Page 1

EWF30

Fireplace

Homeowner’s

Installation and

Operating Manual

SAFETY NOTICE: IF THIS APPLIANCE IS NOT PROPERLY INSTALLED, OPERATED AND MAINTAINED, A HOUSE FIRE MAY RESULT.

TO REDUCE THE RISK OF FIRE, FOLLOW THE INSTALLATION INSTRUCTIONS. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN

DEATH. CONTACT LOCAL BUILDING OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION

INSPECTION REQUIREMENTS IN YOUR AREA.

CFM Specialty Home Products

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

Do Not Discard This Manual: Retain for Future Use

20008662 8/05 Rev. 1

Page 2

Vermont Castings EWF30

Introduction

Thank you for purchasing a Vermont Castings, EWF30 fireplace. An efficient fireplace carefully engineered to bring

you the latest in wood combustion principles and modern foundry technology.

You can count on years of comfortable heating and pleasurable fire viewing if you treat it properly and operate the

EWF30 according to the directions in this owner’s guide.

The EWF30 is listed by Underwriter’s Laboratories, and is in compliance with the standards set forth by the Federal

Environmental Protection Agency, 40 CFR Part 60.532(b), as stated on the permanent label attached to each appliance.

This manual describes the installation and operation of the EWF30 wood heater. This heater meets the US Environ

mental Protection Agency’s emission limits for wood heaters sold after July 1, 1990. Under specific test conditions this

heater has been shown to deliver heat at a rate ranging from 11,000 to 68,600 Btu’s/hr.

For more complete details on the EWF30 performance and specifications, please refer to Page 4.

The EWF30 is designed, tested and listed for burning wood. Do not burn other fuels.

We recommend that you hire a professional installer certified by Wood Energy Technical Training (WETT) to install

your EWF30, or to advise you on the installation should you attempt to install it yourself.

Please read the appropriate sections of this manual before you install and use your EWF30. For information on operation and maintenance of the EWF30, refer to Pages 18 and 22.

The EWF fireplace can use 100% outside air with the AKMST Outside Air Kit installed (supplied with fireplace).

Failure to follow these instructions may result in property damage, bodily injury or even death.

Save These Instructions for Future Reference

-

Table of Contents

Introduction ................................................................ 2

Safety Information ..................................................... 3

Specifications ............................................................

Planning Information ................................................. 7

Installation ................................................................. 8

Operation ................................................................. 18

Maintenance ............................................................ 22

Replacement Parts .................................................. 26

Optional Accessories ...............................................

Warranty ..................................................................

28

31

Proposition 65 Warning: Fuels used in gas, woodburning or oil fired appliances, and the products of

combustion of such fuels, contain chemicals known

to the State of California to cause cancer, birth de-

4

fects and other reproductive harm.

California Health & Safety Code Sec. 25249.6

2

20008662

Page 3

Vermont Castings EWF30

Safety Information

Please Read This Manual Before Installing and Using Fireplace

IMPORTANT:

Read all instructions and warnings carefully before starting installation. Failure to

follow these instructions may result in a possible fire hazard and will void the warranty.

Description

The EWF30 fireplace is a clean burning, non-catalytic,

EPA certified solid fuel, wood burning, heat circulating

fireplace.

Precautions

CFM Specialty Home Products fireplaces and component parts have been highly tested and will operate

safely when installed in accordance with instructions

provided in this manual. Carefully read and understand

all instructions before beginning installation.

If you notice any damage to fireplace or component

parts, immediately report damage to your CFM Specialty Home Products dealer.

Only use CFM Specialty Home Products components

or the warranty will be voided and a fire hazard may be

created.

CFM Specialty Home Products warranty will be voided

by and CFM Specialty Home Products disclaims any

responsibility for the following actions:

• Installation of any damaged fireplace or chim-

ney component;

• Modification of fireplace, chimney assembly

or any component parts thereof; (except for

chase flashings as detailed in CFM Corporation

Chimney Top installation instructions).

• Installation other than as instructed by CFM

Specialty Home Products; or

• Installation and/or use of any component

part not manufactured or approved by CFM

Specialty Home Products in combination or

assembly with a CFM Specialty Home Products fireplace system, notwithstanding any

independent testing laboratory or other third

party approval of such component parts or

accessory.

Any such action may possibly cause a fire hazard.

Consult local building codes to ensure that you are in

compliance before installing the fireplace.

This fireplace and chimney system must be vented to

the out-of-doors.

Do not obstruct or modify air inlets/outlets in any

manner.

Do not install combustible materials on any of the

black fireplace surround.

Burn only solid wood fuel.

The EWF30 is intended for operation with the doors

closed or fully open only with the optional spark

screen in place. The doors must be in the fully

closed position for clean burning operation.

Do not install a solid fuel burning insert or other

products not specified for use with this fireplace.

This fireplace is not approved for installation in

mobile homes.

NOTE: Hairline cracks in hearth brick and ash lips

are not a safety issue and do not need to be replaced.

Drafts

The fireplace should not be located in areas that create

drafts (ie: frequently opened doors and central heating

air inlets/outlets) that hamper the normal flow of air into

the fire.

EWF30

Listed

UL 127 / ULC-S610

Standard for Factory Built Fireplaces

Unit: WFE05H0

20008662

3

Page 4

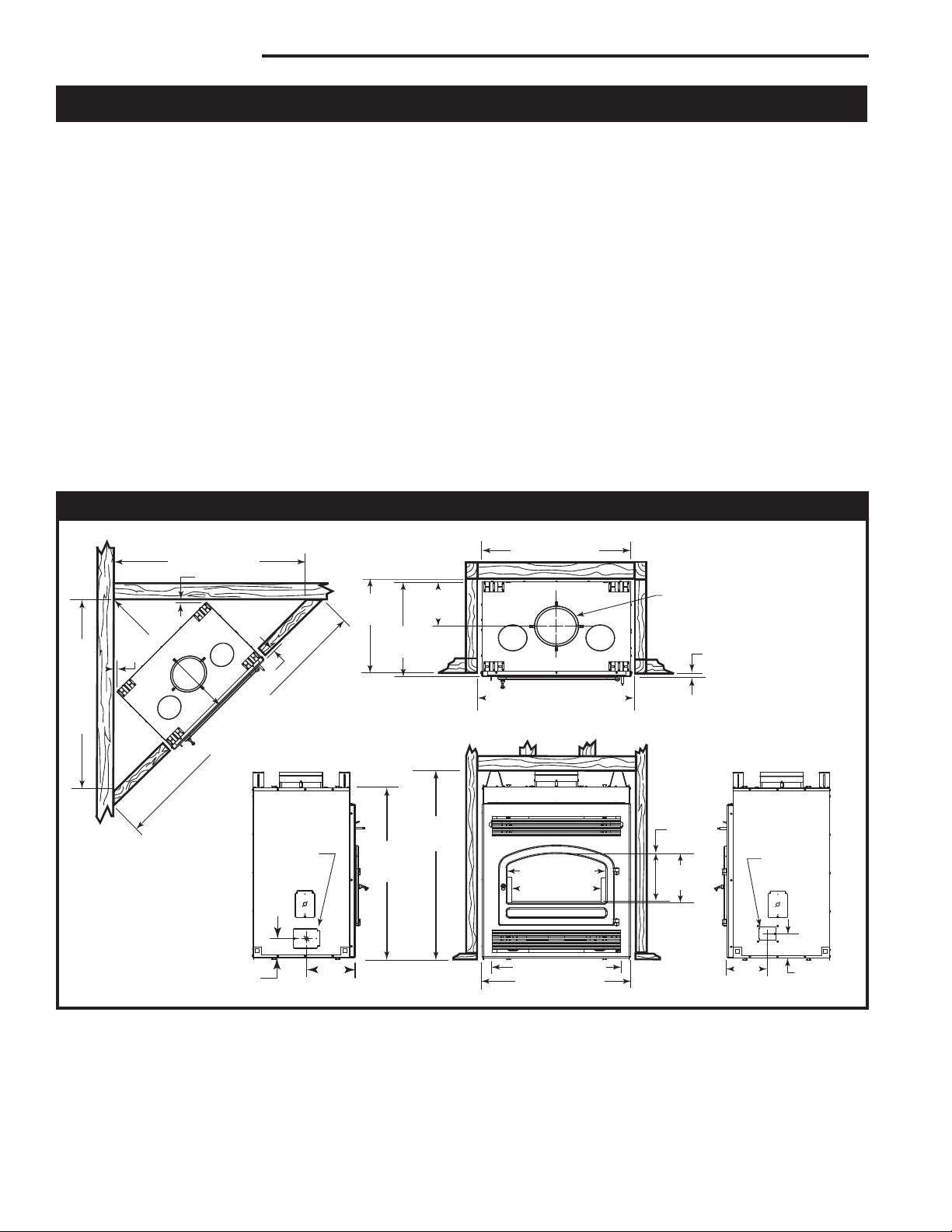

Vermont Castings EWF30

12”

(305 mm)

26”

(660 mm)

27”

(686 mm)

Rough Opening Width 39”

(1000 mm)

37” (949 mm)

11” Dia.

(279 mm)

5/8” (16 mm)

Recessed

Nailing Flange

32” (826 mm)

37” (949 mm)

47"

(1203 mm)

6”

(159 mm)

10”

(254 mm)

Outside Air

43”

(1102 mm)

64" (1635 mm)

64" (1635 mm)

1" (25 mm)

1“

91” (2311 mm)

46

”

(1172 mm)

5/8" (16 mm)

Electrical

Access

4”

(124 mm)

12

”

(318 mm)

25“ (635 mm)

23” (597 mm)

12"

(318 mm)

12”

(305 mm)

EWF30

Specifications

Range of heat output* ............... 11,100 - 40,500 Btu/hr

Maximum heat output** ....... in excess of 55,000 Btu/hr

EPA emissions rating (g/h) ......................................3.5*

Area heated*** .............. Up to 2,400 sq. ft. (223 sq. m)

Size of wood splits ....................18” - 23” (457-584 mm)

Fuel Capacity .......................................... 40lbs. (18 kg)

Loading ..................................................................Front

Flue size .................................................... 8” (203 mm)

Fireplace weight ............................................... 350 lbs.

Primary Air Control ............................................ Manual

Glass panel ......................... High-temperature ceramic

Flue exit position ..................................................... Top

Blower rating ...............................160cfm. (115V, 60Hz)

EWF30 Woodburning Fireplace

*Under specific test conditions used during EPA emis

-

sions standard testing.

**This value can vary depending on how the unit is

operated, and the type and moisture content of the fuel

used. Figure shown is based on maximum fuel consumption obtained under laboratory conditions and on

average efficiencies.

***These values are based on operation in buildingcode conforming homes under typical winter climate

conditions. If your home is of nonstandard construction

(e.g. unusually well insulated, not insulated, built under

ground, etc.) or if you live in a more severe or more

temperate climate, these figures may not apply. Since

so many variables affect performance, consult your Vermont Castings’ Authorized Dealer to determine realistic

expectations for your home.

Fig. 1 EWF30 specifications and framing.

An optional Gravity Vent Kit is available for installation on top of the fireplace as a means to provide additional heat to

the room the fireplace is in or an adjacent room. Installation instructions are provided with the Gravity Vent Kit if using

this option.

4

20008662

Page 5

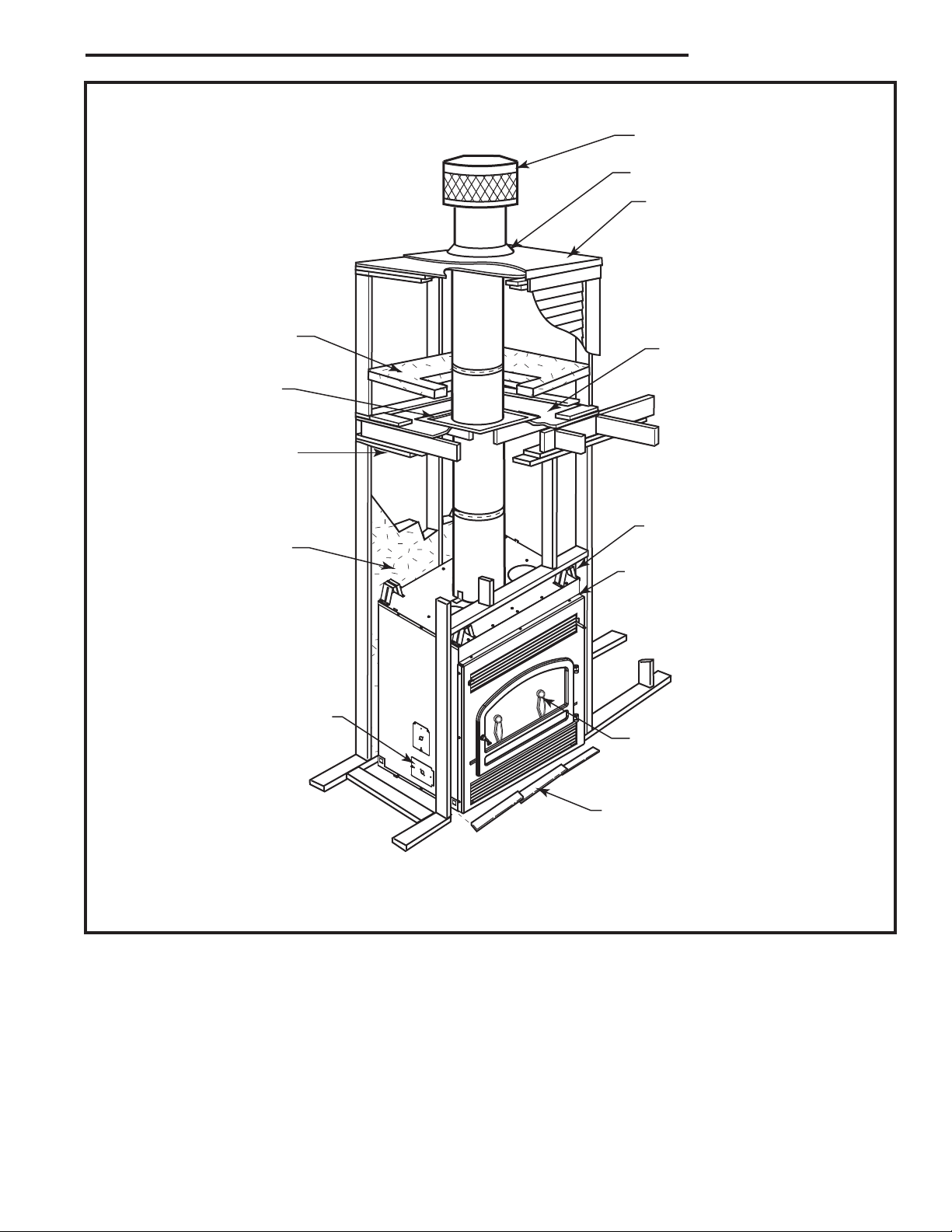

Chase Installation

Insulation methods shown are

optional for cold climate, not a

requirement for unit operation.

Batt Insulation

(cut out around firestop)

Firestop

Ceiling Level

Vermont Castings EWF30

Termination Cap

Storm Collar

Pan Flashing

Draftstop

Batt Insulation

MUST be used in

the Chase.

Electrical Access

Fig. 2 Fireplace and chase parts identification.

Standoff

Brick Ledge

Andiron

Metal Safety Strips

(1,2 or 3 pieces)

FP1561

20008662

5

Page 6

Vermont Castings EWF30

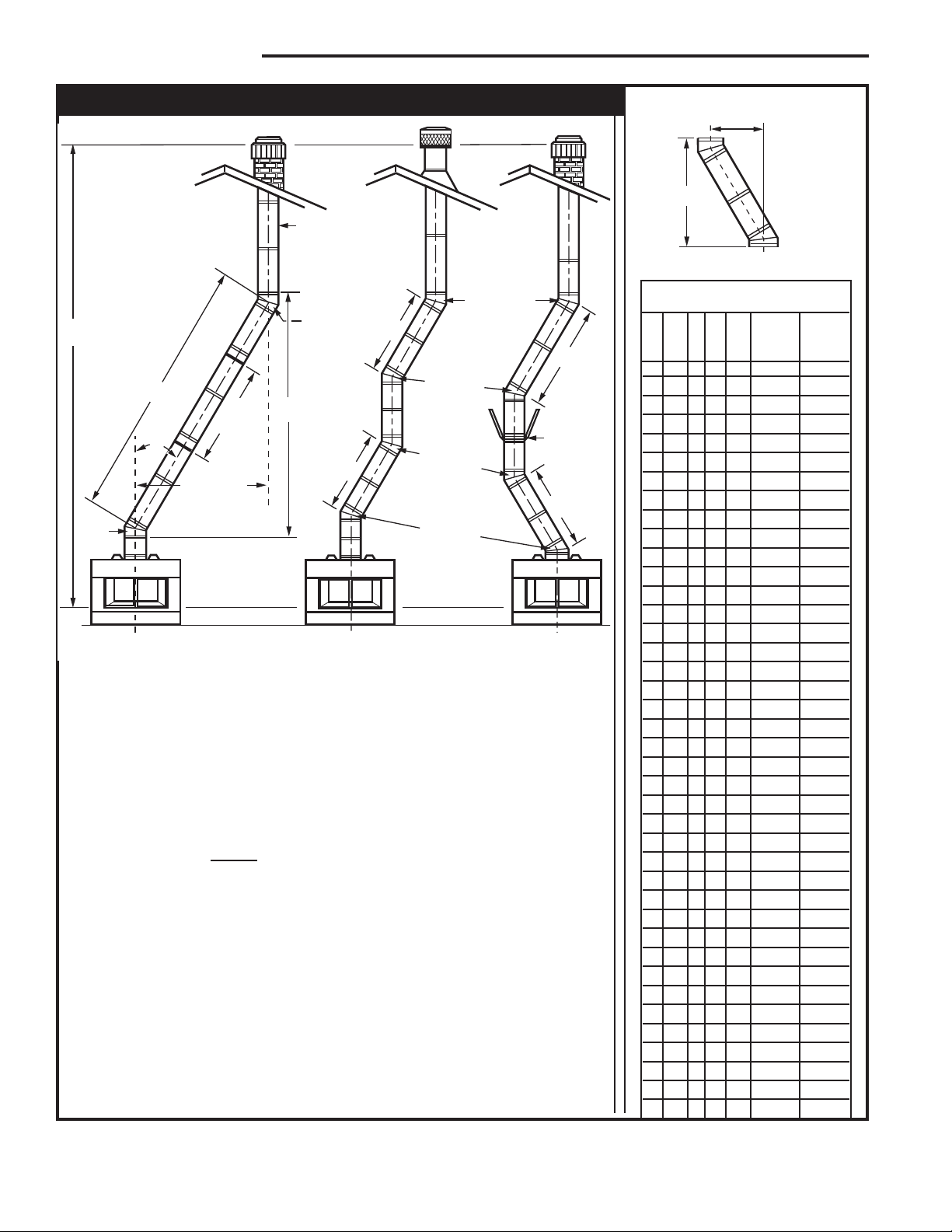

D

Rise

B

G

H

B

Offset

C

E

6 FT.

G

H

A

Hearth

Floor

Chimney

Section

CHIMNEY FLUE EXIT

Elbow

TCS8A

Support

Example 1 Example 2 Example 3

Offset

Rise

Chimney Requirements - Offset Installations

Notes: G + H cannot exceed 20 feet.

Air Space Clearances: “SK” Series (2-wall) = 1¹⁄₂” Min. to Combustibles

“S” Series (3-wall) = 2” Min. to Combustibles

Illustration Key

The following safety rules apply to

offset installations (letters correspond

with illustration above):

A. Height of the chimney is measured

from the hearth to the chimney exit.

Maximum: 50’

Minimum:

Without Elbows 17’0”

With 2 Elbows* 19’0”

With 4 Elbows* 21’0”

B. Do not use more than 4 elbows per

chimney.

Attach the straps of the return (top)

elbow to a structural framing member.

The offset (first) elbow of any pair does

not have straps.

Fig. 3 Chimney system requirements.

EWF30

30°

Return

Elbow

30°

Offset

Elbow

30°

Return

Elbow

30°

Offset

Elbow

C. The chimney cannot be more than 30˚

(45˚ in Canada) from the vertical plane in

any installation*.

D. The maximum length of the angled run

of the total chimney system is 20 feet. (G

plus H cannot exceed 20 feet.)

E. A chimney support (Model SKCS8)

is required every 6 feet of angled run of

chimney. Chimney supports are required

for every 30 feet and 60 feet (SK8 pipe)

or 20 feet and 40 feet (3-wall pipe) of vertical chimney height above the hearth.

Determine the offset distance of your

chimney arrangement from the centerline

of the fireplace to the centerline of the

chimney where it is to pass through the

first ceiling.

NOTE: This offset distance may not be

your full offset distance. See Examples 2

and 3.

FP282

30˚ Elbow Offsets

1’

3’ 4’

1¹⁄₂'

0 0 0 0 0 3” 11”

1 0 0 0 0 8

0 1 0 0 0 11

2 0 0 0 0 13¹⁄₂" 29¹⁄₄"

1 1 0 0 0 16

0 0 1 0 0 20

2 1 0 0 0 21³⁄₄" 43¹⁄₂"

0 0 0 1 0 26

0 1 1 0 0 28

1 0 0 1 0 31¹⁄₂" 60¹⁄₄”

0 1 0 1 0 34

0 0 2 0 0 37

1 1 0 1 1 41¹⁄₂" 77³⁄₄"

0 0 1 1 1 45" 83³⁄₄"

0 1 2 0 1 47¹⁄₄" 87¹⁄₂"

FP269

0 0 0 2 1 51" 94"

0 1 1 1 1 53¹⁄₄" 98"

0 0 3 0 1 56¹⁄₄" 103¹⁄₄"

0 1 0 2 1 59

0 0 2 1 1 62

0 1 3 0 1 64¹⁄₂" 117¹⁄₂"

0 0 1 2 1 68

0 1 2 1 1 70

0 0 0 3 1 74¹⁄₄" 134¹⁄₂"

0 1 1 2 2 78" 140

0 0 3 1 2 81" 146"

0 1 0 3 2 84" 151

0 0 2 2 2 87" 156

0 1 3 1 2 89¹⁄₄" 160¹⁄₄"

0 0 1 3 2 93" 166

0 1 2 2 2 95

0 0 0 4 2 99¹⁄₄" 177³⁄₄"

0 1 1 3 2 101

0 0 3 2 2 104

0 1 0 4 2 107¹⁄₄" 191¹⁄₂"

0 0 2 3 2 110

0 1 3 2 3 114" 203

0 0 1 4 3 117³⁄₄" 209³⁄₄"

0 1 2 3 3 120" 213¹⁄₂"

0 0 0 5 3 123³⁄₄" 220"

Offset

Chimney

Support

Rise

¹⁄₄" 20"

¹⁄₄" 25¹⁄₄"

¹⁄₂" 34¹⁄₄"

¹⁄₄" 40³⁄₄"

¹⁄₄" 51¹⁄₄"

¹⁄₂" 55¹⁄₄"

¹⁄₂" 65¹⁄₂"

¹⁄₂" 70³⁄₄"

¹⁄₄" 108¹⁄₂"

¹⁄₄" 113¹⁄₂"

¹⁄₄" 124"

¹⁄₂" 128"

³⁄₄"

¹⁄₄"

¹⁄₂"

³⁄₄"

¹⁄₄" 170³⁄₄"

¹⁄₄" 181³⁄₄"

¹⁄₄" 186¹⁄₄"

¹⁄₄" 196³⁄₄"

¹⁄₄"

6

20008662

Page 7

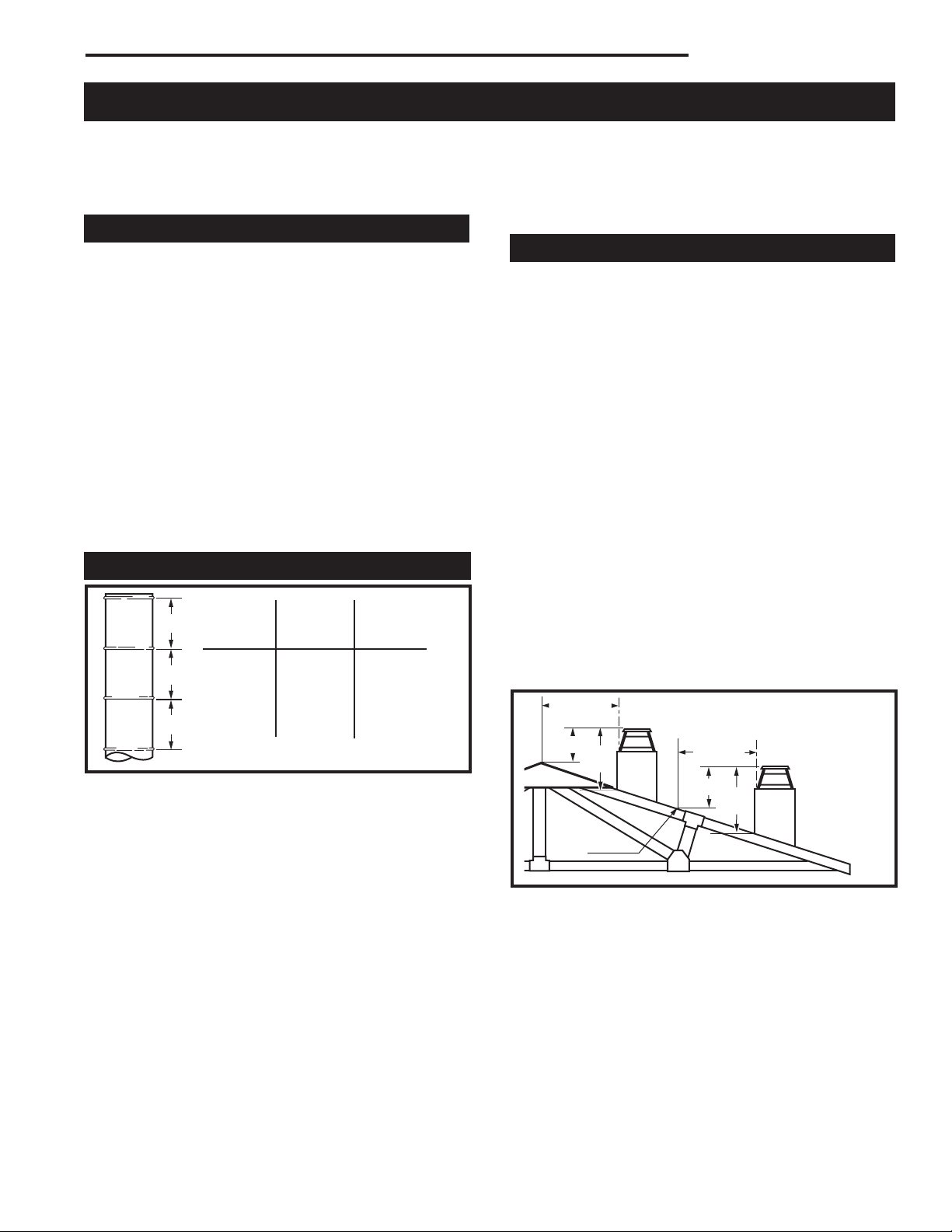

Planning Information

2' Min.

2' Min.

3'

Min.

0 To 10'

3'

Min.

0 To 10'

Reference

Point

L

1

L

1

L

T

TOTAL

LENGTH

(L

T

)

INSTALLED

LENGTH

(L

1

)

"

"

"

"

"

"

"

"

TRIPLE

WALL

81

818

83

84

Vermont Castings EWF30

Planning an installation is very important to ensure

safety and to save time and money. An installer must

predetermine where a fireplace will be set and how the

chimney system will be run.

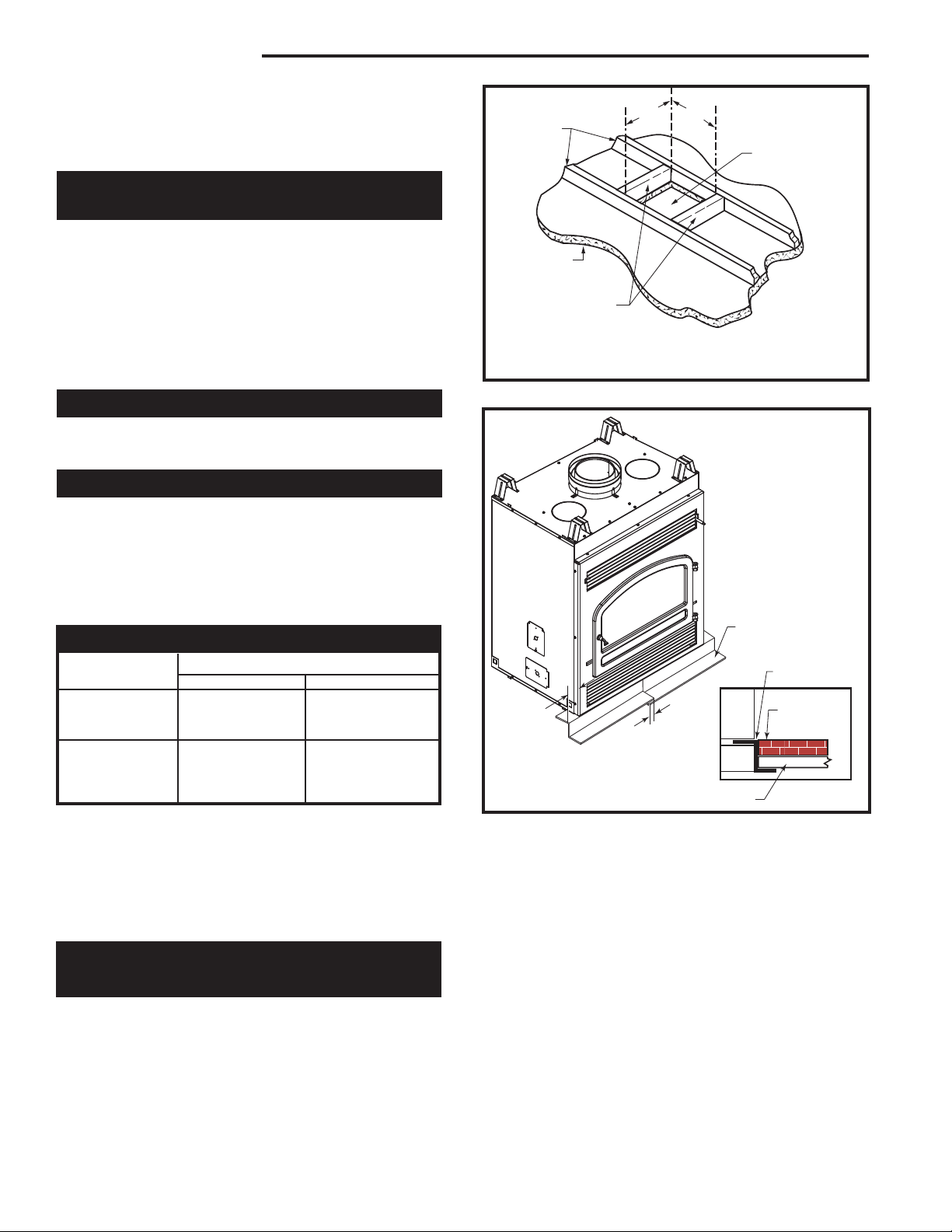

Mounting the Fireplace

The fireplace is shipped with lifting handles attached to

each side with lifting straps. NOTE: The lifting straps

are intended for ligting unit off of the skid and final positioning. Unit should remain on skid until final positioning. After fireplace is in position, the lifting handle and

straps may be removed or left in place.

A fireplace may only be mounted on the following surfaces:

1. A flat combustible surface.

2. A raised wooden platform.

3. A concrete block or other solid object placed beneath

each of the four (4) corners of the fireplace.

The fireplace must be spaced 1” from a combustible

back wall and 1” from a combustible side wall or sup-

port. (Page 13, Fig. 17)

Planning the Chimney Run

TOTAL INSTALLED

TRIPLE LENGTH LENGTH

WALL (L

SK81 11¹⁄₂” 10¹⁄₂”

SK818 17

SK83 35

SK84 47

) (L1)

T

¹⁄₂” 16¹⁄₂”

¹⁄₂” 34¹⁄₂”

¹⁄₂” 46¹⁄₂”

FP288a

5. No more than 2 offsets (4 total 30° elbows in U.S./or

2 total 45° elbows in Canada) per fireplace may be

used.

6. A guy wire stabilizer is required for chimneys extending more than 6’ (1.8m) above a roof line.

The Ten Foot Rule

Major U.S. building codes specify a minimum chimney

height above the roof top. The “Ten Foot Rule” is a fire

safety rule and not a draft rule. To ensure proper draft,

it is recommended that you always meet or exceed the

“Ten Foot Rule,” especially when installing a termination

on a high pitch roof. (Fig. 5)

The key points of the “Ten Foot Rule” are:

1. If the horizontal distance from the chimney to the

peak of the roof is 10’ (3m) or less, the top of the

chimney must be at least 2’ (610mm) above the peak

of the roof, but never less than 3’ (914mm) in height

above the highest point where it passes through the

roof.

2. If a horizontal distance from the chimney to the peak

of the roof is more than 10’ (3m), a chimney height

reference point is established that is on the surface

of the roof a distance of 10’ (3m) from the chimney in

a horizontal plane. The top of the chimney must be

at least 2’ (610mm) above the reference point, but

never less than 3’ (914mm) in height above the highest point where it passes through the roof.

Fig. 4 Installed lengths of chimney sections.

Determine how the chimney will be run, length of run

and chimney components required to complete the

job. (Fig. 4) Never install a chimney below minimum

heights.

In planning a chimney system, it is important to know:

1. The height of a chimney is measured from the hearth

to the exit point on the termination.

2. A chimney cannot be offset more than 30° from a

vertical plane.

3. A chimney may run straight up or it may be necessary to offset it to avoid obstructions.

4. The maximum length of an angled run (total chimney

system) is 20 feet.

20008662

AC246

Fig. 5 Ten Foot Rule illustration.

7

Page 8

Vermont Castings EWF30

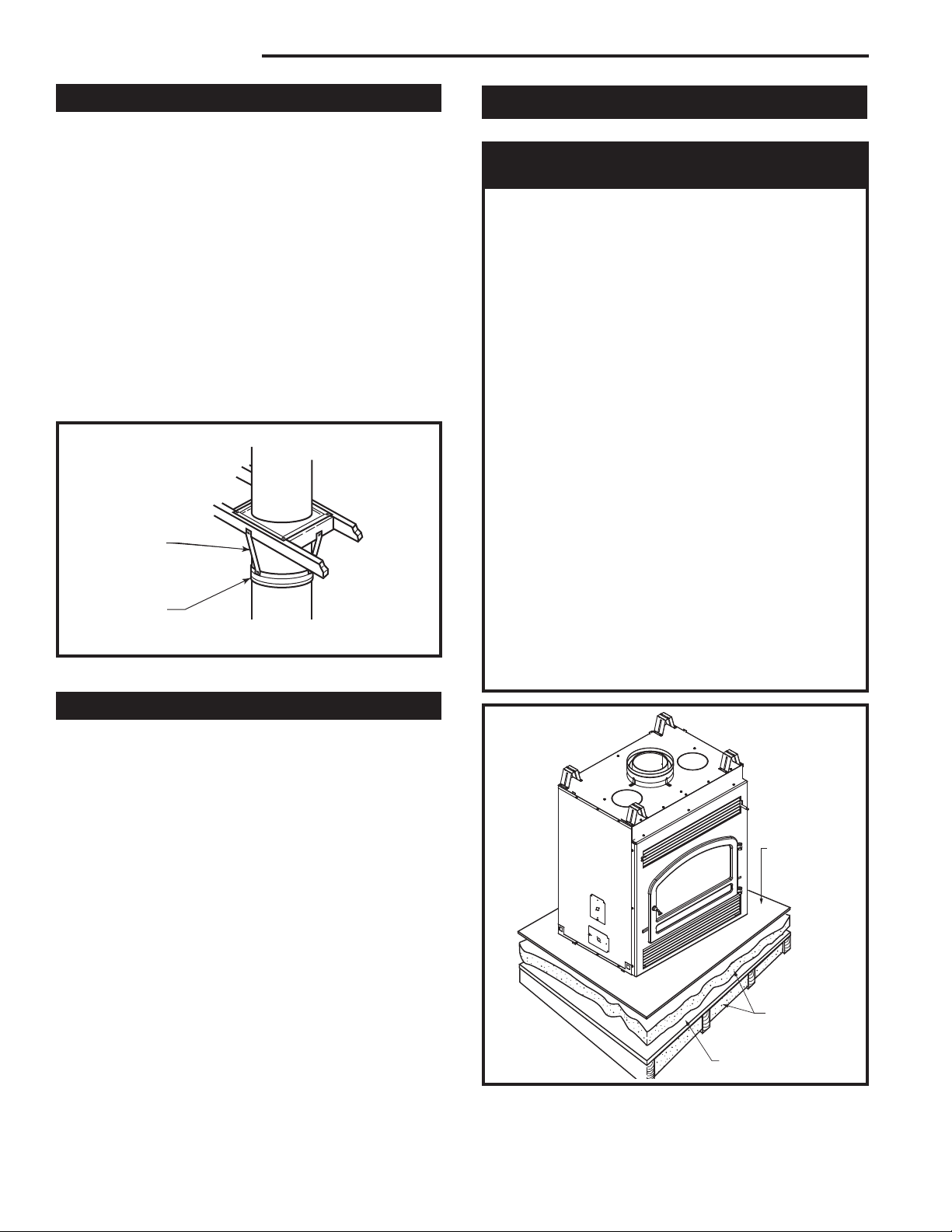

Chimney Supports

The chimney system is supported by the fireplace for

vertical chimney heights less than 30’ (9m) above the

hearth. Chimney supports are required if the vertical

height exceeds 30’ (9m). Locate chimney supports

at ceiling holes or other structural framing at 30’ (9m)

heights. Spacing between chimney supports must not

exceed 30’ (9m). Use Chimney Support Model SKCS8.

(NOTE: The SKCS8 cannot be mounted directly to

the fireplace.) Support provided by elbow straps fulfills

the support requirement only if they are spaced as previously described. (A chimney support is 2¹⁄₂" (64mm)

long when installed.)

Angled chimney runs require a support every 6’ (1.8m)

in addition to the elbow straps. Chimney supports are

used for this function. (Fig. 6)

Chimney Support Strap

TCS8A

FP284a

Fig. 6 Chimney support installation.

Installation

Insulating Fireplace Enclosure

for Cold Climates

If you live in a cold climate, it is not required but

highly recommended that you insulate fireplace

enclosure to eliminate cold air penetration as much as

possible.

Insulate base of fireplace with a noncombustible

insulation rated for a minimum of 300° F. Insulating

is very important for outside wall installations over

a concrete slab. If fireplace is installed on a platform,

insulation should be placed on top of the platform

before fireplace is set. (Fig. 7)

When a fireplace is installed in a chase or on an

outside wall, enclosure should be treated like any

outside wall in a home. Insulation should be installed

on the inside wall as well as the outside wall(s). In a

chase, it is also a good idea to install a firestop at the

first ceiling level above the fireplace and enclose the

chase with sheeting material. Insulation may then be

installed above sheeting material to assure the space

around the fireplace is totally protected. (Fig. 2)

When installing the chimney, DO NOT caulk between

outer pipe and firestop. It is vital that some air be allowed to flow through this very thin gap.

CAUTION: When installing a fireplace in an insu

lated enclosure, be sure all required air spaces

are maintained. (Page 13, Fig. 17)

-

Chase Installation

A chase is a vertical box-like structure which encloses

the fireplace and/or chimney. Chases are typically built

on the outside of the house with fireplace opening cut

into the outer wall of a room. (Page 5, Fig. 2)

If you need help in determining fireplace location or how

the chimney system should be run, contact your Vermont Castings dealer for assistance.

8

Hard

Flat

Surface

Insulation

Platform

FP1562

Fig. 7 Insulating between platform and fireplace.

20008662

Page 9

Vermont Castings EWF30

9"

(241mm)

Framing

Framing can be constructed before or after the fireplace

is set in place, however, most installers build the frame

before setting the fireplace.

Frame fireplace with 2 x 4 lumber or heavier materials. Refer to framing dimensions in Figure 1 for basic

fireplace specifications.

NOTE: Framing should be positioned to accommodate

wall covering and fireplace facing material.

EB1 (Receptacle) Hookup

Option for Circulating Models Only

Wiring should be installed by a certified electrician.

Turn off circuit breaker before wiring models.

Once fireplace is secured, complete wiring the fan kit.

Remove knockout in the center of the back of the EB1

and install listed cable clamps. Feed electrical wire

through listed cable clamp leaving approximately six (6)

inches of wire exposed through the EB1. Secure listed

cable clamp to the wire.

Attach white wire from power source to one (1) wire

of receptacle and secure with nut. Attach black wire

from power source to the other wire of receptacle and

secure with nut. Be sure nuts are secured tightly.

Secure EB1 assembly to inside of electrical box coverplate using two screws. Attach cover to face of the EB1

while being careful to position excess wire completely

within the EB1, then attach coverplate to fireplace.

Chimney Centerline

Actual Centerpoint

Plumb Line

Plumb Bob

Imaginary

Centerpoint

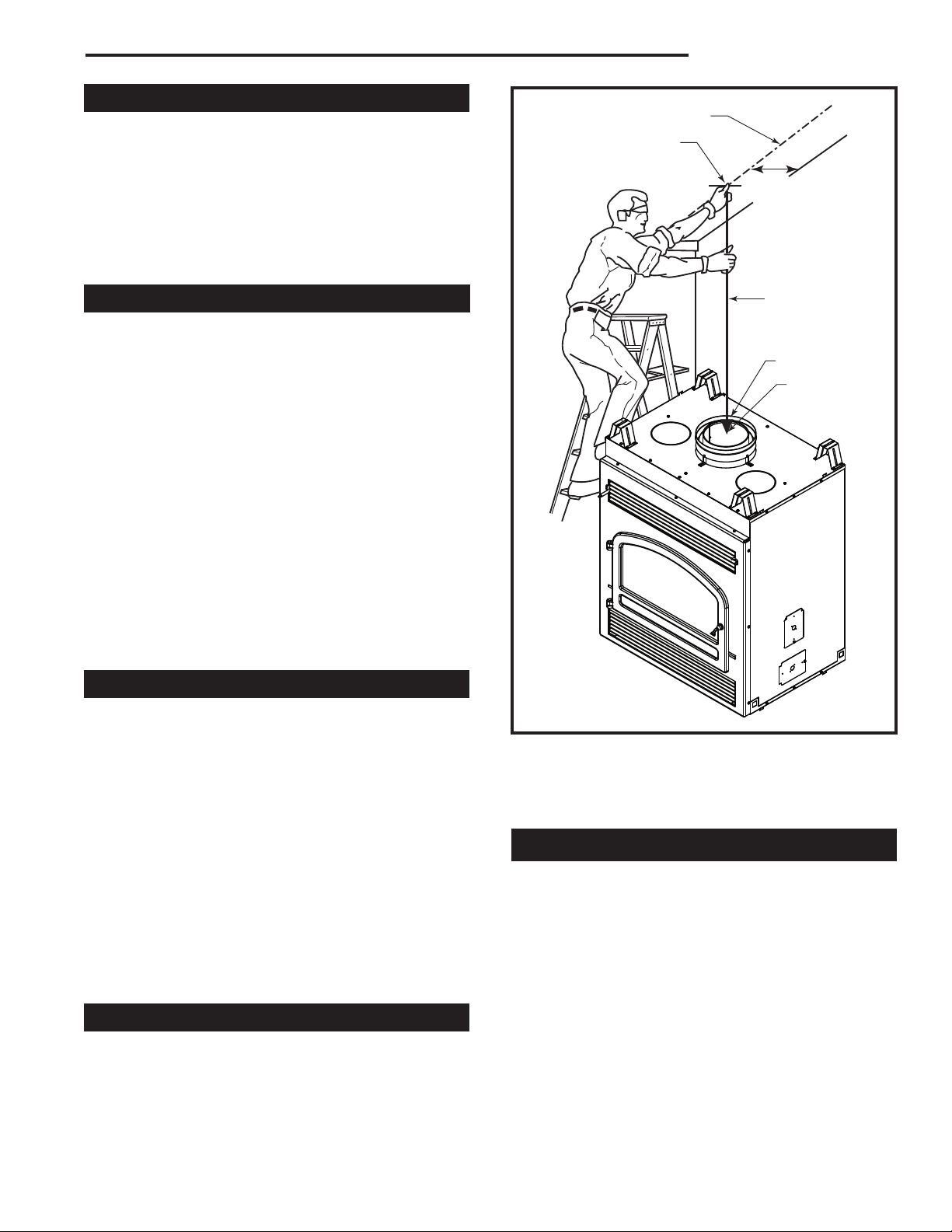

Chimney Set-Up

Since you have already planned the chimney run, you

should know exactly how the installation is to be accomplished - how much pipe is required, the number of

elbows, if any, and type of termination to be used.

CAUTION: Report to your dealer any parts damaged

in shipment, specifically check the end connection of

chimney sections and elbows.

NOTE: Fireplaces may use CFM Corporation Model

SK8, or Model S (three wall) chimney systems. The

BR/BC Series Fireplace will accept the SK8 chimney

system as is; but a TWABR adapter collar is required

when using the Model S (triple wall) chimney system.

The installation procedure described in this manual

applies only to the SK8 system. Either chimney system

may be used, but may not be mixed.

Straight-Up Chimney Installation

To mark the centerline of the flue, put the fireplace

in final position and measure out from the wall: 9¹⁄₂"

(241mm). Mark a spot on the ceiling directly above the

fireplace. Draw a line parallel to the back wall through

this mark. (Fig. 8)

FP1563

Fig. 8 Locate centerline of chimney with plumb line.

Using a plumb bob positioned directly over center point

of fireplace flue collar, mark the ceiling to establish the

chimney center point. (Fig. 8)

Offset Installation

In order to clear an obstruction, it may be necessary to

offset chimney from vertical. This is accomplished by

using elbows. Use the 30˚ Offset Elbow table on Page 6

to determine proper offset and parts required.

Each offset requires two (2) elbows. The second elbow

is equipped with support straps. It is very important to

install the second elbow in each offset as close to the

ceiling or support as possible so that the elbow straps

can be secured to framing members to help support the

weight of the chimney.

Determine offset distance of your chimney arrangement

from centerline of fireplace to centerline of chimney

where it is to pass through ceiling.

20008662

9

Page 10

Vermont Castings EWF30

AB

AB

A "SK" Series framing = 14" X 14" (368 x 368 mm)

B "S" Series framing = 17" X 17" (445 x 445 mm)

Locate center point of the chimney on ceiling as though

a straight up chimney arrangement is to be used. Measure your offset dimension from straight up chimney

center point on ceiling.

Ceiling Chimney Hole/

Possible Obstructions

The size of the hole in ceiling will vary with the angle at

which the chimney passes through ceiling.

Drive a nail up through ceiling at marked chimney

center point. Go to floor above and see where hole

will be cut. Check to see where existing ceiling joists

and other possible obstructions are located...i.e. wiring,

plumbing etc... If necessary, re-position chimney and/or

fireplace to avoid obstructions.

Cutting the Hole

Cover fireplace collar opening and cut proper sized

chimney hole in chimney.

Framing the Ceiling Hole

Frame the ceiling chimney hole as shown in Figure

10. It is good practice to use framing lumber that is the

same size as the ceiling joists; this is a requirement at

attic level.

The following table gives firestop spacer model numbers:

Chimney Hole Size

Angle of Chimney at Ceiling

Size of Chimney Vertical 30°

8" Flue SKFS2A SKFS6A

"SK" Series 14

(368mm x 368mm) (368mm x 648mm)

8" Flue FS2A FS6A

"S" Series 3-Wall 17¹⁄₂" x 17¹⁄₂" 17⁷⁄₈" x 29⁵⁄₈"

(445mm x 445mm) (454mm x 753mm)

Fig. 9 Ceiling chimney hole sizes necessary for installing

firestop spacer.

¹⁄₂" x 14¹⁄₂" 14¹⁄₂" x 25¹⁄₂"

The inside dimension of the frame must be the same

as the hole size selected from Figure 9 in order to provide required the 1¹⁄₂” (38 mm) air space between the

outside diameter of the chimney and the edges of the

framed ceiling hole.

Positioning, Safety Strips,

Securing the Fireplace

Slide fireplace into position.

Safety strips are used to ensure that any combustible

materials in front of the fireplace are protected even

though a noncombustible hearth extension is required.

When the finished extended hearth is added, the top

of the finished hearth must be flush with the bottom of

the fireplace. “Z” shaped metal safety strips have been

10

Existing

Ceiling

Joists

Chimney

Hole

New Framing

Members

Ceiling

FP551b

Fig. 10 Typical frame for ceiling chimney hole.

“Z” Metal Safety

Strips (1 or 2 pcs.)

“Z” Safety Strip

1¹⁄₂”

(38mm)

Fig. 11 Safety strip installation.

1/2” Min.

Overlap

Fireplace

Platform

Hearth Ext.

supplied with the fireplace and are required for instal

Decorative

Hearth

Face

FP1564

lation. The safety strips provided have a 1” offset. For

applications with a greater offset, “Z” shaped strips will

have to be fabricated of metal. Overlap safety strips at

least 1/2” to provide a positive joint. The safety strips

must also extend at least 1¹⁄₂” (38mm) beyond the sides

of the fireplace. (Fig. 11)

NOTE: Safety strips are not required over noncombustible floors where all supports at the base of the fireplace are noncombustible.

Four (4) nailing flanges are supplied with the fireplace

(found on the fireplace hearth). To level the box and

secure it firmly in place, remove the nailing flanges from

the hearth and install at the sides of the fireplace as

shown in Figure 12.

20008662

Page 11

Vermont Castings EWF30

Nail Top

Standoffs

Nail Side

Nailing

Flanges

FP1565

Fig. 12 Fasten fireplace in position.

Installing Outside Air Kit

An outside air kit may be installed on the EWF30.

The AK-MST allows for 100% of required combustion

air to come from outside source. If desired, or if local

codes mandate the use of an air kit, then an AK-MST

is required to complete the installation (from air kit to

the outdoors). If the outside air kit is to be used, the

AK-MST MUST be installed BEFORE the fireplace is

enclosed.

NOTE: Four (4) inch Class 1 air duct, material or metal

duct (not supplied) may be used with AK-MST. (For

installation in New York State, only aluminum, noncombustible flexible or type “O” metal ducting is

permissible.)

of the duct termination and the route of the duct run

between the fireplace and the duct termination.

Duct run must be limited to a maximum distance of 40

feet from the fireplace pipe collar to duct termination.

This will provide the least restriction to air flow. No more

than four (4) 90° elbows can be used. Duct run may

be horizontal, vertical, inclined or any combination of

these. Vertical duct runs must be at least three (3) feet

Duct Termination

Must be More Than 3’

Below Chimney

Duct Termination

40’ Max.

Duct Run

Soffit Termination

Attic

Ceiling

Duct

Installation Precautions

The duct termination should be located so it is exposed

to an out-of-doors opening at least 100 square inches. If

the duct termination must be located in a crawl space or

basement, be sure the termination area has 100 square

inches of ventilation opening to outside air.

The duct termination must be located so it does not

compete for air flow with exhaust fans, gas vent hoods

or other air consuming devices or appliances. It must

not be obstructed by rafters, insulation materials or

other obstructions. The less restrictive the air supply,

the better the AK-MST will perform.

It is a good practice to protect your hands and eyes

during installation by wearing work gloves and safety

glasses.

CAUTION: Do not install termination into a garage

or other area that could contain flammable liquids

or fumes, or into an attic space.

Installation Instructions

Determine the location of the fireplace as described

in the fireplace Installation Manual. Then plan location

Exterior Wall

40’ Max. Duct Run

Rain Cap

Duct Termination

Exterior Wall Termination

Fig. 13 Typical installations.

Duct

FP1060

below the fireplace chimney flue exit. (Fig. 13) You are

now ready to install the AK-MST Outside Air Kit.

1. Remove and discard the outside air cover plate

located at the center of the right side of the fireplace.

Use care not to rub against the sharp edges of this

opening to avoid cuts.

2. Attach the inlet collar with four (4) #10 screws to the

side near the bottom of the fireplace. Slide the duct

over the collar and attach the duct to the collar using

the plastic tie straps or three (3) screws (screws not

20008662

11

Page 12

Vermont Castings EWF30

UP

provided). Continue attaching the ducting together

using three (3) screws at each joint until you have

installed sufficient duct to arrive at your duct termination location.

3. At the termination end, install the duct termination.

This should be installed from the outside of the

home. Cut a hole in the desired location approximately 4¹⁄₂” in diameter, caulk around the hole, and

slide the termination through the opening from outside the home. The termination/rain cap should be

caulked around its perimeter to assure a tight seal.

The rain cap opening should be positioned downward. (Fig. 14)

The AK-MST Outside Air Kit is now installed and ready

for use.

Caulking

Duct Termination

Rain Cap

Pipe Section

Pipe

Rim

Hem

Pipe

Hem

Fig. 15 Install pipe, listening for the snap-lock to fasten.

Elbow Strap

Support Structure

Elbow Strap

(must be tight)

Lance

FP1566

Wall

Fig. 14 Caulk and install duct termination/rain cap in place.

FP1061

Installing the Chimney System

Start by attaching the first chimney section to the collar

on top of the fireplace.

Install the pipe as pictured in Figure 15. When you

get a good lock, you will hear the pipe clearly snap

together. Once sections are snap-locked in place, it is

extremely difficult to get them apart. Make sure the

pipe is firmly snapped and locked together as each

pipe section is mounted.

When installing elbows, only outer pipe will snap- lock.

Middle pipes simply slide into position. Be sure to

always attach straps on upper elbow to a structural

framing member. (Fig. 16)

Continue installing the pipe as required until pipe is

installed up through the ceiling. At this point, you must

install a firestop spacer.

Ceiling Hole

Framing

Angled Strap

Angled Firestop

FP270/271

Fig. 16 Attach straps to a structural framing member.

Chimney Support Strap

(must be tight)

Installing the Firestop Spacer

in the Ceiling Hole

A firestop spacer is used to keep pipe spaced properly

and required for safety.

Nail the firestop spacer (at each corner) to the framing

members of the ceiling hole. NOTE: A firestop spacer

is not required at the roof.

Hole sizes listed in Figure 9 for angled firestop spacers

provide minimum required air space to chimney pipe for

ceiling thickness up to 8” (203mm). When combined

thickness of ceiling material, ceiling joists and flooring

material exceeds 8” (203mm), adjustments must be

made in framing to assure that minimum air spaces to

chimney are maintained.

12

Proper Firestop Spacer Installation

Figure 17 shows different installation procedures for

both an area that is an attic and an area that is not an

attic.

20008662

Page 13

If the area above the ceiling is not an attic, position the

firestop spacer with the flange on the ceiling side and

the angled portion extending up into the hole.

If the area above the ceiling is an attic, position the

firestop spacer with the flange on the top of the framed

hole and the angled portion extending down into the

hole.

Firestop spacers are not available for, nor are they

required on vertical walls.

DO NOT put any sealant around the area where the

outer pipe slides through the firestop spacer. If you seal

this area, it may cause a fire hazard.

Attic Installation

Nails (4)

Firestop Spacer

Joist

Ceiling Installation

Joist

Vermont Castings EWF30

Attic Insulation

Shield

Nails

(4 Required)

Attic Joist

Base

Ceiling

Fig. 18 Attic shield installation (Canadian requirement).

Flanges

FP263

Chimney Supports

If chimney supports are required, they are installed the

same as elbows. Nail chimney support straps to adjacent structural framing, as shown on Figure 16. Bend

straps as necessary and make sure they are secure so

they will support the weight of the chimney. A chimney

support is 2¹⁄₂" (64mm) long when installed. Consider

this dimension when determining how many straight

chimney sections are needed.

NOTE: Chimney supports are generally used in long

runs in a chase installation.

Firestop Spacer

Nails (4)

Fig. 17 Firestop spacer installations.

FP593

Canadian Requirements

for Insulation Shield

In Canada, an attic insulation shield is required to prevent attic insulaiton from contacxting the chimney section. Framing dimensions for the chimney hole should

measure 14¹⁄₂” x 14¹⁄₂” (368 x 368 mm). An attic shield

MUST be installed on top of attic joists (above the floor

level). (Fig. 18)

Continue Installing Pipe to Complete Run

Continue attaching pipe sections to complete system

to next level always being careful that the pipe is firmly

snapped locked in place before proceeding to next pipe

section.

Additional Ceilings

If you encounter additional ceilings, repeat same steps

required for first ceiling installation. See firestop illustra-

tion in Figure 17.

Penetrating the Roof

Run pipe to roofline. Since chimney system must be

vented to the out-of-doors, you must use an approved

CFM Corporation termination.

If a chase is used, refer to the installation manual provided with the termination cap.

Locate Chimney Centerpoint on Roof

Use same procedure detailed in locating center point of

the flue system.

Drive a nail up through roof at the center point. This will

determine center point on outside of the roof.

Cut and Frame Roof Hole

Size of roof hole varies with the type of chimney termination installed. Refer to installation instructions

provided with CFM Corporation chimney termination to

find correct size of roof hole.

20008662

13

Page 14

Vermont Castings EWF30

There must be a 1¹⁄₂” (38 mm) air space between outermost portion of chimney sections and any adjacent

combustible surfaces. (Combustible surfaces include

burnable materials such as: ceiling members, joists,

flooring, combustible insulation and roof structures.)

WARNING: Do not pack required air spaces with

insulation or other materials.

Mark an outline of the roof hole around the center of the

point nail. NOTE: Hole dimensions given in the chimney top installation instructions are horizontal dimensions; therefore, the hole size must be marked on the

roof accordingly.

Cover the opening of the installed chimney so debris

cannot get into the system.

Cut and frame the hole. It is good practice to use framing lumber that is the same size as the rafters. Install

the frame securely because the chimney top and flashing anchored to the frame must be able to withstand

heavy winds.

Install Remainder of Chimney Sections

Since you have already preplanned the height of your

termination according to the Ten Foot Rule, continue to

install pipe to the predetermined height.

Check the chimney top installation instructions for

details on how high above the roof top the chimney sec-

tions (all pipes) should extend.

Install Top Housing or Termination

Finish Wall

Finish the wall with material of your choice. Do not

install a combustible mantel shelf less than 12”

(305 mm) above the firebox grille opening. Do not

install a mantel face plate less than 6” (159 mm)

from top of grille opening. (Fig. 21) If a combustible

material is used below a flat mantel shelf, consult your

local building codes for minimum clearance from top of

fireplace opening to bottom of mantel shelf.

All joints (top, bottom and sides) where wall or decorative facing material meets fireplace surround must be

completely sealed with a noncombustible material. (Figures 20 and 24)

NOTE: No side wall protection is required for fireplaces

installed at 45° to two (2) side walls (corner installation).

Air Space Clearances

Combustible framing material MUST NOT

penetrate AIR SPACE (shaded areas)

1¹⁄₂”

(38 mm)

1” (25mm) Air

Space to Sides

Standoff

Follow the installation instructions provided with the

chimney termination you have selected.

Installing Chimney in a Chase

Refer to Figure 2, Page 5 for an illustration of a typical

chase installation.

CAUTION: Treatment of firestop spacers and construction of chase may vary with type of building. These

instructions are not a substitute for local building codes.

You must check your local building codes to determine

specific requirements for your city or state. NOTE:

Other building materials may be required in addition to

CFM Corporation Firestop Spacers.

Finishing

CAUTION: All joints between the finished wall and

the fireplace surround (steel front) must be sealed with

noncombustible material to prevent cold air leakage into

the room. (Fig. 19)

NOTE: No material may cover black cast face.

Firestop

Wall

Shield

NO material

may cover

cast face

0” Clearance

Hearth Extension

Fig. 19 Minimum clearances to combustibles.

to Floor

1” (25mm)

Space to Back

1” (25mm)

Air Space

to Sides

FP1567

14

20008662

Page 15

Vermont Castings EWF30

6"

(159mm)

Min.

12"

(305mm)

Min.

1"

(38mm)

12"

(305mm)

Max.

*

1"

Ref.

**

Combustible materials

are permitted within a

shaded area shown in

Figure 25 titled

Minimum Wall

Clearances

Mantel Shelf

See mantel drawing for

shelf-to-grille dimension

Noncombustible Finish Mate

rial Only in this Area

Brick Ledge

Cast Front

Top View

FP1200

Fig. 20 Finishing materials placement.

-

Fireplace

Front (Steel)

Must be sealed with

noncombustible material

Side View

Finished Wall

2 x 4 Stud

Standoff

2 x 4 Stud

1” (25mm)

Mantels

The height that a combustible mantel is fitted above the

fireplace is dependent on the depth of the mantel. This

also applies to the distance between the mantel leg (if

fitted) and the fireplace.

For the correct mounting heights and widths, refer to

Figures 21 and 22. When using paint or lacquer to finish

the mantel, such paint or lacquer must be heat resistant

to prevent discoloration.

Combustiible

Mantel and

Trim

Fig. 21 Combustible mantel minimum opening.

20008662

Finished Wall

Header

Standoff

Noncombustible

Material

Brick Ledge

GrilleOpening

Fireplace

Front

FP1398

* 12” (305 mm) from top of grille opening.

** 6” (152 mm) from top of grille opening.

Fig. 22 Combustible mantel clearances.

MA81

Side Wall Protection

Adjacent combustible side walls that are within minimum dimensions shown in Figure 24 of the fireplace

opening must be protected with CFM Corporation Wall

Shield Model SP40 or a specifically built wall shield

described in Figure 19.

The special wall shield design described in Figure 19 is

an alternate method of adding protection to side walls

and can be used in place of the SP40 with the same

wall clearances specified for the SP40. Rt must =1.85

minimum.

Examples of wall shield insulation:

1. Manville - CERAFORM 126, K=.27,

1/2 inches thick

2. EH2416, K = .458,

1 inch thick required.

Hearth Installation

A hearth extension is required to protect a combustible

floor in front of the fireplace. Refer to Figure 25 for minimum dimensions and mounting detail.

NOTE: Hearth Extension must not cover the air

inlet opening of a fireplace.

The hearth extension described in Figure 25 must be a

durable noncombustible material with a minimum (total)

Rt value of 1.09; see Figure 23 for examples. The overall height (above a combustible floor), depth and width

must be as indicated, with the extension centered to the

fireplace opening.

15

Page 16

Vermont Castings EWF30

COMMON MATERIALS AND FACTORS

MATERIAL K*

R

MINIMUM

THICKNESS

EH2416

Common Brick

0.916

5.0

2.18 1.0 in.**

0.10 5.46 in.**

(CFM Corporation)

R Value is for 1/2 inch.

* Units of K = BTU/SQ FT/HR/˚F/IN

** Thickness of Listed Material

The top of insulation must be covered with a non-combustible decorative covering or a piece of .018” minimum sheet metal, to protect hearth extension material.

(Fig. 25)

Secure the hearth extension to the floor to prevent

shifting, using trim molding or other similar means at

three (3) outer edges. Seal crack between the fireplace

hearth and hearth extension with a noncombustible

material. (Figs. 24 and 25)

WARNING: Hearth extension must be installed in

accordance with Figure 24. Top of hearth extension

must be level with bottom of fireplace.

Alternate noncombustible materials may be used

providing the (total) thermal resistance (Rt value) of the

alternate material employed is greater than or equal to

R = 1.09 Thermal resistance (R) or thermal conductivity

(K), may be obtained from manufacturer of the material.

Factors are related by the formula K = 1/R. (Fig. 23)

T = given thickness

R = thermal resistance for a given thickness (T)

K = thermal conductivity

Noncombustible material with a lower R value may

be used, provided thickness of material is sufficiently

greater to maintain an equivalent (total) thermal resis-

tance (Rt).

Example of Determining Hearth Extension

Equivalents

To determine the thickness required for any new material:

Example for Common Brick

NEW K of new material (per inch) thickness

required = X of listed

thickness K of listed material (per inch) material

T (new) = 5.0/0.458 x 0.50 in. = 5.46 in. (new required

thickness).

2 x 4 Header - Do not

Wall Covering

Noncombustible

Decorative

Facing

Seal all cracks

between fireplace surround (steel) and wall

materials with noncombustible material.

Cast Front

Noncombustible

Decorative

Covering

FP1202a

Fig. 24 Sealing gaps.

notch at standoffs

Noncombustible

Material

NOTE: No

material

may cover

black cast

face.

Safety Strips - Must be

overlapped 1/2” minimum

Fig. 23 Hearth extension material factors.

16

FP533ADD

20008662

Page 17

Vermont Castings EWF30

Minimum Wall Clearances

WITH

Noncombustible

Surround Facing

WITHOUT

Noncombustible

Surround Facing

Minimum Hearth Extension Dimensions

(for On-Site Construction)

G

H

G

J

Seal cracks

between the

fireplace

and hearth

extension with

noncombustible

material

"Z" Safety strips

must overlap

" minimum

May install

noncombustible

decorative

covering

OR .018" min.

sheet metal

Fireplace

Opening

Combustible

Floor

9" Required

Firebox

Opening

A - Min. clearance

to combustible

perpendicular wall

B - Min. clearance

to combustible

perpendicular wall when

using noncombustible wall shield*

Side

Wall

Side

Wall

F**

C**

E

E

D

4" Brick

(Example material)

Combustible material permitted within shaded area.

*

Noncombustible wall shield requires 1" EH2416

insulation (minimum R Value = 1.85) between decorative

noncombustible rigid covering and combustible wall.

Minimum height and width is 40" x 40".

**

Dimension/degree of angle will vary depending on thickness

of noncombustible surround facing.

4"

NOTE: No material may

cover black cast face.

Hearth extension must be

flush with bottom of fireplace.

1" Min.

1" Min.

EH2416 or

Equal "R" Value

Shaded area starts

1/2" away from

edge of unit

A B C D E F G H J

EWF30 24” 12” 17° 25° 12” 8” 8” 18” 53”

610 mm 305 mm 305 mm 203 mm 203 mm 457 mm 1346 mm

Fig. 25 Combustible side wall protection and hearth extension dimensions.

20008662

FP1201

17

Page 18

Vermont Castings EWF30

Operation

Attach Handles

The fallaway handle is used to open and close the front

doors. Remove after each use so the handle will not get

hot. Keep in convenient location for each use. (Fig. 26)

Assemble the primary air control and damper handles

by passing the screw through the wood shaft and into

the bright metal hub. Tighten carefully until snug. Do not

overtighten. Wood handle could crack. (Fig. 27)

Steel Handle

Fallaway

Handle

FP1568

Fig. 26 Insert fallaway handle into door handle stub.

Metal Hub

Wood Shaft

Primary Air Control

Damper

FP1570

Fig. 28 EWF30 controls.

The primary air control is located in the upper left

corner of the unit. (Fig. 26) It is the primary source of

air for starting, maintaining, and reviving the fire.

Generally, more air entering the fireplace makes the fire

burn hotter and faster, while less air prolongs the burn.

The air supply is open to the maximum when the control

lever is pushed down, and closed when pulled up. To

vary the burn rate, adjust the control to the desired position in between these extremes; opening the primary air

control makes the unit burn hotter. Closing the control

slows the unit down. You may adjust to any position you

desire.

Screw

FP1569

Fig. 27 Assemble primary air control and damper handles.

(Damper handle shown)

EWF30 Controls

Three controls regulate the performance of the EWF30

fireplace: A primary air control supplies oxygen for the

fire, the damper directs air flow within the fireplace and

a variable-speed fan control, or rheostat, regulates the

warm air flow into the room. (Fig. 28)

Primary Air Control

A single air control regulates the amount of heat the fire

will produce and how long it will burn.

18

The Damper

The damper directs air flow within the fireplace.

The damper is operated by moving the lever located in

the upper right corner of the unit. It has two positions:

Open to start or revive the fire and closed, for normal

operation and to control burn rate. The damper is open

when the lever is pulled out and closed when pushed in.

There are no intermediate settings for the damper.

NOTE: Always open the damper before opening the

doors. Close damper to set burn rate.

20008662

Page 19

Vermont Castings EWF30

The Fan

Heated air from the fireplace is forced into the room by

an internal fan. The control for the fan is in the right

corner of the unit.

“Off” is to the far left. (counterclockwise )

“High” is just to the right of “Off.”

“Low” is to the far right. (clockwise )

Variable adjustment of the fans is possible with any setting between “high” and “low.”

For best results, coordinate fan speed with the setting

of the primary air control. For example, when the air

control lever is set at “low,” also set the fan at “low.”

With the air control set for maximum heat, set the fan at

“high.”

Glass Doors

The EWF30 is intended for use with the doors fully

closed or fully open only when optional spark screen

is installed. (Fig. 29) NOTE: When operated with the

doors open and spark screen in place, the damper

MUST be in the open position.

Correct

KT108b

Fig. 29 Correct door position during operation.

Correct

Optional

Spark

Screen

Burn Only High-Quality Wood

The EWF30 is designed to burn natural wood only; do

not burn fuels other than that for which it was designed.

You will enjoy the best results when burning wood that

has been adequately air-dried. Avoid burning “green”

wood that has not been properly seasoned.

The best hardwood fuels include oak, maple, beech,

ash, and hickory that has been split, stacked, and airdried outside under cover for at least one year.

For areas that do not have a supply of hardwood, commonly burned softwoods include tamarack, yellow pine,

white pine, Eastern red cedar, fir, and redwood. These

too should be properly dried. Your EWF30 will accept

wood up to 23” (584 mm). Longer wood pieces work

better than short ones.

Wood should be stored under cover to maintain dry

ness, and should be dried at least six months for

optimum heating and fire-viewing performance. Even

for short-term storage, however, keep wood a safe

distance from the heater and keep it out of the areas

around the heater used for refueling and ash removal.

-

Use the Air Control Settings

that Work Best for You

No single air control setting will fit every situation. Each

installation will differ depending on the quality of the

fuel, the amount of heat desired, and how long you wish

the fire to burn.

The control setting also depends on your particular

installation’s “draft,” or the force that moves air from

the fireplace up through the chimney. Draft is affected

by such things as the length, type, and location of the

chimney, local geography, nearby obstructions, and

other factors.

Too much draft may cause excessive temperatures

in the fireplace. On the other hand, too little draft can

cause backpuffing into the room and/or the “plugging” of

the chimney or combustor.

How do you know if your draft is excessively high or

low? Symptoms of too much draft include an uncontrollable burn or a glowing-red part of the EWF30 front. A

sign of inadequate draft is smoke leaking into the room

through the fireplace or chimney connector joints, low

heat, and dirty glass.

In some newer homes that are well-insulated and

weather-tight, poor draft may result from insufficient air

in the house. In such instances, an open window near

the fireplace on the windward side of the house will

provide the fresh air needed.

Another option for getting more combustion air to the

fireplace is to duct air directly from the outside to the

fireplace. In fact, in some areas provisions for outside

combustion air are required in all new construction.

Your EWF30 is designed so that it is possible to incor

porate outside air for combustion. Directions for installing the optional AK-MST outside air duct is included

with the kit and beginning on Page 11 of this instruction.

When first using the fireplace, keep track of the settings

of the air controls. You will quickly find that a specific

setting will give you a fixed amount of heat. It may take

a week or two to determine the amount of heat and the

length of burn you should expect from various settings.

Most installations do not require a large amount of

combustion air, especially if adequate draft is available.

Do not for any reason attempt to increase the firing

of your heater by altering the air control adjustment

range outlined in these directions.

-

20008662

19

Page 20

Vermont Castings EWF30

Starting and Maintaining a Wood Fire

Burn solid wood fuel only in the EWF30, and burn it

directly on the grate. Do not elevate the fuel. Do not

burn coal or other fuels.

Minimize thermal stress by allowing the plates to adjust

gradually during an initial break-in fire by following

Steps 1-3 below.

WARNING: Operate your EWF30 only with the

doors fully closed. If the door is left partially open,

gas and flame may be drawn out of the fireplace

opening, creating risks of both fire and smoke.

1. Open the primary air control fully.

2. Open the damper.

3. Lay some crumpled newspapers on the bottom

grate. Place on the paper six or eight pieces of dry,

finely-split kindling. On the kindling lay two or three

larger sticks of split dry wood approximately 1-2”

(25-50 mm).

Do not use chemicals or fluids to start the fire. Do

not burn garbage or flammable fluids such as gasoline, naptha, or engine oil.

Also, never use gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or “freshen up” a fire in this heater. Keep all such liquids well

away from the heater while it is in use.

4. Light the newspaper and close the door. Gradually

build up the fire by adding a few 3-5” (80-120mm)

diameter splits.

If this is your initial break-in fire, let the fire burn brightly,

but not to excess. Control the fire’s intensity by adjust

ing the air control lever. After an hour or so stop adding

wood so that the fire dies out gradually.

For ongoing operation after the initial break-in, continue

to add a few sticks at a time of a progressively larger

size. Continue until you have a live ember bed at least

2-3” (51-76mm) deep. This may take an hour or longer.

CAUTION: THE EWF30 IS HOT WHILE IN OPERATION! KEEP CHILDREN, CLOTHING, AND FURNITURE AWAY. CONTACT MAY CAUSE SKIN BURNS.

NOTE: Some chimneys need to be “primed,” or

warmed up, before they will draw sufficiently to open

the damper. To correct this situation, roll up a couple

pieces of newspaper, place them on top of the kindling

and toward the back of the fireplace, light them, and

close the doors. This should heat the chimney enough

to initiate a draft.

Once the draft is established, open the front door and

light the rest of the fuel from the bottom. Do not light the

main bed of fuel until the chimney begins drawing, and

repeat the procedure as often as necessary if the initial

attempt is unsuccessful.

-

5. Once a good ember bed of at least 2-3” (51-76 mm)

has formed, let the fire burn hot for an additional ten

to fifteen minutes.

6. Close the damper and the primary air control to a

medium-low setting as described on Page 18. The

fire volume will diminish immediately, but the fire

place will continue to heat up. Maintain control of

the fire using the primary air control, and remember:

reduce the setting for less heat, increase the setting for more heat. Refer to the air control settings

information on Page 18 for recommended settings at

different burn rates.

DO NOT OVERFIRE THIS HEATER. Overfiring may

cause a house fire, or can result in permanent damage

to the fireplace. If an exterior part of the EWF30 glows,

you are overfiring.

-

Reloading and Reviving a Wood Fire

• Open the damper and set the air control on “High,”

and wait at least fifteen seconds for the draft to

increase. Open the door slowly.

• Check the ash level, and empty the ash pan if nec-

essary. Replace the pan.

• Add the fuel, smaller pieces first. If it is necessary

to use wood smaller than the 23” (584 mm) optimum size, be sure to fill the firebox as completely as

possible by loading the wood pieces alternately on

the left and right. Split wood will fill the firebox more

completely and reduce the frequency of reloading.

If you have an ember bed of at least 2-3” (51-76 mm),

leave the air control set on “high” for 10-15 minutes. If

the ember bed is less than 2-3” (51-76 mm), you may

have to let it burn longer. Also, depending on the quality

of your wood, the temperature of the firebox and the

draft conditions of your chimney, it may be helpful to

leave the door cracked open for up to 5 minutes. This

will help to ignite freshly loaded wood. NEVER leave

the fireplace unattended unless the door is completely

closed. Overfiring could result from leaving the door

cracked open.

Finally, close the damper and adjust the air control and

fan speed for your desired heat level.

NOTE: If the charcoal bed is relatively thick and your

fuel is well-seasoned, it is possible to add fresh fuel

(smaller pieces first), close the door and damper, and

reset the air control within five minutes.

Special Tactics for Cold-Climate Heating

The EWF30 is capable of producing in excess of

55,000 Btu’s/hour and heating an area of up to 2,400

sq. ft. (223 sq. m) However, many factors affect heating

performance and can influence the extent to which the

EWF30 can heat a given area.

20

20008662

Page 21

Vermont Castings EWF30

A well-insulated home, located in a moderate climate

and with the EWF30 Fireplace located centrally in an

open floor plan, will be easier to heat than a drafty

home in the far north in which the EWF30 is installed on

an exterior wall at the end of a long house.

Different results may be experienced even in the same

installation if you switch from burning good, dry wood to

wood that is partially rotted or inadequately seasoned.

To compensate for these factors in cold climates, it may

be necessary to operate the EWF30 with the air control

set to a higher level more of the time.

Remove and Store Ash Safely

Check the ash pan before reloading the fireplace, and

empty if necessary using the following procedure:

• Open the damper.

• Open the load door.

• Remove the ash pans from under the hearth

brick. CAUTION: Ash may contain hot coals and

must be treated with extreme care. Hold the ash

pan with both hands to avoid dropping or spilling

the ashes.

• Take the pans outdoors and empty the ash into

an ash container.

• Before replacing the ash pan, clear away any ash

that has spilled over the sides and back of the

pan.

• Replace the ash pans and front door.

Empty the ash pans regularly, typically every one to

three days. The frequency will vary depending on how

you operate your EWF30: If you burn more wood at

higher heat output settings, and ash will accumulate

faster.

Ash should be removed frequently and placed outdoors

in a metal container with a tight-fitting lid. The closed

container of ash should be placed on a noncombustible

floor or on the ground, well away from all combustible

materials, pending final disposal. If the ash is disposed

of by burial in soil or otherwise locally dispersed, it

should be retained in the closed container until all cinders have thoroughly cooled. Wood ash may be used

as a garden fertilizer.

CAUTION: Never use your household or shop vacuum

cleaner to remove ash from the fireplace; always remove and dispose of the ash properly.

20008662

21

Page 22

Vermont Castings EWF30

Maintenance

Keep your EWF30 Fireplace Looking New

and Working Its Best

Care of the Cast Iron Surface

An occasional dusting with a dry rag will keep your

EWF30 fireplace looking new.

If the paint needs retouching, first allow the surface

to cool completely. Wire-brush areas needing to be

painted. Touch-up with high temperature fireplace paint

available from your local dealer. Apply the paint sparingly. Two light coats are better than one heavy one.

Pawl

Small Locking Nut

Striker Screw

Large

Locking Nut

Set Screw

Cleaning the Glass

The EWF30 glass system requires a minimum amount

of cleaning. Most carbon deposits that accumulate will

burn off during hot fires.

Ash residue that accumulates on the glass should be

removed periodically to prevent etching. To clean the

glass, follow this procedure:

• Be sure the glass is completely cool.

• Cleaning with water will work in most cases. Use

a glass cleaner especially made for this purpose

only if deposits are especially heavy. (If heavy

deposits are a frequent occurrence, however,

evaluate your operating techniques.)

• Rinse the glass thoroughly.

• Dry the glass completely.

NOTE: The EWF30 glass is coated with a special

material on the outside that helps reflect heat back

into the fire chamber. Do not attempt to remove

this coating.

Adjust the Door Latch Periodically

The front door of the fireplace should close securely to

prevent accidental opening and should close tightly to

prevent air from leaking into the fire chamber. The door

handles will be positioned vertically when the door is

closed.

Over a period of time, the gasket around the door will

compress and the latch may need adjustment. To adjust the handle, follow this procedure (Fig. 30):

1. Loosen the small lock nut with a wrench.

2. Extend the striker screw one turn by turning it with

an Allen wrench.

3. Retighten the lock nut, while at the same time holding the striker screw with the Allen wrench to prevent

its turning.

Test the door seal. Close the door on a dollar bill and

attempt to pull it free. If the bill is freed with little resis-

Handle Stub

Fig. 30 Turn the striker screw to tighten or loosen the door

latch.

tance, the gasket isn’t snug enough at that spot. Continue to make small adjustments until the setting is right.

If additional adjusting of the latch does not enable the

door to seal sufficiently in one area, try “adjusting” the

gasket in that area. Pack more cement or a smaller

diameter gasket into the channel beneath the gasket so

that the main gasket is raised and makes contact with

the door frame. This procedure should solve the problem. If the gasket needs replacing, follow the directions

beginning on Page 23.

ST531

How to Replace Gaskets

The EWF30 uses rope-type fiberglass gaskets to make

a tight seal between some parts. With use, particularly

on those parts that move, gaskets can become brittle

and compressed and can begin to lose their effectiveness. These will need periodic replacement.

All of the gaskets used are made of fiberglass. The four

sizes of replaceable gasket are listed below, along with

their application.

Replaceable Fiberglass Gaskets

Gasket Size... ...And The Parts It Seals

1/2” The door to the front

3/16” The glass seal to the door

1/2” Braided Damper to top plate

Should you need to change a replaceable gasket, wait

until the fire is out and the fireplace has cooled. Be

sure to follow the standard safety procedure for working with dusty materials: Wear safety goggles and a

dust mask. The procedure for replacing gaskets is the

same, regardless of the gasket location. Four easilyaccomplished steps are involved:

22

20008662

Page 23

Vermont Castings EWF30

1. Remove the existing fiberglass gasket by grasping

an end and pulling firmly.

2. Use a wire brush or the tip of a screwdriver to clean

the channel of any remaining cement or bits of gasket.

3. Apply a thin bead of fireplace cement to the newlycleaned groove.

4. Pack a new gasket into the groove. Wait until you

have placed all but a couple inches from the end

before you trim the end to an exact fit.

5. Place door back on fireplace, latch door and keep

closed for 1/2 hour to insure cement has set.

Replacing the Door Gaskets

Remove the door by lifting it straight up off its hinge

pins. Lay it face down on a padded surface.

Follow steps 1-4 as described above.

Replace Damaged Door Glass Immediately

Do not operate the fireplace with damaged glass door.

Use the following procedure for glass replacement.

NOTE: Replace glass only with the replacement glass

made for this unit, available from your authorized

dealer.

• Remove the door and loosen the retaining clips which

hold the glass to the door frame. Remove clips. Use

caution when handling broken glass.

• Examine the gasket that seals the glass to the door

frame. Replace if necessary with gasket obtained from

your local Vermont Castings’ Authorized Dealer. See

the directions for gasket replacement on Page 23.

• Check the flat surface of the door frame, and clear

away debris if necessary.

• Install the new glass.

• Secure the clips, being careful not to overtighten. Be

sure the glass is firmly seated against the gasket.

• Replace door.

The Chimney System

A Clean Chimney System is

Safer and Works Better

Although the combustion system in the EWF30 can reduce creosote formation dramatically, it is not a substitute for regular inspection and cleaning of the chimney

and chimney connector.

Learn to Recognize —

and Avoid — Creosote

The EWF30 has been designed to reduce creosote

build-up significantly. However, regular chimney inspection and maintenance must still be performed. For

safety, good fireplace performance, and to protect your

chimney and chimney connector, inspect your chimney

and chimney connector on a regular schedule. Clean

the system if necessary. Failure to keep the chimney

and connector system clean can result in a serious

chimney fire.

When wood is burned slowly, it produces tar, organic

vapors and moisture which combine to form creosote.

The creosote vapors condense in the relatively cool

chimney flue of a slow-burning fire. As a result, creosote residue accumulates on the flue lining. When ignited, this creosote makes an extremely hot fire within the

flue system that can damage the chimney and overheat

adjacent combustible material. If a significant layer of

creosote has accumulated —1/8” (3mm) or more — it

should be removed to reduce the risk of a chimney fire.

If you do experience a chimney fire, act promptly to:

• Close the primary air control lever and the

damper

• Get everyone out of the house.

• Call the Fire Department.

You should inspect the system every two weeks during

the heating season as part of a regular maintenance

schedule. To inspect the chimney, let the fireplace cool

completely. Remove the termination top. Then, using a

strong light, sight down into the chimney flue.

Clean the chimney using a specially designed brush

the same size and shape as the flue liner. Flexible

fiberglass rods are used to run the brush up and down

the liner, causing any deposits to fall to the bottom of

the chimney where they can be removed through the

damper on top of the fireplace.

If you can not do the chimney inspection yourself, contact your local Vermont Castings’ Authorized Dealer, or

engage a professional chimney sweep to perform the

inspection and cleaning of the chimney.

20008662

23

Page 24

Vermont Castings EWF30

The prefabricated chimney used with your fireplace

should be cleaned from above using an 8” round brush

and the appropriate number of extension rods for complete access.

The chimney cap first must be removed following the

procedure recommended by the manufacturer. After

thoroughly cleaning the chimney, reinstall the chimney

cap according to the manufacturer’s directions.

Maintenance Schedule

Fireplace:

Daily:

• Ash should be removed before the level reaches the

top of the pan. Check each time you re-load, or at

least once a day.

• Keep the area around the fireplace clear of any combustible material.

Yearly Spring Cleaning:

• Remove ash from the fire box and replace with a

moisture-absorbing material (such as Kitty Litter) to

keep the interior of the fireplace dry.

• Touch up painted surfaces with black paint.

24

20008662

Page 25

Vermont Castings EWF30

Chimney Components

Component Description Model Number

U.S.

Round Top Termination Top used to terminate chimney at roof.

(Flashing not included.) RLTSK8

Round Top Termination - Top used to terminate chimney at chase.

Extended (Flashing not included.) RLTSK8L

Flashing Metal finishing required around Contemporary 8-6-12 with 8" flue:

Termination to prevent rain leakage. 0-6/12 pitch

8-12-12 with 8" flue:

6/12-12/12 pitch

Square Termination - Top housing of simulated brick pattern S20B (R,T,W)

Housing available in red, tan or white. Appropriate Must include

adapter required. Flashing included. PLTSK8 or SLTSK8

Adapter Kit Unites Square Termination with chimney CF8CA

pipe (required).

Housing Extensions Extends Square Termination on steep 202036

pitched roofs.

Square Chase Termination Housing used to terminate chimney through CT100

a chase top. Appropriate adapter required.

(Flashing not included.)

Adapter Kit Unites Square Chase Termination with chimney CTSK

pipe (required).

Chase Top Housing Low profile pyramid-style chimney cap used to PTLSK8

terminate chimney through a chase. Includes

adapter. (Flashing not included.)

Chase Top Housing Square chimney cap used to terminate chimney SLTSK8

through a chase. Terra Cotta Masonry. Includes

adapter. (Flashing not included.)

SK8 Chimney Sections Pipe used to build 8" (SK8) flue systems. SK81 (1' Long)

SK818 (1

SK83 (3' Long)

SK84 (4' Long)

SK8 Chimney Elbows Elbow used to create an offset in an 8" SK830-2

chimney system. Only 30˚ elbows available.

Packaged 2 per carton (offset and return).

Firestop Required at each floor level of chimney SKFS2A —

installation. (Plus attic on multi-story installation.) (8" straight flue)

SKFS6A —

(8" 30˚ inclined flue)

Chimney Support Used to support chimney for each of: 30' vertical SKCS8

height and 6' of angled chimney run.

Canada

Chimney Collar Enclosure Installs on the "over the chimney collar" of the CCE-SK

fireplace; provides outside air to assist in cooling

the chimney system.

Attic Insulation Shield Used to prevent insulation from coming in AIS-SK

contact with the chimney system.

SK8 Chimney Sections Used to build chimney systems exposed above SK818CAN (1

roof. SK84CAN (4' Long)

45˚ Chimney Elbows Provides 45˚ offset and return. For Canadian SK845/2

installations only. For use with SK8 chimney only.

(Maximum use of 2, or 1 pair.)

¹⁄₂' Long)

¹⁄₂’ Long)

20008662

25

Page 26

Vermont Castings EWF30

4

51

30, 31

18

23

34

35

36

40

41,42,43

37

38

44,45,46

47

39

27

26

25

50

50

15

7

6

17

8

10

9

14

13

49

21

16

3

2

1

11,12,

32,33

28

20

19

20

19

8

17

5

24

22

52

CFM Specialty Home Products reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products

at any time, without notice.

EWF30 Fireplace

For unit FA3ECB

Ref. Description EWF30

1. Deflector Cabinet Top 54518

2. Louvre Assy Bottom 10000038

3. Louvre Assy Top 10000037

4. Damper, Air Wash Assy 20008641

5. Ashpan 30002240

6. Brick Ash Lip 20008714

7. Andirons 20006298

8. Firebrick Insulation 20008736

9. Glass 20008684

10. Gasket, 1/4” 3ND Black 1203560

11. Front Handle w/Shaft 1/8” Nickel Horizontal 5004245

12. Pawl Assembly, Ash Door 5004025

13. Glass Clip 8.5 30001716

14. Glass Clip 30001715

15. Damper Rod Ext. 20008658

26

20008662

Page 27

Vermont Castings EWF30

EWF30 Fireplace (continued)

Ref. Description EWF30

16. Grate, Flat/Wood 30002087

17. Firebrick, Split 1601103

18. Bracket, Actuator 20008827

19. Brick Retainer 20008904

20. Brick Retainer 20008725

21. Door Gasket 1/2” Dia. Low-D Black 20009127

22. Fountain Sealing Gasket 20009209

23. Fountain Assembly 30002100

24. Shoe Gasket 20009088

25. Refractory, Shoe CDWL 30002243

26. Refractory, Lower Fireback-CDWL 30002244

27. Refractory, Top Fireback-CDWL 30002251

28. Fountain Rear Gasket 20009211

29. Therm Stub w/Ser Scr Assy-NI 5004264

30. Rd Hd Sl 8-32x2-Z Screw 1201243

31. Knob, Therm Handle-Maple Wood-Blk 1600660