VERITAS 05M25.01 Instructions Manual

Jointer Blade Sharpener

05M25.01

The Veritas® Jointer Blade Sharpener will jig planer and jointer knives

and hand plane blades up to 8" in width with bevel angles from 25°

to 45°. Sharpening and adding a micro-bevel to wide blades is easy,

repeatable and accurate when using the jointer blade sharpener.

A half sheet of 15 micron, pressure sensitive adhesive (PSA)

backed silicon carbide micro-abrasive is included with your jointer

blade sharpener. Applied to a fl at surface, it will quickly sharpen

jointer blades. However, other abrasive sheets may be used, such

as chromium oxide or diamond. Sharpening may even be done on a

traditional bench stone (see Additional Tips, Using a Bench Stone).

Instructions

Prepare the Lapping Surface

The PSA-backed micro-abrasive sheet must be applied to a fl at

lapping surface. The infeed or outfeed table of your jointer, or a piece

1

/4" (or thicker) plate glass, is recommended. For greater safety,

of

1

we offer a

/4" thick, 81/2" × 14" tempered glass plate (05M20.12).

Thoroughly clean the glass (or other true surface) before applying

the abrasive sheet. If you are applying the sheet to glass, create a

thin fi lm of water on the glass. This allows you to adjust the position

of the sheet before sticking it down. Position the sheet at one end of

the glass plate so that it covers the full width. To prevent air or water

bubbles from becoming entrapped, either roll a dowel or draw the

edge of a piece of wood across the sheet (working from the center)

to bond it in place.

Do not use water to apply the micro-abrasive sheet to steel, cast

iron, or any other rust-prone surface. Instead, to prevent air bubbles

from becoming entrapped, make initial contact with one edge of the

sheet. Progressively lay the sheet down, using a straightedge as a

squeegee.

Lap the Face of the Blade

Since a sharp edge is the

intersection of two smooth

surfaces, the face or

bottom of the blade must

be perfectly smooth in the

area near the cutting edge

before you attempt to hone

the bevel.

Figure 1: Parts of a blade.

Most manufacturers ship

blades with grinding marks

on the face or bottom that,

if not removed, would leave

a series of fi ne saw teeth on

the tool edge. To avoid these

saw teeth, the face of the

blade must be lapped fl at.

Figure 2: Grinding marks on new blades.

Bevel

Bottom

or Face

The easiest way to lap a new blade is on the 15 micron sheet until

the entire width of the leading edge has a consistent lapping pattern

1

with the manufacturer’s grinding marks removed at least

/16" back

from the leading edge of the blade.

Leading edge

lapped flat

Original

grinding marks

1

/16" Min.

Figure 3: Properly lapped face.

2

Clamping Jointer and Planer Blades

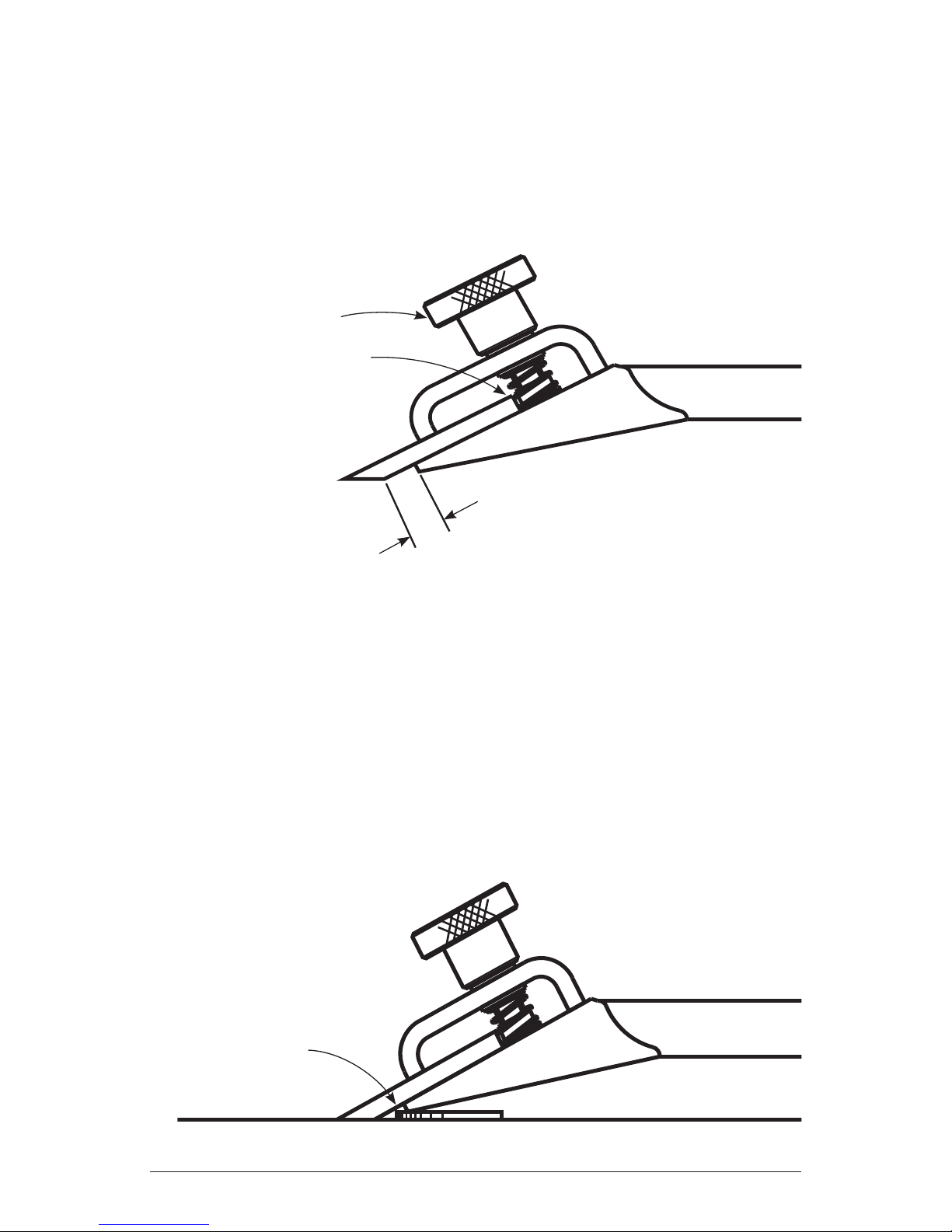

Loosen the thumbnuts securing the three clamps on the jointer blade

sharpener. Position the blade with the bevel facing down under the

short legs of the clamps and lightly tighten the thumbnuts. Turn the

unit over and adjust the blade until it overhangs the edge of the jointer

1

blade sharpener body by about

/8" and is approximately parallel as

shown in Figure 4.

Thumbnut

Note: clamp spring

is touching back

edge of blade

1

/8"

Figure 4: Clamping jointer/planer blades.

Before you fully tighten the thumbnuts, slide them forward until

the clamp springs touch the rear of the blade. This increases the

clamping force, reducing the possibility of the blade shifting during

sharpening (see Figure 4).

Hint: The blade can also be positioned by putting two pennies (one

at each end) under the front of the jointer blade sharpener as it rests

on a fl at surface. Let the bevel of the blade slide down to rest on the

surface, then tighten the thumbnuts.

Penny

Figure 5: Positioning blade using penny method.

3

Loading...

Loading...