Page 1

Gasket Kit #4322

Installation Instructions

for use on the

Defiant Stove

Vermont Castings’ stoves use a rope-type gasket to

make a seal between some parts. With use, this gasket

can become compressed and begin to lose its effectiveness. It should then be replaced.

This kit includes materials to re-gasket a Model #1910

or #1945 Defiant stove. This stove model has glass

panels in the front doors. This kit is not appropriate for

the 1975-1988 model Defiant stoves which do not have

glass panels in the front doors.

Contents

• 3.5’ of 5/16” Glass Fiber Gasket for the damper

• 7’ of 3/16” Glass Fiber Gasket (Glass)

• 4¹⁄₂’ of 5/16” Wire Reinforced Glass Fiber “Armaseal”

for the griddle

• 10.9’ of 3/8” Glass Fiber Gasket for the ash door and

main doors

• 3 oz. Tube of Gasket Cement

Tools Required

Phillips screwdriver

Utility knife or scissors

Wire brush

Small cold chisel

Rubber mallet, or hammer and wood block

Flashlight or droplight

Installation Precautions

Be sure the fire is out and the stove has cooled before

replacing the gasket, and be sure to follow the standard

safety procedure for working with dusty materials: Wear

safety goggles and a dust mask.

Installation Instructions

Gaskets provide a tight seal between moving parts.

Eventually these gaskets will become compressed and

will no longer seal properly. Replacing the gaskets will

improve performance. For a guide to each gasketed

area, refer to the following sections and illustrations.

Regardless of its location, replacing a gasket involves

these steps:

1. Remove the existing gasket by scraping it out of its

channel with an old screwdriver.

2. Clean the gasketing channel with a wire brush. Be

careful with adjacent surfaces, especially if they are

enamelled. Remove any stubborn deposits with a

small cold chisel. Clean both mating surfaces thoroughly to bare metal.

3. Cut the appropriate size gasket to length, allowing

an extra inch.

4. Knead the tube of cement before opening, to mix the

contents thoroughly.

5. Place an unbroken 1/8” bead of gasket cement in

the channel. Do not use too much cement as it may

saturate the gasket; the gasket must remain soft

and resilient. One tube of cement will produce a 1/8”

bead sufficient for all the gasket in this kit.

6. Starting with one end, press the gasket into the

cemented channel. If the gasket goes around and

meets itself, ensure that you have a good joint before trimming the excess gasket. Do not overlap or

leave ragged edges.

7. Seat the gasket by placing it firmly against its normal

mating surface. A slip of waxed paper between the

gasket and its mating surface will help keep the cement from traveling through the gasket and sticking

to the mating surface. Clean away any excess cement.

8. With enamel stoves, be careful to keep cement off

the enamel finish. If cement does accidentally get on

the enamel, wash it off immediately with warm water.

9. Allow to dry. Be sure to remove the waxed paper!

10. If you have questions, refer to the Defiant Owner’s

Manual, or a Vermont Castings Dealer.

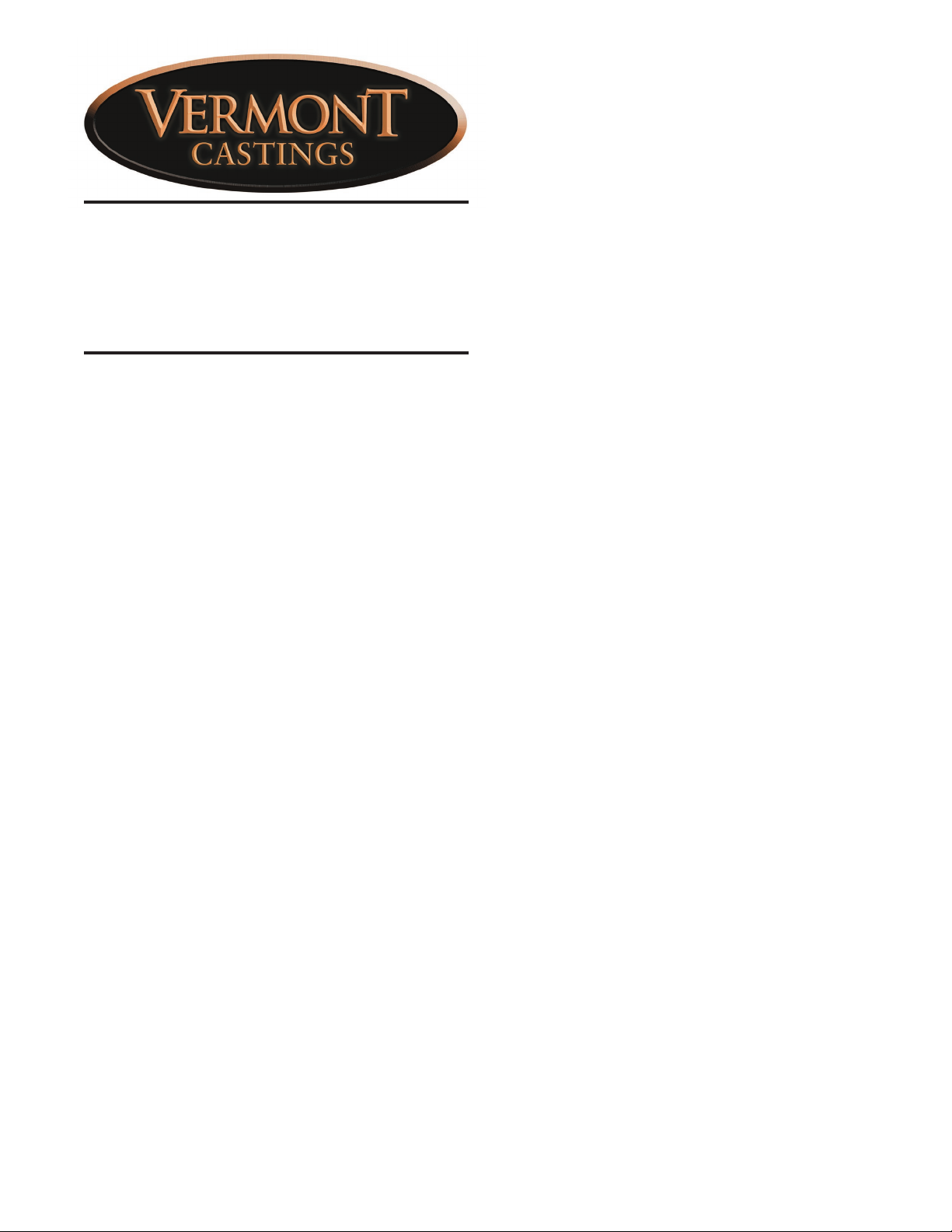

Griddle

Remove the griddle. Pull off the old gasket and clean

the channel with the wire brush. Set the steel reinforced

5/16” gasket in the griddle channel and mark the correct length. Place the gasket on a wood cutting surface

and trim with a utility knife or scissors. Twist the ends

slightly to prevent unraveling. Place a continuous 1/8”

bead of gasket cement in the channel and press the

gasket into place. Replace the griddle and compress

against the gasket by striking around the edges with

the rubber mallet or hammer and block of wood. Do not

strike the stove top.

2003144 8/08 Rev. 6

Page 2

Gasket

KT314

Fig. 1 Griddle gasket.

Ash Door

You may find it helpful to remove the ashpan bracket

from the inside ashdoor; use a 7/16” wrench for this.

Remove the old gasket and clean the gasket channel

thoroughly. Clean the ash door and mating edges of

the ash drop. Cut the required length of 3/8” diameter

gasket plus one inch. Place a continuous 1/8” bead

of gasket cement in the channel and press the gasket

into place, trimming the excess carefully. Replace the

ashpan bracket if you removed it. Close and latch the

ash door to seat the new gasket.

Gasket

Ashpan Bracket

Mounting Points

KT315

Fig. 2 Inside view of ashdoor (ashpan bracket removed).

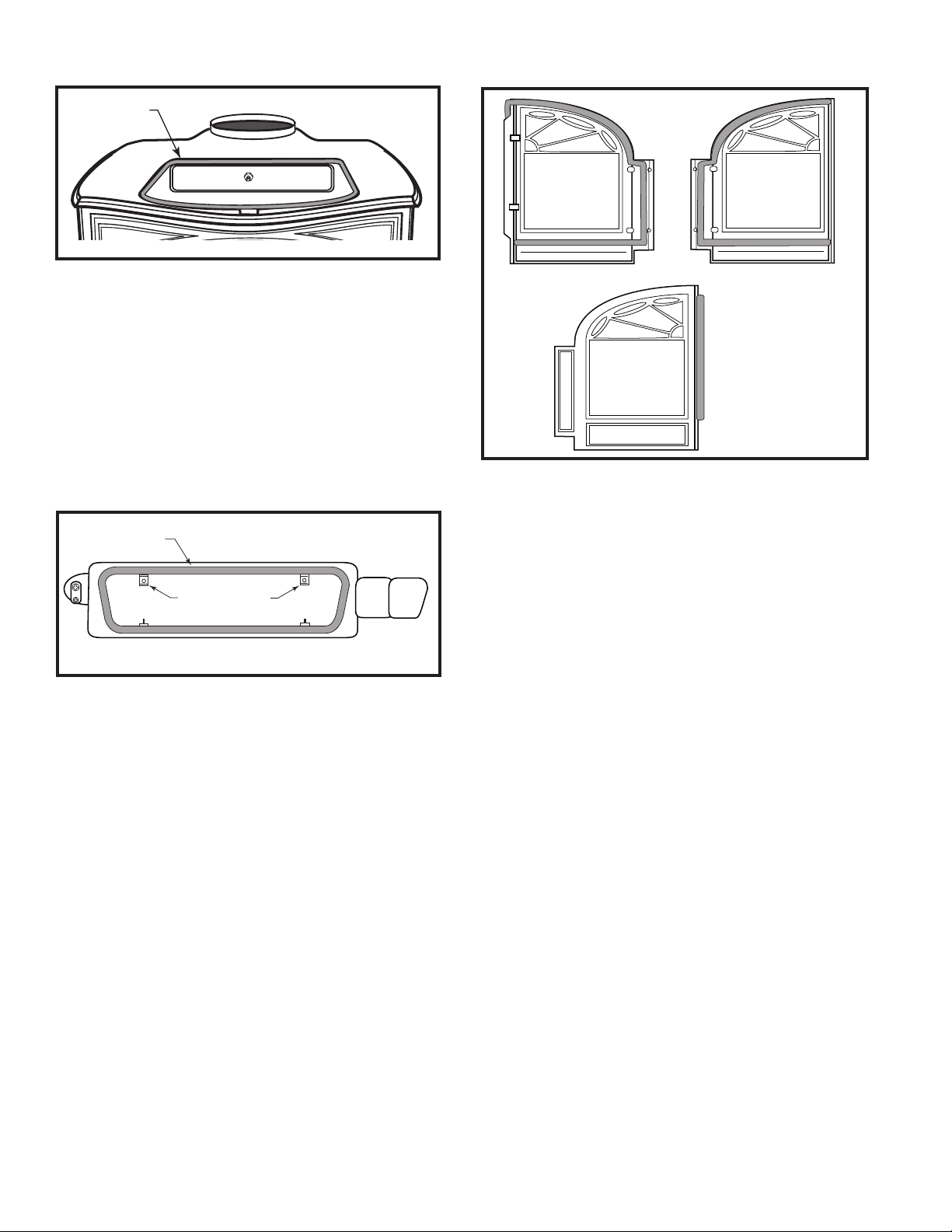

Front Doors

Carefully remove the doors and place them face down

on a padded surface. Note where the gasket ends are

trimmed so you can make an exact replacement.

1. Pull out the old gasket and clean each gasket chan

nel with the wire brush.

2. Lay the new 3/8” diameter fiberglass in place and

trim it to length.

3. Place a continuous 1/8” bead of gasket cement in

the gasket channel and press the trimmed gasket

into place. Remove any excess cement that may

have squeezed out around the gasket.

4. If you are also replacing the glass gasket, go on to

the next section. If you are not dealing with the glass

gasket, replace the doors on the stove and latch the

doors to seat the gasket.

Inside View of

Front Doors

Outside view of

left door showing

gasket on outside

of the door.

KT316

Fig. 3 Door perimeter gasket.

Glass

The Defiant stoves use glass panels with an infrared

reflective coating. Since the coating goes on the room

side of the door, there is a “left” and a “right” pane. Be

sure to mark which is which. In manufacturing, the Defiant has a flat die-cut gasket between the glass and the

door. You will replace this with a 3/16” diameter round

gasket.

1. Remove the door assemblies and place on a padded

surface, inner side up.

2. Remove the screws and retainer clips from both

doors. Pull off the old glass fiber gasket and clean

the support ledge thoroughly.

3. Cut the required replacement gaskets, allowing a

little excess. Place a continuous 1/8” bead of cement

on each support ledge and press the gaskets into

-

place, trimming the excess carefully and removing

any excess cement.

4. Clean only the inside of the panes.

5. Center the glass on the gasket. Be sure to place the

pane with its coated side facing out into the room.

6. Replace the retainer clips and snug down the

screws. Do not overtighten the screws, since the

glass must move a little under heat.

7. Replace the doors on the stove.

Damper

The Defiant’s damper mechanism includes an adjusting screw visible on the face of the damper when the

griddle is open. Be sure the damper is adjusted properly before you decide to replace the gasket. Test the gasket by closing the damper on a group of narrow slips of

2

2003144

Page 3

Rope Gasket

Glass Panel

3. Open the front doors of the stove and remove the

ashes. If necessary, empty the ashpan, and rake the

ashes left and right in the firebox till they fall through

the slots in the grate, and into the ashpan.

4. Lift the baffle off its support brackets. Remove it from

the stove and set it down on a protected surface.

(Fig. 6)

Baffle Support Brackets

Catalytic

Element

KT317

Fig. 4 Glass gasket.

Replacement Glass Gasket

paper all around the perimeter of the damper opening.

With the damper closed and locked, it should not be

possible to pull the papers out without resistance. The

more easily the paper pulls out, the less secure the seal

is at that spot.

1. To adjust the damper seal, loosen the locking hex nut

on the adjusting allen screw. (Fig. 5) Turn the screw

clockwise with a hex wrench, in half-turn increments,

until the damper grips the paper slips securely when

you test the damper’s operation. When you have

achieved a snug seal, fasten the locking nut against

the face of the damper. The seal should not be tight

since the metal parts will expand slightly under heat.

Pressure Adjusting Screw

Allen

Wrench

Fig. 5 Damper adjustment.

Lock Nut

Damper

ST554

2. It is possible, but awkward, to replace the damper

gasket without removing the upper fireback panel

which locates and supports the damper. To remove

the upper fireback assembly, open the damper. Use

an allen wrench to remove the damper handle from

the damper rod on the left side of the stove.

ST555

Fig. 6 Remove the baffle.

Alignment Notches

Left Wedge

Brick Guide

Brick Clip

ST556

Fig. 7 Remove the bricks and brick retainer.

Bricks

Right Wedge

5. Remove the firebricks. Lift off the steel clip and remove the firebricks individually. (Fig. 7)

6. Tap the left and right wedges upward with a rubber

mallet or a hammer and block of wood to protect the

cast iron. (Fig. 7) Remove the wedges and remove

the lower fireback by pulling its top edge toward

yourself. (Fig. 8) Lift the lower fireback out of the firebox and set it on a shielded surface.

7. Four hex head bolts pass through the stove’s outer

back to fasten the upper fireback in place. Remove

these bolts. If the stove has a rear heat shield in

place, you may find it easier to remove the shield

first, and then the upper fireback bolts. You can

leave the heat shield spacers in place.

2003144

3

Page 4

Lower Fireback

Fig. 8 Remove the lower fireback.

ST557

8. From inside the firebox, pull the right-hand end of the

upper fireback toward yourself. Carefully maneuver the left end of the fireback assembly to let the

damper rod clear its hole in the left side of the stove.

Be sure to capture the spacer on the left end of the

damper rod. Remove the assembly from the stove

and set it on a shielded working surface.

Gasket

KT318

Fig. 9 Back view of upper fireback (damper and rod removed).

9. Pull the damper rod out of the upper fireback.

Release the bolts holding the steel tabs in place,

and remove the damper. Pull off the old gasket

and clean off the old cement. Thoroughly clean the

damper plate and around the damper opening in

the upper fireback. Cut a piece of the 5/16” gasket material to length, allowing a one inch excess.

Place a continuous 1/8” bead of gasket cement in

the damper gasket channel. Press the new gasket

in place, trimming off the excess length. (Fig. 9)

Remove any excess cement. Replace the damper,

the steel tabs and bolts, and the damper rod. Close

and lock the damper to seat the gasket. Use waxed

paper between the damper and the upper fireback to

keep the cement from traveling through the gasket

and sticking to the fireback.

10. This is a fine opportunity to inspect the catalyst.

Follow the directions in the Defiant Owner’s Manual

on access, inspection, evaluation and replacement if

needed.

11. Work in reverse order to replace parts once the gas

ket cement has dried on the upper fireback assembly. Be sure to install the spacer on the left end of

the damper rod before installing the upper fireback

assembly.

12. Install the upper fireback assembly, left end first;

pass the damper rod through he hole in the left side

of the stove, then lift the right end of the assembly

into place. Loosely install all four bolts before you

tighten any of them. These bolts should be snug but

not tight, to allow some expansion and movement

under heat.

13. Test the damper operation and the gasket’s snug

ness, as described at the start of this section.

Continue after you are sure the damper operates

properly.

14. Install the lower fireback. Note that there are two

notches in the bottom edge; these must align behind

two mating nubs on the firebox floor.

15. Stand the five firebricks on end in front of the lower

fireback. Note that these stand behind a raised rib

on the firebox floor. (Fig. 7) Join the firebricks by

slipping the steel clip onto their top ends. The clip’s

longer edge should go behind the firebricks, for

easier installation.

16. Replace the left and right wedges. Note that their

rear vertical edges bear against the outermost left

and right edges of the lower fireback. Gently tap the

wedges downward with a rubber mallet or a hammer and a block of wood to cushion the impact. The

wedges should be snug but not overly tight.

17. Replace the baffle by placing its ends on the sup

port brackets which are part of the lower fireback.

The baffle shields the catalytic combustor from direct

flame impingement and must be in place during

operation.

Testing the Gasket Seals

After the cement has had several hours to dry, test the

new door seal by closing and latching the door on slips

of paper placed at approximately 6” intervals along the

top and bottom of the door opening. Be sure to include

the area where the right front door overlaps the left

door. It should not be possible to slide the papers, and

they should be pulled straight out only with considerable resistance. If the paper pulls out easily, readjust

the doors as needed till the doors hold the paper tightly.

Do not apply this test to the glass gasketing - it is not

accessible and does not get the repeated impacts that

other seals receive.

-

MHSC

149 Cleveland Drive • Paris, Kentucky 40361

4

www.mhsc.com

2003144

Loading...

Loading...