Vermeer S650TX Operator's Manual

S650TX

Mini Skid Steer

Operator’s

Manual

S650TX_o1_02

Serial No. 101 Order No. 105400BV8

Cabled Assembly Order No. 296338951

Introduction

This manual explains the proper operation of your machine. Study and understand these instructions thoroughly before operating or

maintaining the machine. Failure to do so could result in personal injury or equipment damage. Consult your Vermeer dealer if you

do not understand the instructions in this manual, or need additional information.

The instructions, illustrations, and specifications in this manual are based on the latest information available at time of publication.

Your machine may have product improvements and features not yet contained in this manual.

Vermeer Corporation reserves the right to make changes at any time without notice or obligation.

Operation instructions are included in the two Operator’s Manuals provided with the machine. The tethered (cabled)

manual must remain attached to the machine for ready reference. Store it in the manual storage box when not in use.

Lubrication and maintenance procedures are in the Maintenance Manual provided with the machine. Refer to it for all

lubrication and maintenance procedures.

Additional copies of the manuals, and Operations and Safety video, are available from your dealer. Reorder numbers are listed on the

front covers of the manuals and on the video.

Copies of this manual, and the Operations and Safety video, are available in Spanish from your dealer.

Su distribuidor dispone de ejemplares en español de este manual y del vídeo de Operaciones y Seguridad.

NOTICE TO OWNER

You are requested to notify Vermeer Corporation when you have purchased a used Vermeer machine. Notify the Customer Data

Department by telephone: 800-829-0051 or 641-628-3141; email: customerdata@vermeer.com; internet: www.vermeer.com or

www.vermeerag.com; or letter: Customer Data Dept., Vermeer Corporation, PO Box 200, Pella IA 50219 USA. Upon request, an

owner of a used Vermeer machine will receive one free set of Operator’s, Maintenance and Parts manuals.

Introduction S650TX Mini Skid Steer

Orientation: Right and left sides of the machine are determined by standing on the operator platform and facing forward.

TRADEMARKS

VERMEER and VERMEER Logo are trademarks of Vermeer Manufacturing Company.

KUBOTA is a trademark of Kubota, Ltd., Osaka, Japan.

S650TX Mini Skid Steer Introduction

VERMEER NEW INDUSTRIAL EQUIPMENT LIMITED WARRANTY

(EFFECTIVE OCTOBER 1, 2008) WARRANTY PERIOD: 12 Months / 1000 Hours

Vermeer Corporation (hereinafter “Vermeer”) warrants each new Industrial product of Vermeer's manufacture to be free from defects

in material and workmanship, under normal use and service for one (1) full year after initial purchase/retail sale or 1000 operating

hours, whichever occurs first. This Limited Warranty shall apply only to complete machines of Vermeer's manufacture, parts are

covered by a separate Limited Warranty. EQUIPMENT AND ACCESSORIES NOT OF VERMEER'S MANUFACTURE ARE

WARRANTED ONLY TO THE EXTENT OF THE ORIGINAL MANUFACTURER'S WARRANTY AND SUBJECT TO

THEIR ALLOWANCE TO VERMEER ONLY IF FOUND DEFECTIVE BY SUCH MANUFACTURER.

EXTENDED WARRANTY OPTIONS ARE AVAILABLE FOR PURCHASE.

WARRANTY TERMS

During the Limited Warranty period specified above, any defect in material or workmanship in any warranted item of Vermeer

Industrial Equipment not excluded below shall be repaired or replaced at Vermeer's option without charge by any authorized

independent Vermeer dealer. The warranty repair or replacement must be made by a Vermeer independent authorized dealer at the

dealer's location. Vermeer will pay for replacement parts and such authorized dealer's labor in accordance with Vermeer's labor

reimbursement policy. Vermeer reserves the right to supply remanufactured replacement parts as it deems appropriate.

RETAIL PURCHASER RESPONSIBILITY

Industrial Equipment as indicated in the Operator’s/Maintenance Manual furnished with each new Industrial Equipment. The cost

of routine or required maintenance and services is the responsibility of the retail purchaser. The retail purchaser is required to keep

documented evidence that these services were performed.

This Vermeer New Industrial Equipment Limited Warranty may be subject to cancellation if the above requirements are not

performed.

Vermeer Industrial Equipment with known failed or defective parts must be immediately removed from service.

Introduction S650TX Mini Skid Steer

: This Limited Warranty requires proper maintenance and periodic inspections of the

EXCLUSIONS AND LIMITATIONS

The warranties contained herein shall NOT APPLY TO:

(1) Any defect which was caused (in Vermeer’s sole judgment) by other than normal use and service of the Industrial

Equipment, or by any of the following; (i) accident (ii) misuse or negligence (iii) overloading (iv) lack of reasonable and

proper maintenance (v) improper repair or installation (vi) unsuitable storage (vii) non-Vermeer approved alteration or

modification (viii) natural calamities (ix) vandalism (x) parts or accessories installed on Industrial Equipment which were

not manufactured or installed by Vermeer authorized dealers (xi) the elements (xii) collision or other accident.

(2) Any Industrial Equipment whose identification numbers or marks have been altered or removed or whose hourmeter has

been altered or tampered with.

(3) Any Industrial Equipment which any of the required or recommended periodic inspection or services have been performed

using parts not manufactured or supplied by Vermeer or meeting Vermeer Specifications including, but without limitation,

engine tune-up parts, engine oil filters, air filters, hydraulic oil filters, and fuel filters.

(4) New Industrial Equipment delivered to the retail purchaser in which the warranty registration has not been completed and

returned to Vermeer within ten (10) days from the date of purchase.

(5) Any defect which was caused (in Vermeer’s sole judgment) by operation of the Industrial Equipment not abiding by standard

operating procedures outlined in the Operator’s Manual.

(6) Engine, battery, and tire Limited Warranties and support are the responsibility of the respective product’s manufacturer.

(7) Transportation costs, if any, of transporting to the Vermeer dealer. Freight costs, if any, of transporting replacement parts to

the Vermeer dealer.

(8) The travel time of the Vermeer dealer’s service personnel to make a repair on the retail purchaser’s site or other location.

(9) In no event shall Vermeer’s liability exceed the purchase price of the product,

(10) Vermeer shall not be liable to any person under any circumstances for any incidental or consequential damages (including

but not limited to, loss of profits, out of service time) occurring for any reason at any time.

(11) Diagnostic and overtime labor premiums are not covered under this Limited Warranty Policy. Oils and fluids are not covered

under this Limited Warranty.

S650TX Mini Skid Steer Introduction

(12) Depreciation damage caused by normal wear, lack of reasonable and proper maintenance, failure to follow operating

instructions, misuse, lack of proper protection during storage.

(13) Accessory systems and electronics not of Vermeer’s manufacture are warranted only to the extent of such manufacturer’s

respective Limited Warranty if any.

(14) Downhole toolage is not covered under this warranty.

(15) Wear items which are listed by product group as follows:

ENVIRONMENTAL

Curtains, Cutter Wheels, Discharge Conveyor Belts, Fuel Filters, Hammers, Hoses, Infeed Conveyor Belts, Infeed Conveyor Chains,

Knives, Oil Filters, Pockets, Rods, Rollers, Rotor Plates, Screens, Service Items, Shear Bar/Bedknife, Sprockets, Teeth, Wear Blocks,

Wea r St rips.

TRACK

Drums, End Idler, Flashings, Pins and Bushings, Pivot Rings, Plastic Wear Strips, Rooter Bands, Scraper Knives, Sprockets, Teeth,

Track Chain, Track Rollers, Trench Cleaner (Crumber), Trip Cleaners, Truck Rollers, Wear Plates.

TRENCHLESS: Brushes, Clamping Vise Parts, Dies, Drive Chuck, Earth Stakes, Fan Belts, Jaws, Leaf Chain, Lights On Light

Kits, Packing Assemblies, Rod, Rod Loader Parts, Rollers, Tooling, Track Chain, Track Guides, Track Idlers, Track Pads, Track

Sprockets, Valve Seats, Wear Bars, Wear Blocks, Water Hoses, Water Swivels, Wear Bars.

UTILITY PRODUCTS

Rollers, Flashings, Pins, Pivot Rings, Plow Blades, Rubber Shielding, Sprockets, Teeth, Tires, Track Chain, Track Idlers, Track

Sprockets, Trench Cleaner (Crumber).

PARTS WARRANTY:

Parts replaced in the warranty period will receive the balance of the first year New Industrial Equipment Limited Warranty, during

the first (12) months or 1000 hours, whichever comes first. Replacement parts after the original machine warranty, are warranted to

be free from defects of material for ninety (90) days or the part will be repaired or replaced, without labor coverage for removal and

reinstallation.

Introduction S650TX Mini Skid Steer

: Base Plates, Boom Wear Items, Buckets, Cable Fingers, Conveyor Belts, Clutches, Cups, Digging Chain, Digging Rims,

: Bearing Seals, Bearings, Belts, Brake Pads, Bolts/Torqued Parts, Chain, Clutches, Clutch Components,

: Augers, Belts, Bearings, Booms, Brake Pads, Bucket, Bushings, Chains, Clutches, Conveyor Belts, End

EXCLUSIONS OF WARRANTIES

HEREIN, VERMEER MAKES NO OTHER WARRANTIES, AND ANY POSSIBLE LIABILITY OF VERMEER

HEREINUNDER IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED, OR STATUTORY, INCLUDING, BUT

NOT LIMITED TO, ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

VERMEER RESERVES THE RIGHT TO MODIFY, ALTER AND IMPROVE ANY PRODUCT WITHOUT INCURRING ANY

OBLIGATION TO REPLACE ANY PRODUCT PREVIOUSLY SOLD WITH SUCH MODIFICATION. NO PERSON IS

AUTHORIZED TO GIVE ANY OTHER WARRANTY, OR TO ASSUME ANY ADDITIONAL OBLIGATION ON VERMEER’S

BEHALF.

NO DEALER WARRANTY

representation or promise on behalf of Vermeer or to modify the terms or limitations of this warranty in any way.

. The selling dealer makes no warranty of its own and the dealer has no authority to make any

: EXCEPT FOR THE WARRANTIES EXPRESSLY AND SPECIFICALLY MADE

MANUFACTURED BY:

VERMEER CORPORATION

Pella, Iowa 50219 USA

S650TX Mini Skid Steer Introduction

VERMEER EQUIPMENT LIMITED WARRANTY RIDER COMPACT SKID STEER FRAME AND LOADER ARMS

3,000-Hour / 3-Year*

(Parts only coverage during extended term)

Vermeer Corporation (hereinafter “Vermeer”) agrees to extend only the parts coverage of the applicable Vermeer Industrial New

Equipment Limited Warranty (the “Standard Limited Warranty”) for the Covered Components of the Specified Models of New

Vermeer Industrial Equipment for the Extended Term, provided that the Equipment is operated and maintained in accordance with

the directions and instructions set forth in the Operator's and Maintenance Manual(s). All conditions, exclusions and limitations of

the Standard Limited Warranty apply.

Specified Models: S600, S600TX, S650TX

Covered Equipment: Tractor main frame and boom loader arms.

Non-Covered Components: Greaseable pins, mounting plates and wear items (as specified on the Vermeer New

Industrial Equipment Limited Warranty).

Extended Term*: Three (3) full years from original retail sale date of the Equipment or 3,000 hours of

machine operation, whichever occurs first. This warranty is extended to the original

purchaser and subsequent owners.

EXCEPT FOR THE STANDARD LIMITED WARRANTY AND THIS RIDER, VERMEER MAKES NO OTHER

WARRANTIES, AND ANY POSSIBLE LIABILITY OF VERMEER HEREUNDER IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS, IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTIES OF

MERCHANTABLILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Introduction S650TX Mini Skid Steer

Receiving and Delivery Report

DEALER PREP

Check or perform the following:

___ Check that all optional and loose items are included with the machine.

___ Check that Operator’s Manual is cabled to machine.

___ Check air cleaner condition.

___ Check engine oil level.

___ Check engine operation.

___ Check machine lubrication.

___ Check bolts for tightness.

___ Check shield installation and condition.

___ Check that auxiliary attachment drive neutral start interlock functions.

___ Check that Ground Drive Joystick and Tilt/Lift Joystick spring-return to NEUTRAL.

___ Check that Operator Presence system functions.

___ Check that machine does not move when controls are in NEUTRAL and the engine is running at full

throttle (operator standing on foot platform).

___ Check that attachment does not tilt with key in OFF position and tilt lever pushed.

___ Check that loader arms do not lower with key in OFF position and lift lever pushed.

___ Check forward and reverse ground drive operation.

___ Check that park brake functions.

___ Check track tension.

___ Check condition of all safety signs and decals.

___ Check all phases of operation.

S650TX Mini Skid Steer Receiving and Delivery Report i

Hydraulics

___ Check hydraulic fluid level.

___ Check hydraulic components for leaks or damage.

___ Check hydraulic controls for proper function.

Attachments

___ Check that Operator’s Manuals supplied by the attachment manufacturer are in the S650TX manual

storage box or in the storage box located on the attachment. Bucket attachment instructions are contained

in this S650

information on attachments authorized for use by Vermeer Corporation.

TX Operator’s Manual. Contact your authorized Vermeer dealer, or visit www.vermeer.com for

DELIVERY

Check and perform the following with the customer:

___ Review all sections of the Operator’s Manual.

___ Grease or oil all lubrication points.

Review of Operation

Review and demonstrate with the customer the various aspects of machine operation:

___ overall explanation of how the machine works

___ machine safety

___ preparing the machine for operation

___ operating the machine

ii Receiving and Delivery Report S650TX Mini Skid Steer

DEALER/CUSTOMER INFORMATION

Dealer Owner

Address Address

City City

State/Province State/Province

Zip/Postal Code Zip/Postal Code

Country Country

S650TX Mini Skid Steer Receiving and Delivery Report iii

IDENTIFICATION NUMBERS - RECORD

Machine Model Number ________________

Machine Serial Number ________________

Engine Model Number ________________

Engine Serial Number ________________

iv Receiving and Delivery Report S650TX Mini Skid Steer

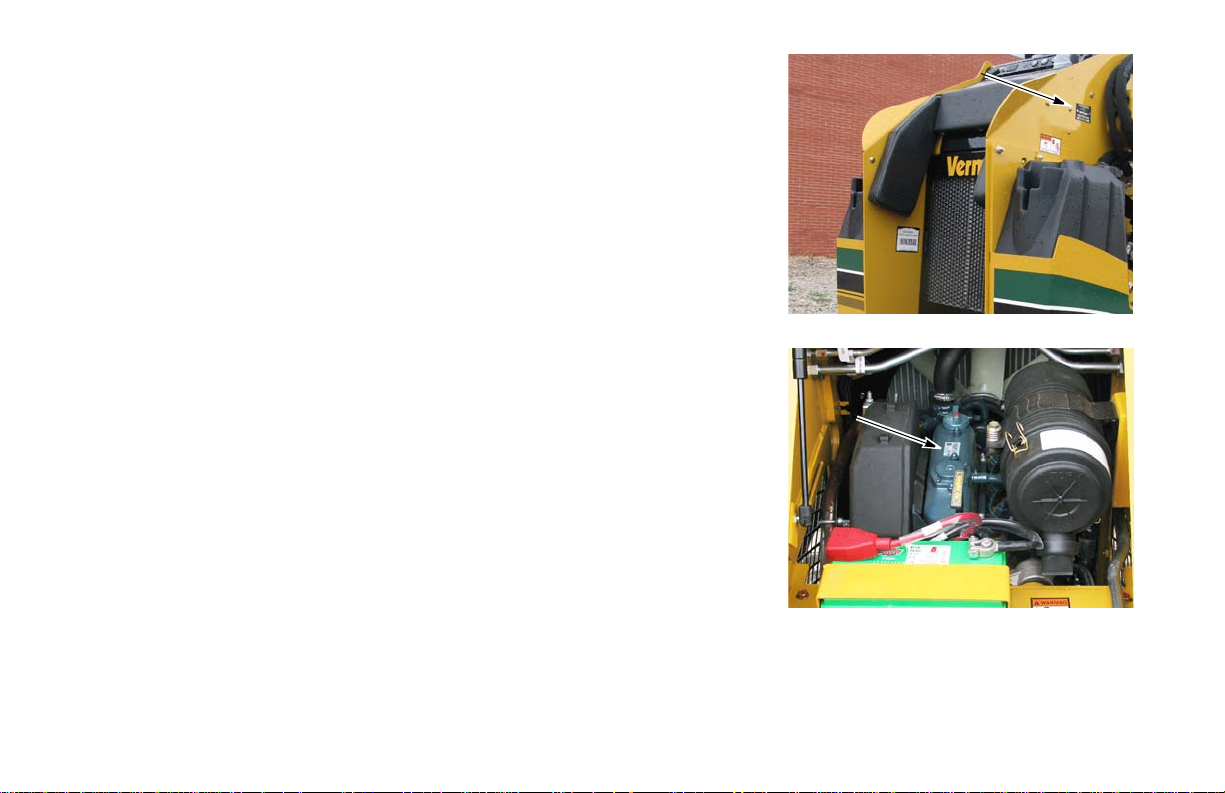

IDENTIFICATION DECALS

These decals provide easy identification of the model and 17-digit identification number for the machine and attachments. The

barcode contains the VIN number and can be scanned with any barcode reading device.

Mini Skid Steer Identification Decal

S650TX Mini Skid Steer Receiving and Delivery Report v

This page intentionally left blank.

Table of Contents

Receiving and Delivery Report . . . . . . . . . . . . . . . . . . . . .i

Dealer Prep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Review of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Dealer/Customer Information. . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Identification Numbers - Record . . . . . . . . . . . . . . . . . . . . . . . . iv

Identification Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Safety Symbol Explanation . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Crystalline Silica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-1

Engine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-1

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-3

Control Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-4

Operator Presence System . . . . . . . . . . . . . . . . . . . . . . . . . .21-7

Park Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-7

Boom Lift/Attachment Tilt Lockout Override . . . . . . . . . . . . .21-7

Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21-8

Starting Procedure . . . . . . . . . . . . . . . . . . . . . . . 22-1

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

Cold Weather Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-2

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-2

Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-2

Jump-Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-2

Battery Explosion - Avoid. . . . . . . . . . . . . . . . . . . . . . . . . 22-3

Battery Burns - Avoid. . . . . . . . . . . . . . . . . . . . . . . . . . . .22-3

Jump-Starting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 22-4

Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . 23-1

Transporting the Machine . . . . . . . . . . . . . . . . . 30-1

Loading/Unloading the Machine . . . . . . . . . . . . . . . . . . . . . . 30-1

Trailer Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1

Trailer Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1

Loading/Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-2

Driving onto Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-3

Driving off Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-5

Loading with Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-6

Towing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-6

Clean Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-8

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-1

Operator Qualifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-1

Personal Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-2

Sound Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-3

S650TX Mini Skid Steer Table of Contents vii

Vibration Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-3

Prepare the Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-4

Locate Buried Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-4

Call Your One-Call System First. . . . . . . . . . . . . . . . . . 40-4

Look for Evidence of Underground Placement. . . . . . . 40-5

Striking a Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-6

Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-6

Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-6

Fiber Optic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-6

Jobsite Assessment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-7

Prepare the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-8

Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-9

Install/Remove. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-9

Attachment - Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-10

Attachment - Remove . . . . . . . . . . . . . . . . . . . . . . . . . . 40-11

Hydraulics - Attach/Detach. . . . . . . . . . . . . . . . . . . . . . . . . 40-12

Hydraulics - Attach . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-13

Hydraulics - Detach. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-13

Operating the Machine . . . . . . . . . . . . . . . . . . . . 50-1

Load Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-1

Driving Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-1

Before Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-1

While Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-2

Safe Operating on Slopes . . . . . . . . . . . . . . . . . . . . . . . . 50-4

Operating the Mini Skid Steer. . . . . . . . . . . . . . . . . . . . . . . . 50-6

Bucket Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-7

Bucket - Install/Remove. . . . . . . . . . . . . . . . . . . . . . . . . . 50-7

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-7

Moving Machine with Load . . . . . . . . . . . . . . . . . . . . . . . 50-8

Filling the Bucket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-9

Digging with the Bucket. . . . . . . . . . . . . . . . . . . . . . . . . . .50-9

Emptying the Bucket. . . . . . . . . . . . . . . . . . . . . . . . . . . .50-10

Backdragging with the Bucket. . . . . . . . . . . . . . . . . . . . .50-10

Backfilling with the Bucket. . . . . . . . . . . . . . . . . . . . . . . .50-11

Operating with Other Vermeer-Authorized Attachments . . .50-11

Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . 60-1

Safety Signs Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .60-1

Maintenance Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-2

Hourmeter - Check for Maintenance Interval. . . . . . . . . . . . .60-2

Machine - Grease. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-2

Recommended Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-2

Engine Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . .60-2

Lift Arm Support Bar - Install/Remove . . . . . . . . . . . . . . . . . .60-3

Shields - Install/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-4

Maintenance Interval Schedule . . . . . . . . . . . . . . . . . . . . . . .60-5

Attachment Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-7

viii Table of Contents S650TX Mini Skid Steer

Section 10: Safety Messages

General safety messages appear in this Safety Messages section. Specific safety messages are located in

appropriate sections of the manual where a potential hazard may occur if the instructions or procedures are not

followed. Messages that are specific to an attachment will be found in the attachment manual.

A signal word “DANGER”, “WAR NING ”, or “CAUTION” is used with the safety alert symbol.

Safety signs with signal word “DANGER”, “WARNIN G ”, or “CAUTION” are located near specific hazards.

DANGER

WARNING

CAUTION

S650TX Mini Skid Steer Safety Messages 10-1

Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

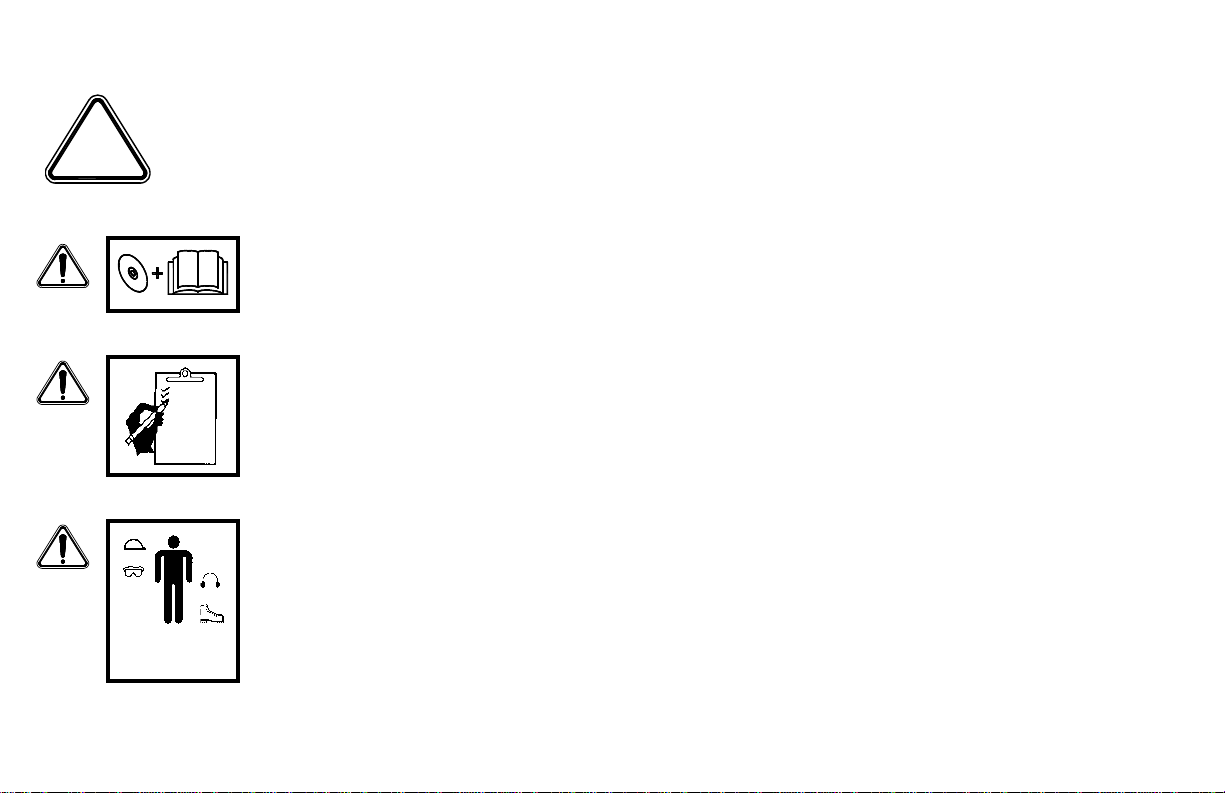

SAFETY SYMBOL EXPLANATION

This is the safety alert symbol. This symbol is used in combination with an exclamation mark or other

symbols to alert you to the potential for bodily injury or death.

WAR N I N G: Read Operator’s Manual and safety signs, and watch the operations and safety

video, before operating machine.

WARNING: Check machine before operating. Machine must be in good operating condition

and all safety equipment installed and functioning properly.

WARNING: Wear personal protective equipment. Wear close-fitting clothing and confine long

hair. Avoid wearing jewelry such as rings, wristwatches, necklaces or bracelets. Always wear:

• a hard hat

• safety glasses

• hearing protection

• safety shoes

Refer to “Personal Protection,” page 40-2.

10-2 Safety Messages S650TX Mini Skid Steer

WARNING: Keep spectators away.

WARNING: Engine exhaust can asphyxiate. Operate only outdoors.

WARNING: Use Shutdown Procedure before servicing, cleaning, repairing, or transporting

machine. Follow Shutdown Procedure, page 23-1.

S650TX Mini Skid Steer Safety Messages 10-3

WARNING: Pressurized fluid can penetrate body tissue and result in serious injury or death.

Leaks can be invisible. Keep away from any suspected leak. Relieve pressure in the hydraulic

system before searching for leaks, disconnecting hoses, or performing any work on the system. If

you must pressurize the system to find a suspected leak, use an object such as a piece of wood or

cardboard rather than your hands. When loosening a fitting where some residual pressure may

exist, slowly loosen the fitting until oil begins to leak. Wait for leaking to stop before

disconnecting the fitting. Fluid injected under the skin must be removed immediately by a

surgeon familiar with this type of injury.

WAR N I N G: Fuel and fumes can explode and burn.

Shut off engine before refueling. No flame. No smoking.

10-4 Safety Messages S650TX Mini Skid Steer

WARNING: Moving parts can crush. Keep hands, feet, and clothing away from power-driven

parts. Keep shields in place and properly secured.

WAR N I N G: Hot fluid under pressure can scald.

Allow engine to cool before opening radiator cap.

S650TX Mini Skid Steer Safety Messages 10-5

CRYSTALLINE SILICA

WARNING: Silica dust can cause illness.

Breathing crystalline silica dust over time can cause silicosis, a disabling, nonreversible and sometimes fatal

disease of the lungs. United States Federal O.S.H.A. has established exposure limits for the jobsite. Avoid

exposure to dust containing crystalline silica particles in excess of these limits.

Because crystalline silica is a basic component of sand and granite, many activities at construction sites such as

trenching, sawing, and boring of material, produce dust containing crystalline silica. When working in soils

containing sand or granite, air monitoring may be necessary to determine whether jobsite conditions expose

workers to excessive levels of crystalline silica dust. Depending upon air monitoring results, the following

measures may be necessary to avoid exposure to excessive levels of crystalline silica dust:

• Be aware of and follow the guidelines of United States O.S.H.A. 29CFR1926.55, or other applicable

regulatory guidelines.

• Reduce dust concentration using water spray or other methods.

• Use a respirator approved for protection from crystalline silica dust.

• If possible, change into disposable or washable work clothes on the jobsite. Shower and change into clean

clothing before leaving the jobsite.

• Do not eat, drink, use tobacco products, or apply cosmetics in areas where there is dust containing

crystalline silica dust. Wash hands before eating, drinking, or using these products.

• Store food, drink, and personal belongings away from the work area.

10-6 Safety Messages S650TX Mini Skid Steer

WARNING: Failure to follow any of the preceding safety instructions or those that follow within

this manual, could result in serious injury or death. This machine is to be used only for those

purposes for which it was intended as explained in this Operator’s Manual.

S650TX Mini Skid Steer Safety Messages 10-7

This page intentionally left blank.

Section 20: Intended Use

The S650TX Mini Skid Steer can be equipped with a variety of attachments for light and medium duty work.

This machine is designed for short runs and operation in confined areas. The stand-up operating station

provides excellent jobsite visibility and ease of platform access. Contact your Vermeer dealer, or visit

www.vermeer.com, for information on the list of authorized attachments. The S650

attachments which have not been evaluated by Vermeer Corporation and authorized for use.

WARNING: Using attachments authorized by Vermeer Corporation is important for your safety.

Using unauthorized attachments may cause difficulties with steering, stopping, stability and other

undesirable performance or handling characteristics. Never use unauthorized attachments.

Always use this machine in accordance with the instructions contained in this manual and the attachment

manuals supplied with the attachments; safety signs on the machine and attachments, and other materials

provided by Vermeer Corporation and the attachment manufacturers.

Proper maintenance and repair is essential for safety, and efficient machine operation. Do not use the machine if

it is not in suitable operating condition.

In addition, ensure new operator is familiar with all the safety signs and control operations.

TX must not be used with

S650TX Mini Skid Steer Intended Use 20-1

This page intentionally left blank.

Section 21: Controls

1

2

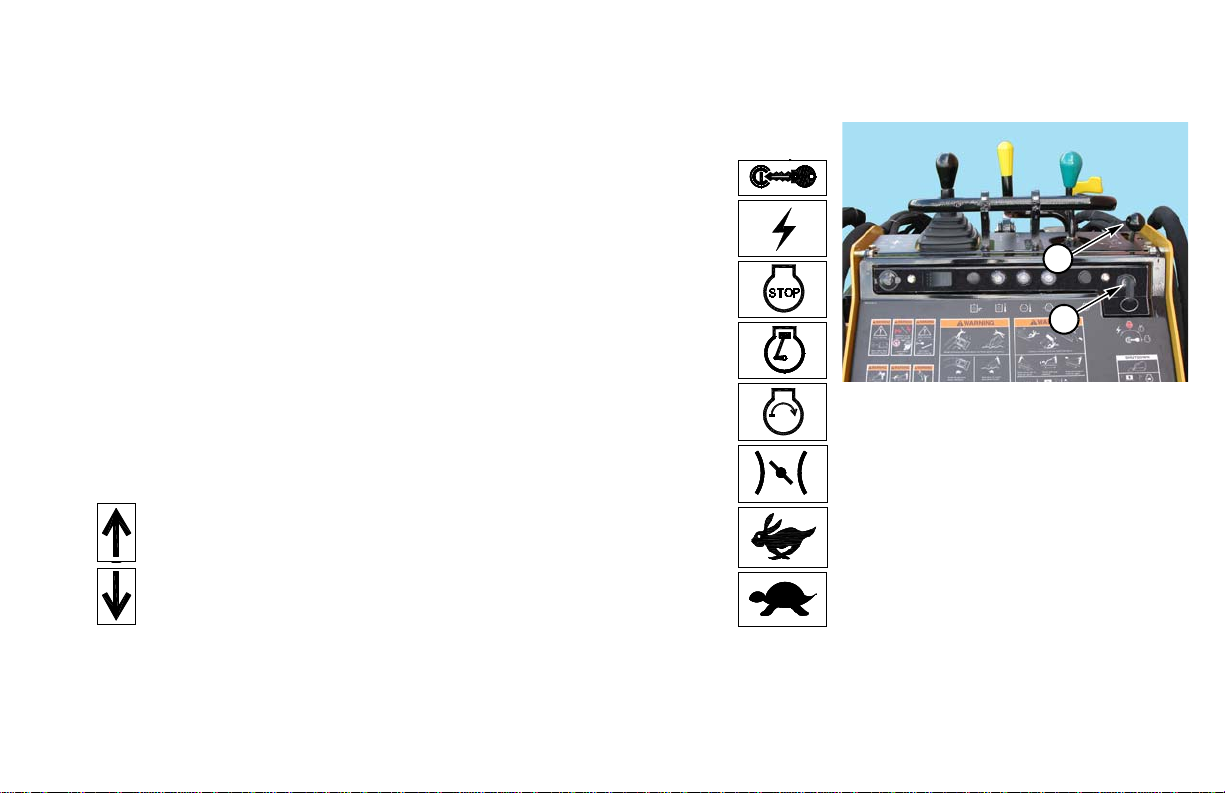

ENGINE CONTROLS

(1) Ignition Switch

Counterclockwise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . accessories

Low engine oil pressure light also comes on in accessories position.

Vertical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . engine STOP

1st position clockwise . . . . . . . . . . . . . . . . . . . . . . . . . . .engine RUN

Electrical system on

2nd position clockwise . . . . . . . . . . . . . . . . . . . . . . . . . engine START

Returns to RUN when released

(2) Throttle Lever

Push forward . . . . . . . . . . . . . . . . . . . . . . . . . . increase engine speed

Pull back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .decrease engine speed

S650TX Mini Skid Steer Controls 21-1

Loading...

Loading...