VERIS INDUSTRIES, INC. HAWKEYE 548 Installation Instructions Manual

INSTALLATION

!CAUTION !

• This product is not intended for life or safety

applications

• Installing sensors in an energized motor control

center or on any energized conductor can be hazardous.

Severe injury or death can result from electrical shock

during contact with high voltage conductors or related

equipment. Disconnect and lockout all power sources

during installation. Applications shown are suggested

means of installing sensors, but it is the responsibility of

the installer to ensure that the installation is in compliance with all national and local codes. Installation should

be attempted only by individuals familiar with codes,

standards, and proper safety procedures for high-voltage

installations. Do not rely on status indications of device

exclusively to determine if power is present in conductor.

1. Ensure power conductor to be monitored is disconnected

and locked out from the power source!

2. Hold the sensor by the base and remove the two screws

located at opposite corners of the unit’s cover. Carefully

pull the cover off of the base. Extract the conduit lockwasher

and K.O. seal and set them and the base aside.

3. Connect wiring system to the hole(s) in the sides of the

base to wire the status and command relay connections.

4. Wire the low voltage leads to avoid the load wiring. Use

copper conductors only for command relay and status

outputs. Tighten terminal blocks to 3.5 lb. in. torque.

5. Set the Jumper block for N.O. or N. C. operation, then

select one of the following (a, b, or c) to match your

installation.

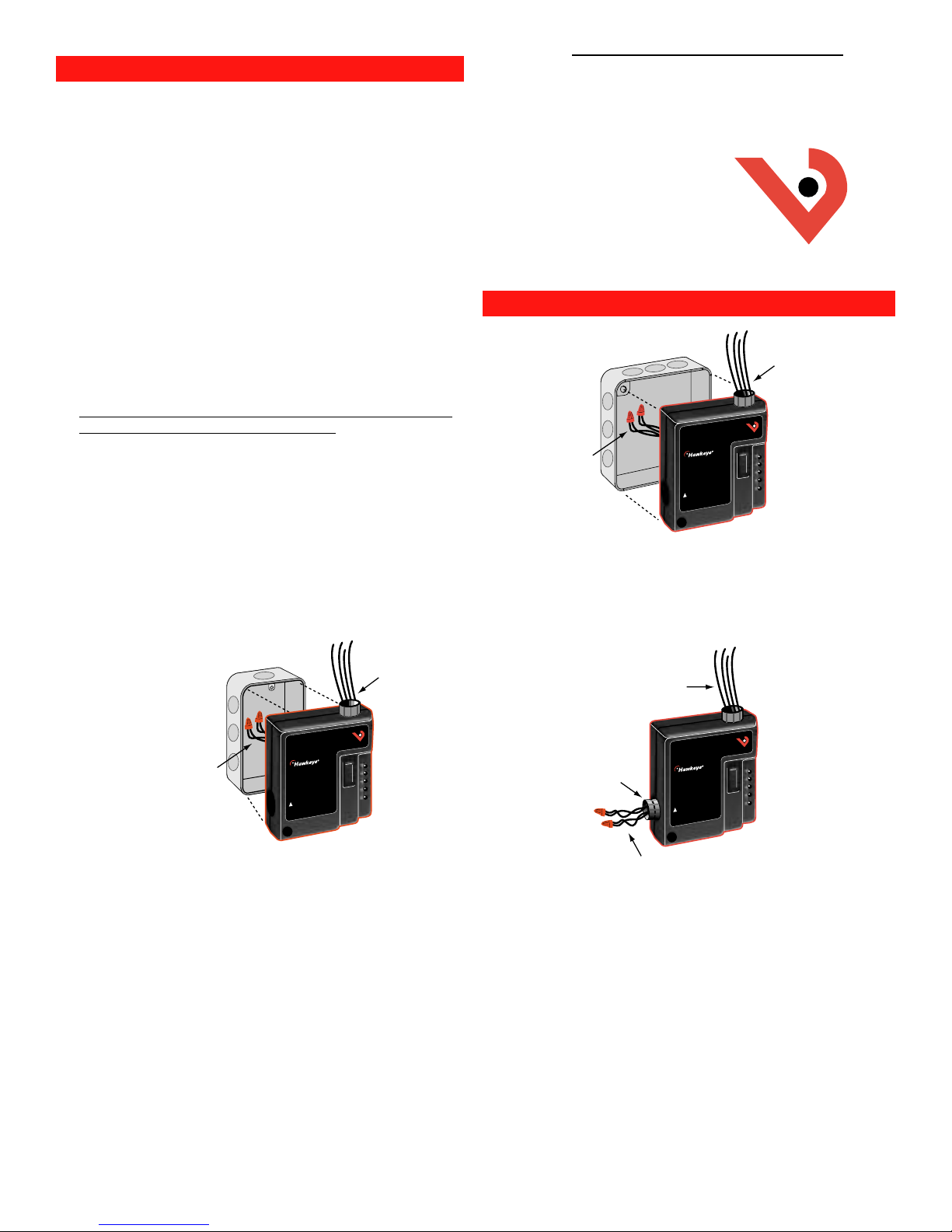

a.)duplex box:

Low Voltage Wires

Installation Instructions

HAWKEYE 548

Solid-State Current Switch

VERIS INDUSTRIES, INC.

10831 S.W. CASCADE BLVD.

http://www.veris.com email:sales@veris.com

INSTALLATION

b.) 4S junction box:

Line Voltage

Wires

1.) Route the two 12 AWG wires through the large hole in

the center of the circuit board. Break the “HOT” lead

to your load and connect these wires to the ends.

2.) Locate the holes through opposite corners of the base.

These holes are used to mount the sensor to the box.

c.) surface mounting:

PORTLAND, OREGON 97223

(503) 598-4564 FAX (503) 598-4664

Low Voltage

Wires

1-800-354-8556

VERIS INDUSTRIES, INC.

PORTLAND, OREGON USA

TOLL FREE USA 1.800.354.8556

TEL USA 1.503.598.4564

FAX USA 1.503.598.4664

548

HAND

OFF

AUTO

CAUTION: Consult instructions

prior to installation

!

STATUS OUTPUT: 1A@30VAC/DC

RELAY COIL: 24VAC/DC; 16mA nom.

RELAY OUTPUT: 16(8)A@250VAC; 3/4 HP

®

RS

OC

SO

SP

SC

Low Voltage

Wires

®

Line Voltage

Wires

VERIS INDUSTRIES, INC.

PORTLAND, OREGON USA

TEL USA 1.503.598.4564

FAX USA 1.503.598.4664

CAUTION: Consult instructions

prior to installation

!

STATUS OUTPUT: 1A@30VAC/DC

RELAY COIL: 24VAC/DC; 16mA nom.

RELAY OUTPUT: 16(8)A@250VAC; 3/4 HP

TOLL FREE USA 1.800.354.8556

548

HAND

OFF

AUTO

®

RS

OC

SO

SP

SC

1.) Route the two 12 AWG wires through the large hole in

the center of the circuit board. Break the “HOT” lead

to your load and connect these wires to the ends.

2.) Hold the base with the circuit board toward you.

Locate the smaller round hole in the circuit board (near

the relay). The hole through the case behind the board

hole, and the slot just above the board are used to

mount the H500 to a duplex (receptacle) box.

PN Z101562 10/8/1998

1/2" Conduit

Fitting

CAUTION: Consult instructions

prior to installation

!

STATUS OUTPUT: 1A@30VAC/DC

RELAY COIL: 24VAC/DC; 16mA nom.

RELAY OUTPUT: 16(8)A@250VAC; 3/4 HP

Line Voltage

Wires

VERIS INDUSTRIES, INC.

PORTLAND, OREGON USA

TEL USA 1.503.598.4564

FAX USA 1.503.598.4664

TOLL FREE USA 1.800.354.8556

548

HAND

OFF

AUTO

®

RS

OC

SO

SP

SC

1.) Use the base as a template to drill mounting holes. Any

of the screw holes in the base may be used to mount

the sensor to wall or device.

2.) Use the side hole (1/2” conduit) near the relay to route

load connections. Break the “HOT” lead to your load

and connect the 12 AWG wires to the ends. Alternately,

cut a hole in the surface of the wall or device to route

the two 12 AWG wires as for the 4S box, above. The cut

hole should be larger than the hole in the base to

avoid chafing the wiring.

CALIBRATION

Note: Testing the solid-state output of this sensor with a

digital ohmmeter may yield inaccurate, but relative readings of

switching (e.g. 6 Megohms.) Use an analog V-O-M for readings

similar to loop values.

1. For under-current status indication: (Belt loss, fan & pump status)

• Turn the set point screw clockwise until the status closed

LED goes out and the status open LED comes on.

• Turn the set point screw counter-clockwise until the status

open LED goes out and the status closed LED comes on.

• Turn the set point screw 1/2 turn counter-clockwise.

• The sensor is now calibrated to provide indication of

current flow below normal full load amps.

Output Status:

Normal: Output closed

Alarm: Output open

2. For over-current status indication: (Locked rotor)

• Turn the set point screw counter-clockwise until the status

open LED goes out and the status closed LED comes on.

• Turn the set point screw clockwise until the status closed

LED goes out and the status open LED comes on.

• Turn the set point screw clockwise 1/2 turn

• The sensor is now calibrated to provide indication of

current flows above normal full load amps

Output Status:

Normal: Output open

Alarm: Output closed

CAUTION!

Status indicators of this device should not be relied on to

determine whether or not the monitored conductor is

connected to a power source. Doing so may result in injury or

death from electrical shock.

For technical assistance, please call 1-800-354-8556

SPECIFICATIONS

Amperage Ratings.........…………........…...0.5 to 20A continuous

Sensor Supply Voltage.........Induced from monitored conductor

Sealing.....................................................................….......NEMA 1

Temperature range.....................................................-15º to 60°C

Humidity range.........................................0-95% non-condensing

Load switching...............................20(6)A@125VAC/30VDC,1/3HP

Relay coil...................................................24VAC/DC; 36mA nom.

Status Output……....................................N.O. 1.0A @ 30 VAC/DC

16(6)A@250VAC,3/4HP

Loading...

Loading...