Vermont Casting DVR33 User Manual

REAR VENTED

DIRECT VENT

GAS FIREPLACE

DVR33

INSTALLATION INSTRUCTIONS & HOMEOWNER'S MANUAL

WARNING! IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electric switch

* Do not use any phone in your building.

* Immediately call your gas supplier from

your neighbours phone. Follow the gas

suppliers instructions.

* If you cannot reach your gas supplier

call the re department

The Vermont Castings,

Majestic products company

410 Admiral Blvd. Mississauga, Ontario, Canada. L5T 2N6

www.majesticproducts.com / www.vermontcastings.com

INSTALLER: DO NOT DISCARD THIS MANUAL - LEAVE FOR HOMEOWNER

OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS AND/OR

LIQUIDS IN THE VICINITY OF THIS OR

Installation and service must be performed

by a qualied installer, service agency or

FOR YOUR SAFETY

DO NOT STORE

ANY OTHER APPLIANCE.

your gas supplier.

10002823

9/00 Rev. 0

Vermont Castings, Majestic Products

TABLE OF CONTENTS

Thank You & Congratulations On Your Purchase of a Vermont Castings, Majestic Products Fireplace.

Please Read The Installation & Operating Instructions Carefully before Using The Appliance.

Important: Read all the instructions and warnings carefully before starting the installation. Failure

to follow these instructions fully may result in a possible re hazard and will void the manufacturers

warranty.

Appliance Installation Instructions

Important curing/burning instructions ........................................................................................3

Locating your replace ...............................................................................................................3

Fireplace dimensions ..................................................................................................................4

Clearance to combustibles ..........................................................................................................5

Mantels........................................................................................................................................5

Hearths ........................................................................................................................................5

Framing and nishing .................................................................................................................5

Final nishing .............................................................................................................................6

Gas specications .......................................................................................................................6

Gas inlet & manifold pressures...................................................................................................6

Gas line installation ....................................................................................................................6

Remote switch installation..........................................................................................................7

EB-1 electrical box connection...................................................................................................7

Converting the appliance from LP to Natural Gas......................................................................8

General Venting Information - Terminal Location.....................................................................10

Venting Installation Instructions

Connecting Direct Vent components ........................................................................................12

Rear vent applications & installation........................................................................................12

How to use the Vent Graph .......................................................................................................14

Vertical sidewall applications & installation ............................................................................14

Below grade installations..........................................................................................................17

Vertical through-the-roof applications & installation ...............................................................18

Venting components list ............................................................................................................20

Operating Instructions

Glass warning ...........................................................................................................................22

General maintenance.................................................................................................................22

Louvre removal.........................................................................................................................22

Glass/Frame removal ................................................................................................................22

Glass Cleaning ..........................................................................................................................22

Installation of logs & lava rock.................................................................................................23

Flame & temperature adjustment..............................................................................................23

Flame characteristics & appearance..........................................................................................23

Lighting instructions .................................................................................................................24

Troubleshooting guide ..............................................................................................................25

Replacement Parts

Part number list.........................................................................................................................27

Parts pictorial ............................................................................................................................29

Optional Accessories

Fan kits......................................................................................................................................30

Ceramic refractory lining..........................................................................................................31

Decorative bay window ............................................................................................................31

Remote controls ........................................................................................................................32

Decorative trim frames .............................................................................................................32

2 DVR33 10002823/0

Vermont Castings, Majestic Products

APPLIANCE INSTALLATION INSTRUCTIONS

This gas replace should be installed by a qualied installer

in accordance with local building codes and with current CAN

/CGA-B149 (. 1 or .2) Installation codes for Gas Burning

Fireplaces and Equipment. If the unit is being installed in a

mobile home the installation should comply with the current

CAN/CSA Z 240 .4 code.

FOR U.S.A Installations follow local codes and/or the current

National Fuel Gas Code. ANSI Z223.1.

FOR SAFE INSTALLATION AND OPERATION PLEASE

NOTE THE FOLLOWING:

1. This replace gives off high temperatures and should be

located out of high trafc areas and away from furniture

and draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this replace and should stay

away to avoid burns or ignition of clothing.

3. Caution, due to high glass surface temperature children

should be carefully supervised when they are in the same

room as the replace.

4. Under no circumstances should this replace be modied.

Parts removed for servicing should be replaced prior to

operating the replace again.

5. Installation and any repairs to this replace should be

carried out by a qualied service person. A professional

service person should be contacted to inspect this replace

annually. Make it a practice to have all of your gas replaces checked annually. More frequent cleaning may

be required due to excess lint and dust from carpeting,

bedding material, etc.

6. Control compartments, burners and air passages in this

replace should be kept clean and free of dust and lint.

Make sure that the gas valve and pilot light are turned off

before you attempt to clean this replace.

7. The venting system (chimney) of this replace should be

checked at least once a year and if needed your venting

system should be cleaned.

8. Keep the area around your replace clear of combustible

materials, gasoline and other ammable vapour and liquids. This replace should not be used as a drying rack for

clothing, nor should Christmas stockings or decorations

be hung on or around the replace.

9. Under no circumstances should any solid fuels (wood,

coal, paper or cardboard etc.) be used in this replace.

10. The ow of combustion and ventilation air must not be

obstructed in any way.

11. When the replace is installed directly on carpeting, vinyl

tile or any combustible material other than wood, the

replace must be installed on a metal or wood panel

extending the full width and depth of the replace.

12. This replace requires adequate ventilation and combustion air to operate properly.

13. This replace must not be connected to a chimney ue

serving a separate solid fuel burning replace.

14. When the replace is not in use it is recommended that the

gas control valve be left in the OFF position.

This appliance has been approved for

after-market mobile home installations

IMPORTANT:

PLEASE REVIEW THE FOLLOWING CAREFULLY

Remove any plastic from trim parts before turning the

replace ON.

It is normal for replaces fabricated of steel to give off

some expansion and/or contraction noises during the start

up or cool down cycle. Similar noises are found with your

furnace heat exchanger or car engine.

It is not unusual for your Majestic gas replace to give

off some odour the rst time it is burned. This is due to

the curing of the paint and any undetected oil from the

manufacturing process.

Please ensure that your room is well ventilated - open all

windows.

It is recommended that you burn your Majestic replace for

a least six (6) hours the rst time you use it. If the optional

fan kit has been installed, place the fan switch in the OFF

position during this time.

LOCATING YOUR FIREPLACE

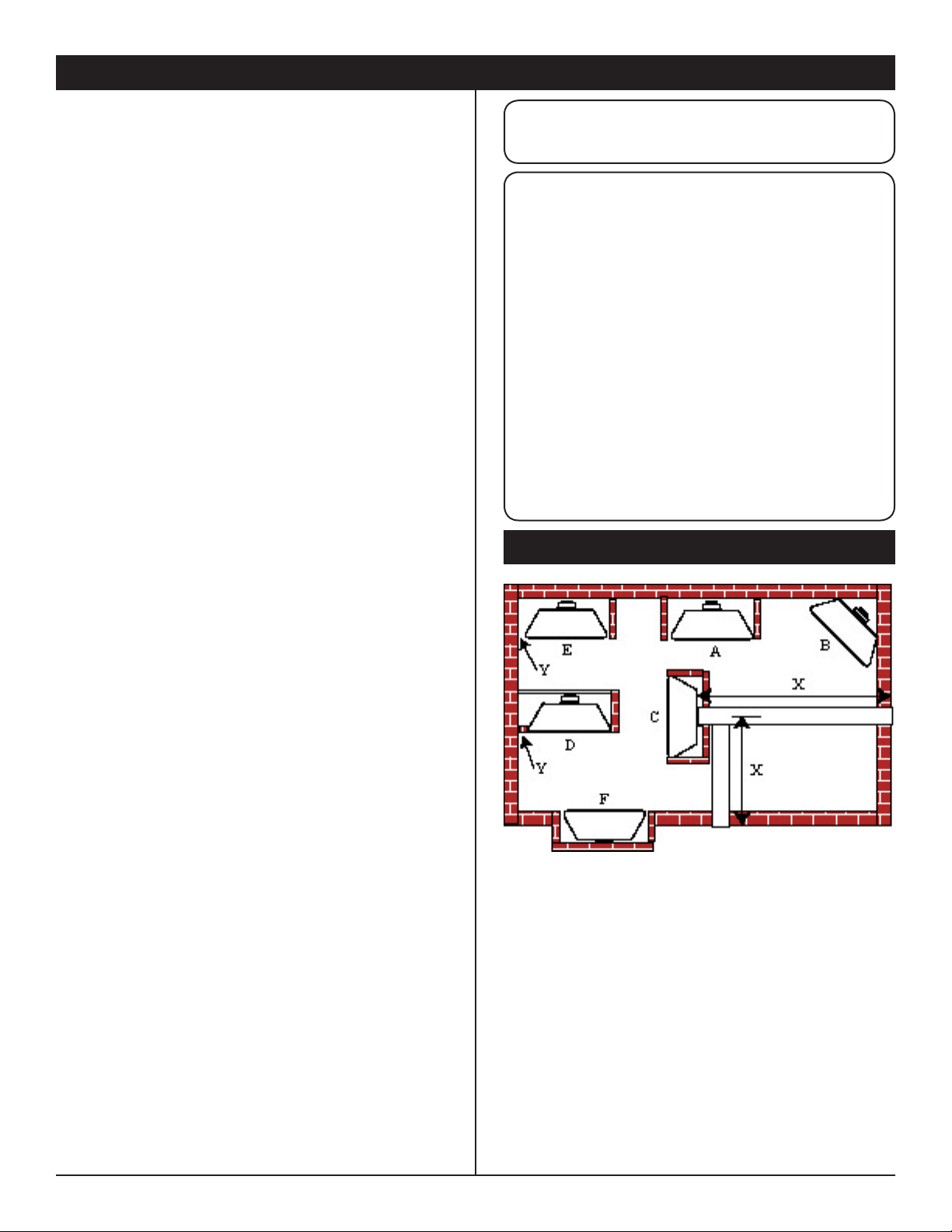

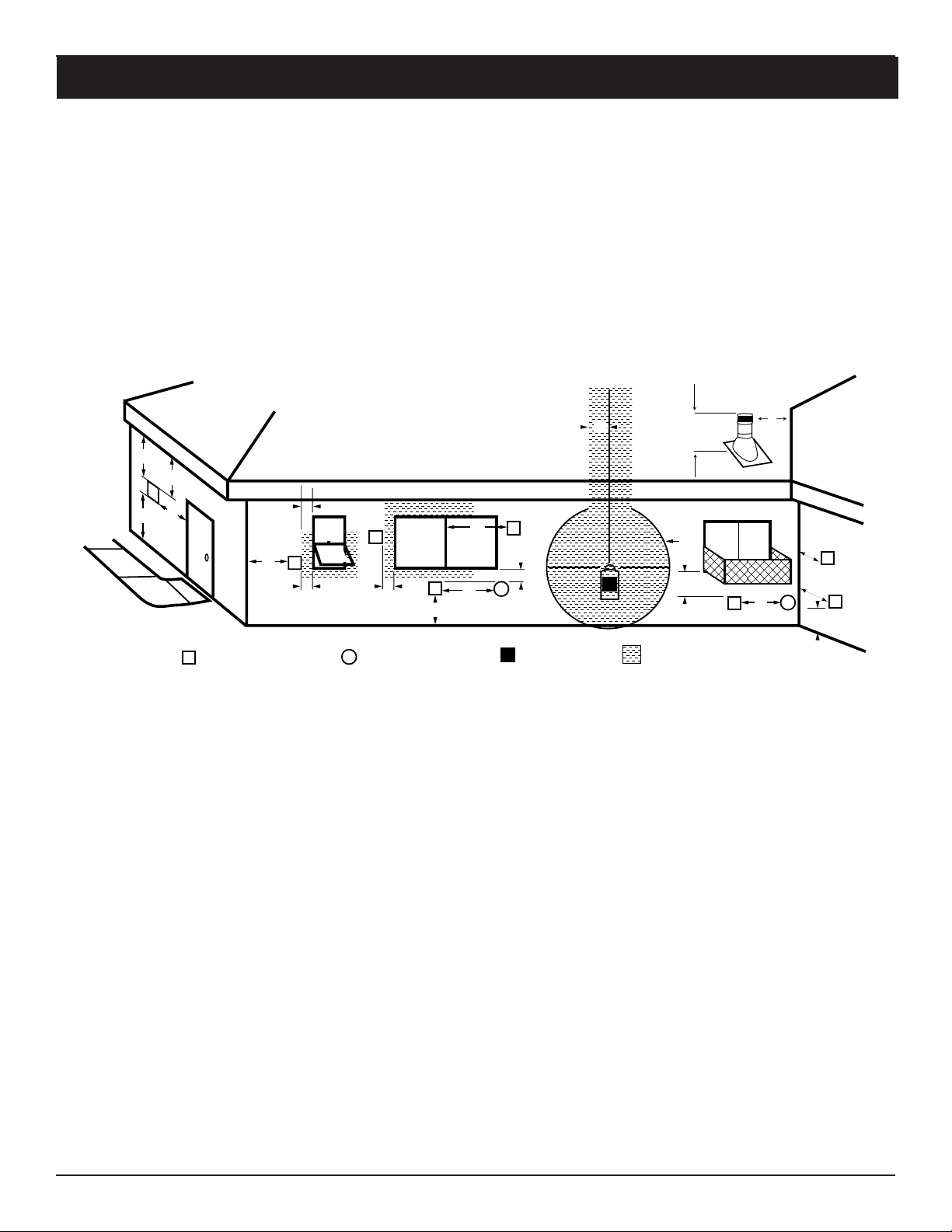

Fig. 1

A - Flat on the wall B - Cross corner

C - **Island D - *Room divider

E - *at on wall, corner F - Chase Installation

Note:

** Island (C) and room divider (D) installation is possible as

long as he horizontal portion of the vent system (X) does not

exceed 20' (6.1 m). See the venting instructions for details

* When you install the appliance in a room divider (D) or at

in a corner (E) you must have a minimum of 6" (152 mm)

between the edge of the replace and the adjacent wall (Y).

10002823/0 DVR33 3

Vermont Castings, Majestic Products

A

B

C

D

E

F

G

H

I

J

K

L

L

M

N

O

P

Q

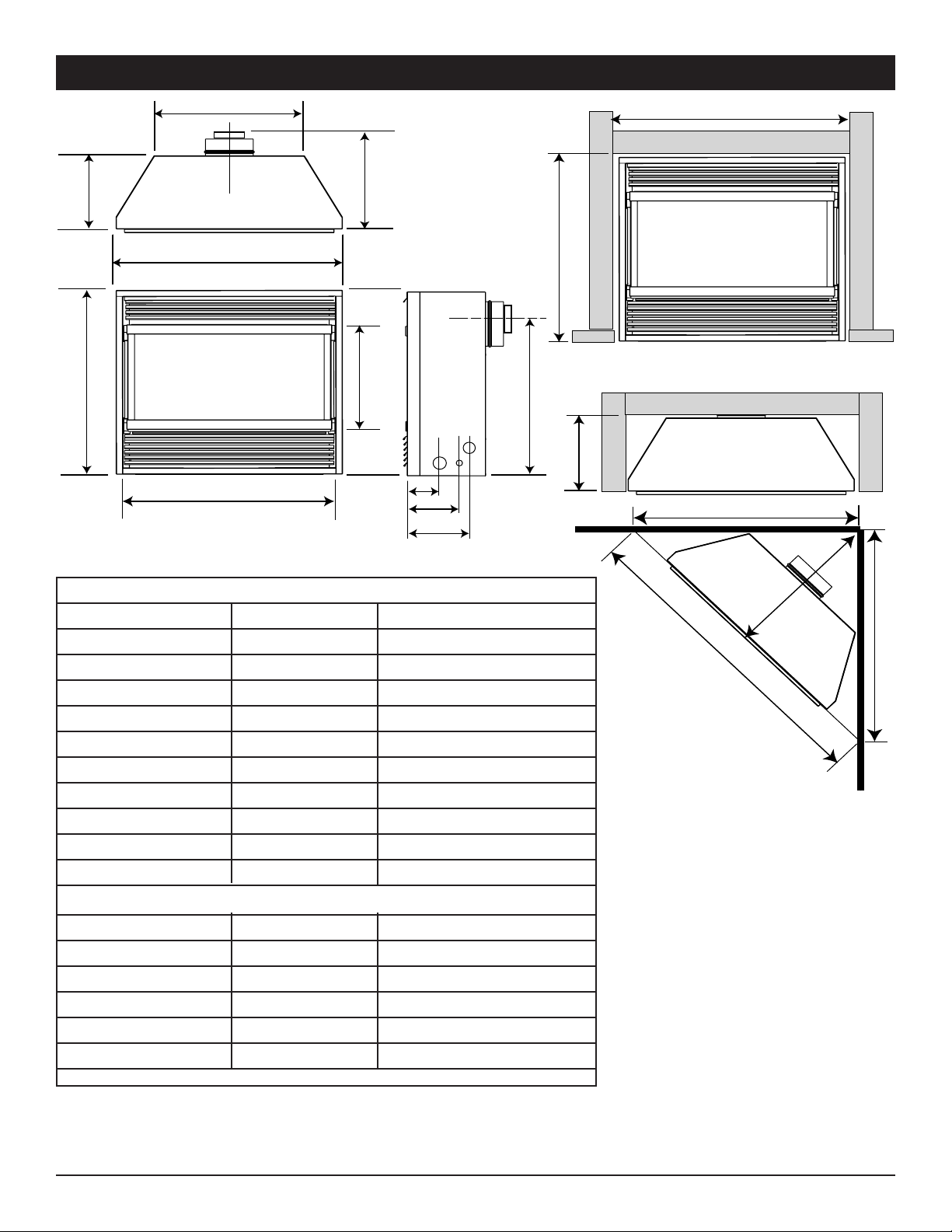

APPLIANCE & FRAMING DIMENSIONS

Appliance Dimensions DVR33

A 838 mm 33"

B 733 mm 28-7/8"

C 416 mm 16-3/8"

D 787 mm 31"

E 560 mm 22-1/16"

F 292 mm 11-1/2"

G 375 mm 14-3/4"

H 622 mm 24-1/2"

I 127 mm 5"

J 191 mm 7-1/2"

K 216 mm 8-1/2"

Framing Dimensions

L 914 mm 36"

M 1295 mm 51"

N 648 mm 25-1/2"

O 305 mm 12"

P 737 mm 29"

Q 851 mm 33-1/2"

4 DVR33 10002823/0

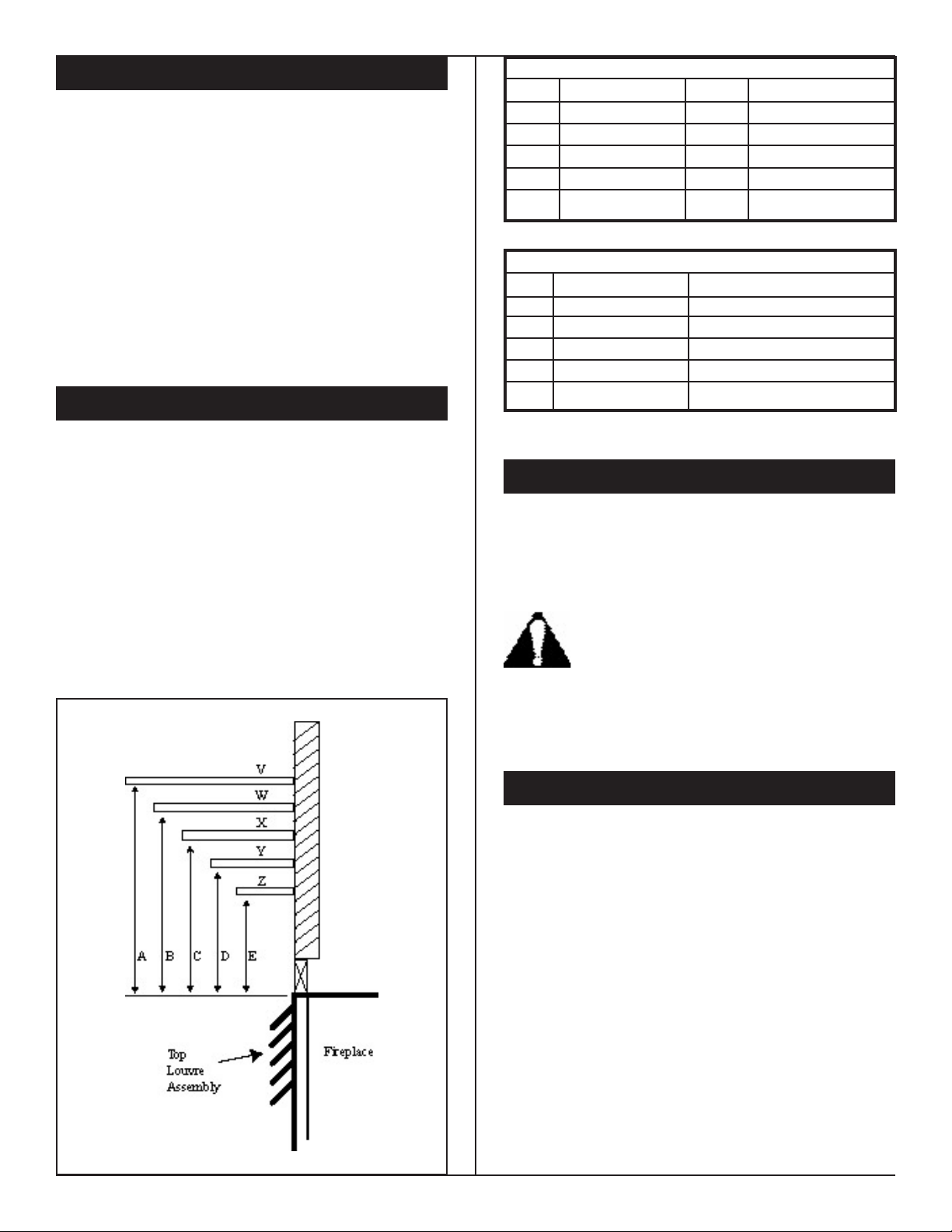

CLEARANCE TO COMBUSTIBLES

Mantel Leg Dimensions (Minimum Width

Ref. Mantel Leg Depth Distance From Edge of Glass

A 10" (254 mm) 10" (254 mm)

B 8" (203) mm) 8" (203 mm)

C 6" (152 mm) 6" (152 mm)

D 4" (101 mm) 4" (101 mm)

E 2" (51 mm) 2" (51 mm)

Mantel Shelf Chart (Minimum Height)

Ref. Mantel Depth Ref. Height above louvre

V 10" (254 mm) A 12" (305 mm)

W 8" (203 mm) B 10" (254 mm)

X 6" (152 mm) C 8" (203 mm)

Y 4" (101 mm) D 6" (152 mm)

Z 2" (50 mm) E 4" (101 mm)

Appliance

Top.................................... 0 mm (0")

Bottom .............................. 0 mm (0")

Vent End ...........................0 mm (0")

Non-vent End.................... 0 mm (0")

Venting

Concentric sections of DV Vent

Top, sides & bottom .........25 mm (1")

Non-concentric sections of DV Vent

Sides and bottom .............. 25 mm (1")

Top.................................... 50 mm (2")

MANTELS

The height that a combustible mantel is installed above the

replace is dependent on the depth of the mantel. This also

applies to the distance between the mantel leg (if tted) and

the replace.

For the correct mounting height refer and widths refer to Fig. 2

and the Mantel Chart below.

The tting of a bay window trim kit does not effect the

distances and reference points referred to in the diagram and

chart.

Non-combustible mantels and legs may be installed at any

height and width around the appliance.

When using paint or lacquer to nish the mantel, such paint

or lacquer must be heat resistant to prevent discolouration.

Vermont Castings, Majestic Products

HEARTH

A hearth is not mandatory but it is recommended for aesthetic

purpose. We recommend a non-combustible hearth which

projects out 12" (305 mm) or more from the front of the

replace.

Cold climate Installation Recommendation:

When installing this unit against a non-insulated exterior wall or chase, it is mandatory

that the outer walls be insulated to conform to

applicable insulation codes.

10002823/0 DVR33 5

FRAMING AND FINISHING

1 Choose the unit location.

2 Place the unit into position and secure it to the oor with

1.5" (38 mm) screws, or nails. The holes to secure the

unit to the oor are located just behind the access door

grille on the left and right side of the unit.

3 Frame in the replace with a header across the top. It is

important to allow for the nished wall face when setting

the depth of the frame.

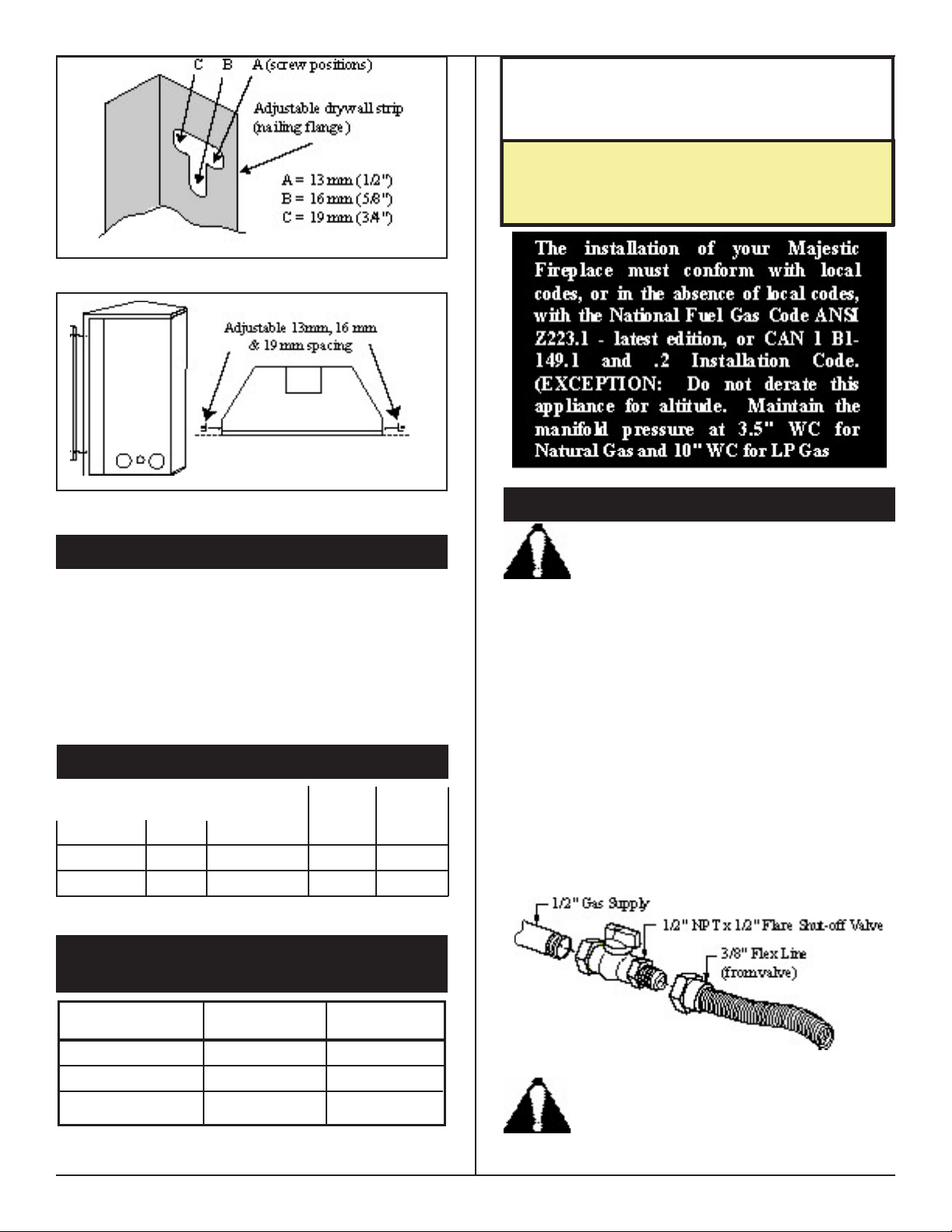

4 Attach the replace to the frame using the adjustable

frame drywall strips (located behind the access door for

shipping). Preset the depth to suit the facing material of

the wall. The strips are adjustable to 1/2"(13 mm), 5/8"

(16 mm) or 3/4" (19 mm), Fig. 3 & 4

5 Screw through the slotted holes in the drywall strip and

into the pre-drilled holes in the replace side. Measure

from the face of the replace to the face of the drywall

strip to conrm the nal depth.

Fig. 2

Vermont Castings, Majestic Products

DVR33

CERTIFIED TO

ANSI Z21.88b-1999 / CSA Z2.33b-M99

Vented Gas Fireplace Heaters

Inlet Minimum

Inlet Maximum

Manifold Pressure

Natural Gas

LP (Propane)

4.5" WC

7" WC

3.5" WC

11" WC

13" WC

10" WC

Fig. 3

Fig. 4

FINAL FINISHING

Non-combustible materials such as brick or tile may be

extended over the edges of the face of the appliance. DO NOT

cover any vent or grille panels.

If a Trim Kit is going to be installed on the replace, the brick

or tile will have to be installed ush with the edges of the

appliance.

GAS SPECIFICATIONS

Max Min

Input Input

Model Fuel Gas Control BTU/h BTU/h

DVR33RN Nat. Millivolt 20,000 14,000

DVR33RP Prop. Millivolt 20,000 15,000

GAS INLET &

MANIFOLD PRESSURES

GAS LINE INSTALLATION

When purging the gas lines, the front glass must

be removed.

The gas pipeline can be brought in through the rear of the

replace as well as the bottom. Knockouts are provided on the

bottom behind the valve to allow for the gas pipe installation

and testing of any gas connection. It is most convenient to

bring the gas line in from the rear right side of the valve as

this allows fan installation or removal without disconnecting

the gas line.

The gas line connection can be made with properly tinned

3/8" copper tubing, 3/8" rigid pipe or an approved ex connector. Since some municipalities have some additional local

codes it is always best to consult your local authority and the

CAN/CGA-B149 (.1 or .2) installation codes.

For U.S.A. Installations consult the current National Fuel Gas

Code, ANSI Z223.1

6 DVR33 10002823/0

Always check for gas leaks with a mild soap and

water solution. Do not use an open ame for

leak testing.

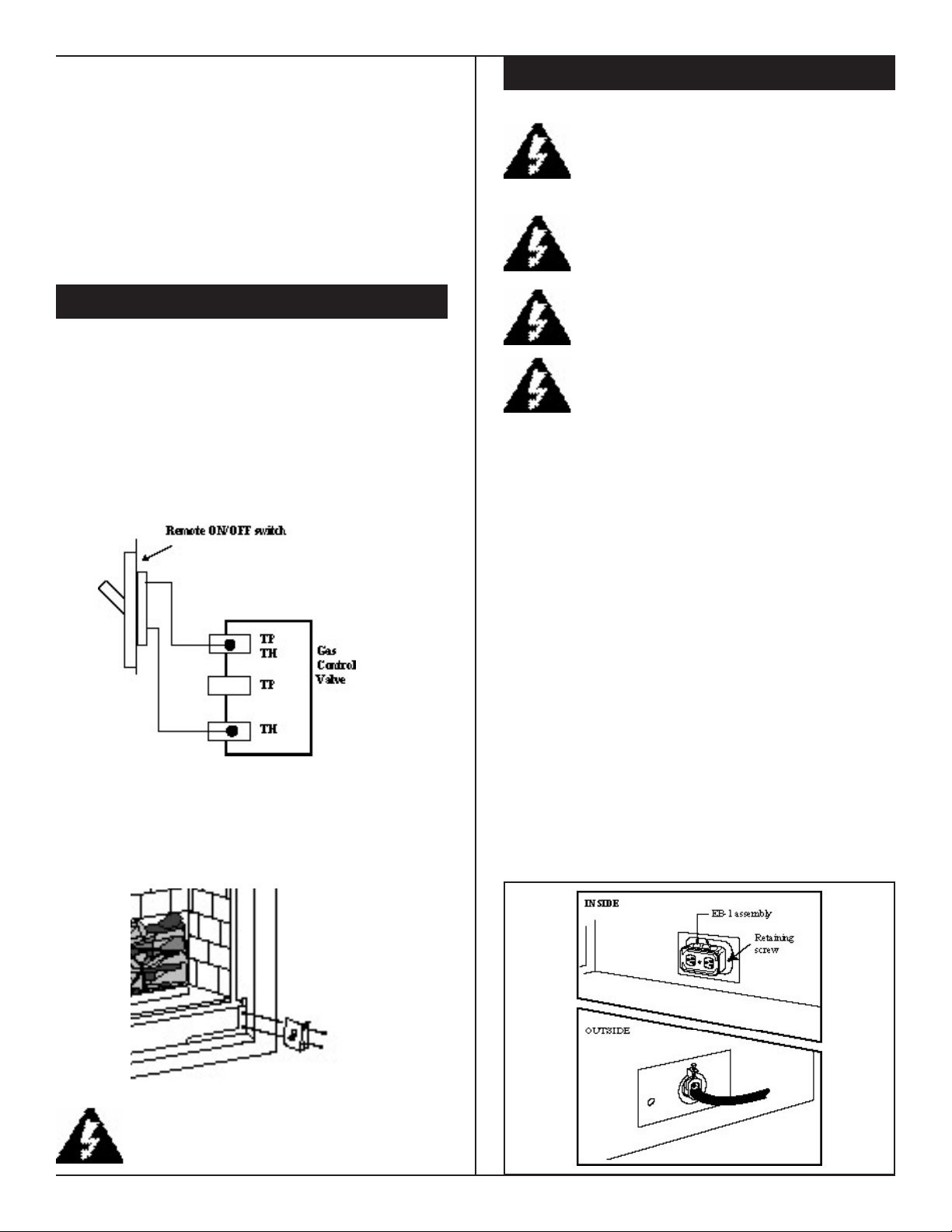

Fig. 5

Vermont Castings, Majestic Products

The gas control is equipped with a captured screw type pressure test point, therefore it is not necessary to provide a 1/8"

test point up stream of the control.

When using copper or ex connectors use only approved ttings. Always provide a union when using black iron pipe so

that the gas line can be easily disconnected for burner or fan

servicing, see Fig 5. See the gas specication for pressure

details and ratings.

The replace valve must not be subjected to any test pressures

exceeding 1/2 p.s.i.. Isolate or disconnect this and any other

gas appliance control from the gas line when pressure testing.

REMOTE ON/OFF SWITCH

Installation

1. Thread the wiring through the holes on the end panels of

the appliance. Take care not to cut the wire or insulation

on metal edges. Route the wire to a conveniently located

receptacle box.

2. Attach the wire to the ON/OFF switch and install the

switch into the receptacle box.

3. Connect the other ends of the wire to the gas control valve

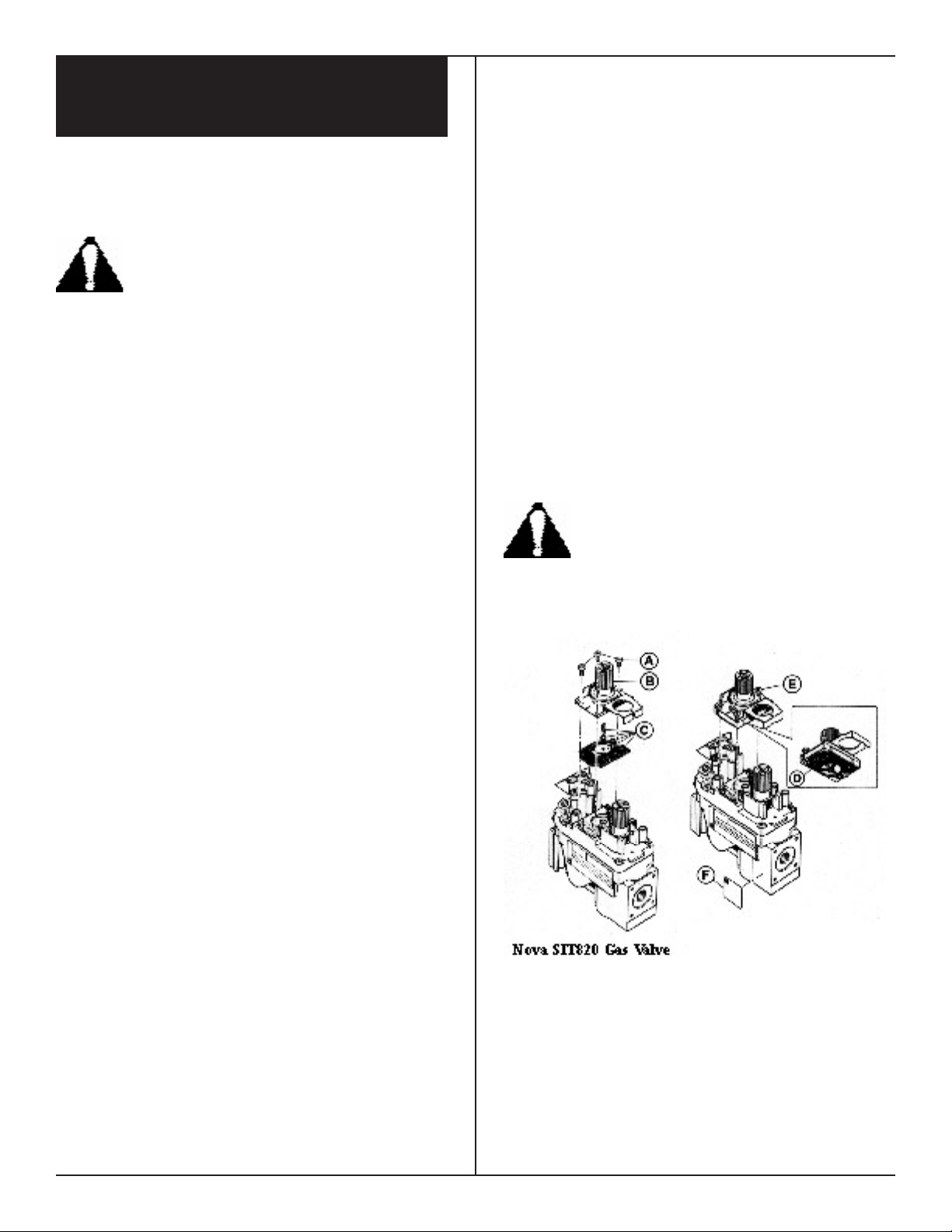

as shown in Fig. 6.

Fig. 6

Alternative Switch Location

The remote switch can be installed on the front/side of the

access door. Simply mount the switch to the bracket provided

and screw the bracket to either side of the frame, lining up the

screws with the pre-punched holes, Fig. 7.

EB-1 ELECTRICAL BOX

The replace, when installed, must be electrically connected and grounded in accordance

with local codes or, in the absence of local

codes, with the current CSA C22.1 Canadian

Electric Code.

For U.S.A. installations follow the local codes

and the national electrical code ANSI/NFPA No

70.

It is strongly recommended that the wiring of

the EB-1 Electrical Junction Box be carried out

by a licensed electrician.

Ensure that the power to the supply line has

been disconnected before commencing this procedure.

The EB-1 Electrical junction box has been supplied standard

on this model to allow for the easy installation of the optional

fan kits.

To connect the EB-1 box to the house electrical supply follow

the steps below.

1. Unscrew the retaining screw from the EB-1 base plate,

Fig. 8 and remove the EB-1 assembly from the appliance

2. Remove the front cover of the EB-1 box.

3. Remove the plug socket assembly from the EB-1 box.

4. Feed the electrical supply line in through the EB-1 opening in the side of the appliance and then through the back

of the EB-1 assembly.

5. Connect the ground wire of the supply line to the green

screw of the socket assembly.

6. Connect the white wire of the power line to the chrome

screw of the socket assembly.

7. Connect the black wire of the power supply line to the

brass screw (polarized) of the socket assembly.

8. Ret the socket assembly back into the electrical box and

replace the cover plate. Secure the cable with the clamp

on the outside of the EB-1 base plate and ret the EB-1

assembly to the appliance with the retaining screw.

Fig. 7

Do not wire the remote ON/OFF switch into any

120 volt power supply

10002823/0 DVR33 7

Fig. 8

Vermont Castings, Majestic Products

CONVERTING THE APPLIANCE

FROM LP TO NATURAL GAS

OR NATURAL GAS TO LP.

This appliance can be converted from Natural Gas to LP gas

(or LP to Natural) with the use of an approved conversion kit.

The kits are specic to individual appliances. Contact your

authorized distributor to obtain the correct kit.

The conversion of this appliance from one gas

to another must be carried out by an authorized

service provider.

1. Disconnect power to the unit and shut off the gas supply.

2. Remove the glass/frame assembly.

3. Carefully remove the logs & lava rock material

4. Remove the screws that are holding the burner housing

in place.

5. Remove the burner housing. Depending on the model of

the appliance you may have to loosen the pilot bracket

retaining screw/nut to allow the pilot and bracket assembly to tilt and give enough clearance to remove the burner

housing.

6. Remove the front and rear orice and replace them with

the corresponding orice supplied in the conversion kit.

That is, use the orice with the smallest hole (from the

kit) to replace the orice with the smallest hole (from the

appliance). Similarly, use the larger orice in the kit to

replace the larger orice in the appliance.

7. SIT Top Convertible Pilot

Gently lift off the pilot hood from the pilot. (Do not

remove the spring clip holding the hood in place). Using

a correctly sized Allen key unscrew the exposed orice.

Insert the new orice supplied in the kit, do not over

tighten the orice. Replace the pilot hood ensuring the

index tab aligns with the notch on the hood.

PSE Pilot

Using a suitable wrench on the hexagonal body unscrew

the pilot hood assembly from the pilot, do not twist the

hood itself. Remove the orice and replace it with the

new orice supplied in the kit. Ret the pilot hood

assembly. Do not over-tighten the pilot hood. The hood

must return to its original alignment. Take care not to

damage the thermocouple, thermopile or igniter.

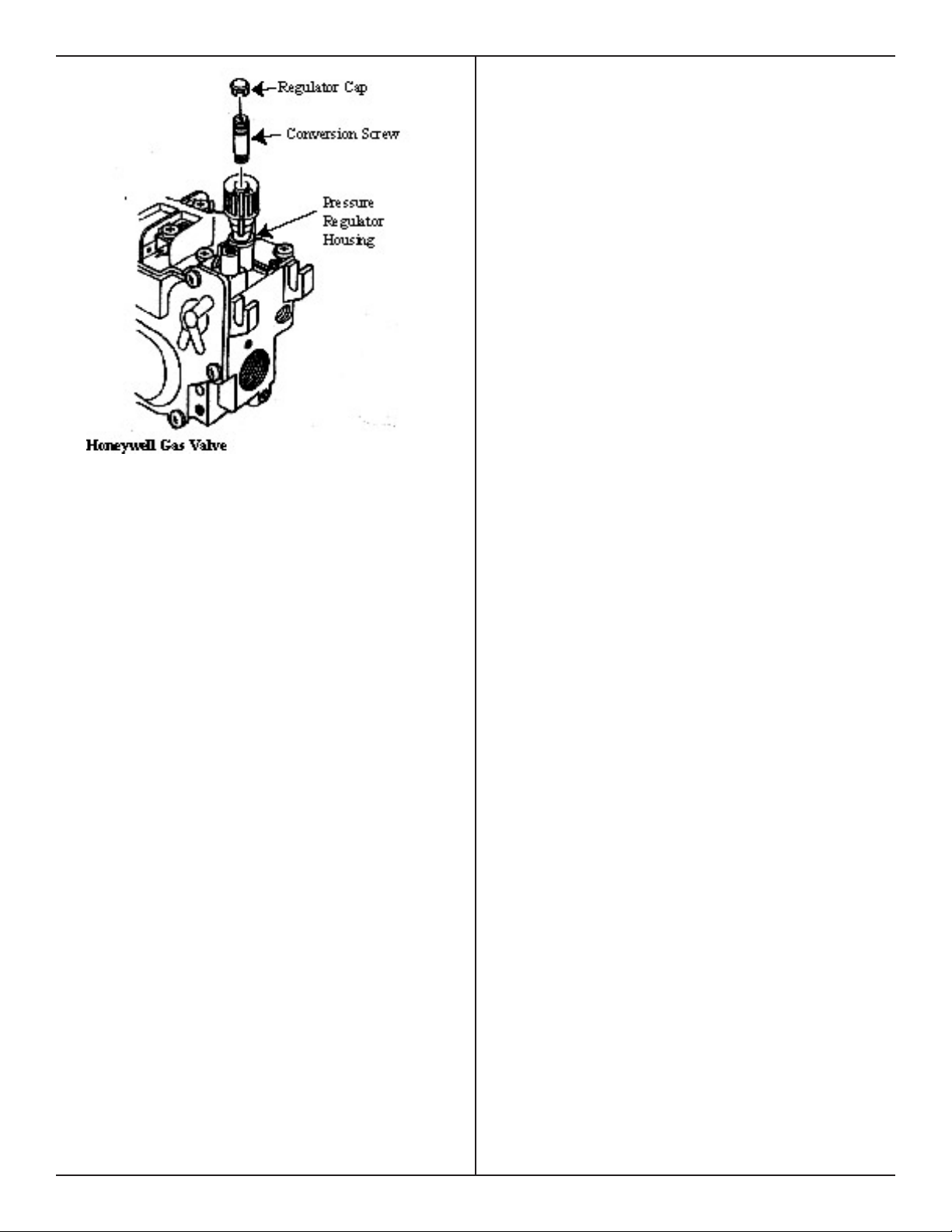

8. SIT 820 NOVA Gas Control Valve (Fig. 9)

a) Using a Torx T20 or slotted screwdriver, remove and

save the three pressure regulator mounting screws (A),

pressure regulator tower (B) and diaphragm (C).

b) Ensure the rubber gasket (D) is properly positioned and

install the new Hi/Lo pressure regulator to the valve using

the new screws (E) supplied with the kit. Tighten screws

securely. (Reference torque - 25 in.Lb).

c) Install the enclosed identication label (F) to the valve

body where it can be easily seen.

Honeywell Gas Control Valve (Fig. 10)

The Honeywell valve tted to this unit is suitable for use

with LP or Natural Gas. It is converted to the required gas

application by the installation of a colour coded "conversion screw".

a) Using a suitable small screwdriver lift out the central

regulator cap from the 'Hi - Lo' knob on the valve.

b) Unscrew the exposed 'conversion screw'.

c) Insert the new colour coded 'conversion screw'. Do not

over-tighten the screw, it must be nger tight.

d) Ret the regulator cap.

e) Mount the conversion label supplied with the conver-

sion screw to the valve in a visible position.

9. Reassemble the replace in the reverse order, except for

the front glass. Leave this off until the unit has been

checked for leaks and the gas supply line has been bled.

10. After bleeding the gas line and checking for leaks with a

soap solution, replace the front glass. Fire up the unit,

check for ame impingement on the logs, adjusting them

if necessary. Check the manifold and supply pressures

against the appliance specications.

The procedure for converting from one gas to

another is the same regardless of the initial gas

used. The only variation is in the orice sizes

and component part numbers. Your authorized

service provider will ensure the correct parts are

used.

Fig. 9

8 DVR33 10002823/0

Fig. 10

Vermont Castings, Majestic Products

10002823/0 DVR33 9

Vermont Castings, Majestic Products

V

V

V

V

V

V

V

V

V

X

X

X

D

E

B

B B

C

B

M

B

A

J

K

A

F

L

G

G

TERMINATION CAP AIR SUPPLY INLET GAS METER RESTRICTED AREA

(TERMINATION PROHIBITED)

H

I

Fixed

Closed

Fixed

Closed

O

p

e

n

a

b

l

e

Openable

Fixed

Closed

G

G

N

N

GENERAL VENTING INFORMATION — TERMINATION LOCATION

Your replace is approved to be vented either through the side

wall, or vertically through the roof.

– Only venting components specically approved and

labelled for this replace may be used.

– Minimum clearances between vent pipes and combusti-

ble materials is one (1") inch (25 mm).

– Venting terminals shall not be recessed into a wall or

siding.

– Horizontal venting must be installed on a level plane

without any incline or decline.

There must not be any obstruction such as bushes, garden sheds,

fences, decks or utility buildings within 24" from the front of the

termination hood.

Do not locate termination hood where excessive snow or ice

build up may occur. Be sure to check vent termination area

after snow falls, and clear to prevent accidental blockage of

venting system. When using snow blowers, make sure snow is

not directed towards vent termination area.

Location of Vent Termination

It is imperative that the vent termination be located observing

the minimum clearances as shown on this page.

*Check with local codes or in absence of same with CAN/

CGA B149 (.1 or .2) Installation Codes (1991) for Canada or

for U.S.A. Installations follow the current National Fuel Gas

Code, ANSI Z223.1.

A = clearance above grade, veranda, porch, deck, or bal-

cony [* 12 inches (305mm) minimum]

B = clearance to window or door that may be opened [12"

(306mm)].

C = clearance to permanently closed window [minimum 12

inches (305mm) recommended to prevent condensation

on window]

D = vertical clearance to ventilated soft located above

the terminal within a horizontal distance of 24 inches

(610mm) from the centre-line of the terminal [18 inches

(458mm) minimum]

E = clearance to unventilated soft [12 inches (305mm) min-

imum].

F = clearance to outside corner see next page

G = clearance to inside corner see next page

H = * not to be installed above a meter/regulator assembly

within 36 inches (914mm) horizontally from the centre-

line of the regulator

† a vent shall not terminate directly above a side-walk or paved driveway which is located between two single

family dwellings and serves both dwellings *

‡ only permitted if veranda, porch, deck, is fully open on a minimum 2 sides beneath the oor *

* as specied in CAN/CGA B149 (.1 or .2) Installation Codes (1991) for Canada or for U.S.A. Installations follow

the current National Fuel Gas Code, ANSI Z223.1.

Note: Local codes or regulations may require different clearances.

I = clearance to service regulator vent outlet [*72 inches

(1828mm) minimum]

J = clearance to non-mechanical air supply inlet to building

or the combustion air inlet to any other replace [ *12

inches (305mm) minimum]

K = clearance to a mechanical air supply inlet [* 72 inches

(1828mm) minimum]

L = † clearance above paved side-walk or a paved driveway

located on public property [*84 inches (2133mm) minimum]

M = clearance under veranda, porch, deck [*12 inches

(305mm) minimum ‡]

N = Clearance above a roof shall extend a minimum of 24"

(610mm) above the highest point when it passes through

the roof surface, and any other obstruction within a

horizontal distance of 18" (450mm).

10 DVR33 10002823/0

Loading...

Loading...