Page 1

SAFETY

ASSEMBLY INSTALLATION OPERATION PARTS LIST

WARNING:

Before operating product, read this

manual and follow all its Safety and

Operating Instructions.

FRANÇAIS/

ESPAÑOL

®

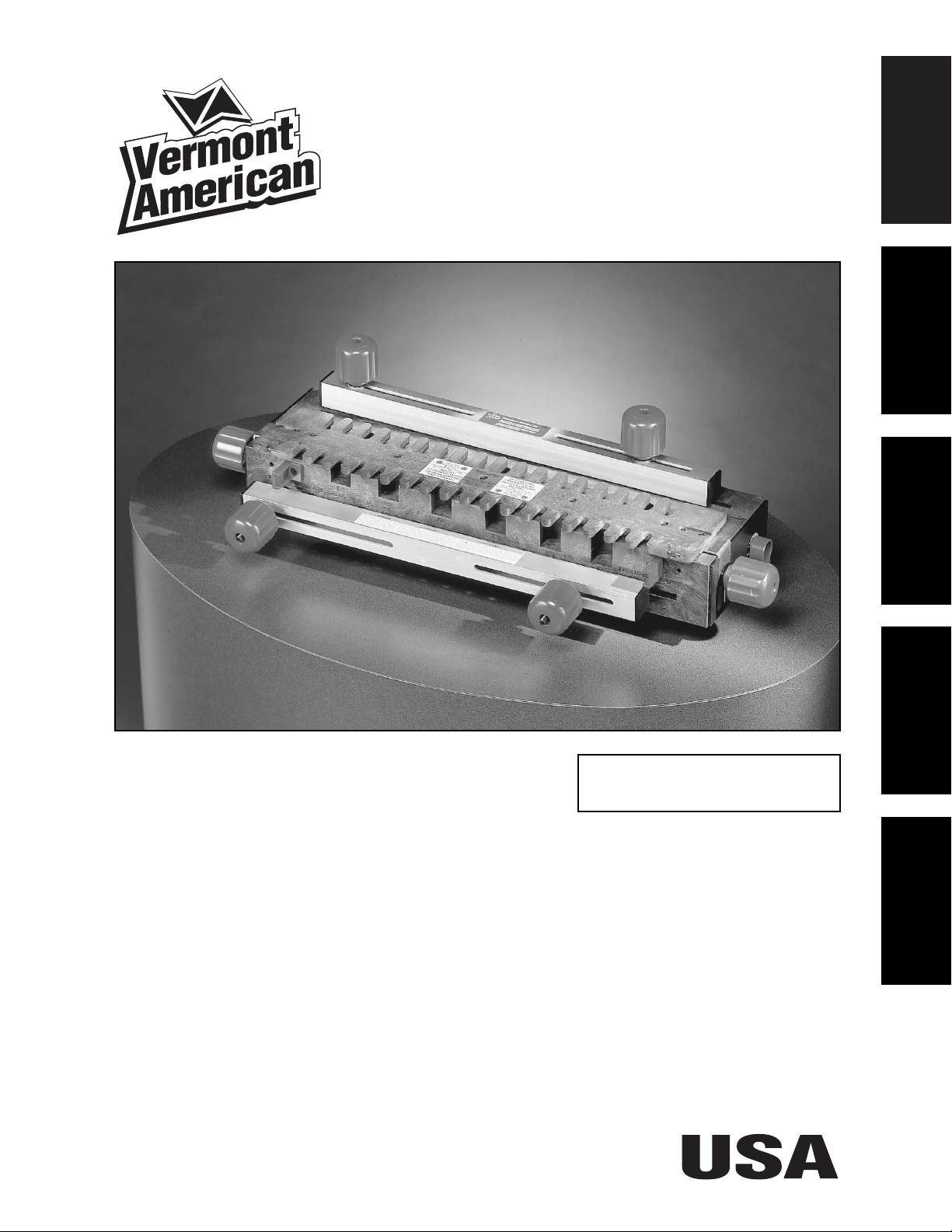

INDUSTRIAL DOVETAIL JIG

MODEL# 23461

IMPORTANT: The following router bits are required for use

with this jig.

• VA #22437, or MAGNA #M91016, 1/4" Straight Router Bit, and

VA #22501, or MAGNA #M91114, 9/16" Dovetail Router Bit

which are used for THROUGH or OPEN JOINTS.

• VA #22500, or MAGNA #M91113, 1/2" Dovetail Router Bit,

which is used for all HALF BLIND JOINTS.

Page 2

2

TABLE OF CONTENTS

General Safety Instructions for Power Tools .......................................... 3

Additional Safety Instructions for Industrial Dovetail Jig ...................... 4

Introduction ................................................................................................ 5

Unpacking and Checking Contents .......................................................... 5

Assembly .................................................................................................... 6

Assembly of the Right Side Template Support to the Dovetail Base .............. 6

Assembly of the Top Clamping Bar to the Dovetail Base.................................. 7

Assembly of the Front Clamping Bar to the Dovetail Base .............................. 9

Assembly of the Cam Handles and Pivot Shaft to the Dovetail Base .............. 10

Assembly of the Front Stop Blocks to the Dovetail Base ................................ 13

Assembly of the Top Stop Blocks to the Dovetail Base .................................... 14

Assembly of the Clamping Knobs to the Dovetail Base.................................... 14

Assembly of the Templates .................................................................................. 15

Alignment of the Templates .................................................................................. 16

Assembly of the Adapter Plate to the Router...................................................... 18

Assembly of the Guide Bushing to the Router .................................................. 21

Installation .................................................................................................. 22

Operation .................................................................................................... 24

Styles of Dovetail Joints ...................................................................................... 24

Half Blind Flush Joint ...................................................................................... 24

Half Blind Flush Offset Joint............................................................................ 25

Half Blind Rabbeted Joint ................................................................................ 25

Open or Through Joint .................................................................................... 26

Adjusting the Depth-of-Cut of the Router Bit...................................................... 26

Clamping the Workpieces to the Dovetail Base ................................................ 28

Making Drawers with Half Blind Flush Joints .................................................... 29

Making Drawers with Half Blind Flush Offset Joints.......................................... 35

Making Drawers with Half Blind Rabbeted Joints .............................................. 35

Making Projects with Open (Through) Joints .................................................... 37

Parts List .................................................................................................... 47

Page 3

3

SAFETY

This manual contains information that is important for you to

know and understand. This

information relates to protecting YOUR SAFETY and

PREVENTING EQUIPMENT

PROBLEMS. To help you rec-

ognize this information, we use

the symbols to the right.

Please read the manual and

pay attention to these sections.

URGENT SAFETY INFORMATION - A

HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE

IMPORTANT SAFETY INFORMATION- A HAZARD THAT MIGHT

CAUSE SERIOUS INJURY OR LOSS

OF LIFE

INFORMATION FOR PREVENTING

DAMAGE TO EQUIPMENT

INFORMATION THAT YOU SHOULD

PAY SPECIAL ATTENTION TO

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

Failure to heed all safety and operating instructions and warnings regarding use of this

product can result in serious bodily injury.

WARNING

1. Know your power tool

Read the owner’s manual carefully. Learn its

application and limitations as well as the specific potential

hazards peculiar to this tool.

2. Ground all tools (unless double insulated)

If tool is equipped with an approved three-conductor cord

and a three-prong grounding type plug, it should be

plugged into a three hole electrical receptacle. If adapter is

used to accommodate a two-hole receptacle, the adapter

wire must be attached

to a known ground (usually the screw securing

receptacle cover plate). Never remove third prong.

Never connect green ground wire to a terminal.

3. Keep guards in place

Maintain in working order, and in proper adjustment and

alignment.

4. Remove adjusting keys and wrenches

Form a habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it

ON.

5. Keep work area clean

Cluttered areas and benches invite accidents.

Floor must not be slippery due to wax or sawdust.

6. Avoid dangerous environment

Do not use power tools in damp or wet locations

or expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space.

7. Keep children away

All visitors should be kept a safe distance from work

area.

8. Make workshop child-proof

Use padlocks, master switches, or remove starter keys.

9. Do not force tools

Do not force tool or attachment to do a job it was

not designed to perform.

10. Use the right tool

They will do the job better and safer at the rate

for which they were designed.

11. Wear correct apparel

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) that may get caught

in moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair. Roll long

sleeves above the elbow.

12. Use safety goggles (Head Protection)

Wear safety goggles (must comply with ANSI Standard

Z87.1) at all times. Also, use face or

dust mask, if cutting operation is dusty, and ear

protectors (plugs or muffs) during extended periods of

operation.

13. Secure work

Use clamps or a vise to hold work when practical. It’s safer

than using your hands, and both hands

are free to operate tool.

14. Do not overreach

Keep proper footing and balance at all times.

15. Maintain tools with care

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

WARNING

CAUTION

SAFETY GUIDELINES – DEFINITIONS

Page 4

1. Always wear eye protection that complies with

ANSI Standard Z87.1.

2. Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using the

Dovetail Jig for hours at a time.

3. For dusty operations, wear a dust mask along

with safety goggles.

4. Do not use this Dovetail Jig with router bits or

guide bushings other than those specified for the

cuts being made.

5. Follow the instructions in your Router Owner’s

Manual.

6.Vibrations caused by the router during use can

cause fasteners to become loose. Before use and

periodically during use, check all fasteners to make

sure that they are all are tight and secure.

7. Do not use this product until all assembly installation steps have been completed, and you have read

and understand all safety and operational instructions in this manual, and the Router Owners Manual.

8. Make sure that the router bit is properly positioned

in the router so that it does not contact the guide

bushing or the template when cutting.

9. The Dovetail Jig must be securely mounted to a

workbench or other stable surface when in use. The

front of the base should overhang the front of the

workbench by no more than 1/4" to provide clearance when clamping workpieces to the Dovetail Jig.

10. Do not use the Dovetail Jig as a work surface.

Doing so may cause damage to the Dovetail Jig,

which can cause it to be unsafe to use. A workbench

should be used for this purpose.

11. This product is designed to cut flat workpieces.

Do not cut or attempt to cut workpieces that are

not flat or that are irregularly shaped.

12. This product is to be used for cutting wood workpieces only. Do not use this product to cut metal

or any other non-wood material.

13. This product has been designed to cut workpieces having thicknesses of 3/8" to 1". Do not use

for workpieces of any other thicknesses.

14. Do not clamp any workpieces to the Dovetail Jig

or make any adjustments to the Dovetail Jig unless

the router has been turned off, the router bit is not

turning, and the Router has been disconnected from

the electrical outlet.

15. When setting “the-depth-of-cut” of the router

bit, make sure that the workpiece is clamped to the

Dovetail Jig in such a manner that the router bit

does not cut into the Dovetail base causing damage to it or possible serious injury to you.

4

16. Disconnect tools before servicing

Before servicing, when changing accessories

such as blades, bits, cutters, etc.

17. Avoid accidental starting

Make sure switch is in OFF position before plugging in.

18. Use recommended accessories

Consult the owner’s manual for recommended accessories

and follow the instructions. The use

of improper accessories may cause hazards.

19. Never stand on tool

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

DO NOT store materi-

als above or near the tool making it

necessary to stand on the tool to reach them.

20. Check damaged parts

Before further use of the tool, any guard or other

part that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or any other part that is

damaged should be properly repaired or replaced.

21. Direction of feed

Feed work into a blade or cutter AGAINST the

direction of rotation of the blade or cutter only.

22. Never leave tool running unattended

Turn power OFF. DO NOT leave tool until it comes

to a complete stop.

23. Keep hands away from cutting area

24. Store idle tools

When not in use, tools should be stored in dry,

high or locked-up place – out of reach of children.

25. Do not abuse cord

Keep cord away from heat, oil and sharp edges.

26. Outdoor extension cords

When tool is used outdoors, use only extension

cords suitable for use outdoors and so marked.

27. Never use in an explosive atmosphere

Normal sparking of the motor could ignite fumes,

flammable liquids, or combustible items.

28. Drugs, alcohol, medication

DO NOT operate tool while under the influence

of drugs, alcohol, or any medication.

Read and Understand this instruction book

completely BEFORE using this product.

.

ADDITIONAL SAFETY INSTRUCTIONS FOR THE

INDUSTRIAL DOVETAIL JIG

Page 5

5

16. ALWAYS UNPLUG THE

ROUTER FROM THE ELECTRICAL OUTLET

BEFORE INSTALLING OR REMOVING ROUTER

BITS FROM THE ROUTER AND WHEN ADJUSTING THE CUTTING DEPTH OF THE ROUTER BIT;

OR WHEN INSTALLING OR CHANGING GUIDE

BUSHINGS.

17. NEVER LIFT THE ROUTER UPWARDS WHEN

THE ROUTER IS “ON”, THE ROUTER BIT IS

ROTATING, AND THE GUIDE BUSHING IS NEAR

OR TOUCHING THE TEMPLATE, BECAUSE THIS

WILL CAUSE THE ROUTER BIT TO CUT INTO

THE TEMPLATE AND DAMAGE IT.

WARNING

INTRODUCTION

• Your Vermont American Industrial Dovetail Jig is an

accessory that is used with Routers allowing you to

make drawers, chests, and similar items requiring

dovetail joints. The joints are used to make the front,

back, and sides of the workpiece.

• Your Industrial Dovetail Jig comes with two templates and two guide bushings for making half-blind

and through or open joints.

• Your Industrial Dovetail Jig also comes with a

universal router adapter plate that will permit the

Industrial Dovetail Jig to be used with most popular

routers.

• The Dovetail Jig will allow you to make 1" spaced

flush, flush-offset, and 3/8" rabbeted half-blind

dovetail joints.

• The Dovetail Jig will also allow you to make 1"

spaced open, or through, dovetail joints.

• Workpieces up to 16" wide can be accommodated.

• Workpieces with thicknesses between 3/8" and 1"

can be accommodated.

• The Dovetail Jig Base has six pockets molded into

its front which are gauges to aid you setting the

“depth-of- cut” for commonly used depths: 3/8", 1/2",

5/8", 3/4", 7/8", and 1".

• Vermont American router bits, #22501 and #22437,

or Magna router bits, #M91113 and #M91016,

WHICH MUST BE PURCHASED SEPARATELY, are

required for making the THROUGH or OPEN joints.

• Vermont American router bit, #22500, or

Magna router bit, #M91114, WHICH MUST BE

PURCHASED SEPARATELY, is required for making

the HALF-BLIND joints.

• Your Vermont American Industrial Dovetail Jig

comes with two templates and two guide bushings.

Each of the templates has a label, describing the

joint that can be cut with it, along with set-up

information, the router bit and the guide bushing

required, and the the stop block setting for a

particular joint.

UNPACKING AND CHECKING CONTENTS

• If any parts are missing or cannot

be accounted for, do not attempt to assemble, install,

or use the Industrial Dovetail Jig until the missing

parts have been obtained and the product has been

assembled correctly.

• Contact customer service at 1-800-742-3869, ext. 8359

for missing or replacement parts.

WARNING

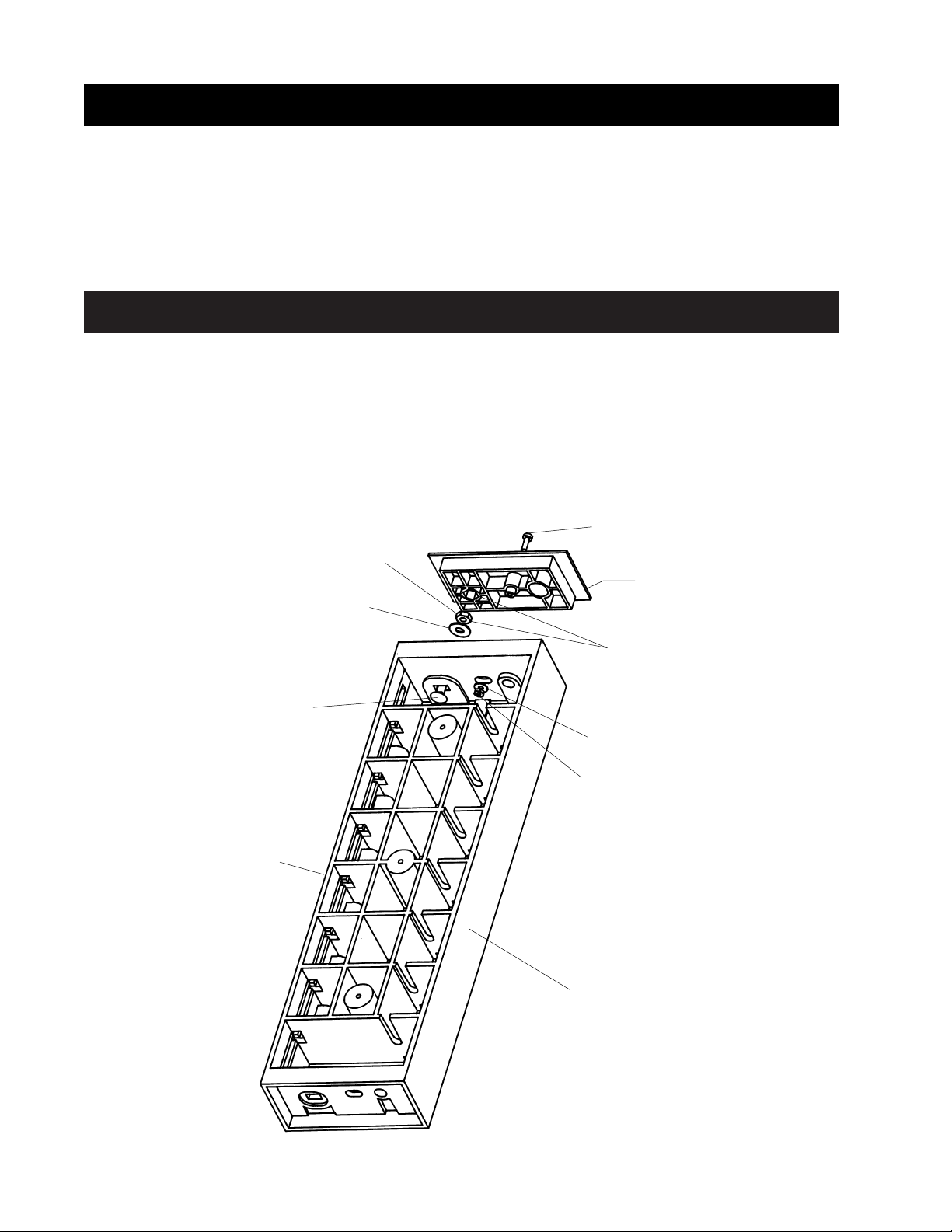

Refer to Parts List on Page 47.

• In order to simplify handling and to minimize any

damage that may occur during shipping, your

Industrial Dovetail Jig is packaged assembled.

• Separate all loose parts from the packing materials

and check each one with the illustrations and list of

parts at the end of this manual to make sure that

all loose parts are present before discarding any

packaging material.

Page 6

6

ASSEMBLY INSTRUCTIONS

IMPORTANT

ALTHOUGH YOUR INDUSTRIAL DOVETAIL JIG

COMES ASSEMBLED, THE FOLLOWING ASSEM-

BLY INSTRUCTIONS ARE BEING INCLUDED FOR

REFERENCE PURPOSES SHOULD IT BECOME

NECESSARY FOR YOU TO DISASSEMBLE AND

REASSEMBLE THE DOVETAIL JIG.

PROCEED TO THE SECTION ALIGNMENT OF

THE TEMPLATES AND THEN CONTINUE WITH

THE SECTIONS FOLLOWING ALIGNMENT OF

THE TEMPLATES.

THE TEMPLATES MUST BE ALIGNED BEFORE

ANY ROUTING IS TO TAKE PLACE.

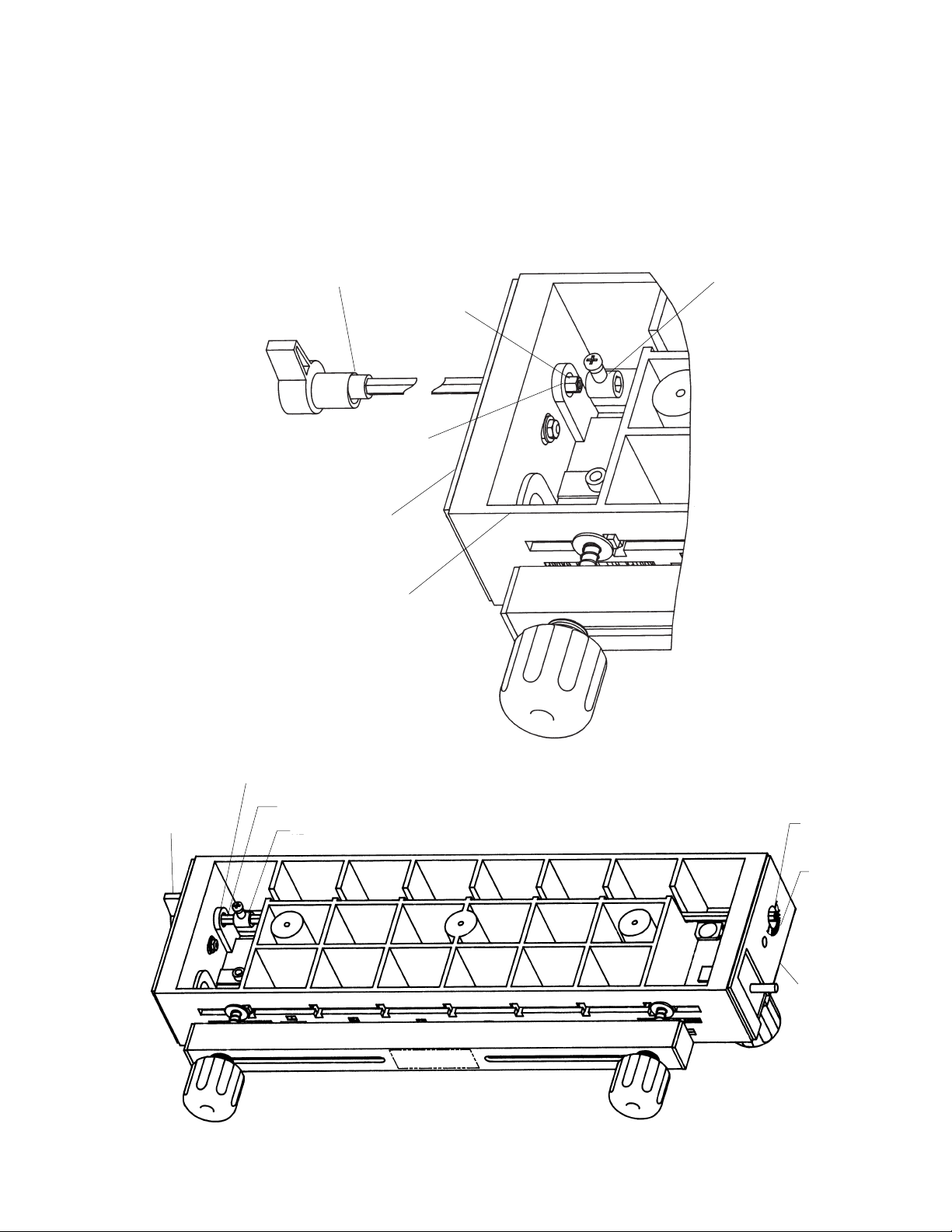

ASSEMBLY OF THE RIGHT SIDE TEMPLATE SUPPORT TO THE DOVETAIL BASE

1. Place the dovetail base topside down on a flat surface.

2. Insert one of the 5/16-18 x 2" long round head square

TOOLS REQUIRED

• A medium sized Phillips screwdriver

• A small or medium adjustable wrench

neck bolts into the slot in the right side of the base.

(NOTE: The right side of the base is identified by the

words RIGHT SIDE molded into it.)

3. Place a 11/32" I.D. x 7/8" O.D. washer onto the bolt as

shown in Figure 1.

4. Thread a 5/16-18 hex nut onto the bolt, as shown, until

it bottoms out against the washer.

5. Back off the nut from the washer between 1/4 and 1/2

5/16-18 HEX NUT

11/32" I.D. X 7/8" O.D. WASHER

5/16-18 X 2" LONG ROUND HEAD

SQUARE NECK BOLT

DOVETAIL BASE

10-32 X 5/8" LONG PANHEAD

MACHINE SCREW

RIGHT TEMPLATE SUPPORT

HEXES MUST LINE UP

# 10-32 HEX NUT

BACK OF DOVETAIL BASE

13/64" I.D. X 9/16" O.D. WASHER

FIGURE 1

Page 7

7

ASSEMBLY

turns. Align the nut so that the corners of the nut are vertically lined up as shown. Note the alignment of the hex

pocket in the template support. The bolt should be free to

move side to side; if it does not, loosen the nut 1/3 turn or

until the corners of the nut point up and down.

6. Assemble the right template support to the right side of

the dovetail base so that the hex nut lines up and fits into

the hex pocket in the right template support. (NOTE: The

right template support has the words RIGHT SIDE molded

into it for identification.)

7. Assemble a #10-32 x 5/8" long panhead machine screw,

a 13/64" I.D. x 9/16" O.D. washer, and a #10-32 hex nut to

the base as shown to hold the template support in place.

Securely tighten the nut and screw.

8. The template support should move freely front to back

along the side of the base. If it does not, it means that the

5/16-18 hex nut is too tight on the bolt and should be loosened. To do this, remove the fasteners assembled in step

7, and remove the template support; repeat steps 4

through 7.

ASSEMBLE THE LEFT SIDE TEMPLATE SUPPORT TO

THE DOVETAIL BASE THE SAME AS THE RIGHT SIDE

TEMPLATE SUPPORT WAS ASSEMBLED.

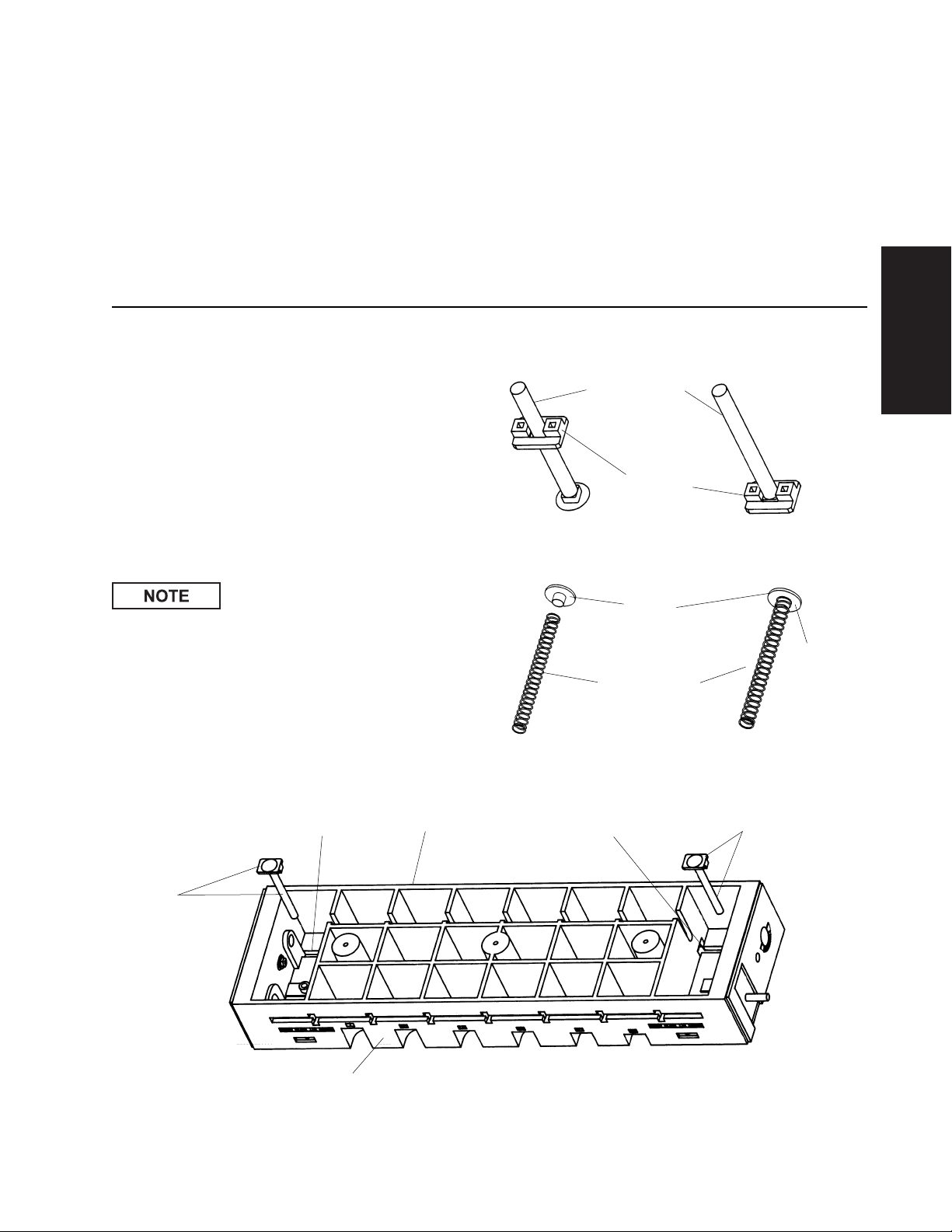

ASSEMBLY OF THE TOP CLAMPING BAR TO THE DOVETAIL BASE

1. Assemble one of the bolt supports to both of the

5/16-18 X 3-1/2" long round head square neck bolts as

shown in Figure 2.

2. Align the square on the bolt with the square hole in the

bolt support. The bolt support is to "bottom-out" against the

bolt as shown in Figure 3.

3. Assemble one of the springs to each of the nylon spring

retainers by pushing the spring over the raised cylindrical

portion of the spring retainer as shown in Figure 3A and

Figure 3B.

4. Position the dovetail base on a flat smooth surface so

the back of the base rests on the surface.

ALTHOUGH BOTH ENDS OF THE

DOVETAIL BASE ARE SHOWN ASSEMBLED IN THE

FOLLOWING FIGURES, THE ACTUAL ASSEMBLY IS

DONE ONE END AT A TIME.

5. From the bottom of the base, insert a bolt with bolt support through the slot in the top of the base so the raised

portion of the bolt support goes into the slot, as shown in

Figure 4.

5/16-18 X 3-1/2"

LONG ROUND

HEAD SQUARE

NECK BOLT

BOLT

SUPPORT

NYLON

SPRING

RETAINER

COMPRESSION

SPRING

SPRING TO

BOTTOM

OUT

AGAINST

SURFACE

FIGURE 4

FIGURE 2 FIGURE 3

FIGURE 3A FIGURE 3B

SLOT IN

DOVETAIL BASE

DOVETAIL BASE

BOLT

AND

BOLT

SUPPORT

FRONT OF DOVETAIL BASE

BOLT AND BOLT

SUPPORT

SLOT IN

DOVETAIL

BASE

Page 8

8

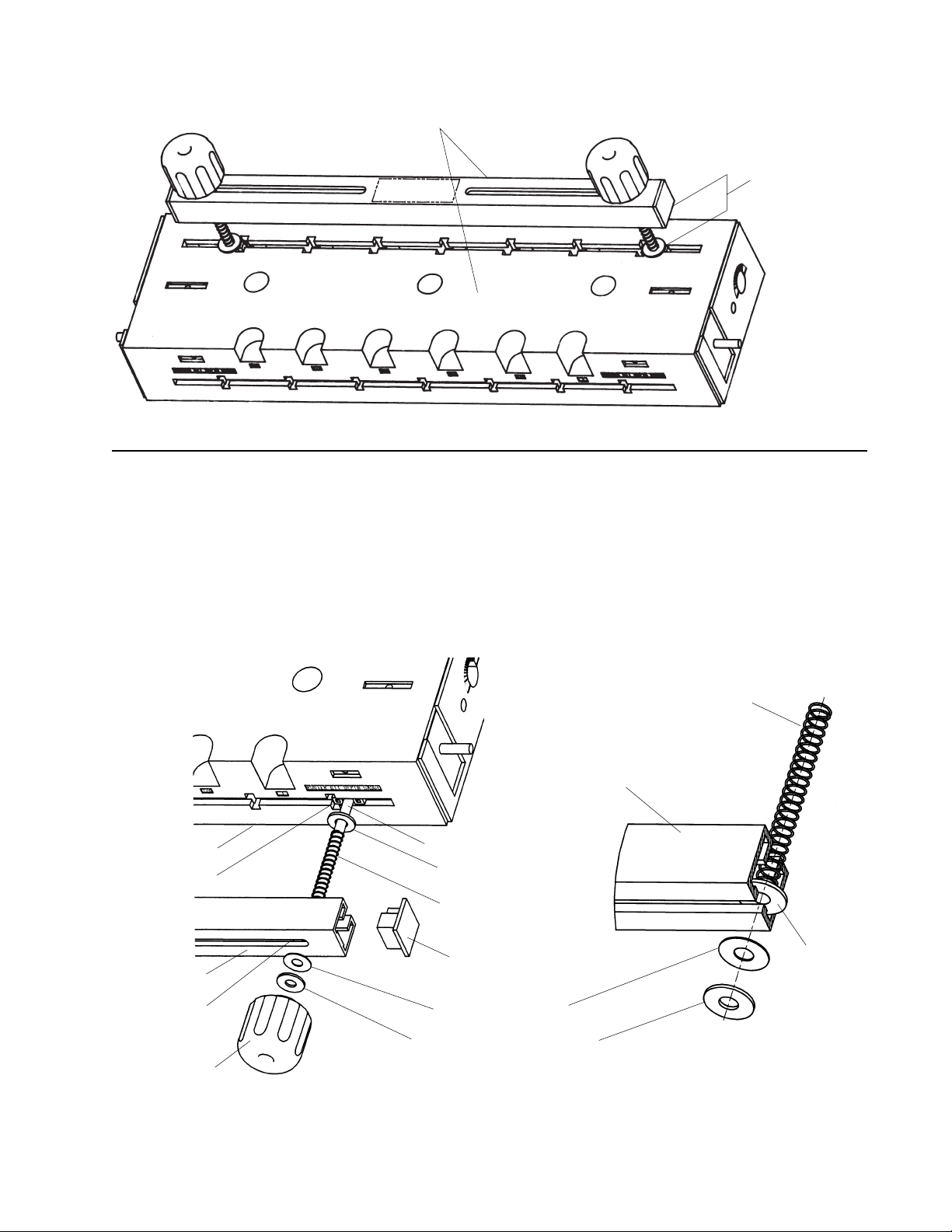

6. Place an 11/32" I.D. X 7/8" O.D. washer and then a

5/16" I.D. X 7/8" O.D. thick nylon washer over the bolt. It

will be necessary to hold the bolt in place when performing

this and the following steps.

HELPFUL HINTS: Position the bolt and the bolt support

under the notch in the rib as shown in Figure 5, to help

hold the bolt in place.

7. Place a spring over the bolt, as shown in Figure 6.

8. Place a 5/16" I.D. X 7/8" O.D. thick nylon washer and

then an 11/32" I.D. X 7/8" O.D. washer over the bolt and

press down on the spring until just the end of the bolt

sticks out past the end of the washer.

9. Slide the clamping bar over the bolt so that the washers

are sandwiched between the spring and the inside of the

clamping bar as shown in Figure 6. NOTE: THE SPRING

MUST PUSH AGAINST THE THICK NYLON WASHERS

AND NOT AGAINST THE STEEL WASHERS.

10. Place an 11/32" I.D. X 7/8" O.D. thin nylon washer and

an 11/32" I.D. X 7/8" O.D. washer over the bolt. It will be

necessary for you to press down on the clamping bar while

doing this.

11. Take one of the clamping knobs and thread it onto the

bolt as shown. DO NOT THREAD the knob completely

onto the bolt––just enough so the knob holds the clamping

bar in place.

12. Repeat above steps 4 through 10 for the other end of

the clamping bar.

13. Assemble the end caps to the ends of the clamping bar

by pressing them in; they are designed to be “force-fit” into

NOTCH

IN RIB

SLOT IN

DOVETAIL

BASE

BOLT AND

BOLT

SUPPORT

FIGURE 5

FIGURE 6 Assemble clamping bar, knobs, end caps on both ends as shown

CLAMPING BAR DETAIL

the bar in one way only. It may be necessary to “tap” them

in by gently hitting them with a rubber mallet or a piece of

wood––since they fit very tightly into the clamping bar.

USE CARE WHEN DOING THIS SO AS NOT TO DAMAGE THE END CAPS.

USE CARE THAT THE CAPS ARE PROPERLY ALIGNED

AS SHOWN WHEN ASSEMBLING THEM TO THE BAR.

14. Tighten the clamping knobs onto the bolts so that the

space between the bottom of the clamping bar should be

parallel to the top of the base.

15. After completing the above steps your Dovetail Jig

should look like the illustration in Figure 7.

CLAMPING KNOB

SPRING AND

NYLON SPRING

RETAINER FIT

INSIDE THE

OPEN SIDE OF

THE CLAMPING

BAR

(SEE CLAMPING

BAR DETAIL)

11/32" I.D.

X 7/8" O.D. WASHER

11/32" I.D. X 7/8" O.D.

THIN NYLON WASHER

CLAMPING BAR

CLAMPING BAR

END CAP

OPEN SIDE OF

THE CLAMPING BAR

POINTS TOWARD

THE TOP SURFACE

OF THE DOVETAIL

BASE

11/32" I.D.

X 7/8" O.D.

THICK

NYLON

WASHER

TOP SURFACE OF

THE DOVETAIL

RIGHT

TEMPLATE

SUPPORT

BOLT

SUPPORT

3 1/2" BOLT

COMPRESSION

SPRING

NYLON SPRING

RETAINER

(RETAINER ABUTS THE

CLAMPING BAR)

11/32" I.D. X 7/8"

O.D. WASHER

11/32" I.D. X 7/8" O.D.

THICK NYLON

WASHER

CLAMPING BAR (SHOWN WITH

END CUT AWAY AND SECTIONED

SO NYLON SPRING RETAINER

PLACEMENT CAN BE SEEN)

COMPRESSION

SPRING

Page 9

9

CLAMPING BAR PARALLEL TO

TOP OF BASE

SPACING TO BE

APPROXIMATELY

1-1/2"

FIGURE 7

ASSEMBLY OF THE FRONT CLAMPING BAR TO THE DOVETAIL BASE

1. Assemble the front clamping bar to the front of the dovetail base following the same procedure used to assemble

the top clamping bar to the dovetail base as shown in

FIGURE 8

CLAMPING BAR

(SHOWN WITH END

CUT AWAY AND

SECTIONED SO

NYLON SPRING

RETAINER PLACEMENT CAN BE

SEEN)

COMPRESSION

SPRING

NYLON

SPRING

RETAINER

(RETAINER

ABUTS THE

CLAMPING

BAR)

4 1/2" BOLT

11/32" I.D. X 7/8" O.D.

THICK NYLON WASHER

COMPRESSION SPRING

CLAMPING BAR

END CAP

11/32" I.D. X 7/8" O.D.

THIN NYLON WASHER

11/32" I.D. X 7/8" O.D.

CLAMPING KNOB

NYLON SPRING

RETAINER

BOLT SUPPORT

DOVETAIL BASE

CLAMPING BAR

Figure 8. The 5/16-18 X 4-1/2" long round head square

neck bolts are used.

Page 10

10

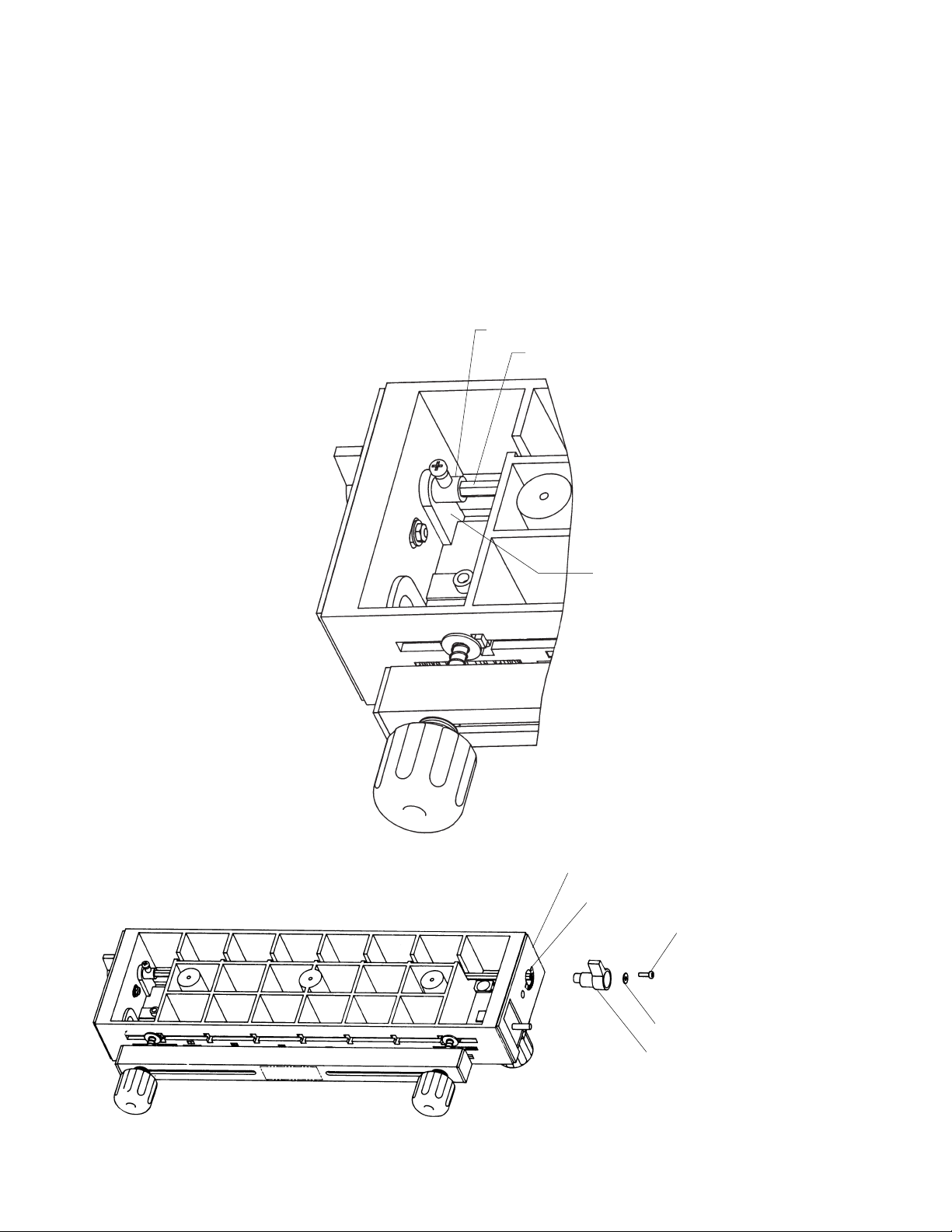

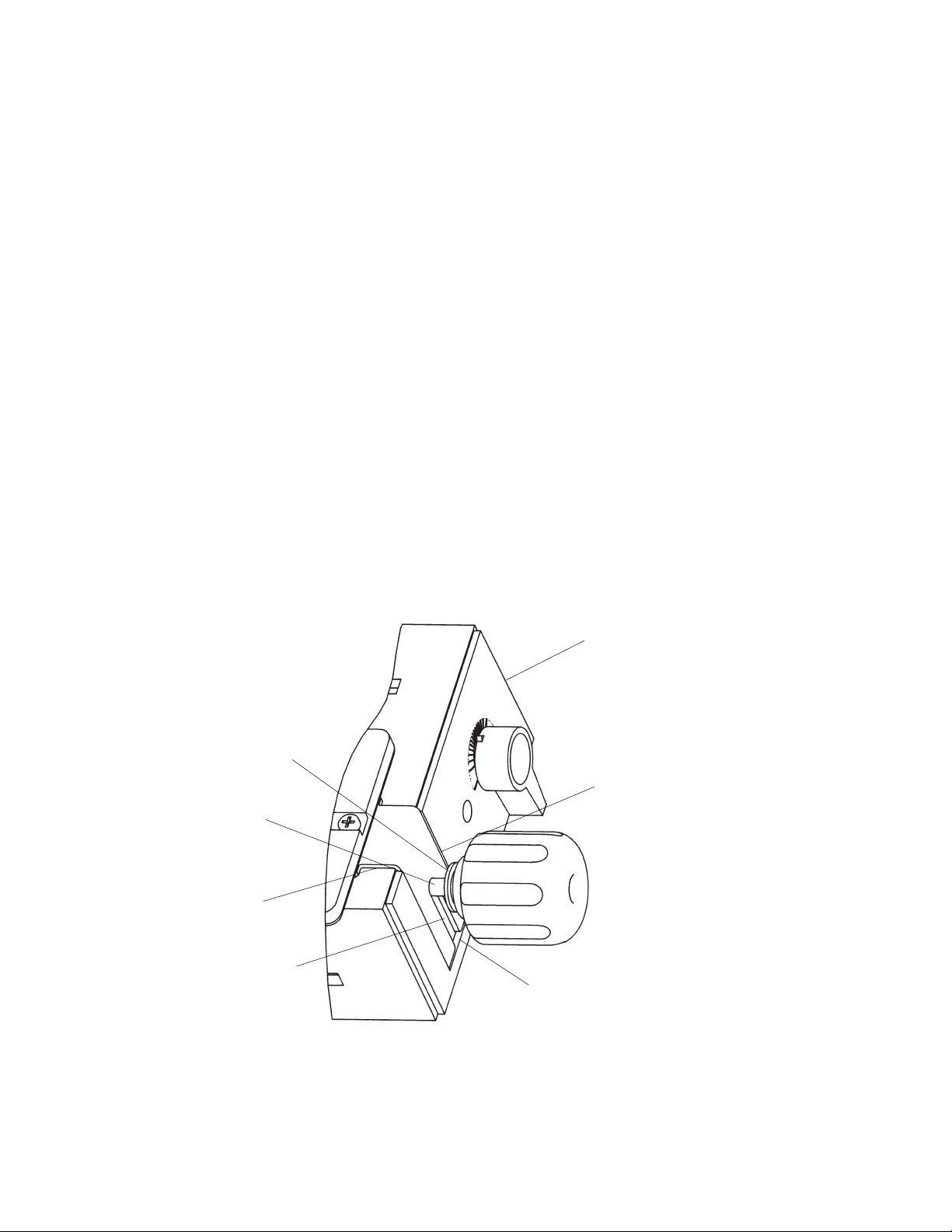

ASSEMBLY OF THE CAM HANDLES AND PIVOT SHAFT TO THE DOVETAIL BASE

• After the cam handles and pivot shaft have been assembled to the base, it will be possible to accurately position

the templates for close fitting joints.

• Note that there are some graduations on both template

supports.

• Rotating the cam handle so that the pointer lines up with

one of the graduations permits accurate front-to-back positioning of the template.

• Cam handles are designed to provide infinite template

adjustment.

• One graduation equals 1/64" of movement of the template.

• Rotating the cam handle so that the lever moves toward

the front of the base, causes the template to also move

towards the front of the base.

•Conversely rotating the cam handle so that the lever

moves toward the back of the base, causes the template

to also move towards the back of the base also.

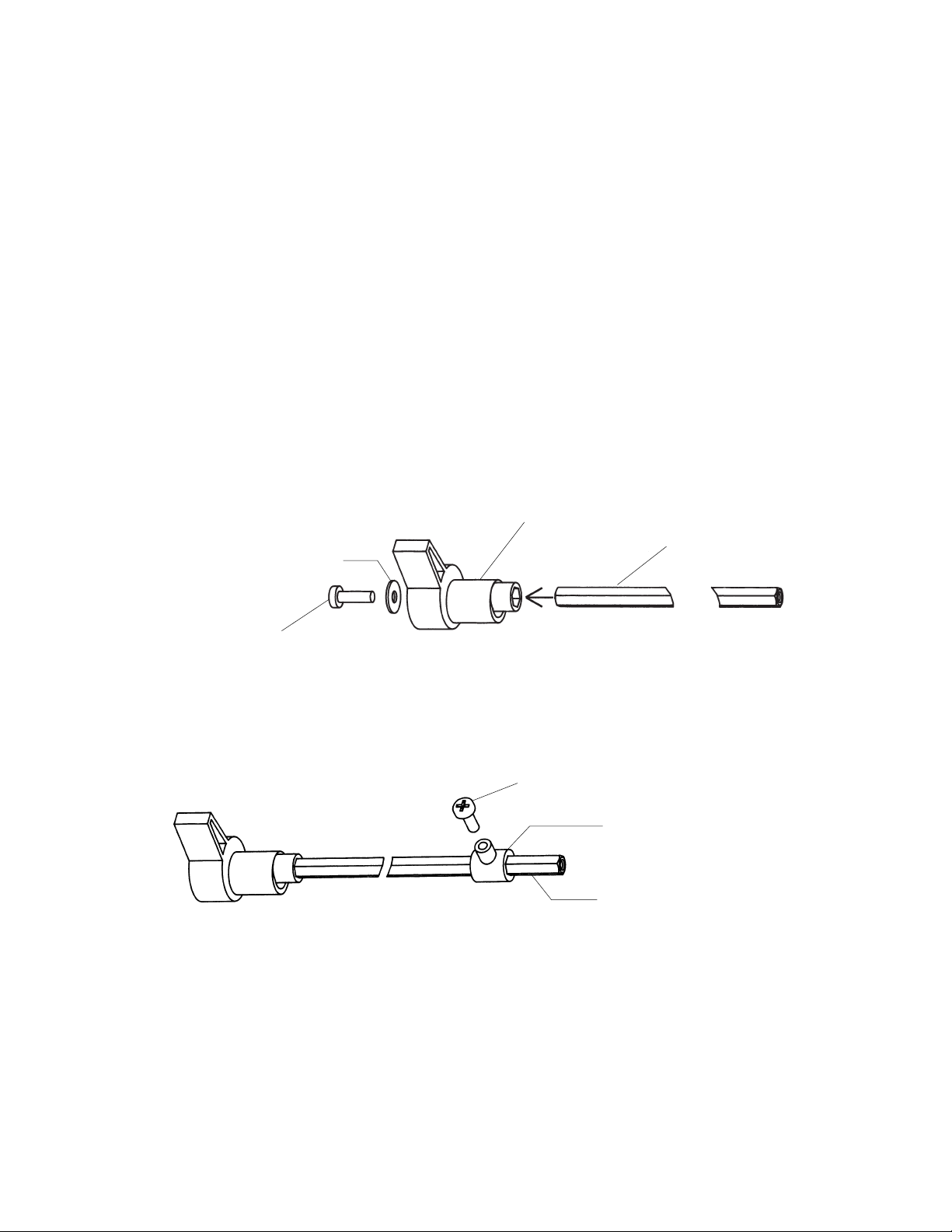

13/64" I.D. X 9/16" O.D. WASHER

#10-32 X 5/8" LONG

PANHEAD MACHINE SCREW

CAM HANDLE

PIVOT SHAFT

#10-16 X 1/2" LONG PANHEAD TAPPING SCREW

RETAINER

PIVOT SHAFT

FIGURE 9

FIGURE 10

1. Assemble one of the cam handles to the pivot shaft

using a #10-32 x 5/8" long panhead machine screw and a

13/64" I.D. x 9/16" I.D. washer. as shown in Figure 9.

2. Use care so that the pivot shaft fits into the hex-shaped

hole in the cam handle. The pivot shaft may fit tightly into

the cam handle; this is normal.

3. Make sure that the pivot shaft bottoms-out inside the

cam handle.

4. Securely tighten the screw.

NOTE: THE NEXT TWO STEPS ARE PRE-ASSEMBLY

STEPS.

5. Slide the retainer over the end of the pivot shaft for

about 2". The retainer may fit tightly; this is normal.

6. Thread the #10-16 x 1/2" long panhead tapping screw

into the hole in the retainer until it bottoms-out against the

pivot shaft. (The screw will fit tightly in the hole.) See

Figure 10.

Page 11

11

7. Loosen the screw about one turn. Remove the retainer

from the shaft and set it aside temporarily.

8. Assemble the pivot shaft with cam handle to the base by

inserting the end of the pivot shaft through the holes in the

right template support and the base.

9 . MAKE SURE THE ORIENTATION OF THE CAM HANDLE IS AS SHOWN IN FIGURE 11.

10. Place the retainer at the location shown in Figure 12

and push the pivot shaft through. THE ORIENTATION OF

THE RETAINER RELATIVE TO THE CAM HANDLE WITH

SCREW MUST BE AS SHOWN.

NOTE: THE RETAINER MAY FIT TIGHTLY ON THE

PIVOT SHAFT; THIS IS NORMAL.

11. Continue pushing the pivot shaft through the holes and

the retainer until the end of the pivot shaft extends out of

the left template support as show in Figure 12.

12. Make sure the end of the cam handle fits into the hole

in the base as shown.

CAM HANDLE

PIVOT SHAFT

RETAINER

HOLE IN BASE

RIGHT TEMPLATE

DOVETAIL BASE

FIGURE 11

FIGURE 12

PIVOT SHAFT

RETAINER

PIVOT

HOLE IN

BASE

LEFT

TEMPLATE

SUPPORT

CAM

HANDLE

HOLE IN BASE

Page 12

12

13. With the cam handle pushed in against the base,

position the retainer against the side wall of the base, as

shown in Figure 13. The retainer should barely touch the

side wall of the base. The purpose of the retainer is to

prevent or minimize the side-to-side of the cam handle and

pivot shaft.

14. Assemble the other cam handle to the other end of the

pivot shaft using a 13/64" I.D. x 9/16" O.D. washer and

a#10-32 X 5/8" long panhead machine screw, as shown in

Figure 14.

15. Make sure that the cam handle lines up with the cam

handle at the other end of the pivot shaft and that the end

RETAINER

SIDE WALL OF BASE

of the cam handle fits into the hole in the base.

16. Tighten the screw securely.

17. Rotate one of the cam handles–It should rotate freely

and move the template supports

18. If this does not happen, loosen the screw on the retainer and move the retainer away from the side wall slightly.

19. Securely retighten the screw.

20. If there is too much side-to-side movement (play) of

the cam handles; loosen the screw in the retainer and

move the retainer closer to the side wall of the base.

21. Securely retighten the screw.

LEFT TEMPLATE SUPPORT

PIVOT SHAFT

#10-32 X 5/8" LONG

PANHEAD MACHINE

SCREW

13/64" I.D. X 9/16" O.D. WASHER

CAM HANDLE

FIGURE 13

FIGURE 14

Page 13

13

ASSEMBLY OF THE FRONT STOP BLOCKS TO THE DOVETAIL BASE

1. Assemble the front stop blocks to the front of the dovetail base, at each end, using #10-32 x 5/8" long flathead

machine screws, 13/64" I.D. x 9/16" O.D. washers, and

#10-32 hex nuts, as shown in Figure 15.

2. Make sure that the open rib portion fits into the slot in

the front of the base. The stop block will fit into the slot in

one position only.

3. Tighten the screw securely onto the nut.

4. Assemble the other front stop block to opposite end of

the dovetail base in the same manner.

DOVETAIL BASE

RIGHT

TEMPLATE

SUPPORT

#10-32 HEX NUT

13/64" I.D. X 9/16"

O.D. WASHER

FRONT STOP BLOCK

SLOT

#10-32 X 5/8" LONG FLATHEAD

MACHINE SCREW

FRONT OF DOVETAIL BASE

SLOT

#10-32 HEX NUT

13/64" I.D. X 9/16" O.D.

WASHER

LEFT TEMPLATE

SUPPORT

FRONT STOP BLOCK

#10-32 X 5/8" LONG

FLATHEAD MACHINE

SCREW

FIGURE 15

FOR REASONS OF CLARITY, THE FRONT

CLAMPING BAR, KNOBS, BOLTS AND

SPRINGS ARE NOT SHOWN

Page 14

14

ASSEMBLY OF THE TOP STOP BLOCKS TO THE DOVETAIL BASE

• The top stop blocks are assembled to the top of the

dovetail base in one of two ways depending upon which

style of dovetail joint is to be cut:

a. HALF-BLIND FLUSH JOINTS—The “A” on the stop

block faces toward the “middle of the base”.

b. HALF-BLIND RABBET JOINTS—The “B” on the

stop block faces toward the “middle of the base”.

c. THROUGH JOINTS—The “A” on the stop block

faces toward the “middle of the base”.

• Since the flush joint is the more commonly used joint, the

following instructions apply to the assembly of the stop

blocks for this style joint.

1. Position the dovetail Jig right side up on a flat surface

2. Assemble one of the top stop blocks to the top surface

of the base using a #10-32 x 7/8" long flathead machine

ASSEMBLY OF THE CLAMPING KNOBS TO THE DOVETAIL BASE

1. Assemble 11/32" I.D. x 7/8" O.D. washers onto the 5/1618 bolts at both ends of the dovetail base as shown in

Figure 17.

2. Assemble the clamping knobs onto the bolts as shown.

screw, as shown in Figure 16. The screw threads into the

hole in the bottom of the slot.

3. Make sure that the “A” faces the “middle of the base”.

4. Make sure the open rib portion of the stop block fits into

the slot in the top surface of the base.

5. Assemble the remaining top stop block to the opposite

end of the base in the same manner

6.Again make sure that the “A” faces the “middle of the

base”.

7. Tighten both screws securely.

8. To reposition the stop blocks for rabbet joints, simply

loosen the screws just enough so that the ribs on the stop

blocks come out of the slot. The stop block is then rotated

180° to the alternate position, so the “B” faces the middle

of the base, and securely retighten the screws.

5/16-18 X 2" LONG ROUND

HEAD SQUARE NECK BOLT

5/16-18 X 2" LONG ROUND

HEAD SQUARE NECK BOLT

11/32" I.D. X 7/8"

O.D. WASHER

CLAMPING

KNOB

CLAMPING

KNOB

11/32" I.D. X 7/8"

O.D. WASHER

1/2" SPACING BETWEEN

WASHER AND TEMPLATE

SUPPORT (BOTH ENDS)

FIGURE 16

FIGURE 17

#10-32 X 7/8" LONG FLAT HEAD

MACHINE SCREW

#10-32 X 7/8" LONG FLAT

HEAD MACHINE SCREW

RIB ON STOP BLOCK

TOP STOP BLOCK

RIB ON STOP BLOCK

SLOT IN TOP

OF BASE

TOP STOP BLOCK

MIDDLE OF THE BASE

SLOT IN TOP

OF BASE

3. Thread the clamping knobs onto the bolts so that the

spacing between the washer and the template supports is

approximately 1/2".

4. Set the dovetail base aside for the time being and continue on with the next section.

Page 15

15

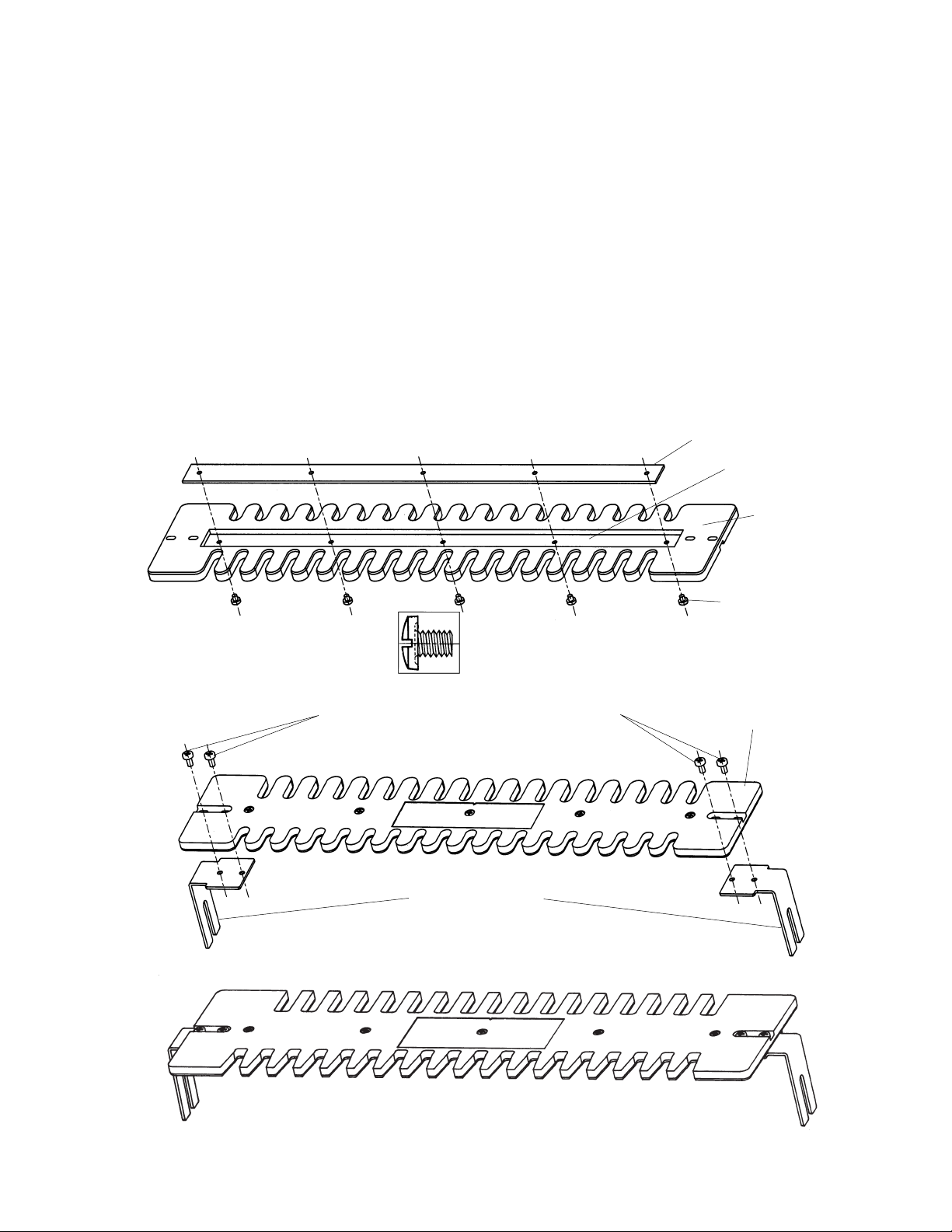

FIGURE 20

FIGURE 19

FIGURE 18

#10-32 X 3/16" LONG PANHEAD MACHINE

TEMPLATE

TEMPLATE BRACKET

TEMPLATE STIFFENER

RECTANGULAR SLOT

TEMPLATE

#8-36 X 3/16" LONG

PANHEAD MACHINE

SCREW

SLOTTED BINDING HEAD

MACHINE SCREW

ASSEMBLY OF THE TEMPLATES

• Place the template stiffener into the rectangular slot in the

underneath side of the template, as shown in Figure 18.

NOTE: THE TEMPLATE FOR CUTTING HALF-BLIND

JOINTS IS BEING USED AS AN ILLUSTRATION IN THE

FOLLOWING FIGURES.

1. Thread a #8-36 x 3/16" long panhead machine screw

through each of the five holes in the template and into the

threaded holes in the template support, as shown in

Figure 18 and securely tighten all of the screws.

NOTE: ON SOME EARLY VERSIONS OF THIS PRODUCT, A SLOTTED BINDING HEAD MACHINE SCREW

HAS BEEN SUBSTITUTED FOR THE PANHEAD SCREW

SPECIFIED FOR ASSEMBLING THE TEMPLATE SUPPORTS TO THE TEMPLATES. (SEE THE SCREW ILLUSTRATION IN FIGURE 18.)

2. Assemble the template brackets to the template using

four #10-32 x 3/8" long panhead machine screws, as

shown in Figure 19.

3. MAKE SURE THAT THE TEMPLATE BRACKETS ARE

ASSEMBLED TO THE UNDERNEATH SIDE OF THE

TEMPLATE, AS SHOWN IN FIGURE 19, AND THAT THE

ALIGNMENT OF THE BRACKETS IS ALSO AS SHOWN

IN THE FIGURE.

4. IT IS NOT NECESSARY FOR THE SCREWS TO BE

TIGHTENED AT THIS STAGE; THE TEMPLATE BRACKETS SHOULD BE FREE TO MOVE WITH RESPECT TO

THE TEMPLATE OR ELSE IT WILL NOT BE POSSIBLE

TO ALIGN THE TEMPLATE AS DESCRIBED IN THE

NEXT SECTION.

5. The assembled template should look like the illustration

in Figure 20.

6. Assemble the template stiffener and the template brackets to the TEMPLATE FOR CUTTING THROUGH JOINTS

using the same method described in the preceding steps 1

through 5. Refer to Figure 20.

Page 16

16

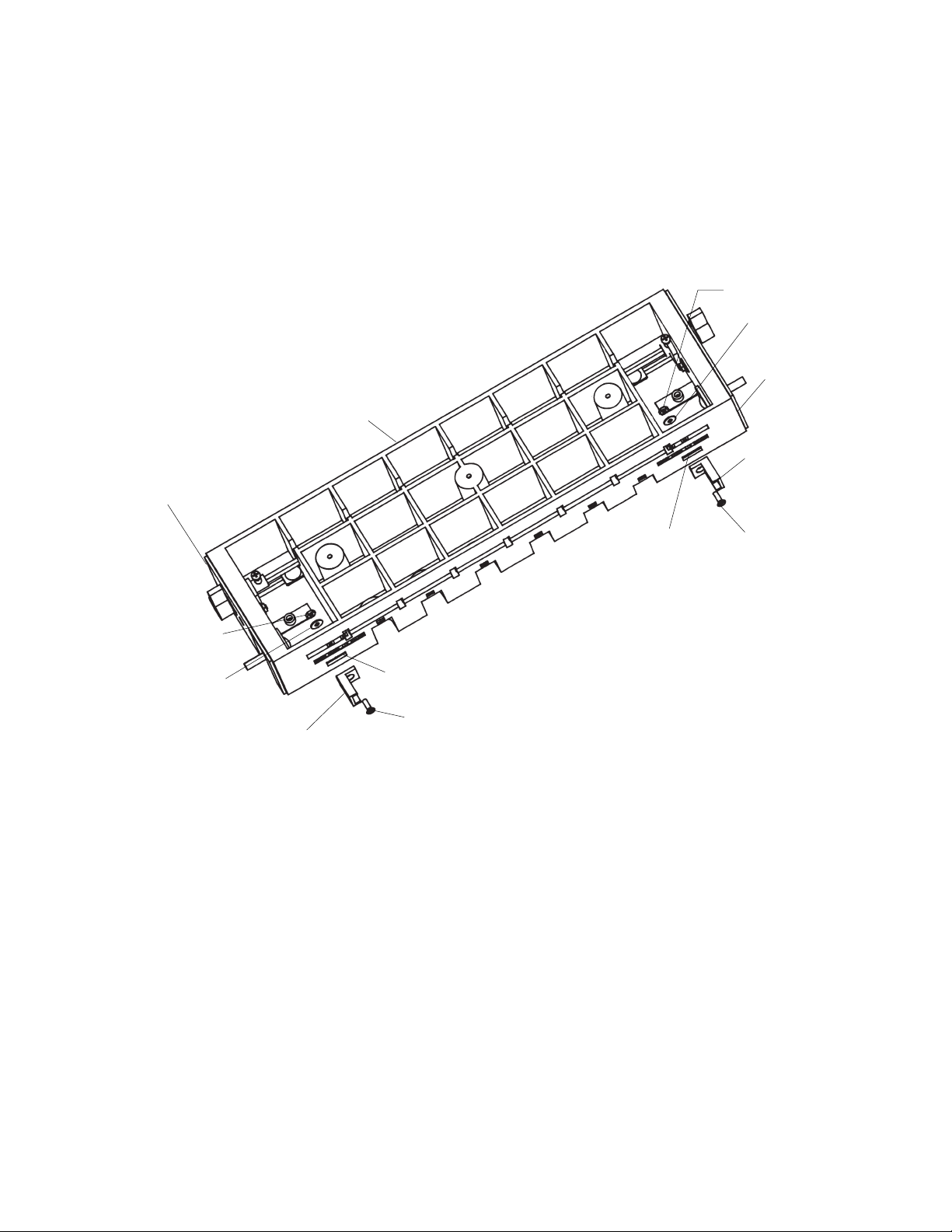

ALIGNMENT OF THE TEMPLATES

• In order for the Dovetail Jig to function properly, it is

necessary for the templates to be aligned with respect to

dovetail base. The reason for this, is that dovetail cuts are

at both ends of the Dovetail Jig. When properly aligned,

the result being all mating corners will always be lined up.

• NOTE: THE TEMPLATE FOR CUTTING HALF-BLIND

JOINTS IS BEING USED AS AN ILLUSTRATION IN THE

FOLLOWING FIGURES.

1. With the dovetail base still having the 1/2" spacing

between the washer and the template supports (Refer to

Figure 17), assemble the template assembly to the dovetail base so that:

a) the slot in the template bracket fits over the bolt

b) the leg of the template bracket is between the washer

and the template support, and

c) the legs fit into the slots in the template supports, as

shown in Figure 21.

d) NOTE: THIS PROCEDURE MUST BE FOLLOWED

WHENEVER THE TEMPLATE IS INSTALLED ON THE

DOVETAIL JIG. IT IS MOST IMPORTANT THAT LEG

OF THE TEMPLATE BRACKET ALWAYS BE

BETWEEN THE WASHER AND THE TEMPLATE SUPPORT OR ELSE THE TEMPLATE WILL NOT BE

PROPERLY POSITIONED FOR CUTTING ACCURATE

DOVETAILS.

For initial setup, Allow the legs of the template bracket to

“bottom out” in the slots in the template supports as

shown in Figure 21.

• TO REMOVE THE TEMPLATE FROM THE DOVETAIL

JIG, LOOSEN THE CLAMPING KNOBS SO THAT SPACING BETWEEN THE TEMPLATE BRACKET AND THE

WASHER IS ABOUT 1/2"; GENTLY LIFT THE TEMPLATE

UPWARD FROM THE DOVETAIL BASE SO THAT THE

TEMPLATE BRACKET CLEARS THE SLOTS IN THE

TEMPLATE SUPPORT AND STORE IN A CONVENIENT

LOCATION.

2. Lightly tighten the clamping knobs at both ends of the

base so that the template brackets are held in place

against the template supports as shown in Figure 21.

3. Move the template from side to side on the template

brackets so that it is centered with respect to the template

brackets. This means that the template and brackets

should look like one of the following figures: Figure 22,

Figure 23. or Figure 24. Move template front-to-back so

that front edge of template is parallel with the front of the

dovetail base. In each condition the template and the template brackets MUST be symmetrical with each other. The

figures do not show the complete Dovetail Jig, but only the

underneath side of the template with template brackets

correctly positioned, in order that the correct positions of

RIGHT TEMPLATE SUPPORT

WASHER

BOLT

TEMPLATE BRACKET

SLOT IN THE TEMPLATE BRACKET

SLOT IN THE TEMPLATE SUPPORT

TEMPLATE BRACKET “BOTTOMS-OUT” AGAINST

THIS SURFACE (BOTH ENDS OF DOVETAIL BASE)

FIGURE 21

Page 17

17

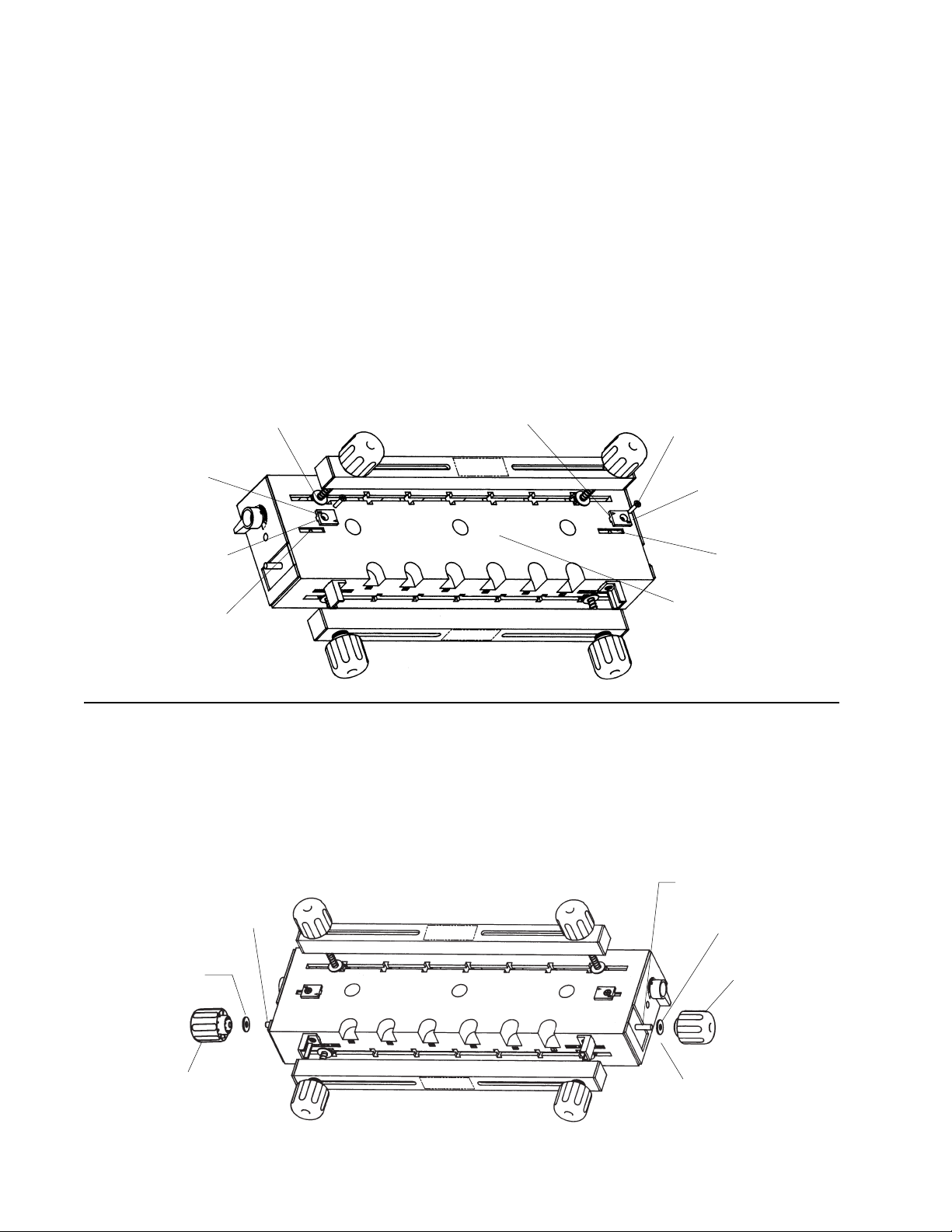

CONDITION ONE: TEMPLATE BRACKETS PROTRUDE BEYOND TEMPLATES

TEMPLATE

DISTANCE BETWEN THESE

SURFACES MUST BE EQUAL

AT BOTH ENDS

TEMPLATE BRACKET

CONDITION TWO: TEMPLATE PROTRUDES BEYOND TEMPLATES BRACKETS

TEMPLATE

DISTANCE BETWEN THESE

SURFACES MUST BE EQUAL

AT BOTH ENDS

TEMPLATE BRACKET

CONDITION THREE: TEMPLATE EVEN WITH TEMPLATE BRACKETS

TEMPLATE

DISTANCE BETWEN THESE

SURFACES MUST BE EQUAL

AT BOTH ENDS

TEMPLATE BRACKET

FIGURE 22

FIGURE 23

FIGURE 24

Page 18

18

4. After the template brackets have been correctly positioned on the template securely tighten the four screws

holding the template brackets to the template.

5. Remove the template assembly from the base and set it

aside for now.

6. Align the other template assembly in the same manner.

IT SHOULD BE NOTED THAT YOU MAY FIND, THAT

AFTER MAKING SOME SAMPLE CUTS, SLIGHT

ADJUSTMENTS MAY BE REQUIRED. HOW TO MAKE

THESE ADJUSTMENTS IS EXPLAINED IN TWO OF THE

FOLLOWING SECTIONS: “TROUBLESHOOTING FOR

HALF BLIND JOINTS” or “TROUBLESHOOTING FOR

OPEN (THROUGH) JOINTS”.

7. Remove the template assembly from the base and

set it aside for now. (Figure 25 below, is an example of

INCORRECTLY positioned template brackets.)

FIGURE 25

TEMPLATE BRACKET

THE TEMPLATE EXTENDS

BEYOND THE TEMPLATE

BRACKET

CONDITION FOUR: THIS CONDITION IS NOT CORRECT –

TEMPLATE BRACKET EXTENDS BEYOND THE TEMPLATE AND

THE TEMPLATE EXTENDS BEYOND THE TEMPLATE BRACKET.

• SIMPLY MAKE SURE BRACKETS ARE POSITIONED THE SAME AT EACH END

TEMPLATE

TEMPLATE BRACKET

THE TEMPLATE

BRACKET EXTENDS

BEYOND THE

TEMPLATE

ASSEMBLY OF THE ADAPTER PLATE TO THE ROUTER

ALWAYS MAKE SURE THAT THE ROUTER IS "TURNED

OFF" AND THAT THE ELECTRICAL CORD HAS BEEN

UNPLUGGED FROM THE ELECTRICAL OUTLET

BEFORE ASSEMBLING THE ADAPTER PLATE AND A

GUIDE BUSHING TO THE ROUTER; OR WHEN MAKING

ANY ADJUSTMENTS, OR CHANGING ROUTER BITS IN

THE ROUTER.

1. Remove any router bit currently installed in the router.

WARNING

2. Remove the router base plate now on the router, by

removing the screws holding the base plate to the router.

3. Depending on the make of router, either three or four of

the following screw types and sizes will have been used:

a) #8 (.164 dia) Pan Head Screw

b) #10 (.190 dia) Pan Head Screw

c) #8 (.164 dia) Flat Countersunk Head Screw

d) #10 (.190 dia) Flat Countersunk Head Screw

4. Compare the screws removed with those shown in

Figure 26.

FIGURE 26

SCREW “a” SCREW “b” SCREW “c” SCREW “d”

Page 19

19

5. If the screws look like Screw "a" or Screw "b", use either

three or four of the 13/64" ID x 15/32" OD washers when

installing the adapter plate to the router as shown in

Figure 27.

6. Your Dovetail Jig comes with four countersunk bushings

with an 11/64" hole and four countersunk bushings with a

13/64" hole. Refer to Figure 28.

FIGURE 27 FIGURE 28

FIGURE 29

7. If the screws look like Screw "c", use either three or four

of the bushings with an 11/64" dia. hole when installing

the adapter plate to the router as shown in Figure 29.

8. If the screws look like Screw "d", use either three or four

of the bushings with a 13/64" dia. hole when installing the

adapter plate to the router as shown above in Figure 29.

PAN HEAD

SCREW

PAN HEAD

SCREW

WASHER

WASHER

PAN HEAD SCREW

PAN HEAD SCREW

WASHER

WASHER

ROUTER

Ø 11/32

ADAPTER PLATE

Ø 11/64

Ø 25/64

Ø 13/64

#8 FLAT

HEAD

SCREW

#8 FLAT HEAD

SCREW

BUSHING

WITH Ø11/64

HOLE

BUSHING WITH

Ø11/64 HOLE

#8 FLAT HEAD SCREW

#8 FLAT HEAD SCREW

BUSHING WITH Ø11/64 HOLE

BUSHING WITH

Ø11/64 HOLE

ROUTER

ADAPTER PLATE

Page 20

20

FIGURE 30

FIGURE 31

FIGURE 32

The figures below show the views of the adapter plate as it

would appear when installed on a router with the router

turned over with the router base facing upward.

Three of the most popular mounting hole configurations

are shown.

Figure 30 shows the mounting arrangement using three

screws.

Figure 31 shows the mounting arrangement using four

screws when the screws are at 45 degrees to the side of

the front of the router.

Figure 32 shows the mounting arrangement using four

screws when the screws are in line with the front of the

router.

In most cases, the adapter plate will fit your router.

However, in those cases where the router is extremely

small or extremely large, rated at 1-3/4 HP or larger, the

adapter plate cannot be used.

9. Set the router upside down on a workbench or other flat

stable surface.

10. Position the adapter plate on the router so that the

threaded holes in the router base line-up with slots (or

holes) in the adapter plate.

The recessed arrow in the adapter plate should point

toward the front of the router.)

11. Line-up the center of the hole in the adapter plate with

the collet hole in the router. This will ensure accurate cuts.

12. Using the screws removed in Step 2 above, in combination with either the washers or countersunk bushings,

assemble the adapter plate to the router. If the bushing are

used the heads of the screws must be flush with, or slightly below the top of the bushing.

THE TOPS OF THE SCREWS MUST NOT PROTRUDE

ABOVE THE TOP SURFACE OF THE ADAPTER PLATE.

If for some reason the countersunk head screws being

used are too short, too long, or protrude above the top of

the adapter plate, obtain pan head screws that are 1/4" or

3/8" long with the proper thread from a hardware store or

DYI outlet. Use these with the washers, instead of the

bushings, to assemble the adapter plate to the router.

13. TIGHTEN ALL SCREWS SECURELY.

14. Check to see that center of the router collet hole still

lines-up with the large center hole in the adapter plate.

15. If it does not loosen the screws and reposition the

adapter plate so the hole lines-up with the router collet hole.

16. TIGHTEN ALL SCREWS SECURELY.

Page 21

21

ASSEMBLY OF THE GUIDE BUSHING TO THE ROUTER

1. Place the router upside down on a flat surface. For certain routers it may be necessary to support the router for it

to remain in this position.

2. Place the proper guide bushing required for the type of

dovetail to be cut under the router adapter plate as shown

in Figure 33.

3. MAKE SURE THAT THE ORIENTATION OF THE

GUIDE BUSHING IS AS SHOWN.

4. Position the guide bushing so that the three threaded

holes in the guide bushing line-up with the countersunk

holes in the adapter plate.

5. Thread a #10-32 x 3/8" long flathead machine screw

into each of the holes.

6. SECURELY TIGHTEN THE SCREWS. Refer to Figure

34.

FIGURE 33

FIGURE 34

ROUTER

ADAPTER PLATE

#10-32 X 3/8" LONG

FLATHEAD MACHINE SCREW

#10-32 X 3/8" LONG

FLATHEAD MACHINE SCREW

GUIDE

BUSHING

ASSEMBLY

(1/2" DIAMETER

SHOWN)

NOTE THE

ORIENTATION

OF THE GUIDE

BUSHING

#10-32 X 3/8" LONG

FLATHEAD MACHINE SCREW

ROUTER

ADAPTER PLATE

GUIDE BUSHING ASSEMBLY

(1/2" DIAMETER SHOWN)

NOTE THE ORIENTATION

OF THE GUIDE BUSHING

Page 22

22

INSTALLATION

THE DOVETAIL JIG MUST ALWAYS

BE FIRMLY AND SECURELY MOUNTED TO A SOLID

AND FIRM WORK SURFACE, SUCH AS A WORKBENCH, BEFORE USE. FAILURE TO DO SO COULD

CAUSE THE DOVETAIL JIG TO TIP OVER OR SLIDE

ALONG THE WORK SURFACE, RESULTING IN PROPERTY DAMAGE AND SERIOUS PERSONAL INJURY.

MOUNTING THE DOVETAIL JIG TO A WORK SURFACE

OR WORKBENCH USING CLAMPS.

USING THIS MOUNTING METHOD ALLOWS YOU TO

MOUNT THE DOVETAIL JIG SO THAT IT CAN BE EASILY INSTALLED, FOR USE, AND REMOVED, FOR STORAGE, WITHOUT PERMANENTLY TAKING UP SPACE ON

YOUR WORKBENCH.

1. Make a solid wood mounting board, 32" long x 6-1/4"

wide x 3/4" thick.

WARNING

2. Remove the template assembly from the dovetail base if

there is one there currently.

3. Drill three 1/8" diameter holes, 3/4" deep into the mounting board as shown in illustration.

4. Position the Dovetail Jig on the top of the mounting

board so the holes in the base line up with the drilled

holes in the mounting board.

5. Secure the Dovetail Jig to the mounting board using

three 13/64" I.D. x 9/16" O. D. washers and three #10-16

x 1" long panhead self tapping screws as shown in

Figure 35.

9. Applying a small amount of soap to the screw threads

will make it easier to thread the screws into the holes.

10. Line up the front of the mounting board with the front

of a workbench or other sturdy surface.

11. Using two clamps, such as C-clamps, firmly clamp the

Dovetail Jig to the workbench by clamping on the mounting board as shown in Figure 36 and Figure 36A.

12. Make sure that the mounting board lines up with the

front of the workbench.

TO THE FRONT OF THE

DOVETAIL BASE

1/8” DIAMETER DRILL

TO THE FRONT OF THE

DOVETAIL BASE

FIGURE 35

Page 23

23

INSTALLATION

FRONT SURFACE OF THE BASE

FRONT SURFACE OF THE MOUNTING BOARD

FRONT SURFACE OF THE WORKBENCH

FIGURE 36A

FIGURE 36

CLAMP HERE

CLAMP HERE

FRONT SURFACE

OF THE MOUNTING BOARD

FRONT SURFACE OF

THE WORKBENCH

FRONT SURFACE OF THE BASE

Page 24

24

DRAWER SIDE (TAIL PIECE)

TAILS

PINS

DRAWER SIDE (TAIL PIECE)

DRAWER BACK (PIN PIECE)

DRAWER FRONT (PIN PIECE)

OPERATION

STYLES OF DOVETAIL JOINTS

• Four different styles of dovetail joints can be made with

the Dovetail Jig using your router.

• These joints are described in the following sections.

Half Blind Flush Joint

• The Half Blind Flush Joint is used when the height of

both the drawer front and the drawer back is the same

height as the drawer sides; and the length of both the

drawer front and the drawer back is the same as the width

of the drawer.

See Figure 37.

NOTE: THE NORMAL DEPTH OF CUT FOR A HALF

BLIND FLUSH JOINT IS 3/8".

FIGURE 37

Page 25

25

OPERATION

FIGURE 38

FIGURE 39

Half Blind Flush Offset Joint

• The Half Blind Flush Offset Joint is used when:

The height of both the drawer front and the drawer back is

the same height as the drawer sides; the length of the

drawer front is 1/8" longer (1/16" on a side) than the width

of the drawer; and the length of the drawer back is the

same as the width of the drawer.

See Figure 38.

• To obtain the offset, cut a 1/16" deep by 3/8" wide rabbet

on the opposite ends on the inside of the drawer front.

NOTE: THE NORMAL DEPTH OF CUT FOR A HALF

BLIND FLUSH OFFSET JOINT IS 3/8".

DRAWER SIDE (TAIL PIECE)

DRAWER SIDE (TAIL PIECE)

DRAWER BACK (PIN PIECE)

TAILS

PINS

DRAWER FRONT (PIN PIECE)

1/16" OFFSET

Half Blind Rabbeted Joint

• The Half Blind Rabbeted Joint is used when:

The drawer front overlaps the opening for the drawer on all

four sides of the of the drawer opening (top, bottom, and

two sides) that is; the length of the drawer front is 3/4"

longer (3/8" on a side) than the width of the drawer; the

height of the drawer front is also 3/4" higher (3/8" on side)

than the height of the drawer; the length of the drawer back

is the same as the width of the drawer; and the height of

the drawer back is the same as the height of the drawer.

See Figure 39.

• To obtain this joint, cut a 3/8" deep by 3/8" wide rabbet

around the inside periphery of the drawer front.

NOTE: THE NORMAL DEPTH OF CUT FOR A HALF

BLIND RABBETED JOINT IS 3/8".

DRAWER FRONT (PIN PIECE)

3/8" WIDE RABBET AROUND THE

PERIPHERY OF THE DRAWER FRONT

DRAWER SIDE (TAIL PIECE)

DRAWER BACK (PIN PIECE)

TAILS

DRAWER SIDE (TAIL PIECE)

Page 26

26

FIGURE 40

FIGURE 41

Open or Through Joint

• The Open or Through Joint is similar to the Half Blind

Joint except that joint seams are visible on the front, back,

and sides of the workpiece; on the Half Blind Joints, the

seams are visible only on the sides of the workpiece.

• Although this style of joint can be also used for drawers,

its most popular use is for making boxes, and small and

large chests.

• The height of both the front and the back of the drawer

or chest is the same height as the sides of the drawer or

chest; and the length of both the front and the back of the

drawer or chest is the same as the width of the drawer or

chest.

See Figure 40.

NOTE: THE DEPTH OF CUT IS DETERMINED BY THE

THICKNESSES OF THE FRONT, BACK AND SIDE

PIECES.

• The front and back pieces (sometimes called “tail

pieces”) are cut independently from the side pieces (sometimes called “pin pieces”).

• The “pin pieces” are cut first using one edge of the template and a dovetail router bit. The depth of cut is equal to

the thickness of the “tail pieces”.

• The “tail pieces” are cut next using the other edge of the

template and a straight router bit. The depth of cut is equal

to the thickness of the “pin pieces”. Adjustments are made

at this point to obtain joint fit.

TAILS

TAILS

PINS

PINS

SIDE (PIN PIECE)

SIDE (PIN PIECE)

FRONT (TAIL PIECE)

BACK (TAIL PIECE)

ADJUSTING THE DEPTH-OF-CUT OF THE ROUTER BIT

ALWAYS MAKE SURE THAT THE

ROUTER IS "TURNED OFF" AND THAT THE ELECTRICAL CORD HAS BEEN UNPLUGGED FROM THE

ELECTRICAL OUTLET BEFORE ASSEMBLING OR

REMOVING ROUTER BITS TO THE ROUTER.

• You will note that there are six pockets along the front

surface of the dovetail base, and that they are identified by

a dimensions such as 3/8, 1/2,–up to 1. These pockets are

used to set the depth-of-cut of a router bit.

To use proceed as follows:

• DO NOT USE WITH A TEMPLATE ASSEMBLED TO

THE BASE.

• DO NOT INSTALL ROUTER BITS TO THE ROUTER

UNLESS THE CORRECT GUIDE BUSHING HAS BEEN

ASSEMBLED TO THE BASEPLATE FIRST.

1. Install the desired router bit to the router as explained in

your Router Owner’s Manual. See Figure 41.

A MINIMUM ROUTER BIT SHANK ENGAGEMENT OF

3/4" IS REQUIRED IN THE COLLET OF THE ROUTER.

2. TIGHTEN THE COLLET NUT SECURELY.

3. Position the router over the pocket with the required

depth-of-cut.

WARNING

ROUTER BIT

BASEPLATE

GUIDE

BUSHING

MAKE SURE THAT THE ROUTER

BIT IS ALIGNED WITH OR CENTERED IN THE HOLE IN

THE GUIDE BUSHING. TO DO THIS, LOOSEN SCREWS

HOLDING BASE OR ADAPTER PLATE TO ROUTER,

CENTER GUIDE BUSHING HOLE WITH RESPECT TO

ROUTER BIT AND RETIGHTEN SCREWS SECURELY.

CAUTION

Page 27

27

4. Gradually move the router bit outward, by using the

depth-of-cut feature on the router, until the tip of the router

bit touches the bottom of the pocket, as shown in

Figure 42 and Figure 42A.

5. Lock the router in position.

6. The desired depth-of-cut has been set.

7. To set a depth-of-cut NOT provided for on the dovetail

base, simply place the unused template on the router

baseplate, as shown in Figure 43. The height from the

baseplate to the end or tip of the router bit will then be the

required depth of cut.

ROUTER BIT

DEPTH OF CUT

TEMPLATE

BASEPLATE

ROUTER

ROUTER BIT

POCKET

ROUTER

ROUTER BIT

POCKET

FIGURE 42

FIGURE 42A

FIGURE 43

WHEN SETTING THE DEPTH OF

CUT, MAKE ABSOLUTELY SURE THAT THE COLLET

NUT DOES NOT CONTACT (TOUCH) THE GUIDE BUSHING. THIS CAN CAUSE THE GUIDE BUSHING TO HEAT

UP EXCESSIVELY DURING CUTTING WHICH CAN

CAUSE DAMAGE TO THE TEMPLATE. TO CORRECT

THIS SITUATION OR PREVENT IT FROM OCCURRING

REPOSITION THE ROUTER BIT IN THE ROUTER.

CAUTION

Page 28

28

CLAMPING THE WORKPIECES TO THE DOVETAIL BASE

• The clamping bars have been specially designed to allow

the clamping forces to be applied next to the workpieces

for more efficient clamping. This is accomplished by being

able to position the clamping knobs in close proximity or

next to the workpieces.

• Figure 44 illustrates the positioning of the clamping bars

and the clamping knobs when the workpieces are clamped

to the LEFT SIDE of the Dovetail Jig.

• Figure 45 illustrates the positioning of the clamping bars

and the clamping knobs when the workpieces are clamped

to the RIGHT SIDE of the Dovetail Jig.

• Note the closeness of the clamping knobs to the workpieces. When not in use clamping knobs and the support-

INSIDE SURFACE OF DRAWER

FRONT (OR BACK) FACES UP

WORKPIECE CLAMPED TO

THE TOP OF THE BASE

TOP STOP BLOCK

WASHER MUST BE CLEAR

OF THE WORKPIECE

FRONT STOP BLOCK

INSIDE SURFACE OF DRAWER SIDE

FACES OUT

WASHER MUST BE CLEAR

OF THE WORKPIECES

WORKPIECE CLAMPED TO

THE FRONT OF THE BASE

WORKPIECE CLAMPED TO THE TOP OF THE BASE

WORKPIECE CLAMPED TO

THE FRONT OF THE BASE

FRONT STOP BLOCK

WASHER MUST BE

CLEAR OF THE

WORKPIECE

TOP STOP BLOCK

WASHER MUST BE CLEAR OF THE WORKPIECES

INSIDE SURFACE

FRONT CLAMPING BAR

TOP CLAMPING BAR

INSIDE SURFACE

ing bolts and springs are free to be moved along the slots

in the base.

• CAUTION: WHEN CLAMPING, MAKE SURE THAT THE

CLAMPING KNOBS ARE NOT POSITIONED SO CLOSE

TO THE WORKPIECES THAT THE WASHERS BECOME

TRAPPED UNDER THE WORKPIECES.

• FOR ACCURATE JOINTS, THE WORKPIECES MUST

"BUTT-UP" AGAINST BOTH THE TOP AND THE FRONT

STOP BLOCKS TO ENSURE THE EXACT POSITIONING

OF THE WORKPIECES.

• TO ENSURE ACCURATE JOINTS AND SAFE OPERATION, WOOD SHAVINGS AND ACCUMULATED DUST

MUST BE REMOVED FROM THE DOVETAIL JIG

BEFORE EACH SETUP, EITHER BY USING A BRUSH

OR BY VACUUMING.

FIGURE 44

FIGURE 45

Page 29

29

FIGURE 46

MAKING DRAWERS WITH HALF BLIND FLUSH JOINTS

• The thickness of both the front and back (pin pieces)

must be at least 1/2". The thickness of the sides (tail

pieces) must be at least 3/8".

A partial tail will be cut for side (tail piece) thicknesses up

to 9/16". This is normal and will not affect the joint or its

appearance.

• Figure 46 shows a drawer and the workpieces that make

it up. This figure is similar to Figure 38, except that it

shows the workpieces unassembled (or an exploded view

of the drawer).

• In addition, the figure shows where the four corners of

the drawer are cut on the Dovetail Jig.

CORNERS 1 AND 3 are cut on the LEFT SIDE of the

Dovetail Jig.

CORNERS 2 AND 4 are cut on the RIGHT SIDE of the

Dovetail Jig.

• Trial cuts are strongly recommended using scrap wood to

ensure that the final workpieces are of the desired quality.

CORNER #1

(CUT AT THE LEFT SIDE OF

THE DOVETAIL JIG)

CORNER #4

(CUT AT THE RIGHT SIDE OF

THE DOVETAIL JIG)

CORNER #2

(CUT AT THE RIGHT SIDE OF

THE DOVETAIL JIG)

CORNER #3

(CUT AT THE LEFT SIDE OF

THE DOVETAIL JIG)

DRAWER FRONT

PINS

TAILS

SURFACE LINES UP

WITH FRONT STOP

BLOCKS

DRAWER

RIGHT

INSIDE OF DRAWER

SURFACE LINES

UP WITH TOP

STOP BLOCKS

DRAWER BACK

DRAWER

LEFT SIDE

OUTSIDE OF

DRAWER

SURFACE LINES UP WITH

FRONT STOP BLOCKS

Page 30

30

MARK “DRAWER

RIGHT SIDE TOP

SURFACE”

MARK “2”

MARK “DRAWER BACK INSIDE SURFACE” (SHOWN HIDDEN)

MARK “DRAWER

LEFT SIDE

INSIDE SURFACE”

(SHOWN HIDDEN)

MARK

“DRAWER

LEFT SIDE

TOP SURFACE”

MARK “4”

MARK “DRAWER FRONT TOP SURFACE

MARK “1”

MARK “DRAWER FRONT

INSIDE SURFACE”

MARK “DRAWER RIGHT

SIDE INSIDE SURFACE”

MARK “DRAWER BACK

TOP SURFACE”

MARK “3”

VERMONT

AMERICAN #22500

OR

MAGNA #M91113

DOVETAIL

ROUTER BIT

.40" DIA. GUIDE BUSHING

GENERAL PREPARATIONS

a. The workpieces comprising the drawer, that is, front,

back, left side, and right side should be cut to the proper

length, width, and thickness(es).

b. Make sure that all surfaces are smooth and square with

each of the other surfaces.

c. Line up the workpieces on a flat surface, standing on

edge, as shown in Figure 47.

d. With a soft lead pencil mark the front, back, left side,

and right side, as shown in Figure 47. This is to aid you in

MAKE SURE THAT THE ROUTER BIT

IS ALIGNED WITH OR CENTERED IN THE HOLE IN THE

GUIDE BUSHING. TO DO THIS, LOOSEN SCREWS

HOLDING BASE PLATE OR ADAPTER PLATE TO

ROUTER, CENTER GUIDE BUSHING HOLE WITH

RESPECT TO ROUTER BIT AND RETIGHTEN SCREWS

SECURELY.

WHEN SETTING THE DEPTH OF

CUT, MAKE ABSOLUTELY SURE THAT THE COLLET

NUT DOES NOT CONTACT (TOUCH) THE GUIDE BUSHING. THIS CAN CAUSE THE GUIDE BUSHING TO HEAT

UP EXCESSIVELY DURING CUTTING WHICH CAN

CAUSE DAMAGE TO THE TEMPLATE. TO CORRECT

THIS SITUATION OR PREVENT IT FROM OCCURRING,

REPOSITION THE ROUTER BIT IN THE ROUTER.

CAUTION

CAUTION

positioning the workpieces on the Dovetail Jig, prior to cutting the dovetails.

e. Assemble the .40" guide bushing to the router baseplate, as described in a previous section. This the smaller

of the two guide bushings furnished with this product.

f. Install Vermont American #22500 or Magna #M91113

dovetail router bit, to the router as described in your

Router Owner’s Manual. Shank engagement should be a

minimum of 3/4".

FIGURE 47

Page 31

31

FIGURE 48

FIGURE 49

THE FOLLOWING DESCRIBES THE PROCEDURE TO

BE FOLLOWED FOR CUTTING CORNERS 1 AND 3

1. FOR CORNER #1, position the drawer front on the top

of the base so that it lines up with the front of the base and

the top surface abuts the left top stop block. THE INSIDE

OF THE DRAWER FRONT FACES AWAY FROM THE

TOP OF THE BASE. The words "INSIDE SURFACE"

marked in (d) in the Section, GENERAL PREPARATIONS,

should be visible.

2. Lightly clamp the drawer front in place.

3. Position the drawer RIGHT side against the front of the

g. Adjust the depth of cut to 3/8" using the depth gauge on

the base of the Dovetail Jig, as described in a previous

section.

This setting is approximate and some adjustment may be

required.

h. Position both of the top stop blocks so that the "A" faces

the "middle of the base" as shown in Figure 48.

i. Position the cam handle so that the pointer points to the

center graduation as shown in Figure 48.

LEFT TOP STOP BLOCK

“A” FACES TOWARD MIDDLE

OF BASE

“A” FACES TOWARD MIDDLE

OF BASE

RIGHT TOP STOP BLOCK

POINTER POINTS

TO CENTER

GRADUATION

RIGHT FRONT STOP BLOCK

LEFT FRONT STOP BLOCK

base so that the top surface abuts the left front stop block.

THE INSIDE OF THE DRAWER SIDE FACES AWAY

FROM THE FRONT OF THE BASE.

The words "INSIDE SURFACE" marked in (d) in the

Section, GENERAL PREPARATIONS, should be visible.

4. Line up the workpieces so that the end of the drawer

side lines up with the drawer front as shown in Figure 49.

5. Securely clamp the drawer side to the base.

6. Securely clamp the drawer front to the base.

7. Make sure that the parts remain lined up.

THE END OF THE DRAWER

SIDE MUST BE LEVEL AND

FLUSH WITH THE INSIDE

SURFACE OF THE DRAWER FRONT (OR BACK)

DRAWER FRONT

“INSIDE SURFACE” SHOULD BE

VISIBLE ON THIS SURFACE

TOP OF THE BASE

AUXILIARY TEMPLATE

SUPPORT (AS NEEDED)

FRONT OF THE BASE

DRAWER RIGHT SIDE

“INSIDE SURFACE” SHOULD BE

VISIBLE ON THIS SURFACE

NOTE: WORKPIECES WILL BE POSITIONED ON THE JIG AS

Page 32

32

8. Assemble the DOVETAIL TEMPLATE FOR HALF BLIND

JOINTS to the Dovetail Jig so that THE TEMPLATE

BRACKETS FIT BETWEEN THE WASHERS AND THE

TEMPLATE SUPPORTS as shown Figure 50.

NOTE: MAKE SURE THE TEMPLATE CLAMPING

KNOBS ARE LOOSE TO MAKE TEMPLATE ADJUSTMENT. AFTER ADJUSTMENT IS MADE, RETIGHTEN

TEMPLATE CLAMPING KNOBS.

9. Make sure that the short fingers on the template, as

shown in Figure 50, faces toward the front of the base.

10. Make sure that the template is flush and parallel with

the workpieces clamped to base. For narrow drawer fronts,

the use of an auxiliary support for the template is recommended. Its purpose is to aid in supporting the router while

cutting. It can be made from a piece of scrap wood; but its

thickness must be the same as the drawer front. (Refer to

Figure 49.)

11. Clamp the template in place by tightening the clamping

knobs.

12. BEFORE MAKING ANY CUTS

MAKE SURE THAT THE BIT WILL NOT CUT INTO THE

BASE OR ANY OTHER COMPONENT OF THE DOVETAIL JIG. THIS CAN CAUSE DAMAGE TO THE DOVETAIL JIG; OR LOSS OF CONTROL OF THE ROUTER

WHICH CAN RESULT IN SERIOUS BODILY INJURY. A

TRIAL RUN WITH THE ROUTER TURNED OFF AND

UNPLUGGED FROM THE ELECTRICAL OUTLET IS

STRONGLY RECOMMENDED.

13. TURN THE ROUTER ON.

14. Cut the dovetail by moving the router from LEFT TO

RIGHT, with the guide bushing following the template. DO

NOT FORCE ANYTHING; MOVE THE ROUTER IN SLOW

AND SMOOTH FASHION.

15. To ensure a smooth and uniform joint, retrace the previous cut by moving the router from RIGHT TO LEFT with

the guide bushing again following the template.

WARNING

SHORT FINGERS

DOVETAIL TEMPLATE

FOR HALF BLIND JOINT

WASHER

DRAWER FRONT

DOVETAIL CUTS

DRAWER

RIGHT SIDE

FIGURE 50

FIGURE 51

16. NEVER LIFT THE ROUTER

UPWARDS WHEN THE ROUTER IS ON AND THE

ROUTER BIT ROTATING OR WHEN THE GUIDE BUSHING IS NEAR TO OR TOUCHING THE TEMPLATE. THIS

CAN CAUSE DAMAGE TO THE DOVETAIL JIG; OR

LOSS OF CONTROL OF THE ROUTER WHICH CAN

RESULT IN SERIOUS BODILY INJURY.

17.After the cut has been made, the workpieces should

look like those illustrated in Figure 51.

WARNING

Page 33

33

FIGURE 52

FIGURE 53

18. Remove the workpieces from the Dovetail Jig and

check how the workpieces fit together. Some adjustments

may be required.

Refer to the section TROUBLESHOOTING on page 37.

19. FOR CORNER #3, position the drawer back on the top

of the base so that it lines up with the front of the base and

the top edge surface abuts the left top stop block. THE

INSIDE OF THE DRAWER BACK FACES UP. The words

"INSIDE SURFACE" marked in (d) in the Section, GENERAL PREPARATIONS, should be visible. See Figure 52.

20. Lightly clamp the drawer back in place.

21. Position the drawer LEFT side against the front of the

base so that the top surface abuts the left front stop block.

“INSIDE SURFACE” SHOULD BE VISIBLE

ON THIS SURFACE

TOP OF THE BASE

AUXILIARY TEMPLATE SUPPORT

(AS NEEDED)

FRONT OF THE BASE

“INSIDE SURFACE” SHOULD BE VISIBLE

ON THIS SURFACE

DRAWER LEFT SIDE

DRAWER BACK

DRAWER BACK

DOVETAIL CUTS

DRAWER LEFT SIDE

THE INSIDE OF THE DRAWER SIDE FACES UP. The

words "INSIDE SURFACE" marked in (d) in the Section,

GENERAL PREPARATIONS, should be visible

22. Line up the workpieces so that the end of the drawer

side lines up with the drawer back as shown in Figure 52.

23. Continue as in Steps 5 through 16 above.

24. After the cut has been made, the workpieces should

look like those illustrated in Figure 53.

25. Remove the workpieces from the Dovetail Jig and

check how the workpieces fit together. Some adjustments

may be required.

Refer to the section TROUBLESHOOTING on page 37.

Page 34

34

THE FOLLOWING DESCRIBES THE PROCEDURE TO

BE FOLLOWED FOR CUTTING CORNERS 2 AND 4

CORNERS 2 AND 4 are cut in the same way as 1 and 3

except they are positioned on the right side of the Dovetail

Jig as shown Figure 54.

• BEFORE MAKING ANY CUTS

MAKE SURE THAT THE BIT WILL NOT CUT INTO THE

BASE OR ANY OTHER COMPONENT OF THE DOVETAIL JIG. THIS CAN CAUSE DAMAGE TO THE DOVETAIL JIG.

• NEVER LIFT THE ROUTER

UPWARDS WHEN THE ROUTER IS ON AND THE

ROUTER BIT ROTATING OR WHEN THE GUIDE BUSHING IS NEAR TO OR TOUCHING THE TEMPLATE. THIS

CAN CAUSE DAMAGE TO THE DOVETAIL JIG.

CAUTION

CAUTION

AUXILIARY TEMPLATE SUPPORT

(AS NEEDED)

TOP OF THE BASE

FRONT OF THE BASE

DRAWER RIGHT SIDE

“INSIDE SURFACE” SHOULD BE VISIBLE ON THIS SURFACE

“INSIDE SURFACE” SHOULD BE

VISIBLE ON THIS SURFACE

DRAWER BACK

• After the cut has been made, the workpieces should look

like those illustrated in Figure 53.

• The finished front, back, and sides should look like those

in Figure 46.

• Before gluing the front, back, and sides together,

some provision must be made for installing the bottom, such as dadoing or cutting a groove around the

inside of the drawer parts.

• Your drawer is now ready to be glued together.

FIGURE 54

NOTE: WORKPIECES WILL BE POSITIONED ON THE JIG AS

Page 35

35

FIGURE 55

MAKING DRAWERS WITH HALF BLIND FLUSH OFFSET JOINTS

GENERAL PREPARATIONS

a. The length of the drawer front is 1/8" longer than the

length of the drawer back.

b. When cutting corners 1 and 4; the cam handle is rotated

two graduations toward the back of the base, thus moving

the template 1/32" toward the back of the base. (Refer to

Figure 55).

NOTE: MAKE SURE THE TEMPLATE CLAMPING

KNOBS ARE LOOSE TO MAKE TEMPLATE ADJUSTMENT. AFTER ADJUSTMENT IS MADE, RETIGHTEN

TEMPLATE CLAMPING KNOBS.

c. When cutting corners 2 and 3; the cam handle is positioned vertically, as shown in Figure 48.

d. All other GENERAL PREPARATIONS are the same as

those used for "MAKING DRAWERS WITH HALF BLIND

FLUSH JOINTS".

THE PROCEDURE FOR CUTTING THESE JOINTS IS

THE SAME AS THAT USED FOR "MAKING DRAWERS

WITH HALF BLIND FLUSH JOINTS".

• After all dovetail cuts have been made, cut a 1/16" deep

by 3/8" deep rabbet on opposite ends of the drawer front.

• The finished front, back, and sides should look like those

in Figure 38.

• Before gluing the front, back, and sides together, some

provision must be made for installing the bottom, such

“A” FACES

MIDDLE OF BASE

BACK OF

THE BASE

POINTER POINTS

TO THE SECOND GRADUATION

TOWARD THE BACK OF THE BASE

FROM THE CENTER GRADUATION

as dadoing or cutting a groove around the inside of the

drawer parts.

• Your drawer is now ready to be glued together.

• Remove the pencil markings by light sanding or with a

soft eraser after the drawer parts have been glued

together.

Page 36

36

LEFT TOP STOP BLOCK

“B” FACES TOWARD MIDDLE OF BASE

LEFT FRONT STOP BLOCK

RIGHT FRONT STOP BLOCK

“B” FACES TOWARD

MIDDLE OF BASE

RIGHT TOP STOP BLOCK

POINTER POINTS TO

CENTER GRADUATION

FIGURE 56

THE PROCEDURE FOR CUTTING CORNERS 1 AND 4

IS THE SAME AS THAT USED FOR "MAKING DRAWERS WITH HALF BLIND FLUSH JOINTS" EXCEPT

• Position BOTH top stop blocks so that the “B” faces the

middle of the base as shown in Figure 56.

• Use the side of the template that has the longest fingers.

• Position the template and workpieces as shown in

Figure 57. Cut the dovetail as described in the section,

MAKING DRAWERS WITH HALF BLIND FLUSH JOINTS.

• Before gluing the front, back, and sides together,

some provision must be made for installing the bottom, such as dadoing or cutting a groove around the

inside of the drawer parts.

• Your drawer is now ready to be glued together.

• Remove the pencil markings by light sanding or with a

soft eraser after the drawer parts have been glued

together.

FIGURE 57

CLAMPING KNOB

DOVETAIL TEMPLATE FOR

HALF BLIND JOINTS

CLAMPING KNOB

WASHER

TEMPLATE BRACKET

MAKING DRAWERS WITH HALF BLIND RABBETED JOINTS

GENERAL PREPARATIONS

a. The length of the drawer front is 3/4" longer than the

length of the drawer back.

b. The height of the drawer front is 3/4" higher than the

height of the drawer back and drawer sides.

• IT IS EXTREMELY IMPORTANT THAT THE TEMPLATE

BE PROPERLY ALIGNED WHEN MAKING THESE

JOINTS, OR ELSE, IN ADDITION TO THE JOINT SPACING NOT BEING EQUAL, AS SHOWN IN FIGURE 60

BELOW, THE TOP SURFACES OF THE SIDES, FRONT,

AND BACK WILL NOT “LINE-UP” PROPERLY EITHER.

REFER TO THE SECTION “ALIGNMENT OF THE TEMPLATES.” (Figure 60 illustrates a Flush Dovetail Joint.)

• All other GENERAL PREPARATIONS, except as noted

below in the procedure, are the same as those used for

“MAKING DRAWERS WITH HALF BLIND FLUSH

JOINTS”.

Page 37

37

FIGURE 58 – JOINT IS TOO SHALLOW

FIGURE 59 – JOINT IS TOO DEEP

FIGURE 60 – JOINT SPACING IS NOT UNIFORM

TROUBLESHOOTING

• If the joint is too loose: INCREASE the depth of cut by

INCREASING the amount by which the router bit extends

beyond the baseplate by 1/64'’ to 1/32" and make a trial

cut. Continue adjusting until desired joint fit is attained.

• If the joint is too tight: DECREASE the depth of cut by

DECREASING the amount by which the router bit extends

beyond the baseplate by 1/64'’ to 1/32" and make a trial

cut. Continue adjusting until desired joint fit is attained.

• If the joint is too shallow: Refer to Figure 58. Loosen

the clamping knobs holding the template brackets and

move the template INWARD half the additional depth

needed by turning the cam handles. Retighten the clamping knobs.

• If the joint is too deep: Refer to Figure 59. Loosen the

clamping knobs holding the template brackets and move

the template OUTWARD by turning the cam handles half

the distance needed. Retighten the clamping knobs.

• If the joint is not uniformly spaced from top surface

of drawer: Refer to Figure 60. (See the Section "ALIGNMENT OF THE TEMPLATES".) With the template clamped

to the base, loosen the four screws securing the template

to the template brackets, and move the template slightly to

the left. Tighten the four screws and make a trial cut. If

moving the template to the left did not correct the condition, but made it worse, loosen the screws and move the

template to the right a small amount. Tighten the four

screws and make a trial cut. Continue moving the template

to the right until the condition is completely corrected.

MAKE SURE TO SECURELY TIGHTEN THE FOUR

SCREWS. If moving the template to the left improves the

condition, continue moving the template to the left until the

condition is completely corrected. Make sure the template

remains parallel to the front of the dovetail base. MAKE

SURE TO SECURELY TIGHTEN THE FOUR SCREWS.

AFTER THE TEMPLATES HAVE BEEN CORRECTLY

REALIGNED, THEY SHOULD REQUIRE NO FURTHER

ADJUSTMENTS IF THEY ARE HANDLED WITH CARE.

DRAWER

LEFT SIDE

DRAWER FRONT

SIDE

EXTENDS

OUT PAST

FRONT

SIDE

EXTENDS

OUT PAST

FRONT

DRAWER

BACK

DRAWER FRONT

DRAWER

LEFT SIDE

DRAWER

BACK

BACK

EXTENDS

OUT

PAST

SIDE

BACK

EXTENDS

OUT PAST

SIDE

SPACING GREATER

THAN DRAWER FRONT

DRAWER BACK

DRAWER LEFT SIDE

SPACING LESS THAN

DRAWER BACK

DRAWER FRONT

Page 38

38

MAKING PROJECTS WITH OPEN (THROUGH) JOINTS

• The thickness of both the front and the back (tail pieces)

must be between 3/8" and 1".

• The thickness of the sides (pin pieces) must also be

between 3/8" and 1".

• Figure 61 shows a project and the workpieces that make

it up. This figure is similar to Figure 40, except that it

shows the workpieces unassembled.

• Trial cuts are strongly recommended using scrap wood to

ensure that the final workpieces are of the desired quality.

CORNER #1 CORNER #4

CORNER #2 CORNER #3

PROJECT

RIGHT SIDE

TAILS

INSIDE OF PROJECT

SURFACE LINES UP WITH

FRONT STOP BLOCK

OUTSIDE

OF

PROJECT

PROJECT BACK

PINS

PROJECT FRONT

SURFACE LINES

UP WITH FRONT

STOP BLOCKS

OUTSIDE OF

PROJECT

PROJECT LEFT SIDE

GENERAL PREPARATIONS

a. The workpieces comprising the project, that is, front,

back, left side and right side should be cut to the proper

length, width and thickness(es).

b. Make sure that all surfaces are smooth and square with

each of the other surfaces.

c. Line up the workpieces on a flat surface, standing on

edge, as shown in Figure 62.

d. With a soft lead pencil mark the front, back and two

sides, as shown in Figure 62, also. This is to aid you

in positioning the workpieces on the Dovetail Jig, prior

to

cutting the dovetails.

e. Position both of the top stop blocks so that the "A" faces

the "middle of the base" as shown in Figure 48.

f. Position the cam handle so that the pointer points to the

center graduation as shown in Figure 48.

FIGURE 61

Page 39

39

MARK “PROJECT FRONT TOP SURFACE”

MARK “1”

MARK “4”

MARK “2”

MARK “3”

MARK “PROJECT

RIGHT SIDE TOP

SURFACE”

MARK “PROJECT

BACK OUTSIDE

SURFACE”

MARK “PROJECT

LEFT SIDE OUTSIDE

SURFACE”

MARK “PROJECT

LEFT SIDE TOP

SURFACE”

MARK “PROJECT FRONT OUTSIDE

SURFACE” (SHOWN HIDDEN)