Verlinde STAGEMAKER ECO LCxSRA SERIES, STAGEMAKER ECO LC8SRA, STAGEMAKER ECO LC4SRA Owner's Manual

VERLINDE se réserve le droit de modifier sans préavis les caractéristiques de son matériel

VERLINDE reserves the right to alter or amend specifications of its products without notice

01/2017 VESEGBLCXSRA01A

OWNER’S MANUAL

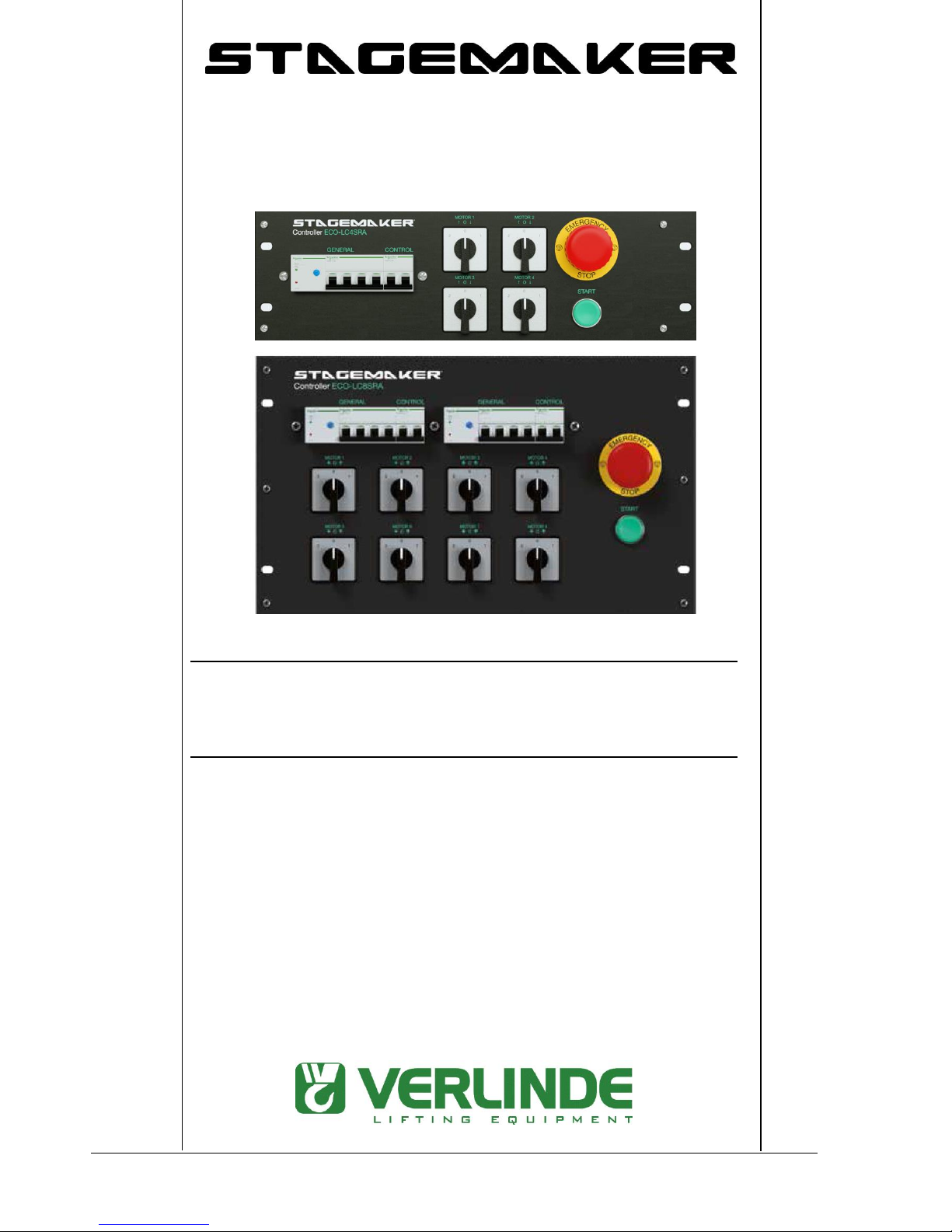

ECO LCxSRA CONTROLLERS

OWNER’S MANUAL

2/14

VERLINDE se réserve le droit de modifier sans préavis les caractéristiques de son matériel

VERLINDE reserves the right to alter or amend specifications of its products without notice

12/2014 VESEFRSCXSRA01A

TABLE OF CONTENTS

1- INTRODUCTION: Purpose of this guide 4

1.1 Characteristics 4

1.2 Safety instructions 5

1.3 Waranty 7

1.4 CE 8

2 - GENERAL PRESENTATION OF THE SYSTEM 9

2.1- General operating conditions 9

2.2 - Routine maintenance and repairs 9

2.3 Preventive maintenance 10

3-BASIC PRINCIPLE OF OPERATION 10

3.1- Light signalling 10

Presence of control voltage Erreur ! Signet non défini.

3.3- Connections Erreur ! Signet non défini.

3.4- Operating the controller 12

Starting up 12

3.5 Operating 12

APPENDICES

Examples of uses

Dimensional data

OWNER’S MANUAL

3/14

VERLINDE se réserve le droit de modifier sans préavis les caractéristiques de son matériel

VERLINDE reserves the right to alter or amend specifications of its products without notice

12/2014 VESEFRSCXSRA01A

GLOSSARY

Objectif de ce document

ES

Emergency stop

PB

Pushbutton

LV

Low voltage

OWNER’S MANUAL

4/14

VERLINDE se réserve le droit de modifier sans préavis les caractéristiques de son matériel

VERLINDE reserves the right to alter or amend specifications of its products without notice

12/2014 VESEFRSCXSRA01A

Purpose of this guide

The purpose of this guide is to accurately describe the operation of the system from the user's point of view.

It firstly sets out the general operation of the system then details the hardware and software.

1- INTRODUCTION

STAGEMAKER® CONTROLLER was specifically developed to control VERLINDE STAGEMAKER® SR

series electric chain hoist. Controllers are available with 4 or 8 channels; they fit into a 19" rack flight case.

For more extensive applications, STAGEMAKER® CONTROLLERs can be interconnected to control systems

integrating 16 motors or even more. The standard system provides for the simultaneous activation of all the

preselected motors by means of the START button. Other interconnections are available on request.

STAGEMAKER® CONTROLLER® fully complies with the most recent European electricity standards (IEC

standards / EMC directive) and is approved by APAVE (French inspection authority). They offer great flexibility,

toughness and safety.

1.1 Characteristics / ECO controller equipment for type A hoists (Direct control):

Max. power per channel: 1.8 kW / 400V 3Phases

Power supply: 400/ 415 V 3PH+N – 50/60Hz.

Power-in plug 32 A 5p CE with phase reversing

Phase monitoring indicating lamp.

Multi 16 connector output for group of motors

And in addition plug CE form 4p 16A out for each motor

Short circuit protections : power & control circuit

Thermal protection per group of 4 motors

- Max. power per channel :1,8 kW / 400v 3 Ph

OWNER’S MANUAL

5/14

VERLINDE se réserve le droit de modifier sans préavis les caractéristiques de son matériel

VERLINDE reserves the right to alter or amend specifications of its products without notice

12/2014 VESEFRSCXSRA01A

1.2 Safety instructions -

THINGS TO DO:

•Place the controller in a protective cover (if a standard protective cover is not provided).

•Manipulate the controller with the handles located at front or on sides.

•Store the controller in its normal working position sheltered from aggressive environments (dust, humidity,

etc).

•Make sure the controller is systematically clean and free from corrosion.

•The installation of the controller must be carried out by a skilled technician.

•Make sure that connecting cables are in good condition and that the connectors are properly installed.

•Make sure connecting cables are always installed symmetrically.

•If the hoist direction does not correspond with Up / Down signals on the controller, check intermediary wiring

and change two phases.

•If none of the hoists correspond with signals, change the phases using the inversion device in the CE plug or

the reversing switch (careful to cut power beforehand).

•Only use authentic spares to replace parts.

•Always be ready to hit the emergency stop button during operations. All functions shall then be disabled.

•Before starting, make sure that the load is properly secured and installed on the hook. The safety latches must

be properly closed.

•Make sure the load is well balanced before moving it.

•Make sure that each hoist is perpendicular with the load and that it hangs freely on its chain before starting

any simultaneous action.

•If the system is used in the open air, use adequate guards against inclement weather.

•Operate the equipment under standard working conditions (ambient temperature, environment, etc.).

•The handling of single items or sets of beams must be entrusted to experienced operators.

•Take all necessary precautions to ensure the load is evenly distributed and avoid overloading any singe hoist

in the case of multiple use. Each hoist must be carefully checked before such use.

•Inform the supervisor of any dangerous functioning or of one which is not reassuring.

(Abnormal noise, abnormal behaviour, etc.).

Equipment used in the open air must be protected as much as possible from inclement weather.

Loading...

Loading...