Page 1

VERMEIREN

TRACER

I N S T R U C T I O N M A N U A L

M O D E D ’ E M P L O I

G E B R U I K S A A N W I J Z I N G

G E B R A U C H S A N W E I S U N G

I S T R U Z I O N I P E R L ' U S O

MANUAL DE INSTRUCCIONES

I N S T R U K C J A O B S Ł U G I

Page 2

Page 3

CONTENTS

Section Page

Contents................................................................................................ .............................................1

Preface................................................................................................................................ ...............2

Technical details ................................................................................................................................2

General notes ....................................................................................................................................3

Applicability........................................................................................................................................3

Contents of the consignment .............................................................................................................3

Explanation of symbols......................................................................................................................3

Operating elements............................................................................................................................4

Adjusting the steering unit..................................................................................................................4

DX2 steering unit ...............................................................................................................................4

Seat and back....................................................................................................................................10

Mechanical adjustment of the back....................................................................................................10

Electric seat recline (option)...............................................................................................................10

Electric back adjustment (option).......................................................................................................11

Leg supports ......................................................................................................................................11

Armrests................................................................................................ .............................................12

Battery charger ..................................................................................................................................12

Charging the batteries........................................................................................................................13

Batteries.............................................................................................................................................14

Removal and replacement of the batteries ........................................................................................14

Connecting the batteries....................................................................................................................15

Battery storage...................................................................................................................................15

Thermal fuses ....................................................................................................................................15

Parking brakes...................................................................................................................................16

Tyres..................................................................................................................................................16

Changing the tyres.............................................................................................................................16

Pushing the wheelchair......................................................................................................................19

Transporting the wheelchair...............................................................................................................19

Transporting by car ............................................................................................................................19

Using ramps.......................................................................................................................................20

Accessories................................ ........................................................................................................20

• Individual headrest (L55).............................................................................................................20

• Leg supports................................................................................................................................21

• Supporting system for persons (B58)..........................................................................................21

• Torso supports (L04)...................................................................................................................21

For your safety...................................................................................................................................22

Making regular checks.......................................................................................................................22

Care ...................................................................................................................................................23

• Covers ................................ .........................................................................................................23

• Plastic parts.................................................................................................................................23

• Outer coating...............................................................................................................................23

• Electronics casing........................................................................................................................23

Inspection...........................................................................................................................................24

Disinfection ........................................................................................................................................24

Storage ..............................................................................................................................................26

Guarantee..........................................................................................................................................27

Conformity..........................................................................................................................................27

Disposal .............................................................................................................................................

27

Fault analysis.....................................................................................................................................28

E

Page 4

E

TRACER

01/2010

2

PREFACE

First of all we want to thank you for putting your trust in us by selecting one of our wheelchairs.

The electric wheelchairs supplied by Vermeiren are the result of reseach and experience over many

years. During development simplicity of operation and servicing were especially emphasised.

But the expected working life of your vehicle depends essentially on your care and maintenance. This

instruction manual will help you to familiarise yourself with the operation of your wheelchair and advise

you about keeping your electric wheelchair in a good operating condition to ensure a long working life.

This instruction manual reflects the latest level of development of the product. However, our firm,

Vermeiren, reserves the right to introduce changes without any obligation to adapt or replace

previously delivered models.

Kindly keep in mind that your wheelchair will be in an excellent working condition and function

perfectly even after many years, if you follow our advice.

For any further questions, please consult your specialist dealer.

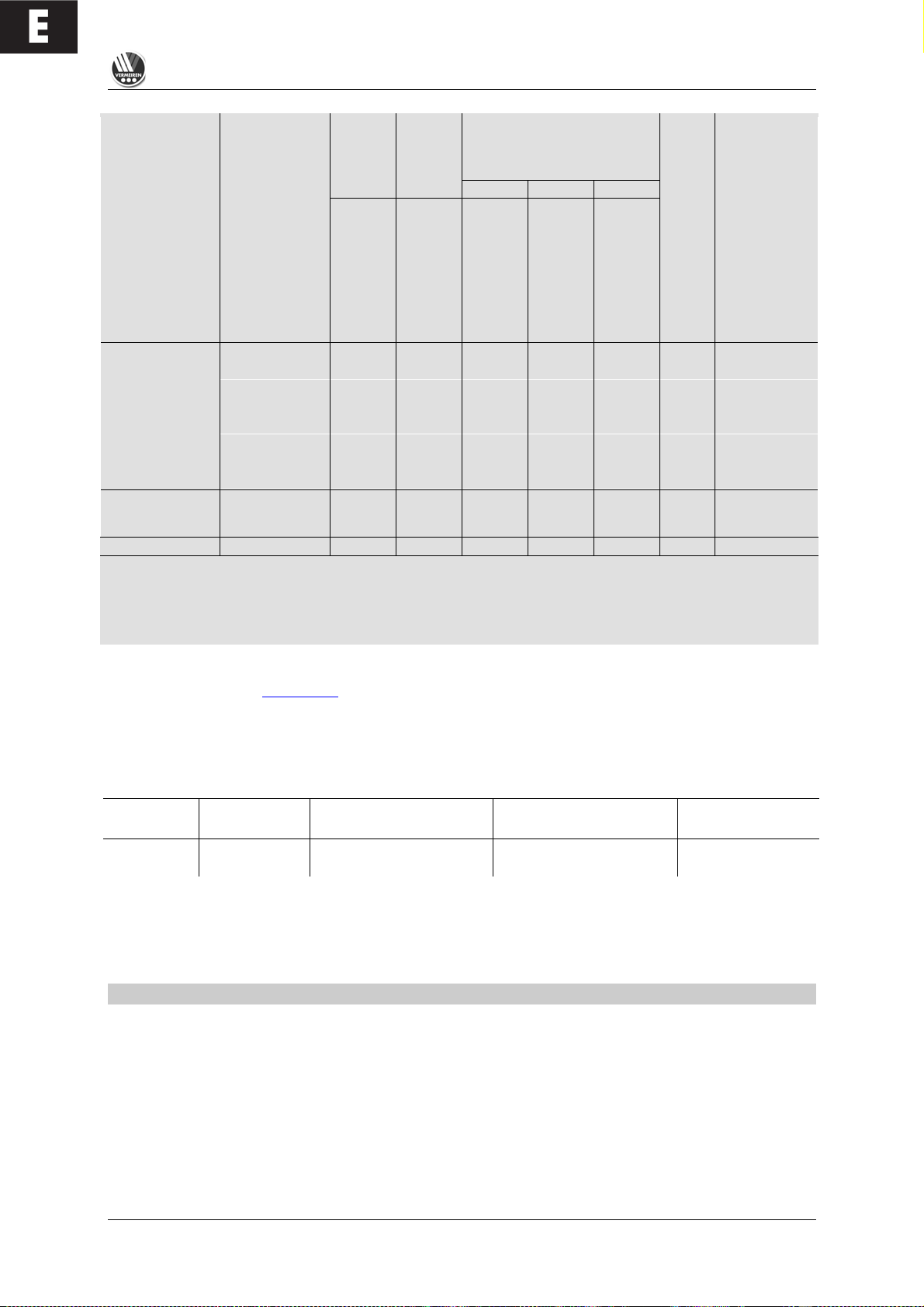

TECHNICAL DETAILS

Default (as delivered) settings specified. If different leg supports/head supports/seating systems/batteries or attachments are

used, the relevant specifications (cm / kg / °) will change too.

TRACER

TRACER 50+

Length (without leg supports)

87 cm

87 cm

Length (with leg supports)

119 cm

119 cm

Height (backrest included)

109 cm

109 cm

Width (total)

66 - 72 cm

74 - 82 cm

Seat depth

45 cm

50 cm

Height of seat

55 cm

58 cm

Height of backrest

60 cm

60 cm

Height of armrests (seat cushion)

20 - 24 cm

20 - 24 cm

Height of armrests (floor cushion)

71 - 74 cm

71 - 74 cm

Motors

2 x 200 W CD/Merrits

2 x 300 W (A.M.T)

Weight (batteries included)

+/- 119 kg

+/- 128 kg

Nominal load (max. load)

max. 125 kg

max. 150 kg

Max. speed

10 km/h (for Germany: max. 6 km/h)

Travel range*

Approx. 35 km

Max. climbing ability*

10° (17%) when sitting upright

Max. obstacle height

70 mm Class B (when sitting upright)

Batteries

2 x 12V/70Ah AGM

Battery charger

Impulse S (8 A) external

Control unit

DC (DX2) / electromagnetic brake system

Operating temperature of the electronics

between -20° Celsius and +40° Celsius

Thermal fuses

30 AMP

Use class

B

Operating pressure, steering wheels**

Max. 3.5 bar

Operating pressure, driving wheels**

Max. 2.5 bar

Turning circle

Approx. 140 cm

We reserve the right to introduce technical changes. Measurement tolerance +/- 1.5 cm / ° / kg

* When battery charge, tyre profile and ground are optimal

** Since different tyres may be used, please note the correct operating pressure of the tyres you use.

Page 5

E

TRACER

01/2010

3

GENERAL NOTES

The TRACER electric wheelchair is designed for outdoor use, but it can also be used indoors because

of its manoeuvrability and compact construction.

No driving license or insurance policy are required to operate the TRACER electric wheelchair. We do,

however suggest that you take out a private insurance policy.

We wish to point out that electromagnetic sources (e.g. mobile phones, etc.) can cause interference

and that the wheelchair's electronics can also affect other electric appliances.

Even if you have been instructed by your specialist dealer about the operational elements of your

electric wheelchair and their use, we recommend that you read the following pages carefully before

you first use it.

APPLICABILITY

The many types of equipment and accessory and the modular construction allow full use by persons

disabled by

• Paralysis

• Loss of limbs (leg amputation)

• Limb defects / deformation

• Stiff or damaged joints

• Diseases like heart problems, poor circulation, disturbance of balance or "Kachexie" as well as for

aged persons.

When considering individual requirements

• body size and weight

• physical and psychological condition

• residential circumstances and

• the environment

should also be taken into consideration.

Guarantees can only be honoured when the product is used under the specified conditions and

for the intended purposes.

CONTENTS OF THE CONSIGNMENT

• The frame structure including the motors, the seat, and the back unit

• Footrests (standard: B06; removable, can be turned aside)

• 2 x batteries including the battery boxes

• Battery charger

• Steering electronics

• Tools (Allen keys)

• Instruction manual

EXPLANATION OF THE SYMBOLS

Observe the safety instructions!

Read the instruction manual before use!

Position: Parking brakes activated (electronic driving possible)

Position: Parking brakes deactivated (free running and pushing possible, no electronic driving)

During free running, be careful with slopes and inclinations

Separate recovery and recycling of electric and electronic devices

Page 6

E

TRACER

01/2010

4

THE OPERATING ELEMENTS

The electric wheelchair is delivered fully assembled. Only the footrests have to be fixed (see the

relevant description). Your dealer d e livers the wheelchair fully assembled and explains the v ario us

operating elements and their use. However, for your own safety we provide a further, detailed

explanation of the different parts.

The steering and control unit built into your electric wheelchair enables you to control all the driving,

steering and braking processes of the vehicle. The wheelchair's electrical unit and electronics are

constantly being m onitored internally. Any fault in the electronics is indicated on the steering unit and,

if necessary, the wheelchair is switched off for reasons of safe ty (see the chapte r on fault analysis) .

Consult your specialist dealer if this happens.

The TRACER model can be fitted with equipment w hich can electrically adjust the inclination of the

seat and the backrest, as well as the height of the footrests.

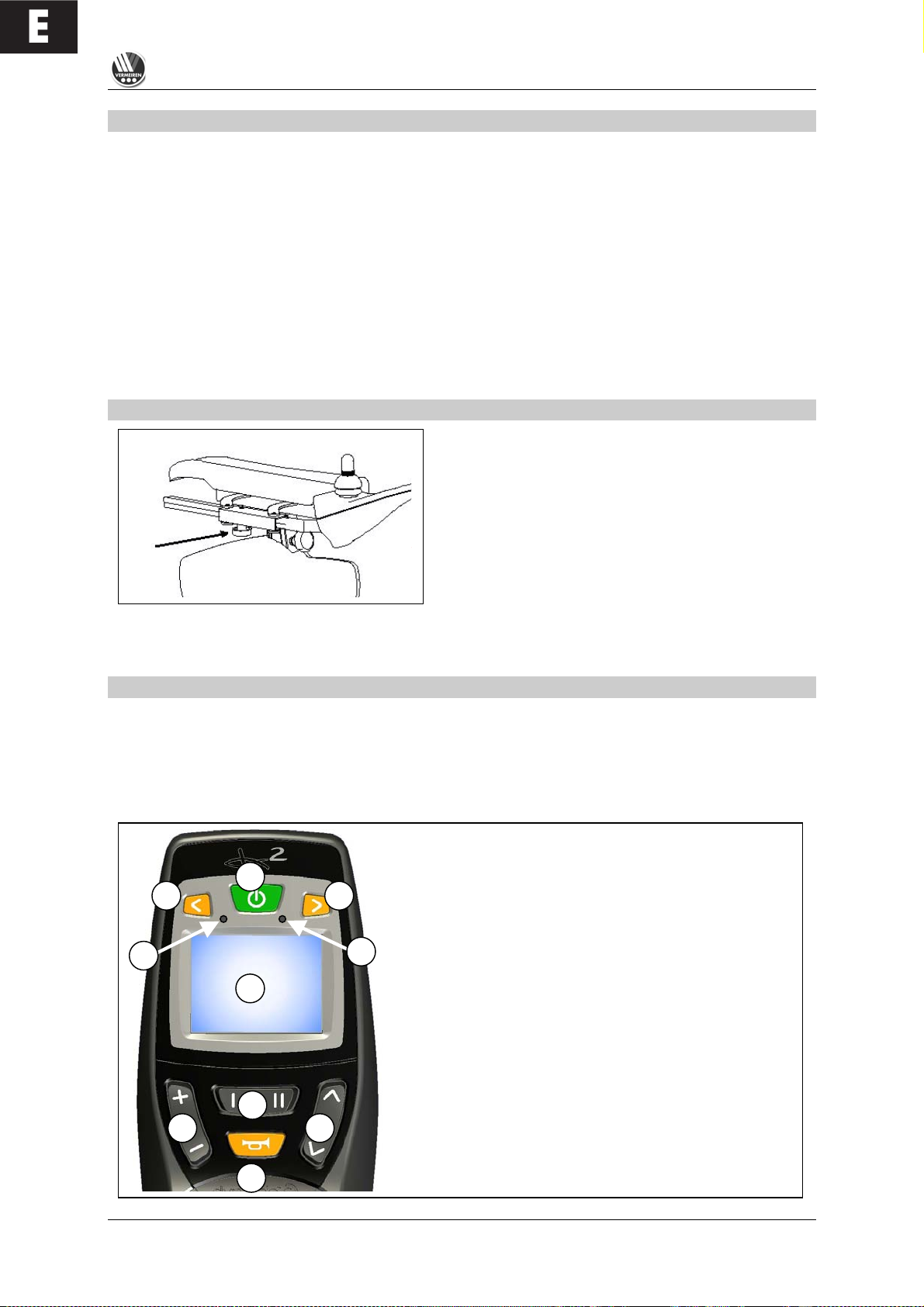

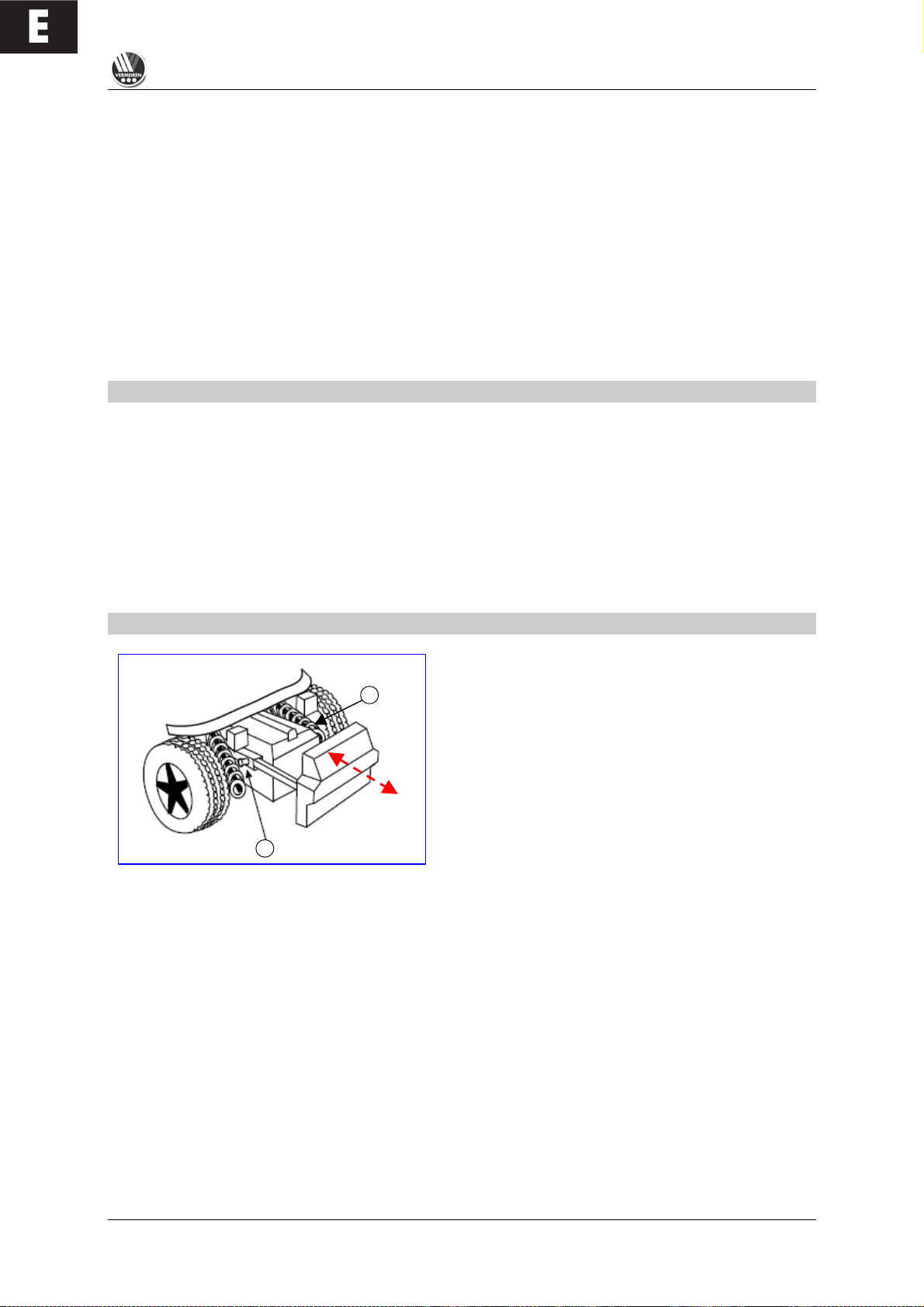

ADJUSTING THE STEERING UNIT

The steering unit's horizontal position can be changed

by loosening screw (1). The unit can then be adjusted

as desired, or removed. Screw (1) must then be

retightened properly. If screw (1) is p u lled to the side,

the steering unit can be tu r n e d to the side.

L Make sure that the steering unit's connection cable stays clear of the pincer mechanism.

DX2 STEERING UNIT

The steering and control unit built into your electric wheelchair enables you to control all the vehicle's

driving, steering and braking processes and to control other adjusting motors (options: lifting column

and seat/back adjuster and leg supports). The wheelchair's electrical unit and electronics are

constantly being monitored internally. Any fault in the electronics is indicated on the operating display

(6) a nd the status display (1) a n d , if n e ce s sa ry , the wheelchair may be switched off for reasons of

safety (see the chapter on fault analysis).

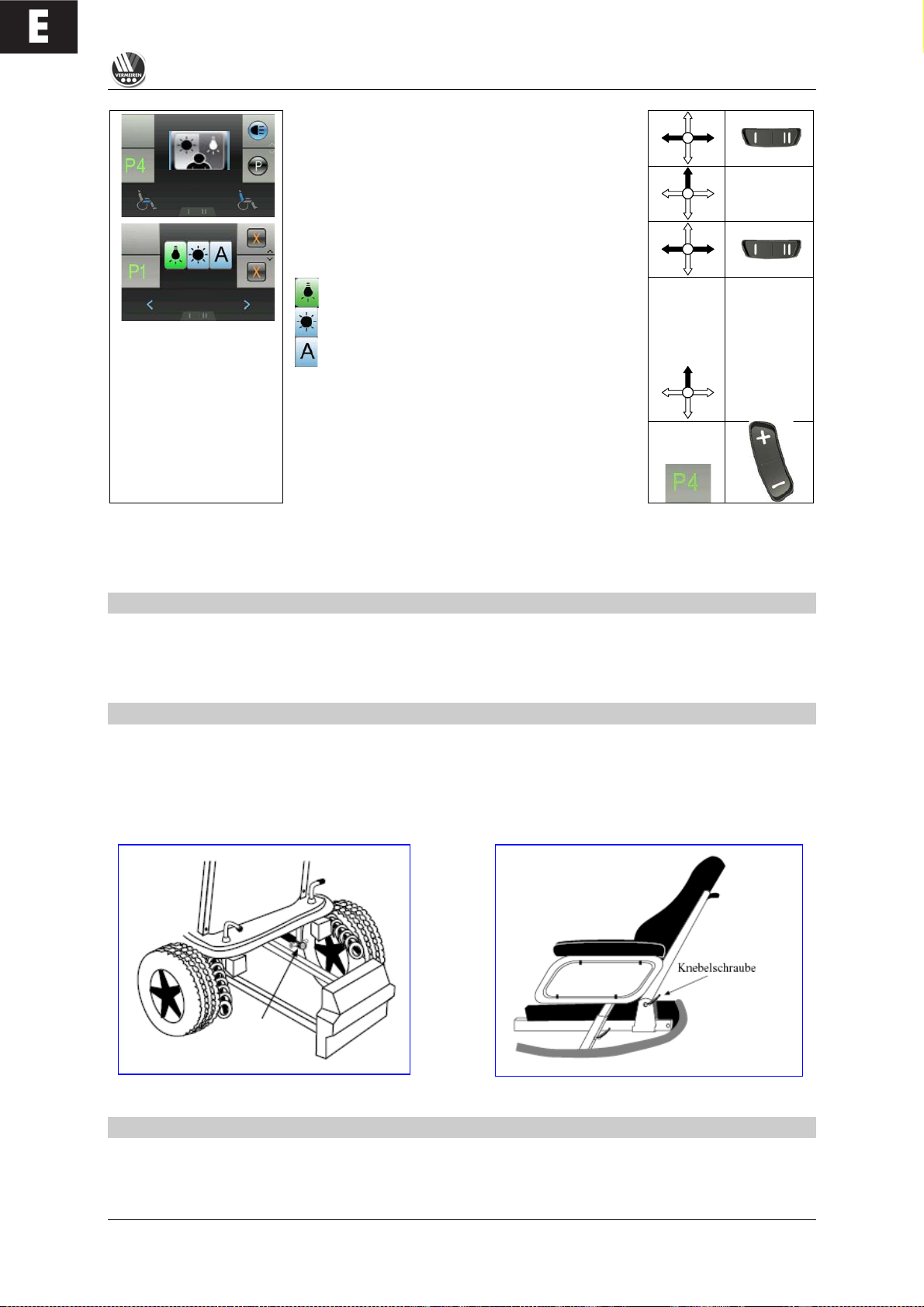

1 = Display (colour)

2 = "ON / OFF" button

3 = "LEFT INDICATOR" + "LIGHT" button

4 = "RIGHT INDICATOR" + "WARNING INDICATOR" button

5 = "HORN" button

6 = Fault code/operating display

7 = Brightness sensor

8 = "DRIVE PROFILE" button

9 = "SELECT FIELD" button

10 = "SELECT MENU" button

1 2 3

4 5 6 7 8

9

10 1

Page 7

E

TRACER

01/2010

5

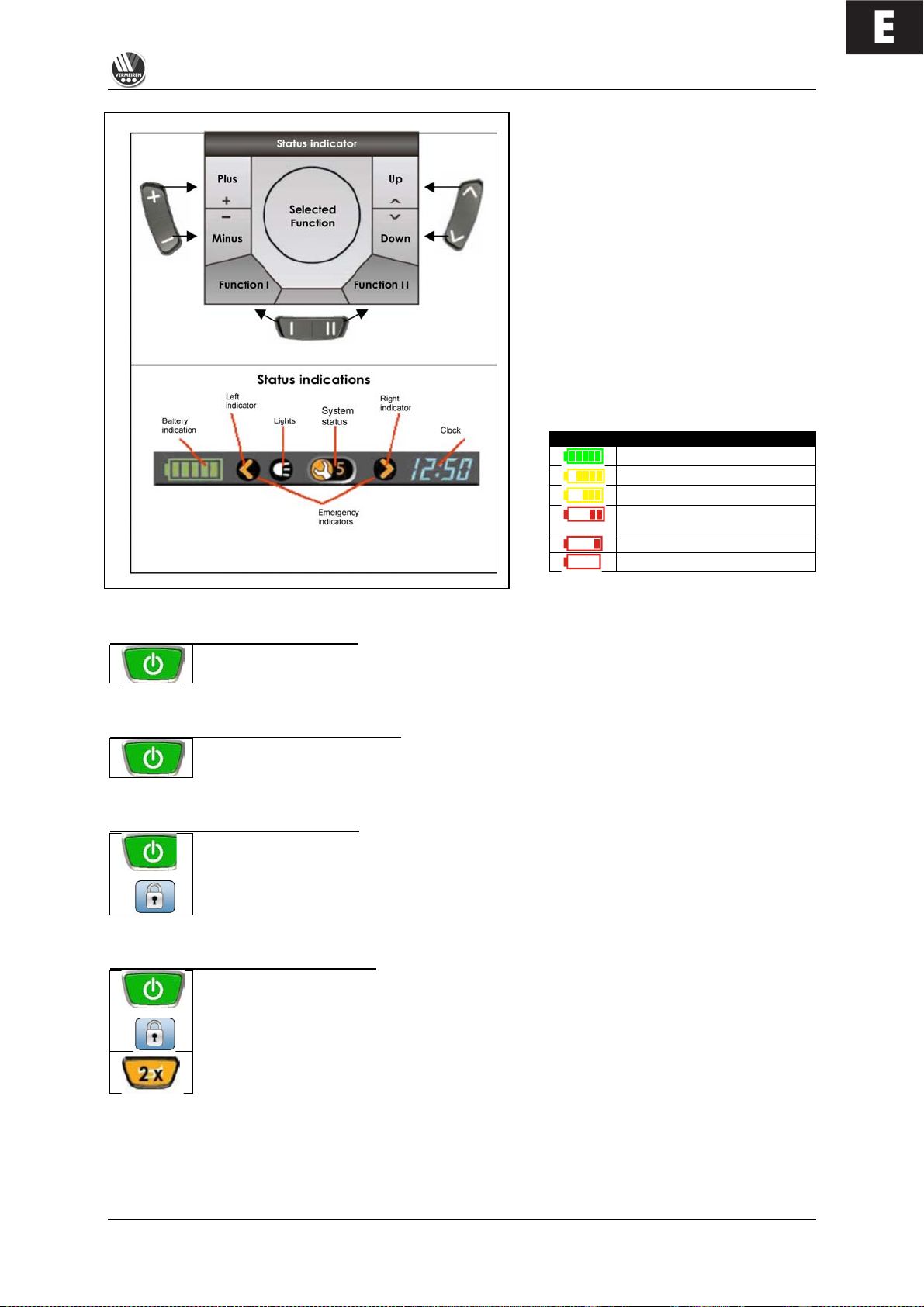

The function buttons (8), (9) and (10)

enable functions to be selected that

are displayed in the assigned fields on

the screen.

The status display is constantly visible

in the upper part of the display and

always shows the batteries' charge

level and the current time.

The light, indicator and warning light

displays only appear when the

relevant function is selected. The

system status display appears when

there is a fault or an event, and

displays the relevant event or fault

code (1-12).

Display

Meaning

Battery fully charged

Battery fully charged

Battery half charged

Battery will soon be low, charge

it

Battery is low, charge it soon

Battery is dead, charge now

Start the steering / control unit

Press the ON/OFF button (2) and the operating display (6) will briefly flash on and the

screen will show the drive level (1-5) last used.

Switch off the steering / control unit

Press the ON/OFF button (2) and the system will switch off.

Lock the steering / control unit

If you keep the ON/OFF button (2) pressed for longer than 4 seconds, the steering unit

will be locked.

The lock symbol will briefly appear in the display.

Unlock the steering / control unit

When the ON/OFF button (2) is pressed...

... the lock symbol will appear in the display.

When you press the horn button (5) twice while the lock symbol is showing, the control

unit will be unlocked. The drive level (1-5) last used will appear in the display (1-5).

4 secs.

Page 8

E

TRACER

01/2010

6

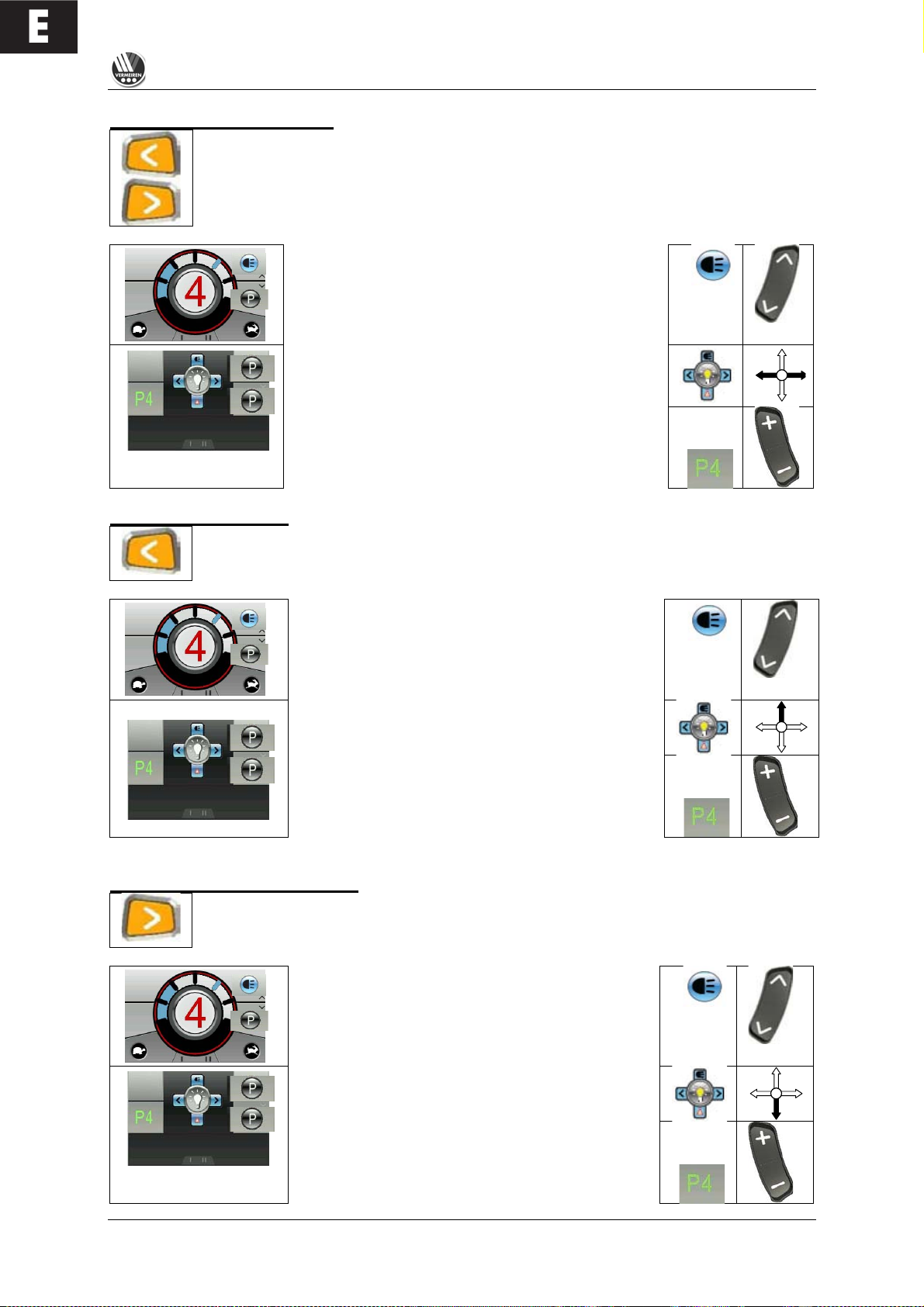

Switch the indicators on/off

To switch the drive direction display on and off, press buttons (3) or (4) for whichever

indicator you wish, left or right. When you activate a drive direction, it will flash in the

status display.

or

Select the light function using the field selection

button (9) and the display will show the light selection

menu.

To switch the flash function (left or right) on or off,

move the joystick in the appropriate direction left or

right.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

Switch the light on/off

To switch the light on and off, keep the button for the left-hand indicator (3) pressed for

longer than 3 seconds. When the light function is switched on its symbol will light up in

the status display.

or

Select the light function using the field selection

button (9) and the display will show the light

selection menu.

Push the joystick upwards to switch the light on or

off.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

Switch the warning light on/off

To switch the warning light on and off, keep the button for the right-hand indicator (4)

pressed for longer than 3 seconds. When the warning light function is switched on its

symbol will light up in the status display.

or

Select the light function using the field selection

button (9) and the display will show the light

selection menu.

Push the joystick downwards to switch the

warning light on or off.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

Page 9

E

TRACER

01/2010

7

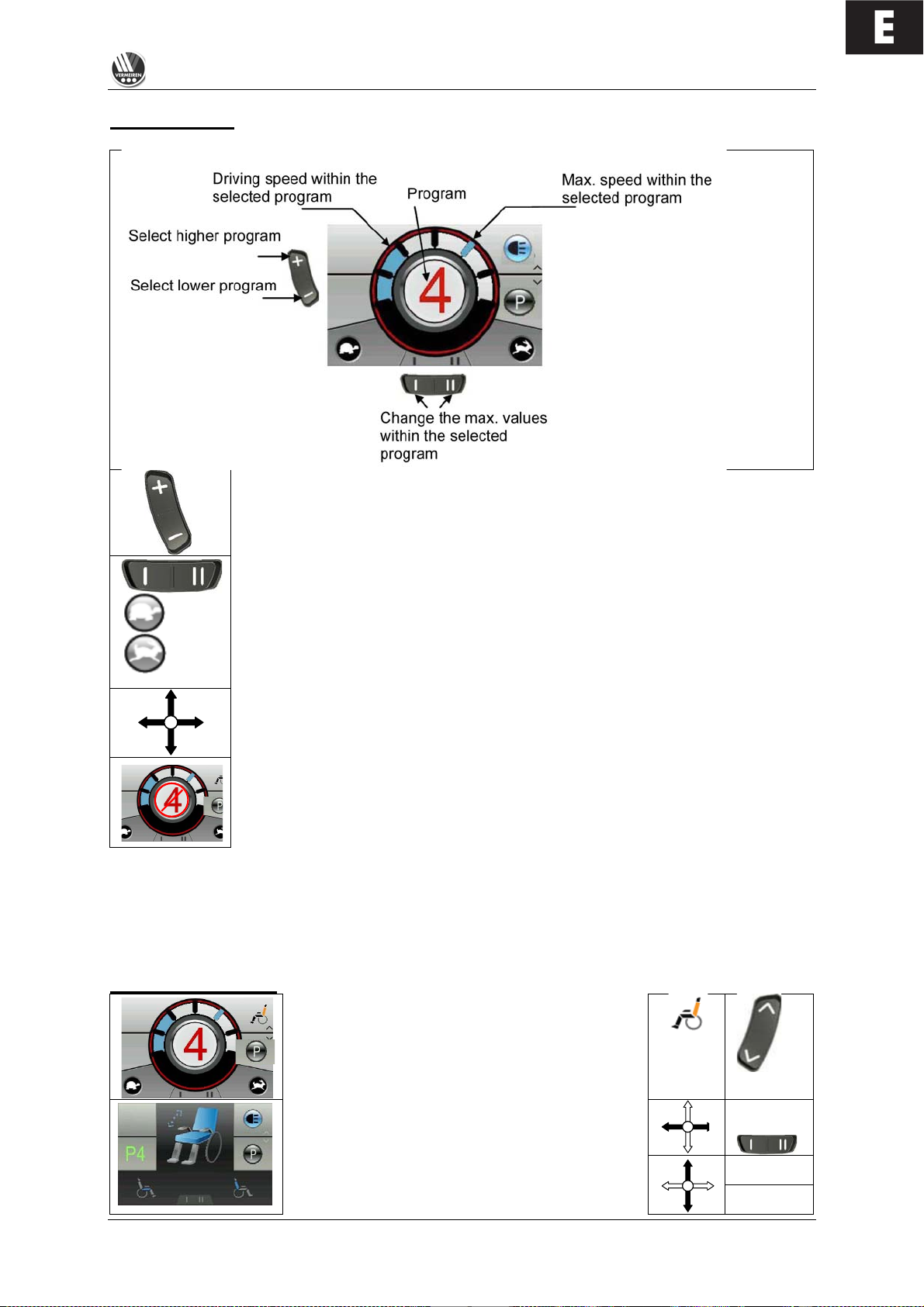

Drive functions

In drive mode use the drive profile button (8) to select a higher or lower driving

program (drive profile 1-5). These drive programs are programmed in the factory

to rise from slow to fast. T h e d rive p ro g ra m you select a ppears in red text in the

middle of the display.

slower faster

The top speed in any drive program can be changed using the menu selection

button (10) in the drive program selected.

To drive the wheelchair in the direction you wish, m ove the joystick to the position

you want.

If the loading socket is p lugged in, the wheelchair w ill b e lo c k ed for drive functions.

If the joystick is moved, the d is p la y will also briefly show a red wa rning bar.

L Make sure that the steering lever is in the neutral (central) position when pressing the on/off

button, otherwise the electronics will be blocked. This block can be lifted by switching the

control unit off and then on again.

L Always adapt your speed to the prevailing environmental conditions.

Electric adjustments

Select the program function using the field

selection button (9) and the display will show the

menu for the adjust functions.

Select left/right with the joystick or the menu

selection button (10) until the adjust function you

want appears in the centre of the display.

Return

function

To adjust the selected function, move the joystick

in the direction you w a nt up or down.

Start

function

Page 10

E

TRACER

01/2010

8

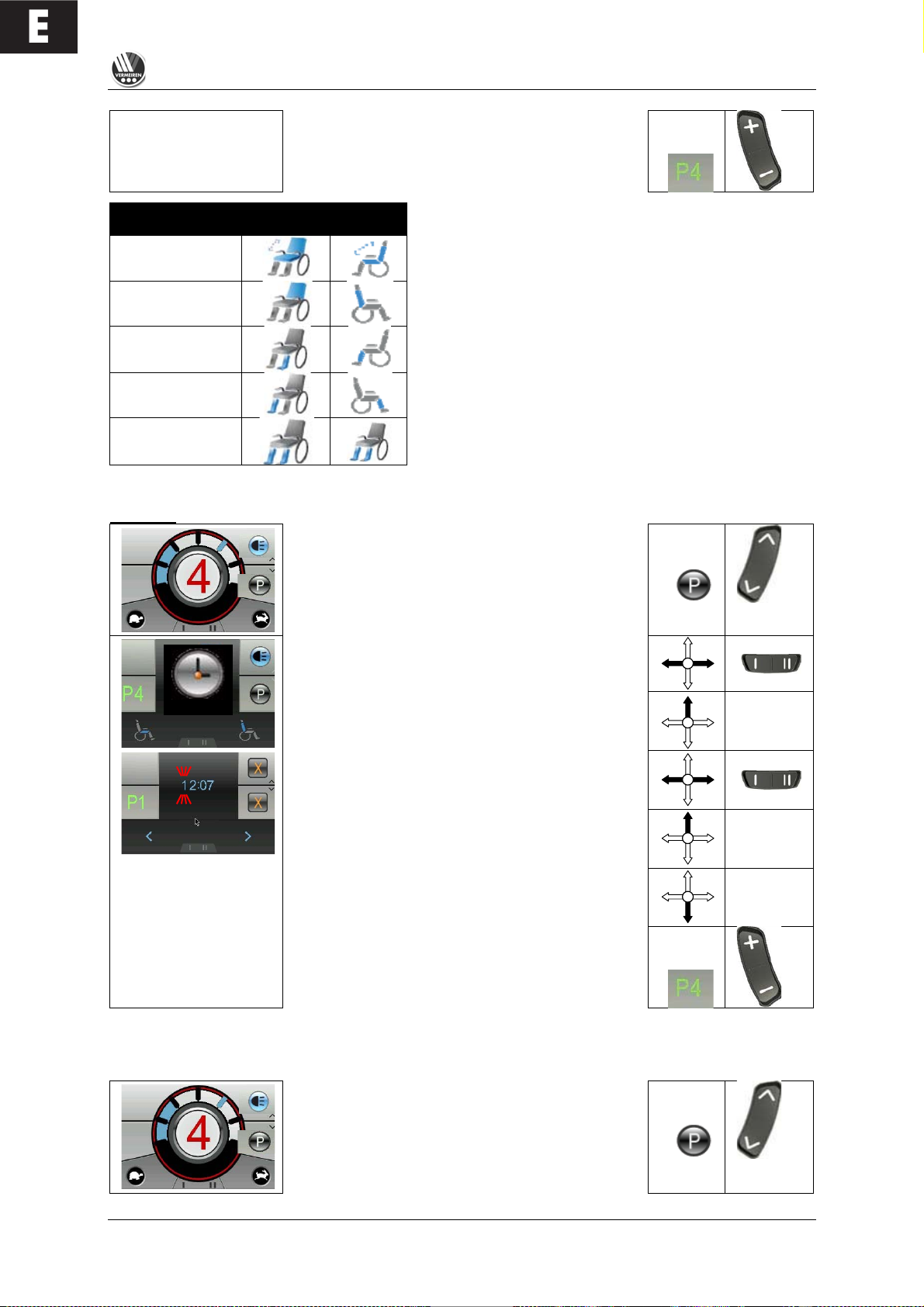

To switch back to the driving program, select the

drive profile button (8) in drive mode.

Adjust function

In

Display

Display

Menu

Seat inclination

Angle of backrest

Leg support

left

Leg support

right

Leg supports

simultaneous

The only functions displayed in the menu selection and

the centre of the display are those which exist on your

wheelchair and have been enabled.

L Make sure that no objects and/or persons are

inside the swinging range of the adjust functions,

since this could cause damage and/or injury.

L For your safety the adjust functions can only be

activated when all four wheels of the wheelchair

are standing still. The driver programs are

disabled while the adjust functions are active.

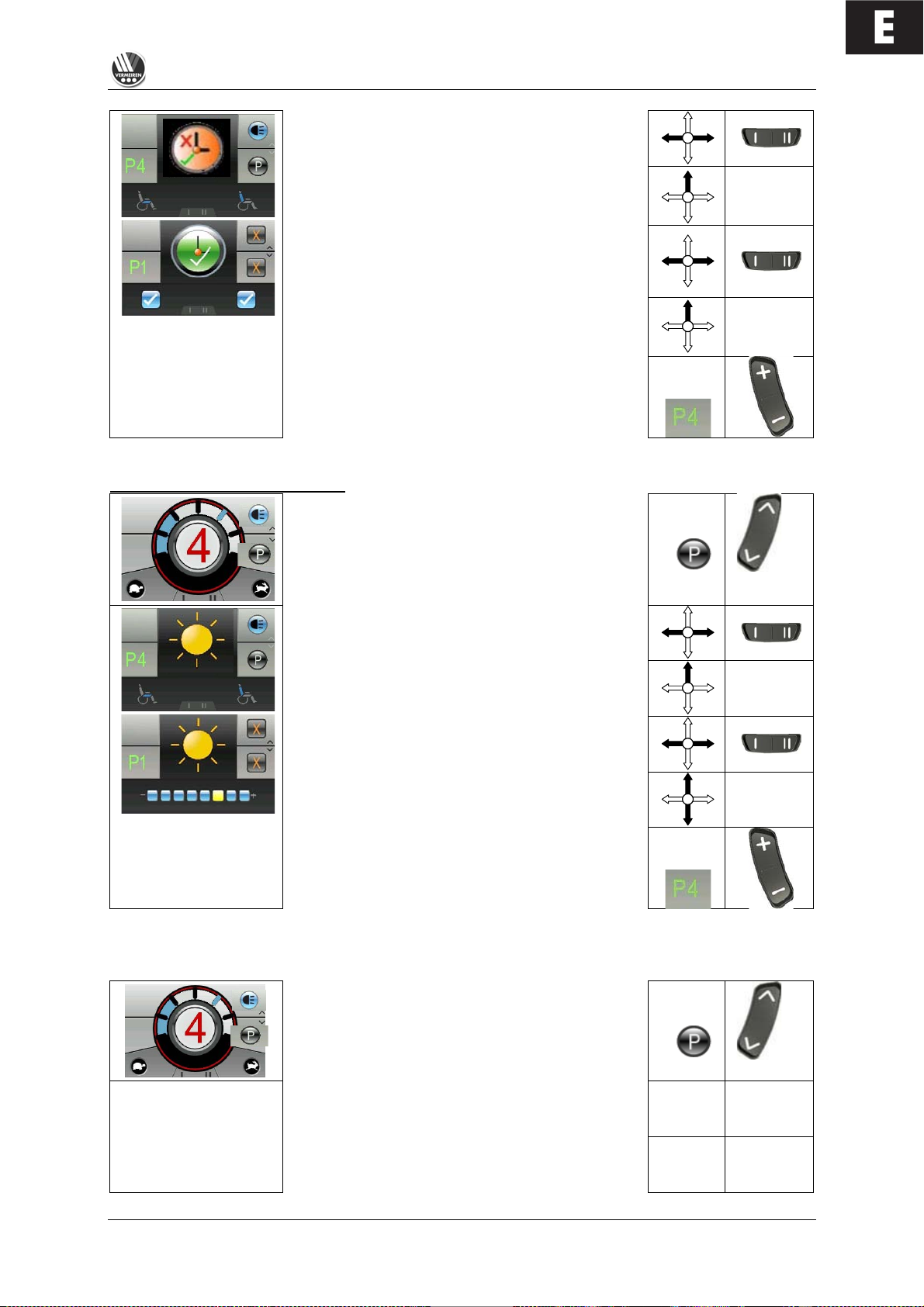

Set time

Select the program function using the field

selection button (9) and the display will show the

menu for the special functions.

Select left/right with the joystick or the menu

selection button (10) until the time function you

want appears in the centre of the display.

If you want to set the time, confirm by moving the

joystick upwards.

The time digit waiting to be set flashes. To change

other digits, you can select left/right with the

joystick or use the menu selection button (10).

To adjust the digits, select upwards with the

joystick.

To save the new time, confirm by moving the

joystick downwards.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

By default, the factory sets the time to be visible in the status display. To change this option, proceed

as follows:

Select the program function using the field

selection button (9) and the display will show the

menu for the special functions.

Page 11

E

TRACER

01/2010

9

Select left/right with the joystick or the menu

selection button (10) until the time function you

want appears in the centre of the display.

If you want to change the display option for the

time, confirm by moving the joystick upwards.

The option currently selected will appear in the

menu and the centre of the display. To change

this, select left/right with the joystick or the

left/right menu selection button (10).

To save the option you want, confirm by moving

the joystick upwards.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

Adjust the screen brightness

Select the program function using the field

selection button (9) and the display will show the

menu for the special functions.

Select left/right with the joystick or the menu

selection button (10) until the brightness function

you want appears in the centre of the display.

If you want to change the brightness of the

display, confirm by moving the joystick upwards.

Adjust the brightness of the display by moving the

joystick left/right or selecting the left/right menu

selection button (10).

To save the brightness you have selected, confirm

by moving the joystick upwards or downwards.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

By default, the factory sets the brightness of the display to be automatically adjusted to match the light

conditions. To change this function, proceed as follows:

Select the program function using the field

selection button (9) and the display will show the

menu for the special functions.

Select left/right with the joystick or the menu

selection button (10) until the brightness function

you want appears in the centre of the display.

If you want to change the brightness function,

confirm by moving the joystick upwards.

Page 12

E

TRACER

01/2010

10

Select left/right with the joystick or the menu

selection button (10) until the brightness function

you want appears in the centre of the display.

If you want to chan g e the brightness function,

confirm by moving the joystick upwards.

Adjust the display's brightness function by moving

the joystick left/right or selecting the left/right

menu selection button (10).

= inwards

= outwards

= automatically (via light sensor (7))

To save the brightness function you have

selected, confirm by moving the joystick upwards.

To switch back to the driving program, select the

drive profile button (8) in drive mode.

If you have special r e q uirements, you can as k your

specialist dealer to enter an individual driving program.

SEAT AND BACK

In the standard version your TRACE R has a fixed sea t and a fixed backrest which can b e adjusted

mechanically. As an optional extra the seat can be inclined electrically and the back can also be

adjusted electrically.

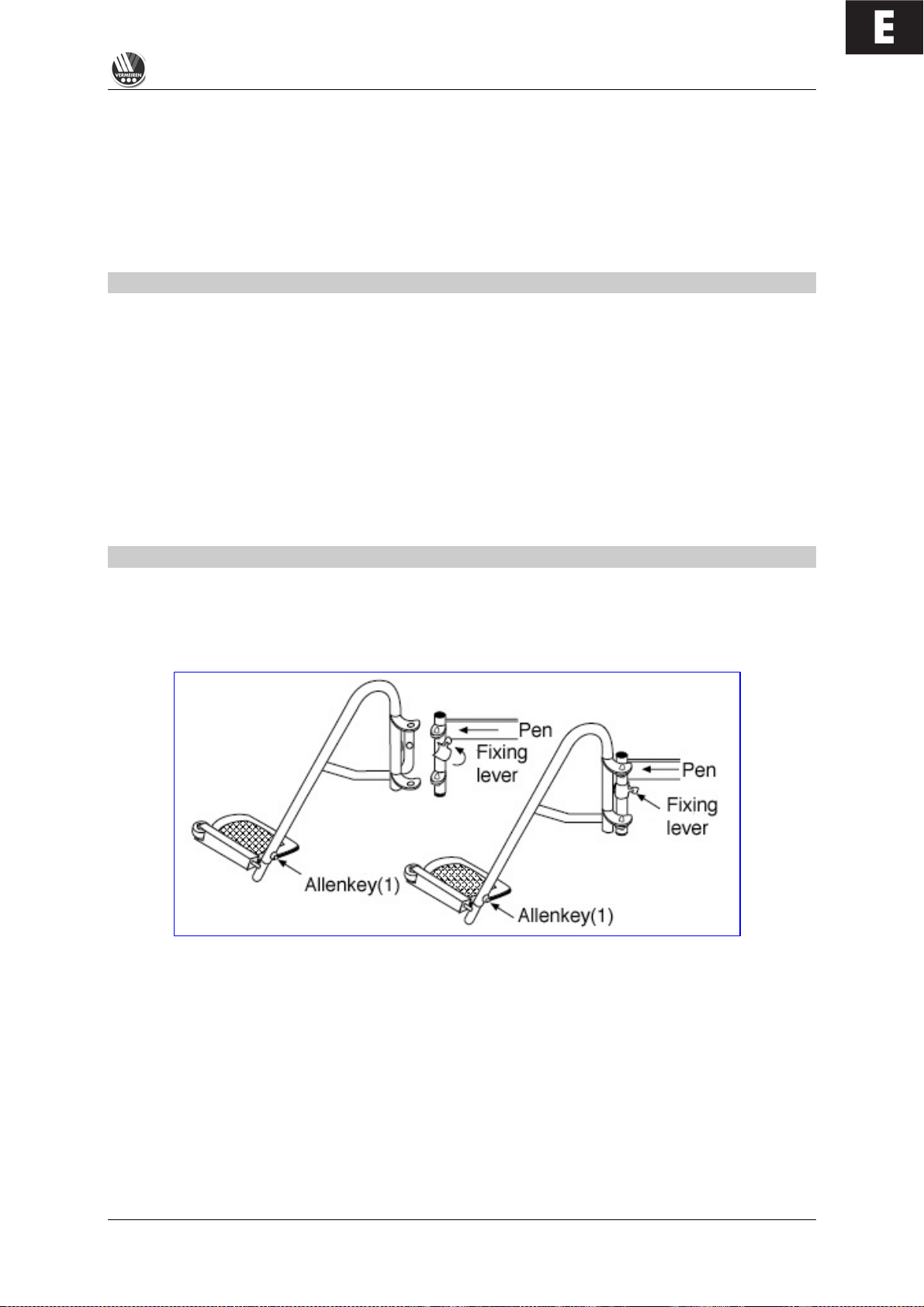

MECHANICAL ADJUSTMENT OF THE BACK

For easier stowing of the electric wheelchair in a vehicle, the back can be folded down forwards or

backwards. Open the lid of the battery box (see the chapter "Removal and replacement of the

batteries"). Above the battery box on the right-hand side are bolts which can be pulled out quickly by

loosening the clasps. You ha v e no w s eparated the connection between the back and the frame. The

backrest can be tilted to the front or to the rear, and removed, after loosening the screw handles on

the lower side of the bac k u n it. (The back can be fixed ag a in b y reversing this process).

ELECTRIC SEAT INCLINE (option)

If you chose th e electric seat tilting option, your wheelchair will have been fitted with the system before

delivery. To operate this, it is only necessary to switch the steering unit on. The driving program then

switches itself on. If you want to adjust the angle of your seat, you just need to use the function button

for adjusting the seat. T h e c o n tr o l in d ic a to r on the DX control unit s h o ws that you have selecte d th is

Lever screw

Fig. B

Fig. A

knob

Page 13

E

TRACER

01/2010

11

function (on the G90 co n tro l unit, the selected symbol flashes). You can then ad ju st the slope of the

seat by pushing the joystick fo rwards or pulling it backward s .

L Make sure that no objects and/or persons are inside the swinging range of the wheelchair,

either in front or at the rear, since this could cause damage and/or injury.

L For your safety this adjust function can only be activated when all four wheels of the

wheelchair are standing still. When this function is selected, the driving program is disabled.

ELECTRIC BACK ADJUSTMENT (option)

The back can be adjusted in a similar way to the seat angle. You only have to select button the

relevant button on the steering unit an d y ou c an the n tilt the ba c k a s y ou w ish .

L Make sure that no objects and/or persons are inside the swinging range of the wheelchair,

either in front or at the rear, since this could cause damage and/or injury.

L For your safety this function can only be used when all four wheels of the wheelchair are

standing still. When this function is selected, the driving program is disabled.

L Make sure that you do not set the backrest too far over backwards, since this can displace the

centre of gravity too far to the back and cause tipping over.

L For your own safety you should not drive the wheelchair in an inclined or tilted position, since it

would severely limit your visibility.

LEG SUPPORTS

The basic model of your electric wheelchair is equipped with leg supports which allow your legs to rest

comfortably. You can adjust the length of the foot supports continuously, turn them aside, or even

remove them completely. T h es e adjustments s hould be carried out by a third person w ith the required

technical knowledge. Consult your specialist dealer if these adjustmen ts become necessar y. If you

want to carry out these adjustments yourself, you should read the following sections carefully.

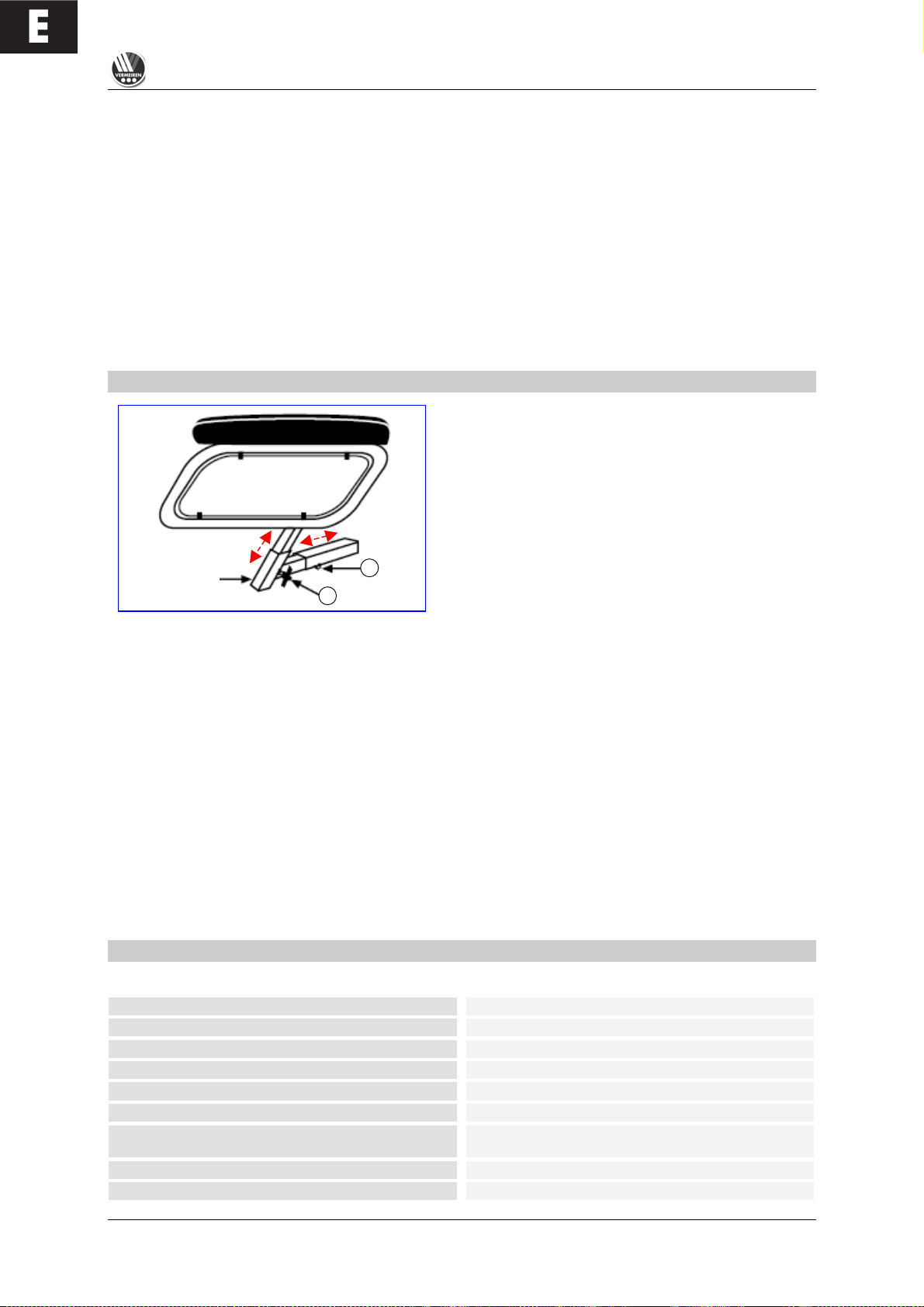

When you want to fix the footrests, hang one leg support sideways on the outside and then turn it

inwards until it stops. The fixing lever (F igure B) must point backwards. If the leg s u pports do not

engage immediately, push them lightly inwards. Do the same on the other sid e. To remove the

footrests, reverse this pro cess.

L When handling the leg supports, make sure that you hold on to the upper curve to prevent

your fingers from getting caught and hurt.

Turn the footplates out of the way for climbing in and out com fortably. T he footplates are designed for

resting your feet securely on them; in addition, your fe e t are pre ve n ted from moving sideways

unnecessarily. Use the Allen keys provided to adjust the length of the leg supports. There is a

countersunk Allen screw (Figure A) on the rear side of the leg support for fixing the footplate. By

loosening this screw th e footplate can be adjusted to the length of your leg. It mus t b e tightened

properly afterwards.

Fig. A

Fig. B

Page 14

E

TRACER

01/2010

12

1

2

Frame

L Make sure that the footplate is at least 6 cm above the ground to avoid scraping the ground

when moving. This could damage the wheelchair and endanger its operational safety. The

user might also get hurt.

L Do not stand on the footplates; they are only designed for letting your feet rest on

them.

L When the leg supports are adjusted, no persons or parts should be within their reach,

otherwise there is danger of injury and/or damage.

If there are patterns of illness and/or disabilities which mean ther e is no guarantee that your legs

would rest constantly on the leg supports, you may select from other available leg supports. Kindly ask

your specialist dealer if you have queries in this regard.

ARMRESTS

The height of the armrests can be adjusted by

loosening screw (1) and pulling the armrest

upwards.

To adjust the width between the armrests, you only

have to loosen screw (2) and place the armrest in

the desired position. The s c r e w must be tightened

properly afterwards.

L Make sure that all fixing screws are properly

tightened b e fo re using the whe e lc h air,

otherwise injury and/or damage can be

caused.

L Never pick the wheelchair up for transportation by grasping the armrests, but take hold of solid

frame parts only.

The armrest containing the steering electronics can only be detached if the electronics have been

removed previously.

L The armrests may only be removed when there is no chance of the wheelchair user

falling out sideways.

If chan g e s , damage, or wear of the suspension are noticeable, kindly consult your specialist dealer

who can remedy these defects.

L To avoid endangering your safety, do not use the w heelchair if you see that the mountings have

changed, been damaged, or have worn out.

L If you make any changes to the armrests and/or the armrest retainers, you do so en tirely at

your own risk. Then your insurance claims lapse immediately.

BATTERY CHARGER

To charge the batteries, only use the battery charger supplied - IMPULSE S (8 A).

Primary voltage

230 Vac – 50/60 Hz – single phase

Secondary nominal voltage

24 V

Secondary maximum voltage

35 V

Secondary power

max. 8 A

Battery type

Lead-sulphuric acid: gel

Battery capacity

60 Ah – 85 Ah (80% capacity charged within 8 hours)

Safeguards

Protected against reverse polarisation, electrical

surges and extreme temperature

Nominal output

270 W

Efficiency

min. 80% (when fully loaded)

Page 15

E

TRACER

01/2010

13

Ambient temperature

0° C to +40° C

Unit dimensions

H 70 x W 150 x D 200 mm

Protection range

IP 21, Protection Class II

Total weight

Approx. 1.3 kg

Mains cable length

1.9 m

Charge cable length

2.4 m

Ambient storage temperature

-15° C to +50° C

Relative storage humidity

max. 95% (non-condensing)

Conformity

EMC Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

We reserve the right to introduce technical changes.

CHARGING THE BATTERIES

As the IMPULSE S (8 A) charger aligns the charge curve with the AGM batteries' charge level, you

can recharge your wheelchair after each use. This avoids any aggressive battery charging and the

"memory effect".

Recharge the wheelchair, at the latest, when the charge indicator on the steering unit goes into the red

zone. If, despite this, you continue driving, eventually only the last red diode lights up and flashes

continually, indicating that the batteries are nearly flat. If you disregard this warning signal, too, an

error message will shortly appear indicating that the batteries can no longer provide power for driving.

The batteries should therefore be charged before these error messages appear, using the supplied

battery charger IMPULSE S (8 A). Avoid the batteries becoming drained, in any case.

• SETTING UP THE CHARGER

When setting up the charger, ensure that it is well-ventilated on all sides. A minimum of 10 cm space

should be left free around the unit for this purpose. If the charger is insufficiently ventilated so that the

unit heats up, the charging rate will fall which will extend the charging time. If the charger overheats (>

+50° C), it will stop charging.

The charger should only be used from a wall socket with a voltage of 230V – 50/60Hz and in wellventilated, dry areas.

• FIRST USE

First put the plug into the wall socket. After an LED combination has lit up, the charger switches to

STANDBY. Both LEDs (green and yellow) are active.

Next, connect the charger cable with the three-pin plug to the loader socket on the electric

wheelchair's steering unit. Once connected to the batteries, the charger automatically begins charging.

Now only the yellow LED is active.

When charging is complete, the yellow LED goes out and the green LED comes on. Now remove the

charger cable from the steering unit. The charger switches back to STAND-BY mode (yellow and

green LEDs active).

If the charger cable is not removed, a tiny current will keep the batteries topped up (trickle charging).

L When charging is complete, always remove the plug from the steering unit first and only then

the mains plug from the wall socket.

• INDICATORS

Yellow LED

Green LED

Charger switched off (not plugged into the mains)

!

!

"

!

Charger has just been switched on and displays the

charging characteristic that has been set

!

"

Stand-by

#

#

Charging

#

!

Full

!

#

Fault

"

"

! = Off # = On " = Flashing

Page 16

E

TRACER

01/2010

14

If you decide not to use your electric wheelchair for an appreciable period, you must nevertheless

recharge it regularly to keep it in a running condition ready for immediate use.

L If the batteries are not used for an appreciable period, they discharge slowly by themselves

(drainage). Then it becomes impossible to recharge them with the battery charger supplied.

So charge the batteries at least once a month even if they are not being used.

L Only use the battery charger supplied to charge the batteries.

L The manufacturer accepts no liability for damage caused by improper charging.

L Never interrupt the charging cycle. The charger shows when the charging cycle is finished.

(green LED remains active).

For further information, please refer to the user instructions provided with the charger.

BATTERIES

The standard for your electric wheelchair is two closed, 12V/70Ah AGM batteries. The batteries used

with your electric wheelchair are drive batteries which only attain full capacity after a few charging and

use cycles.

If the batteries lose their power after long usage, or if they are damaged, get them both replaced by a

specialist dealer only.

L We accept no liability for damage caused through using other types of battery.

L Do not use the batteries at temperatures below +5°C or above +50°C (the ideal is: +20°C).

L If the batteries are opened, all manufacturer liability and all claims will become void.

REMOVAL AND REPLACEMENT OF THE BATTERIES

Kindly obey the following instructions when removing the batteries for servicing or for transportation:

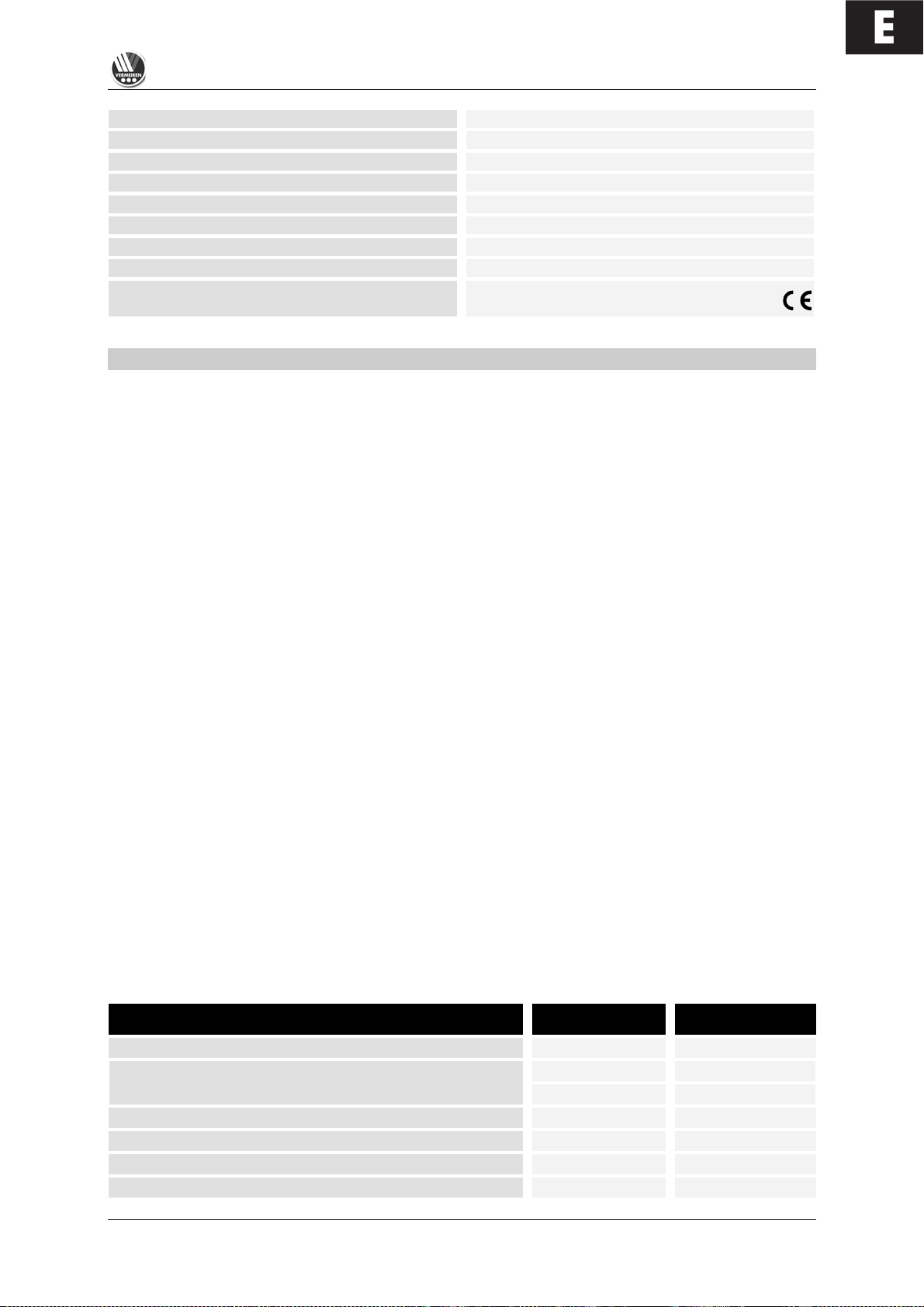

Pull up the knobs (1) and pull the battery drawer

backwards. Now you can grasp the first battery by its

handle and pull it backwards on the rail. Then you can

lift the first battery out of the wheelchair by means of

the handgrip on the battery box. To remove the

second battery box, push your hand beneath the

battery box. There is a hollow which allows you to

take hold of the battery box from below and pull it

backwards with a slight upwards motion.

Now this battery box can also be lifted out of the wheelchair by grasping the handle. When replacing

the battery boxes, you reverse the process and only need to push the battery boxes backwards.

L To avoid bruising, make sure that your hands are not caught between the handle and the

frame tube when battery boxes are pulled out.

L Make sure that the batteries are safely put down outside the wheelchair.

L When replacing the batteries, make sure that they are positioned correctly and that the plugs

on the battery boxes are on the left side.

L Both connectors of the battery boxes, one at the front and the other at the rear, must be

plugged in first, otherwise there is no connection to the electronics.

L Make sure that the plugs are connected properly after replacing the battery boxes. If the rear

cover does not fit over the knobs (1), it means that the plugs have not connected properly.

When transporting the wheelchair, it is not necessary to remove the batteries from their boxes. When

removal of the batteries becomes necessary (e.g. replacing the batteries), note the following:

• Remove the battery box lid by loosening the screws on the handle.

• Lift the lid off.

1

1

Page 17

E

TRACER

01/2010

15

• Put the handle back on the battery to allow it to be carried.

• On one side the battery box is connected to the battery by an Allen screw. Unscrew this and

remove it.

• The battery can be lifted out of the battery box by the handle after the pole clamps have been

removed.

• Reverse these processes when replacing the batteries.

L These tasks should be undertaken by the specialist dealer.

L Make sure that no tools or other conducting objects make contact with both poles of the

batteries, or the resulting electric currents can cause injuries.

L No work involving the batteries and the electronics should be undertaken in damp conditions.

L When connecting the batteries, you should consult the circuit diagram on the battery box lid.

L The manufacturer is not liable for damage/injury caused by improper handling.

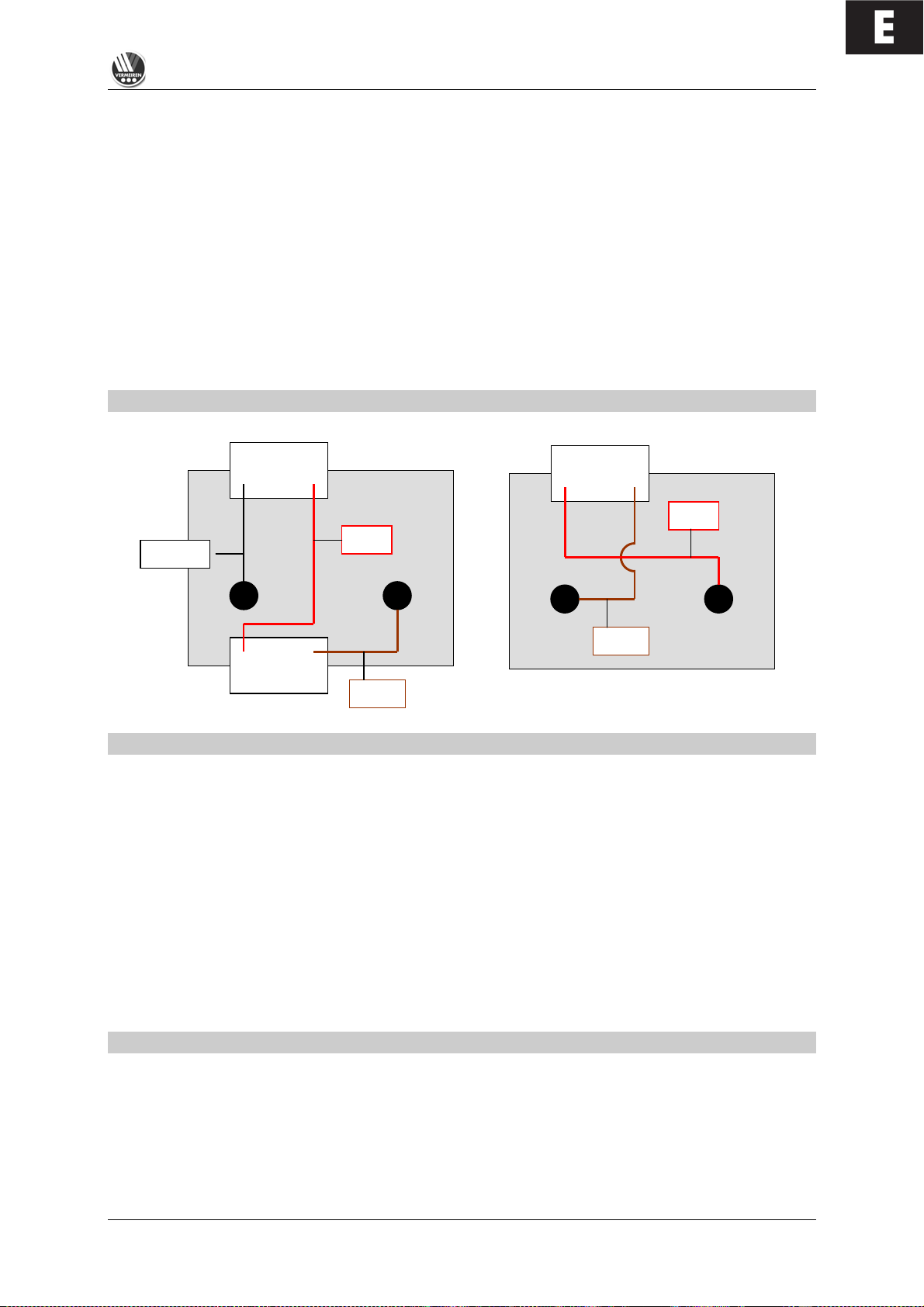

BATTERY CONNECTIONS

BATTERY STORAGE

If you do not use your wheelchair for a long while, you can leave it connected to the battery charger.

Charging is automatically controlled by the battery charger. If you remove and store the batteries,

kindly note the following:

• Remove the cable clamps from the poles of the battery.

• The positive pole must be covered by at least one pole cap.

• Only grasp the batteries by two opposite sides of the unit.

• Ensure no objects get in between the poles (a short-circuit could occur!).

• Batteries should only be stored in dry, well-ventilated spaces at a temperature between +5°C and

+45°C.

• Leave batteries in their battery boxes so they are protected from damp, etc.

• Protect the plugs and sockets of the battery boxes against corrosion.

• Protect the batteries against drainage (see "Charging the batteries" section).

L If batteries are not used, they can completely drain.

Your dealer will be happy to advise you on storage and with inspecting your batteries.

THERMAL FUSES

To protect the motor against overload, on the right side of the seat frame there is a thermal fuse that

will automatically cut off the motor to prevent overheating and thus rapid wear and tear or

breakdowns. This can occur if you go up or down slopes that exceed the maximum gradient indicated.

Nominal loads exceeding the maximum could also trigger the safety mechanism. If you try to drive

with the brakes on, it could also result in overload. The values to comply with are indicated in the

“Technical Details” section. To be able to use the wheelchair again, remove the overload and wait till

the motor has cooled off, and then gently press in the thermal fuse again. The system is now ready for

use again.

Battery I

- +

24 V

- +

!

!

Black

Red

Brow

- +

Battery II

+ -

Brow

Red

OUTPUT

Page 18

E

TRACER

01/2010

16

PARKING BRAKES

In addition to electromagnetic braking, your electric wheelchair can also be equipped with fixed

braking for each driving wheel. These must then be set for the wheels. When pneumatic tyres are

used, the parking brake can only function when the tyres are inflated hard enough (see the section

"Technical details").

L Note that the tyre pressure should always correspond to the values given in the section "Technical

details", otherwise the action of the parking brakes would be reduced or even be zero.

L Note that the parking brakes are not supposed to be used for braking while driving. The real

function of the parking brakes is to prevent the wheelchair from rolling away after it has

stopped. If it is used for reducing the speed while driving, injury and/or damage could result.

If the brakes lose their function through wear and tear and/or the covers and hoses have been

damaged, we advise you to consult your specialist dealer who has the tools and the knowledge for

repairing / replacing the defective parts.

L When unsuitable tools are used or through improper maintenance

damage and/or loss of function could result.

If you wish to adjust the parking brakes yourself, use a suitable Allen key to loosen the two screws

which hold the brake suspension on the rail. Then push the brake unit to the desired position and

retighten the two Allen screws and check whether the braking action is correct.

L Brake adjustments not complying with the manufacturer's instructions are done at your own

risk (only in the case of built-in parking brakes). No liability is applicable.

L Rather let your dealer adjust the parking brakes; he is trained on our products and will comply

with all relevant prescribed safety measures.

L Note that the parking brakes are not supposed to be used for braking while driving. The real

function of the parking brakes is to prevent the wheelchair from rolling away after it has

stopped. If it is used for reducing the driving speed, injuries could follow.

If you are not satisfied with the braking behaviour of your wheelchair, consult your specialist dealer

immediately; he will then adjust the brakes properly.

L If water, oil, or other kinds of dirt have soiled the wheels of the wheelchair, then the braking

action of the parking brakes would be impaired. Check the condition of the wheels every time

before using the wheelchair.

L If the brakes lose their effectiveness because of wear and tear and/or damage to the

tyres/inner tubes, kindly consult your specialist dealer, since special machines are required for

changing the "PU" tyres. The end-user is not able to change the "PU" tyres.

TYRES

The TRACER electric wheelchair is fitted with 3.00-8 driving wheels (standard pneumatic) and 260x85

steering wheels (standard pneumatic). Consult your specialist dealer about other wheel combinations.

He will advise you as to which combinations are suitable for your individual requirements.

L Make sure that the wheels are always inflated correctly, otherwise the driving behaviour might

be affected. The correct pressures for the tyres are given in the chapter "Technical details". In

addition, you should always check the pressure values appearing on the tyres themselves.

L We do not provide any guarantee for wheels not supplied by the manufacturer.

TYRE CHANGING

If you want to change the tyres or inner tubes, you should note the following:

Before you can remove a tyre, you must let all the air out of the tube, and insert a tyre lever between

the tyre and the rim. Then slowly and carefully push the lever downwards. This will pull the tyre over

the edge of the rim. If you then move the lever along the rim, the tyre will jump out. Now carefully

remove the tyre from the rim and then remove the tube.

L There must be no air in the tube before it can be removed.

Page 19

E

TRACER

01/2010

17

L If handled improperly, the rim might be damaged. We recommend you get your dealer to do

this work.

Note the following before inserting the new inner tube:

Check the rim bed and the inside wall of the tyre for foreign matter and clean these properly if

necessary. Check the condition of the rim bed, especially around the position of the air valve. Please

use only genuine original replacement parts. No liability is accepted for damage caused by nongenuine replacement parts. Kindly contact your specialist dealer.

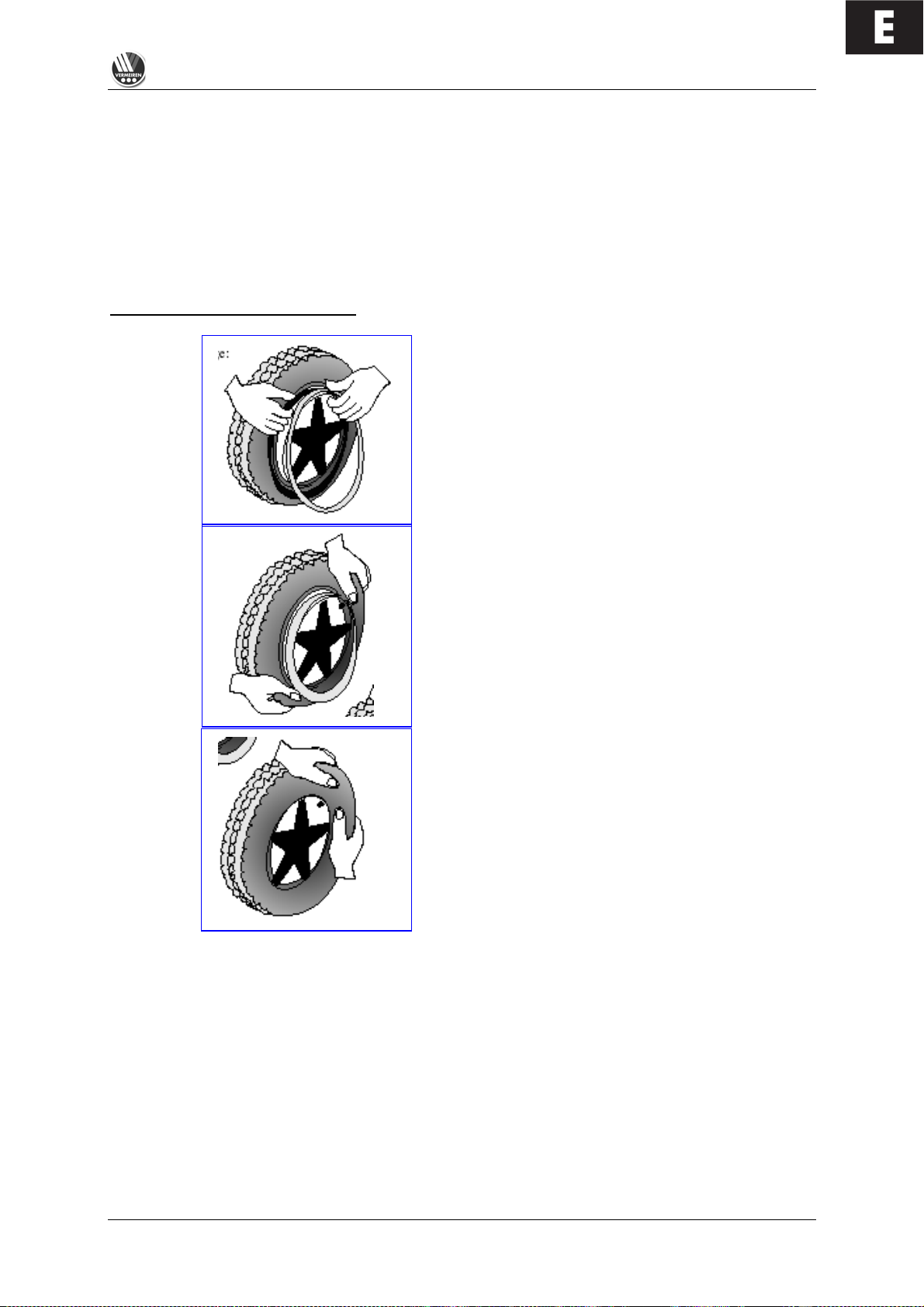

WHEN PLASTIC RIMS ARE USED

Place the rim belt in position over the air valve before

inserting it into the rim. Then the rim belt can be pulled

over easily. Check whether all spoke heads are

covered (in the case of a plastic rim a rim belt is not

required).

Push the tyre over the edge of the rim, starting behind

the air valve. Inflate the tube slightly until it is round,

and place it inside the tyre.

If the inner tube fits snugly inside the tyre without any

folds (if there are folds, let some air out), then you can

push the upper side of the tyre gently onto the rim with

both hands, beginning behind the airvalve.

Check all around on both sides that the tube is not pinched between the rim and the edge of the tyre.

Lightly push the air valve inwards and pull it out again to make sure that the tyre is positioned properly

in the region of the air valve.

To ensure that the wheel is inflated correctly, admit only so much air initially that the tyre can still be

easily pushed inwards by using your thumbs. If the check-lines are equidistant from the edge of the

rim on both sides of the tyre, then the tyre is centered properly. If not - let out the air and position the

tyre afresh.

Now the tyre can be inflated to its full operating pressure (note the maximum) and the valve cap

should be replaced.

Page 20

E

TRACER

01/2010

18

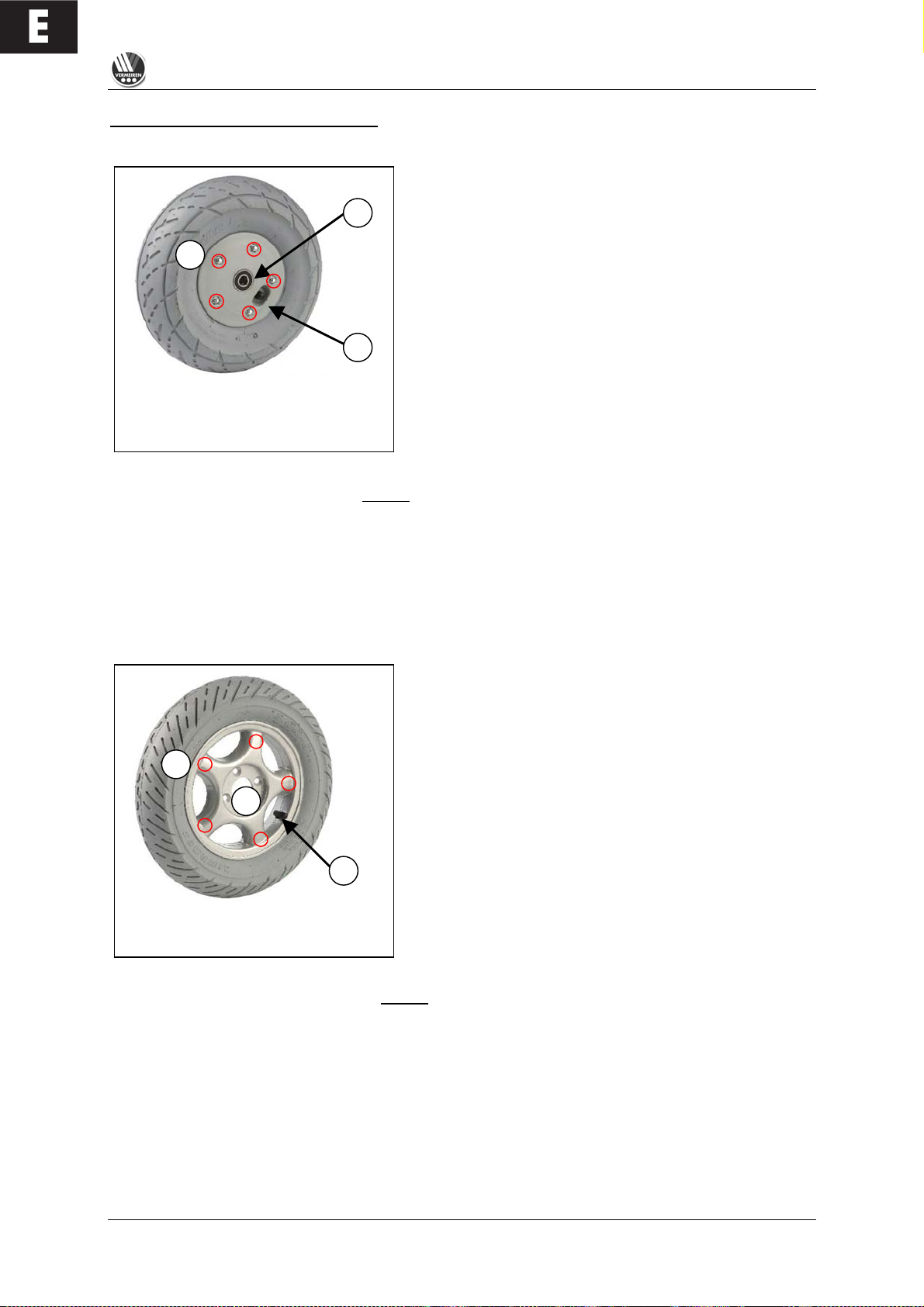

WHEN ALUMINIUM RIMS ARE USED

STEERING WHEELS

A. Loosen the screw on the steering wheel axle and

remove it from the steering whee l fork.

B. Let the air out of the steering wheel by lightly pressing

the pressure pin on the v a lv e .

C. Loosen the 5 screws that hold the split rim together.

Now separate the rim sides.

ASSEMBLY

Insert the partly-filled inner tu b e in to th e ty r e .

C. Connect the two sides of the rim through the tyres and

use the 5 connecting screws to screw the rim

together.

B. Make sure that the valve juts out of the valve opening

in the rim.

A. Put the wheel back into the front wheel fork and inflate

the wheel.

L

Before taking the rim apart always let the air out of the tyres, or the sides of the rim could

come apart explosively and cause injury!

L Make sure that the inner tube does not get caught in the sides of the rim

L Only inflate the wheels to the max. tyre pressure ( see "Technical details")

L Check to see that all the screws on the wheels are firmly tightened before using the

wheelchair.

DRIVE WHEELS

A. Unscrew and remove the axle nut on the drive wheel

and the 4 screws that attach the wheel to the flange.

B. Let the air out of the wheel by lightly pressing the

pressure pin on the valve.

C. Unscrew the 5 screws on the inside of the rim.

Separate the rim sides.

ASSEMBLY

Insert the partly-filled inner tu be into the tyre.

C. Connect the two sides of the rim through the tyres and

screw them back again.

B. Put the valve through the hole for it in the rim.

A. Put the wheel back on the flange and secure the

wheel by hand-tightening the axle nut. Inflate the

wheel to the recommended tyre pressure.

L

Before disassembling the rims, always let the air out of the tyres !

L When assembling, make sure that the inner tube does not get caught between the sides of the

rim.

L Only inflate the wheels to the max. tyre pressure (see "Technical details")

L Check to see that all the screws on t h e wheels are firmly tightened befo r e using the

wheelchair.

L Screw adhesive (e.g. Loctite) should be applied to the screws on the flange. Screw adhesive

will only work if the thread is free of grease and particles.

L Improper assembly voids any warranty claim.

A B C

A B C

Page 21

E

TRACER

01/2010

19

1

1

L When inflating the tyres, always check that the pressure is correct. The correct pressure is

given on the tyre walls (also refer to "Technical details").

L Use only inflating equipment which complies with regulations and indicates the pressure in

bar, or use the supplied air pump. We do not accept any liability for damage caused by using

inflation equipment n o t s u pplied by the manufac tu r e r .

PUSHING THE WHEELCHAIR

The wheelchair can be pushed by an attendant. Turn the locking lever outwards (inwards in the case

of the TRACER 50+); this allows the wheelchair to be pushed freely. Now the wheelchair will no longer

be driven by the motors, nor will it be braked by the motors.

When pushing the wheelchair, make sure that the

controls are switched off and that you only push it on

level terrain.

When the locking lever is in this direction, edriving is enabled; the electromagnetic brake

is activated.

When the locking lever is in this direction,

your wheelchair is in the free-wheeling

position; the electromagnetic brake is

deactivated.

Without the braking effect of the motors which

is abse n t when the wheelchair is being

pushed, the wheelchair can accidentally move

or turn. (Use the parking brakes to secure the

wheelchair !).

TRANSPORTING THE WHEELCHAIR

Before lifting up the wheelchair, all moveable parts must be dismantled (footrests, armrests, and

steering unit).

L When raising the wheelchair, it should only be grasped by fixed parts of the frame.

L To prevent damage, the steering unit and armrests should be removed for transportation.

L When assembling, make sure that all screws are retightened properly.

To prevent the wheelchair from moving about, switch the locking mechanism behind the backrest to

electronic driving (it must be engaged). In addition, engage the parking brakes if present in your

model. If you require further belt securing systems, make sure that they are only attached to solid

parts of the frame.

If you want to be tak e n up or down stairs with the wheelchair, you will need a wheelchair ramp

or wheelchair lift system.

L At least two persons are required to move the wheelchair up or down stairs or over single

steps.

L When being transported, no persons or objects should be below the wheelchair, to prevent

personal injury or damage to the wheelchair.

TRANSPORTING BY CAR

When inside a vehicle the wheelchair must be securely fastened by means of the built-in safety b e lt s

or by specially provided belt systems.

Nobody is permitted to sit in a wheelchair which is transported in a vehicle.

L Make sure that the wheelchair is fastened by fixed parts of the frame only.

L Check that the wheelchair cannot slide in any direction.

Page 22

E

TRACER

01/2010

20

L Engage all parking brakes in addition to the electromagnetic brake of the wheelchair.

L Loose parts taken from the wheelchair must be stowed securely.

For transportation by public vehicles for disabled persons you should request information from the

organisation concerned about compliance with the currently applicable prescriptions and norms for

such transport.

For transportation in other vehicles (airplanes, buses, ships, trams, trains, etc.) you should consult the

operator concerned about whether you and your wheelchair could be safely transported according to

the relevant rules and norms.

L We do not accept any liability for damage and/or injuries resulting from transportation by third

parties. Transportation is at your own risk.

If you have further questions about transportation, kindly consult your specialist dealer.

He/she shall gladly assist you further.

USING RAMPS

If you are considering ramps for overcoming obstacles, kindly note the following:

For your own safety you should drive on ramps at the slowest possible speed. If the wheelchair has

optional adjustment functions, ensure that

1. the back has been set to upright (if there is one)

2. the angled seat has been set to horizontal (if there is one)

3. the leg supports have been set so that no collision can occur while passing the obstacle.

L The manufacturer can accept no liability for any damage or injury that may arise from the

adjustment functions being extended when being used on a ramp.

If another person is pushing you, note that the large weight of the electric wheelchair exerts

appreciable reverse forces.

If your helper does not have the strength to push the wheelchair up the ramp, you must immediately

secure it by engaging the motor adjustment (Notstop).

L Observe the instructions on the maximum load of the ramps used.

L Use a restraining safety belt to secure yourself in your wheelchair.

L We do not accept any liability for injury or damage caused by an improper choice of ramps.

ACCESSORIES

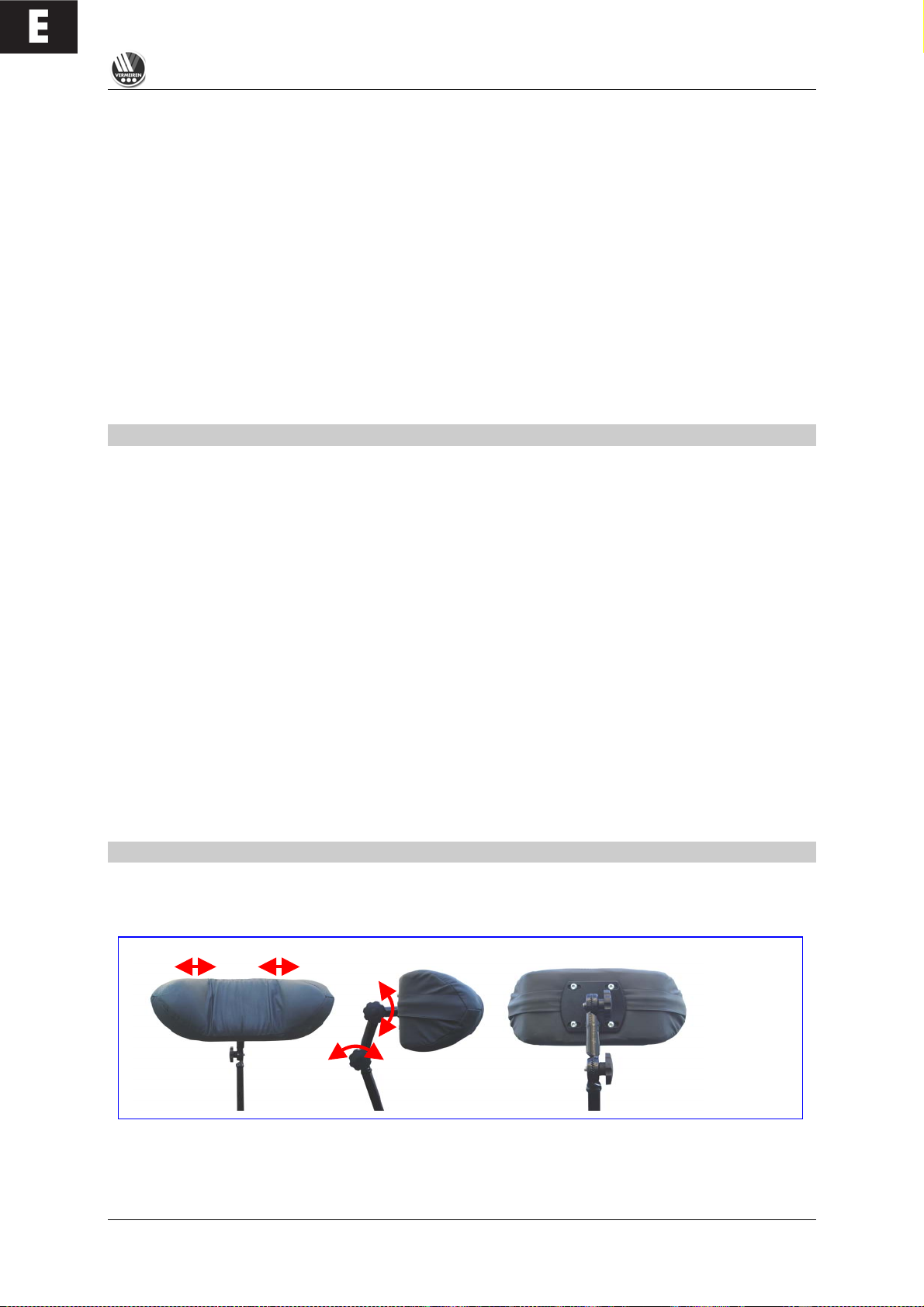

! INDIVIDUAL HEADREST (L55)

The standard backrest can be enhanced by an individually adjustable head support supplied by us.

This comprises a cushioned headrest which can be set in various positions by means of a gearwheel

(see diagram).

The receptacle screwed in the upper third of the back, can be fixed to the centre of the back for

inserting the headrest. The height of the headrest can be adjusted and then tightened at the desired

height. The holes required for fixing the headrest have already been drilled in the back unit.

Page 23

E

TRACER

01/2010

21

1

2

L Make sure that the headrest is inserted at least to the marked position to be fixed securely and

reliably.

The depth of the headrest can be adjusted by slightly loosening the adjusting screws to allow

movement of the sprocket gears. Then you can adjust the headrest to your needs and secure it by

retightening the adjusting scre w s . If the adjusted position is not satisfactory, you can repeat this

process.

L Ensure that the back of your head is supported when relaxed in an upright sitting position.

L Before using the headrest all fixing screws must be tightened properly, since injuries might

result when it slips downwards unintentionally.

You can secure your head against tipping sideways by lightly pressing the side panels of the headrest

inwards and to the fr o n t.

L Do not exert too much pressure on the side panels otherwise bruising may result.

L Do not clap the side panels together violently, otherwise they might break off, causing possible

injury as well as loss o f fu nction.

Structural alterations to the headrest would void any warranty.

LEG SUPPORTS

If the leg sup ports supplied with the wheelchair do not mee t your requirem e n ts , you could consider leg

supports with adjustable height. Because the footrest attachment is standardised, it can be assembled

in the same way as d e s c r ib ed in the section on foot s upports.

Kindly consult your specialist dealer if you have questions abo u t o ther footrest systems; he shall gladly

advise you about the indication and function of our available foot supports.

PERSONAL SAFETY SYSTEM (B58)

For your safety we offer you a standardised safety belt which is equipped with a snap-on fastener, like

those mounted in cars and v a n s . This can be fix e d by means of bolts inserted in th e bolt holes on b oth

sides of the seat frame next to the backframe attachments. To ensure proper fixing, self-locking

("nylock") nuts should be used.

If the belt has been dismantled, only new genuine nuts provided by the manufacturer should be used

for re-attachment.

L To ensure the validity of the warranty, entrust this work to your specialist dealer.

L Before using the seatbelt, make sure that all screws are properly tighte n e d.

Please consult your specialist dealer if you require other safety belt systems. He/she shall gladly

assist you further.

BODY SUPPORTS (L04)

If yo u r uppe r body require s strong e r bracin g than that

provided by the standard backrest, we offer a lateral

support system which can be mounted on the

backrest. The guiding rail is mounted vertically about

6 cm behind the backrest to one side. The screw

threads set in the ba c k , can b e used for this purpose

(older models can be upgraded by using wood

screws). The supporting rods are inserted from the

rear and secured by the two Phillips screws. When

adjusting the height and depth of the supports, slightly

loosen the Philips screws (1) and position the

supports to your liking. Then retighten the Philips

screws (1).

To adjust the depth of the supports, you can loosen screws (2) and set them to the desired depth.

Page 24

E

TRACER

01/2010

22

L Make sure that all screws are properly tightened after the assembly, otherwise the stability of

the supports is endangered, and injury/damage can occur.

L Make sure that the rail system is properly mounted and that nothing obstructs its functional

integrity.

L If the wheelchair is not fully assembled when delivered, only your specialist dealer who has

suitable tools and knowledge of the fittings, may perform the mounting procedure.

L Improper assembly leading to damage voids any warranty claim.

L While the body supports are fitted, you should sit still and in a natural position in your

wheelchair to allow correct fitting.

L Make sure that no objects and/or body parts are located between the supports and the back of

the supports when they are pulled tight, otherwise bruising and/or damage might occur.

If you have further questions about the indications and function of the supports, kindly contact your

specialist dealer. He will be happy to answer your questions.

FOR YOUR SAFETY

Some safety tips are given below for your security:

L To prevent injury and/or damage to your wheelchair, make sure that no objects and/or body

parts are caught in the spokes of the driving wheels.

L Do not step on the footplate when getting in or out of the wheelchair. The footplates must be

folded up beforehand, or the leg supports should be swung outwards out of the way.

L You should investigate the effects of shifting the centre of gravity on the behaviour of the

wheelchair for example on gradients, on laterally sloping ground, or when overcoming

obstacles, only when a helper is present to secure and support you.

L If you want to pick up something (lying in front of, on the side, or to the rear of the wheelchair),

you should not lean too far out to avoid tipping over because of the displacement of the centre

of gravity.

L Always follow the instructions for using your wheelchair. For example, avoid driving without

brakes against an obstacle (step, edge of the curb) or dropping down from steps.

L Stairs may only be negotiated when aided by another person. If devices and furnishings like

ramps or lifts are available, use them.

L Check that the profile depth of the tyres is adequate.

L Obey traffic regulations when driving on public roads.

L When driving your wheelchair, you should not be under the influence of alcohol or medicine as

in the case of driving other vehicles. This also applies to indoor driving.

L When travelling outdoors, adapt your driving to weather and traffic conditions.

L Check that the rear reflectors of your wheelchair are not covered by dirt and/or other objects.

L When driving in the dark, wear bright clothing to be more visible, or clothing with reflectors,

and make sure that the reflectors of the wheelchair are clearly visible.

L Be careful when using sources of fire such as cigarettes, since they can set the seat and back

covers alight.

L Make sure that the maximum load (125 kg for the TRACER / 150 kg for the TRACER 50+) is

not exceeded.

MAKING REGULAR CHECKS

As with any technical product, your wheelchair, too, requires regular checks if it is to be kept fullyfunctional. The steps to be taken to fully enjoy the advantages of your wheelchair even after protracted

use, are described below.

Page 25

E

TRACER

01/2010

23

! BEFORE DRIVING

1. Check the tyres for visible damage and/or soiling. Remove any dirt as it could impair the

motion and road-holding capacity of the tyres. When a tyre is damaged, please go see an

authorized workshop for repair.

2. Use the drive electronics' display to check that the driving, braking and adjustment

features are fully-functional. If these functions are impaired, contact your dealer.

3. Check the pressure of the tyres and inflate them if necessary (see section "Technical

details").

4. Make sure that all screws are tightened properly.

! APPROX. EVERY 8 WEEKS

Depending on the frequency of use check the following:

1. That the armrests are working

2. Movable parts of the footrests

3. The condition of the covers and cushioning materials.

4. The tread depth of the wheels

! APPROX. EVERY 6 MONTHS

Depending on the frequency of use check the following:

1. Cleanliness

2. General condition

3. That the charger is working

4. Operation of the steering wheels

If the rotation resistance is too great, clean the bearings of the steering wheels. If this is

insufficient, please consult your dealer.

L In cases of lost functionality, repairs and inspections, consult your dealer.

CARE

Your electric wheelchair requires regular care to keep it in a pleasant condition. To do this, note the

following:

L Steam or high-pressure cleaning is forbidden !

! COVERS

Clean the covers with hot water. You can remove stubborn dirt by washing with a mild commercial

detergent. Stains can be removed by using a sponge or a soft brush.

L Do not use strong cleaning liquids like solvents, nor use hard brushes.

L We shall decline all liability for damage caused by the use of improper cleaning agents.

L Take care that you do not soak the covers.

! PLASTIC PARTS

Clean all plastic parts of your wheelchair with commercial plastic cleaners. Read the specific product

information and only use soft sponges or cloths.

! SURFACE LAYERS

The high quality of the surface layer guarantees optimal protection against corrosion. If the outside of

the frame has been damaged by scratches or otherwise, you can protect the area by applying varnish

obtainable from your specialist dealer.

! ELECTRONICS CASING

Only wipe the steering unit with a cloth moistened

by a few drops of a commercial domestic cleaner.

Do not use any abrasives or sharp-edged polishing equipment like a metal scrubber or brush, since

these can scratch the surface of the steering unit and destroy its water repelling property.

L Regularly check the plug connectors for corrosion or damage, since it could affect the

efficiency of the electronics.

L Before any maintenance work, disconnect the batteries to prevent any unwanted current flow.

L The manufacturer accepts no liability for damage caused by poor maintenance.

Page 26

E

TRACER

01/2010

24

INSPECTION

In principle we recommend annual inspections, but at least before usage is resumed. The following

checks must at least be performed and documented by authorized persons:

• Check the cabling (especially for: crushing, abrasion, cuts, visible insulation of the inner

conductor, visible metallic veins, kinks, lumpiness, color changes of the outer sleeve, brittle

spots)

• Visual inspection of the frame parts to check for plastic deformation and/or wear and tear

(basic frame, seat frame, back frame, side parts, leg supports, motor suspensions)

• Electric leads to be securely placed to avoid shearing, crushing and other mechanical stresses

and strains.

• Visually check all housings for damage, screws must be securely fixed, seals and gaskets

should not exhibit visible damage.

• Review the charger's residual diversion current (

A

) based on VDE 0702

• Review the charger's insulation resistance (

MO

) based on VDE 0702

• Check the functioning of the armrests and leg supports (locking, load, deformation, wear and

tear caused by loads)

• Check the functioning of the drives (during a test drive " noises, speed, free running, etc.), if

necessary: Measure the performance, first with no load, and then with the nominal load

("SWL") to investigate the wear and tear of the motors by comparing the values of the electric

current with the values at delivery, condition and function of the carbon rod, the condition of

the collector, remove debris from the motor housing and the collector, etc.)

• Check the condition of the batteries, covers, tubes, and tyres.

Checking measurements may only be carried out by skilled persons trained on the wheelchair at least

and at least under the supervision of an electrician who knows the checking instruments and

processes. Only an electrician is able to release the electric wheelchair for use after successful

checking measurements or servicing. The service must be confirmed in the service plan when at least

the above-mentioned aspects have been checked.

L The manufacturer is not liable for damage caused by deficient or improper inspections.

DISINFECTION

Only a hygiene technician or someone appointed by him can disinfect your wheelchair and this should

be done every time before its use is resumed or before it is provided to a different person. All parts of

the wheelchair can be treated with a disinfectant cloth. In principle all surfaces of a system or a

product have to be disinfected before passing it on to another user, or when it is known that the user

carries an infective vector. In these cases the measures of the federal law on epidemics have to be

considered.

Disinfectants may only be applied by authorised persons trained in the functioning and

application of disinfectants.

L Wear suitable protective clothing because the disinfectants can irritate the skin on contact. For

this purpose you should also take note of the product information for the solutions concerned.

L You employ unauthorised persons at your own risk.

L No liability is accepted by the manufacturer of the wheelchair for damage and injury caused by

the improper handling of disinfectants.

Page 27

E

TRACER

01/2010

25

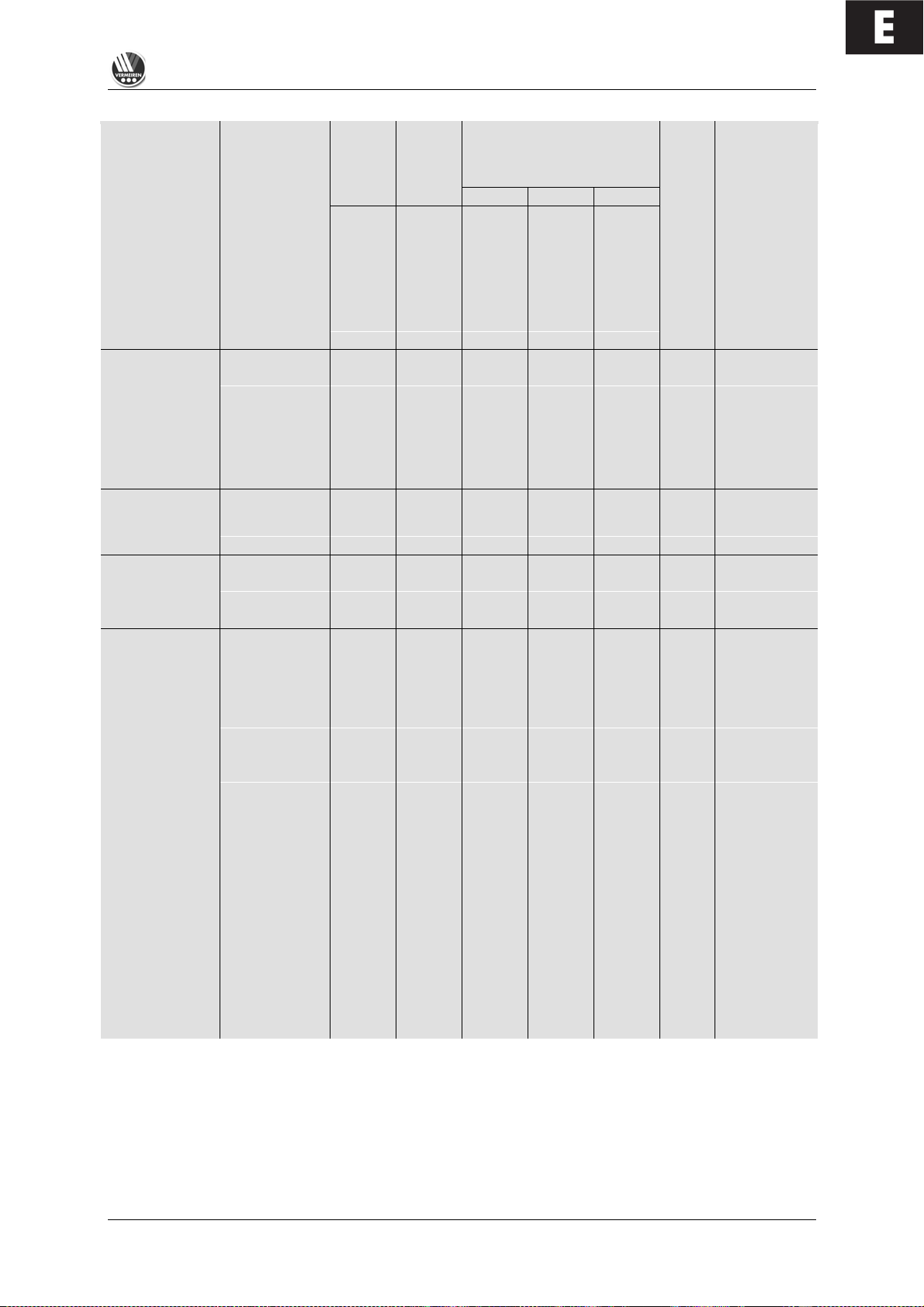

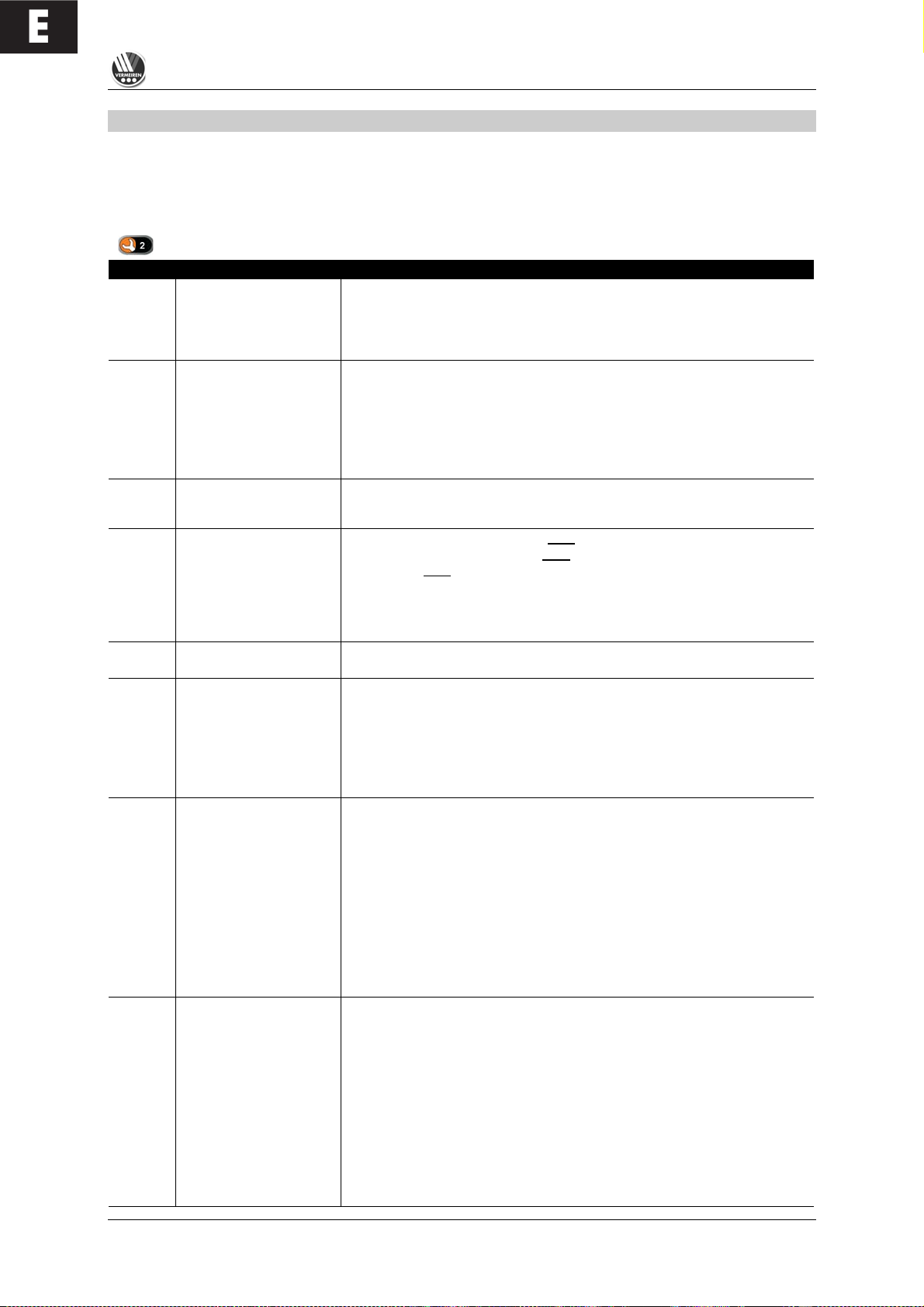

We recommend the following disinfectants for scrubbing (based on the list of the Robert Koch Institute, RKI):

Surface

disinfection

(scrubwashing

Disinfecting excretions

1 part sputum or stool + 2 parts

diluted solution or 1 part urine + 1

part diluted solution

Washingdisinfection

disinfection)

Sputum

Stools

Urine

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Active substance

Name

%

Hrs. % Hrs. % Hrs. % Hrs. % Hrs.

Effective

range

Manufacturer

or

Supplier

Amocid

1

12 5 6 5 4 5 6 5 2 A Lysoform

Gevisol

0,5

12 5 4 5 4 5 6 5 2 A Schülke & Mayr

Helipur

6 4 6 4 6 6 6 2 A

B.Braun Petzold

m-cresol soap

solution DAB 6

1

12 5

4

A

Mucocit-F 2000

1

12 A Merz

Phenol

1

12 3 2 A

Phenol or

phenol derivatives

Velicin forte

5 4 5 6 A

Ecolab

Chloramine-T DAB

9

1,5

12

2,5 2 5 4 A1 B

Clorina

1,5

12

2,5 2 5 4 A1 B

Lysoform

Chlorine, organic or

inorganic substances

with active chlorine

Trichlorol

2

12 3 2 6 4

A1 B

Lysoform

Apesin AP1002

4 4 AB

Tana Chemie

Pure Dismozon2

4 1 AB

Bode Chemie

Perform2

3 4 AB

Schülke & Mayr

Percompounds

Wofesteril2

2 4 AB

Kesla Pharma

Aldasan 2000

4 4 AB

Lysoform

Antiseptica

Surface

Disinfection 7

3

6

AB

Antiseptica

Aldospray Conc.

3 4 AB

Lysoform

Apesin AP30

5 4 A

Tana Chemie

Bacillocid Spezial

6 4 AB

Bode Chemie

Buraton 10F

3 4 AB

Schülke & Mayr

Desomed A 2000

3 6 AB

Desomed

Hospital dis-

infection cleaner

8

6

AB

Dreiturm

Desomed Perfekt

7 4 A

Desomed

Fink-Antisept B

8 6 AB

FINKTEC

Formaldehyde

solution DAB 10

(formalin)

1,5

12 3 4

AB

Incidin perfekt

1

12 3 4

AB

Ecolab

Kohrsolin

2

12 3 4

AB

Bode Chemie

Lyso FD 10

3 4 AB

Schülke & Mayr

Lysoform

4

12 5 6

AB

Lysoform

Lysoformin

3

12 5 6

AB

Lysoform

Lysoformin 2000

4 6 AB

Lysoform

Melsept

2

12 4 6

AB

B.Braun Petzold

Formaldehyde

and/or other

aldehydes or

derivatives

Melsitt

4

12

10 4 AB

B.Braun Petzold

(…)

Page 28

E

TRACER

01/2010

26

Surface

disinfection

(scrubwashing

Disinfecting excretions

1 part sputum or stool + 2 parts

diluted solution or 1 part urine + 1

part diluted solution

Washingdisinfection

disinfection)

Sputum

Stools

Urine

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Active substance

Name

%

Hrs. % Hrs. % Hrs. % Hrs. % Hrs.

Effective

range

Manufacturer

or

Supplier

Minutil 2 12 6 4

AB

Ecolab

Multidor

3 6 AB

Ecolab

Nüscosept

5 4 AB

Dr.Nüsken Chemie

Optisept

7 4 A

Dr.Schumacher

Pursept-FD

7 4 AB*

Merz

Septoclean FDN

3 6 AB

Haka Kunz

Tegodor

3 6 AB

Goldschmidt

Formaldehyde

and/or other

aldehydes or

derivatives

Ultrasol F

3

12 5 4

AB

Fresenius

Franko-DES

2

12 A Franken

Tensodur 103

2

12 A MFH

>Marienfelde<

Lime-wash3

20 6 A3 B

1

Insufficiently effective against myco-bacteria when disinfecting surfaces, especially in the presence of blood.

2

Not suitable for disinfecting blood-contaminated or porous surfaces (e.g. raw wood).

3

Useless for tuberculosis; preparation of lime-wash: 1 part dissolved lime (calcium hydroxide) + 3 parts water.

*Virus effectiveness tested in compliance with the RKI test method [German Federal Health Circular 38 (1995) 242] .

A: suitable for killing vegetative bacterial germs including myco-bacteria as well as fungi, including fungal spores.

B: suitable for deactivating viruses.

The current state of the disinfectants included in the RKI list can be ascertained at the Robert Koch

Institute (Home page: www.rki.de

).

All steps taken for disinfecting rehabilitation equipment and their components or other accessory parts,

are recorded in a disinfection report which contains at least the following information with product

documentation appended:

Table 2 – Example of a disinfection book

Date of the

disinfection

Reason

Specification

Substance and concentration

Signature

Abbreviations used in column 2 (reason):

V = suspected infection IF = infection case W = repetition I = inspection

Kindly consult your specialist dealer if you have further queries about disinfection; he will

gladly assist you.

STORAGE

• Store in a dry place (between + 5 °C and + 45 °C).

• The relative humidity of the air should be between 30% and 70%.

• Air pressure between 700 hPa and 1060 hPa.

• Disconnect the power plug of the battery charger.

• For the batteries, see the chapter on “Battery Storage”.

• Check internal cables for squashing and the prevention of kinks.

• Store all removed parts together in one place (or mark them if necessary) to avoid mixing up

with other products when re-assembling (e.g. the charger).

• Components must be stored without being subjected to any load. Grasp the wheelchair by

solid frame parts only.

Page 29

E

TRACER

01/2010

27

GUARANTEE

Excerpt from the "General business conditions":

(…)

5. The guarantee period for warranty claims is 24 months.

(…)

The guarantee excludes damage arising from structural changes to our products, insufficient

maintenance, defective or improper handling or storage or the use of pirate parts. Likewise, the

guarantee excludes parts or working parts subject to natural wear and tear.

(…)

The terms of the guarantee may differ from country to country. Please contact your dealer for further

information.

CONFORMITY

The TRACER electric wheelchair complies with the requirements of the European directive:

- 93/42/EEC (Med ica l Products Directive)

and the product norms:

- (DIN) EN 12182: 1999

- (DIN) EN 12184: 1 9 9 9

DISPOSAL

The manufacturer is responsible for taking back and recycling the e lec tric wheelchair and shall

meet the requirements of European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment. You can find out from your local waste disposal company where you can take the

electrical wheelchair to be recycled free of charge. It m ay not be disposed of with domestic

waste.