Verlinde TVI Series Instruction Manual

VERLINDE reserve the right to alter or amend the above information without notice

07/2016

ANGLAIS

INSTRUCTION MANUAL

ELECTRIC WINCH TVI SERIE

Product Distributed in Ireland by:

601, Western Industrial Estate,

Dublin 12, Ireland T: + 353 (

0)1

4584836 E: sales@prolift.ie

www.prolift.ie

2/30

03/2016

To ensure the constant improvement of its products, VERLINDE reserves the right to change the equipment as

described below and, in this case, to supply products which differ from the illustrations in this instruction manual.

All rights reserved

Summary

1 - Contents .................................................................................................................................................. 2

2 - What not to do ......................................................................................................................................... 3

3 - Compulsory regulatory inspections by the user ...................................................................................... 3

4 - Introduction to the machines ................................................................................................................... 4

5 - Handling - Storage .................................................................................................................................. 7

6 - Installation and start-up ........................................................................................................................... 7

7 - Servicing and maintenance ..................................................................................................................... 14

8 - Decommissioning .................................................................................................................................... 15

9 - Spare parts .............................................................................................................................................. 15

10 - Troubleshooting ....................................................................................................................................... 16

11 - Declaration of conformity ......................................................................................................................... 17

12 - Appendixes .............................................................................................................................................. 18

1 – Contents

All users are asked to read the start-up instructions carefully before using the winch for the first time. These

instructions will help the user to become familiar with the winch and to use it to the best of its capabilities. The

start-up instructions contain important information on how to use the winch in a safe and correct manner.

Observing these instructions can help prevent risks, minimize repair costs, reduce down time and increase the

reliability and useful life of the winch. The instruction manual must always be available at the winch operation

location. In addition to the start-up instructions and the regulations relating to accident prevention, it is important

to consider current rules in terms of TVIl safety and professional standards in force in each country.

This machine is covered by European regulations and, more specifically, machinery directive

2006/42/CE, EMC directive 2004/108/EC and low-voltage directive 2006/95/EC, as well as standard EN

14492/1.

The TVI Series winches can be used to perform lifting and pulling operations.

When used for lifting, European regulations require the use of certain equipment, including a limit stop and a

load limiter (above 1000 kg).

The user must make sure that this equipment is in place (optionally available from the manufacturer) before

undertaking any lifting operation.

Please ensure that the operator is qualified to operate the winch under the conditions laid down in this

manual. This is to respect the safety of workers and the environment.

The capacity indicated on the winch corresponds to the maximum operational capacity (M.O.C.), which may

not be exceeded in any case.

This winch may not be used to lift personnel under any circumstances.

Do not lift or carry loads while personnel remains in the danger zone.

Do not authorize personnel to walk under a hanging load.

Never leave a load hanging or under tension without supervision.

Never begin to handle a load without fixing it correctly and making sure that all personnel has left the danger

zone.

Before each use, the operator must check that the machine, its ropes, its hook, its markings and its restraints

are in good condition.

3/30

03/2016

The operator must make sure the load is hooked so that the winch, the rope and the load do not pose any

risk for him or other personnel.

The winches can be handled within a range of ambient temperatures between -10° C and +50° C. Please

consult the manufacturer in the case of extreme operating conditions.

Warning: When the ambient temperature is less than 0°C, the brake must be tested in order to make sure it

has no operating faults caused by frost.

All uses of the winches must strictly conform to accident prevention and safety measures for the country

where they are being used.

The manufacturer accepts no responsibility for the consequences of the machines being used or installed in

ways other than described in the manual, or for the consequences of altering or replacing original parts or

components with parts or components from other sources without its written agreement.

YOU ARE ALSO REQUIRED TO OBSERVE THE APPLICABLE RECOMMENDATIONS IN YOUR

COUNTRY.

2 - What not to do

Before using the winch, make sure there is no risk of overloading due to adherence to the floor, suction,

jamming, etc. of the load. In addition to the above, avoid all the incorrect uses and operations indicated

below. It is dangerous and prohibited to:

unwind the drum completely (always leave 2 to 3 coils).

pull at an angle.

swing the load.

use ropes with a diameter and texture that do not comply with the specifications of this manual (FEM 1 Am –

ISO M4)

use damaged or spliced ropes.

use hooks without catches, not suitable for the loads specified on the winch, or in bad condition.

insert objects into the moving parts.

service winches while they are loaded or receiving power.

use the rope of the machine as a sling.

tap on the control box (heating the motor and the electrical controls).

3 – Compulsory regulatory inspections by the user

This equipment has been designed to be subjected to the following tests:

Dynamic proof test at coefficient 1.1

Static proof test at coefficient 1.25

Users are required to conform to the regulations in force in their own countries.

In the case of France:

Order of 1 March 2004 on the testing of lifting machines and accessories:

The amendments to the regulations regarding the use and testing of lifting machines and accessories, in force

since 1 April 2005, impose new obligations on all users:

Adaptation exam, which consists of checking that the lifting machine is suitable for the work the user intends

to carry out as well as for the risks to which the workers are exposed and that the planned operations are

compatible with the conditions for using the machine as defined by the manufacturer.

Assembly and installation exam, which consists of making sure that the lifting machine is assembled and

installed in a safe manner, in accordance with the manufacturer's instruction manual.

4/30

03/2016

Periodic general inspections, including an exam of the state of conservation and operating tests.

Tests for starting or restarting service in the event of changing the operation site, changing the configuration

or the conditions for use on the same site, following dismantlement and reassembly of the lifting machine,

after any considerable replacement, repair or transformation affecting the core components of the lifting

machine, following any accident caused by a failure in a core component of the lifting machine.

The tests must be performed in strict observance of protocol. They aim to provide preventive maintenance,

detecting any damage or faults that can create a risk.

VERLINDE provides an upkeep / maintenance manual for each piece of equipment. It is very important to make

sure that the individuals using the hoist are familiar with the equipment and its correct operation.

VERLINDE agencies are available and may, upon request or by contract, intervene and maintain the winch if

necessary.

If any replacement parts are needed, please specify the following information so that we may supply the

appropriate parts:

- the complete name of the winch

- the complete name of the hoisting motor if necessary

- the serial number of the winch

The 3 items above are listed on the ID plates attached to the winch, motors and on the inspection certificates.

For further information, please contact the winch manufacturer or the distributor.

Manufactured by :

Manufactured by:VERLINDE

VERNOUILLET- FRANCE

2, Boulevard de l'industrie

B.P. 59 28501 VERNOUILLET CEDEX

Phone: +33 (0)2.37.38.95.95

Fax: +33 (0)2.37.38.95.99

4 – Introduction to the machines

4.1 - General

These winches are designed for pulling or lifting loads from 1000 to 10000 kg.

Their FEM classification is 1 Am (ISO: M4)

The TVI Series winches are equipped with the following:

Reduction gear with planetary gears, completely watertight.

Motor 1 speed, three-phase 230/400 V 50 Hz, protection rating IP 55. Operating limits from -10ºC to

+50ºC (without declassification).

24 V very-low voltage control including:

Contactors

Power line isolator

Thermal circuit breaker

Disconnectable button box (2 buttons + emergency stop), 3 m of cable.

5/30

03/2016

Very-low voltage control with variable speed drive (compulsory above 5 tons), comprising:

Power line isolator

Variable-frequency drive

Braking resistance

Button box (2 buttons + emergency stop + potentiometer), not disconnectable, 3 m of cable.

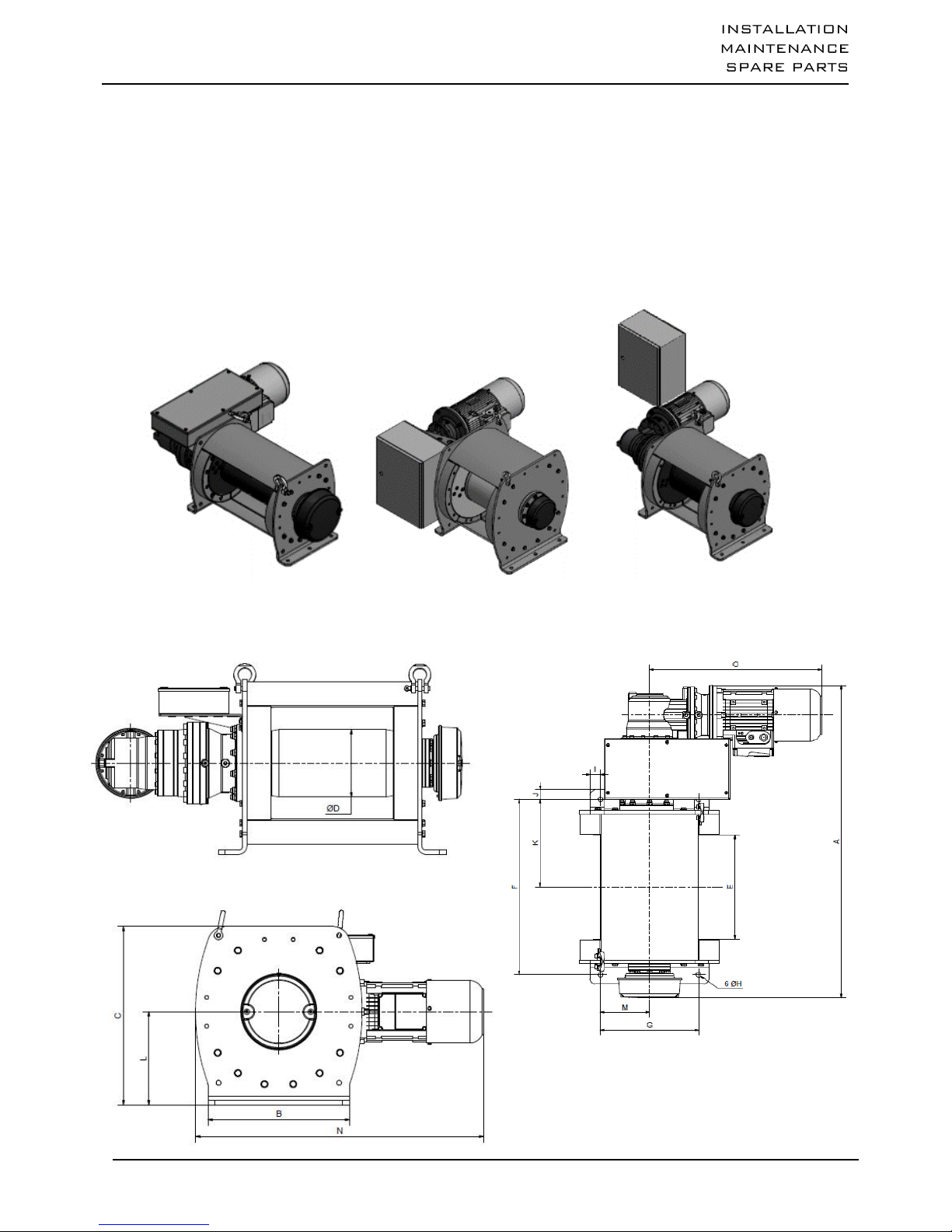

4.2 - Dimensions

Depending on models :

Above the motor (1) on its side (2) or away (3)

6/30

03/2016

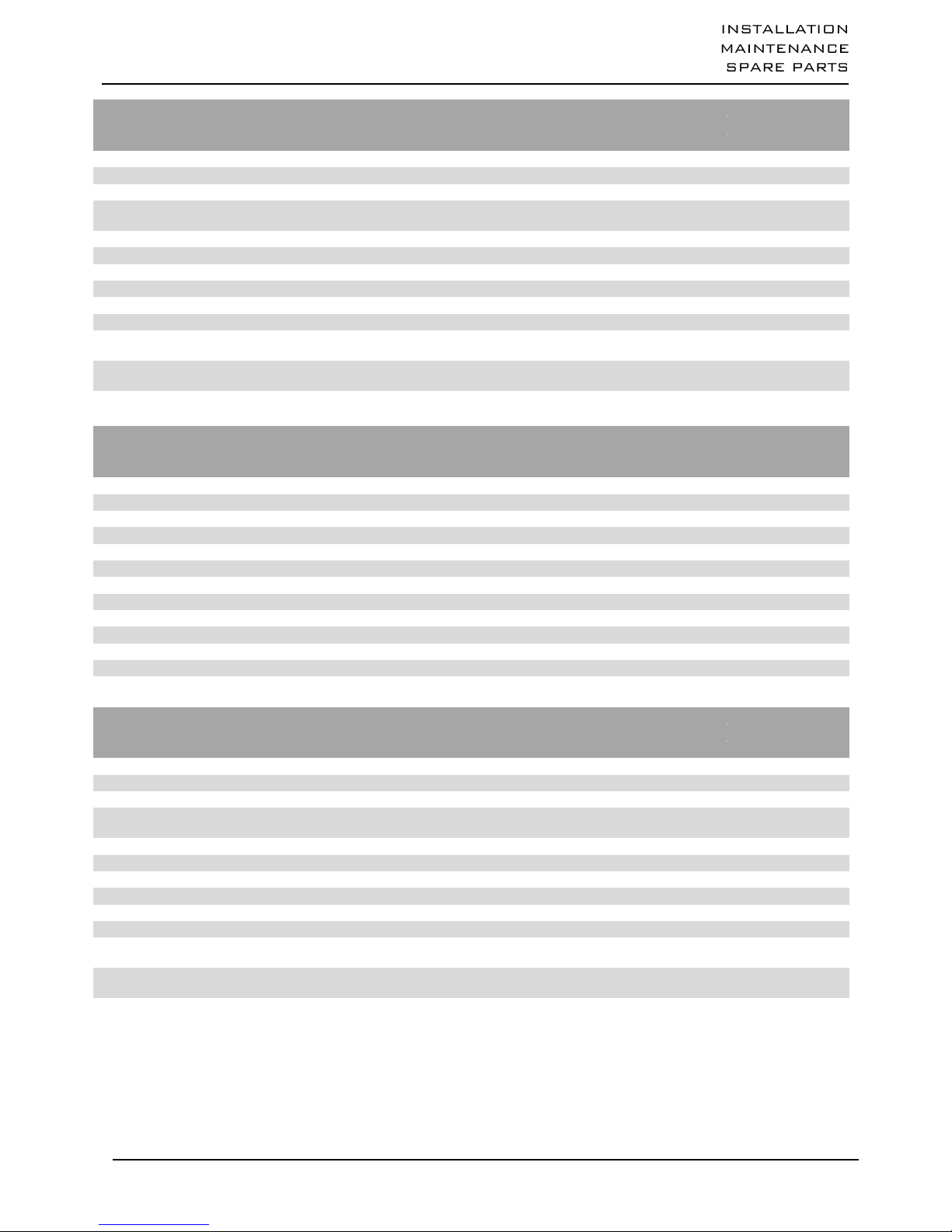

a. Low voltage control – Models with 1 speed

b. Low voltage control – Models with frequency inverter

4.3 - Models available

Warning: . the rope diameter shown above corresponds to the recommended rope according to FEM 1 Am /

ISO M4 classification. It also corresponds to the capacity on the last layer.

. it is compulsory to ensure that the resistance coefficient of the rope complies with the lifted load

(FEM 1 Am / ISO M4).

TVI

1 T

2 T

3 T

4 T

5 T

6 T

7 T

8 T

9 T

10 T

05BT/10BT

05BT/09BT

03BT/06BT

02BT/05BT

03BT/07BT

02BT/06BT

02BT/06BT

02BT/05BT

02BT/05BT

03BT/05BT

Position of the electrical unit

(1)

(1)

(1)

(1)

(1) / (2)

(1) / (3)

(1) / (2)

(1) / (2)

(1) / (2)

(1) / (2)

A in mm

911

1050/1045

1065/1090

1169/1194

1194/1220

1224/1250

1241/1267

1241/1267

1288/1087

1314/1288

B in mm

290

420

420

520

520

650

700

700

840

840

C in mm

375

500

500

665

665

765

870

870

975

975

D in mm

125

219,1

219,1

292

292

323,9

355,6

355,6

406,4

406,4

E in mm

350

350

350

350

350

350

350

350

350

350

F in mm

525

590

590

600

600

600

720

720

720

720

G in mm

240

330

330

420

420

420

620

620

750

750

H en mm

12

16

16

22

22

22

30

30

32

32

I in mm

25

45

45

50

50

115

40

40

45

45

J in mm

23

32

32

30

30

30

50

50

47

47

K in mm

263

295

295

300

300

300

360

360

360

360

L in mm

188

262

262

350

350

395

455

455

515

515

M in mm

120

165

165

210

210

210

310

310

375

375

N in mm

716/748

823/902

823/902

905/984

954/1190

1013/1181

1103/1271

1133/1271

1176/1314

1176/1314

0 in mm

548/578

578/657

578/657

578/657

627/795

627/795

662/830

692/830

692/830

692/830

TVI

1 T

2 T

3 T

4 T

5 T

6 T

7 T

8 T

9 T

10 T

05VV/10VV

05VV/09VV

03VV/06VV

02VV/05VV

03VV/07VV

02VV/06VV

02VV/06VV

02VV/05VV

02VV/05VV

03VV/05VV

Position of the

electrical unit

(1)

(1) / (3)

(1) / (3)

(1) / (2)

(2) / (3)

(2)

(2)

(2)

(2)

(2)

A in mm

911

1050/1045

1065/1090

1169/1194

1194/1220

1224/1250

1241/1267

1241/1340

1288/1087

1288/1367

B in mm

290

420

420

520

520

650

700

700

840

840

C in mm

375

579/500

579/500

737/665

665

765

870

870

975

975

D in mm

125

219,1

219,1

292

292

323,9

355,6

355,6

406,4

406,4

E in mm

350

350

350

350

350

350

350

350

350

350

F in mm

525

590

590

600

600

600

720

720

720

720

G in mm

240

330

330

420

420

420

620

620

750

750

H en mm

12

16

16

22

22

22

30

30

32

32

I in mm

25

45

45

50

50

115

40

40

45

45

J in mm

23

32

32

30

30

30

50

50

47

47

K in mm

263

295

295

300

300

300

360

360

360

360

L in mm

188

262

262

350

350

395

455

455

515

515

M in mm

120

165

165

210

210

210

310

310

375

375

N in mm

716/748

823/902

823/902

905/1052

1022/1122

1067/1220

1103/1271

1133/1271

1176/1314

1176/1314

0 in mm

548/578

578/657

578/657

578/657

627/795

627/795

662/830

692/830

692/830

692/830

7/30

03/2016

TVI

Low voltage control – Models with 1 speed

1 T 2 T 3 T 4 T 5 T

05BT

10BT 05BT

09BT 03BT

06BT 02BT

05BT 03BT

07BT

Capacity on the 1rst layer kg

1255 2420 3765 4985 6230

Capacity on the last layer (kg)

1000 2000 3000 4000 5000

Nb of layers

3 3 3 3 3

Wire rope capacity at 1rst layer

m *

17 20 16 16 16

Max. rope capacity (m)

60 71 59 60 60

Rope diameter (mm)

8 11,5 14 18 18

Speed on the 1rst layer m/min

4

8,5 4,5

8 2,5

4,5 2

3,5 2,5

6

Speed on the last layer (m/min)

5

10,5 5,5

9,5 3,5

5,5 2,5

4,5 3

7,5

FEM

1Am 1Am 1Am 1Am 1Am

Motor (kW)

1,1

2,2 2,2

4 2,2 4

2,2

4 3

9,2

Supply

3 Ph - 230/400

V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

Weight (winch without wire

rope) kg

140

150 260

280 260

280 440

470 450

530

TVI

Low voltage control – Models with 1 speed

6 T 7 T 8 T 9 T 10 T

02BT

06BT 02BT

06BT 02BT

05BT 02BT

05BT 03BT

05BT

Capacity on the 1rst layer kg

7480 8725 9975 11120

12355

Capacity on the last layer (kg)

6000 7000 8000 9000

10000

Nb of layers

3 3 3 3 3

Wire rope capacity at 1rst layer m *

16 15 15 16 16

Max. rope capacity (m)

60 60 60 62 62

Rope diameter (mm)

20 22 22 24 24

Speed on the 1rst layer m/min

1,5

5 1,5

4,5 2

4 1,5

4 2

3,5

Speed on the last layer (m/min)

2

6 2

5,5 2,5

5 2

4,5 2,5

4,5

FEM

1Am 1Am 1Am 1Am 1Am

Motor (kW)

3

9,2 3

9,2 4

9,2 4

9,2 5,5

9,2

Supply

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

Weight (winch without wire rope) kg

580

660 840

910 850

910 1160

1230 1180

1230

TVI

Low voltage control – Models with frequency inverter

1 T 2 T 3 T 4 T 5 T

05VV

10VV 05VV

09VV 03VV

06VV 02VV

05VV 03VV

07VV

Capacity on the 1rst layer kg

1255 2420 3765 4985 6230

Capacity on the last layer (kg)

1000 2000 3000 4000 5000

Nb of layers

3 3 3 3 3

Wire rope capacity at 1rst layer

m *

17 20 16 16 16

Max. rope capacity (m)

60 71 59 60 60

Rope diameter (mm)

8 11,5 14 18 18

Speed on the 1rst layer m/min

4

8,5 4,5

8 2,5

4,5 2

3,5 2,5

6

Speed on the last layer (m/min)

5

10,5 5,5

9,5 3,5

5,5 2,5

4,5 3

7,5

FEM

1Am 1Am 1Am 1Am 1Am

Motor (kW)

1,1

2,2 2,2

4 2,2 4

2,2

4 3

9,2

Supply

3 Ph - 230/400

V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

Weight (winch without wire

rope) kg

150

155 270

300 270

300 450

500 480

540

8/30

03/2016

TVI

Low voltage control – Models with frequency inverter

6 T 7 T 8 T 9 T 10 T

02VV

06VV 02VV

06VV 02VV

05VV 02VV

05VV 03VV

05VV

Capacity on the 1rst layer kg

7480 8725 9975 11120

12355

Capacity on the last layer (kg)

6000 7000 8000 9000

10000

Nb of layers

3 3 3 3 3

Wire rope capacity at 1rst layer m *

16 15 15 16 16

Max. rope capacity (m)

60 60 60 62 62

Rope diameter (mm)

20 22 22 24 24

Speed on the 1rst layer m/min

1,5

5 1,5

4,5 2

4 1,5

4 2

3,5

Speed on the last layer (m/min)

2

6 2

5,5 2,5

5 2

4,5 2,5

4,5

FEM

1Am 1Am 1Am 1Am

1Am

Motor (kW)

3

9,2 3

9,2 4

9,2 4

9,2 5,5

9,2

Supply

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph - 230/400 V

3 Ph -

230/400 V

Weight (winch without wire rope) kg

610

670 870

920 880

920 1190

1250

1210

1250

* Rope and hook extra.

The diameter of the wire rope corresponds to the capacity on the last layer

4.4 - Options

The TVI Series winches can be supplied with the following options:

Clock-type limit switch

Easily adjustable, this system guarantees safety by setting top and bottom limits.

IP 65 limit switch

Electronic load limiter

Device with display which stops the winch in the event of an overload without breaking the kinematic chain.

Slotted drum

Enables correct winding of the rope on the first layer.

Secondary brake

Emergency trouble shooting hand wheel

Multi rope grooved drum

Lower chassis

Tarpauline cover

Special paint (C4, C5M)

Rope presser roller

Essential complement for the slotted drum if the rope is not permanently tight.

Manual unblocking of the brake with automatic return

Manual control

Handwheel or crank associated with a brake unblocking system.

Rope-slack switch

Detects rope that is not under tension.

2

nd

rope attachment

Option for creating a back-and-forth system or for lifting a load at two points.

Timer

Allows the user to add up the total time of winch operation and makes it easier to use the maintenance log.

Phase order detector

Allows the winch not to be connected with raising / lowering inversion.

Hauling radio control

Adjustable speed drive hauling radio control

Lifting radio control

Proportional adjustable speed drive lifting radio control

Any other requirements : consult us.

9/30

03/2016

4.5 - Classification FEM

There are eight groups of mechanisms:

FEM

1 Dm

1 Cm

1 Bm

1 Am

2m

3m

4m

5m

ISO

M 1

M 2

M 3

M 4

M 5

M 6

M 7

M 8

To determine the group of a given lifting device, winch or hoist, three essential parameters must be

considered:

4.5.1. - Maximum load to be lifted

Including the weight of the rope and any lifting accessories used (hook, etc.) unless these have a total

weight equal to or less than 5% of the load to be lifted.

4.5.2. - Strain condition

Specifies the proportions in which the lifting machine is used with maximum load or reduced load. Four

characterized strain conditions are identified in this way:

Light

Lifting machines exceptionally subjected to the maximum

strain and commonly to very light strains.

k ≤ 0.5

Medium

Lifting machines often subjected to the maximum strain

and commonly to light strains.

0.5 < k ≤ 0.63

Heavy

Lifting machines frequently subjected to the maximum

strain and commonly to medium strains.

0.63 < k ≤ 0.8

Very

heavy

Lifting machines regularly subjected to the strains near to

the maximum strain.

0.8 < k ≤ 1

4.5.3. – FEM classification

Strain

condition

Average operating time per day, in hours

30’

1 h

2 h

4 h

8 h

16 h

More than

16 h

Light

1 Dm

1 Cm

1 Bm

1 Am

2m

3m

4m

Medium

1 Cm

1 Bm

1 Am

2m

3m

4m

5m

Heavy

1 Bm

1 Am

2m

3m

4m

5m

Very heavy

1 Am

2m

3m

4m

5m

5 – Handling - Storage

When handling the winch, use slings that are compatible with the slinging points provided for this purpose on

the winch.

Warning: the angle formed between the hook and the two slinging points must be at most 45º.

Lift and set down the winch with care, without letting it fall, bearing in mind the offset centre of gravity.

For further information on the weight of the winch, consult the Technical Specifications chapter.

These winches must be protected from the elements, in a dry and clean location, at temperatures comprised

between -10ºC and +50ºC.

Loading...

Loading...