Page 1

CER TIF IED

D

E

S

I

G

N

�

C

E

R

T

I

F

I

E

D

Builder Top Vent

Direct Vent

Models: 33LDVT, 36LDVT

39LDVT, 43LDVT

INSTALLER/CONSUMER

SAFETY INFORMATION

PLEASE READ THIS MANUAL

BEFORE INSTALLING AND USING

APPLIANCE

WARNING!

IF THE INFORMATION IN THIS

MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS:

Installation Instructions and

Homeowner’s Manual

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from your neighbor’s phone. Follow

the gas suppliers instructions.

• If you cannot reach your gas

supplier call the fire department.

DO NOT STORE

OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS

OR ANY OTHER APPLIANCE.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

10007852 5/07 Rev. 9

Page 2

LDVT Series Direct Vent Gas Fireplace

Table of Contents

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING THIS APPLIANCE.

Thank you and congratulations on your purchase of a CFM Corporation fireplace.

IMPORTANT: Read all instructions and warnings carefully before starting installation.

Failure to follow these instructions may result in a possible fire hazard and will void the warranty.

Installation & Operating Instructions

Important Curing/Burning Instructions .................................................................................3

Fireplace Dimensions ..........................................................................................................4

Locating Your Fireplace ....................................................................................................... 5

Clearance to Combustibles .................................................................................................5

Mantels ...............................................................................................................................5

Hearth ............................................................................................................................... 6

Framing & Finishing ............................................................................................................6

Final Finishing .....................................................................................................................6

Gas Specifications ............................................................................................................... 6

Gas Inlet and Manifold Pressures .......................................................................................6

High Elevations ...................................................................................................................7

Gas Line Installation ............................................................................................................7

Remote Switch Installation .................................................................................................. 7

Alternate Switch Location ....................................................................................................7

EB-1 Electrical Box .............................................................................................................. 8

Electronic Gas Control Valve .............................................................................................. 8

General Venting Information

General Venting Information-Termination Location .......................................................... 10

General Information on Assembling Vent Pipes ................................................................ 11

How to Use the Vent Graph...................................... .........................................................12

Vertical Sidewall Applications & Installation ......................................................................12

Below Grade Installations.. ................................................................................................ 16

Vertical Through-the-Roof Applications & Installations ......................................................17

Venting Components .........................................................................................................20

Operating Instructions

Glass Information ..............................................................................................................21

Louvre Removal ................................................................................................................21

Window Frame Assembly Removal ...................................................................................21

Glass Cleaning .................................................................................................................. 21

Installation of Logs, Lava Rock & Ember Material ............................................................ 22

Flame & Temperature Adjustment ..................................................................................... 24

Flame Characteristics ........................................................................................................ 24

Lighting & Operating Instructions ......................................................................................26

Troubleshooting .................................................................................................................28

Fuel Conversion Instructions .............................................................................................30

Maintenance

Cleaning the Standing Pilot Control System .....................................................................31

Replacement Parts ...................................................................................................................... 32

Optional Accessories

Fan Kits .............................................................................................................................35

Wiring Instructions .............................................................................................................36

Ceramic Refractory Kits ....................................................................................................36

Remote Controls ...............................................................................................................36

Optional Trim Kits ..............................................................................................................37

Screen Door Kits ...............................................................................................................37

Filigree Louvre Kit .............................................................................................................37

Warranty ....................................................................................................................................... 39

Energuide ..................................................................................................................................... 40

2

10007852

Page 3

LDVT Series Direct Vent GaS Fireplace

�

Installation & Operating Instructions

This gas fireplace should be installed by a qualified

installer, preferably NFI or WETT (Canada) certified, in

accordance with local building codes and with current CSA-

B149.1 Installation codes for Gas Burning Appliances and

Equipment. For USA Installations follow local codes and/or

the current National Fuel Gas Code. ANSI Z223.1/NFPA 54.

In the Commonwealth of Massachusetts, all gas fitting

and installation of this heater shall only be done by a

licensed gas fitter or licensed plumber.

FOR SAFE INSTALLATION AND OPERATION PLEASE

NOTE THE FOLLOWING:

1. This fireplace gives off high temperatures and should be

located out of high traffic areas and away from furniture and

draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this fireplace and should stay

away to avoid burns or ignition of clothing.

3. CAUTION: Due to high glass surface temperature chil-

dren should be carefully supervised when in the same

room as fireplace.

must be installed on a metal or wood panel extending the

full width and depth of the fireplace.

12. This fireplace requires adequate ventilation and combustion

air to operate properly.

13. This fireplace must not be connected to a chimney flue

serving a separate solid fuel burning fireplace.

14. When the fireplace is not in use it is recommended that the

gas control valve be left in the OFF position.

15. These units have been approved for bedroom use.

33LDVT / 36LDVT / 39LDVT / 43LDVT

Certified To

ANSI Z21.88-2005 / CSA 2.33-2005

Vented Gas Fireplace Heaters

WARNING: Check with your electronics manufacturer

before installing a television or other electronic device above this fireplace.

This appliance may be installed in an aftermarket

permanently located, manufactured home or mobile home,

where not prohibited by local codes.

This appliance is only for use with the type of gas indicated

on the rating plate. This appliance is not convertible for

use with other gases, unless a certified kit is used.

Th e LDV T has been appro ved for m obile home

installations.

4. Under no circumstances should this fireplace be modified.

Parts removed for servicing should be replaced prior to

operating this fireplace again.

5. Installation and any repairs to this fireplace must be per

formed by a qualified installer, service agency or gas supplier. A professional service person should be contacted to

inspect the fireplace annually. More frequent cleaning may

be required due to excess lint and dust from carpeting, bedding material, etc.

6. Control compartments, burners and air passages in this fireplace should be kept clean and free of dust and lint. Make

sure that the gas valve and pilot light are turned off before

you attempt to clean this fireplace.

7. The venting system (chimney) of this fireplace should be

checked at least once a year and if needed your venting

system should be cleaned.

8. Keep the area around your fireplace clear of combustible

materials, gasoline and other flammable vapour and liquids.

This fireplace should not be used as a dry-ing rack for cloth

ing, nor should Christmas stockings or decorations be hung

on or around the fireplace.

9. Under no circumstances should any solid fuels (wood, coal,

paper or cardboard etc.) be used in this fireplace.

10. The flow of combustion and ventilation air must not be obstructed in any way.

11. When the fireplace is installed directly on carpeting, vinyl tile

or any combustible material other than wood, this fireplace

10007852

-

IMPORTANT:

PLEASE REVIEW THE FOLLOWING CAREFULLY

Remove any plastic from from parts before turning the

fireplace ON.

It is normal for fireplaces fabricated of steel to give off

some expansion and/or contraction noises during the

start up or cool down cycle. Similar noises are found

with your furnace heat exchanger or car engine.

It is not unusual for your gas fireplace to give off some

odor the first time it is burned. This is due to the curing

of the paint and any undetected oil from the manufacturing process.

Please ensure that your room is well ventilated-open

all windows.

It is recommended that you burn your fireplace for at least

ten (10) hours the first time you use it. If the optional fan

kit has been installed, place the fan switch in the “OFF”

position during this time.

-

Proposition 65 Warning: Fuels used in gas, woodburning or oil fired appliances, and the products of

combustion of such fuels, contain chemicals known to

the State of California to cause cancer, birth defects

and other reproductive harm.

California Health & Safety Code Sec. 25249.6

3

Page 4

LDVT Series Direct Vent Gas Fireplace

F

V - Rough Opening Width

Rough

Opening

Height

Rough

Opening

Depth

S

S

T

R

E

G

J

D

A

Q

B

K

L

M

O

Gas Line

Access

Gas Line

Access

Low

Voltage

Electrical

Access

Electrical

Access

I

U

C

P

Low

Voltage

Access

N

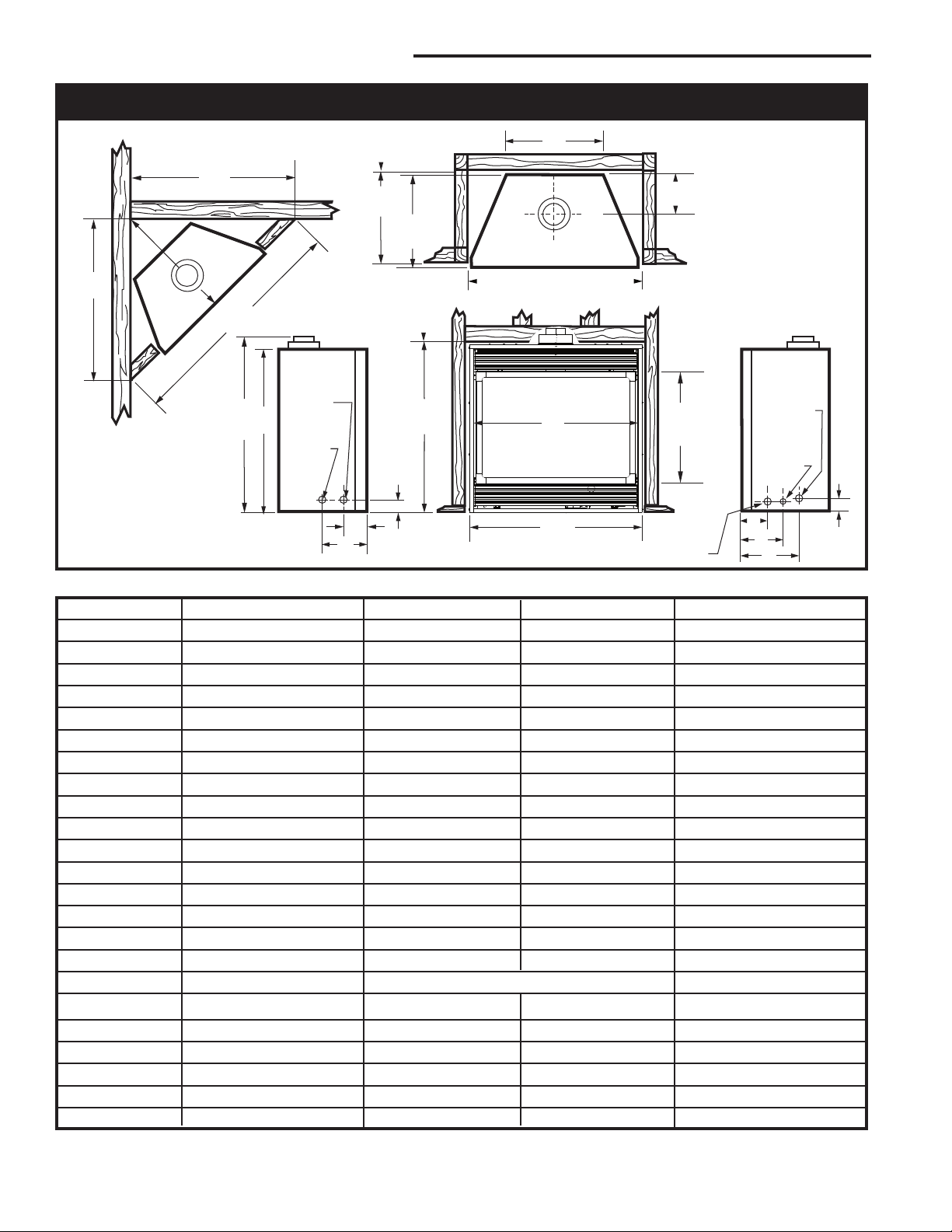

Fireplace Dimensions

Fig. 1 Fireplace specifications and framing dimensions.

Ref. 33LDVT 36LDVT 39LDVT 43LDVT

A 33” (838 mm) 36” (914 mm) 39” (991 mm) 43” (1092 mm)

B 28⁷⁄₈” (733 mm) 34¹⁄₄” (870 mm) 34¹⁄₄” (870 mm) 37” (940 mm)

C 31¹⁄₄” (794 mm) 34¹⁄₄” (870 mm) 37¹⁄₄” (946 mm) 41¹⁄₄” (1048 mm)

D 18³⁄₈” (466 mm) 23” (584 mm) 23” (584 mm) 25³⁄₄” (654 mm)

E 22³⁄₄” (578 mm) 24” (610 mm) 27” (686 mm) 31” (788 mm)

F 14” (356 mm) 16” (406 mm) 16” (406 mm) 16” (406 mm)

G 31³⁄₄” (806 mm) 37” (939 mm) 37” (939 mm) 39³⁄₄” (1010 mm)

H -- -- -- -- -- -- -- --

I 6” (152 mm) 6³⁄₄” (170 mm) 6³⁄₄” (170 mm) 6³⁄₄” (170 mm)

J 4⁵⁄₈” (118 mm) 5⁵⁄₈” (143 mm) 5⁵⁄₈” (143 mm) 5⁵⁄₈” (143 mm)

K 6³⁄₈” (162 mm) 8” (203 mm) 8” (202 mm) 8” (203 mm)

L 8⁷⁄₈” (225 mm) 11⁷⁄₈” (302 mm) 11⁷⁄₈” (302 mm) 11⁷⁄₈” (302 mm)

M 2” (51 mm) 2” (51 mm) 2” (51 mmj) 2” (51 mm)

N 3³⁄₈” (86 mm) 3¹⁄₄” (83 mm) 3¹⁄₄” (83 mm) 3¹⁄₄” (83 mm)

O 4

P 6³⁄₈” (162 mm) 9¹⁄₄” (235 mm) 9¹⁄₄” (235 mm) 9¹⁄₄” (235 mm)

Framing Dimensions

Q 29

R 14¹⁄₂” (368 mm) 16¹⁄₂” (419 mm) 16¹⁄₂” (419 mm) 16¹⁄₂” (419 mm)

S 35

T 50

U 25¹⁄₄” (641 mm) 28¹⁄₈” (714 mm) 30⁷⁄₈” (784 mm) 31¹⁄₄” (794 mm)

V 33¹⁄₂” (851 mm) 36¹⁄₂” (927 mm) 39¹⁄₂” (1003 mm) 43¹⁄₂” (1105 mm)

4

⁵⁄₈” (118 mm) 6³⁄₄” (172 mm) 6³⁄₄” (172 mm) 6³⁄₄” (172 mm)

⁵⁄₈” (753 mm) 35” (889 mm) 35” (889 mm) 37³⁄₄” (959 mm)

³⁄₄” (908 mm) 39³⁄₄” (1010 mm) 43¹⁄₈” (1095 mm) 44¹⁄₈” (1121 mm)

¹⁄₂” (1238 mm) 55¹⁄₄” (1403 mm) 60⁷⁄₈” (1546 mm) 62³⁄₈” (1584 mm)

10007852

Page 5

Y

E

A

B

C

D

F

Y

B

X

X

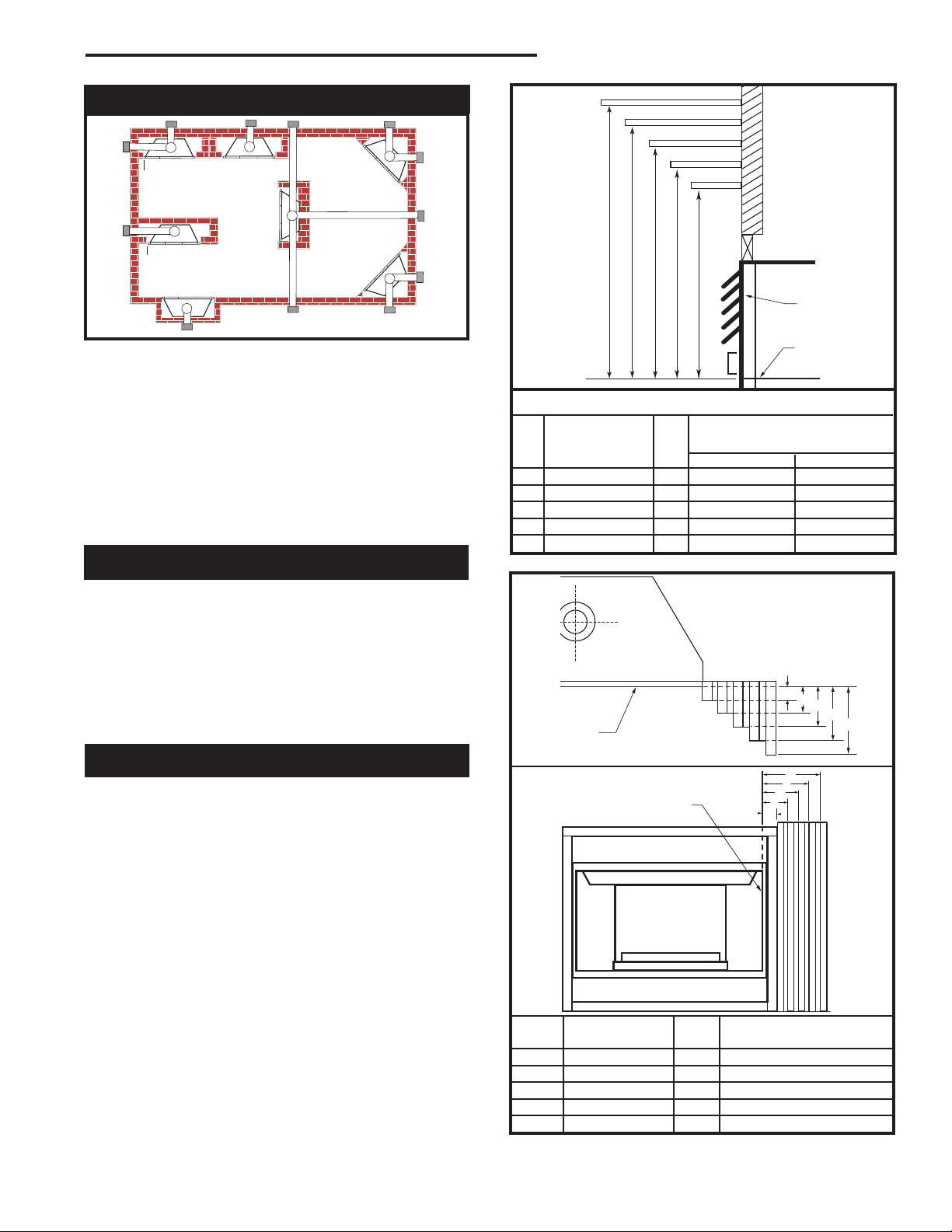

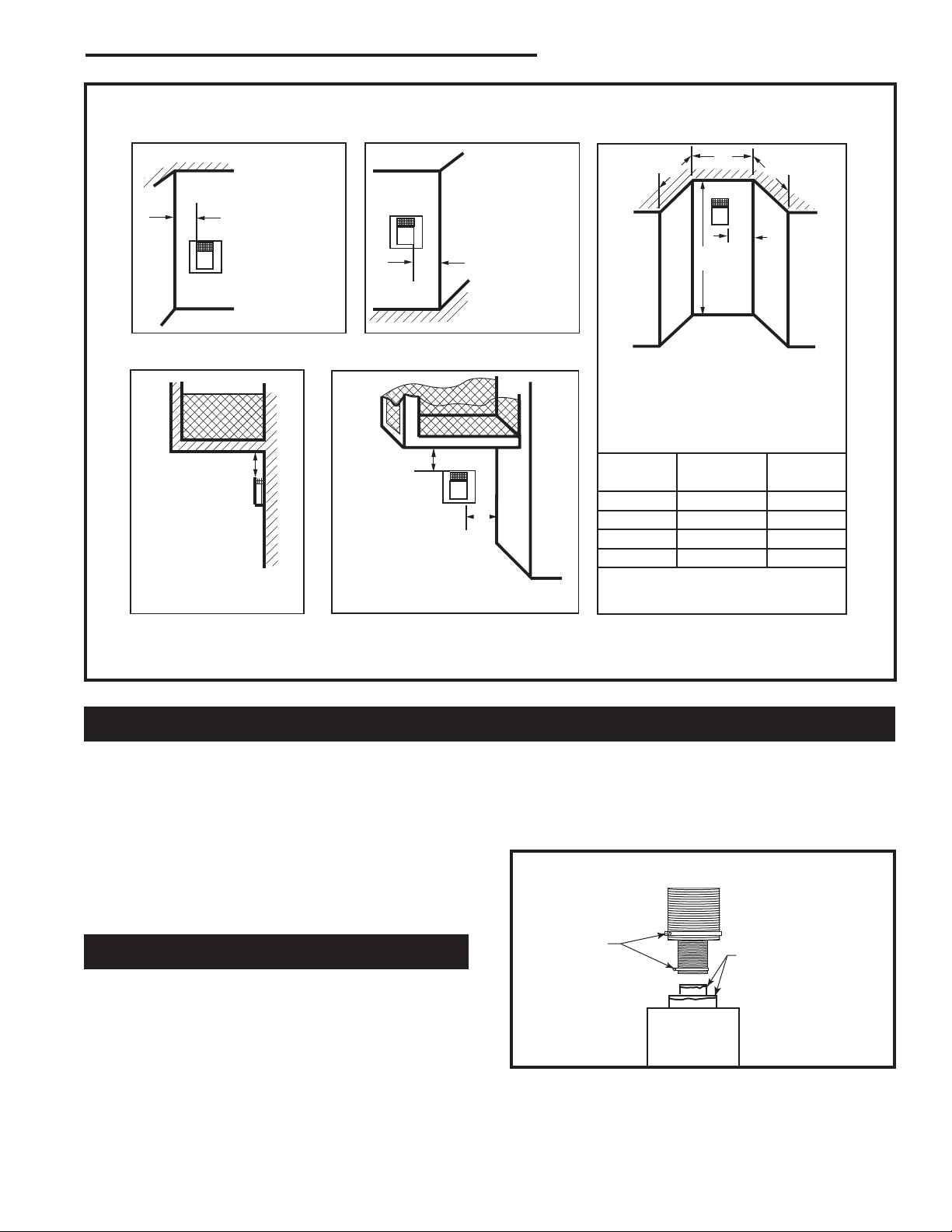

Locating Your Fireplace

A B C

D

E

V

W

X

Y

Z

Fireplace

J

F

G

H

I

Mantel

Leg

O

N

M

L

K

LDVT Series Direct Vent GaS Fireplace

Top Louvre

Assembly

Fig. 2 Locate gas fireplace.

A - Flat on wall B - Cross corner C - **Island

D - *Room divider E - *Flat on wall corner F - Chase installation

Y - 6” minimum

Note (Fig. 2):

** Island (C) and Room Divider (D) installation is possible as

long as the horizontal portion of the vent system (X) does not

exceed 20’ (6m). See details in manual Venting Section.

* When you install your fireplace in(D) Room divider or (E)

Flat on wall corner positions (Y), a minimum of 6” (152mm)

clearance must be maintained from the perpendicular wall and

the front side edge of the fireplace. See (Y) in Fig. 2.

Clearance to Combustibles

Top of Unit to Ceiling ................................ 36” (914mm)

Appliance

Top ...........................................................

Bottom ......................................................

Side ..........................................................

Back .........................................................

Venting

Concentric sections of DV Vent

Top, bottom & sides ...............................

Mantels

The height that a combustible mantel is fitted above the

fireplace is dependent on the depth of the mantel. This

also applies to the distance between the mantel leg (if

fitted) and the fireplace.

For the correct mounting height and widths refer to

Figures 3a and 3b.

The fitting of a bay window trim kit does not effect

the distances and reference points referred to in the

diagram and chart.

Noncombustible mantels and legs may be installed at

any height and width around the appliance.

When using paint or lacquer to finish the mantel, such

paint or lacquer must be heat resistant to prevent

discoloration.

10007852

0” (0mm)

0” (0mm)

0” (0mm)

0” (0mm)

1” (25mm)

Top of

CFM146

Combustion

Chamber

Mantel Chart

Mantel Shelf Mantel from Top

Ref. or Breast Plate Ref. of Combustion Chamber

Depth 36/39/43 LDVT 33LDVT

V 10” (254 mm) A 17” (432 mm) 16

W 8” (203 mm) B 15” (381 mm) 14

X 6” (152 mm) C 13” (330 mm) 12¹⁄₂” (318 mm)

Y 4” (101 mm) D 11” (279 mm) 10¹⁄₂” (267 mm)

Z 2” (51 mm) E 9” (229 mm) 8

Fig. 3a Combustible mantel minimum installation.

Black

Surround

Face

Side of

Combustion Chamber

Mantel Mantel Leg FromSide

Ref. Leg Depth Ref. of Comb. Opening

F 10” (254 mm) K 11

G 8” (203 mm) L 9

H 6” (152 mm) M 7¹⁄₂” (191 mm)

I 4” (101 mm) N 5¹⁄₂” (140 mm)

J 2” (51 mm) O 3

Fig. 3b Combustible mantel leg minimum installation.

¹⁄₂” (292 mm)

¹⁄₂” (241 mm)

¹⁄₂” (89 mm)

¹⁄₂” (419 mm)

¹⁄₂” (368 mm)

¹⁄₂” (216 mm)

CFM170

5

Page 6

LDVT Series Direct Vent Gas Fireplace

A

B

Hearth

A hearth is not mandatory but is recommended for

aesthetic purposes. We recommend a noncombustible

hearth which projects out 12” (305mm) or more from the

front of the fireplace.

Cold climate installation recommendation:

When installing this unit against a noninsulated exterior wall or chase, it is

mandatory that the outer walls be insulated

to conform to applicable insulation codes.

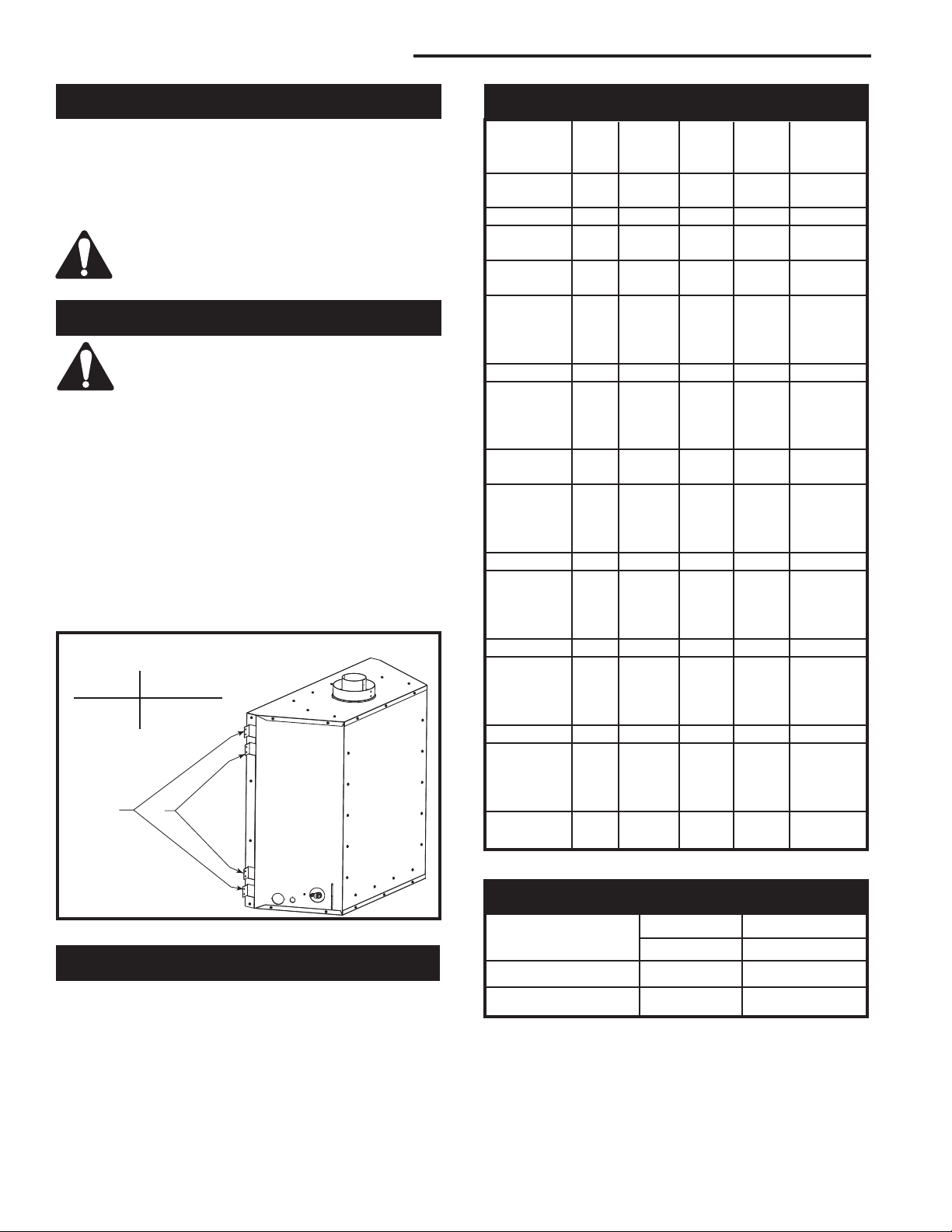

Framing and Finishing

Check fireplace to make sure it is levelled

and properly positioned.

To mount the appliance:

1. Choose the location.

2. This unit comes with four (4) flanges pre-mounted

on both sides of the fireplace to allow two different

drywall thicknesses to be used. Flange “A” is for

1/2” drywall while flange “B” is for 5/8” drywall.

3. Bend the desired flanges out 90° on both sides of

the fireplace. Slide the fireplace into the framed

opening until the flanges contact the front surfaces

of the framing. Level the unit and secure it firmly in

place.

Flange Location for Desired Drywall Depth

Flange Drywall

Position Depth

A 1/2” / 13 mm

B 5/8” / 16 mm

Gas Specifications

Max. Min. Air

Gas Input Input Shutter

Model Fuel Control BTU/h BTU/h Adj.

33LDVTRN Nat Millivolt 16,000 11,200 3/16”

Open

33LDVTRP Prop Millivolt 16,000 12,000 Fully Open

33LDVTEN Nat 24V 16,000 11,200 3/16”

Hi/Lo Open

33LDVTEP Prop* 24V 16,000 12,000 Fully Open

Hi/Lo

36LDVTRN Nat Millivolt 19,500 13,650 Top &

Bottom

Hole Half

Closed

36LDVTRP Prop Millivolt 19,500 14,625 Fully Open

36LDVTEN Nat 24V 19,500 13,650 Top &

Hi/Lo Bottom

Hole Half

Closed

36LDVTEP Prop* 24V 19,500 14,625 Fully Open

Hi/Lo

39LDVTRN Nat Millivolt 23,000 16,100 Top &

Bottom

Hole Half

Closed

39LDVTRP Prop* Millivolt 22,500 16,875 Fully Open

39LDVTEN Nat 24V 23,000 16,100 Top &

Hi/Lo Bottom

Hole Half

Closed

39LDVTEP Prop* 24V 22,500 16,875 Fully Open

43LDVTRN Nat Millivolt 26,000 18,200 Top &

Bottom

Hole Half

Closed

43LDVTRP Prop* Millivolt 24,000 18,000 Fully Open

43LDVTEN Nat 24V 26,000 18,200 Top &

Hi/Lo Bottom

Hole Half

Closed

43LDVTEP Prop* 24V 24,000 18,000 Fully Open

Hi/Lo

*Using conversion kit

FP1546

Gas Inlet and Manifold Pressures

Fig . 4 Nailing flanges.

Final Finishing

Noncombustible materials such as brick or tile may be

extended over the edges of the face of the appliance.

DO NOT cover any vent or grille panels.

If a Trim Kit is going to be installed on the fireplace, the

brick or tile will have to be installed flush with the edges

of the appliance.

6

Natural LP (Propane)

Inlet Minimum 5.5” w.c. 11.0” w.c.

Inlet Maximum 14.0” w.c. 14.0” w.c.

Manifold Pressure 3.5” w.c. 10.0” w.c.

10007852

Page 7

LDVT Series Direct Vent GaS Fireplace

TP

TH

TP

TH

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the current ANSI Z223.1/NFPA 54 and/or local codes having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

Gas Line Installation

When purging gas line, the front window

frame removed.

The gas pipeline can be brought in through the rear

of the fireplace as well as the bottom. Knockouts are

provided on the bottom behind the valve to allow for the

gas pipe installation and testing of any gas connection.

It is most convenient to bring the gas line in from the

rear right side of the valve as this allows fan installation

or removal without disconnecting the gas line.

The gas line connection can be made with properly

tinned 3/8” copper tubing, 3/8” rigid pipe or an approved

flex connector. Since some municipalities have additional local codes, it is always best to con- sult your

local authority and the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 in the USA or the CSA-B149.1 installation codes.

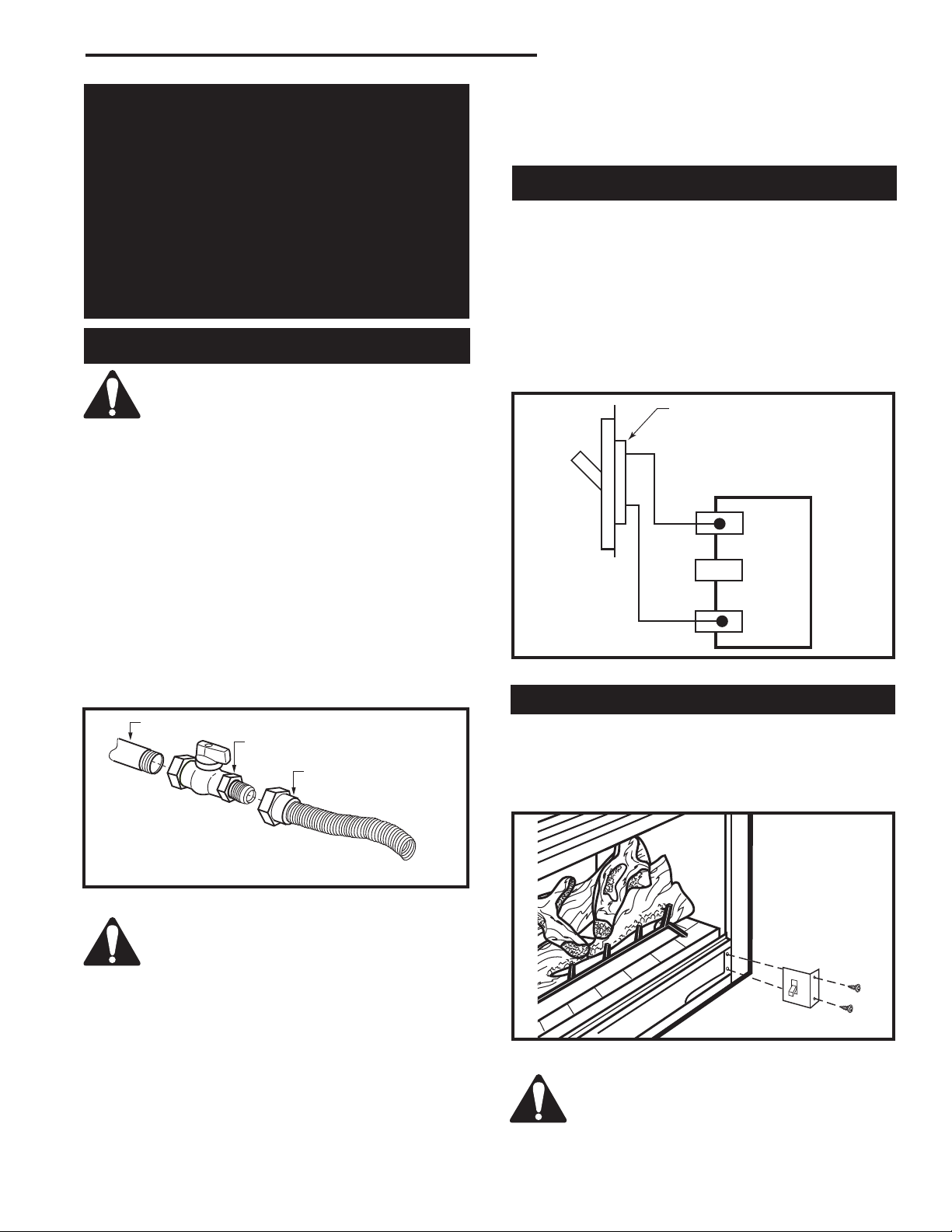

1/2” Gas Supply

1/2” NPT X 1/2” Flare Shut-off Valve

3/8” Flex line

(from valve)

The fireplace valve must not be subjected to any test

pressures exceeding 1/2 psi. Isolate or disconnect this

or any other gas appliance control from the gas line

when pressure testing.

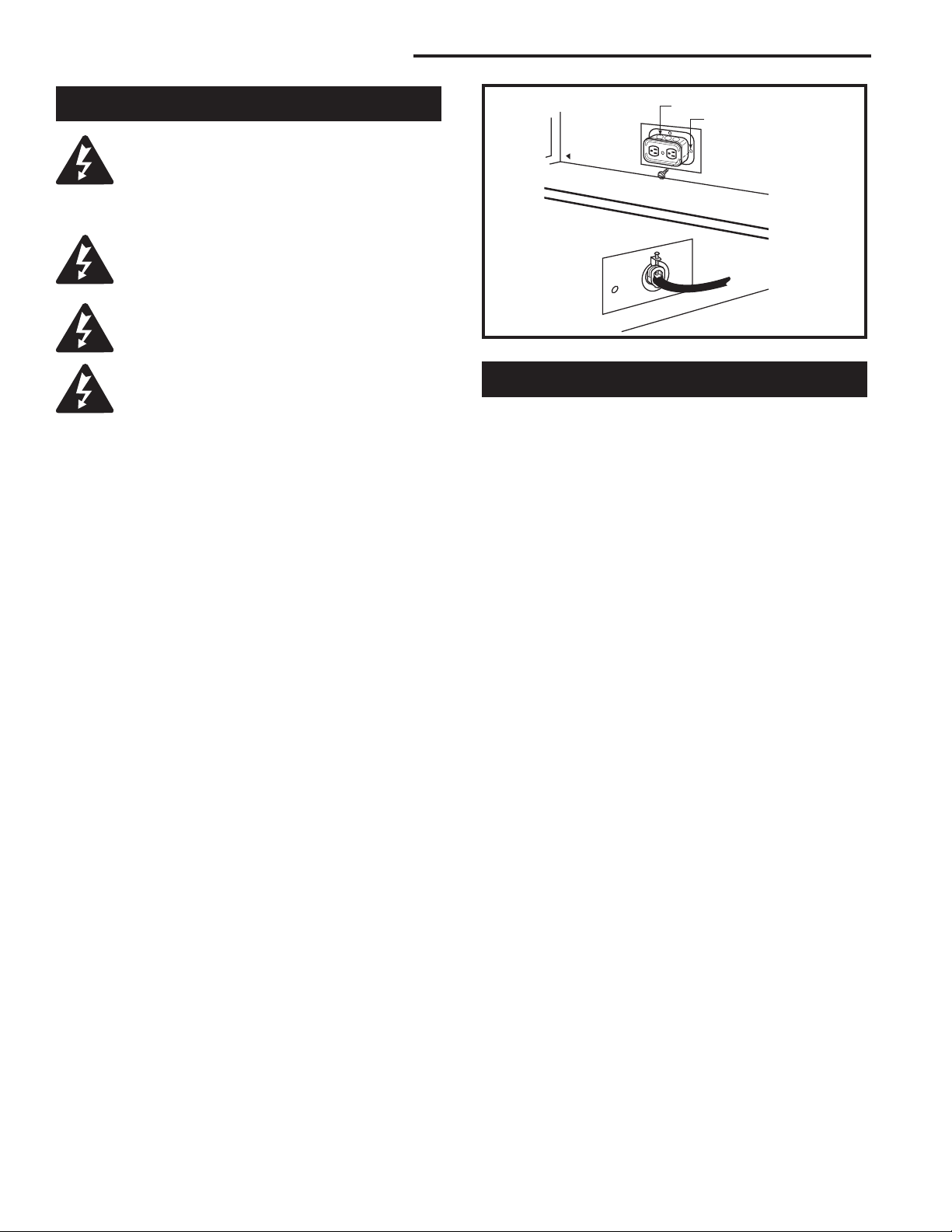

Remote ON/OFF Switch

Installation:

1. Thread the wiring through holes on the end panels

of appliance. Take care not to cut wire or insulation

on metal edges. Route the wire to a conveniently

located receptacle box.

2. Attach the wire to the ON/OFF switch and install the

switch into the receptacle box.

3. Connect the other ends of the wire to the gas control

valve. (Fig. 6)

Remote ON/OFF

Switch or Thermostat or

Remote Control

Gas

Control

Valve

FP1224

Fig. 6 Remote switch wiring diagram.

Alternate Switch Location

The remote switch can be installed on the front/side of

the access door. Simply mount the switch to the bracket

provided and screw the bracket to either side of the

frame, lining up the screws with the pre-punched holes.

(Fig. 7)

FP297A

Fig. 5 Typical gas supply installation.

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to provide a 1/8” test point up stream of the control.

When using copper or flex connector use only approved

fittings. Always provide a union when using black iron

pipe so that the gas line can be easily disconnected for

burner or fan servicing . See gas specifications for pressure details and ratings.

10007852

FP1024

Fig. 7 Alternate switch location.

Do not wire the remote ON/OFF wall switch

for the gas fireplace to the 120 volt power

supply.

7

Page 8

LDVT Series Direct Vent Gas Fireplace

OUTSIDE

INSIDE

BACK OF UNIT

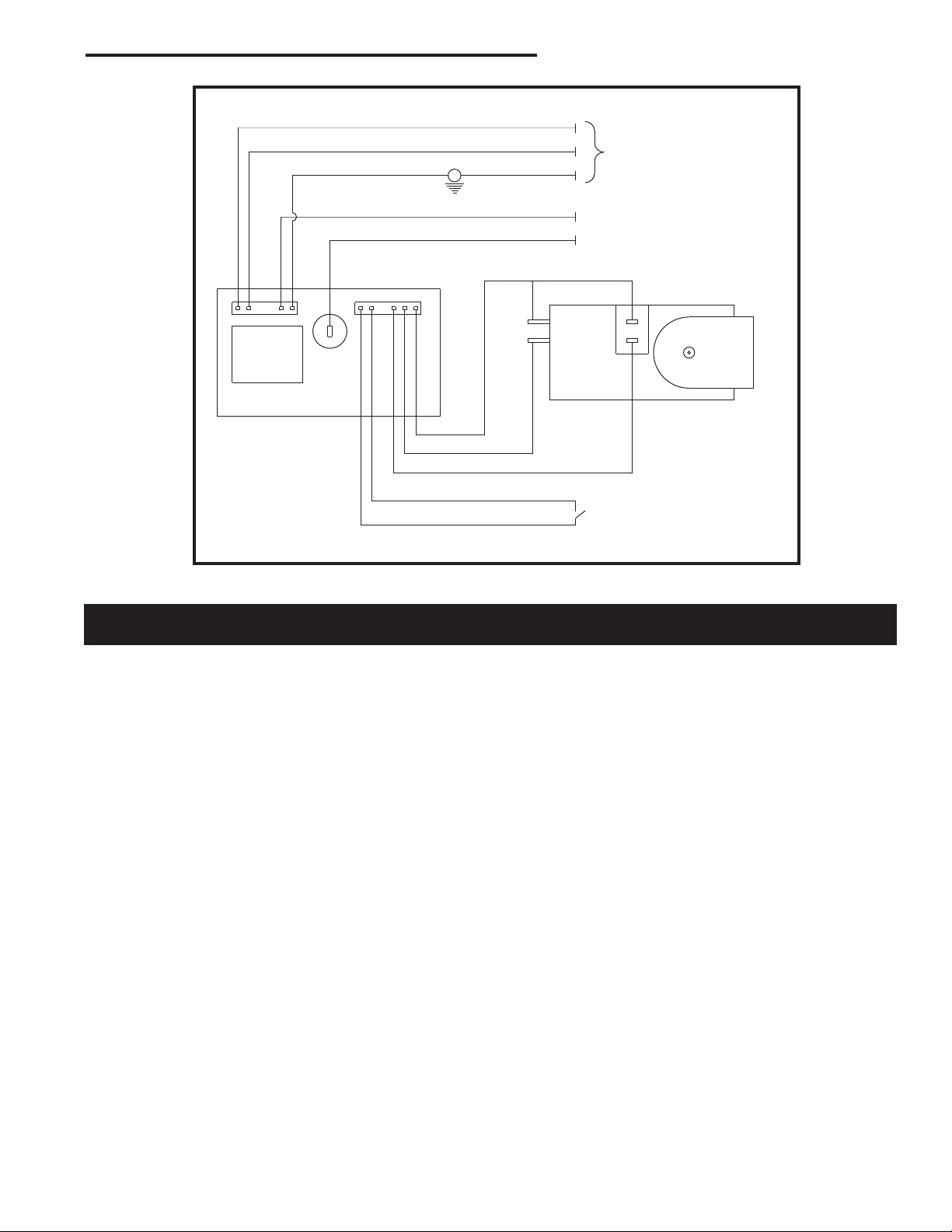

EB-1 Electrical Box

The fireplace, when installed, must be electrically connected and grounded in accordance with local codes or, in the absence

of local codes, with the current CSA C22.1

Canadian Electrical Code.

For USA installations follow local codes

and the national electrical code ANSI/

NFPA No. 70.

It is strongly suggested that the wiring of

the EB-1 Electrical Junction Box be carried

out by a licensed electrician.

Ensure that the power to the supply line

has been disconnected before commencing this procedure.

The EB-1 Electrical junction box has been fitted stand

ard on this model to allow for the easy connection of an

optional fan kit.

To connect the EB-1 box to the house electrical supply

follow the steps below.

1. Unscrew retaining screw from EB-1 base plate (Fig.

8) and remove the EB-1 assembly from the appliance.

2. Remove the front cover of the EB box.

3. Remove the plug socket assembly from the EB-1

box.

4. Feed the supply line in through the EB-1 opening in

the side of the appliance and then through the back

of the EB-1 assembly. (Fig. 8)

5. Connect the black wire of the power supply line to

the brass screw (polarized) of the socket assembly.

6. Connect the white wire of the power line to the

chrome screw of the socket assembly.

7. Connect the ground wire of the supply line to the

green screw of the socket assembly.

8. Refit the socket assembly back into the electrical

box and replace the cover plate. Secure the cable

with the clamp on the outside of the EB-1 base

plate and refit the EB-1 assembly to the unit with the

screw removed in step 1.

-

Electrical Box

Retaining Screw

FP580

Fig. 8 EB-1 receptacle.

Electronic Gas Control Valve

This appliance may be fitted with a Synetek ignition

module.

Installation of the remote on/off switch or wall thermostat on electronic ignition units.

1. Thread the wiring through the holes on the side

panels of the appliance. Take care not to cut the wire

or insulation on metal edges. Route the wire to a

conveniently located receptacle box.

2. Attach the wire to the ON/OFF switch and install the

switch into the receptacle box.

3. Connect the white wire from the wall switch or wall

thermostat to the white wire terminal from the electronic module. Connect the black wire from the wall

switch or the red wire from the wall thermostat, to

the red wire terminal from the electronic module.

8

10007852

Page 9

LDVT Series Direct Vent GaS Fireplace

POWER CORD

CIRCUIT BOARD

ON/OFF SWITCH

OR

WALL THERMOSTAT

VALVE

RED

WHITE

BLUE

YELLOW

PURPLE

BLACK

WHITE

GREEN

PILOT SENSING

PILOT IGNITER

ORANGE

L1

L2

M

O

P

O

Fig. 9 SIT822 Valve with Synetek electronic control wiring diagram.

General Venting

Your fireplace is approved to be vented either through

the side wall, or vertically through the roof.

• Only CFM Corporation venting components spe-

cifically approved and labelled for this fireplace

may be used.

• Vent terminations shall not be recessed into a wall

or siding.

• Horizontal venting which incorporates the twist lock

pipe must be installed on a level plane without an

inclining or declining slope.

• Horizontal venting which incorporates the use of flex

venting shall have an inclining slope from the unit of

1” (25 mm) per 24” (610 mm).

FP1571

There must not be any obstruction such as bushes,

garden sheds, fences, decks or utility buildings within

24” (610 mm) from the front of the termination hood.

Do not locate termination hood where excessive snow

or ice build up may occur. Be sure to check vent termination area after snow falls, and clear to prevent accidental blockage of venting system. When using snow

blowers, make sure snow is not directed towards vent

termination area.

Location of Vent Termination

It is imperative the vent termination be located observing the minimum clearances as shown on the next

page.

*Check with local codes or in absence of same with

CSA-B149.1 Installation Codes (1991) for Canada

or follow the current National Fuel Gas Code, ANSI

Z223.1/NFPA 54 for installations in the USA.

10007852

9

Page 10

LDVT Series Direct Vent Gas Fireplace

V

V

V

V

V

V

V

X

X

X

D

E

B

B

B

C

B

M

B

A

J

K

F

L

VENT TERMINATION AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

H

I

Operable

Operable

Fixed

Closed

V

B

INSIDE

CORNER DETAIL

V

A

G

N

N

CFM145a

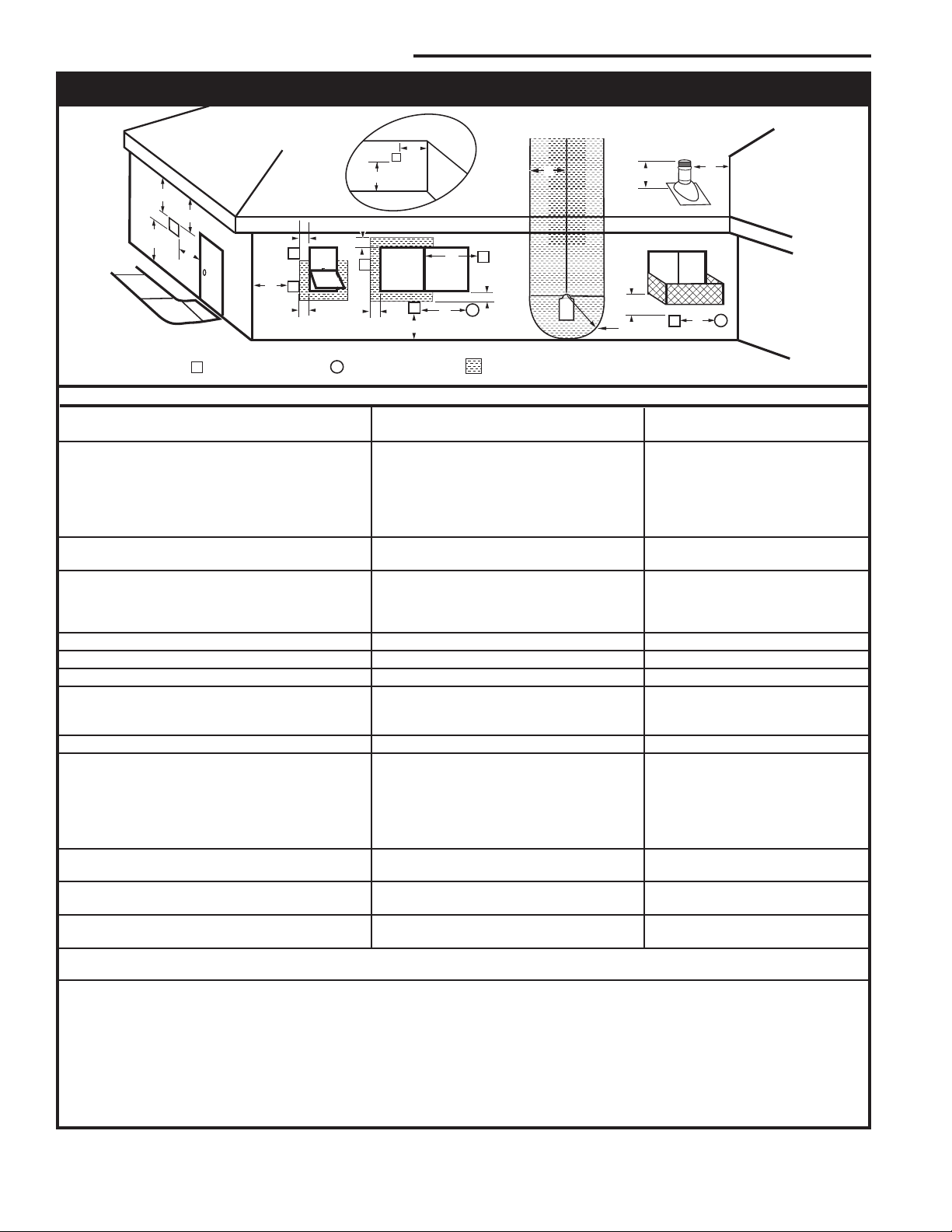

General Venting Information - Termination Location

Canadian Installations1 US Installations

2

A = Clearance above grade, veranda, porch, 12” (30cm) 12” (30cm)

deck, or balcony

B = Clearance to window or door that may be 6” (15cm) for appliances 6” (15cm) for appliances

opened < 10,000Btuh (3kW), 12” (30cm) < 10,000 Btuh (3kW), 9”

for appliances > 10,000 Btuh (3kW) and (23cm) for appliances > 10,000

< 100,000 Btuh (30kW), 36” (91cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30cm) for

appliances > 50,000 Btuh (15kW)

C = Clearance to permanently closed window 12” (305mm) recommended to 12” (305mm) recommended to

prevent window condensation prevent window condensation

D = Vertical clearance to ventilated soffit located

above the terminal within a horizontal 18” (458mm) 18” (458mm)

distance of 2’ (610mm) from the center

line of the terminal

E = Clearance to unventilated soffit 12” (305mm) 12” (305mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner (see next page) see next page see next page

H = Clearance to each inside of center line 3’ (91cm) within a height of 15’ (5m) 3’ (91cm) within a height of 15’

extended above meter/regulator assembly above the meter/regulator assembly (5m) above the meter/regulator

assy

I = Clearance to service regulator vent outlet 3’ (91cm) 3’ (91cm)

J = Clearance to nonmechanical air supply inlet 6” (15cm) for appliances < 10,000 6” (15cm) for appliances

to building or the combustion air inlet to any Btuh (3kW), 12” (30cm) for < 10,000 Btuh (3kW), 9”

other appliances appliances > 10,000 Btuh (3kW) and (23cm) for appliances > 10,000

< 100,000 Btuh (30kW), 36” (91cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30cm) for

appliances > 50,000 Btuh (15kW)

K = Clearance to a mechanical air supply inlet 6’ (1.83m) 3’ (91cm) above if within 10

feet (3m) horizontally

L = Clearance above paved sidewalk or paved 7’ (2.13m)† 7’ (2.13m)†

driveway located on public property

M = Clearance under veranda, porch, deck or 12” (30cm)‡ 12” (30cm)‡

balcony

N = Clearance above a roof shall extend a minimum of 24” (610mm) above the highest point when it passes through the roof

surface, and any other obstruction within a horizontal distance of 18” (450mm).

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Codes

† A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and

serves both dwellings

‡ only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the floor:

NOTE: 1. Local codes or regulations may require different clearances.

2. The special venting system used on Direct Vent Fireplaces are certified as part of the appliance, with clearances tested and

approved by the listing agency.

3. CFM Corporation assumes no responsibility for the improper performance of the appliance when the venting system does not

meet these requirements.

Fig. 10 Vent termination locations.

10

10007852

Page 11

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

G =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

G

Balcony with no side wall

M =

Combustible &

Noncombustible

12" (305 mm)

M

Balcony with perpendicular side wall

M = 24" (610 mm)

P = 20” (508 mm)

M

F

Alcove Applications*

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

E = Min. 6” (152 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O = 8’ (2.4 m) Min.

O

P

*NOTE: Termination in an alcove space (spaces open only on one side and with an overhang) is permitted with the dimensions

specified for vinyl or non-vinyl siding and soffits. 1. There must be a 3’ (914 mm) minimum between termination caps. 2. All

mechanical air intakes within 10’ (1 m) of a termination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All

gravity air intakes within 3’ (914 mm) of a termination cap must be a minimum of 1’ (305 mm) below the termination cap.

Fig. 10a Termination clearances.

Canadian Installations:

General Information on Assembling Vent Pipes

The venting system must be installed in accordance

with the current CSA-B149 .1 installation code.

USA Installations:

The venting system must conform with local codes and/

or the current National Fuel Gas code ANSI Z223.1/

NFPA 54.

Only venting components manufactured by CFM Corporation can be used in Direct Vent systems.

Flex Vent Pipes

Before joining the flex vent pipe to the unit, apply a

bead of high temperature sealant* (provided) to the 4”

pipe exiting the fireplace. Secure flex vent pipe in place

with a hose clamp (provided).

*Be sure the flex pipe overlaps at least 1” (25 mm) onto

the collars of the fireplace and termination. If the ter

mination has an internal bead, be sure to overlap and

secure 1” (25 mm) past the bead.

-

10007852

LDVT Series Direct Vent GaS Fireplace

No.

of Caps D

1 3’ (914 mm) 2 x D

2 6’ (1.8 m) 1 x D

3 9’ (2.7 m) 2/3 x D

4 12’ (3.7 m) 1/2 x D

D

= # of Termination caps x 3

Min.

C

= (2 / # termination caps) x D

Max.

* Be sure the vent is actually crushed before proceeding. Apply a tug to be sure the vent will not slip off the

collars.

Repeat process with 7” flex vent pipe. The same procedure must be performed on the vent side.

Hose Clamp

Fig. 11 Apply high temperature sealant to 4” and 7” pipes.

C

Min.

Apply High Temperature

Sealant

Max.

Actual

Actual

Actual

Actual

Actual

584-15

FP1471

11

Page 12

LDVT Series Direct Vent Gas Fireplace

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

eg: A

eg: B

Twist Lock Pipes

When using CFM Corporation twist-lock pipe it is not

necessary to use sealant on the joints. The only areas

of the venting system that need to be sealed with high

temperature silicone sealant are the sliding joints of any

telescopic vent section used in the system.

To join the twist lock pipes together, simply align the

beads of the male end with the grooves of the female

end, then while bringing the ends together, twist the

pipe until the flange on the female end contacts the

external flange on the male end. It is recommended that

you secure the joints with three (3) sheet metal screws,

however this is not mandatory with twist lock pipe.

To make it easier to assemble the joints we suggest

putting a lubricant (Vaseline or similar) on the male end

of the twist lock pipe prior to assembly.

Vertical dimension from the floor of the fireplace to

the center of the horizontal vent pipe

Male End

Screw Holes

Fig. 12 Twist-lock pipe joints.

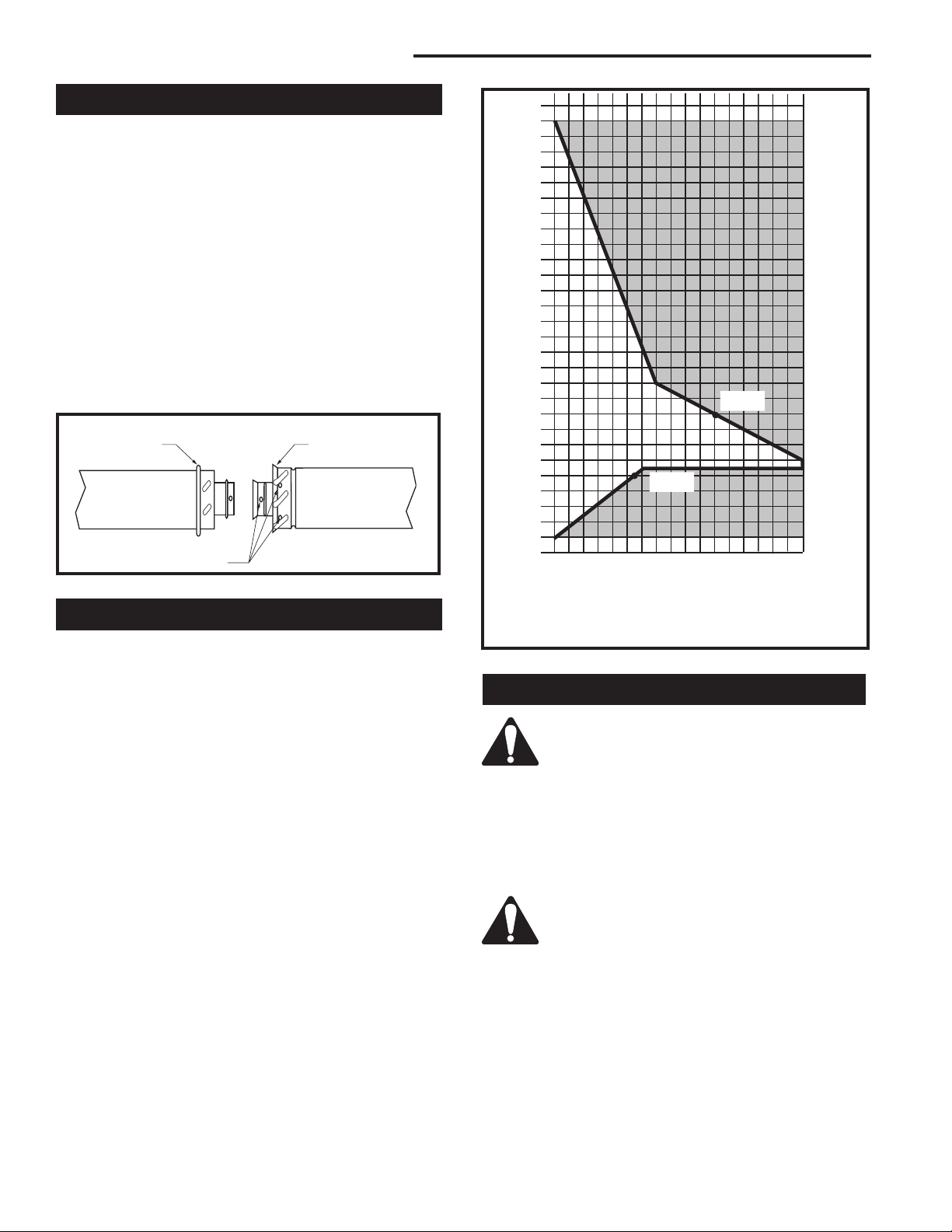

How to Use the Vent Graph

The vent chart should be read in conjunction with the

following vent installation instructions to determine the

relationship of the vertical and horizontal dimensions of

the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph. (Fig. 13)

locate the point intersecting with the slanted graph

line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same.

Example A:

If the vertical dimension from the floor of the fireplace

is 11’ (3.4 m) the horizontal run to the face of the outer

wall must not exceed 14’ (4.3 m).

Example B:

If the vertical dimension from the floor of the unit is 7’

(2.14 m), the horizontal run to the face of the outer wall

must not exceed 8¹⁄₂’ (2.6 m).

12

Female End

TWL100

Horizontal dimension from the outside face of the wall to

the center of the fireplace vent flange

Sidewall vent graph showing the relationship between vertical

and horizontal dimensions for a Direct Vent flue system.

Fig. 13 Sidewall venting graph. (Dimensions in feet)

Vertical Sidewall Applications

Since it is very important that the venting system maintain its balance between

the combustion air intake and the flue

gas exhaust, certain limitations as to vent

configurations apply and must be strictly

adhered to.

The vent graph showing the relationship between vertical and horizontal side wall venting will help to determine the various dimensions allowable.

Minimum clearance between vent pipes

and combustible materials is one 1”

(25mm) on top, bottom and sides unless

otherwise noted.

When the vent termination exits through foundations

less than 20” (508mm) below siding outcrop, the vent

pipe must flush up with the siding.

It is always best to locate the fireplace in such a way

that minimizes the number of offsets and horizontal

vent length of vent pipe from the flue collar of the fireplace to the face of the outer wall.

10007852

Page 13

20' (6m)

7.5' (2.3m)

Pipe

3'

(914mm)

7.5'

(2.3m)

A

B

A + B = 17' (5.2m) Max.

1

2

3

4

Straps Every

3’ (914mm)

Pipe Straps

Every 3’ (914mm)

Firestop/Zero

Clearance Sleeve

FP1012

Fig. 14 Support straps for horizontal runs.

Horizontal plane means no vertical rise exists on this

portion of the vent assembly.

• The maximum number of 90° elbows per side wall

installations is three (3).

• If a 90° elbow is fitted directly onto the fireplace

flange the maximum horizontal vent run before the

termination or a vertical rise is 36” (914mm).

• If a 90° elbow is used in the horizontal vent run

(level height maintained) the maximum horizontal

vent length is reduced by 36” (914mm). This does

not apply if the 90° elbows are used to increase or

redirect a vertical rise.

Example: According to the chart the maximum

horizontal vent length in a system with a 7.5’ (2.3 m)

vertical rise is 20’ (6m) and if a 90° is required in the

horizontal vent it must be reduced to 17’ (5.2 m).

In Figure 16, Dimension A plus B must not be

greater than 17’ (5.2 m).

LDVT Series Direct Vent GaS Fireplace

1 x 90° elbow in horizontal plane = 3’ (914mm)

FP1238

Fig. 16 Maximum vent run with elbows.

• The maximum number of 45° elbows permitted per

side wall installation is two (2). These elbows can be

installed in either the vertical or horizontal run.

• For each 45° elbow installed in the horizontal run,

the length of the horizontal run MUST be reduced by

18” (457 mm). This does not apply if the 45° elbows

are installed on the vertical part of the vent system.

• The maximum number of elbow degrees in a system

is 270°. (Fig. 17)

Example:

Elbow 1 = 90°

Elbow 2 = 45°

Elbow 3 = 45°

Elbow 4 = 90°

Total angular variation = 270°

Fig. 15 Maximum horizontal vent run.

10007852

FP1237

1 + 2 + 3 + 4 = 270°

FP1239

Fig. 17 Maximum number of elbow degrees.

13

Page 14

LDVT Series Direct Vent Gas Fireplace

X

X

Vertical Sidewall Installation

Twist Lock Pipe

STEP 1

Locate vent opening on the wall. It may be necessary

to first position the fireplace and measure to obtain hole

location. Depending on whether the wall is combustible

or noncombustible, cut opening to size. (Fig. 18)

For combustible walls first frame in opening.

NOTE: When using flex vent, the opening will have to

be measured according to the 1/2” (13 mm) rise in 12”

(305 mm) vent run.

Combustible Walls:

x 240 mm) hole through the exterior wall and frame as

shown.

Noncombustible Walls:

be 7¹⁄₂” (190 mm) in diameter.

Vent Opening for Combustible Wall

9³⁄₈”

(240mm)

(Fig. 18) Cut a 9³⁄₈”H x 9³⁄₈”W (240

(Fig. 18) Hole opening must

9³⁄₈”

(240mm)

Framing

Detail

Adjustable

Zero Clearance

Sleeve

#8 Screws

(2)

Firestop

Adjustable Zero Clearance Sleeve

Fig. 19 Adjustable zero clearance sleeve.

Max. Length

12” (305mm)

#8 Screws (2)

#8 Screws

(2)

ZCS101

Fireplace Hearth

Opening for Noncombustible Wall

7¹⁄₂”

(190mm)

VO584-100

Fig. 18 Locate vent opening on wall.

STEP 2

Measure wall thickness and cut zero clearance sleeve

parts to proper length (MAXIMUM 12”/305 mm). As

semble sleeve and attach to firestop with #8 sheet

metal screws (supplied). Install firestop assembly. (Fig.

19)

Zero clearance sleeve is only required for

combustible walls.

STEP 3

Place fireplace into position. (Fig. 20) Measure the ver

tical height (X) required from the base of the flue collars

to the center of the wall opening.

FP1240

Fig. 20 Vertical height requirement.

STEP 4

Attach the appropriate venting component(s) to the

inner and outer flue collars of the fireplace using three

(3) screws. (Fig. 21) Follow with the installation of the

inner and outer elbow. Again secure joints with three (3)

sheet metal screws.

Fig. 21 Horizontal length requirement.

14

FP1241

10007852

Page 15

STEP 5

12"

(305mm)

6"

(152mm)

5"

(127mm)

6"

(172mm)

Measure the horizontal length requirement including

a 2” (51 mm) overlap, ie from the elbow to the outside

wall face plus 2” (51 mm) (or the distance required if

installing a second 90° elbow). (Fig. 21)

Always install horizontal venting on a level

plane.

STEP 6

Use appropriate length of pipe sections - telescopic or

fixed - and install the horizontal vent sections. The sections which go through the wall are packaged with the

starter kit, and can be cut to suit if necessary. (Fig. 22)

Sealing vent pipe and firestop gaps with

high temperature sealant will restrict cold

air being drawn in around fireplace.

LDVT Series Direct Vent GaS Fireplace

FP1243

Fig. 23 Apply high temperature sealant to collars or terminations.

Support horizontal pipes every 3’ (914 mm) with metal

pipe straps. Make sure the horizontal vent pipe is installed on a level horizontal plane.

FP1242

Fig. 22 Through the wall.

STEP 7

Guide the vent terminations 4” and 7” collars into their

respective vent pipes. Double check that the vent pipes

overlap the collars by 2” (51 mm). Secure the termination to the wall with screws provided and caulk around

the wall plate to weatherproof. (Fig. 23) As an alternative to screwing the termination directly to the wall you

may also use expanding plugs or an approved exterior

construction adhesive. You may also attach the termination with screws through the inner body into the 4”

(102 mm) vent pipe however for this method you must

extend the 4” (102 mm) pipe approximately 6” (152

mm) beyond the outer face of the wall.

Vertical Sidewall Installation

Flex Vent Pipe

NOTE: The 40” (1016 mm) flex vent is used for 90° off

the top of the unit then out the back wall.

Follow Step 1 and 2 on Page 14.

Step 3

Install the four (4) spacer springs on the 4” flex vent

pipe. When installing the spacer springs around the 4”

pipe, stretch the spring to approximately 15” (381 mm),

wrap the spring around the pipe and interlock the ends

of the spacer spring approximately 2” (51 mm). Measure 6³⁄₄” (172 mm) from the end of the pipe. Place the

next spring 5” (127 mm) from the previously installed

spring. Place the next spring 6” (152 mm) from the last

spring. Finally place the last spring 12” (305 mm) from

the last spring installed. (Fig. 24)

4” Flex Vent

Pipe

Spacer Spring

10007852

FP1474

Fig. 24 Install spacer springs.

15

Page 16

LDVT Series Direct Vent Gas Fireplace

6" (165mm)

Step 4

Install the 4” (102 mm) flex vent pipe to the appliance

collar as described on Page 11. Secure the end with the

first spring 6³⁄₄” (172 mm) from the flex pipe end to the

unit.

Step 5

Slide the 7” (178 mm) flex vent pipe over the 4” flex

vent pipe and secure the 7” collar as described on Page

11.

Step 6

Bend the flex pipe horizontal so the bottom of the

horizontal pipe measure 6¹⁄₂” (165mm) from the top of

the unit immediately after the 90° formation. (Fig. 25)

Be sure to follow the 1” (25mm) rise in a 24” (610mm)

horizontal run rule.

Step 7

Install the 4” flex then 7” flex to the termination.

1. Establish vent hole through the wall. (Fig. 18)

2. Remove soil to a depth of approximately 16” (406

mm) below base of snorkel. Install drain pipe. Install

window well (not supplied). Refill hole with 12” (305

mm) of coarse gravel leaving a clearance of approximately 4” (102 mm) below snorkel. (Fig. 26)

3. Install vent system.

4. Ensure a watertight seal is made around the vent

pipe coming through the wall.

5. Apply high temperature sealant caulking (supplied)

around the 4” and 7 “ snorkel collars.

6. Slide the snorkel into the vent pipes and secure to

the wall.

7. Level the soil to maintain a 4” (102 mm) clearance

below snorkel. (Fig. 26)

Do not back fill around snorkel. A clearance

of at least 4” (102 mm) must be maintained

between snorkel and the soil.

Zero Clearance

Sleeve

(if required)

Firestop

7” Pipe

Screws

7TDVSNORK

(Snorkel)

4” (102mm)

Clearance

Min.

FP1475

Fig. 25 Bend flex vent at 90° so horizontal portion is 6¹⁄₂”

(165 mm) off top of unit.

Below Grade Installations

When it is not possible to meet the required vent terminal clearances of 12” (305mm) above grade level a

snorkel vent kit is recommended. It allows installation

depth of down to 7” (178mm) below grade level. The 7”

is measured from the center of the horizontal vent pipe

as it penetrates through the wall.

If venting system is installed below

ground, we recommend a window well with

adequate and proper drainage.

Ensure sidewall venting clearances are observed.

If installing a snorkel a minimum 24” (610 mm) vertical

rise is necessary. The maximum horizontal run with

the 24” (610 mm) vertical pipe is 36” (914 mm). This

measurement is taken from the collar of the fireplace

(or transition elbow) to the face of the exterior wall.

Refer to the Sidewall Vent Graph for extended

horizontal run if the vertical rise exceeds 24” (610 mm).

Window

24” (610mm)

Minimum*

Drain

Foundation Wall

*A minimum of 24” (610mm) ver

tical pipe must be installed when

using the 7TDVSNORK Kit.

*The 22” (559mm) vertical rise

(center to center) of the snorkel

may be included for calculationof

max. horizontal run.

BG402

Fig. 26 Below grade installation.

Well

Gravel

-

If the foundation is recessed, use recess brackets (not

supplied) for securing lower portion of the snorkel.

Fasten brackets to wall first, then secure to snorkel

with self drilling #8 x 1/2 sheet metal screws. It will be

necessary to extend vent pipes out as far as protruding

wall face. (Fig. 27)

16

10007852

Page 17

1

2

3

4

Max. 8' (2.4m)

Snorkel

Max. 10' (3m)

Max. Height

40' (12m)

Min. Height

7' (2.3m)

Foundation Recess

Recess Brackets

Watertight Seal

Around Pipe

Fig. 27 Snorkel installation, recessed foundation.

Wall Screws

Sheet Metal

Screws

BG401

Vertical Through-the-Roof Applications

This Gas Fireplace has been approved for:

• Vertical installations up to 40’ (12 m) in height. Up

to a 10’ (3 m) horizontal vent run can be installed

within the vent system using a maximum of two 90°

elbows. (Fig. 28)

LDVT Series Direct Vent GaS Fireplace

Example: Maximum horizontal length

0 x 45° elbows = 10’ (3 m)

1 x 45° elbows = 8

¹⁄₂’ (2.6 m)

2 x 45° elbows = 7’ (2.1 m)

• A minimum of an 8’ (2.4 m) vertical rise.

• Two sets of 45° elbows offsets within these vertical

installations. From 0 to a maximum of 8’ (2.4 m) of

vent pipe can be used between elbows. (Fig. 29)

• 7DVCS must be used to support offsets. (Fig. 31)

This application will require that you first determine

the roof pitch and use the appropriate starter kit.

(Refer to Venting Components List)

• The minimum height of the vent above the highest

point of penetration through the roof is 2’ (610 mm).

(Fig. 33)

Pipe Straps Every

3’ (914mm)

Fig. 28 Support straps for horizontal runs.

• Up to two 45° elbows may be used within the

horizontal run. For each 45° elbow used on the

horizontal level the maximum horizontal length must

be reduced by 18” (457 mm).

1 + 2 + 3 + 4 = 270°

FP1244

FP1245

Fig. 29 Typical offset application.

10007852

17

Page 18

LDVT Series Direct Vent Gas Fireplace

11"

(279mm)

11"

(279mm)

Min.

2' (610 mm)

Vertical Through-the-Roof Installation

1. Locate your fireplace.

2. Plumb to center of the (4” (102 mm) flue collar from

ceiling above and mark position.

3. Cut opening equal to 9

4.

Proceed to plumb for additional openings through

the roof. In all cases, the opening must provide a

minimum of 1” (25mm) clearance to the vent pipe, i.e.,

the hole must be at least 9³⁄₈” x 9³⁄₈” (240 x 240 mm).

5. Place fireplace into position.

6. Place firestop(s) #7DVFS or Attic Insulation Shield

#7DVAIS into position and secure. (Fig. 30)

Attic Insulation

Shield

³⁄₈” x 9³⁄₈” (240 x 240 mm).

Typical Roof Support

Application

Fig. 31 Roof and ceiling supports.

Typical Ceiling Sup

-

port Application

CFM110

Joist

Ceiling Installation

Fig. 30 Place firestop spacer(s) and secure.

Upper Floor

Joist

Firestop Spacer

Nails (4)

CFM100a

7. Install roof support (Fig. 31) and roof flashing making

sure upper flange of flashing is below the shingles.

(Fig. 32)

8. Install appropriate pipe sections until the venting is

above the flashing. (Fig. 32)

9. Install storm collar and seal around the pipe.

10. Add additional vent lengths for proper height. (Fig.

33)

#8 Sheet Metal Screws

(3 per joint)

Sealant

Storm Collar

TWL101a

Fig. 32 Roof flashing.

CFM190

Fig. 33 Minimum termination to roof clearance.

18

If there is a room above ceiling level,

firestop spacer must be installed on both

the bottom and the top side of the ceiling

joists. If an attic is above ceiling level a

7DVAIS (Attic Insulation Shield) must be

installed.

The enlarged ends of the vent section

always face downward. (Fig. 32)

10007852

Page 19

Vertical Restrictor Plate

36LDVT, 39LDVT, 43LDVT

When installing the 36LDVT, 39LDVT or 43LDVT with a

vertical through-the-roof configuration flue system, the

restrictor plate (#10008048) supplied with the appliance

MUST BE FITTED TO THE APPLIANCE at the installation.

NOTE: Do not use the restrictor plate supplied with

the vertical termination cap.

1. Remove the rear log support. Save the two (2)

screws.

2. Remove the two (2) nuts and save them.

3. Place the restrictor plate (Fig. 34) and secure it with

the two (2) nuts.

4. Replace the rear log support to the same location

as before and secure it with the screws removed in

Step 1.

LDVT Series Direct Vent GaS Fireplace

Rear Log Support

Restrictor Plate

Fig. 34 Assembling the restrictor plate.

FP1555

10007852

19

Page 20

LDVT Series Direct Vent Gas Fireplace

Venting Components

7TDVRVT - Through the wall Rear Vent Termination

Starter Kit Model 7TDVSK - Sidewall Venting (Twist Lock Pipe)

Model 7FDVSK - Sidewall Venting (Flex Vent Pipe)

Models 7TDVTK/TV - Hot Touch Termination Kits

Model 7TDVTVTK/TV - Cool Touch Termination Kit

Starter Kit - Model 7TDVSKV - Vertical Venting

for 7TDVSKV-A order 1/12 to 6/12 roof pitch

for 7TDVSKV-B order 7/12 to 12/12 roof pitch

for 7TDVSKV-F order flat roof

Starter Kit for Below Grade Installation

Model 7TDVSKS -Snorkel Kit (Twist Lock Pipe)

Model 7FDVSKS -Snorkel Kit (Flex Vent Pipe)

Starter Pipe

Model 7TDVP 20/8 - 24” Starter Pipe Bulk

Model 7FDVP 30/8 - 30” Flex Pipe Bulk

45o Elbow

7TDV45 for Rear Vent to Vertical Vent

or Vertical/Horizontal Offsets

90o Transition Elbow

7TDVRT90 for Rear Vent to Vertical Vent

90° Elbow

7TDV90 Vertical/Horizontal Offset

Telescopic vent sections

7TDVP1117 -11” to 17” adjustable length

7TDVP3567 -35” to 67” adjustable length

Pipe sections for vertical or horizontal venting

Model 7TDVP8” - 4 per box

Model 7TDVP12” - 4 per box

Model 7TDVP24” - 4 per box

Model 7TDVP36”

Model 7TDVP48”

Firestop Spacer

Model 7DVFS

20

Attic Insulation Shield

Model 7DVAIS

Vertical/Horizontal Combination Offset Support

Model 7DVCS

10007852

Page 21

LDVT Series Direct Vent GaS Fireplace

1.

2.

�

Operating Instructions

Glass Information

Only glass approved by CFM Corporation

should be used on this fireplace.

• The use of any non-approved replacement glass will

void all product warranties.

• Care must be taken to avoid breakage of the glass.

• Do not operate appliance with glass front

removed, cracked or broken.

• Replacement glass (complete with frame

window) is available through your CFM

Corporation dealer and should only be installed

by a licensed qualified service person.

Louvre Removal

6. Tilt the glass frame out slightly at the bottom, lift the

frame up and away from the fireplace.

7. To replace the glass frame reverse the procedure.

Lower Clamps

Window

Frame Assembly

Window

Frame

Assembly

Fig. 36 Window frame assembly removal.

Push

Clamp

Handle

Pull

Clamp

Hook

FP1228

The top louvre

panel is removed

by lifting the

panel vertically

and pulling it

away from the

appliance. (Fig.

35)

The lower access

door is hinged

along the bottom

edge and is

folded down to

allow access

FP1227

Fig. 35 Remove top louvre assembly.

Window Frame Assembly Removal

1. Turn the fireplace OFF (including the pilot)

2. If the unit has been operating allow time for the

components to cool.

3. Remove the top louvre assembly.

4. Open the lower louvre panel.

5. Release the two clamps securing the lower edge of

10007852

the frame by pulling down on the handles. (Fig. 36)

Louvre

Glass Panel

Glass Cleaning

It is necessary to periodically clean the glass. During

start-up condensation, which is normal, forms on the

inside of the glass. This condensation causes lint, dust

and other airborne particles to cling to the glass surface.

Also initial paint curing may deposit a slight film on the

glass. It is therefore recommended that the glass be

cleaned two or three times with a non-ammonia based

household cleaner and warm water (We recommend

gas fireplace glass cleaner) within the first few weeks of

operation.

After the initial cleaning process the glass should be

cleaned two or three times during each operating

season depending on the environment in the house.

Clean the glass after the first two weeks of

operation.

Do not clean glass when hot.

Do not use abrasive cleaners.

Do not strike or slam glass.

21

Page 22

LDVT Series Direct Vent Gas Fireplace

Installation of Logs, Lava Rock & Ember Material

The logs are fragile and should be handled

with care. Keep the packaging material out

of the reach of children and dispose of the

material in a safe manner.

The individual logs can be easily identified

by the numbers cast on the underside of

each log.

Log Identification Chart

Location 33LDVT 36LDVT 39LDVT 43LDVT

Front Left A43 B160 BC15 BD16

Front Right -- B159 BC16 BD17

Front Center -- B161 B138 B138

Rear -- B158 BC14 BD15

Rear Left A41 -- -- - Rear Right A42 -- -- - Top Center A44 -- -- BD18

Log Installation

1. Remove the top louvre assembly.

2. Open the bottom louvre.

3. Remove the window frame assembly.

4. Remove log box from inside firebox.

5. Unpack the logs from packaging and remove each

log from its wrapping material. Set aside the ember

and the lava rock bags.

As with all plastic bags - these are not toys

and should be kept away from children and

infants.

33LDVT

1. Place rear log left (A41) on rear bracket (ensure the

notch on the left end locates against the bend up on

the left side of rear bracket.)

2. Place rear log right (A42) on rear bracket (ensure

the notch on the right end locates against the bend

up on the right side of rear bracket) and just rest the

cut out from front log onto the front support.

3. Place front log left (A43). Use the log’s bottom hole

to locate it onto rear log left (A41) and just rest bottom cut out log onto the front support.

4. Place top log center (A44). Use the log’s bottom

hole to locate it onto the knob on the rear log right

(A42) and the top log center rest onto rear log left.

5. Place ember material on top of burner. Scatter the

ember material over the tiles on the front area of the

burner housing. (Fig. 44) Do not pack the ember

material. Separate it when unpacked and keep it

in a fluffy and loose condition for a more realistic

ember effect.

6. Scatter the lava rock material around the firebox

base.

Do not place any of the lava rock material

on the burner housing assembly.

22

Top Center

Rear Left

(A41)

Front Left

(A43)

Fig. 37 Correct log placement for 33LDVT.

(A44)

Rear Right

(A42)

LG382

10007852

Page 23

36LDVT

LDVT Series Direct Vent GaS Fireplace

1. Place rear log (B158) on rear bracket (ensure log is seated properly to

the bracket and located to the two

pins), so it will not move from side to

side and is firmly positioned on the

bracket.

2. Place front left log (B160). Use the

log’s bottom hole to locate it onto

the front support and just rest on top

of the rear log.

3. Place front right log (B159). Use the

log’s bottom hole to locate it onto

the front support and the top hole to

the knob onto the rear log.

4. Place front center log (B161) on top

of the two small shelves at the front

log support and between the left

and right logs.

5. Place ember material on top of

burner. Scatter the ember material

over the tiles on the front area of

the burner housing. (Fig. 45) Do not

Fig. 38 Correct log placement for 36LDVT.

pack the ember material. Separate it when unpacked

and keep it in a fluffy and loose condition for a more

realistic ember effect.

6. Scatter the lava rock material around the firebox

base.

Front Left

(B160)

Rear

(B158)

Front Right

Front Center

(B161)

(B159)

LG481

Do not place any of the lava rock material

on the burner housing assembly.

39LDVT

1. Place rear lob (BC14) on rear bracket

(ensure log is centered and seated

properly to the log support).

2. Place front left log (BC15). Use log’s

bottom hole to locate it onto the front

support and just rest on top of the

rear log.

3. Place front right log (BC16). Use log’s

bottom hole to locate it onto the front

support and the top hole to the knob

on the rear log.

4. Place front center log (B138) on top

of the two small shelves at the front

log support, and between the left and

right logs.

5. Place ember material on top of

burner. Scatter the ember material

over the tiles on the front area of the

burner housing. (Fig. 46) Separate it

when unpacked and keep it in a fluffy

and loose condition for a more realistic ember effect.

Front Left

(BC15)

Fig. 39 Correct log placement for 39LDVT.

Do not place any of the lava rock material

on the burner housing assembly.

Front Right

(BC16)

Front Center

(B138)

Rear

(BC14)

LG414

10007852

23

Page 24

LDVT Series Direct Vent Gas Fireplace

Turn

counterclockwise

to decrease

flame height

Turn clockwise

to increase

flame height

L

O

H

I

Turn

counterclockwise

to increase

flame height

Turn clockwise

to decrease

flame height

43LDVT

1. Place rear log (BD15) on rear bracket

(ensure log is centered and seated

properly to the log support).

2. Place front left log (BD16). Use log’s

bottom notch to locate it onto the front

support and just rest on top of the

burner housing assembly.

3. Place front right log (BD17). Use log’s

Front

Left

(BD16)

bottom notch to locate it onto the front

support and just rest on top of the

burner housing assembly.

4. Place ember material on top of burner.

5. Scatter the ember material over the

tiles on the front area of the burner

housing. (Fig. 40) Do not pack the

ember material. Separate it when

unpacked and keep it in a fluffy and

loose condition for a more realistic

ember effect.

6. Place front center log (B138) on top of

the two small shelves at the front log

support, and between the left and right

logs.

Fig. 40 Correct log placement for 43LDVT.

7. Place top center log (BD18) on top of

the rear log using the hole locator under the log and

on top of front right log.

8. Scatter lava rock material round the firebox base.

Rear

(BD15)

Lava Rock

Top Center

(BBD18)

Front Right

(BD17)

Lava

Rock

Ember Material

Front Center

(B138)

LG434

Do not place any of the lava rock material

on the burner housing assembly.

Flame Characteristics

Flame & Temperature Adjustment

RN/RP & EN/EP Models

For units equipped with ‘HI/LO’ valves the flame

adjustment is accomplished by rotating the ‘HI/LO’

adjustments knob located near the center of the gas

control valve. (Fig. 41-42)

Fig. 41 Flame adjustment knob for Honeywell valve.

Fig. 42 Flame adjustment knob for SIT valve.

It is important to periodically perform a visual check of

the pilot and burner flames. Compare them to Figures

43 and 44.

If the flame patterns appear abnormal contact a

qualified service provider for service and adjustment.

SIT RN/RP

SIT EN/EP

FP1541

Fig. 43 Correct pilot flame appearance.

24

10007852

Page 25

LG384

LDVT Series Direct Vent GaS Fireplace

33LDVT

Glowing Embers

36LDVT

LG415

LG482

Glowing Embers

39LDVT

Glowing Embers

43LDVT

LG435

Fig. 44 Correct burner flame appearance for the LDVT fireplaces.

10007852

Glowing Embers

25

Page 26

LDVT Series Direct Vent Gas Fireplace

P

I

L

O

T

O

F

F

O

F

F

5

4

3

2

1

O

F

F

P

i

l

o

t

3/8" - 1/2"

Lighting and Operating Instructions

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This heater has a pilot which must be lit manu

ally. When lighting the pilot follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

heater area for gas. Be sure to smell next to

the floor because some gas is heavier than air

and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any fireplace

• Do not touch any electric switch

• Do not use any phone in your building

• Immediately call your gas supplier from a

neighbor’s phone.

Lighting Instructions

-

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call

the Fire Department

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, do not try to repair it, call a

qualified service technician. Applying force or any

attempted repair may result in a fire or explosion.

D. Do not use this fireplace if any part has been under

water. Immediately call a qualified service technician to inspect the heater and to replace any part of

the control system and any gas control which has

been under water.

1. STOP! Read the safety information above.

2. Turn off all electrical power to the fireplace.

3. For MN/MP/TN/TP appliances ONLY, go on to

Step 4. For RN/RP appliances turn the ON/OFF

switch to “OFF” position or set thermostat to

lowest level.

4. Open control access panel.

5. Push in gas control knob slightly and turn clockwise to “OFF”.

Euro SIT SIT NOVA

Honeywell

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety information above. If you do not smell gas, go to the

next step.

7. Remove glass door before lighting pilot. (See

Glass Frame Removal section).

8. Visibly locate pilot by the main burner.

9. Turn knob on gas control counterclockwise

to “PILOT”.

10. Push the control knob all the way in and hold.

Immediately light the pilot by repeatedly depressing the piezo spark ignitor until a flame appears.

Continue to hold the control knob in for about one

(1) minute after the pilot is lit. Release knob and it

will pop back up. Pilot should remain lit. If it goes

out, repeat steps 5 through 8.

• If knob does not pop up when released, stop

and immediately call your service technician or

gas supplier.

• If after several tries, the pilot will not stay lit,

turn the gas control knob to “OFF” and call your

service technician or gas supplier.

11. Replace glass door.

12. Turn gas control knob to “ON” position.

13. For RN/RP appliances turn the ON/OFF switch to

“ON” position or set thermostat to desired setting.

14. Turn on all electrical power to the fireplace.

To Turn Off Gas To Heater

1. Turn the ON/OFF switch to Off position or set

the thermostat to lowest setting.

2. Turn off all electric power to the fireplace if

service is to be performed.

26

3. Open control access panel.

4. Push in gas control knob slightly and turn clockwise to “OFF”. Do not force.

5. Close control access panel.

10007852

Page 27

LDVT Series Direct Vent GaS Fireplace

HI

LO

Lighting and Operating Instructions

For Fireplaces equipped with SIT822 Gas Valve (EN or EP)

Warning:If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury and loss of life.

FOR YOUR SAFETY READ THE FOLLOWING WARNINGS

BEFORE LIGHTING THE APPLIANCE

A. This fireplace is equipped with an ignition device

which automatically lights the pilot. DO NOT try to

light the pilot by hand.

B. BEFORE OPERATING, smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than the air

and will settle on the floor.

What to do if you smell gas

• Do not try to light any appliance

• Do not operate any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone.

Lighting Instructions

1. STOP! Read the safety information above before

continuing.

2. Turn off all electrical power to the appliance.

3. This appliance is equipped with an ignition device

which automatically lights the pilot. DO NOT try to

light the pilot by hand.

4. Access the gas control by lowering the lower

access door (louvre assembly).

Follow the gas suppliers instructions.

• If you cannot contact your gas supplier call

the Fire Department

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand do not try to repair it, call

a qualified service technician. Force or attempting

repair may result in a fire or explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and replace

any part of the control system and any gas control

that has been under water.

5. Turn the remote switch, if used, OFF. Turn the

wireless remote, if used, OFF.

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas STOP. Follow instructions B in the safety

warnings above. If you do not smell gas go onto the

next step.

7. Close the access door.

8. Turn ON all electrical power to the appliance.

9. Turn remote switch or wireless remote to “ON”.

10. If the appliance will not operate, follow the

instructions TURNING OFF THE GAS TO THE

APPLIANCE and call your service technician or

gas supplier.

Turning Off the Gas to the Appliance

1. Turn the remote switch to the “OFF” position.

2. Turn OFF all electrical power to the fireplace if

service is required.

3 Open the lower access panel.

4. Turn the shut-off valve on the flexible gas line to

the “OFF” position.

10007852

1/2” Gas Supply

1/2” NPT x 1/2” Flare Shut-Off

Valve

Valve in the on position

3/8” Flex Line

(From Valve)

FP297A

27

Page 28

LDVT Series Direct Vent Gas Fireplace

Troubleshooting Honeywell Millivolt Valve

Remove Window Frame Assembly Before Service Work

START CHECK

Gas Supply On

YES

Pilot Lights With Piezo

Ignitor

YES

Pilot Stays Lit

YES

NO

NO

NO

• Supply Line Hooked Up

• Shutoff Valve Open

• Lockout Has Engaged. Wait 60

Seconds And Try Again.

• For Spark At Electrode While

Depressing Piezo

1/8" Gap To Pilot Hood Needed.

• All Wiring Connections

• Replace Piezo Ignitor

• For Air In The Lines

• Thermopile Needs A Min.

325mv. Adjust Pilot Flame

Height.

• All Wiring Connections

• Replace Thermopile

• Thermocouple Needs A Min. Of

14mv

• Defective Valve. Turn To Pilot,

Meter Should Read Greater

Than 100mv. If Not, Replace.

28

Pilot Lights Main Burner

YES

SYSTEM OK

NO

• Valve Is Turned On

• Wall Switch Is Not Turned On.

Watch For Grounded Wires!

• Thermopile Needs A Min. 325mv.

• Plugged Burner Orifice

10007852

Page 29

LDVT Series Direct Vent GaS Fireplace

Troubleshooting the Gas Control System

SIT 822 Valve with Synetek Electronic Control

Operating Diagram

Normal Operation

ON/OFF Switch Closed?

YES

Safe Start Check On?

YES

0 Sec Purge

Ignition Trial: 30 sec Spark ON

Pilot Valve ON. Has Flame

been Detected within 30 sec?

Spark Off. Main Valve ON.

Pilot Flame Continuously

Monitored

NO

NO

Abnormal Operation

5 sec Inter-Trial Delay

LED: Steady Flash?

Lockout: Flame detected out of sequence

Reset by interrupting ON/OFF switch or

power for 10 sec

LED: 5 Flashes?

Reverse power cord polarity

LED: 2 Flashes?

Reset by interrupting ON/OFF

switch for power for 10 sec

YES

Pilot, Valve OFF, Spark OFF

Have three ignition trials been completed?

NO

Pilot Flame Sense OK?

ON/OFF Switch Opened?

YES

Pilot and Main Valve OFF?

YES

0 sec Post Purge?

Heating Cycle Complete LED:

OFF

NO

LED: 3 Flashes?

Lockout: Flame Loss

Reset by interrupting ON/OFF switch or

power for 10 sec

Main Valve OFF, Spark ON

YES

Has flame been detected within 30 sec?

NO