Vermeiren 708 delight Instruction Manual

E

F

NL

D

I

....... p02 - p21

....... p22 - p41

....... p42 - p60

....... p61 - p80

....... p81 - p99

708 D

06/2008

2

CONTENTS

Section Page

Contents.............................................................................................................................................2

Preface...............................................................................................................................................3

Technical details ................................................................................................................................3

General notes ....................................................................................................................................4

Applicability........................................................................................................................................4

Contents of the consignment .............................................................................................................4

Tools ..................................................................................................................................................5

The operating elements .....................................................................................................................5

Folding the wheelchair .......................................................................................................................5

Anatomical seat (optional) .................................................................................................................5

Anatomical back (optional).................................................................................................................6

Leg supports ......................................................................................................................................6

Armrests.............................................................................................................................................7

Parking brakes ...................................................................................................................................8

Tyres ..................................................................................................................................................9

Tyre changing ...................................................................................................................................9

Transporting the wheelchair...............................................................................................................11

Using ramps.......................................................................................................................................11

Taking the wheelchair in a car ...........................................................................................................11

Using the wheelchair..........................................................................................................................12

Accessories........................................................................................................................................14

• Armrests ..........................................................................................................................................14

• Leg supports....................................................................................................................................15

• Personal safety belt (B58) ...............................................................................................................15

• Prevention of tipping over (B78) ......................................................................................................15

• Moving the axle back (AMP)............................................................................................................15

• Transit wheelchair (T30)..................................................................................................................15

• Lowering the height of the seat (S)..................................................................................................15

• Drum brakes for the helper (B74) ....................................................................................................15

• Floating axles (B80).........................................................................................................................15

For your safety ...................................................................................................................................16

Storage ..............................................................................................................................................16

Servicing ............................................................................................................................................16

Care ...................................................................................................................................................17

• Covers .............................................................................................................................................17

• Plastic parts .....................................................................................................................................17

• Surface layers..................................................................................................................................17

Inspection...........................................................................................................................................18

Disinfection ........................................................................................................................................18

Guarantee ..........................................................................................................................................21

Statement of conformity .....................................................................................................................21

Disposal .............................................................................................................................................21

Service ...............................................................................................................................................100

E

708 D

06/2008

3

Notice to the specialist dealer:

This Instruction Manual is part and parcel of the product and must accompany every wheelchair sold.

Last updated: June-2008

All rights reserved, including translation.

No part of this manual may be reproduced in any form whatsoever (print, photocopy, microfilm or any other

process) without written permission of the publisher, or processed, duplicated, or distributed by using electronic

systems.

N.V. VERMEIREN, 2008

PREFACE

First of all we want to thank you for putting your trust in us by selecting one of our wheelchairs.

The electric wheelchairs supplied by Vermeiren are the result of research and experience over many

years. During the development simplicity of operation and servicing was especially emphasised.

But the expected working life of your vehicle depends essentially on your care and maintenance. This

instruction manual will help you to get acquainted with the operation of your wheelchair and advise

you about keeping your electric wheelchair in a good operational condition to ensure a long working

life. This instruction manual reflects the latest level of development of the product. However, our firm,

Vermeiren, reserves the right to introduce changes without any obligation to adapt or replace

previously delivered models.

Kindly keep in mind that your wheelchair will be in an excellent working condition and function

perfectly even after many years, if you follow our advice.

For any further questions, please consult your specialist dealer.

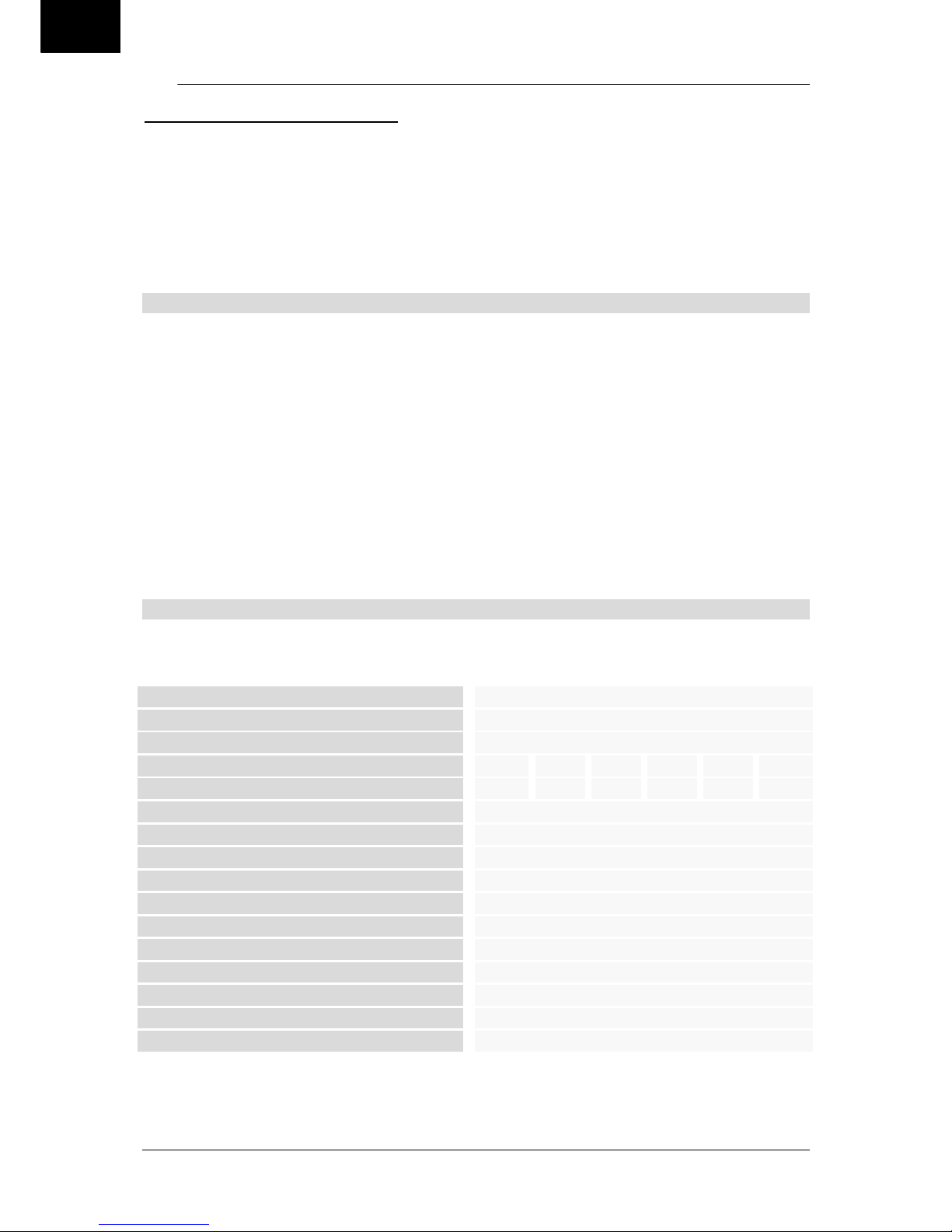

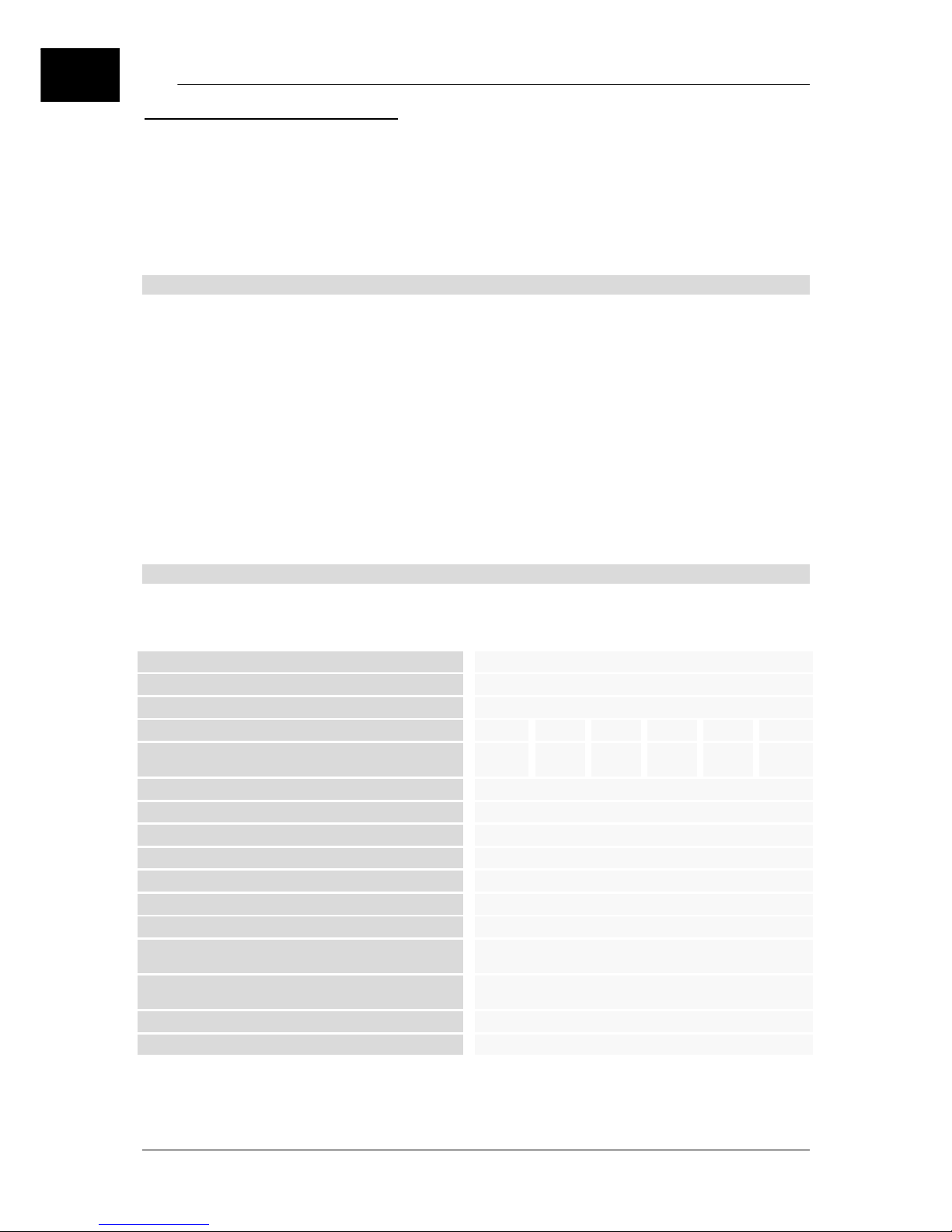

TECHNICAL DETAILS

(given in terms of the standard adjustments when delivered)

The figures might differ when other leg and head supports are used or extra parts are fitted.

Length (without leg supports)

81 cm

Length (with leg supports)

106 cm

Height (backrest included)

92 cm

Width of the seat

39 cm

42 cm

44 cm

46 cm

48 cm

50 cm

Total width (depends on seat widths)

56 cm

59 cm

61 cm

63 cm

65 cm

67 cm

Seat depth

43 cm

Height of seat

50 cm

Height of backrest

42 cm

Height of armrests (seat cushion)

22 cm

Height of armrests (floor cushion)

72 cm

Weight (armrests/leg supports included)1)

approx. 17 – 20 kg

Nominal load (max. load)

120 kg

Tyre pressure, steering wheels 2)

Max. 2.5 bar

Tyre pressure, rear (driving) wheels 2)

Max. 3.5 bar

Max. climbing ability 3)

10,5 % / 6°

Max. obstacle height

6 cm

We reserve the right to introduce technical changes. Measurement tolerance +/- 1.5 mm / kg / °

1)

Depends on seat width and tyres

2)

Tyre pressure given is for standard pneumatic tyres. If using tyres made by another manufacturer, please refer to the tyre

cover for details of the pressure.

3)

When tyres are in good condition and pressurised, and surface is flat.

E

708 D

06/2008

4

GENERAL NOTES

In the "708 D" model, you have acquired a wheelchair developed entirely for your comfort. The model

has been designed exclusively for individual indoor and outdoor use by disabled persons and for the

conveyance of other people. This wheelchair can be adjusted to individual requirements as explained

below. So please read the instruction manual carefully to acquaint yourself with your wheelchair.

APPLICABILITY

The wheelchair is intended to be used to transport a person either actively (by using the driving wheel

grips) or passively (propelled by an attendant). The different types of fittings and accessories, and the

modular construction, allow full use by persons disabled by

• paralysis

• loss of limbs (leg amputation)

• limb defects / deformation

• stiff or damaged joints

• illnesses like heart insufficiencies and poor circulation, balance disturbances or "Kachexie", and

also for aged persons.

This list does not, in principle, obviate its use in the case of other and/or additional ailments and

disabilities. But in such cases an authorised person should always verify in advance that the product

can be used properly in terms of functionality, safety and technical issues, and that it will not put the

user at risk.

When providing for individual requirements

• Body size and weight (max. load 120 kg)

• physical and psychological condition

• residential circumstances and

• the environment

should also be taken into consideration.

Your wheelchair should only be used on surfaces where all four wheels are touching the ground and

there is enough contact to propel all the wheels equally. You should practise specially to cope with

uneven surfaces (cobblestones, etc.), slopes and curves (swerving to the side, etc.) and to get past

obstacles (e.g. kerbs). Moving on surfaces such as ice, grass, gravel, foliage and other firm or loose

surfaces that impede movement can be particularly hazardous.

It should not be used as a seat in a vehicle. The nominal load of 120 kg should not be exceeded, and

no more than one person should be propelled. The wheelchair is not to be used as a ladder, a resting

place for heavy or hot objects, or for other purposes that are not the active or passive propelling of a

person. With mats, carpeted floors and loose floor coverings, the floor coverings themselves may be

damaged and the wheelchair may tip over. The manufacturer can assume no liability if the wheelchair

is used in combination with products or fittings made by other manufacturers or components that

change the purpose for which it is intended.

Guarantees can only be met when the product is used under the prescribed conditions and for

the intended purposes.

CONTENTS OF THE CONSIGNMENT

• Wheelchair including back and seat system, and driving and steering wheels.

• Foot supports

• Armrests

• Pump (with pneumatic tyres only)

• Instruction manual

• Tools (Allen keys)

NOTE TO DEALER:

When you receive the goods, please check that the product supplied is complete and fully functional.

Warranty claims are only valid if the manufacturer (supplier) is notified in writing within a period of two

weeks. In the case of any defect that is not immediately evident, warranty claims are only valid if the

manufacturer (supplier) is notified in writing within two weeks after it is detected. We shall remedy

defects in the manner of our choosing - either by carrying out a repair or by providing a replacement.

E

708 D

06/2008

5

TOOLS

The following tools are required for assembling and adjusting your wheelchair:

• Phillips screwdriver

• Allen keys (sizes 4 and 5)

• Ring and open-ended spanners (sizes 10/13)

• Ring spanner (size 19)

• Open-ended spanner (size 11)

L Assembly and adjustments should only be carried out by authorised persons.

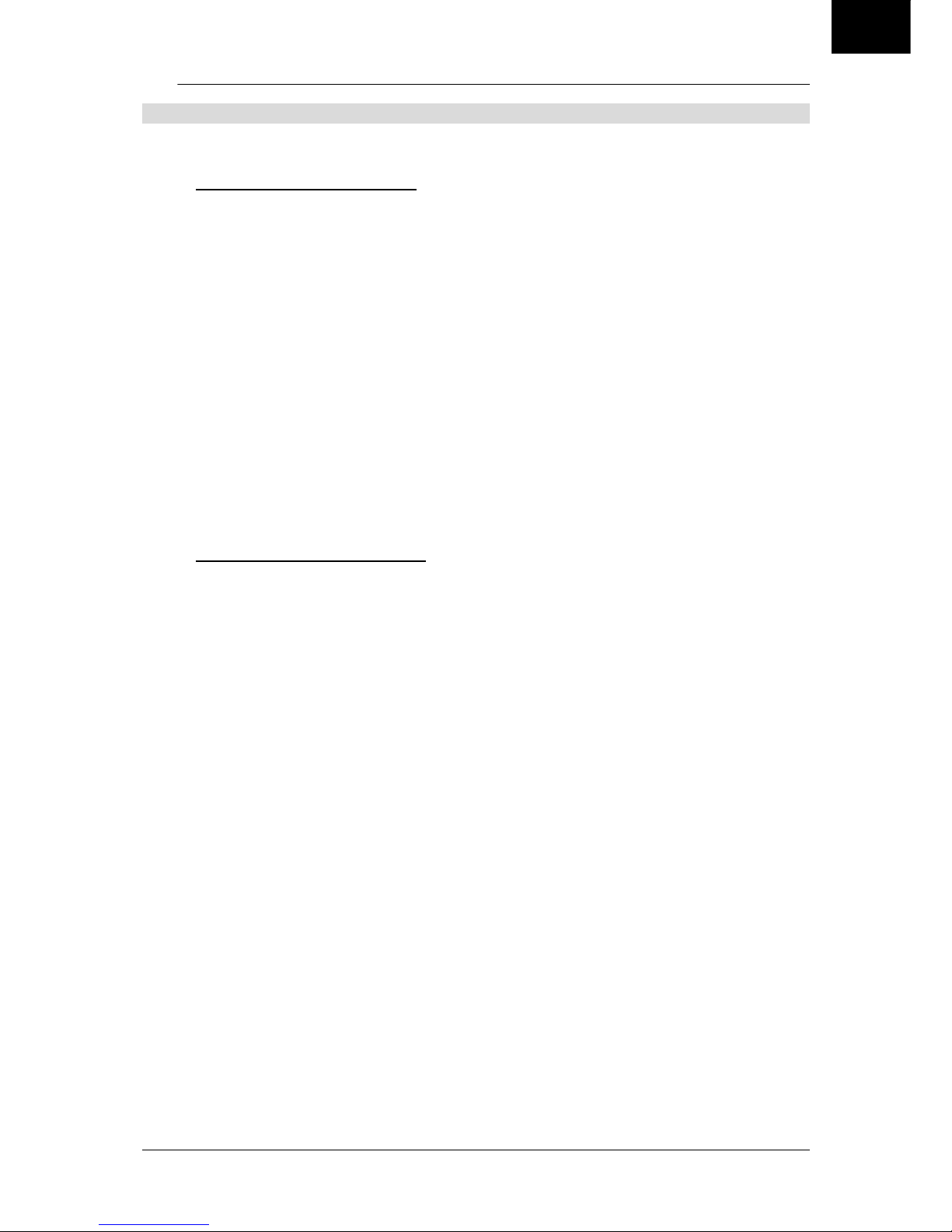

THE OPERATING ELEMENTS

The wheelchair should be delivered, already fully assembled, by authorised persons who will also

explain the various operating elements and how to use them. However, for your own safety, we here

provide another detailed explanation of the various parts.

FOLDING THE WHEELCHAIR

Your wheelchair can be folded up so that it can be transported or stored.

Folding

• Fold up the leg supports' footplates (see "Leg Supports" chapter)

• If necessary, remove leg supports (see "Leg Supports" chapter)

• Take hold of the flexible seat cover in the middle, at the front and the back, and pull it upwards.

• If necessary, remove the fixed seat and/or the fixed backrest (see chapters "Seat", "Back")

• Fold up the entire frame of the wheelchair to the armrests.

Unfolding

• Press the seat tubing downwards with both hands.

• If necessary, add the leg supports (see "Leg Supports" chapter).

• If necessary, add the fixed seat and/or the fixed backrest (see chapters "Seat", "Back")

L Every time the leg supports are put back, check that the seat and locking mechanism is correct.

L Keep objects and people away from the wheelchair's folding range.

L Folding and unfolding on carpeted floors or similar is difficult (tyres will rub).

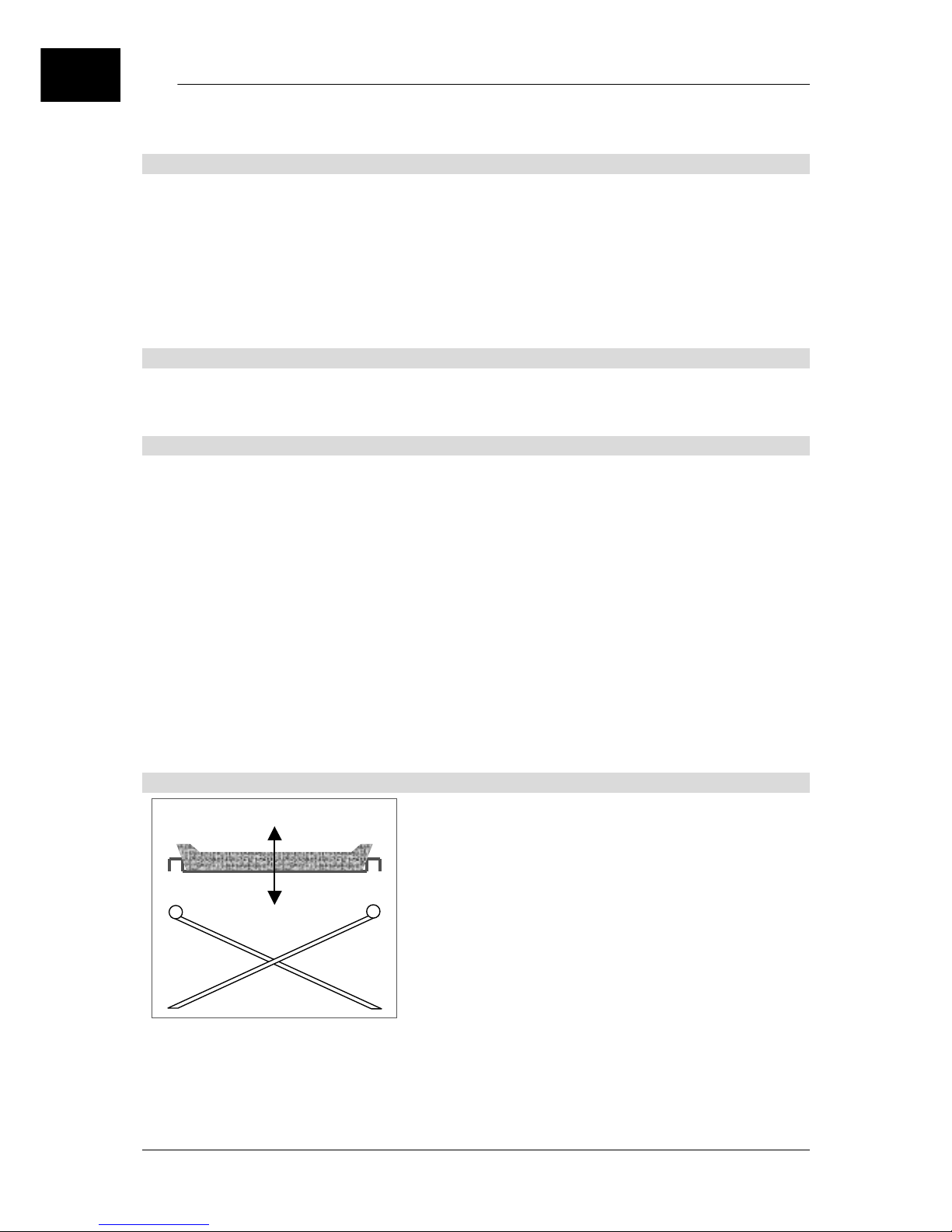

ANATOMICAL SEAT (OPTIONAL)

Your wheelchair will normally be supplied with a flexible,

padded seat. If you have opted for an anatomical seat, place

it on the tubular cross-hinge so that the seat's supports

engage equally with the cross-hinge. In the wooden base you

will find slots that are placed in the hinge's cross-pieces. To

fold up the wheelchair, remove the seat by pulling it upwards.

L Check that the seat is secure before use.

L Keep all object and bodily parts away from the area

between the seat and the cross-hinge.

E

708 D

06/2008

6

ANATOMICAL BACK (OPTIONAL)

Your wheelchair will normally be supplied with a flexible,

padded backrest. To use the anatomical backrest, proceed

as follows:

• Unscrew the flexible backrest.

• Loosely screw on the brackets for the backrest.

• Insert the backrest into the brackets from above.

• Tighten the screws holding the brackets for the

backrest.

• Insert and tighten the safety screws for the

backrest.

• Add the armrests (see "Armrests" chapter).

L Use suitable tools (a Phillips screwdriver).

L Check that the backrest is secure before use.

L Avoid getting your fingers caught during the assembly process.

L Avoid damaging the screws / washers.

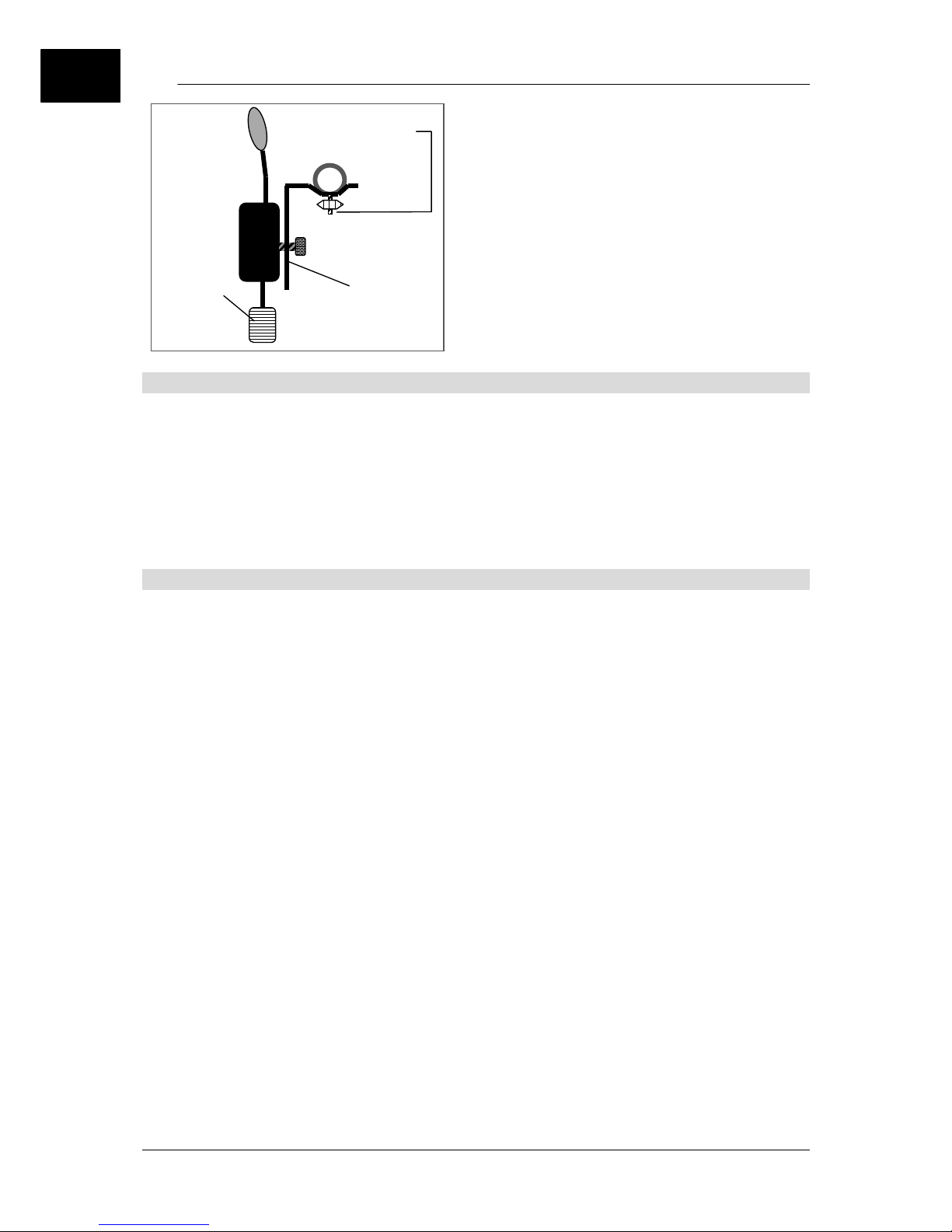

LEG SUPPORTS

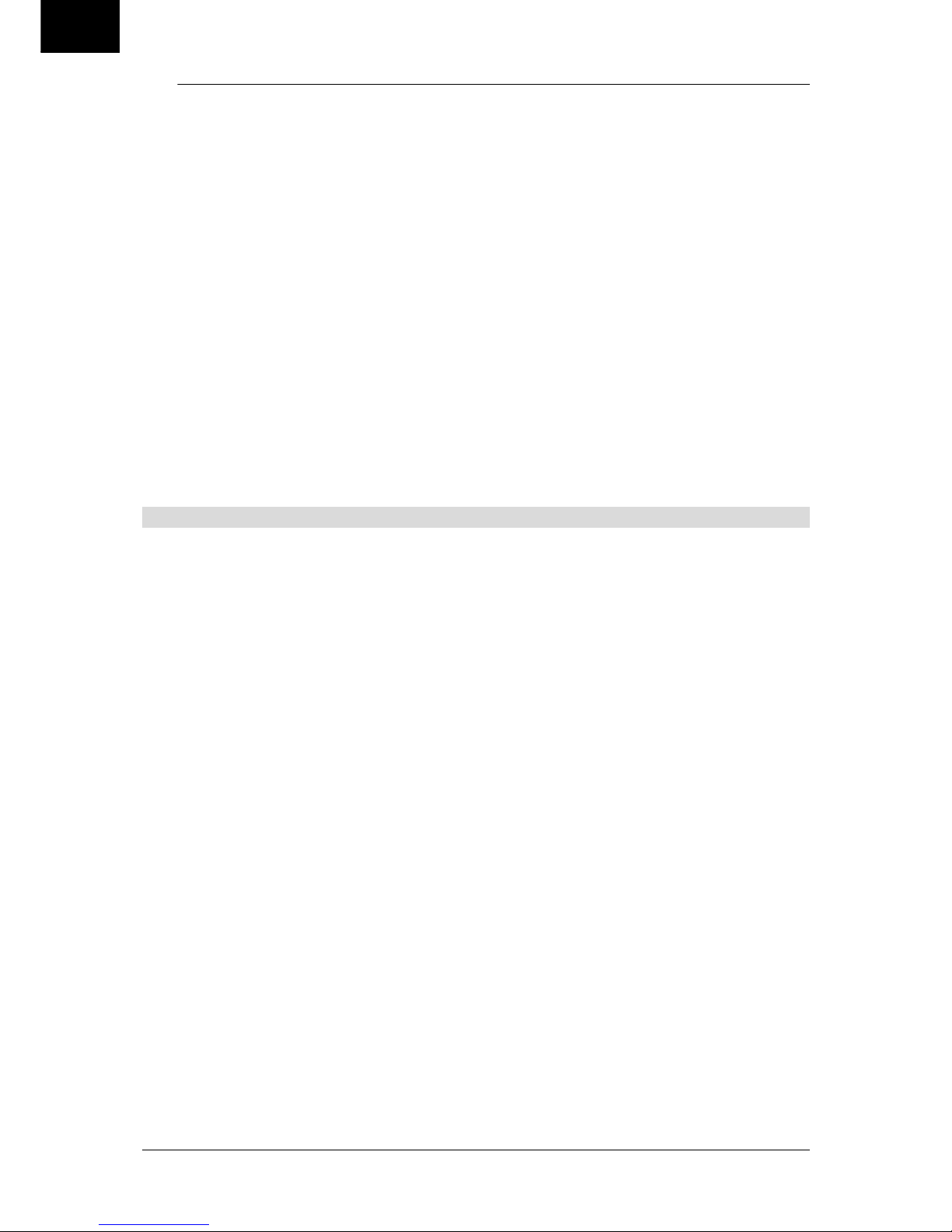

Removing the leg supports

First remove the calf strap by unhooking it on

both sides.

Push back the lever near the leg support

attachment.

Now you can swing the leg support to one side

and lift it out of the pins.

L Keep objects and people away from the leg

supports' swing range.

Attaching the leg supports

Insert the leg supports from the side into the pins

located on the frame.

Swing the leg support inwards until the lock

automatically stops it (if this lock is a little stiff,

press it gently back).

Now replace the calf strap in the hooks.

L Before use, make sure that the leg supports

are securely locked in place.

L Keep objects and people away from the leg

supports' swing range.

2 3 1

2

3

1

E

708 D

06/2008

7

Adjusting the length of the leg supports

• Loosen the Allen screw on the lower end of the

upper part of the leg support.

• Pull the hexagonal inner tube out to the required

length.

• Tighten the Allen screw once more.

L When withdrawing the hexagonal tube,

ensure that at least 5 cm of the tube remains

in the upper part of the leg support.

L There must be a gap of at least 6 cm between the ground and the footplate, or the

wheelchair's leg supports will knock against the ground when it is moving.

L Never stand on the footplates. They should only be used to rest the feet on. You could fall !

L The manufacturer cannot assume liability for damage caused by the leg supports hitting the

ground.

Before getting in and out - Fold up the footplates!

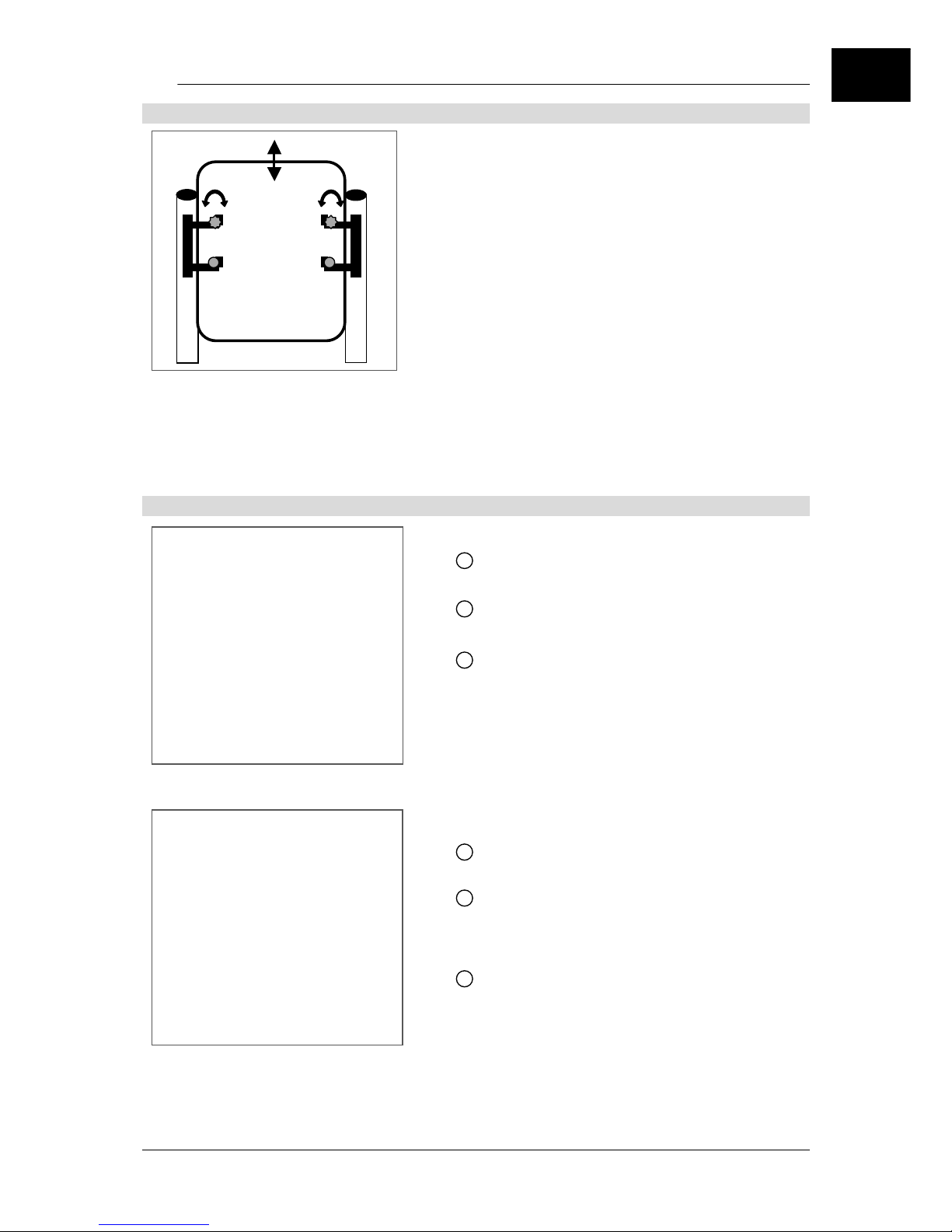

ARMRESTS

In the standard model the armrests can be folded down to the rear or removed backwards. The

arresting device (2) is mounted on the frame tube (1) to secure the armrests.

Removing the armrest

Press the operating lever (1) of the armrest locking device (2). Pull the armrest up and out, or fold it

away to the rear.

Do the opposite when replacing the armrest, but note that the rear bolt of the armrest (3) is inserted

first before the front bolt (4) is lowered into the armrest socket (2). If the operating lever (1) does not

lock automatically after emplacing the armrest, secure it manually.

When positioning an armrest, note that there is a guiding and stopping block (5) behind the back tube

which ensures the lateral stability of the armrests. The supporting belts are located on the rear armrest

tube. When tilted, the armrest cannot really help.

L Before use, make sure that the armrests are securely locked in place.

L Never grasp the wheelchair by the armrests when picking it up for transportation, but only by

solid frame parts (see also the chapter "For your safety".)

2

4

3

1

5

E

708 D

06/2008

8

PARKING BRAKES

As part of the standard range each driving wheel of your wheelchair is equipped with a parking brake.

They must be adjusted according to the tyres used.

Parking brake / pneumatic tyres

When pneumatic tyres are used, the parking brake can only function when the tyres are inflated hard

enough (see the Section "Technical details").

L Note that the tyre pressure should always correspond to the values given in the Chapter

"Technical details", otherwise the action of the parking brakes would be reduced or even be

zero.

L Note that the parking brakes are not supposed to be used for braking while driving. Their real

function is to prevent the wheelchair from rolling away when it is parked. If the parking brakes

are activated while traveling, it might cause injury and/or damage.

If the brakes lose their function through wear and tear and/or the covers and hoses have been

damaged, we advise you to consult your specialist dealer who has the tools and the knowledge to

repair / replace the defective parts.

L Unsuitable tools or improper handling might cause damage and/or loss of function.

L Brake adjustments undertaken by unauthorised persons are done at your own risk. Then the

manufacturer does not accept any liability.

L Rather let your specialist dealer adjust the parking brakes; he is trained on our products and

will comply with all relevant prescribed safety measures.

Parking brake / Solid rubber tyre

In the case of solid rubber tyres the parking brake can only function if the distance between the brake

pad and the surface of the tyre is such that the wheels cannot move when the brake is engaged. The

brakes can be adjusted by using suitable tools (see "parking brake / pneumatic tyres"). For reasons of

safety we advise you to let your specialist dealer undertake this job.

L Note that the parking brakes are not supposed to be used for braking while driving. Their sole

purpose is as a parking brake, to prevent the wheelchair from rolling away. If the parking

brakes are activated while traveling, it might cause injury and/or damage.

If you are not satisfied with the braking behaviour of your wheelchair, consult your specialist dealer

immediately; he will then adjust the brakes properly.

L If water, oil, or other kinds of dirt have soiled the wheels of the wheelchair (whether pneumatic

or solid rubber), then the braking action of the parking brakes could be impaired. Check the

condition of the wheels every time before using the wheelchair.

L If the brakes lose their effectiveness because of wear and tear and/or damage to the

tyres/inner tubes, kindly consult your specialist dealer, since special machines are required for

changing the "PU" tyres. The end-user is not able to change the "PU" tyres.

E

708 D

06/2008

9

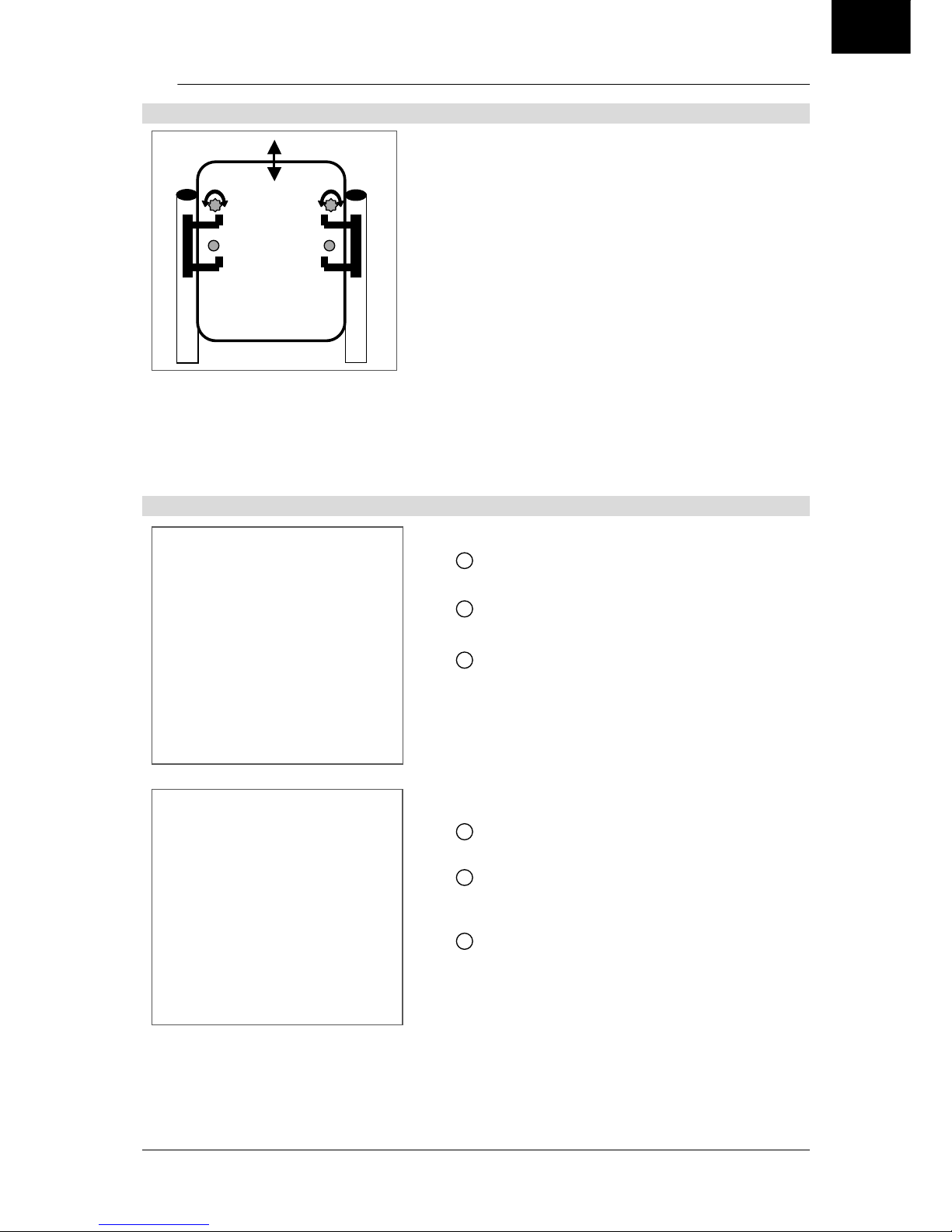

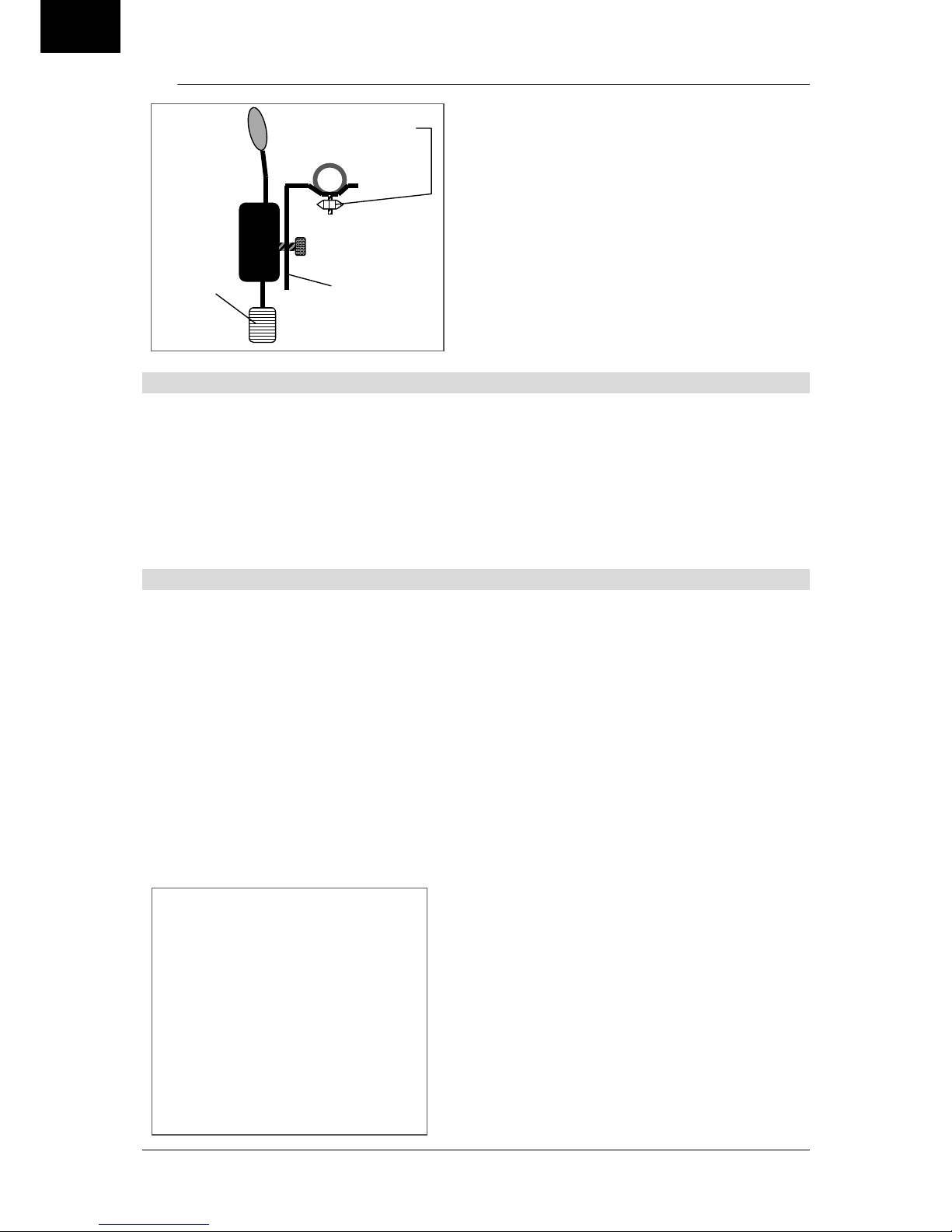

Adjusting the parking brake

• Loosen the self-locking nut on the brakeplate,

but do not remove.

• Move the brake as you require.

• Tighten the self-locking nut.

• Check that the brake works and brakes properly.

TYRES

Your wheelchair is available in various wheel combinations. The standard wheel configuration is 24" x

1 3/8 driving wheels and 8" x 1 ¾ steering wheels. Kindly consult your specialist dealer for other wheel

combinations; he would gladly advise you about the best configuration for your individual

requirements.

L Always make sure that the wheels are sufficiently inflated, since it could affect the driving

behaviour (see the chapter on "Technical details").

L We do not accept any guarantee for wheels not supplied by the manufacturer.

TYRE CHANGING

If you want to change the tyres or inner tubes, you should note the following:

After letting all the air out of the tube, insert a tyre lever between the tyre and the rim for the purpose

of removing the tyre. Then slowly and gently push the tyre lever downwards. This will pull the tyre over

the edge of the rim. If you then move the lever along the rim, the tyre will jump out. Now carefully

remove the tyre from the rim and then remove the tube.

L There must be no air in the tube before it can be removed.

L If handled improperly, the rim might be damaged. Rather let an expert perform these activities.

Note the following before inserting the new inner tube: Check the rim bed and the inside wall of the

tyre for foreign matter and clean these properly if necessary. Check the condition of the rim bed,

especially around the position of the air valve.

Please use only genuine original replacement parts. We do not accept any liability for damage caused

by non-genuine parts. Kindly contact your specialist dealer.

FITTING:

Place the rim belt in position over the air valve before

inserting it into the rim. Then the rim belt can be pulled

over easily. Check that all spoke heads are covered

(a rim belt is not required in the case of a plastic rim).

Brakerubber

Brakeplate

Self-locking nut

E

708 D

06/2008

10

Push the tyre over the edge of the rim, starting behind

the air valve. Inflate the tube slightly until it is round,

and place it inside the tyre.

If the tube fits snugly inside the tyre without any folds

(in the case of folds: let out some air), then the upper

side of the tyre can be pressed lightly onto the rim

with both hands, starting at the air valve.

Check all around on both sides that the tube is not pinched between the rim and the edge of the tyre.

Lightly push the air valve inwards and pull it out again to make sure that the tyre is positioned properly

in the region of the air valve.

To ensure that the wheel is inflated correctly, admit only so much air initially that the tyre can still be

easily pushed inwards by using your thumbs. If the check-lines are equidistant from the edge of the

rim on both sides of the tyre, then the tyre is centered properly. If not - let out the air and position the

tyre afresh.

Now the tyre can be inflated to its full operating pressure (note the maximum) and the valve cap

should be replaced.

L When mounting a tyre, make sure that no objects or body parts are pinched between the tyre

and the rim, since that could cause damage and/or injury.

L Only an expert can guarantee correct assembly. Work not done by your specialist dealer,

would void any warranty claims.

L When inflating the tyres, always check that the pressure is correct. The correct pressure is

given on the tyre walls (also refer to "Technical details").

L Use only inflating equipment which complies with regulations and indicates the pressure in

bar, or use the supplied air pump. We do not accept any liability for damage caused by

inflating equipment not supplied by the manufacturer.

E

708 D

06/2008

11

TRANSPORTING THE WHEELCHAIR

When transporting your wheelchair, you should note the following:

Before picking up the wheelchair all movable parts must be removed (foot supports, armrests, etc.).

L When raising the wheelchair, it should only be grasped by fixed parts of the frame.

L To prevent damage, the leg supports and armrests should be detached during transportation.

L When assembling, make sure that all screws are retightened properly.

If you require to be moved upwards or downwards on a staircase, tip the wheelchair slightly

backwards. The wheelchair can then be pushed forwards step by step with the driving wheels bearing

the weight. A second person is required to secure the wheelchair in front by taking hold of the front of

the frame after removing the leg supports.

L At least two persons are required for moving the chair up or down staircases or over single

steps.

L Note that, when the footrests have been removed, the legs of the user are not secured;

danger of injury !!

L When being transported, you should be protected by suitable safety belt systems (information

obtainable from your specialist dealer).

L When being transported, sit quietly in your wheelchair and avoid jerky movements.

L If you cannot sit quietly when being transported because of illness or disability (e.g. slightly

spastic, etc.), then at least two persons are required to secure the wheelchair on both sides by

taking hold of fixed parts of the frame.

L When being transported, make sure that your arms do not protrude outside the wheelchair.

L When being transported, no persons or objects should be below the wheelchair, to prevent

personal injury or damage to the wheelchair.

USING RAMPS

If you consider ramps for overcoming an obstacle, please note the following:

For your own safety you should only drive on ramps at the slowest speed required.

If a helper is pushing you, you must realise that the weight of the wheelchair increases the forces

which might cause it to roll backwards.

If the helper is unable to push the wheelchair up a ramp, you should immediately engage the parking

brake.

L Observe the instructions on the maximum load of the ramps used.

L Use a restraining belt to secure yourself in your wheelchair.

L We do not accept any liability for injury or damage caused by an improper choice of ramps.

TAKING THE WHEELCHAIR IN A CAR

The wheelchair must be secured inside the car by means of existing safety belts or a specially

provided belt system. You, too, should use a suitable belt system to secure yourself.

You can ask your specialist dealer about suitable securing systems which would guarantee safe

transportation in motor vehicles.

L Make sure that the wheelchair is fastened by fixed parts of the frame only.

L Check that the wheelchair cannot slide in any direction.

L P" the parking brakes of the wheelchair.

E

708 D

06/2008

12

L Loose parts taken from the wheelchair must be stowed securely.

L The wheelchair should not be used either to transport patients, or as a car seat.

For transportation in public vehicles provided for disabled persons, we recommend that you should

ask the organisation concerned about the currently valid regulations and rules for the transportation of

wheelchairs. Then you can ensure proper transportation with suitable security systems.

For transportation in other vehicles (airplanes, buses, ships, trams, trains, etc.) you should ask the

operator concerned whether you and your wheelchair can be transported safely.

L We do not accept any liability for damage and/or injuries resulting from transportation by third

parties. Transportation occurs at your own risk.

If you have further questions about transportation, kindly consult your specialist dealer. He shall gladly

assist you further.

USING THE WHEELCHAIR

The driving wheels are fitted with tyre grips to enable you to use your wheelchair. If you are propelling

yourself, please observe the following guidelines:

L When passing through restricted passages, e.g. doorways and other types of bottleneck, take

care that you do not harm your hands.

L If the tyre grips get damaged, get your specialist dealer to replace them as soon as possible,

so that you do not harm your hands and to ensure that you are always able to manoeuvre the

wheelchair safely.

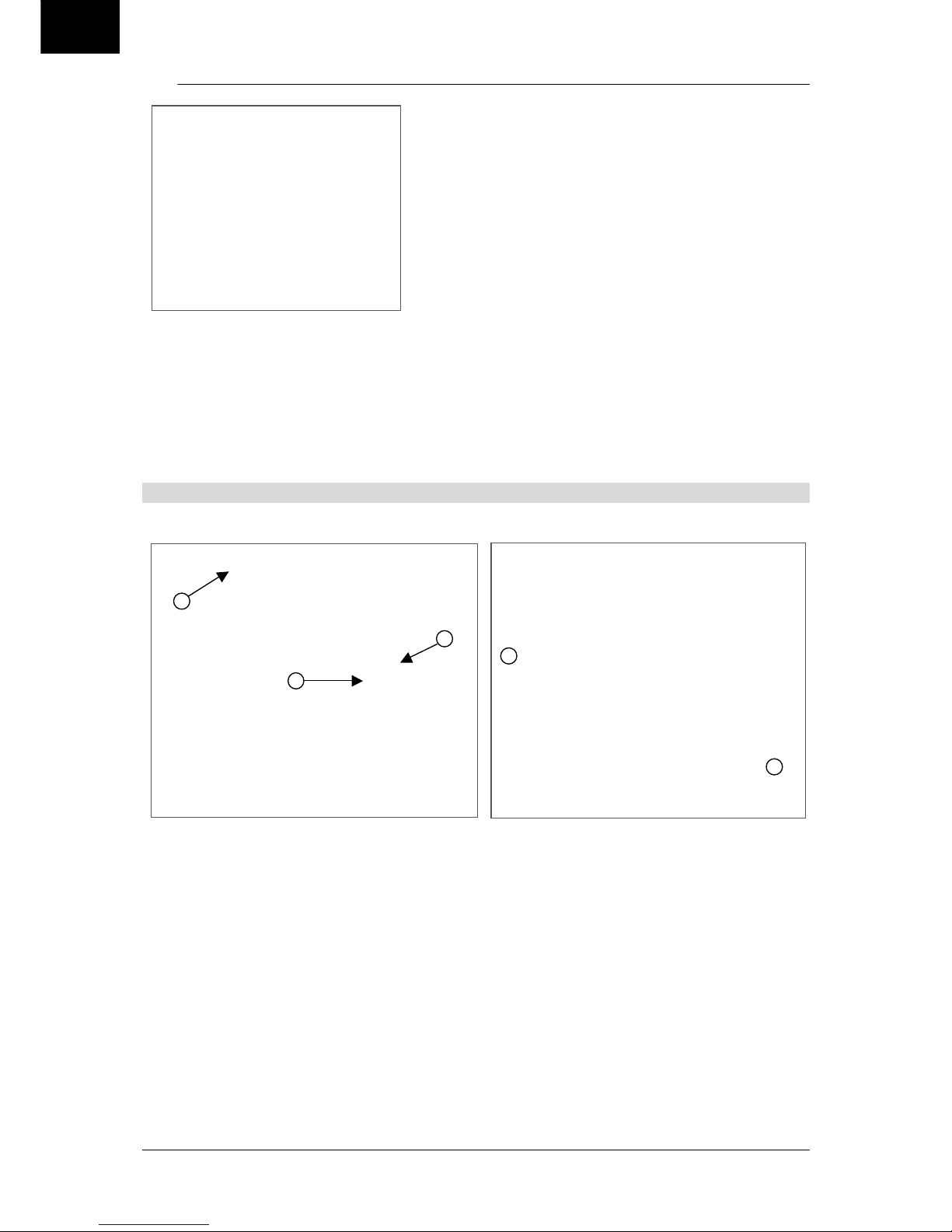

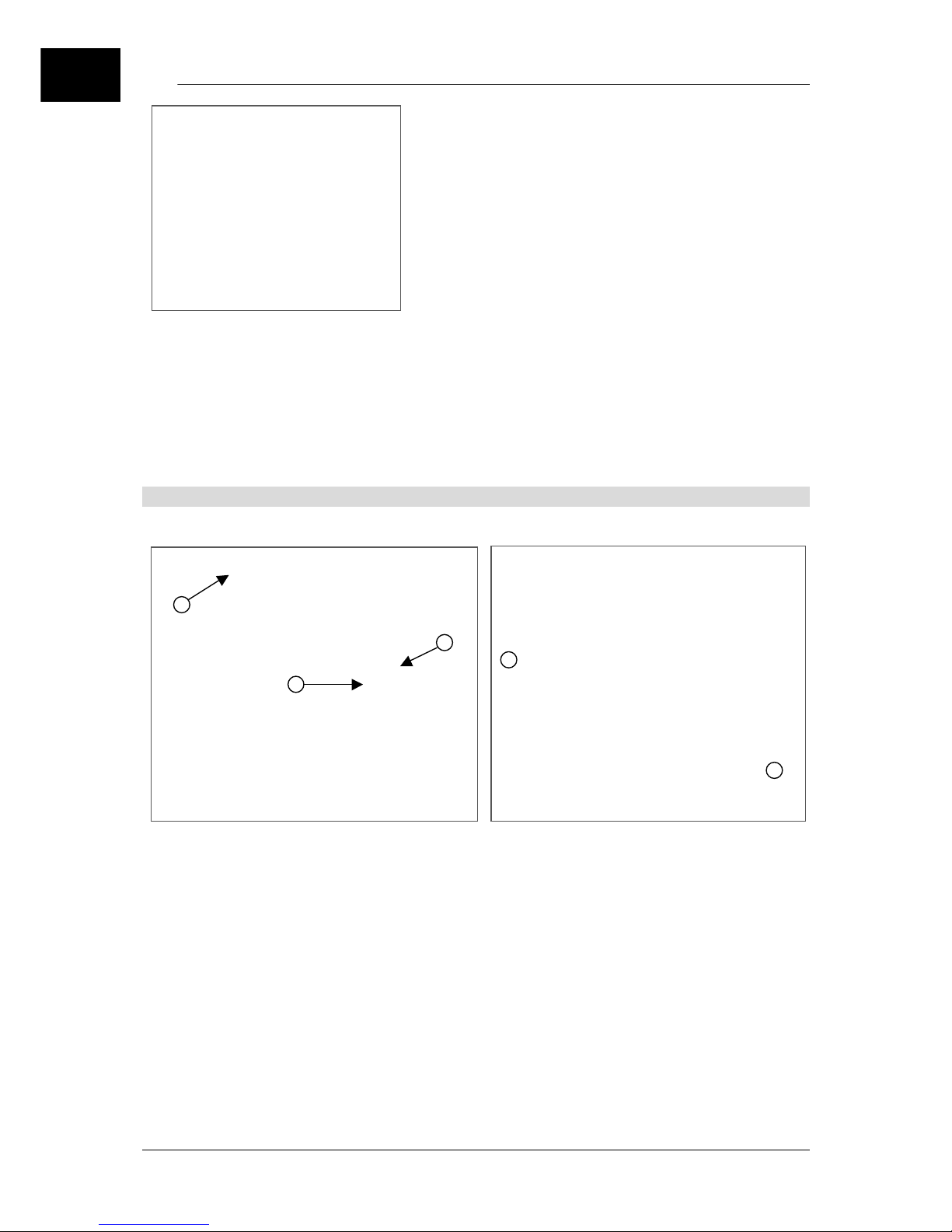

STARTING THE WHEELCHAIR

To move the wheelchair, lean your upper body forwards a little and grasp the tyre grips at their highest

point with your hands.

FORWARD MOVEMENT

From the starting position, push both arms forwards using equal force until they are straight. The torso

should remain largely immobile as this is done. When the hands release the tyre grips, the arms

should remain fixed in this position for a brief moment. The arms should now be stretched out and

facing downwards. After this brief pause in the stretched position, the hands should swing loosely

back to the starting position.

STEERING THE WHEELCHAIR WHILE ON THE MOVE

Always lean the upper body backwards first !

Slow the tyre grips on the side to which you wish to steer or turn.

When slowing the tyre grips, first allow them to slide between your thumbs and your bent fingers, then

grip firmly and, when the wheel stops, pull backwards.

STEERING AND TURNING THE WHEELCHAIR WHILE STATIONARY

Lean the upper body well back and pull back the tyre grips on the side to which you want to turn. Exert

smooth, equal pressure when pulling!

When turning in a stationary position, push the other hand on the outer wheel forwards at the same

time.

BACKWARD MOVEMENT

Lean the upper body well backwards. Using your hands, push long and with equal pressure away from

the highest point of the wheel.

BRAKING WHEN MOVING BACKWARDS

To brake while moving backwards, lean your upper body forwards and hold the tyre grips as far

forward as possible.

E

708 D

06/2008

13

MOVING TO AND FROM THE WHEELCHAIR

Position the wheelchair at an angle of approx. 30 - 45° to the chair or bed. The steering wheels should

be in the "Reverse" position. Now fix your wheelchair in position by putting on the parking brakes on

both sides. Remove both the leg supports (see the "Leg Supports" section). Now remove the armrest

on the side of the wheelchair where you wish to get out (see the "Armrests" section).

Note the following:

1) Slide your bottom as far forwards as you can on the seat

and

2) place your foot which is nearest to the chair/bed on the

floor.

Support yourself on the wheelchair (the edge of the seat) with one arm and the chair or bed with the

other. NOTE: Danger of tipping!

Now swing your bottom over or slide it over to the seat. If moving from a chair/bed to the wheelchair,

omit Point 2), but otherwise proceed as described above.

L The parking brakes must always be applied during this procedure, or you could get hurt or

damage something.

L If your illness/disability means that you are unable to move in and out of the wheelchair on

your own, always get help from someone who is familiar with the procedure.

L Getting into and out of the wheelchair is done at your own risk. The manufacturer admits no

liability claims.

STEPS / KERBS (ATTENDANT)

In principle, you should only tackle obstacles with the help of an

attendant.

Push the wheelchair to the edge of the obstacle and push down with

one foot on the tipping lever. This is located on the lower end of the

frame. At the same time, gripping the handles, pull the wheelchair

gently backwards.

Place the front wheels on the obstacle and put your foot back on the

ground. Then raise the wheelchair using the handles and push

forwards until the rear wheels are over the obstacle.

L To drop down, follow the procedure in reverse. The wheelchair should never be lowered over

steps / kerbs in the forwards position.

L There is a particular risk of tipping when you are traversing obstacles/steps/kerbs !

L Ensure that your attendant has enough strength for the procedure.

STEPS / KERBS (MOVING UPWARDS)

To get over a kerb or a step, it is vital that you approach it head-on.

Lean your upper body backwards a little.

L Practise tipping by having an attendant ensure that the

wheelchair does not roll over by holding the handles.

L The anti-tip device (if fitted) may need to be removed. N.B:

DANGER OF TIPPING!

E

708 D

06/2008

14

Tip the wheelchair a little and place the front wheels on the obstacle.

Bend the upper body and propel the wheelchair forwards until the

driving wheels reach the obstacle.

Slowly raise the driving wheels by pulling the tyre grips.

L N.B: BEWARE OF ROLLING BACKWARDS!

STEPS / KERBS (MOVING DOWNWARDS)

Approach the obstacle head-on and bend your upper body forwards a

little to shift your weight.

Tip the wheelchair on the driving wheels.

L The anti-tip device (if fitted) may need to be removed. N.B:

DANGER OF TIPPING!

Roll over the obstacle with the driving wheels and then, by slightly

shifting your body weight, place the steering wheels back on the

ground.

L Practise dropping down by having an attendant ensure that

the wheelchair does not roll over by holding the handles.

L If you shift your body weight too much, the wheelchair could

tip over and you could hurt yourself !

L Remember to replace the anti-tip device !

L As there is normally a greater risk of tipping over when dealing with obstacles, ask someone

else to help you.

L The manufacturer cannot assume liability for damage caused by overloading or banging

incurred while overcoming an obstacle.

If you have any further questions on using the wheelchair, kindly consult your specialist

dealer. He shall gladly assist you further.

ACCESSORIES

ARMRESTS

Depending on the purpose, various armrests can be fitted. They are simply hung on the suspensions

provided on the back tube (see the chapter on "Armrests").

B02- Long side parts with a long resting place for the arm provide protection against falling out

when the wheelchair is overturned.

B03- Desk armrests are available which allow you to drive against a table without having to detach

the armrests.

B05- These armrests can be adjusted to the length of your arms and thus allow you always to rest

your forearms.

Your specialist dealer would gladly advise you about which kind of armrest is most suitable for you.

E

708 D

06/2008

15

LEG SUPPORTS

We also have various different leg supports from which you can choose one which would suit your

individual requirements best.

B06- Standard detachable leg supports which can be swung aside.

BZ8- Leg supports of which the angle and the height is individually adjustable. For this purpose they

are equipped with adjustable calf plates.

BZ7- These leg supports are similar to the BZ8 but are ca. 7 cm longer to accommodate tall patients

with long lower legs.

PERSONAL SAFETY BELT (B58)

For your safety we offer a safety belt (B58) fitted with loops for pulling over the backrest tube. In

addition to ease of operation the spring lock provides a high level of safety.

ANTI-TIPPING DEVICE (B78)

For your safety we also offer the possibility of preventing the wheelchair from tipping over backwards.

This device (B78) is simply mounted on the bottom tube of the backframe. We recommend this fitting

for restless patients or inexperienced users. Your specialist dealer would gladly advise you about the

meaningfulness of such a system for you.

MOVING THE AXLE BACK (AMP)

If the centre of gravity of the person being propelled has moved backwards (e.g. if a leg has been

partly or fully amputated) and this has caused the wheelchair to lose its stability, stability can be

restored by attaching an axle block to move the driving wheels about 7 cm backwards.

TRANSIT WHEELCHAIR (T30)

Instead of the 24" driving wheels with tyre grips, 12" driving wheels can be used. This is only useful if

the wheelchair is to be used as an attendant-propelled (transit) wheelchair, because as such it can no

longer be driven actively. The total length of the wheelchair is significantly shorter for transport

purposes (e.g. in a car boot).

LOWERING THE HEIGHT OF THE SEAT (S)

In some situations, users may wish to help propel the wheelchair with their feet, so their feet must

reach the floor. If the standard seat height of 50 cm does not permit this, smaller wheels can be used

to reduce the height of the wheelchair seat to 46 cm.

DRUM BRAKES FOR THE ATTENDANT (B74)

If an attendant is to propel your wheelchair and wishes to ensure complete control on sloping

surfaces, the wheelchair can be fitted with drum brakes whose brake levers are mounted on the

handles of the wheelchair. These brakes can also be used as parking brakes as the brake levers are

designed to lock.

L You should be aware that this will increase the overall width of the wheelchair by about 1 cm.

FLOATING AXLES (B80)

To make the wheelchair easier to transport, it can be fitted with floating axles instead of the fixed,

screwed driving axles. To do this, press the knob in the centre of the axle from the outside and then

withdraw the entire wheel from the axle seating in the frame. The floating axle will remain in the hub.

To replace the wheel, press the knob again and insert the axle as far as you can into the axle seating

in the frame. Release the knob and try to pull the wheel back out. The two bearings on the ends of the

axle should lock the wheel and prevent it springing back out of the seating.

L Before every journey, check that the floating axles are fully and properly engaged.

Our extensive range of accessories provides further possibilities for individual requirements. Kindly

contact your specialist dealer. He would gladly advise you.

L The manufacturer can accept no liability for fittings and attachments that are incorrectly added.

E

708 D

06/2008

16

FOR YOUR SAFETY

L To prevent injury and/or damage to your wheelchair, make sure that no objects and/or body

parts are caught in the spokes of the driving wheels.

L The parking brakes should be applied before getting into and out of the wheelchair.

L When getting into and out of the wheelchair, do not stand on the footplates. These should be

folded up beforehand, or the leg supports should be swung completely outwards out of the

way.

L Investigate the effects of shifting the centre of gravity on the behaviour of the wheelchair for

example on up or down gradients, on laterally sloping ground, or when overcoming obstacles.

Obtain support from an attendant.

L If you want to pick up something (lying in front of, on the side, or to the rear of the wheelchair),

you should not lean too far out to avoid tipping over because of the displacement of the centre

of gravity.

L When moving through doors, arches, etc, ensure that there is enough room at the sides so

that you do not get your hands or arms caught or crushed and so that no damage is done to

the wheelchair.

L Only use your wheelchair according to regulations. For example, avoid uncontrolled rolling

against obstacles (steps, kerbs, doorframes, etc) or dropping down from ledges. The

manufacturer cannot assume liability for damage caused by overloading, banging or other

improper use.

L Stairs may only be negotiated when aided by another person. If furnishings like drive-on

ramps or lifts are available, use them.

L Check the profile depth and the inflation pressure of the tyres.

L When moving on the public highway, you are subject to the rules of the road.

L When driving your wheelchair, you should not be under the influence of alcohol or medicine as

in the case of driving other vehicles. This also applies to indoor driving.

L When traveling outdoors, adapt your driving to weather and traffic conditions.

L When transporting the wheelchair, never pick it up by grasping movable parts (armrests, leg

supports, etc.), but take hold of solid frame parts only.

L To be better visible when driving in the dark, wear the brightest possible clothing or clothes

with reflectors, and check that the reflectors mounted on the sides and rear of the wheelchair

are clearly visible.

L Be careful when using possible causes of fire such as cigarettes since they may set the seat

and back covers alight.

L Never exceed the maximum load (max. 120 kg).

STORAGE

• Store in a dry place (between + 5 °C and + 45 °C).

• The relative humidity of the air should be between 30% and 70%.

• Air pressure between 700 hPa and 1060 hPa.

• Provide sufficient covering or packaging to protect the wheelchair from rust and foreign bodies

(e.g. salt water, sea air, sand, dust).

• Store all removed parts together in one place (or mark them if necessary) to avoid mixing up

with other products when re-assembling.

• Components must be stored without being subjected to strains.

SERVICING

Your wheelchair also requires servicing like any other technical product. The activities which have to

be performed to ensure that you would fully enjoy the advantages of your wheelchair even after long

periods of use, are described below.

BEFORE DRIVING

- Check the tyres for visible damage and/or soiling. Remove any dirt since it could impair

the functioning of the parking brakes. When a tyre is damaged, kindly go to an authorised

workshop for repairs (also refer to the chapter on "Tyre changing").

- Ensure that screw fastenings (e.g. the seat, back, wheels) are secure.

E

708 D

06/2008

17

- Before driving off, check the efficiency of the parking brakes. If they do not function

properly, consult your specialist dealer (see also the chapter on "Parking brakes").

- Check the pressure of the tyres and inflate them if necessary (refer also to the chapters

"Tyre changing" and "Technical details").

APPROX. EVERY 8 WEEKS

- Depending on the frequency of use lubricate the following parts lightly:

Movable parts of the arm rest mechanism

Bearings of the brake levers

Movable parts of the footrests

APPROX. EVERY 6 MONTHS

- Depending on the frequency of use check the following:

Cleanness

General condition

Operation of the steering wheels

If the rolling resistance is too great, the wheel bearings have to be cleaned. If this is

insufficient, kindly consult your specialist dealer.

Repairs or the fitting of replacement parts should only be undertaken by your specialist dealer. Only

genuine parts may be used. We do not accept any liability for damage caused by the use of nongenuine parts or accessories not supplied by the manufacturer.

CARE

Your wheelchair requires regular care when you also want it to be visually attractive. Please take note

of the following hints:

COVERS

Clean covers with a cloth moistened with hot water. Use a mild commercial detergent for removing

stubborn dirt. Stains can be removed by using a sponge or a soft brush.

L Do not use strong cleaning liquids like solvents, nor use hard brushes.

L We shall decline all liability for damage due the use of improper cleaning liquids.

L Take care that you do not soak the covers.

L Steam cleaning is not suitable for these covers. If steam is used, your guarantee is voided.

PLASTIC PARTS

Clean all plastic parts of your wheelchair with commercial plastic cleaners. Read their specific product

information and only use a soft brush or soft sponge.

SURFACE LAYERS

The high quality of the surface layer guarantees optimal protection against corrosion. If the outer coat

is damaged by scratching or in some other way, get your specialist dealer to repair the affected

surface. When cleaning, only use warm water and normal household detergents and soft brushes and

cloths. Ensure that no wetness gets into the wheels.

Occasional greasing of the movable parts (also refer to the section "Servicing") will ensure that you

enjoy the benefit of your wheelchair for many years to come. Initially the chrome parts only require

rubbing with a dry cloth. Dull spots or stubborn dirt can best be removed by using a suitable

commercial chrome polish. If steel parts are lightly greased with vaseline premature dulling of the

chrome can be avoided.

To guarantee the long-term preservation of your wheelchair, we recommend that you take it once a

year to your specialist dealer for inspection. These inspections can be signed off in the "Service plan"

section.

E

708 D

06/2008

18

INSPECTION

In principle we recommend one inspection every twelve months, and a minimum of one before usage

is resumed. All of the following checks must be performed and documented by authorized persons:

• Check the frame parts and the hinged tubes for plastic deformation, tears and impaired

functioning

• Visually check for damage to the paintwork (danger of corrosion)

• Check the operation of the wheels (free running, level rolling, axle play, tyres, profile, condition

of the rims, air pressure (in the case of pneumatic tyres), etc.)

• Check the solidity and seating of all screws

• Verify the amount of grease on the metal joints of movable parts

• The condition and security of the guides and axles of the steering wheels (castor nuts)

• Visually check all plastic parts for tears and brittle spots

• Check the functioning of the armrests and leg supports (locking, load, deformation, wear and

tear caused by loads)

• Check the operation of other detachable parts (e.g. anti-tipping device, personal safety belt,

headrest, fitting of back/seat, container for walking stick, etc.)

• Verify completeness of the delivery condition

• Is the instruction manual available?

The service must only be signed off in the service plan if a minimum of all the above-mentioned

aspects have been checked. If your specialist dealer is incapable of performing the required services,

please contact the manufacturer. We shall gladly refer you to authorized specialist dealers in your

area.

The manufacturer is not liable for damage caused by lacking or improper service.

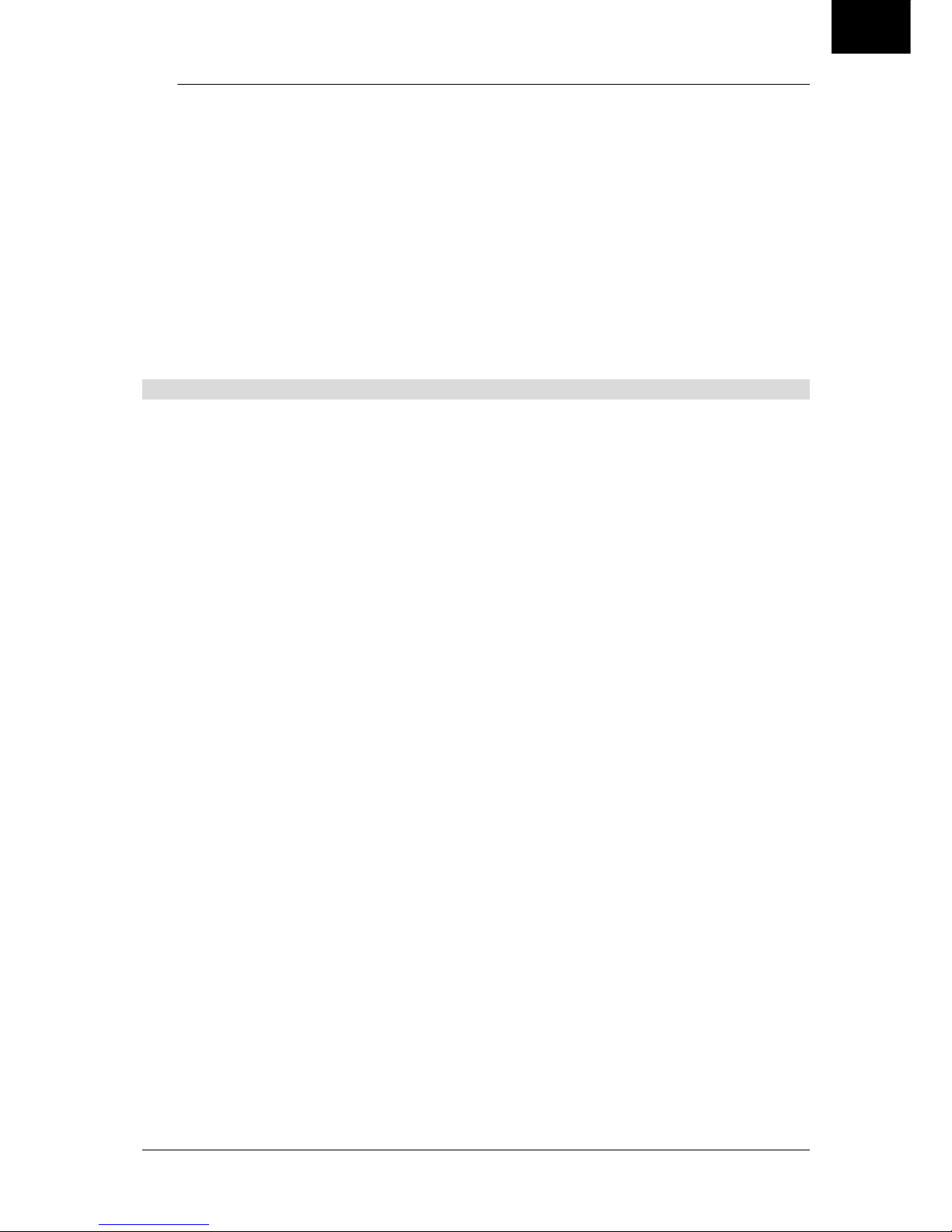

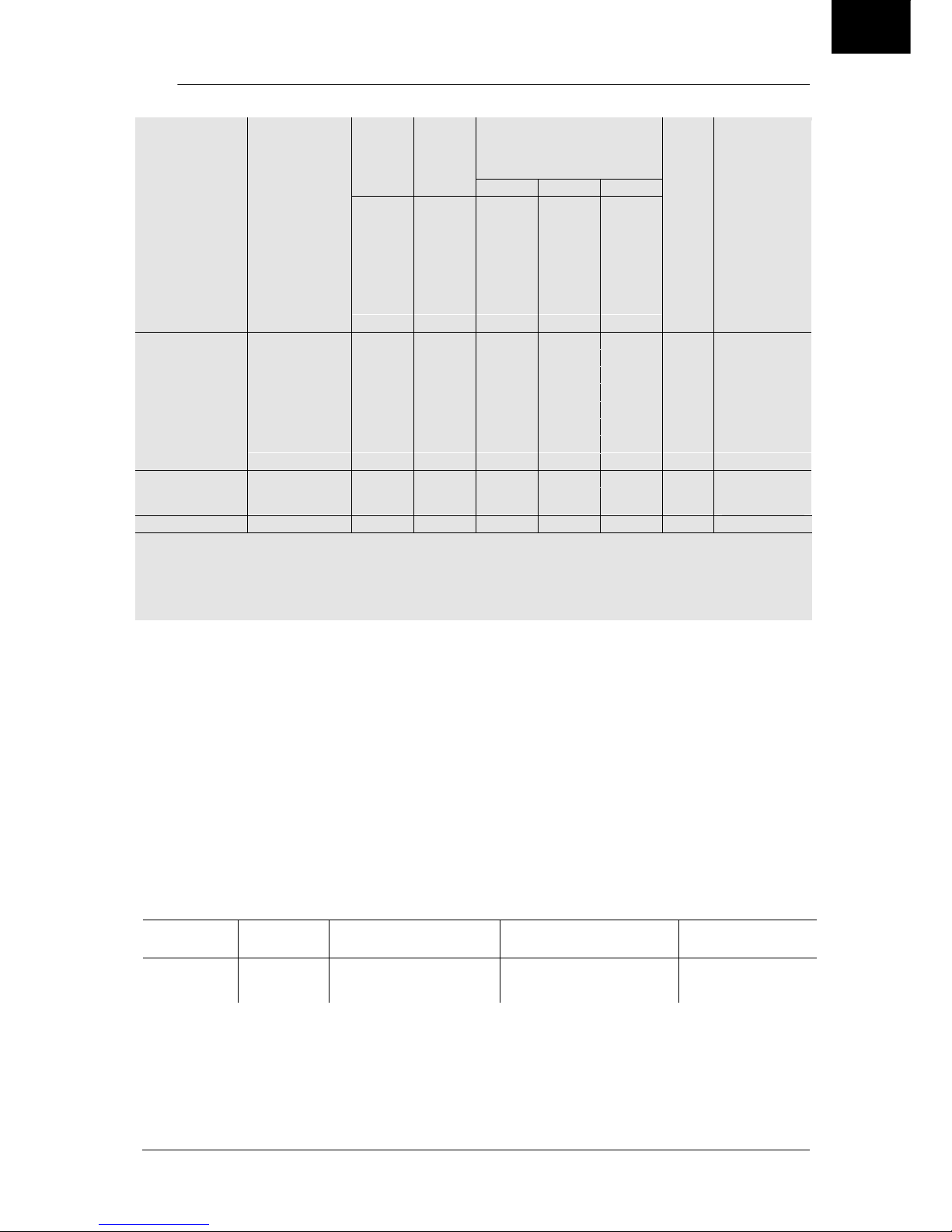

DISINFECTION

Only a hygiene technician or someone appointed by him can disinfect your wheelchair and this should

be done every time before its use is resumed. All parts of the wheelchair can be treated with a

disinfectant cloth. In principle all surfaces of a system or a product must be disinfected before handing

it over to a new user, at least once a year (e.g. when it is inspected) or when infections are detected in

the user. Then the measures of the Federal Epidemic Law must be applied.

We recommend the following disinfectants for scrubbing (based on the list provided by the

Robert Koch Institute, RKI):

E

708 D

06/2008

19

Surface

disinfection

(scrubbing

wiping dis-

Disinfection of excretions

1 part sputum or stools + 2 parts

diluted solution or 1 part urine + 1

part diluted solution

Laundry

disinfection

Infection)

Sputum

Stools

Urine

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Active substance

Name

%

Hr. % Hr. % Hr. % Hr. % Hr.

Area of

effectiv

eness

Manufacturer

or

Supplier

Amocid

1

12 5 6 5 4 5 6 5 2 A Lysoform

Gevisol

0.5

12 5 4 5 4 5 6 5 2 A Schülke & Mayr

Helipur

6 4 6 4 6 6 6 2 A

B.Braun Petzold

m-cresylic soap

solution DAB 6

1

12 5

4

A

Mucocit-F 2000

1

12 A Merz

Phenol 1 12 3 2 A

Phenol or

phenol derivative

Velicin forte

5 4 5 6 A

Ecolab

Chloramin-T DAB 9

1.5

12

2.5 2 5 4 A1 B

Clorina

1.5

12

2.5 2 5 4 A1 B

Lysoform

Chlorine, organic or

inorganic substances

with active chlorine

Trichlorol

2

12 3 2 6 4

A1 B

Lysoform

Apesin AP1002

4 4 AB

Tana Chemie

Dismozon pur2

4 1 AB

Bode Chemie

Perform2

3 4 AB

Schülke & Mayr

Per combinations

Wofesteril2

2 4 AB

Kesla Pharma

Aldasan 2000

4 4 AB

Lysoform

Antiseptica

Flächen-

desinfektion 7

3

6

AB

Antiseptica

Aldospray-Konz.

3 4 AB

Lysoform

Apesin AP30

5 4 A

Tana Chemie

Bacillocid Spezial

6 4 AB

Bode Chemie

Buraton 10F

3 4 AB

Schülke & Mayr

Desomed A 2000

3 6 AB

Desomed

Desinfektions-

reiniger Hospital

8

6

AB

Dreiturm

Desomed Perfekt

7 4 A

Desomed

Fink-Antisept B

8 6 AB

FINKTEC

Formaldehyde

solution DAB 10

(Formalin)

1.5

12 3 4

AB

Incidin perfekt

1

12 3 4

AB

Ecolab

Kohrsolin

2

12 3 4

AB

Bode Chemie

Lyso FD 10

3 4 AB

Schülke & Mayr

Lysoform

4

12 5 6

AB

Lysoform

Lysoformin

3

12 5 6

AB

Lysoform

Lysoformin 2000

4 6 AB

Lysoform

Melsept

2

12 4 6

AB

B.Braun Petzold

Formaldehyde

and/or other

aldehydes or

derivatives

Melsitt

4

12

10 4 AB

B.Braun Petzold

(…)

E

708 D

06/2008

20

Surface

disinfection

(scrubbing

wiping dis-

Disinfection of excretions

1 part sputum or stools + 2 parts

diluted solution or 1 part urine + 1

part diluted solution

Laundry

disinfection

Infection)

Sputum

Stools

Urine

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Diluted solution

Time to take effect

Active substance

Name

%

Hr. % Hr. % Hr. % Hr. % Hr.

Area of

effectiv

eness

Manufacturer

or

Supplier

Minutil 2 12 6 4

AB

Ecolab

Multidor

3 6 AB

Ecolab

Nüscosept

5 4 AB

Dr.Nüsken Chemie

Optisept

7 4 A

Dr.Schumacher

Pursept-FD

7 4 AB*

Merz

Septoclean FDN

3 6 AB

Haka Kunz

Tegodor

3 6 AB

Goldschmidt

Formaldehyde

and/or other

aldehydes or

derivatives

Ultrasol F

3

12 5 4

AB

Fresenius

Franko-DES

2

12 A Franken

Tensodur 103

2

12 A MFH

>Marienfelde<

Lime-wash

20 6 A3 B

1

Not effective against myco-bacteria when service disinfecting, especially in the presence of blood.

2

Not suitable for disinfecting blood-contaminated or porous surfaces (e.g. raw wood).

3

Useless for tuberculosis; preparation of lime-wash: 1 part dissolved lime (calcium hydroxide) + 3 parts water.

* Checked for effectiveness on viruses in accordance with checking methods of the RKI (Federal Health Reporting 38 (1995) 242).

A: suitable for killing vegetative bacterial germs including myco-bacteria as well as fungi, including fungal spores.

B: suitable for deactivating viruses.

Disinfective substances may only be applied by authorized professional staff trained in the

functioning and application of disinfectives.

L You should wear suitable protective clothing because the disinfectants could irritate your skin.

For this purpose you should also take note of the product information of the solutions

concerned.

L You employ unauthorized persons at your own risk.

L The manufacturer shall decline all liability for damage or injuries due to the improper handling

of disinfectants.

The current state of the disinfectants included in the RKI list can be obtained from the Robert Koch

Institute (Home page: www.rki.de).

All steps taken to disinfect rehabilitation equipment, their components or other accessory parts are to

be recorded in a disinfection report containing a minimum of the following information (with product

documentation appended):

Table 2 – Example of a disinfection book

Date of the

disinfection

Reason

Specification

Substance and concentration

Signature

Abbreviations used in column 2 (reason):

V = suspected infection IF = infection case W = repetition I = inspection

Kindly consult your specialist dealer if you have

further queries on matters relative to disinfection;

he will gladly assist you.

E

708 D

06/2008

21

GUARANTEE

Excerpt from the "General business conditions":

(…)

Excerpt from the "General Business Conditions":

(…)

5. The guarantee period for warranty claims is 24 months. As a result of our superior quality

requirements, we can increase the time bar on warranty claims beyond these fundamental, statutory

requirements for

(…)

- Frame and cross-hinge of standard wheelchairs 5 years

The guarantee excludes damage arising from structural changes to our products, insufficient

maintenance, defective or improper handling or storage or the use of pirate parts. Likewise, the

guarantee excludes parts or working parts subject to natural wear and tear.

(…)

STATEMENT OF CONFORMITY

The manufacturer or his authorized representative:

N.V. VERMEIREN N.V.

Address:

Vermeirenplein 1/15, B-2920 Kalmthout (Belgium)

declares that

all wheelchairs, Model 708 D (0910)

are made in full conformity with the following European guidelines -- including the latest changes -- and

with the national laws on which these guidelines are based:

MDD 93/42/EWG (Medical products)

and that the following harmonized European standards are maintained:

(DIN) EN 12182, (DIN) EN 12183

Date : 01. November 2003 Place: Kalmthout (Belgium)

Signature:

M. Van Herck

DISPOSAL

When disposing of the wheelchair, contact your local disposal centre or return the product to your

specialist dealer who, after submitting it to a hygienic procedure, will be able to send it back to the

manufacturer who will dispose of and recycle it correctly, separating it into its component materials.

Packaging materials can be taken to disposal or recycling centres or to your specialist dealer.

E

708 D

06/2008

22

TABLE DES MATIÈRES

Chapitre Page

Table des matières ............................................................................................................................22

Avant-propos......................................................................................................................................23

Caractéristiques techniques...............................................................................................................23

Généralités / Domaine d’utilisation ....................................................................................................24

Etendue de la fourniture.....................................................................................................................24

Outillage .............................................................................................................................................25

Les organes de commande ...............................................................................................................25

Plier le fauteuil roulant .......................................................................................................................25

Siège anatomique (option).................................................................................................................25

Dossier anatomique (option)..............................................................................................................26

Repose-jambes..................................................................................................................................26

Accoudoirs .........................................................................................................................................27

Freins de stationnement ....................................................................................................................28

Pneus.................................................................................................................................................29

Remplacement des pneus .................................................................................................................29

Transport du fauteuil roulant ..............................................................................................................31

Transport via des rampes ..................................................................................................................31

Transport dans la voiture ...................................................................................................................32

Entraînement à l’utilisation du fauteuil roulant ...................................................................................32

Accessoires........................................................................................................................................35

• Accoudoirs.......................................................................................................................................35

• Repose-jambes................................................................................................................................35

• Ceinture de sécurité de la personne (B58) ......................................................................................35

• Protection contre le basculement (B78)...........................................................................................35

• Déplacement de l’essieu vers l’arrière (AMP) Kit amputé ...............................................................35

• Modèle poussette (T30)...................................................................................................................35

• Faible hauteur de siège (S) Kit surbaissé........................................................................................35

• Frein à tambour pour l’accompagnateur/accompagnatrice (B74)....................................................35

• Axe à Démontage rapide (B80) .......................................................................................................36

Pour votre sécurité.............................................................................................................................36

Stockage ............................................................................................................................................37

Maintenance ......................................................................................................................................37

Entretien.............................................................................................................................................37

• Revêtements....................................................................................................................................37

• Pièces en matière plastique.............................................................................................................38

• Revêtement de surface....................................................................................................................38

Inspection...........................................................................................................................................38

Désinfection .......................................................................................................................................38

Garantie .............................................................................................................................................41

Déclaration de conformité..................................................................................................................41

Recyclage ..........................................................................................................................................41

Service ...............................................................................................................................................100

F

708 D

06/2008

23

Avertissement pour les revendeurs :

Ce mode d’emploi fait partie intégrante du produit et doit être remis avec chaque fauteuil roulant.

Édition : juin 2008

Tous droits, également ceux de la traduction, réservés.

Aucune partie de ce mode d’emploi ne peut être reproduite sous quelque forme que ce soit (impression,

photocopie, microfilm ou autre procédé) sans l’autorisation écrite de l’éditeur ou traitée, reproduite ou diffusée à

l’aide de systèmes électroniques.

N.V. Vermeiren N.V., 2008

AVANT-PROPOS

Nous tenons tout d’abord à vous remercier pour la confiance que vous nous accordez en optant pour

l’un de nos fauteuils roulants.

Les fauteuils roulants Vermeiren sont le résultat de longues années d’études et d’expériences. Lors

de la phase de développement, nous avons attaché une importance particulière à la simplicité

d’emploi et d’entretien. La durée de vie de votre véhicule dépend fortement du soin dont vous faites

preuve lors de son utilisation. Ce mode d’emploi doit vous aider à vous familiariser avec l’utilisation de

votre fauteuil roulant et vous donner quelques conseils pour maintenir votre fauteuil roulant en état de

fonctionnement et lui assurer une longue durée de vie.

Ce mode d’emploi reflète l’état le plus récent du développement du produit. La société Vermeiren se

réserve toutefois le droit d’apporter des modifications sans obligation d’adapter ou de remplacer les

modèles livrés précédemment. N’oubliez pas que le respect de nos instructions vous permettra de

conserver votre fauteuil roulant en parfait état de conservation et de fonctionnement, même après des

années d’utilisation.

Si vous avez d’autres questions, veuillez vous adresser à votre revendeur.

CARACTÉRISTIQUES TECHNIQUES

(spécifiées pour le réglage standard)

Les caractéristiques changent si vous utilisez d’autres repose-jambes/ appui-têtes ou d’autres

accessoires :

Longueur (sans repose-jambes)

81 cm

Longueur (avec repose-jambes)

106 cm

Hauteur (avec dossier)

92 cm

Largeurs d’assise

39 cm

42 cm

44 cm

46 cm

48 cm

50 cm

Largeur totale (en fonction des largeurs

d’assise)

56 cm

59 cm

61 cm

63 cm

65 cm

67 cm

Profondeur d’assise

43 cm

Hauteur d’assise

50 cm

Hauteur de dossier

42 cm

Hauteur d’accoudoir (siège-rembourrage)

22 cm

Hauteur d’accoudoir (rembourrage-sol)

72 cm

Poids (accoudoirs/repose-jambes compris)1)

env. 17 – 20 kg

Charge nominale (charge utile max.)

120 kg

Pression de gonflage des pneus des roues

directrices 2)

max. 2,5 bars

Pression de gonflage des roues motrices/roues

arrière 2)

max. 3,5 bars

Pente max. franchissable 3)

10,5 % / 6°

Hauteur max. des obstacles

6 cm

Sous réserve de modifications techniques. Tolérance dimensionnelle +/- 1,5 cm / kg/ °

1)

en fonction des largeurs d’assise et des pneus

2)

pression de gonflage spécifiée pour des pneumatiques standard Si vous utilisez des pneus autres, vérifiez les pressions de

gonflage indiquées sur le flanc du pneu.

3)

si les pneus sont en bon état, la pression de gonflage correcte et la surface lisse

F

708 D

06/2008

24

GÉNÉRALITÉS

Avec le modèle « 708 D », vous avez fait l’acquisition d’un fauteuil roulant entièrement conçu pour

votre confort. Le modèle sert exclusivement aux personnes à mobilité réduite pour une utilisation

individuelle lors du transport indépendant et assisté à l’intérieur et à l’extérieur. Ce fauteuil roulant

propose divers équipements indiqués ci-après. Lisez attentivement le mode d’emploi pour vous

familiariser avec votre fauteuil.

DOMAINE D’UTILISATION

Le fauteuil roulant sert au transport actif (utilisation de la main courante) ou passif (avec l’aide d’un

tiers) d’une personne. Les variantes d’équipement et d’accessoires, ainsi que la construction

modulaire, permettent une utilisation en cas de handicap moteur dû à

• des paralysies

• la perte de membres (amputation des jambes)

• un défaut/une déformation des membres

• des contractures/lésions des articulations

• des maladies comme l’insuffisance cardiaque et circulatoire, les troubles de l’équilibre ou la

cachexie, et pour les gériatriques.

Cette liste n’est pas exclusive, il existe d’autres cas de maladie ou de handicaps, mais il est

nécessaire auparavant de faire vérifier par une personne autorisée si ce produit donne toutes les

garanties d’utilisation et de sécurité requises et n’entraîne aucun danger pour son utilisateur.

En cas de prise en charge individuelle, il faut en outre tenir compte

• de la taille et du poids (charge utile max. 120 kg)

• état physique et psychique

• habitation

• environnement

Votre fauteuil roulant doit être utilisé uniquement sur des sols permettant le contact des quatre roues

et une adhérence suffisante pour garantir l’entrainement régulier des roues. Il convient de suivre une

formation spécifique de conduite sur les surfaces irrégulières (pavés, etc.), les déclivités et les virages

(embardées latérales, etc.), ainsi que pour le passage d’obstacles (p.ex. bordures de trottoirs). Les

déplacements sur des surfaces comme la glace, l’herbe, le ballast, le feuillage et autres sols stables

ou non rendant la circulation difficile sont particulièrement dangereux.

Ce fauteuil ne peut être utilisé comme siège dans un véhicule automobile. La charge nominale

consentie ne saurait être supérieure à 120 kg et il est exclu de transporter plus d’une personne sur ce

fauteuil. Le fauteuil roulant ne saurait servir d’échelle, de support pour des objets lourds ou brûlants

ou à des fins autres que le transport actif ou passif d’une personne. Si le sol est recouvert de tapis, de

moquettes ou de revêtements de sol simplement posés, ceux-ci risquent d’être abîmés et le fauteuil

risque de basculer. Le fabricant décline toute responsabilité en cas de combinaison avec des produits

ou des équipements tiers, et en cas d’utilisation d’accessoires modifiant la destination du produit.

Une garantie ne peut être offerte que si le produit est utilisé dans les conditions prédéfinies et

aux fins prévues.

ÉTENDUE DE LA FOURNITURE

• Fauteuil roulant, y compris le mécanisme dossier/siège, les roues motrices, les roues directrices

• Repose-pieds

• Accoudoirs

• Pompe (uniquement en cas de pneus à air)

• Mode d’emploi

• Outil (clé pour boulons à six pans creux)

AVERTISSEMENT POUR LES REVENDEURS :

Après réception de la marchandise, vérifiez que le produit est complet et en bon état de

fonctionnement. La garantie s’applique uniquement si les défauts sont signalés par écrit au fabricant

(fournisseur) dans un délai de deux semaines. La garantie s’applique aux vices cachés uniquement

s’ils sont signalés par écrit au fabricant (fournisseur) dans un délai de deux semaines après leur

F

708 D

06/2008

25

découverte. En cas de défaut, nous appliquons la garantie au choix en décidant s’il convient de

réparer ou de remplacer les éléments.

OUTILLAGE

Les outils suivants sont nécessaires pour le montage et le réglage de votre fauteuil roulant :

• Tournevis cruciforme

• Tournevis pour vis à six pans creux (grandeur 4 et 5)

• Clé polygonale/clé à fourche (grandeurs 10 / 13)

• Clé polygonale (grandeur 19)

• Clé à fourche (grandeur 11)

L Les montages et les réglages seront exclusivement effectués par des personnes habilitées à cet

effet.

LES ORGANES DE COMMANDE

Votre revendeur vous livre le fauteuil roulant entièrement monté par une personne autorisée qui vous

explique les différents organes de commande et leur utilisation. Pour votre propre sécurité, nous

allons vous expliquer à nouveau en détail les différents éléments de commande.

PLIER LE FAUTEUIL ROULANT

Vous pouvez replier le fauteuil roulant pour le transporter ou le stocker.

Pliage

• Relever les repose-pieds ou les repose-jambes (voir chapitre « Repose-jambes »).

• Le cas échéant, retirer les repose-pieds (voir chapitre « Repose-pieds »)

• Saisir la housse de siège souple dans son milieu à l’avant et à l’arrière, puis tirer vers le haut.

• Le cas échéant retirer le siège fixe et/ou le dossier fixe (voir chapitre « Siège », « Dossier »)

• Replier en entier le cadre du fauteuil sur les accoudoirs.

Dépliage

• Appuyer des deux mains vers le bas sur les tubulures du siège.

• Le cas échéant, monter les repose-jambes (voir chapitre « Repose-jambes »)

• Le cas échéant, placer le siège fixe et/ou le dossier fixe (voir chapitre « Siège », « Dossier »)

L Après chaque montage des repose-jambes, vérifier leur position et leur bon verrouillage.

L Aucune personne ou objet dans la zone de pliage du fauteuil roulant.

L Le pliage et le dépliage est plus difficile sur la moquette (frottement des roues).

SIEGE ANATOMIQUE (OPTION)

Votre fauteuil roulant est livré de série avec un siège souple

rembourré. Si vous avez choisi un siège anatomique, posez

celui-ci sur le compas tubulaire déplié de manière à ce que

les suspensions du siège s’encastrent de façon uniforme sur

le compas. Le support en bois est équipé d’encoches qui

sont placées sur les traverses du compas. Pour plier le

fauteuil roulant, retirez le siège en le tirant vers le haut.

L Avant toute utilisation, vérifier que le siège a une

bonne assise.

L Il ne faut placer aucun objet ou partie du corps entre le

siège et le compas.

F

708 D

06/2008

26

DOSSIER ANATOMIQUE (OPTION)

Votre fauteuil roulant est livrée de série avec un dossier

souple rembourré. Si vous utilisez un dossier anatomique,

procédez comme suit :

• Dévisser la toile de dossier,

• Visser sans serrer les supports du dossier.

• Placer le dossier dans les supports en haut en

bas.

• Serrer les vis des supports de dossier.

• Serrer les vis de sécurité du dossier.

• Mettre en place les accoudoirs (voir chapitre

« accoudoirs »)

L Utilisez les outils appropriés (tournevis cruciforme).

L Avant toute utilisation, vérifier que le dossier a une bonne tenue.

L Veillez à ne pas vous pincer lors du montage.

L Ne pas endommager les vis et les rondelles.

REPOSE-JAMBES

Retrait du repose-pied

Retirez en premier la bande de maintien de la

jambe en la décrochant des deux côtés.

Repoussez le levier placé près de la suspension

du repose-pied.

Le repose-pied peut être basculé et dégagé de

ses pivots.

L Il ne doit y avoir aucune personne ou objet

dans la zone de basculement du repose-pied.

Installation du repose-pied

Placez les repose-pieds latéralement dans les

deux pivots situés sur le cadre.

Faites basculer le repose-pied vers l’arrière

jusqu’à enclenchement automatique (si le

mécanisme joue difficilement, appuyez

légèrement sur le dispositif de verrouillage).

Raccrochez la bande de maintien de la jambe.

L Avant utilisation, vérifiez que les repose-

jambes sont bien verrouillés.

L Aucune personne ou objet dans la zone de

basculement du repose-pied.

2 3 1

2

3

1

F

708 D

06/2008

27

Réglage de la longueur du repose-pied

• Desserrez la vis à six pans située à l’extrémité

inférieure de la partie haute du repose-pied.

• Tirez sur le tube intérieur à six pans pour le placer

à la longueur souhaitée.

• Ensuite, resserrez la vis.

L Tirez sur le tube à six pans de sorte qu’il reste

au moins 5 cm de tube dans la partie haute

du repose-pied.

L Il doit rester un espace d’au moins 6 cm entre le sol et la palette, afin que le repose-jambes ne

touche pas le sol pendant la conduite.

L Ne montez jamais sur les palettes, ils servent uniquement à poser les pieds - Risque de

chute !

L Le fabricant décline toute responsabilité pour les dégâts causés par une collision des repose-

jambes.

Avant de s’asseoir et de sortir : toujours relever les patins !

ACCOUDOIRS

De série, les accoudoirs peuvent se rabattre vers l’arrière ou s’enlever. L’arrêt (2) prévu sur le tube du

cadre (1) permet de bloquer les accoudoirs.

Dépose de l’accoudoir

Appuyez sur le levier de commande (1) de l’arrêt d’accoudoir (2). Tirez l’accoudoir vers le haut ou

rabattez-le vers l’arrière.

Pour accrocher l’accoudoir, procédez en sens inverse en veillant à accrocher d’abord le bouchon

arrière de l’accoudoir (3) et à enfoncer ensuite seulement le bouchon avant (4) dans l’arrêt

d’accoudoir (2). Si le levier de commande (1) ne se bloque pas automatiquement après le verrouillage

de l’accoudoir, bloquez-le manuellement.