Page 1

Rear V ented

Direct V ent Models

DVRS3

DVRSL

DVRSR

Installation Instructions & Homeowner's Manual

WARNING! IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electric switch

* Do not use any phone in your building.

* Immediately call your gas supplier from

your neighbours phone. Follow the gas

suppliers instructions.

* If you cannot reach your gas supplier call the

fire department.

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

The Vermont Castings

Majestic Products Company

410 Admiral Blvd., Mississauga

Ontario, Canada L5T 2N1

www.majesticproducts.com / www.vermontcastings.com

INSTALLER: DO NOT DISCARD THIS MANUAL - LEAVE FOR HOMEOWNER

- 1 -

FOR YOUR SAFETY

DO NOT STORE

OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

* Installation and service must be performed

by a qualified installer, service agency or

your gas supplier.

10001293

11/01 Rev. 1

Page 2

TABLE OF CONTENTS

Please read the Installation & Operating Instructions before using this appliance.

Thank you and congratulations on your purchase of a Majestic fireplace.

IMPORTANT: Read all instructions and warnings carefully before starting installation. Failure to follow these instructions

may result in a possible fire hazard and will void the warranty.

Installation Instructions 3

General Information ...................................................................................................... 3

Important Curing/Burn Information ............................................................................... 3

Locating your Fireplace ................................................................................................ 3

Fireplace Dimensions ................................................................................................... 4

Mantels & Mantel Chart ................................................................................................ 4

Clearance to Combustibles........................................................................................... 5

Framing & Finishing...................................................................................................... 5

Final Finishing............................................................................................................... 5

Hearth ................................................................................................................. 5

Gas Specifications ........................................................................................................ 5

Gas Line Installation ..................................................................................................... 6

Remote Switch Installation ........................................................................................... 6

General Venting Information 7

Termination Clearances................................................................................................ 8

ASSEMBLING VENT PIPES WITH CRIMPED ENDS................................................. 9

Rear Venting Applications ..................................................................................... 9

Rear Wall Installation............................................................................................. 9

Vertical Sidewall Applications .............................................................................. 10

How to Use The Vent Graph................................................................................ 12

Sidwall Venting Graph ......................................................................................... 12

Vertical Sidewall Installation ................................................................................ 12

Below Grade Installations .................................................................................... 14

Vertical Through the Roof Applications ............................................................... 15

Vertical Through the Roof Installations................................................................ 16

DVR Series Crimped End Venting Components ................................................. 17

ASSEMBLING TWIST LOCK VENT PIPES .............................................................. 18

Rear Venting Applications................................................................................... 18

Rear Wall Installation........................................................................................... 19

Vertical Sidewall Applications .............................................................................. 20

How to Use The Vent Graph................................................................................ 21

Sidwall Venting Graph ......................................................................................... 21

Vertical Sidewall Installation ................................................................................ 22

Below Grade Installation...................................................................................... 23

Vertical Through the Roof Applications............................................................... 25

Vertical Through the Roof Installation................................................................. 25

DVR Series Twist Lock Venting Components..................................................... 26

Operating Instructions 27

General Glass Information.......................................................................................... 27

Louvre Removal.......................................................................................................... 27

Side Glass Removal ................................................................................................... 27

Front Glass Removal .................................................................................................. 27

Glass Cleaning ........................................................................................................... 28

Ceramic Refractory Installation................................................................................... 28

Installation of Logs...................................................................................................... 29

Lava Rock ............................................................................................................... 29

Ember Material Placement ......................................................................................... 29

Lighting & Operating Instructions (820 Millivolt Gas Valve)........................................ 30

Trouble Shooting (820 Millivolt Gas Valve)................................................................. 31

Flame Adjustment....................................................................................................... 32

Flame Characteristics ................................................................................................. 32

Inspecting the Venting System ................................................................................... 32

Maintenance ............................................................................................................... 32

Cleaning The Standing Pilot Control System.............................................................. 32

Replacement Parts Pictorial 33

Replacement Parts List............................................................................................... 34

Options 35

Fan Kit - FK24............................................................................................................. 35

Remote Control........................................................................................................... 35

- 2 -

Page 3

INSTALLATION AND OPERATING

INSTRUCTIONS

This gas appliance should be installed by a qualified installer in

accordance with local building codes and with current CAN /CGAB149 (. 1 or .2) Installation codes for Gas Burning Appliances and

Equipment. or for U.S.A Installations follow local codes and/or the

current National Fuel Gas Code. ANSI Z223.1.

FOR SAFE INSTALLATION AND OPERATION OF YOUR

MAJESTIC DIRECT VENT FIREPLACE PLEASE NOTE

THE FOLLOWING:

1 . This fireplace gives off high temperatures and should

be located out of high traffic areas and away from

furniture and draperies.

2. Children and adults should be alerted to the hazards of

the high surface temperatures of this fireplace and

should stay away to avoid burns or ignition of clothing.

IMPORTANT:

PLEASE REVIEW THE FOLLOWING

CAREFULLY

It is normal for fireplaces fabricated of steel to give

off some expansion and/or contraction noises

during the start up or cool down cycle. Similar

noises are found with your furnace heat exchanger

or car engine.

It is not unusual for your

give off some odour the first time it is burned. This

is due to the curing of the paint and any undetected

oil from the manufacturing process.

Majestic

gas fireplace to

Please ensure that your room is well

ventilated - open all windows.

3. CAUTION: Due to high glass surface temperature

children should be carefully supervised when they

are in same room as your fireplace.

4. Under no circumstances should this fireplace be modified. Parts having to be removed for servicing should

be replaced prior to operating this fireplace again.

5. Installation and any repairs to this fireplace should be

carried out by a qualified service person. A professional service person should be contacted to inspect

this fireplace annually. Make it a practice to have all

of your gas fireplaces checked annually. More

frequent cleaning may be required due to excess

lint and dust from carpeting, bedding material, etc.

6. Control compartments, burners and air passages in this

fireplace should be kept clean and free of dust and lint.

Make sure that the gas valve and pilot light are turned

off before you attempt to clean this fireplace.

7. The venting system (chimney) of this fireplace should

be checked at least once a year and if needed your

venting system should be cleaned.

8. Keep the area around your fireplace clear of combustible materials, gasoline and other flammable vapour

and liquids. This fireplace should not be used as a

drying rack for clothing, nor should Christmas stockings or decorations be hung in the area of it.

9. Under no circumstances should any solid fuels (wood,

coal, paper or cardboard etc.) be used in this fireplace.

10.The flow of combustion and ventilation air must not be

obstructed in any way.

11.Whether the fireplace is installed directly on carpeting,

vinyl tile or any combustible material other than wood,

this fireplace must be installed on a metal or wood

panel extending the full width and depth of the fireplace.

12.This fireplace requires adequate ventilation and

combustion air to operate properly.

LOCATING YOUR

INSTA-FLAME

It is recommended that you burn your

fireplace for a least six (6) hours the first time you

use it. If optional fan kit has been installed, place

fan in the "OFF" position during this time.

LOCATING YOUR

MAJESTIC

Majestic

GAS FIREPLACE

GAS FIREPLACE

A) Wall Installation

B) Island Installation (through the wall or vertical)

Note (Fig. 1):

** Island (B) installation is possible as long as the horizontal

portion of the vent system (X) does not exceed 20 feet

(6100mm). See details in Venting Section.

The minimum clearance between all glass sides and any

parallel walls is 3 feet (914mm). A minimum clearance of 3"

(76mm) must be maintained from any wall adjacent to one

of the glass sides (Fig. 1).

Fig. 1

- 3 -

Page 4

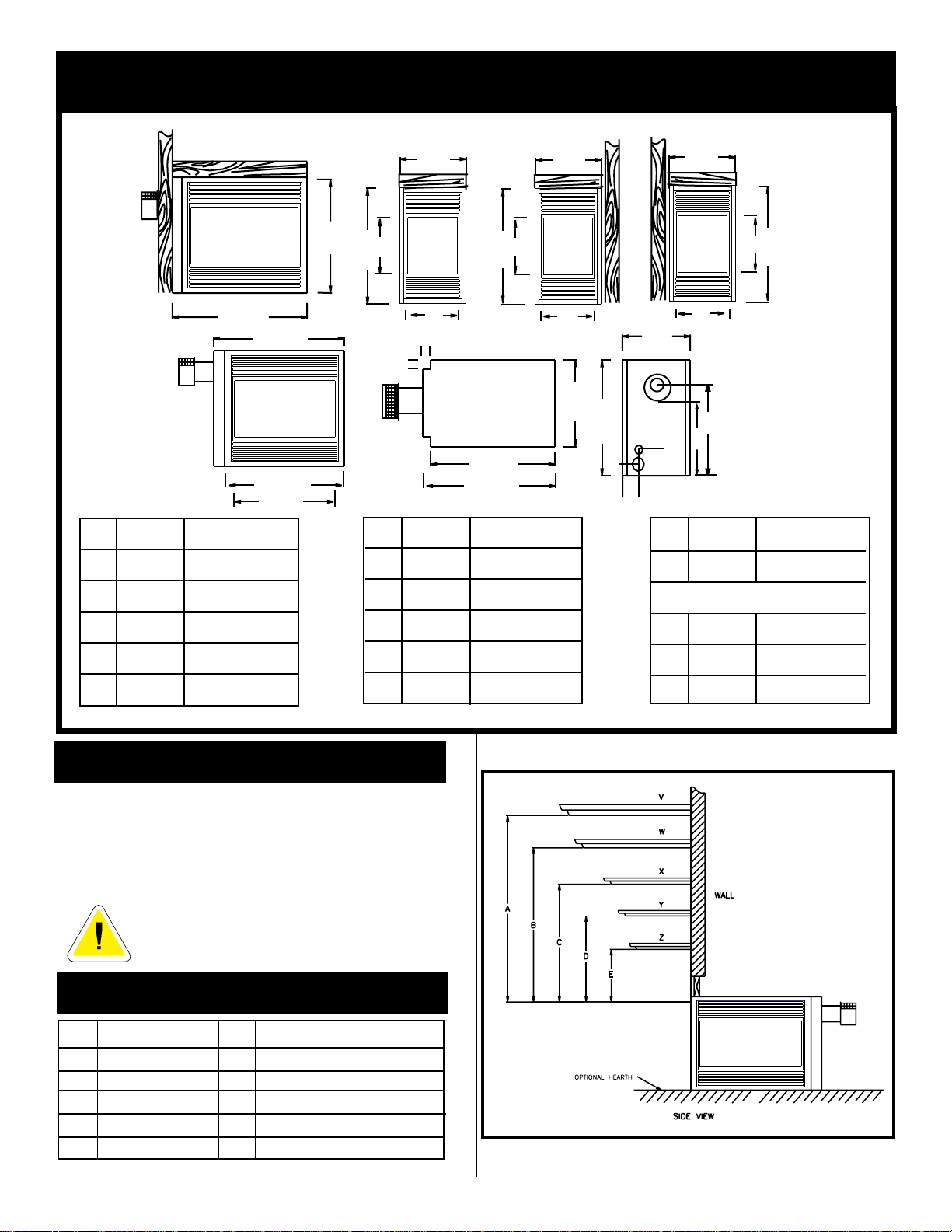

FIREPLACE DIMENSIONS

P

A 38

B 34

C 34

1/2"

1/4"

3/4"

978mm

870mm

882mm

D 21" 533mm

E 33" 838mm

F 17

1/4"

438mm

DVRS3

O

Q

A

C

E

D

B

F

M

N

C

A

G 22" 559mm

H 24

1/2"

622mm

I 29" 737mm

J2

1/2"

63mm

K 4" 102mm

L3

1/4"

83mm

DVRSR DVRSL

O

D

B

F

G

B

J

L

O

BD

F

G

I

H

K

M3

3/4"

95mm

N 2" 50mm

FRAMING & FINISHING

O 22" 559mm

P 38

Q 34

3/4"

1/2"

984mm

876mm

MANTELS

Depending on the width of the mantel it may be installed

higher or lower from the top of the louvre opening. See

drawing and chart below for proper installation height of

your combustible mantel piece. Non-combustible mantels

may be installed at any height above the appliance opening.

When using paint or lacquer to finish the

mantel, such paint or lacquer must be

heat resistant to prevent discolouration.

MANTEL CHART

Ref. Mantel Width Ref. Height from Top Louvre

V 10" (254 mm) A 12" (305 mm)

W 8" (203 mm) B 10" (254 mm)

X 6" (152 mm) C 8" (203 mm)

Y 4" (101 mm) D 6" (152 mm)

Z 2" ( 51 mm) E 4" (101 mm)

Fig. 2

- 4 -

Page 5

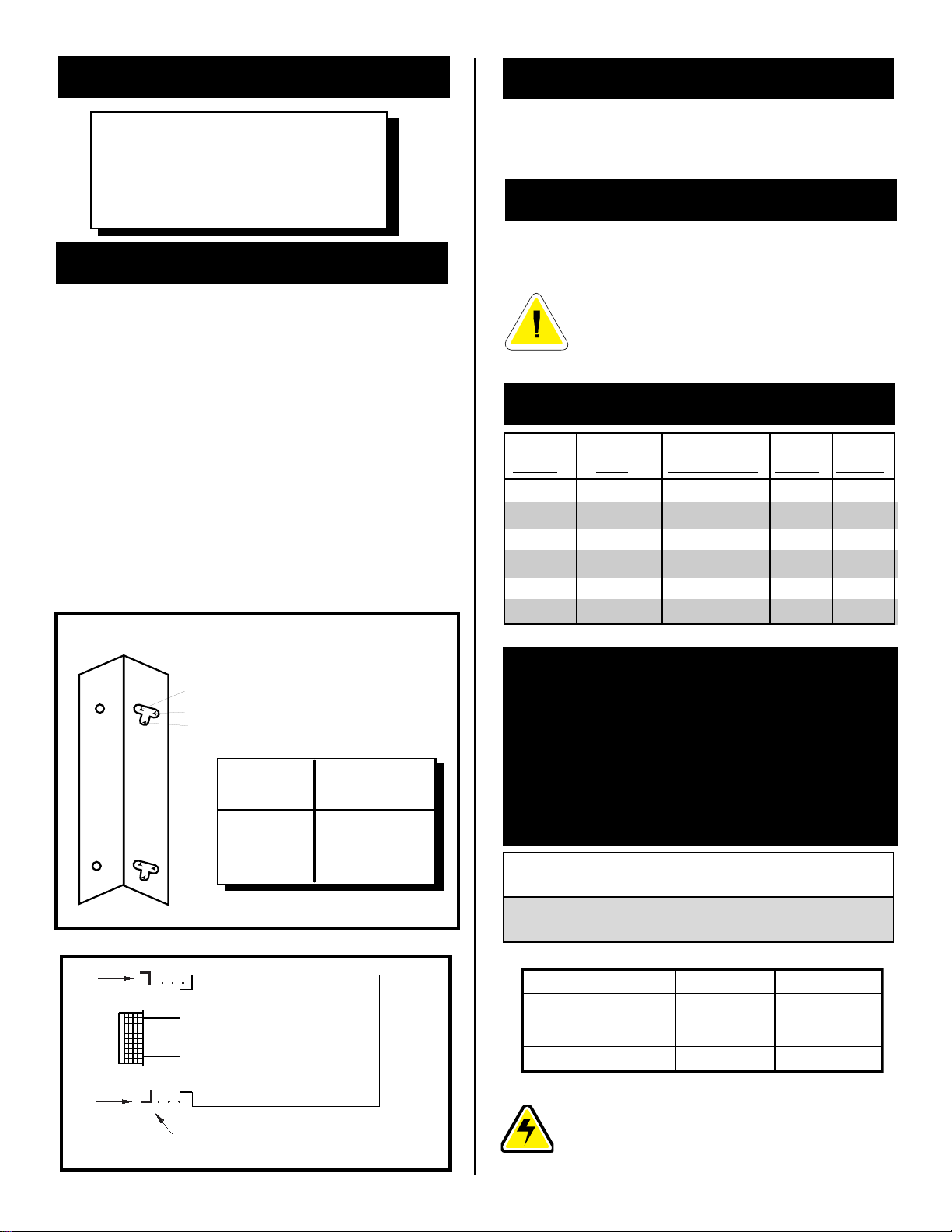

CLEARANCE TO COMBUSTIBLES

GAS INLET & MANIFOLD PRESSURES

Input Minimum

Input Maximum

Manifold Pressure

NATURAL

LP (Propane)

11" wc

13" wc

10" wc

4.5" wc

7" wc

3.5" wc

FINAL FINISHING

Rear ........ 0 mm/0 inches

Floor........ 0 mm/0 inches

Top.......... 0 mm/0 inches

Front & Side Glass 36" (914mm) to

parallel wall

Side Glass to adjacent wall 3" (76mm)

FRAMING AND FINISHING

1. Choose fireplace location.

2. Place fireplace into position and secure to floor with

1-1/2" screws, or nails. The holes to secure the

fireplace to the floor are located just behind the

access door grill on the left and right hand side of the

fireplace.

3. Frame in fireplace with a header across the top. It is

important to allow for finished face when setting the

depth of the frame.

4. Attach fireplace to frame using adjustable frame

drywall strips(located behind access door for

shipping). Preset depth to suit facing material

(adjustable to 1/2" , 5/8" or 3/4" depths). Fig. 3.

5. Screw through slotted holes in drywall strip and

then screw into pre-drilled holes on fireplace side.

Measure from face of fireplace to face of drywall

strip to determine final depth. (Fig. 3 & 4)

Non-combustible materials such as brick and tile can be

extended over the outer face of the unit

louvres or glass door)

.

(Do not cover

HEARTH

A hearth is not mandatory but it is recommended for

aesthetic purposes. We recommend a non-combustible

hearth which does not obstruct louvre opening.

Cold climate installation recommendation:

When installing this unit against a noninsulated exterior wall or chase, it is

mandatory that the outer walls be insulated

to conform to applicable insulation codes.

GAS SPECIFICATIONS

MAX. MIN.

MODEL FUEL GAS CONTROL B.T.U.H B.T.U.H.

DVRS3RN Natural Gas Millivolt Hi/Lo 34,000 23,800

DVRS3RP Propane Gas Millivolt Hi/Lo 34,000 25,500

DVRSL RN Natural Gas Millivolt Hi/Lo 34,000 23,800

DVRSL RP Propane Gas Millivolt Hi/Lo 34,000 25,500

DVRSR RN Natural Gas Millivolt Hi/Lo 34,000 23,800

DVRSR RP Propane Gas Millivolt Hi/Lo 34,000 25,500

INPUT INPUT

ADJUSTABLE DRYWALL STRIP

C

A

(NAILING FLANGE)

B

SCREW

POSITION

A

B

C

1/2" / 13mm

5/8" / 16mm

3/4" / 19mm

ADJUSTABLE DRYWALL STRIP, NAILING FLANGE

1/2", 5/8" AND 3/4" SPACING

DRYWALL

DEPTHS

Fig. 3

Fig. 4

The installation of your Majestic Fireplace

must conform with local codes, or in the

absence of local codes, with National Fuel

Gas Code, ANSI Z223.1 — latest edition, or

CAN 1 B1-149.1 and .2 Installation Code.

(EXCEPTION: Do not derate this appliance

for altitude. Maintain the manifold pressure

at 3.5 inches W.C. for Natural Gas and 10

inches W.C. for LP gas.)

DVRS3 / DVRSL / DVRSR

CERTIFIED TO

ANSI Z21.88-1998 / CSA 2.33 - M98

Vented Gas Fireplace Heaters

Do not use this fireplace if any part of it has

been under water. Immediately call a qualified

service technician to inspect the fireplace and

replace any part of the control which has been

under water.

- 5 -

Page 6

This appliance may be installed in an aftermarket

permanently located, manufactured (mobile) home,

where not prohibited by local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless an available certified kit is used.

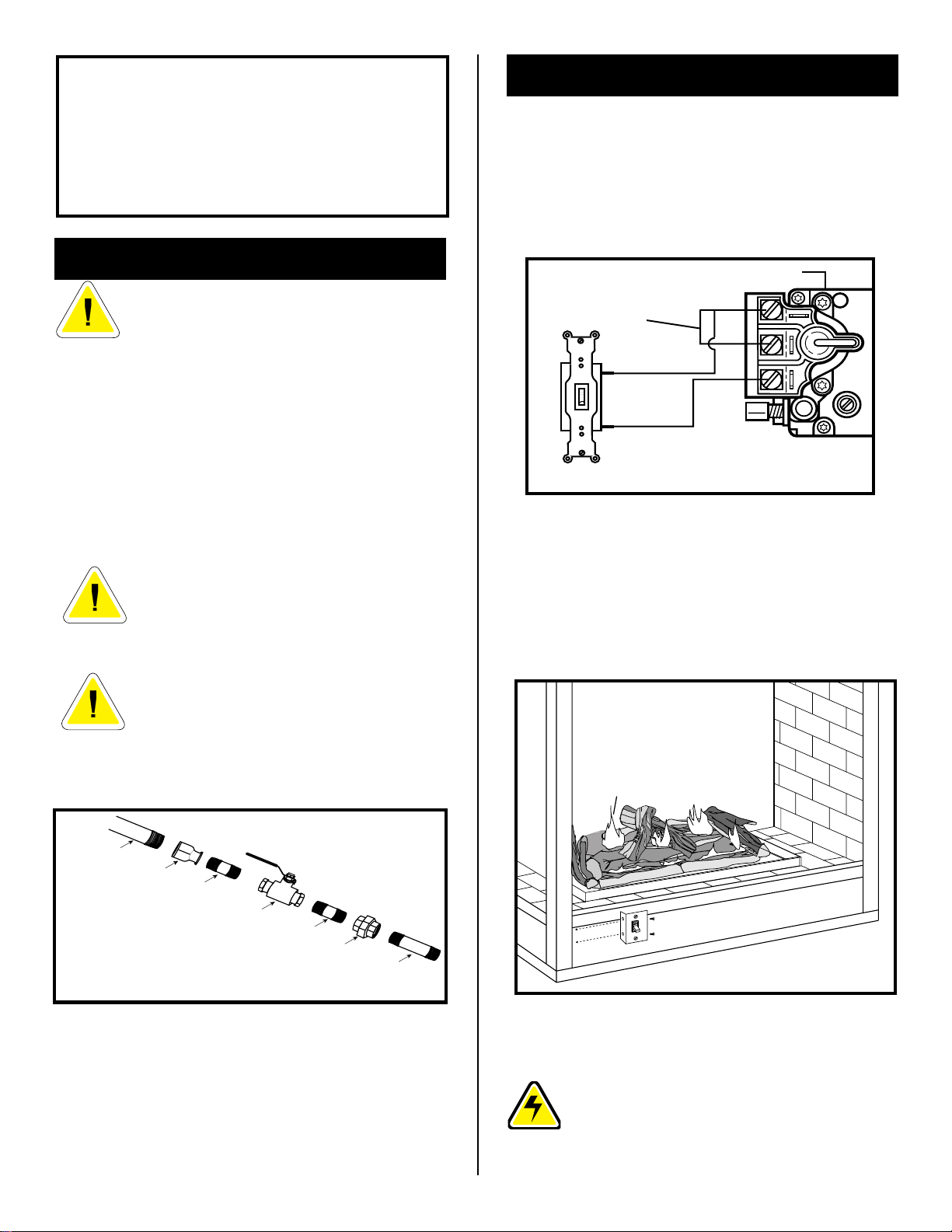

GAS LINE INSTALLATION

When purging gas line one of the glass

sides must be removed.

The gas pipeline can be brought in through the rear right

side (see Fireplace Specifications) of the appliance as well

as the bottom. Knockouts are provided at convenient

locations to allow for the gas pipe installation and testing of

any gas connection. It is most convenient to bring the

gas line in from the rear right side, as this allows fan

installation or removal without disconnecting the gas

line.

The gas line connection can be made with

properly tinned 3/8" copper tubing, 3/8"

rigid pipe or an approved flex connector.

Since some municipalities have some

additional local codes, it is always best to

consult your local authority and the CAN/

CGA-B149 (1. or .2) Installation code or for

U.S.A Installations consult the current

National Fuel Gas Code, ANSI Z223.1

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

REMOTE SWITCH INSTALLATION

1. Thread wire through the electrical knockout located on

rear of fireplace. Do not cut wire or insulation on metal

edges. Ensure that wire is protected. Run the other

end to a conveniently located wall receptacle box.

2. Attach wire to switch and install switch into receptacle

box. Attach cover plate to switch.

3. Connect wiring to gas valve. (Fig. 6)

VALVE

TPTH

THERMOPILE

TP

TH

P

I

L

T

O

ON/OFF SWITCH OR

MILLIVOLT THERMOSTAT

ALTERNATE SWITCH LOCATION:

Remote switch can be installed on the front side of the

access door. Simply mount the switch to the switch bracket

provided. Screw the bracket on either side of the frame,

lining up the screws with the pre-punched holes. (Fig. 7)

Fig.6

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to provide

a 1/8" test point up stream of the control.

1/2" GAS SUPPLY

1/2" X 3/8" REDUCER

Typical gas supply installation

3/8" NIPPLE

3/8" X 3/8" SHUT OFF VALVE

3/8" NIPPLE

3/8" UNION

3/8" NIPPLE

Fig..5

When using copper or flex connector use only approved

fittings. When using black iron pipe always provide a

union so that gas line can be easily disconnected for

burner or fan servicing. See Fig. 5. See gas specification

for pressure details and ratings.

The fireplace valve must not be subjected to any test

pressures exceeding 1/2 psi. Isolate or disconnect this or

any other gas appliance control from the gas line when

pressure testing.

Fig. 7

DO NOT WIRE MILLIVOLT REMOTE WALL

SWITCH FOR GAS FIREPLACE TO A 120V

POWER SUPPLY.

FOR LIGHTING INSTRUCTIONS PLEASE

TURN TO PAGE 30.

- 6 -

Page 7

GENERAL VENTING

Your fireplace is approved to be vented either through

the side wall, or vertical through the roof.

- Only Majestic venting components specifically

approved and labelled for this fireplace may be

used.

- Minimum clearances between vent pipes and

combustible materials is one (1") inch (25 mm),

except where stated otherwise.

- Venting terminals shall not be recessed into a wall

or siding.

- Horizontal venting must be installed on a level

plane without an inclining or declining slope.

There must not be any obstruction such as bushes, garden

sheds, fences, decks or utility buildings within 24" from the

front of the termination hood.

Do not locate termination hood where excessive snow or

ice build up may occur. Be sure to check vent termination

area after snow falls, and clear to prevent accidental

blockage of venting system. When using snow blowers,

make sure snow is not directed towards vent termination

area.

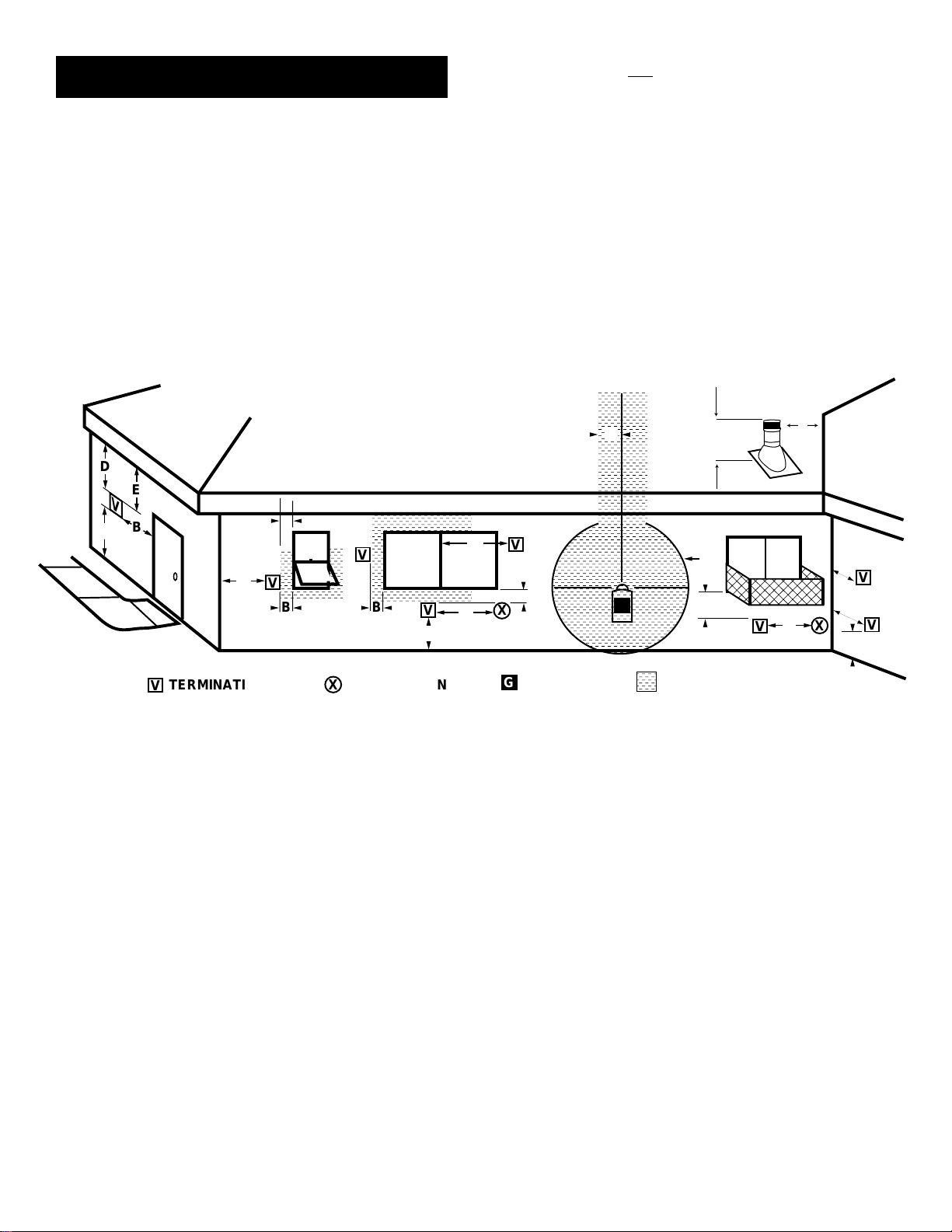

Location of Vent Termination

It is imperative that the vent termination be located observing the minimum clearances as shown on this page.

*Check with local codes or in absence of same with CAN/CGA

B149 (.1 or .2) Installation Codes (1991) for Canada or for U.S.A.

Installations follow the current National Fuel Gas Code, ANSI

Z223.1.

D

E

V

B

L

TERMINATION CAP AIR SUPPLY INLET GAS METER RESTRICTED AREA

V

C

Fixed

Fixed

Closed

Closed

Openable

F

V

B

V

Openable

B

X

V

A

A = clearance above grade, veranda, porch, deck, or

balcony [* 12 inches (305mm) minimum]

B = clearance to window or door that may be opened

C = clearance to permanently closed window [minimum

12 inches (305mm) recommended to prevent con-

densation on window]

D = vertical clearance to ventilated soffit located above

the termina/ within a horizontal distance of 24 inches

(610mm) from the centre-line of the terminal [18

inches (458mm) minimum]

E = clearance to unventilated soffit [12 inches (305mm)

minimum

F = clearance to outside comer see next page

G = clearance to inside comer see next page

H = * not to be installed above a meter/regulator assem-

bly within 36 inches (914mm) horizontally from the

centre-line of the regulator

Fixed

Closed

J

H

B

V

B

X

G

G

(TERMINATION PROHIBITED)

N

I

M

N

K

V

I = clearance to service regulator vent outlet [*72 inches

(1828mm) minimum]

J = clearance to non-mechanical air supply inlet to

building or the combustion air inlet to any other

fireplace [ *12 inches (305mm) minimum]

K = clearance to a mechanical air supply inlet [* 72 inches

(1828mm) minimum]

L = † clearance above paved side-walk or a paved

driveway located on public property [*84 inches

(2133mm) minimum]

M = clearance under veranda, porch, deck [*12 inches

(305mm) minimum ‡]

N = Clearance above a roof shall extend a minimum of

24" (610mm) above the highest point when it passes

through the roof surface, and any other obstruciton

within a horizontal distance of 18" (450mm).

G

V

G

X

V

A

† a vent shall not terminate directly above a side-walk or paved driveway which is located between two single family

dwellings and serves both dwellings *

‡ only permitted if veranda, porch, deck is fully open on a minimum 2 sides beneath the floor *

* as specified in CAN/CGA B149 (.1 or .2) Installation Codes (1991) for Canada or for U.S.A. Installations follow the

current National Fuel Gas Code, ANSI Z223.1.

Note: Local codes or regulations may require different clearances.

- 7 -

Page 8

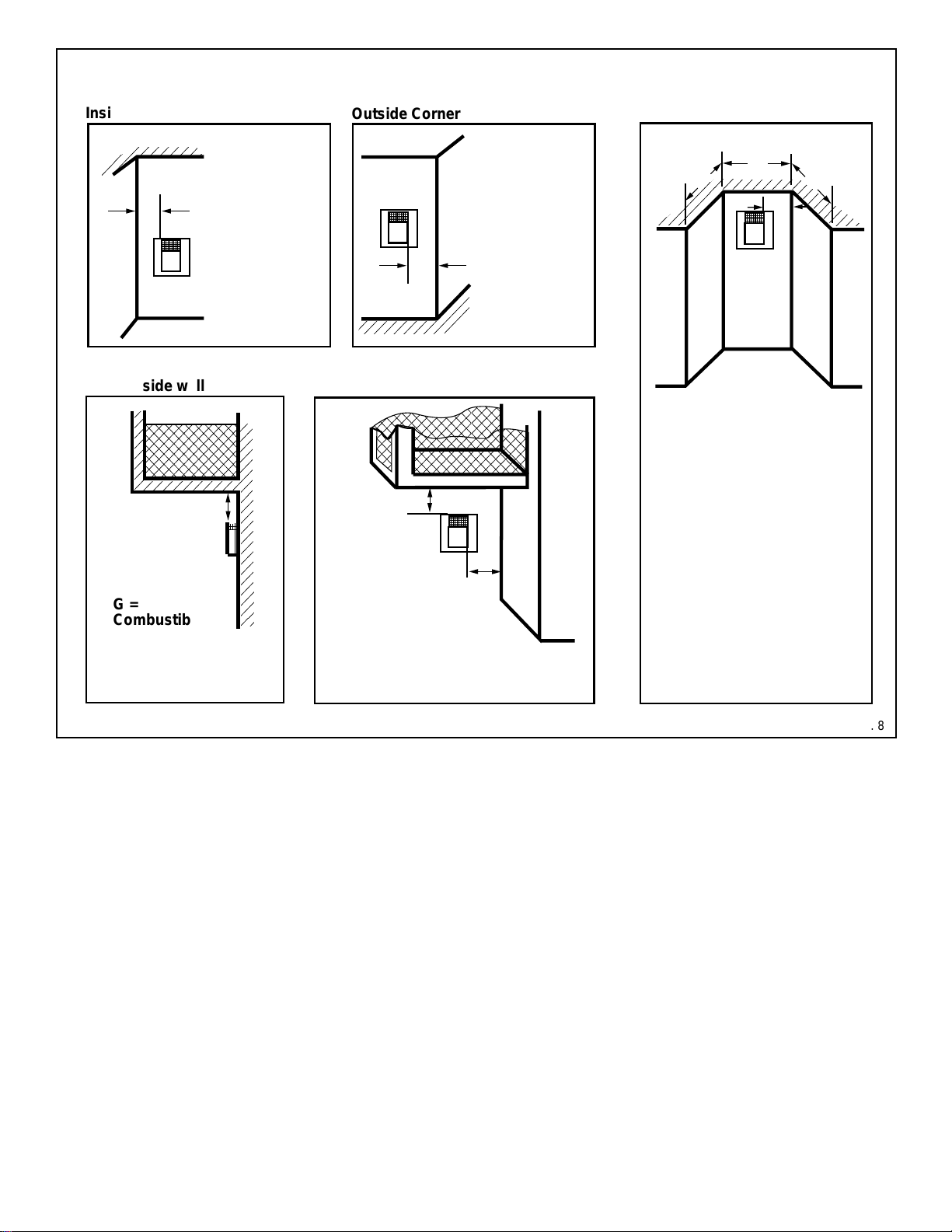

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

Inside Corner

A

V

Balcony with no side wall

G =

Combustible

24"(610mm)

Non-Combustible

18"(457mm)

A =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

G

V

Outside Corner

B =

Combustible

6"(152mm)

V

Noncombustible

2"(50mm)

B

Balcony with perpendicular side wall

H

V

J

Combustible &

Non-Combustible

H = 24"(610mm)

J = 20"(508mm)

Recessed Location

D

C

C

E

V

C = Maximum depth of 48"

(1219mm) for recessed

location.

D = Minimum width for back wall

of a recessed location.

Combustible 38"(965mm)

Noncombustible 24"(610mm)

E = Clearance from corner in

recessed location.

Combustible 6"(152mm)

Noncombustible 2"(50mm)

Fig. 8

- 8 -

Page 9

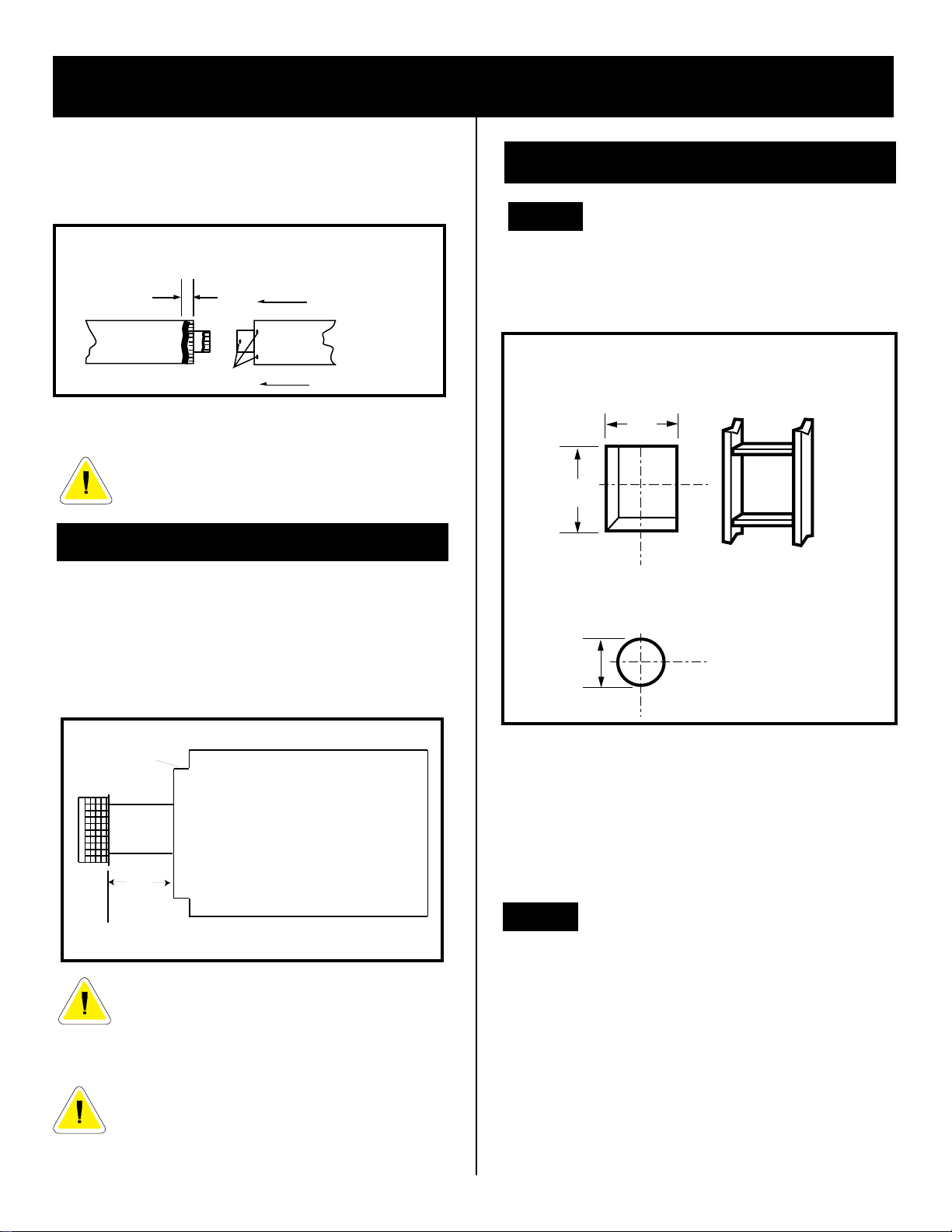

GENERAL INFORMATION ON ASSEMBLING

THE VENT PIPES WITH CRIMPED ENDS

Before joining elbows and pipes apply a bead of high

temperature sealant to crimped end of 4" and 7" elbow or

pipe. (Fig. 9)

Join pipes and secure joints with three (3) sheetmetal

screws. (See Fig. 9) Wipe off excess sealant.

BEAD LOCATION

1" FROM CRIMPED END OF PIPE

1''

REAR WALL INSTALLATIONS

STEP 1

Locate vent opening on wall. To locate hole centre consult

with appropriate fireplace specifications, page 4. Frame as

shown below.

Straight Out Thru the Wall Application

Screw Holes

Fig. 9

*IMPORTANT* Minimum clearance between vent pipes

and combustible materials is one (1") inch (25 mm) on

bottom, sides and top.

Only Majestic venting components

specifically approved and labelled for

this fireplace may be used.

REAR VENTING APPLICATIONS

Note: It is not necessary to seal the vent pipe joints

for any straight out the wall rear vent applications.

Note:

Maximum Vent Length .......................... 20" (508mm)- Fig. 10

Vent Starter Kit Model 7DVRVT must be

used in straight out the wall rear vent applications.

REAR OF

UNIT

Vent Opening —

Combustible Wall

(240mm)

3/8

"

9-

3/8

"

10(255mm)

(framing detail)

Vent Opening —

Noncombustible Wall

1/2

"

7(190mm)

Fig. 11

Combustible Walls. Cut a 10-3/8"H x 9-3/8"W (265mm

x 240mm) hole through the exterior wall and frame as

shown. Fig. 11.

20"

(508mm)

Fig. 10

Minimum clearance between vent pipes

and combustible materials is one (1")

inch (25 mm) on sides and bottom and

two (2") inch (50 mm) on top.

When vent termination exits through

foundation less than 20" (508mm) below

siding outcrop, the vent pipe must flush

up with the siding. A 7DVSS must also

be used.

Non-Combustible Walls: Hole opening must be 7.5"

(190mm) in diameter. To locate hole centre consult with

appropriate fireplace specifications, page 4.

STEP 2

Measure wall thickness and cut adjustable zero clearance

sleeve parts to proper length (MAXIMUM 12"/305mm).

Adjust sleeve to maximum (10-3/8 x 9-3/8). and attach to

firestop with #8 sheet metal screws (supplied). (Fig. 12)

Install firestop assembly.

- 9 -

Page 10

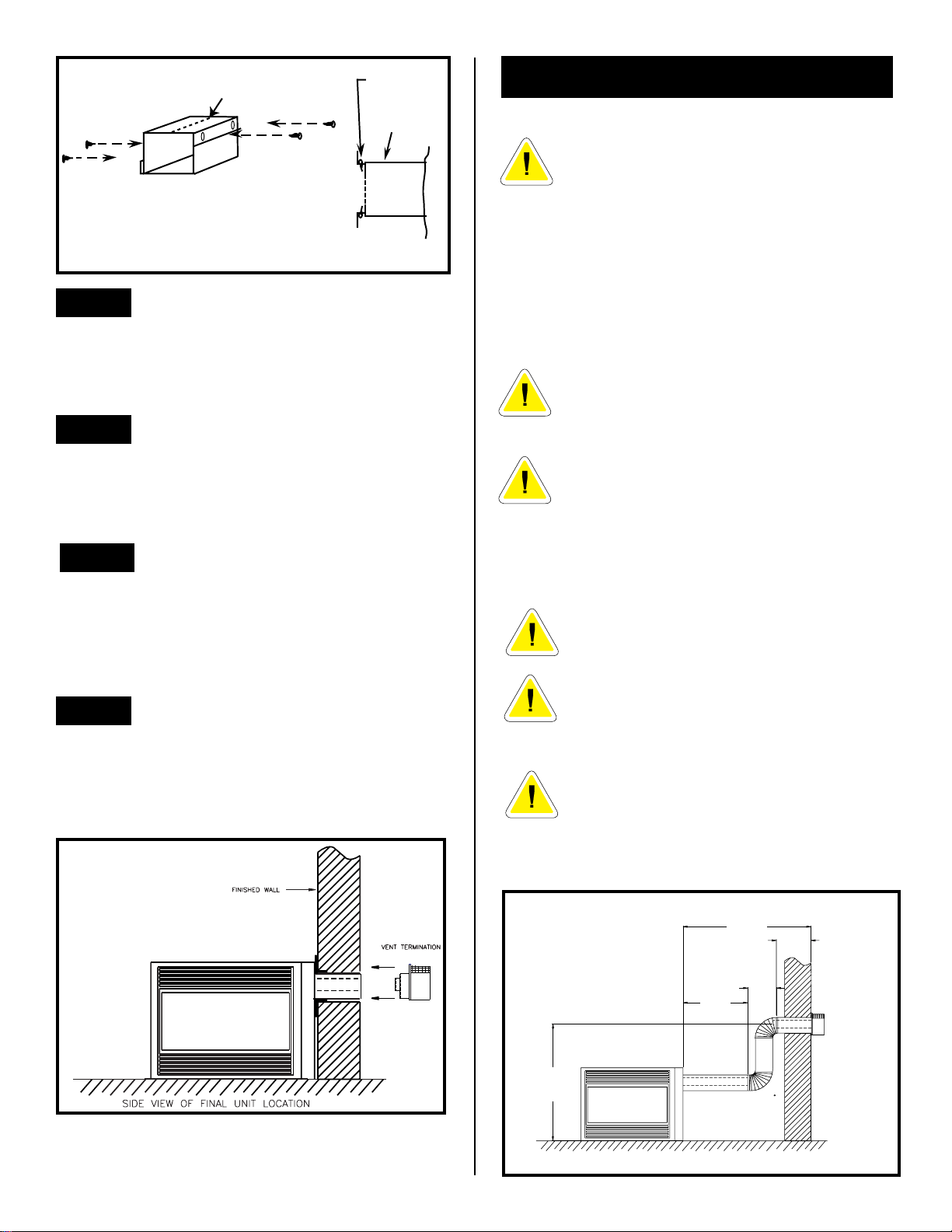

#8

SCREWS(2)

ADJUSTABLE

ZERO CLEARANCE

SLEEVE

Fig. 12

#8

SCREWS(2)

ADJUSTABLE ZERO

CLEARANCE SLEEVE

Maximum Length

12" (294mm)

#8

SCREWS(2)

FIRESTOP

STEP 3

Measure from fireplace collar to face of outside wall (add 2"

for vent pipe overlap. Mark pipes and cut to length. It is very

important that the two pipes are flush with the outside wall

once the fireplace is in its final location. Fig. 13.

STEP 4

Slip 4" and 7" pipes onto respective flue collars. Make sure

to fix to the fireplace collar the 4" pipe with three (3) screws

before fixing the 7" pipe on the 7" collar. Both pipes must

be on a level plane. Fig. 13.

STEP 5

Guide the vent termination 4" collar into the 4" pipe then the

7" collar into the 7" pipe. Do not force the venting into

position. If the pipes do not line up with the termination

collars, disassemble pipes and reattach to the fireplace

collar. (Fig. 13)

STEP 6

Secure fireplace to floor through floor holes and adjustable

frame drywall strip (nailing flange) to frame. (See Framing

& Finishing Section)

VERTICAL SIDEWALL APPLICATIONS

Vent Starter Kit 7DVSK, plus Transition Elbow

7DVRT90 must be used in Vertical Sidewall

installations.

inside the 7" pipe coming off the 7DVRT90

transition elbow.

Since it is very important that the venting system

maintain its balance between the combustion air intake

and the flue gas exhaust, certain limitations as to vent

configurations apply and must be strictly adhered to.

The graph showing the relationship between vertical and

horizontal side wall venting will help to determine the

various vent lengths allowable. Fig. 19.

Minimum clearance between vent pipes and

combustible materials is one (1") inch (25

mm) on top, bottom and sides unless

otherwise noted.

When vent termination exits through

foundation less than 20" below siding outcrop,

the vent pipe must flush up with the siding. A

7DVSS must also be used.

It is always best to locate the fireplace in such a way that

minimizes the number of offsets and horizontal vent

length.

The horizontal vent run refers to the total

length of vent pipe from the flue collar of the

fireplace to the face of the outer wall.

Horizontal plane means no vertical rise

exists on this portion of the vent assembly.

For some installations, it may be desireable

to have some amount of the horizontal vent

run immediately after the fireplace. A vertical rise must be used but can be located

anywhere in the vent system, to meet the

perimeters identified in the venting graph.

The 4" pipe must be centred

Fig. 13

- 10 -

The maximum horizontal vent run is 20 feet (6100mm)

when the vertical vent rise is 7.5 feet (2286mm). Fig. 14

MAXIMUM

20ft.

7.5'

90"

(2286mm)

SIDE VIEW

(6100mm)

15ft.

(4572

mm)

Vertical Dimension

8ft. minimum when

horizontal run is

20 ft.

12"

(305

mm)

7DVT90

ELBOW

48"

(1220mm)

VENT

TERMINATION

Fig. 14

Page 11

VERTICAL SIDEWALL APPLICATIONS

The maximum number of 90 degree elbows per side wall

installation is four (4), (includes 7DVRT90 off back of unit)

The maximum number of 45 degree elbows permitted per

side wall installation is two (2). These elbows can be

installed in either the vertical or horizontal run.

The maximum number of elbow degrees in a system is

270º. (This does not include transition elbow from rear

vent to vertical vent).

Sample: 1 - 90º

2 - 45º

3 - 45º

4 - 90º

When one 90º elbow is installed directly onto another off

the back of the fireplace the maximum horizontal vent

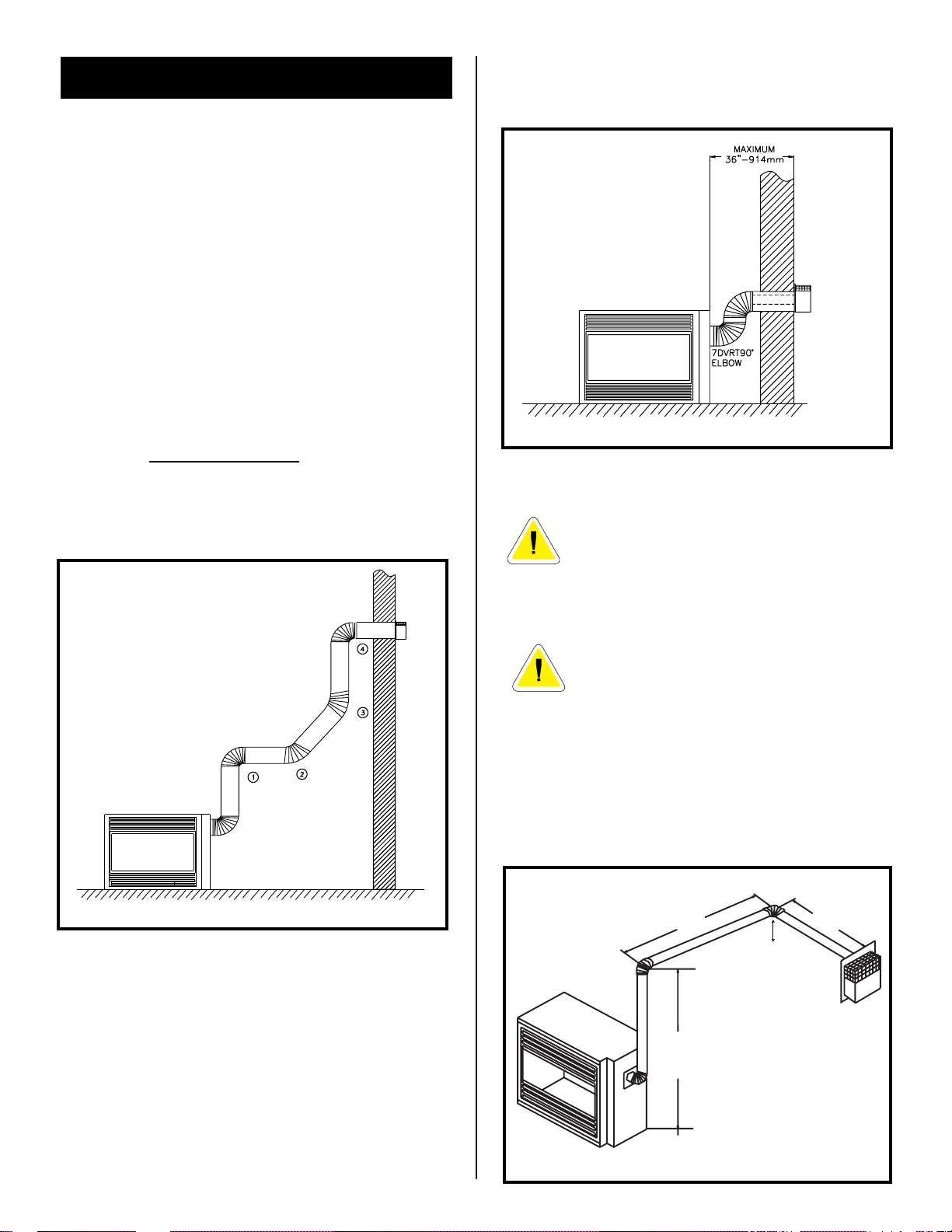

length is 36" (914mm). Fig. 16.

SIDE VIEW

Fig. 15

Fig. 16

Total - 270º

Fig. 15

For each 45 degree elbow installed in the

horizontal run (while maintaining a constant

horizontal plane), the length of the horizontal

run MUST be reduced by 18" (457mm). This

does not apply if the 45 degree elbows are

installed on the vertical part of the vent

system.

If a 90 degree elbow is used in the horizontal

vent run (level height maintained) the maximum horizontal vent length is reduced by 36

inches. Fig. 18. This does not apply if the 90

degree elbows are used to increase or redirect a vertical rise.

Example: According to the vent chart the maximum

horizontal vent length is 20 ft.when the vertical height is 8

ft. from fireplace base height. If one 90 degree elbow is

required in the horizontal vent it must be reduced to 17 ft.

120"

3048mm

90º elbow=3'

84"

2134mm

- 11 -

7'

90"

2286mm

Fig. 17

Page 12

HOW TO USE THE VENT GRAPH

1. Determine the height of the centre of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph (Fig. 18),

locate the point it intersects with the slanted graph

line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same.

EXAMPLE A:

If the vertical dimension from the floor of the unit is 11

feet (3352mm) the horizontal run to the face of the outer

wall must not exceed 14 feet (4267mm).

EXAMPLE B:

If the vertical dimension from the floor of the unit is 7 feet

(2133mm), the horizontal run to the face of the outer wall

must not exceed 8-1/2 feet (2590mm).

VERTICAL SIDEWALL VENTING GRAPH

(Dimensions in Feet)

VERTICAL SIDEWALL INSTALLATION

STEP 1

Locate vent opening on the wall. It may be necessary to first

position the fireplace and measure to obtain hole location.

Depending on whether the wall is combustible or noncombustible, cut opening to size. Fig. 19.

(For combustible walls first frame in opening).

VERTICAL SIDEWALL APPLICATION

Vent Opening —

Combustible Wall

(240mm)

3/8

"

9-

9-

3/8

"

(240mm)

(framing detail)

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

eg: B

eg: A

VERTICAL DIMENSION FROM THE FLOOR OF THE UNIT

TO THE CENTRE OF THE HORIZONTAL VENT PIPE

COMBUSTIBLE WALLS (Fig. 19): Cut a 9-3/8"H x 9-3/8"W (240

mm x 240 mm) hole through the exterior wall and frame as shown

NON-COMBUSTIBLE WALLS (Fig. 19): Hole opening must be

7.5" (190 mm) in diameter.

STEP 2

Fiig. 20. Measure wall thickness and cut adjustable zero

clearance sleeve parts to proper length (MAXIMUM 12"/

305mm). Adjust sleeve to minimum (9-3/8" x 9-3/8") and

attach to firestop with #8 sheet metal screws (supplied).

Install firestop assembly.

Vent Opening —

Noncombustible Wall

7-

1/2

"

(190mm)

Zero clearance sleeve is only required for

combustible walls.

Fig. 19

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

SEE PAGE 14 FOR VENTING

REQUIREMENTS FOR SNORKELS.

Fig. 18

- 12 -

Page 13

FIRESTOP

#8

SCREWS(2)

ADJUSTABLE

ZERO CLEARANCE

SLEEVE

Fig. 20

#8

SCREWS(2)

Maximum Length

12" (294mm)

ADJUSTABLE ZERO

CLEARANCE SLEEVE

#8

SCREWS(2)

STEP 3

(Fig. 21) Apply a bead of high temperature sealant to the

inner and outer flue collars of the fireplace and using

appropriate venting component(s) attach to fireplace with

three (3) screws. Follow with the installation of the inner

and outer elbow. Again secure joints with three (3) sheet

metal screws. Wipe off any excess high temperature

sealant.

STEP 5

(Fig. 23) Use the appropriate length of pipe section –

telescopic or fixed – and install. The 20" (508mm) section

of pipe which goes through the wall is packaged with the

7DVSK kit, and can be cut to suit if necessary.

Sealing vent pipe and firestop gaps with hitemperature sealant will restrict cold air being

drawn in around fireplace.

BEAD OF

SILICONE

Fig. 21

STEP 4

(Fig. 22) Measure the horizontal length requirement

including a 2" (50mm)overlap, i.e. from the elbow to the

outside wall finish plus 2" (or the distance required if

installing a second 90º elbow).

Always

install

horizontal

venting on

a level

plane.

Fig. 22

Fig. 23

STEP 6

(Fig. 24) Apply high temperature sealant to 4" and 7"

collars one inch away from crimped end. Guide the vent

termination 4" and 7" collars into their respective vent

pipes. Double check that the vent pipes overlap the collars

by 2" (50mm). Secure the termination to the wall with

screws provided and caulk around the wall plate to

weatherproof.

- 13 -

Page 14

Fig. 24

BELOW GRADE INSTALLATIONS

When it is not possible to meet the required vent terminal

clearances of 12 inches (305mm) above grade level a

model 7DVSKS vent kit is required. It allows installation

depth of down to 7 inches (178mm) below grade level. The

7 inches is measured from the centre of the horizontal vent

pipe as it penetrates through the wall.

If venting system is installed below ground,

we recommend a window well with adequate

and proper drainage.

INSTALLATION

Ensure sidewall venting clearances are observed.

The maximum horizontal run with 24" (610mm)

vertical rise is 36" (914mm) from the back of the

fireplace to the face of the exterior wall. See

vent graph (Fig. 18) for extended horizontal run

if the vertical exceeds 24" (610mm).

1. Establish vent hole through the wall. See page 12

2. Remove soil to a depth of approximately 16"

(406mm) below base of snorkel. Install window well

(not supplied). Refill hole with 12" (305mm) of

coarse gravel leaving a clearance of approximately

4" (100mm)below snorkel. (Fig. 25)

3. Install vent system. See page 12, Steps 2 through

5.

4. Ensure a watertight seal is made around the vent

pipe coming through the wall.

5. Apply high temperature sealant caulking (supplied)

around the 4 and 7 inch 7DVSKS's snorkel collars.

6. Slide into vent pipe and secure to the wall.

7. Level the soil so as to maintain a 4"

(100mm)clearance below snorkel (Fig. 25).

STEP 7

Support the horizontal pipes every 36 inches (914mm) with

metal pipe straps. Make sure that the horizontal vent pipe

is installed on a level horizontal plane.

STEP 8

Recheck the fireplace to make sure that it is levelled,

properly positioned, and nailed or screwed to the floor.

If applied, the fireplaces adjustable frame drywall strips

(nailing flanges) should be fastened. See "Framing &

Finishing.

A MINIMUM OF 24" (610mm)

VERTICAL PIPE MUST BE

INSTALLED WHEN USING

THE 7DVSKS KIT

DO NOT BACK FILL AROUND SNORKEL.

SOIL SHOULD NOT BE LESS THAN 4"

(100mm) BELOW SNORKEL.

- 14 -

7DVSKS

(SNORKEL)

GROUND LEVEL

4" (100mm) MIN. CLEARANCE

DRAIN

WINDOW

WELL

Fig. 25

Page 15

FOUNDATION

RECESS

WATERTIGHT

SEAL

AROUND

PIPE

SNORKEL

WALL

SCREWS

e) The maximum number of elbow degrees in

system is 270º (this does not include transition

elbow from rear vent to vertical vent).

SHEET METAL

SCREWS

Fig. 26

If the foundation is recessed, use recess brackets (not

supplied) for securing lower portion of the snorkel. Fasten

brackets to wall first and then secure to snorkel with self

drilling #8 x 1/2 sheet metal screws. It will be necessary to

extend vent pipes out as far protruding wall face (Fig. 26).

VERTICAL THROUGH THE

ROOF APPLICATIONS

MAXIMUM

10 FT. (3408mm)

MINIMUM 8 FT.

MAXIMUM 40 FT.

VERTICAL RISE

PIPE STRAPS

EVERY 3 FT. (914mm)

Fig. 28

Fig. 27

This Gas Fireplace has been approved for,

a) Vertical installations up to 40 feet (12 metres) in height.

Up to a 10 ft.(3048mm) horizontal vent run can be

installed within the vent system using a maximum of

three 90º elbows.

b) Up to two 45º elbows may be used within the horizontal

run. For each 45º elbow used on the horizontal level

the maximum horizontal length must be reduced by 18

inches (457mm).

Example: Maximum horizontal length

0 - 45º elbows 10 ft. (3048mm)

1 - 45º elbows 8.5 ft. (2590mm)

2 - 45º elbows 7 ft. (2133mm)

c) A minimum of an 8 ft. vertical rise.

d) Two sets of 45 degree elbow offsets within these

vertical installations. From 0 to a maximum of 8 ft.

(2438mm) a vent pipe can be used between elbows.

(Fig. 30)

Sample: 1 - 90º

2 - 45º

3 - 45º

4 - 45º

5 - 90º

Total - 270º

f) 7DVCS must be used to support offsets. (Fig. 30).

This application will require that you first determine the roof

pitch and use the appropriate 7DVSKV (A,B or F). (see

Venting Components, page 17)

- 15 -

Page 16

SIDE VIEW

MAX. 8 Ft.

(2438mm)

MAX. 8 Ft.

(2438mm)

40 FEET

(12.2m)

8 FEET

(2.44m)

Fig. 29

MAX.

MIN.

TYPICAL 7DVCS

APPLICATION

Fig. 30

TYPICAL ROOF

SUPPORT

APPLICATION

Fig. 31

VERTICAL THRU THE ROOF INSTALLATION

1. Locate your fireplace.

2. Plumb to centre of the (4") 90º transition elbow

(7DVRT90) from ceiling above and mark position.

3. Cut opening equal to 9-3/8" x 9-3/8" (240 mm x 240

mm).

4. Proceed to plumb for additional openings through the

roof. In all cases, the opening must provide a minimum

of 1 inch clearance to the vent pipe, i.e., the hole must

be a minimum of 9-3/8" x 9-3/8" (240 mm x 240 mm).

5. Place firestop(s) 7DVFS into position and secure. (Fig.

33)

6. Install roof support (Fig. 31) and roof flashing making

sure upper flange of flashing is below the shingles.

(Fig. 34)

7. Install appropriate pipe sections until above the flashing. (See Fig. 34 for #'s 7, 8 and 9).

8. Install storm collar and seal around the pipe. (Fig. 34)

9. Add additional vent lengths for proper height. (Fig. 34)

10. Apply high temperature sealant to 4" and 7" collars of

vent termination and install.

VENT TERMINATION

ROOF

ATTIC INSULATION

MAX.

40 FEET

(12.2m)

MIN.

8 FEET

(2.44m)

24" Min.

(610mm)

JOISTS

ATTIC INSULATION

SHIELD

TYPICAL STRAIGHT-UP INSTALLATION

STORM COLLAR

ROOF FLASHING

ROOF SUPPORT

CEILING JOISTS

Fig. 32

Attic

Insulation

Shield

Ceiling

Installation

11"

11"

11"

11"

JOIST

UPPER FLOOR

JOIST

FIRESTOP

SPACER

NAILS (4)

Fig. 33

Fig. 33. If there is a room above ceiling level,

firestop spacer must be installed on both the

bottom and the top side of the ceiling joists. If an

attic is above ceiling level a 7DVAIS (Attic

Insulation Shield) must be installed.

Fig. 34. The enlarged ends of the vent section

always face downward.

Clearance above a roof shall extend a minimum of 24" (610mm) above the highest point

when it passes through the roof surface, and

any other obstruciton within a horizontal

distance of 18" (450mm).

- 16 -

SHEETMETAL

SCREWS (#5) —

3 PER JOINT

SEALANT

STORM

COLLAR

Fig. 34

Page 17

DVR SERIES CRIMPED VENTING COMPONENTS

7DVRVT - Through the wall Rear Vent Termination

Starter Kit -Model 7DVSK - Sidewall Venting

Starter Kit - Model 7DVSKV - Vertical Venting

for 7DVSKV-A order 1/12 to 6/12 roof pitch

for 7DVSKV-B order 7/12 to 12/12 roof pitch

for 7DVSKV-F order flat roof

Starter Kit - Model 7DVSKS -Snorkel Kit

for Below Grade Installation

45º elbow kit

7DVT45 for Vertical Installation Offsets

90º transition elbow kit

7DVRT90 for Vertical Sidewall Applications

or thru-the-roof.

Telescopic vent sections

7DVP610 - 6" to 10" adjustable length

7DVP1018 - 10" to 18" adjustable length

7DVP1834 - 18" to 34" adjustable length

7DVP3466 - 34" to 66" adjustable length

Pipe sections for vertical or horizontal venting

Model 7DVP8" - 4 per box

Model 7DVP12" - 4 per box

Model 7DVP24" - 4 per box

Model 7DVP36"

Model 7DVP48"

Firestop Spacer

Model 7DVFS

Attic Insulation Shield

Model 7DVAIS

Vertical/Horizontal Combination Offset Support

Model 7DVCS

7DVSS Siding Shield (to protect siding)

- 17 -

Page 18

GENERAL INFORMATION ON ASSEMBLING

THE TWIST LOCK VENT PIPES

When using CFM Majestic twist lock pipe it is not necessary to use silicone to seal the twist lock joints. The only

areas that need silicone are the collars on the fireplace,

the telescoping pipe (if used) and the horizontal termination connection (when necessary).

To join the pipes together, simply align the beads of the

male end with the grooves of the female end and while

joining the two together, twist the pipe until the flange on

the female end touches the external bead on the male

end. Secure the joints with three sheet metal screws.

To make easier to assembly, we suggest putting lubricant (vaseline or similar) on the male end of the twist

lock pipe.

TWIST LOCK PIPE JOINT

Screw Holes

Crimped pipe and new twist lock pipe.

REAR VENTING APPLICATIONS

Note: It is not necessary to seal the vent pipe joints

for any rear vent applications.

Minimum clearances between vent pipe and combustible materials are as follows:

To p - 2" (50 mm)

Sides - 1" (25 mm)

Bottom - 1" (25 mm)

Note:

used in rear vent applications.

Maximum Vent Length .........................................20" - Fig. 35

Maximum Number of Elbows .............. One 45" Elbow - Fig.36

Vent Starter Kit Model 7TDVRVT must be

.............................20" - With 45 Elbow

Fig. 35

20" (508mm)

It is possible to use CFM Majestic 4" & 7" direct vent

crimped pipe and elbows in your system, with the new

CFM Majestic 4" & 7" Direct Vent Twist Lock Pipe.

You must use the crimped pipe first in the system off

the appliance.

1. Install expanded end of crimped pipe or elbow onto

the 4" & 7" collars off the fireplace with high temperature sealant and 3 screws.

2. If you wish to continue your system with your 4" & 7"

crimped pipe or elbow apply high temperature

sealant on crimped end of pipe at 2" in from end and

fasten the next pipe with 3 sheet metal screws.

3. When you wish to continue your system with the

New Twist Lock pipe or elbow, apply high temperature sealant on crimped end of pipe at 1-1/2" from

end, and slip the female end of the twist lock pipe

over the crimped end of the pipe and secure with 3

sheet metal screws. Continue the installation with

twist lock pipe placing the female end over the male

end and fastening with 3 sheet metal screws.

You do not have to use high temperature sealant

when using twist lock pipe between the female and

male ends of the twist lock.

20"

508mm

45°

TOP VIEW

CROSS CORNER VENT

TO THE LEFT.

TOP VIEW

20"

508mm

Fig. 36

TOP VIEW

CROSS CORNER VENT

TO THE RIGHT.

45°

Except on: 1.Adjustable lengths (telescoping joint only)

2.Crimped collar on existing fireplaces.

3.Terminations where required.

- 18 -

Page 19

REAR WALL INSTALLATIONS

Minimum clearance between vent pipes and

combustible materials in one (1") inch (25 mm)

on sides and bottom and two (2") inch (50 mm)

on top.

STEP 1

Locate vent opening on wall.

STEP 4

If the fireplace has crimped ends on the inner and outer flue

collars, apply a bead of high temperature sealant and using

the appropriate venting component(s) attach to the fireplace with three (3) screws. If the fireplace has no crimps

on the end of the flue collars, the use of high temperature

sealant is not necessary just secure the component with

three (3) screws. Both pipes must be on a level plane. Fig.

40.

Vent Opening —

Combustible Wall

(240mm)

3/8

"

9-

3/8

"

10(254mm)

(framing detail)

Vent Opening —

Noncombustible Wall

1/2

"

7(190mm)

Combustible Walls. Cut a 10-3/8"H x 9-3/8"W (265mm

x 240mm) hole through the exterior wall and frame as

shown. Fig. 37.

Non-Combustible Walls: Hole opening must be 7.5"

(190mm) in diameter. To locate hole centre consult with

appropriate fireplace specifications, page 4.

STEP 2

Measure wall thickness and cut adjustable zero clearance

sleeve parts to proper length (MAXIMUM 12"). Adjust

sleeve to maximum (10-3/8 x 9-3/8). and attach to firestop

with #8 sheet metal screws (supplied). (Fig. 38) Install

firestop assembly.

Maximum Length

12" (294mm)

#8

SCREWS(2)

#8

SCREWS(2)

Fig. 37

#8

SCREWS(2)

ADJUSTABLE

ZERO CLEARANCE

SLEEVE

ZERO

CLEARANCE

SLEEVE

FIRESTOP

TYPICAL VIEW OF CORNER INSTALLATION

Fig. 39

STEP 5

Guide the vent termination 4" collar into the 4" pipe then the

7" collar into the 7" pipe. Do not force the venting into

position. If the pipes do not line up with the termination

collars, disassemble elbows or pipes and reattach to the

fireplace collar. (Fig. 40)

STEP 6

Recheck the fireplace to make sure that it is levelled,

properly positioned, and nailed or screwed to the floor.

If applied, the fireplaces adjustable frame drywall strips

(nailing flanges) should be fastened. See "Framing &

Finishing.

FINISHED

WALL

VENT

TERMINATION

Fig. 38

ADJUSTABLE ZERO

CLEARANCE SLEEVE

FIRESTOP

STEP 3

Measure from fireplace collar or elbow face to face of

outside wall (add 1-1/2" for vent pipe overlap). Mark pipes

and cut to length. It is very important that the two pipes are

flush with the outside wall once the fireplace is in its final

location.

Fig. 40

- 19 -

Page 20

VERTICAL SIDEWALL INSTALLATIONS

,

,

,

VERTICAL SIDEWALL APPLICATIONS

Since it is very important that the venting system

maintain its balance between the combustion air intake

and the flue gas exhaust, certain limitations as to vent

configurations apply and must be strictly adhered to.

The graph showing the relationship between vertical and

horizontal side wall venting will help to determine the

various vent lengths allowable. Fig. 45.

Minimum clearance between vent pipes and

combustible materials is one (1") inch (25

mm) on top, bottom and sides unless

otherwise noted.

When vent termination exits through

foundation less than 20" below siding outcrop,

the vent pipe must flush up with the siding. A

7DVSS must also be used.

It is always best to locate the fireplace in such a way that

minimizes the number of offsets and horizontal vent

length.

The horizontal vent run refers to the total

length of vent pipe from the flue collar of the

fireplace to the face of the outer wall.

The maximum number of 90 degree elbows per side wall

installation is four (4), (includes 7TDVRT90 off back of unit)

The maximum number of 45 degree elbows permitted per

side wall installation is two (2). These elbows can be

installed in either the vertical or horizontal run.

When one 90o elbow is installed directly onto another off

the back of the fireplace the maximum horizontal vent

length is 36" (914mm). Fig. 42.

MAXIMUM

3' (914mm)

7TDVRT90

ELBOW

SIDE VIEW

Fig. 42

Horizontal plane means no vertical rise

exists on this portion of the vent assembly.

For some installations, it may be desirable to

have some amount of the horizontal vent run

immediately after the fireplace. A vertical

rise must be used but can be located anywhere in the vent system, to meet the perimeters identified in the venting graph.

The maximum horizontal vent run is 20 feet (6100mm)

when the vertical vent rise is 7.5 feet (2286mm). Fig. 41

MAXIMUM

15 ft.

(4572mm)

20 ft. (6100mm)

(305mm)

12"

48"

(1220mm)

For each 45 degree elbow installed in the

horizontal run (while maintaining a constant

horizontal plane), the length of the horizontal

run MUST be reduced by 18" (457mm). This

does not apply if the 45 degree elbows are

installed on the vertical part of the vent

system.

If a 90 degree elbow is used in the horizontal

vent run (level height maintained) the maximum horizontal vent length is reduced by 36

inches. Fig. 43. This does not apply if the 90

degree elbows are used to increase or redirect a vertical rise.

Example: According to the vent chart the maximum

horizontal vent length is 20 ft.when the vertical height is 7.5

ft. from fireplace base height. If one 90 degree elbow is

required in the horizontal vent it must be reduced to 17 ft.

7.5 ft. MINIMUM

WHEN HORIZONTAL

90" (2286mm)

VERTICAL

DIMENSION

RUN IS 20 ft.

SIDE VIEW

7TDVRT90

ELBOW

Fig. 41

- 20 -

Page 21

84"

2134mm

120"

3048mm

o

elbow=3'

90

90"

2286mm

Fig. 43

The maximum number of elbow degrees in a system is

270 o. (This does not include transition elbow from rear

INSERT

vent to vertical vent.) Fig. 44

Sample: 1 - 90

2 - 45

3 - 45

4 - 90

o

o

o

o

HOW TO USE THE VENT GRAPH

1. Determine the height of the centre of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph (Fig. 45),

locate the point it intersects with the slanted graph

line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same. (See examples

Fig. 43).

EXAMPLE A:

If the vertical dimension from the floor of the unit is 11

feet (335cm) the horizontal run to the face of the outer

wall must not exceed 14 feet (427cm).

EXAMPLE B:

If the vertical dimension from the floor of the unit is 7 feet

(214cm), the horizontal run to the face of the outer wall

must not exceed 8-1/2 feet (259cm).

SIDEWALL VENTING GRAPH

(Dimensions in Feet)

Total - 270

o

Fig. 44

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

eg: B

eg: A

VERTICAL DIMENSION FROM THE FLOOR OF THE UNIT

TO THE CENTRE OF THE HORIZONTAL VENT PIPE

- 21 -

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

SEE PAGE 23 FOR VENTING

Fig. 45

REQUIREMENTS FOR SNORKELS.

Page 22

VENT SIDEWALL INSTALLATION

*IMPORTANT* Minimum clearance between vent pipes

and combustible materials is one (1") inch (25 mm) on

bottom, sides and top.

Vent Starter Kit 7TDVSK, plus Transition

Elbow 7TDVRT90 must be used in

Vertical Sidewall installations.

The 4"

pipe must be centred inside the 7" pipe

coming off the 7TDVRT90 transition

elbow.

STEP 1

Locate vent opening on the wall. It may be necessary to first

position the fireplace and measure to obtain hole location.

Depending on whether the wall is combustible or noncombustible, cut opening to size. Fig. 46 or 47.

(For combustible walls first frame in opening. Fig. 47).

Vent Opening —

Combustible Wall

(240mm)

3/8

"

9-

STEP 2

Fig. 49. Measure wall thickness and cut adjustable zero

clearance sleeve parts to proper length (MAXIMUM 12").

Adjust sleeve to minimum (9-3/8" x 9-3/8") and attach to

firestop with #8 sheet metal screws (supplied). Install

STEP 2

firestop assembly.

Zero clearance sleeve is only required for

combustible walls.

Fig. 49

#8

SCREWS(2)

Maximum Length

12" (294mm)

ADJUSTABLE ZERO

CLEARANCE SLEEVE

#8

SCREWS(2)

FIRESTOP

#8

SCREWS(2)

ADJUSTABLE

ZERO CLEARANCE

SLEEVE

FIRESTOP

STEP 3

(Fig. 50) Apply a bead of high temperature sealant to the

inner and outer flue collars of the fireplace and using

appropriate venting component(s) attach to fireplace with

three (3) screws. Follow with the installation of the inner

and outer elbow. Again secure joints with three (3) sheet

metal screws. Wipe off any excess high temperature

sealant.

9-

3/8

"

(240mm)

Fig. 46

(framing detail)

Fig. 47

Vent Opening —

Noncombustible Wall

7-

1/2

"

(190mm)

Fig. 48

COMBUSTIBLE WALLS (Fig. 46): Cut a 9-3/8"H x 9-3/8"W (240

mm x 240 mm) hole through the exterior wall and frame as shown

NON-COMBUSTIBLE WALLS (Fig. 48): Hole opening must be

7.5" (190 mm) in diameter.

ENSURE PIPES

ARE CONCENTRIC

X

7TDVRT90

BEAD OF

SEALANT

(IF NECESSARY)

Fig. 50

STEP 4

(Fig. 51) Measure the horizontal length requirement plus

1-1/2" overlap, i.e. from the elbow to the outside wall finish

plus 1-1/2" (or the distance required if installing a second

90º elbow).

X

Always

install

horizontal

venting

on a

Fig. 51

level

plane.

- 22 -

Page 23

STEP 5

,

,

(Fig. 52) Use the appropriate length

of pipe section – telescopic or fixed

– and install. The 20" section of

pipe which goes through the wall is

packaged with the 7TDVSK kit, and

can be cut to suit if necessary.

Sealing vent pipe and

firestop gaps with high

temperature sealant will

restrict cold air being

drawn in around fireplace.

Fig. 52

X

BELOW GRADE INSTALLATIONS

When it is not possible to meet the required vent terminal clearances of 12 inches (305mm) above grade level

a model 7TDVSKS vent kit is recommended. It allows

installation depth of down to 7 inches (178mm) below

grade level. The 7 inches is measured from the centre

of the horizontal vent pipe as it penetrates through the

wall.

If venting system is installed below ground,

we recommend a window well with adequate

and proper drainage.

STEP 6

(Fig. 53) Apply high temperature sealant to 4" and 7"

collars one inch away from crimped end. Guide the vent

terminations 4" and 7" collars into their respective vent

pipes. Double check that the vent pipes overlap the collars

by 2". Secure the termination to the wall with screws

provided and caulk around the wall plate to weatherproof.

X

Fig. 53

X

INSTALLATION

Ensure sidewall venting clearances are observed.

The maximum horizontal run with 24" vertical

rise is 36" (915mm) from the back of the

fireplace to the face of the exterior wall. See

vent graph (Fig. 45) for extended horizontal

run if the vertical exceeds 24".

1. Establish vent hole through the wall. See page 22

2. Remove soil to a depth of approximately 16" below

base of snorkel. Install window well (not supplied).

Refill hole with 12" of coarse gravel leaving a clearance of approximately 4" below snorkel. (Fig. 54)

3. Install vent system. See page 22, Steps 2 through

5.

4. Ensure a watertight seal is made around the vent

pipe coming through the wall.

5. Apply high temperature sealant caulking (supplied)

around the 4 and 7 inch 7TDVSKS's snorkel collars.

6. Slide into vent pipe and secure to the wall.

7. Level the soil so as to maintain a 4" clearance below

snorkel (Fig. 54).

STEP 7

Support the horizontal pipes every three (3) feet (92 cm)

with metal pipe straps. Make sure that the horizontal vent

pipe is installed on a level horizontal plane.

STEP 8

Recheck the fireplace to make sure that it is levelled,

properly positioned, and nailed or screwed to the floor.

If applied, the fireplaces adjustable frame drywall strips

(nailing flanges) should be fastened. See "Framing &

Finishing" section.

- 23 -

ZERO CLEARANCE

SLEEVE IF REQUIRED

FIRESTOP

7TDVRT90

A MINIMUM OF 24"

(608MM) VERTICAL

PIPE MUST BE

INSTALLED WHEN

USING THE 7TDVSKS

KIT.

7TDVRT90

7TDVSKS

SCREWS

FOUNDATION WALL

*

A minimum of 24"/608mm

vertical pipe must be installed

when using the 7TDVSKS kit.

(SNORKEL)

MINIMUM

4" CLEARANCE

GROUND

WINDOW WELL

GRAVEL

DRAIN

Fig. 54

Page 24

DO NOT BACK FILL AROUND SNORKEL.

SOIL SHOULD NOT BE LESS THAN 4"

BELOW SNORKEL.

FOUNDATION

RECESS

WATERTIGHT

SEAL

AROUND

PIPE

SNORKEL

WALL

SCREWS

SHEET METAL

SCREWS

Fig. 55

If the foundation is recessed, use recess brackets (not

supplied) for securing lower portion of the snorkel. Fasten

brackets to wall first and then secure to snorkel with self

drilling #8 x 1/2 sheet metal screws. It will be necessary to

extend vent pipes out as far protruding wall face (Fig. 55).

VERTICAL THROUGH THE

ROOF APPLICATIONS

c) A minimum of an 8 ft. vertical rise.

d) Two sets of 45 degree elbow offsets within these

vertical installations. From 0 to a maximum of 8 ft. a

vent pipe can be used between elbows. (Fig. 57)

e) 7DVCS must be used to support offsets. (Fig. 58)

This application will require that you first determine the roof

pitch and use the appropriate 7TDVSKV (A,B or F). (see

Venting Components, page 26)

Fig. 57

MAX. 8 Ft.

(2438mm)

MAX. 8 Ft.

(2438mm)

MAX.

40 FEET

(12.2m)

MIN.

8 FEET

(2.44m)

TYPICAL 7DVCS

APPLICATION

Fig. 58

MAXIMUM

10 FT

(3048mm)

MINIMUM

8 FT./

MAXIMUM

40 FT.

VERTICAL

RISE

PIPE STRAPS

EVERY 3'

(914mm)

Fig. 56

This Gas Fireplace has been approved for,

a) Vertical installations up to 40 feet (12 metres) in height.

Up to a 10 ft. horizontal vent run can be installed within

the vent system using a maximum of three 90o elbows.

b) Up to two 45o elbows may be used within the horizontal

run. For each 45o elbow used on the horizontal level

the maximum horizontal length must be reduced by 18

inches.

Example: Maximum horizontal length

0- 45o elbows 10 ft.

1- 45o elbows 8.5 ft.

2- 45o elbows 7 ft.

Fig. 59

SIDE VIEW

ROOF

ATTIC INSULATION

MAX.

40 FEET

(12.2m)

MIN.

8 FEET

(2.44m)

VENT TERMINATION

24" Min.

(610mm)

JOISTS

ATTIC INSULATION

SHIELD

TYPICAL ROOF

SUPPORT

APPLICATION

STORM COLLAR

ROOF FLASHING

ROOF SUPPORT

CEILING JOISTS

Fig. 60

TYPICAL STRAIGHT-UP INSTALLATION

The minimum height of the vent above the highest

point of penetration throught the roof is 2 feet. See

Fig. 60.

- 24 -

Page 25

VERTICAL THROUGH THE ROOF INSTALLATION

1. Locate your fireplace.

2. Plumb to centre of the (4") 90o transition elbow

(7TDVRT90) from ceiling above and mark position.

3. Cut opening equal to 9-3/8" x 9-3/8" (240 mm x 240

mm).

4. Proceed to plumb for additional openings through the

roof. In all cases, the opening must provide a minimum

of 1 inch clearance to the vent pipe, i.e., the hole must

be at least 9-3/8" x 9-3/8" (240 mm x 240 mm).

5. Place fireplace into position and secure to floor.

6. Place firestop(s) 7DVFS into position and secure. (Fig.

61)

7. Install roof support (Fig. 36) and roof flashing making

sure upper flange of flashing is below the shingles.

(Fig. 62)

8. Install appropriate pipe sections until above the flashing. (See Fig. 59 for #'s 7, 8 and 9).

9. Install storm collar and seal around the pipe.

10. Add additional vent lengths for proper height. (Fig. 62)

Attic

Insulation

Shield

11"

11"

JOIST

Fig. 62

Fig. 61

Ceiling

Installation

11"

11"

UPPER FLOOR

JOIST

FIRESTOP

SPACER

NAILS (4)

Fig. 61 If there is a room above ceiling level,

firestop spacer must be installed on both the

bottom and the top side of the ceiling joists. If an

attic is above ceiling level a 7DVAIS (Attic

Insulation Shield) must be installed.

Fig. 62 The enlarged ends of the vent section

always face downward.

SHEETMETAL

SCREWS (#5) —

3 PER JOINT

SEALANT

STORM

COLLAR

- 25 -

Page 26

DVR SERIES TWIST LOCK VENTING COMPONENTS

7DVRVT - Through the wall Rear Vent Termination

Starter Kit -Model 7TDVSK - Sidewall Venting

Starter Kit - Model 7TDVSKV - Vertical Venting

for 7TDVSKV-A order 1/12 to 6/12 roof pitch

for 7TDVSKV-B order 7/12 to 12/12 roof pitch

for 7TDVSKV-F order flat roof

Starter Kit - Model 7TDVSKS -Snorkel Kit

for Below Grade Installation

45o elbow kit

7TDV45 for Vertical/Horizontal Offsets

90o transition elbow kit

7TDVRT90 for Vertical Sidewall Applications

or thru-the-roof.

Telescopic vent sections

7TDVP1218 - 12" to 18" adjustable length

7TDVP3566 - 35" to 64" adjustable length

Pipe sections for vertical or horizontal venting

Model 7TDVP8

Model 7TDVP12

Model 7TDVP24

Model 7TDVP36

Model 7TDVP48

Firestop Spacer

Model 7DVFS

Attic Insulation Shield

Model 7DVAIS

Vertical/Horizontal Combination Offset Support

Model 7DVCS

7DVSS Siding Shield (to protect siding)

- 26 -

Page 27

OPERATING INSTRUCTIONS

GENERAL GLASS INFORMATION

Only glass approved for use in Majestic

products may be used for replacement.

1 . The use of subsitute glass will void all product warranties.

2. Care must be taken to avoid breakage of the glass.

3. Under no circumstances should this appliance be

operated without the glass front or with a broken glass

front. Replacement of the glass (with gasket) as

supplied by the manufacturer should be done by a

licenced qualified service person.

LOUVRE REMOVAL

(Fig. 63) To remove top louvre pull louvre up and then

lift out.

2.

GLASS

PANEL

LOUVRE

Fig. 63

1.

SIDE GLASS REMOVAL

1. Shut off gas.

2. Let the fireplace cool if it has been operating.

3. Remove side top louvre. (See Louvre Removal)

4. Open the side lower louvre assembly.

5. Release the two clamps at the bottom of the window

frame by pulling down on the clamp handles.

6. Lift off the glass frame as shown.

7. To reinstall glass follow the above procedure in

reverse. (Fig. 64)

GLASS

CLAMPS

WINDOW

FRAME

FRAME

FIREPLACE

FRONT

PULL

CLAMP HOOK

PUSH

CLAMP HANDLE

WINDOW

FRAME

Fig. 64

FRONT GLASS REMOVAL

ONLY FOR SERVICE - TO CLEAN THE

GLASS THERE IS NO NEED TO REMOVE IT.

1 Shut off gas.

2. Let the fireplace cool if it has been operating.

3. Remove side glass (See Side Glass Removal).

4. Remove logs

5. Remove bottom refractory.

(CAUTION - LOGS AND REFRACTORY COULD BE HOT).

6. Remove plate cover.

7. Remove grate assembly.

8. Remove two burner assemblies and log support.

9. Remove front upper and lower window brass by

pulling off frame.

10. Undo 10/24 nuts located on side trim mounting

frame. Remove trim frame.

11. Push from front side of glass bottom into fireplace

while holding glass from inside fireplace till screw

studs are out of trim frame.

12. Lift out glass front.

13. To reinstall glass follow the above procedure in

reverse. (Fig. 65)

- 27 -

Fig. 65

Page 28

GLASS CLEANING

SIDE

REFRACTORY

REAR

REFRACTORY

BOTTOM END

REFRACTORY

BOTTOM SIDE

REFRACTORY

BOTTOM

REFRACTORY

MANIFOLD SIDE

DVRSL/DVRSR Fig. 67

It will be necessary to clean the glass periodically. During

start-up condensation, which is normal, forms on the inside

of the glass and causes lint, dust and other airborne

particles to cling to the glass surface. Also initial paint

curing may deposit a slight film on the glass. It is therefore

recommended that the glass be cleaned two or three times

with a non-ammonia household cleaner and warm water

(we recommend gas fireplace glass cleaner). After that the

glass should be cleaned two or three times during each

heating season depending on the circustances present.

Clean glass after first two weeks of

operation.

CERAMIC REFRACTORY INSTALLATION

DVRS3 (Fig. 66)

Rear refractory is already installed

from factory.

1 . Unpack ceramic refractory from its carton. HANDLE

REFRACTORY CAREFULLY.

2. Place bottom refractory manifold side onto fireplace

floor and slide under rear refractory.

3. Place bottom sides onto fireplace floor.

4. Place bottom end refractory onto fireplace floor.

Rear and side refractory are already

installed from factory.

1 . Unpack ceramic refractory from its carton. HANDLE

REFRACTORY CAREFULLY.

2. Place bottom rear refractory manifold side onto fireplace floor and slide under rear refractory.

3. Place bottom side refractory onto fireplace floor.

4. Place bottom end refractory onto fireplace floor.

BOTTOM SIDE

REFRACTORY

BOTTOM END

REFRACTORY

BOTTOM

REFRACTORY

MANIFOLD SIDE

Fig. 67

REAR

REFRACTORY

BOTTOM SIDE

REFRACTORY

Fig. 66

- 28 -

Page 29

INSTALLATION OF LOGS

Left and right side are defined using the

manifold as reference. Facing the

manifold,the left side is on your left and the

right side is on your right.

1 . Remove left and right side glass. (See "Glass Re-

moval" section)

2. Remove logs from packaging.

As with all plastic - these are not toys and

should be kept away from children and

infants.

3. Place main log manifold side (B18).

4. Place main log (B19).

5. Place left log manifold side (B20).

6. Place left log (B21).

7. Place right log manifold side (B22).

8. Place right log (B23).

9. Place crossover log (B24).

10. Place ember material on top of burners.

Top logs must be placed properly onto

notches

RIGHT SIDE VIEW

Fig. 70

LAVA ROCK

The lava rock provided with this fireplace must be

placed on the firebox base on either side of the burner

assembly.

Under no circumstances should

this lava rock be placed on any

part of the burner assembly.

B24

B23

LEFT SIDE VIEW

B21

B19

B22

B20

B18

Fig. 68

Fig. 69

EMBER MATERIAL PLACEMENT

Separate the ember material into small pieces, roughly

1/2" in diameter and place onto the burner in front of the

front logs. Do NOT pack down, leave in fluffy, loose

conditionfor most realistic ember effect.

- 29 -

Page 30

LIGHTING AND OPERATING INSTRUCTIONS

L

FOR FIREPLACES EQUIPPED WITH SIT 820 MILLIVOLT GAS VALVE

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This fireplace has a pilot which must be lit manually.

When lighting the pilot follow these instructions exactly.

B. BEFORE LIGHTING smell all around the fireplace area for

gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any fireplace.

• Do not touch any electric switch

• Do not use any phone in your building

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the Fire

Department

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this

label

2. Turn the On/Off switch to Off position or set the

thermostat to lowest setting.

3. Turn off all electric power to the fireplace.

4. Open control access panel.

5. Remove glass door before lighting pilot. (See Glass

Door Removal).

6. Push in gas control knob slightly and turn clockwise

to "OFF".

7. Wait fifteen (15) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas, STOP! Follow "B" in the safety information

above on this label. If you don't smell gas, go to

the next step.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this fireplace if any part has been under water.

Immediately call a qualified service technician to inspect

the fireplace and to replace any part of the control system

and any gas control which has been under water.

8. Visibly locate pilot by main burner.

9. Turn knob on gas control counterclockwise

to "PILOT".

10. Push in control knob all the way and hold in.

Immediately light the pilot by repeatedly depressing

the piezo spark ignitor until a flame appears.

Continue to hold the control knob in for about one

(1) minute after the pilot is lit. Release knob and it

will pop back up. Pilot should remain lit. If it goes

out, repeat steps 5 through 8.

• If knob does not pop up when released, stop and

immediately call your service technician or gas

supplier.

• If the pilot will not stay lit after several tries, turn

the gas control knob to "OFF" and call your service

technician or gas supplier.

11. Turn gas control counterclockwise to

"ON" position.

12. Replace glass door.

13. Turn on all electric power to the fireplace.

14. Turn the On/Off switch to On position or set

thermostat to desired setting.