

the

primary

A

with a Vent

switch)

Other

hood include cendensation on

windows and/or

may

monoxide, a colourless, odourless,

gas.

if spillage

CAUSES

CORRECTIVE

Incorrect

lf

the

occur.

air may

causing

be

tions,

sizing

occurs when flue

vent system and back up into

symptom of appliances

Safety Shutoff System

is

unexplained appliance

symptoms

result

also

A simple spillage test can

is

suspected; see owners

flue

of

noticeable

in the release

OF SPILLAGE

ACTION

Vent

Sizing

is too

vent

vent

lf the

cool flue

spillage. The

checked. Check manufacturer's

appliance input rating,

tables.

small

is too

gases

vent

or

gases

gas

spillage

odours.

AND

(H)

too short,

large,

excessive

and

cap size

and

cannot

the dwelling.

walls and

But spillage

highly toxic

be

spillage

reduce

should

appropriate

exit

equipped

(flue

spill

shutoffs.

at the draft

carbon

of

conducted

manual.

may

dilution

draft,

also

instruc-

Negative

An

extremelly

adequate combustion

mechanical exhaust

range vent may

exchange

ing to correct

Flue Gas Cooling

Venting exposed

temperatures

tion

massive

heat. lf the

is reduced and

materials,

when necessary.

Down

tn certain

relationships

objects,

draft

its heighl, or

pressure

system

or

lose heat

masonry

flue

insulate

Drafts

wind

pressure

high

negatively.

use

in the

tight

this

spillage

with

house

such

worsen

must

Problem.

venting

needed

chimneys

gases

and

conditions

nearby

Relocate

approved

an

and

be installed

to extremelY

Dwelling

may

venting

a dryer

as

problem.

the

In

of single

cool

may

protect

conditions

wallconstruc-

maintain

to

absorb

excessively,

result.

properly'

and

structures

vent

the

high

not supply

air. Use

the

Use

in certain

rnay

cap,

wind cap.

of

vent

or

An

air

dwell'

cold

draft;

needed

draft

proper

reline

and

atfect

raise

16

Page 19

DECORATIUE

COLI.AR

INSTALLATION

Supplied

to

use to

hiding

1.

Center

provided.

with

enable

your

Drill

Install

the

your

venting

G400

you

inside

to

gas

unit

give

your

regular

I NSTALLATION

collar

3 marks

venting

vent

on

using

followed

opening

118"

by

is

a decorative

unit that

6" stove

I

NSTRUCTIONS

and

drill

and install collar

black

mark

6"

pipe

collar

"woodstove"

pipe.

holes

you

as

you

may wish

look

places).

(3

with

3 screws

go.2.

by

IMPORTANT

pipe

6"

for

use as venting.

is

fo

be

used

for

appearance

See venting instrucfrons.

17

only.

/f

ls

NOf

approved

Page 20

269

Mississau

5

Meado

ga

,

(800)

wv

Ontari

668-5323

al

e Boule

o

L5

N

8A3

vard

Canada

CFM Corporation

www.cfmco

rp

.com

Loading...

Loading...