Page 1

DV Power Vent System

D

E

S

I

G

N

C

E

R

T

I

F

I

E

D

CER TIF IED

Model 7PDVS

WARNING!

IF THE INFORMATION IN THIS MANUAL IS

NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE,PERSONAL INJURY

OR LOSS OF LIFE.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Extinguish all flames.

• Immediately call your gas supplier from

your neighbours phone. Follow the gas

suppliers instructions.

• If you cannot reach your gas supplier call

the fire department.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPOURS AND

LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

• Installation and service must be performed

by a qualified installer, service agency or

your gas supplier.

Homeowner’s Installation and

Operating Manual

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

10003262 8/06 Rev. 3

Page 2

DV Power Vent System

General Information ....................................................................................................3

Power System Parts and Description ......................................................................... 4

Clearance to Combustibles ........................................................................................5

Table of Contents

Restrictor Plate Orifice Size and Models Chart ..........................................................

Installing the DV Power Vent System .........................................................................

Changing the Restrictor Orifice Plate .............................................................7

Install the Vent Pipes and the DV Power Vent System Box ........................... 8

Venting Up ......................................................................................................9

Venting Down ................................................................................................10

DV Power Vent System Setup .................................................................................. 11

Checking the Pressure Switch Position ........................................................ 11

Wire Connections ......................................................................................... 11

Adding Deflectors to Vent Termination .......................................................... 12

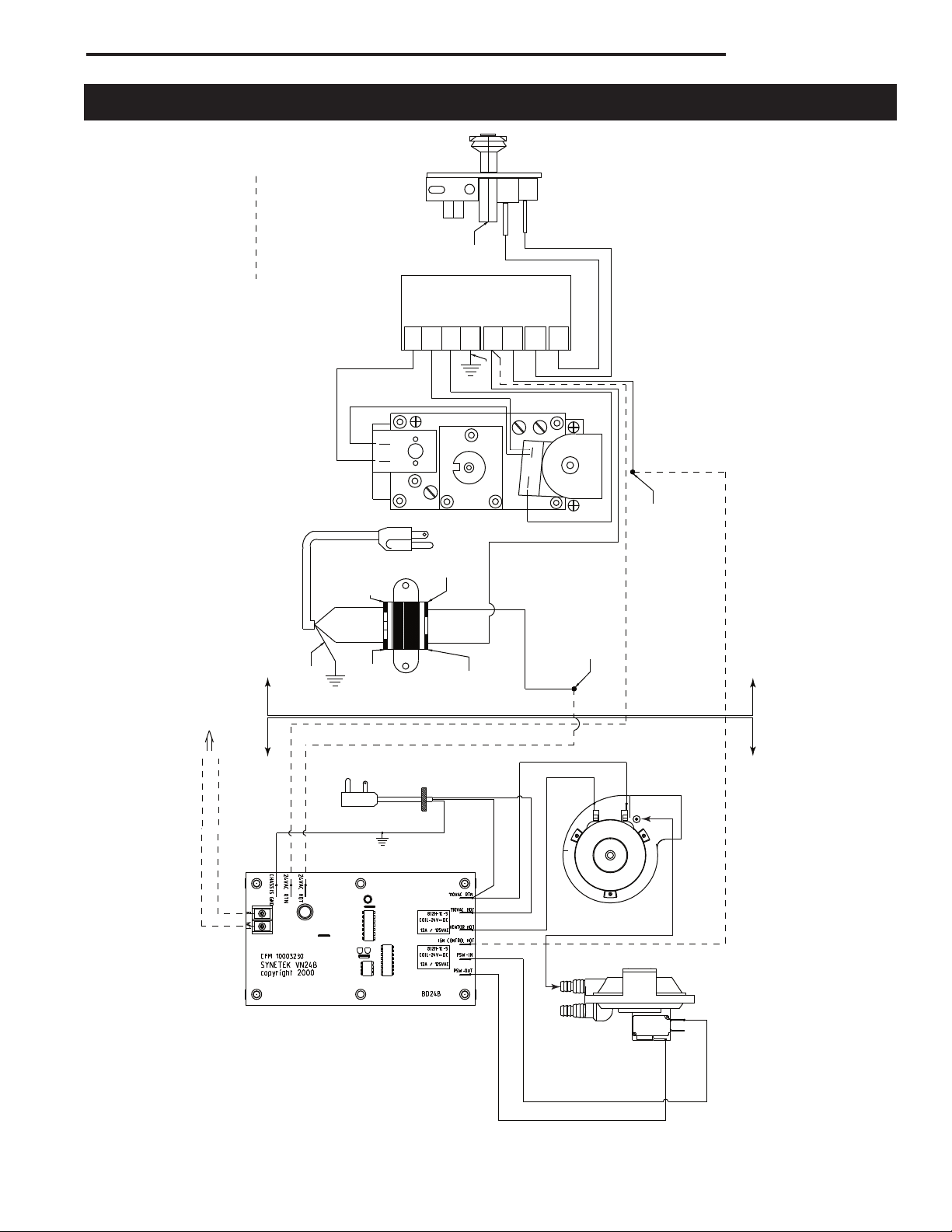

Wiring Diagram (Honeywell Ignition Module) ................................................

Wiring Diagram (Synetek Igntion Module) ....................................................14

Operation Instructions ..............................................................................................15

Maintenance ............................................................................................................. 15

Changing the Restrictor Plate Orifice After System is Installed ................................

Troubleshooting (Honeywell Electronic Ignitor) ........................................................

13

16

18

6

7

Troubleshooting (Synetek Electronic Ignitor) ............................................................

Replacement Parts ................................................................................................... 20

2

19

10003262

Page 3

General Information and Instructions for

the DV-Power Vent System Model 7PDVS

DV Power Vent System

• This DV Power Vent System was designed to be

used only on units with electronic ignition (EN or EP).

• This DV Power Vent System was certified by CSA

to be used only with CFM Corporation Direct Vent

models, as listed in this manual.

• This DV Power Vent System can be used with any

CFM Corporation side wall vent termination kits,

vertical vent termination kits or snorkel kits (rear vent

termination not to be used).

• This DV Power Vent System must be installed by a

qualified professional according to these instructions.

• Plan the venting layout before starting the installa-

tion.

• Maximum TOTAL allowable system length is 40FT

of straight pipe, plus up to five 90 degree elbows.

Any combination of 45 and 90 degree elbows up to a

maximum of 450 degrees is allowed. It is NOT permissible to substitute elbows for length of horizontal

or vertical straight pipe.

• Can be vented down to a maximum of 12FT, meas-

ured from the center line of the highest section to the

centre line of the lowest section between the fireplace

and the DV Power Vent box.

• Minimum vent length of straight pipe between fire-

place and the DV Power Vent box is:

10 feet for units with input up to 33,000BTU/h;

15 feet for units with inputs from 33,000BTU/h

to 40,000BTU/h.

• Maximum vent length of straight pipe between the

DV Power Vent System box and the vent termination

is 6 FT.

• Only vent components manufactured by CFM Corpo-

ration are approved for use with this DV Power Vent

System.

• All 4” and 7” venting connections (twist-lock or

crimped ends) to be sealed with high temperature

silicone.

• The 4” and 7” pipes connected to the inlet side of the

DV Power Vent System box to be fitted inside the 4”

pipe and the 7” collar.

• Leave a permanent access for inspection and service

of the DV Power Vent System box.

• Confined area definition: when the distance of the

four walls around the sides of the Power Vent Box to

the stand-offs is 3” or less in average.

• When the DV Power Vent box is installed in a con-

fined area, the access door needs to have a minimum size of 12” X 12” and it must be ventilated with

a minimum of 10% open area. In a confined area

installation a minimum distance of 12” (1FT), needs

to be left between the Power Vent Box and the fifth

wall. (Refer to Figures on Page 5).

• When the DV Power Vent box is installed in an un-

confined area, the access door doesn’t need to be

ventilated.

• The power vent motor shaft MUST ALWAYS BE ori-

ented horizontally for proper operation.

• The pressure switch diaphragm MUST ALWAYS BE,

in a vertical position and the hose connection pointing down, NEVER up.

• Disconnect power supply when installing or servicing

the fireplace or the power vent system.

10003262

3

Page 4

DV Power Vent System

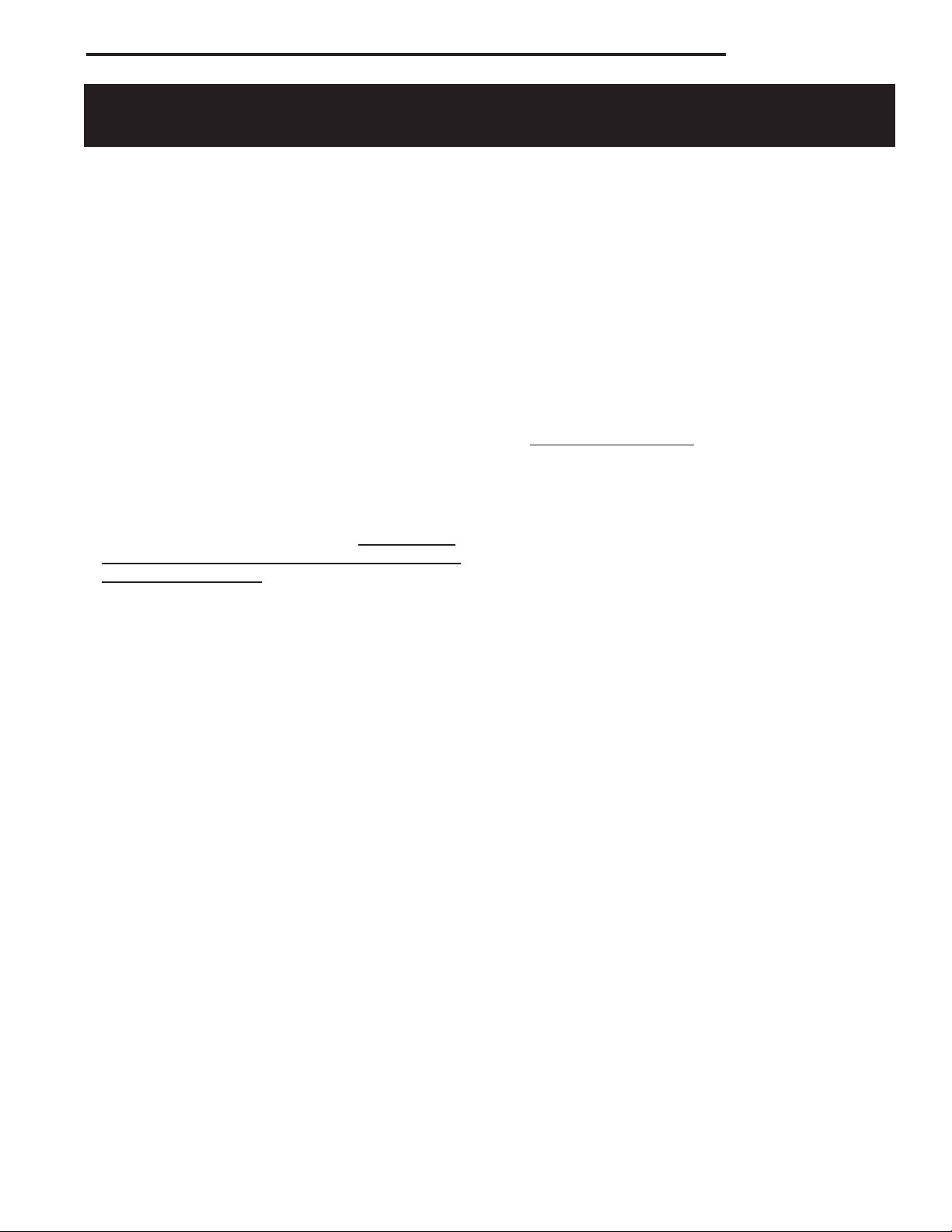

DV Power Vent System Parts and Description:

1. DV POWER VENT box assembled with a 6FT power cord.

2. Two deflectors to be added to the side wall vent termination.

3. Assorted restrictor orifice plates to be used according to the instructions for specific models.

4. Installation and Operating Instruction Manual.

1

4

3

2

4

10003262

Page 5

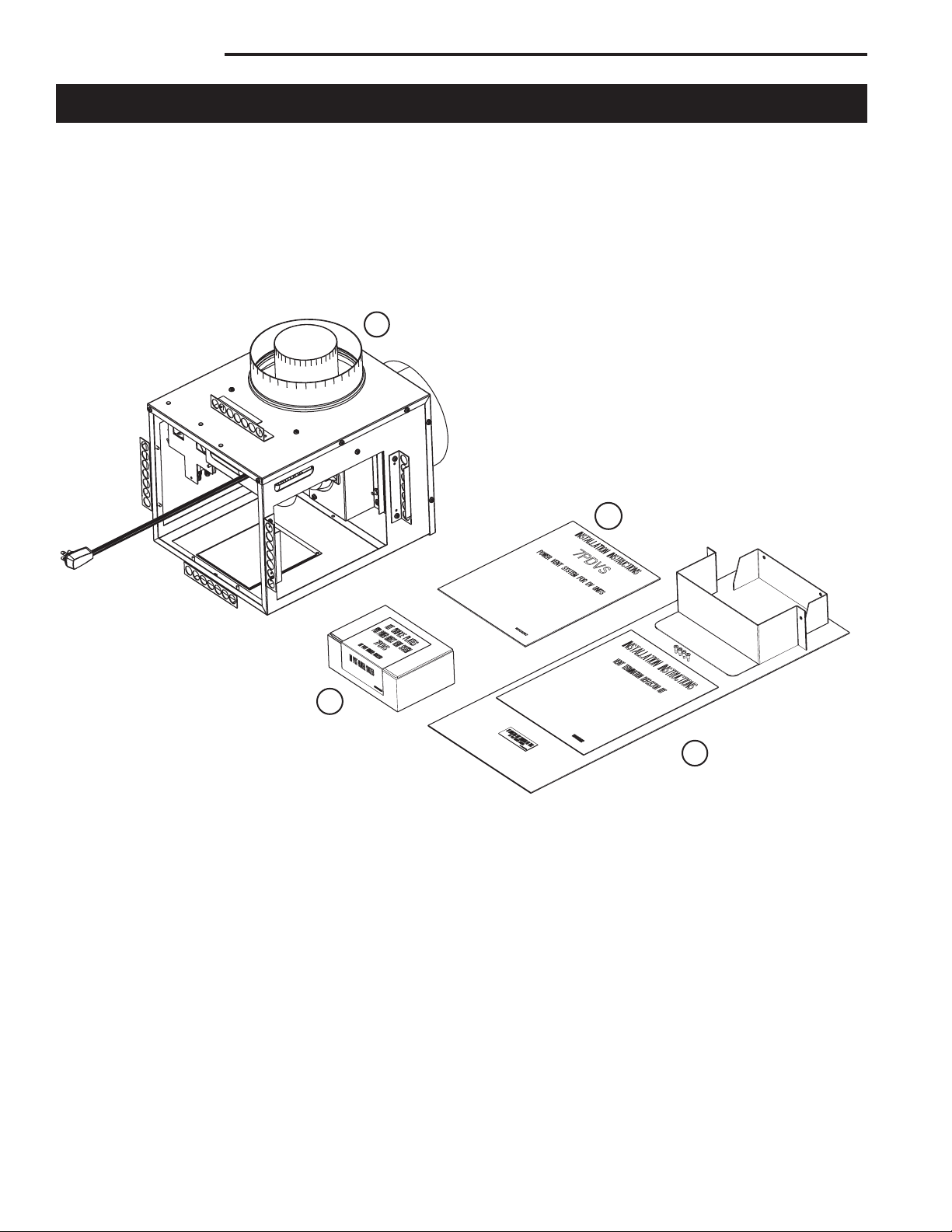

DV Power Vent System

12"

Min.

12"

Min.

Clearance to Combustible Materials and Access Door

• The DV Power Vent System box needs a minimum 1” clearance all around the box.

The DV Power Vent System box already has a 1” stand-off on all sides.

• Pipes from the fireplace to the DV Power Vent System box and from the box to the vent termination need:

• Clearance to combustible materials of 1” all around the pipe on vertical sections.

• Clearance to combustible materials of 1” on sides and bottom, and 2” on the top of horizontal sections.

Confined Area Access Door Suggestions

10003262

5

Page 6

DV Power Vent System

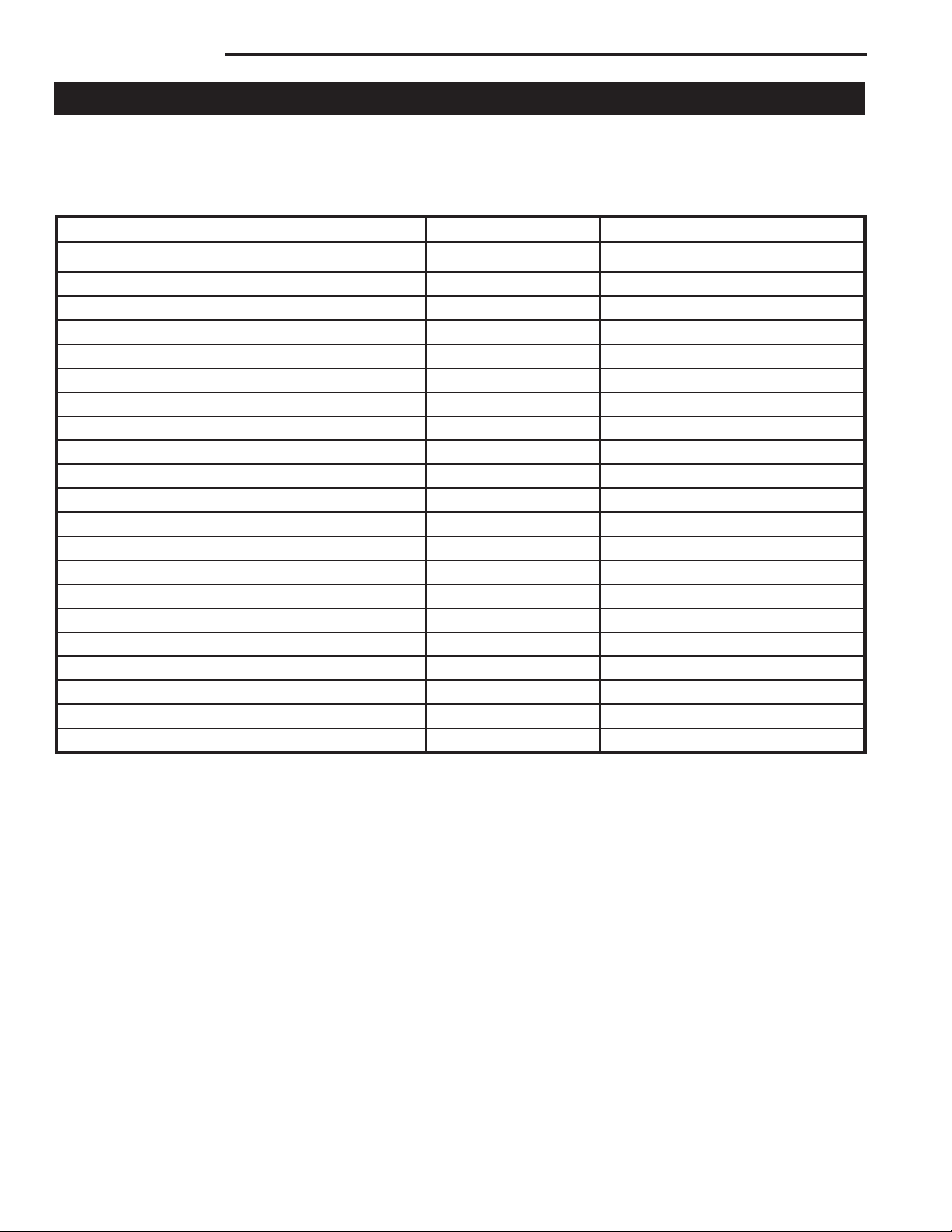

Restrictor Orifice Sizes and Models

After you plan the venting lay-out and before the installation of the power vent box, check the following chart to make

sure the correct orifice is installed.

The power vent box is shipped with the 29/32” restrictor plate orifice in place, used for 36LDVT or 36LDVR models.

For all other models, replace the restrictor plate orifice with the correct size according to the following chart:

Models Input (BTU/h) Restrictor Orifice Size

33BDVT or 33BDVR 15,000 23/32”

36BDVT or 36BDVR 18,000 29/32”

DVR33 20,000 31/32”

39BDVT or 39BDVR 22,000 31/32”

43BDVT or 43BDVR 25,000 1”

DVRT36 25,000 1”

DV360 30,000 1

DVRT39 30,000 1¹⁄₃₂”

DVRT43 33,000 1

360DVS2 or 360DVS3 or 360DVSL or 360DVSR 38,000 1

DV580 38,000 1

33LDVR or 33LDVT 16,000 29/32”

36LDVR or 36LDVT 19,500 29/32”

39LDVR or 39LDVT (NG) 23,000 31/32”

39LDVR or 39LDVT (LP) 22,500 31/32”

43LDVR or 43LDVT (NG) 26,000 1”

43LDVR or 43LDVT (LP) 24,000 1”

33XDVR 21,500 31/32”

33XDV 21,500 31/32”

36XDV 27,500 1

39XDV 31,000 1

¹⁄₃₂”

¹⁄₁₆”

¹⁄₄”

¹⁄₄”

³⁄₈”

¹⁄₃₂”

6

10003262

Page 7

Installing the DV Power Vent System

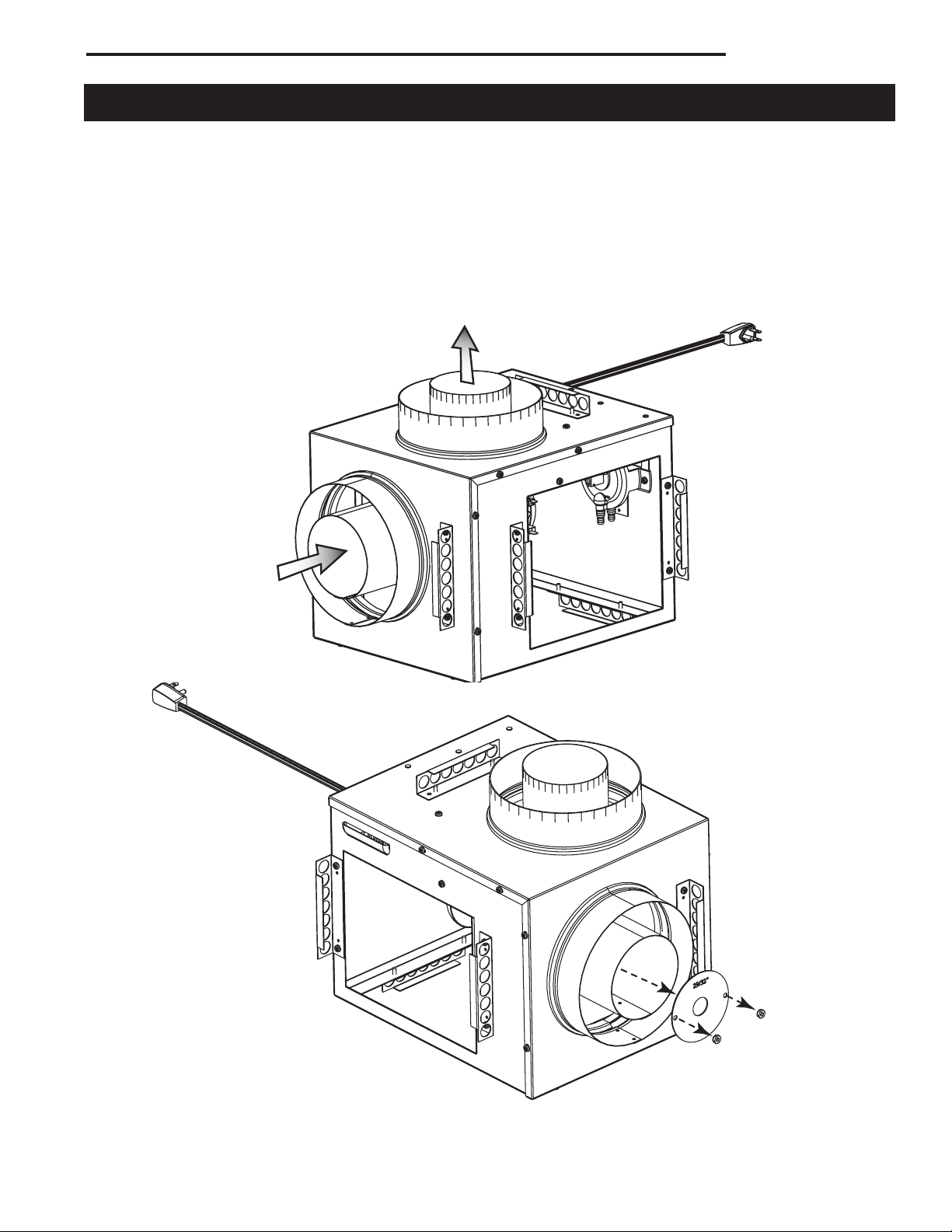

1-Changing the Restrictor Orifice Plate:

Before installation of the power vent box (RECOMMENDED):

A. From the inlet side, remove the two 3/8” nuts holding the orifice plate.

B. Remove the orifice plate.

C. Install the correct restrictor orifice plate according to the chart above.

D. Place back the two nuts to hold the restrictor orifice plate and tighten.

Outlet

(To vent termination)

DV Power Vent System

Inlet

(From fireplace)

10003262

7

Page 8

DV Power Vent System

Inlet

Outlet

Inlet

Outlet

Inlet

Outlet

Inlet

Outlet

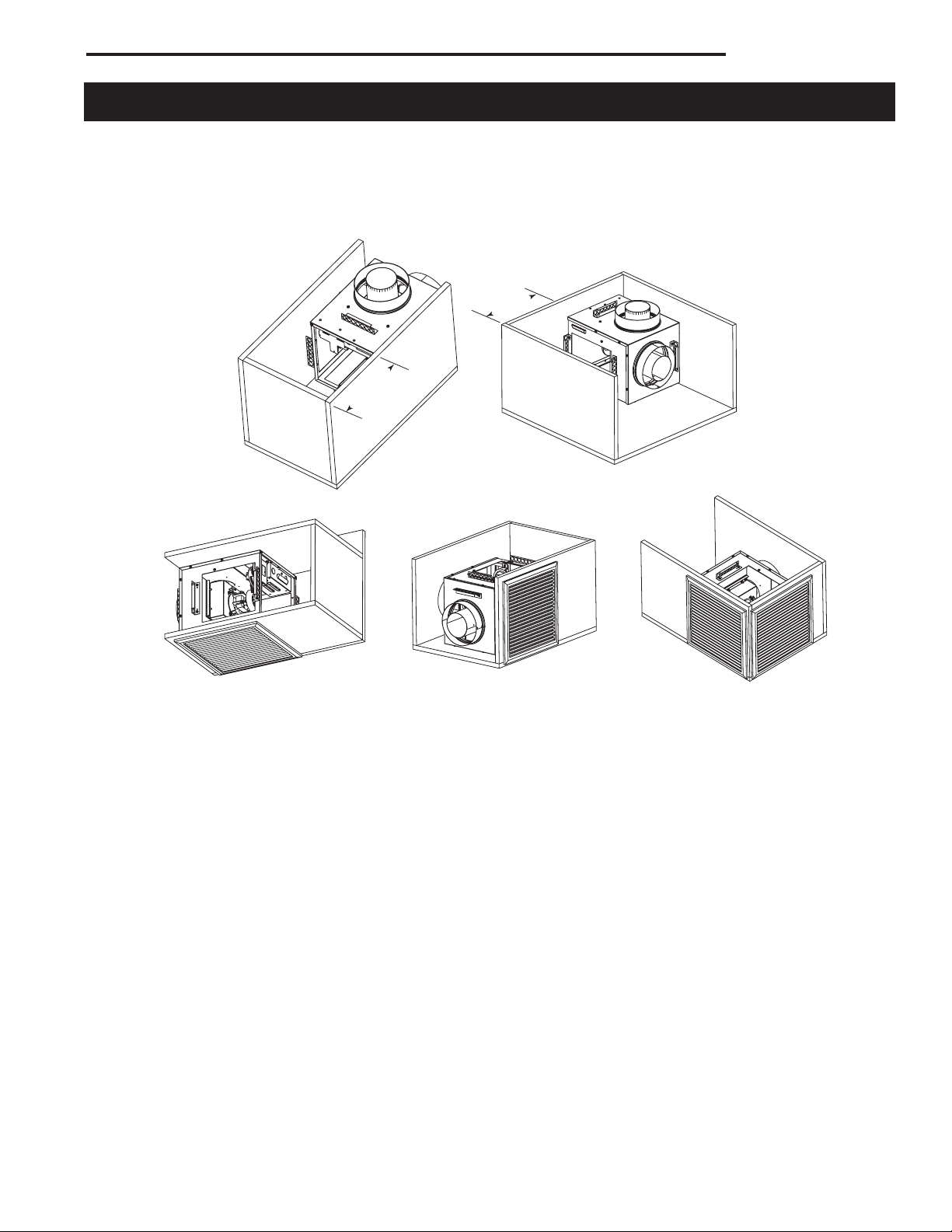

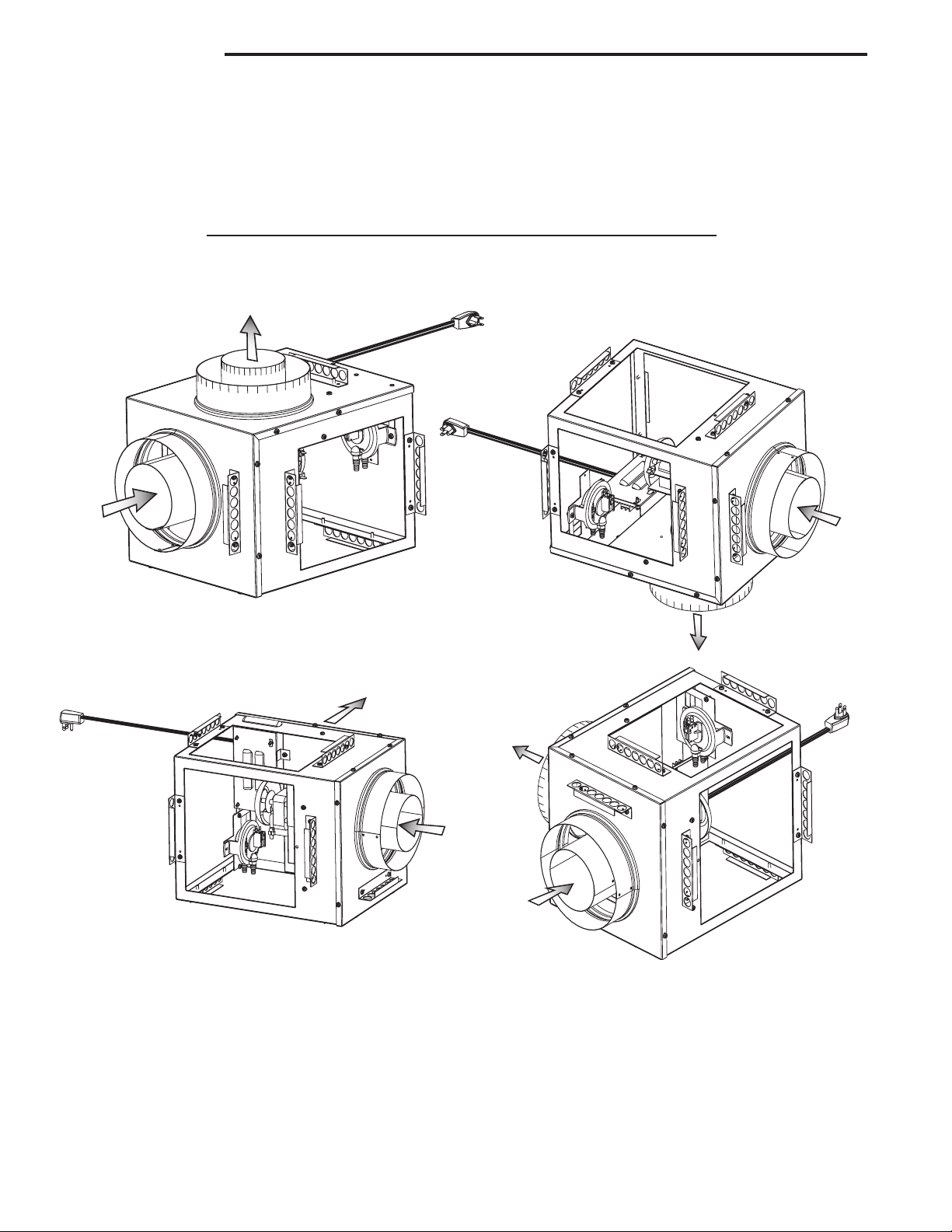

2-Install the Vent Pipes and the DV Power Vent System Box:

Install pipes and elbows according to the lay-out from

the unit to the Power Vent System Box and from it to

the vent termination. Follow the vent installation according to the fireplace manual recommendations.

Four different ways to install the Power Vent System Box.

Remember that the blower shaft MUST ALWAYS BE in

a horizontal plane and the pressure switch diaphragm

MUST ALWAYS BE in a vertical plane with the hose

connections pointing down.

8

10003262

Page 9

L

6

L

7

L

5

L

2

L

4

L

3

L

1

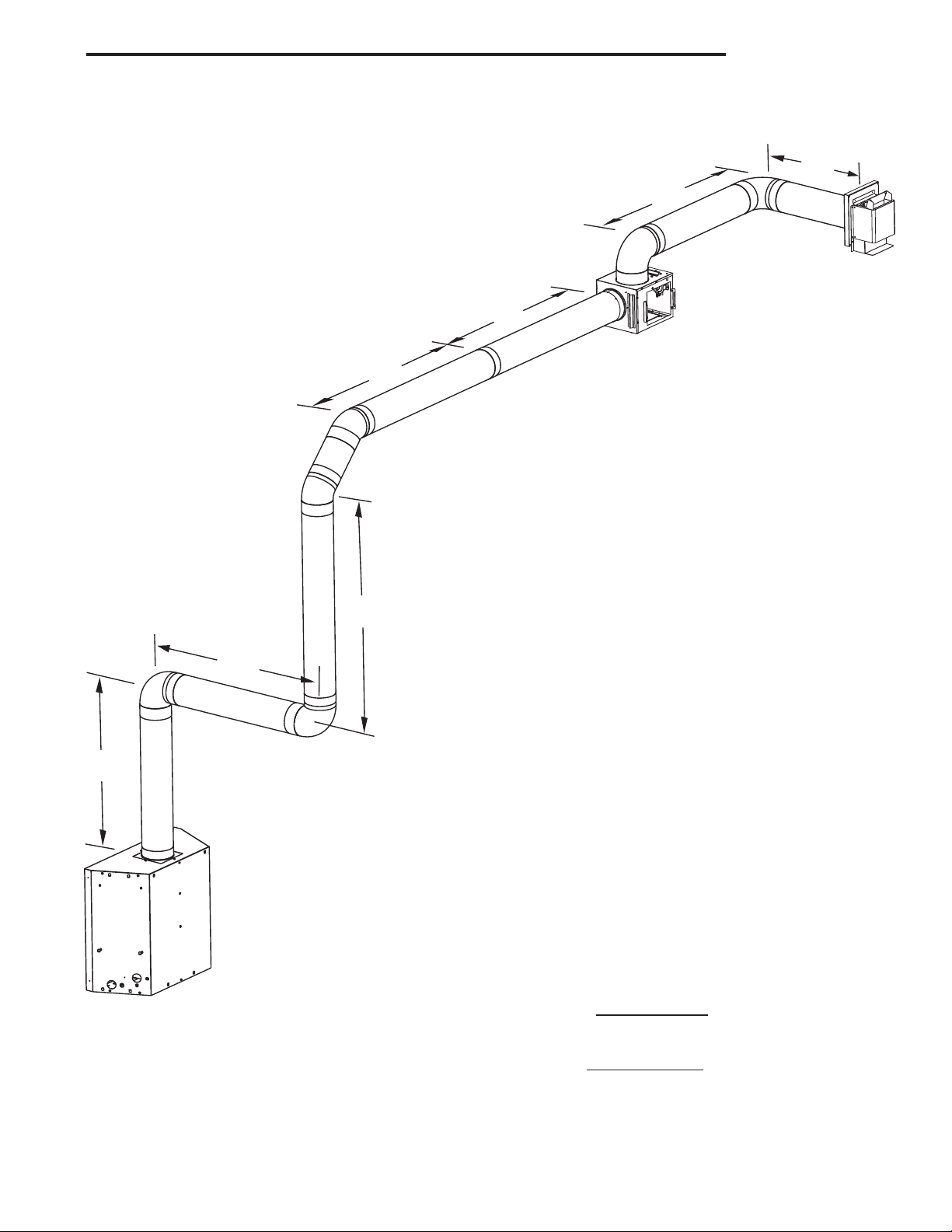

Venting Up:

A - Maximum 40FT of straight pipe.

DV Power Vent System

B - Minimum 10FT of straight pipe for units up to 33,000BTU/h,

Minimum 15FT of straight pipe for units from 33,000BTU/h

to 40,000BTU/h.

A = L1+L2+L3+L4+L5+L6+L

B = L1+L2+L3+L4+L

C = L6+L

7

In the above example there are:

4 times 90 degrees elbows = 360 degrees

2 times 45 degrees elbows = 90 degrees

Total elbow degrees = 450 degrees

Installation is OK

C - Maximum 6FT of straight pipe.

7

5

10003262

9

Page 10

DV Power Vent System

L

6

L

5

L

2

L

4

L

3

L

1

Venting Down:

A - Maximum 40FT of straight pipe.

B-Minimum 10FT of straight pipe for units up to 33,000BTU/h,

Minimum 15FT of straight pipe for units from 33,000BTU/h

to 40,000BTU/h.

C-Maximum 6FT of straight pipe.

D-Maximum 12FT down.

A = L1+L2+L3+L4+L5+L

B = L1+L2+L3+L

C = L5+L

D = L1+L

6

2

6

4

In the above example there are:

4 times 90 degrees elbows = 360 degrees

2 times 45 degrees elbows = 90 degreees

Total elbow degrees = 450 degrees

Installation is OK

10

10003262

Page 11

DV Power Vent System

Screw

Nut

3- DV Power Vent System Setup:

3.1 - Checking the Pressure Switch Position:

The pressure switch diaphragm must be in a vertical plane.

The pressure switch hose connections should NEVER point up. The BEST position is pointing down, but can

be pointed to the sides.

Depending on the final location of the DV Power Vent System box, the pressure switch hose connection needs

to be checked. If the hose connection position needs to be adjusted, follow these steps:

1. Check the pressure switch location;

2. If the hose connection is pointing down, you do not need to change the pressure switch position;

3. If the hose connection location needs to be adjusted, remove the two screws holding the pressure switch to

the bracket.

4. Rotate the pressure switch clockwise or counterclockwise (whichever is better to reach the new position);

5. Re-attach the pressure switch to the bracket with the same screws removed in Step 4.

6. Check all wire connections according to the wiring diagram.

7. Check hose connections between the pressure switch and the blower. Make sure the hose is not kinked.

(Refer to Figure A)

3.2 - Wire Connections:

• Remove one screw and one nut that are holding the circuit board cover in place. (Refer to Figure B) Bring

the cover, with the circuit board, the power cord and all the existing wires attached to it, to a rest position.

(Refer to Figure C)

• Make all connections between the DV Power System box and the unit according to the wiring diagram. Use

18 gauge AWS wire with minimum 2/64” insulation.

• For connections to the circuit board, use 3/16” Quick Connect female spade terminals, all others are

screwed connections.

• The DV Power Vent System can be hard wired. To hard wire the DV Power Vent System, disconnect the

power cord from the circuit board and replace it with hard wiring according to the connections shown in the

wiring diagram.

Figure B

10003262

Figure A

Figure C

11

Page 12

DV Power Vent System

3.3 - Adding Deflectors to the Side Wall Vent Termination:

1. Open the plastic bag and check all components.

(One Top Deflector, one Bottom Deflector, four self-tapping screws)

2. Install the bottom deflector using two screws provided with the kit. Refer to Figure A.

3. Open the top screen and install the top deflector. Refer to Figure B. Attach the top deflector using two screws

provided with the kit.

4. After installing the top and bottom deflectors the vent termination should look like Figure C.

5. Close the top screen to the same way it was before.

CFM512

A

CFM513

B

CFM514

C

12

10003262

Page 13

COM

NO NC

BLUE

YELLOW

WHITE

RTN

HOT

BLACK

BLACK

90fl FEMALE

1/4" QC TERMINAL

YELLOW

BLACK

24 VAC RET

WHITE

GREEN

BLACK

BLACK

120 VAC HOT

GREEN

OR ON/OFF SWITCH

TO WALL THERMOSTAT

BUSHING

40VA TRANSFORMER

90fl FEMALE

BLUE

24 VAC HOT

NOVA SIT 822 VALVE

LO

HI

BLACK

9

SPARK

5 6

GREEN

42 3

ORANGE

24V

PILOT

HONEYWELL IGNITION MODULE

GND

24V

GND

PV

MV/VP

SENSE

8

1/4" QC TERMINAL

120 VAC

ORANGE

RED

MV

WIRE SPEC.:

FIELD SUPPLIED

MINIMUM INSULATION 2/64"

18 AWS SOLID, LOW VOLTAGE

& INSTALLED WIRES

WHITE

1

RTN

Power Vent Kit

Fireplace

Power Vent Kit

Fireplace

Hose

Wiring Diagram (Honeywell Ignition Module)

DV Power Vent System

10003262

13

Page 14

DV Power Vent System

COM

NO NC

BLUE

YELLOW

WHITE

RTN

HOT

BLACK

WHITE

GREEN

OR ON/OFF SWITCH

TO WALL THERMOSTAT

BUSHING

WIRE SPEC.:

FIELD SUPPLIED

MINIMUM INSULATION 2/64"

18 AWS SOLID, LOW VOLTAGE

& INSTALLED WIRES

Power Vent Kit

LED

J2

120Vac Hot

120Vac Rtn

Fan Rtn

Fan Hot

Key

Flame Sense

Chasis / Burner Ground

1/4” Male Tab

J1

24Vac Hot (R)

Thermostat (W)

Key

Pilot Valve Hot

Main Valve Hot

Pilot / Main Valve Rtn.

CFM 10007939

Synetek

Ignition Module

L1

120/220 Vac (Hot)

L2

120/220 Vac (Rtn)

Ignitor

Sensor

Burner Ground

Main Valve

Pilot Valve

Fireplace

Power Vent Kit

Fireplace

Hose

Wiring Diagram (Synetek Ignition Module)

LED Codes

ON Normal operation

2 Flash Ignition trial lockout

3 Flash Flame loss lockout

5 Flash 120V AC reversed polarity

or board not sensing ground

Steady Flash Flame detected out of al-

lowed sequence or internal

fault, hardware error

14

10003262

Page 15

DV Power Vent System

Operation of the DV Power Vent System

Turn the switch ON/OFF or the wall thermostat, to the ON position.

Blower will start immediately and will purge the unit and the vent system for 45 seconds. At that point, the pilot will light

and the main burner(s) will follow.

When the switch ON/OFF or the wall thermostat, is turned to OFF, the main burner and the pilot will shut-down immediately and the blower will run for 45 seconds to clear the flue gases before turning OFF.

If the unit is ON but the flame is unstable (ON and OFF continuously), turn the switch to the OFF position and call a

serviceman to check the installation.

Maintenance

The DV Power Vent System box is a maintenance free system. The motor bearings are pre-lubricated for extended life

and no further lubrication is required.

It is recommended however to have the system checked once a year by a qualified professional.

10003262

15

Page 16

DV Power Vent System

Changing the Orifice Plate After the DV Power Vent Box is Installed

If there is a need to change the restrictor plate orifice on the DV Power Vent System box, follow the steps below:

A. Turn the power OFF to fireplace and power vent.

B. Remove the blower’s cover (two parts):

• Remove the hose attached to the blower casing.

• Remove two screws. Refer to Figure A.

• Remove two nuts from the right side cover.

• Remove the right side cover by pulling it out. Refer to Figure B.

• Remove two nuts from the left side cover.

• Remove the left side cover by pulling it out. Refer to Figure C.

C. Remove the two nuts that hold the pressure switch bracket. Do not disconnect any wire or the hose. Just bring the

pressure switch still attached to the bracket to a rest position, to give you access to the screws that hold the blower

bracket. Refer to Figure D.

D. Disconnect the wires from the blower.

E. Remove the four screws that hold the blower bracket. Be careful not to drop the blower.

F. Slide down the blower to release it from the top extrusion and carefully bring the sub-assembly (blower with the bracket

and the gasket) to the outside of the box to replace the orifice; Be careful not to damage the gasket, otherwise you

will have to replace it. Refer to Figure E.

G. Remove the two 3/8” nuts holding the orifice plate. Refer to Figure F.

H. Get from the orifice plate kit the correct restrictor orifice size for the unit you are installing (check chart for restrictor

orifice size X unit model).

I. Install the correct orifice plate into the same location as the previous one.

J. Place back the two nuts.

K. Reinstall the blower. Make sure the exhaust of the blower is properly inserted into the opening.

L. Re-attach the blower bracket with the four screws removed in step “C”.

M. Connect the wires to the blower (see wiring diagram).

N. Re-attach the pressure switch to the original position and secure the two nuts removed in step “B”.

O. Re-install both covers to the blower:

• Install the left side and secure it with the nuts.

• Install the right side and secure it with the nuts.

• Re-attach the two screws.

• Re-attach the hose to the blower connection.

P. Check all wires according to the wiring diagram and the hose connections to make sure everything is properly

in place.

16

10003262

Page 17

Screws

Figure A

DV Power Vent System

Figure D

Figure B

Figure C

Figure E

10003262

Figure F

17

Page 18

DV Power Vent System

Troubleshooting the Power Vent System

SIT 822 Valve with Honeywell Electronic Ignitor and Synetek Power Vent Board

Service must be performed by a qualified installer, service agency or your gas supplier.

BEFORE COMMENCING TO TROUBLE SHOOT THE UNIT:

1. Check if there is power to the unit (fireplace) and to the power vent box.

2. Check if there is gas to the unit (fireplace).

3. The ignition control in the fireplace is equipped with a lockout device which will put the unit into a lockout condition after three attempts to ignite the pilot.

Follow the steps in the chart below to reset the control: Turn the On/Off switch to the off position, or turn the thermostat to the off position.

Wait 10 seconds and then turn to the “on” position.

4. If this is the first time that the unit has been fired, check the wiring of the unit against the wiring diagram before commencing troubleshooting.

START

Power vent motor

is working?

YES

ON/OFF switch or wall thermostat “ON”?

Is there 120V power to the fireplace and power vent?

NO

Are all wiring connections tight? (Turn off Power before checking)

YES

Is there 24V at the power vent circuit

board at the 24VAC Hot Terminal?

NO

Is there 24V from the transformer?

NO

Replace Transformer

YES

YES

Is there 120V Power to the motor?

NO

Replace Power Vent Circuit Board

Check Wiring

YES

Replace

Blower

Does the Pilot

Spark?

Pilot Burner

Lights?

Does Spark

Pilot Lights?

Does Main

Burner Light?

YES

YES

Stop When

YES

YES

NO

Is there 24V power at terminal

six (24V) at the ignition board?

YES

Is the lead to the spark electrode

attached or arcing to ground?

Is the electrode cracked?

NO

Replace Ignition Module

NO

Is there 24V power at terminal

3 (PV) during spark cycle?

NO

Replace Ignition Module

NO

Does pilot flame cover

the flame rod?

Check Pilot for obstruction

Check Gas Pressure

Adjust Pilot Flame

Is there 24V power at terminal

NO

1 (MV) during spark cycle?

Replace Ignition Module

NO

NO

YES

NO

Is the Pressure

Switch Closed?

YES

Replace Power

Vent Circuit Board

YES

YES

Is pilot gas line blocked?

Is pilot orifice blocked?

Are wires to valve loose

or corroded?

Is flame rod corroded?

Is pilot hood corroded?

Is flame rod insulator cracked?

Is wire to flame rod damaged?

Are wires to valve

loose or corroded?

NO

NO

Is there a blockage in the vent?

Is there water/dirt in the hose from

blower to the pressure switch?

Are hose connections loose?

Is the hose cracked?

NO

Is there manifold pressure?

Replace Gas Valve

Replace Gas Valve

NO

Replace Ignition Module

NO

NO

YES

Replace

Pressure

Switch

Check

position

of pilot.

Is orifice

blocked?

System Runs

Continuously

Until Switched

Off?

Does 24V power get interupted at terminal six (24V) at the ignition module?

18

Is the correct size of orifice restrictor installed in the power vent?

Does the pilot flame covers the flame rod?

NO

Is the flame rod wire in good condition?

Is there continuity to ground from the pilot burner?

YES

Does pressure switch open during operation?

NO

NO

Replace ignition module

YES

WARNING: Never jump the pressure switch out of this

system. Property damage, injury or death may result.

YES

Is vent partially blocked?

Is there water/dirt in hose to

pressure switch?

Are hose connections loose?

Is the hose cracked?

Replace power vent circuit board

NO

Replace

Pressure

Switch

10003262

Page 19

DV Power Vent System

Troubleshooting the Power Vent System

SIT 822 Valve with Synetek Electronic Ignitor and Synetek Power Vent Board

Service must be performed by a qualified installer, service agency or your gas supplier.

BEFORE COMMENCING TO TROUBLE SHOOT THE UNIT:

1. Check if there is power to the unit (fireplace) and to the power vent box.

2. Check if there is gas to the unit (fireplace).

3. The ignition control in the fireplace is equipped with a lockout device which will put the unit into a lockout condition after three attempts to ignite the pilot.

Follow the steps in the chart below to reset the control: Turn the On/Off switch to the off position, or turn the thermostat to the off position.

Wait 10 seconds and then turn to the “on” position.

4. If this is the first time that the unit has been fired, check the wiring of the unit against the wiring diagram before commencing troubleshooting.

START

Power vent motor

is working?

Does the Pilot

Spark?

YES

Check R & W from ignition control board are not crossed between power

vent circuit board and ignition control board. (R) 24V AC Hot must connect to 24V AC Hot at power vent circuit board. (W) Thermostat must

connect to ignition control Hot at power vent circuit board.

YES

ON/OFF switch or wall thermostat “ON”?

Is there 120V power to the fireplace and power vent?

NO

Are all wiring connections tight? (Turn off Power before checking)

Is the LED light on the ignition control board giving an error code? (Refer to Page 14)

YES

Is there 24V at the power vent circuit

board at the 24VAC Hot Terminal?

NO

NO

Is there 24V power at terminal

7 (24V) at the ignition board?

YES

Is the lead to the spark electrode

attached or arcing to ground?

Is the electrode cracked?

NO

Replace Ignition Module

YES

NO

Is the Pressure

Switch Closed?

Replace Power

Vent Circuit Board

Is there 120V Power to the motor?

Replace Power Vent Circuit Board

NO

YES

YES

NO

Replace ignition control board

Is there a blockage in the vent?

Is there water/dirt in the hose from

blower to the pressure switch?

Are hose connections loose?

Is the hose cracked?

Is the hose connected to the low

pressure side of the pressure

switch?

NO

Replace

Blower

Replace

Pressure

Switch

Pilot Burner

Lights?

Does Spark

Stop When

Pilot Lights?

Does Main

Burner Light?

System Runs

Continuously

Until Switched

YES

YES

YES

Off?

Does 24V power get interupted at terminal 7 (24V) at the ignition module?

NO

Is there 24V power at terminal

3 (PV) during spark cycle?

NO

Replace Ignition Module

NO

Does pilot flame cover

the flame rod?

Check Pilot for obstruction

Check Gas Pressure

Adjust Pilot Flame

Is there 24V power at terminal

NO

2 main valve hot during spark

cycle?

Replace Ignition Module

Is the correct size of orifice restrictor installed in the power vent?

Does the pilot flame covers the flame rod?

NO

Is the flame rod wire in good condition?

Is there continuity to ground from the pilot burner?

Does pressure switch open during operation?

Replace ignition module

NO

NO

YES

NO

NO

YES

YES

YES

Is pilot gas line blocked?

Is pilot orifice blocked?

Are wires to valve loose

or corroded?

Is flame rod corroded?

Is pilot hood corroded?

Is flame rod insulator cracked?

Is wire to flame rod damaged?

Are wires to valve

loose or corroded?

NO

YES

YES

WARNING: Never jump the pressure switch out of this

system. Property damage, injury or death may result.

NO

Is there manifold pressure?

Replace Gas Valve

Is vent partially blocked?

Is there water/dirt in hose to

pressure switch?

Are hose connections loose?

Is the hose cracked?

Is the hose connected to the

low pressure side of the pressure switch?

Replace power vent circuit board

Replace Gas Valve

NO

Replace Ignition Module

NO

YES

NO

Check

position

of pilot.

Is orifice

blocked?

Replace

Pressure

Switch

10003262

19

Page 20

DV Power Vent System

1

2

3

5

4

6

7

14

11

15

16

9

10

8

CFM Corporation reserves the right to make changes in design, materials, specifications, prices and discontinue colors and products at any time,

without notice.

7PDVS DV Power Vent System

Ref. Description 7PDVS

1. Hose High Temperature 10003405

2. Shield Heat Blower Right Assy 10003673

3. Shield Heat Blower Left Assy 10003672

4. Blower 10003214

5. Gasket Blower 10003066

6. Gasket Blower Plate 10002280

7. Pressure Switch 10003213

8. Circuit Board 10003230

9. Cover Circuit Board 10003610

10. Power Cord 10003095

11. Gasket Flue Pipe 10002237

12. Hose Clamp (Not Shown) 10003267

13. Wires (Circuit Board To Pressure Switch And Blower) (Not Shown) 10003317

14. Plate Restriction Orifice Size 29/32” 10003260

15. Kit Deflector Vent Termination 10003315

16. Kit Orifice Plates (Includes Items 17 To 25) 10003258

17. Plate Restriction Orifice Size 23/32” 10002274

18. Plate Restriction Orifice Size 25/32” 10004194

19. Plate Restriction Orifice Size 27/32” 10004195

20

10003262

Page 21

DV Power Vent System

7PDVS DV Power Vent System (continued)

Ref. Description 7PDVS

20. Plate Restriction Orifice Size 31/32” 10003261

21. Plate Restriction Orifice Size 1” 10003277

22. Plate Restriction Orifice Size 1

23. Plate Restriction Orifice Size 1

24. Plate Restriction Orifice Size 1

25. Plate Restriction Orifice Size 1

¹⁄₃₂” 10003328

¹⁄₁₆” 10003329

¹⁄₄” 10003499

³⁄₈” 10009616

10003262

21

Page 22

DV Power Vent System

22

10003262

Page 23

DV Power Vent System

10003262

23

Page 24

CFM Corporation

2695 Meadowvale Blvd. • Mississauga, Ontario, Canada L5N 8A3

800-668-5323 • www.cfmcorp.com

Loading...

Loading...