Page 1

TM

EnvironmEntal SEnSorS

inStallation GUiDE

PD SerieS

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

PD SerieS

Digital Pressure/Vacuum Gauge with Display

and Analog 4-20 mA Output

Installer’s Specifications

Measurement Units Select able: psi, bar, kg/cm2, ATM, in. Hg, in. H2O*

Accuracy** < ±0.5% of F.S., BFLS

Overange Protection 2x rated pre ssure

Burst Pre ssure 5x rated pressure or 5000 psi, whichever is less

Temperature Ranges:

Operating (Ambient) -10° to 70°C (15° to 158°F)

Storage -40° to 65°C (-4 0° to 150°F)

Thermal Limits:

Compensated Range 0° to 55°C (32° to 131°F)

TC Zero < ±1.5% of F.S.

TC Span < ±1.5% of F.S.

Connection ¼" NPT, male

Power*** 7.5 to 32 VDC

Housing Polycarbonate

Environmental Protec tion NEMA 4, IP65

Output 4-20 mA loop powered

* in. H2O units available on ≤250 psi range devices only

** Accuracy includes non-linearity, hysteresis and non-repeatability measured at 25°C/77°F

*** Select a loop p ower supply and total loop resistance such that when the loop current is 20 mA,

the gauge will have at least 7.5 VDC at its terminals.

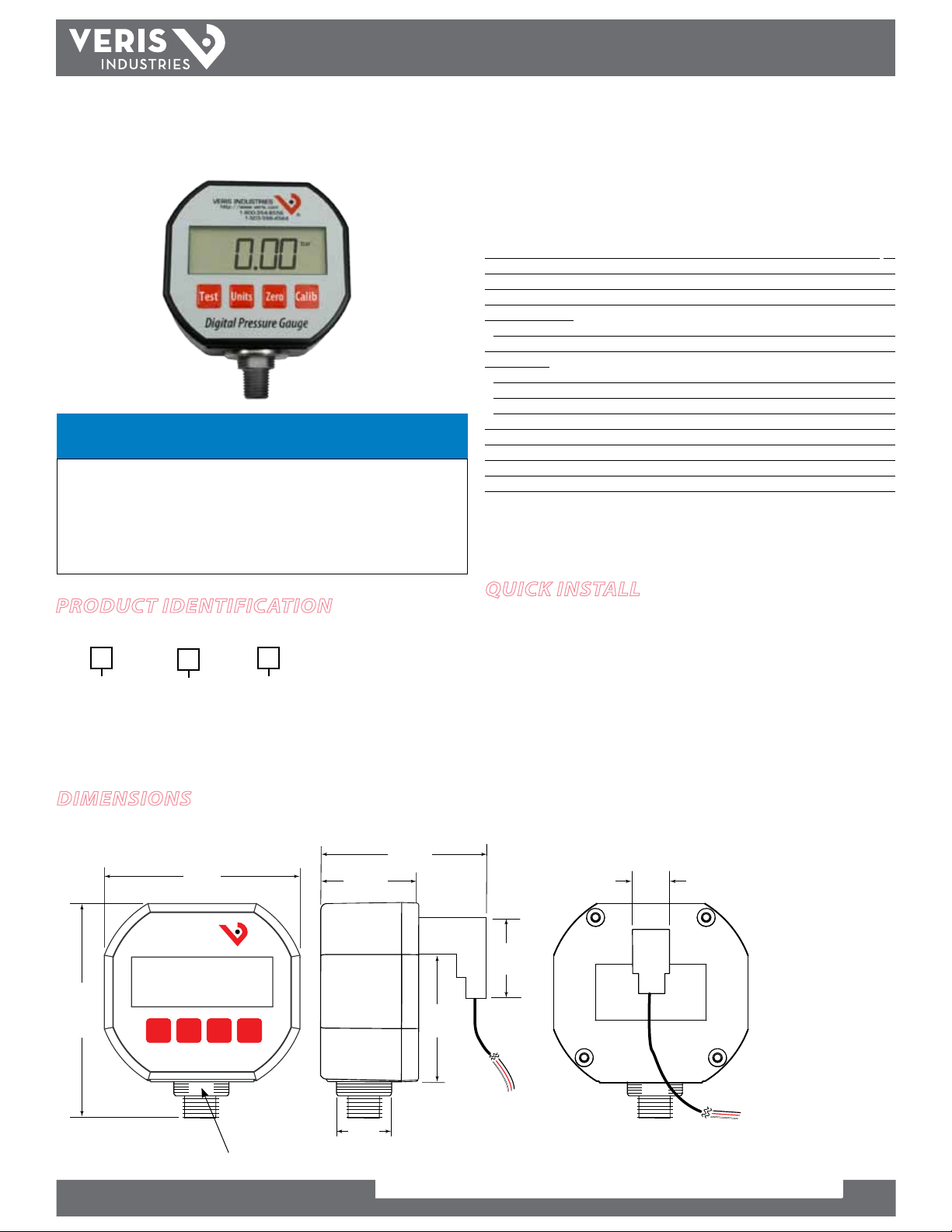

ProDuct iDentification

Range

Material

PD A M

50 = 0 to 50 psig

100 = 0 to 100 psig

250 = 0 to 250 psi g

500 = 0 to 500 ps ig

1000 = 0 to 1000 ps ig

= 17 - 4 SS

Output

= 4-20 mA

Dimensions

Front Side Rear

3.6”

(90mm)

VERIS INDUSTRIES

http://www.veris.com

1-800-354-8556

1-503-598-4564

4.2”

(106mm)

Test Units

Zero

Calib

1.8”

(46mm)

2.8”

(72mm)

quick install

1. Select a location for the installation suitable to the gauge’s physical dimensions

that will allow access to the display and keypad. Plan for a ¼" M-NPT connection

or a hose to a ¼" tting.

2. Thread the gauge onto the tting. Apply tightening torque only to the metal

wrench ats, not to the PD housing. Use a 5/8” wrench. Do not overtighten.

3. Wire the device. See the wiring diagram in this guide.

4. Remove the protective lm from the gauge front.

5. Program the gauge.

0.7”

(17mm)

1.4”

(36mm)

2.2”

(56mm)

Digital Pressure Gauge

(Tighten with a 5/8” wrench at this spot. Do not tighten by t wisting the plastic PD housing.

5/8”

Wrench Flat

ZL0055-0D PAGE 1 ©2012 Veris Industries 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 2

TM

PD SEriES

inStallation GUiDE

DescriPtion

PD analog digital pressure gauges are media isolated, so they can be used with any

gas, liquid, or solid compatible with 17-4 PH stainless steel within the specied

pressure range. The transducer consists of a one-piece, high-strength pressure sensor

that uses no silicone oils, welds, O-rings, or seals. The sensor is coupled to a 4-20 mA

loop powered internal display and keypad. The keypad controls setup and operation

of the sensor as described below.

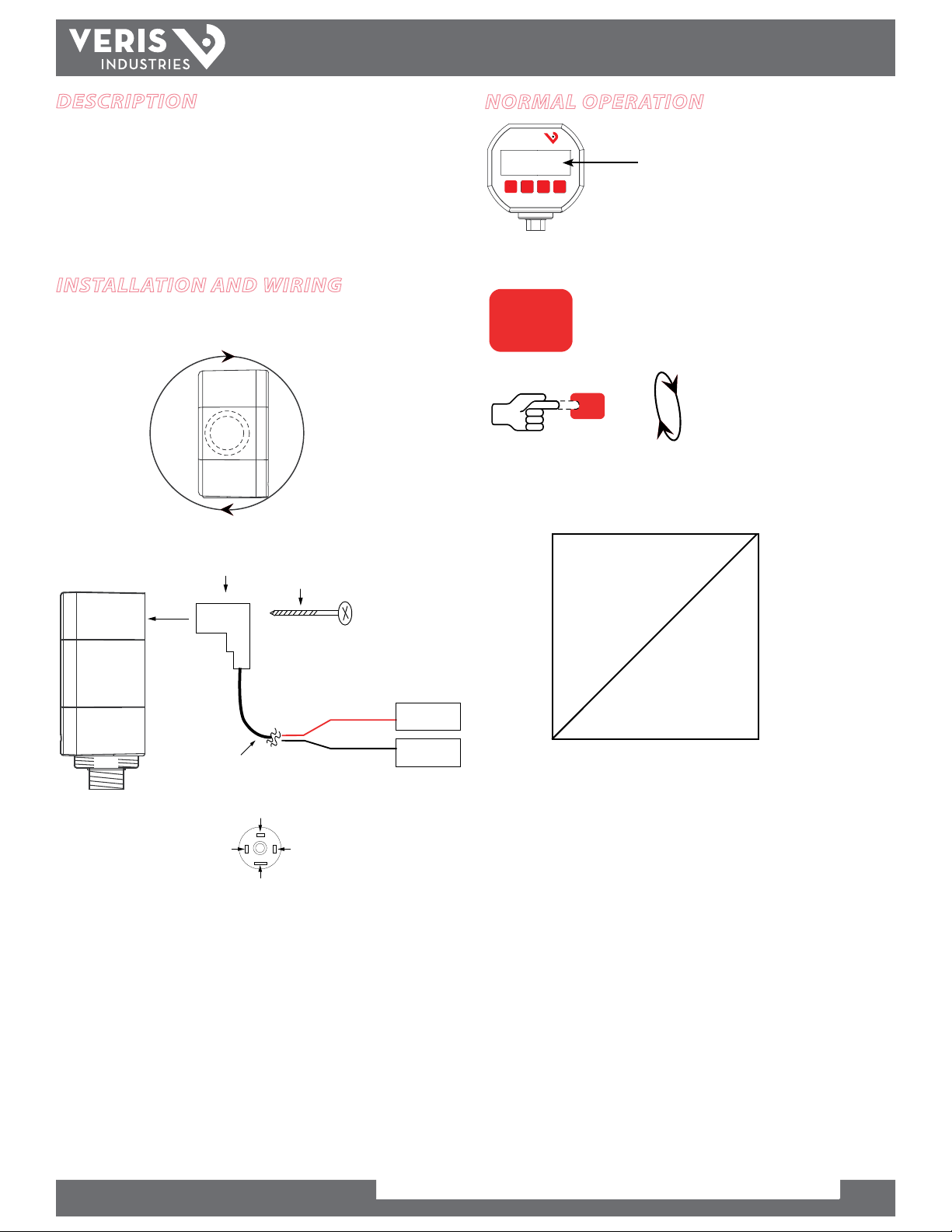

installation anD Wiring

Allow space to turn the PD Analog onto the pipe or tting during mounting. The PD is

delivered with the connector attached to the device.

4.25”

108mm

+

normal oPeration

VERIS INDUSTRIES

http://www.veris.com

1-800-354-8556

®

1-503-598-4564

Pressure readin g appears in the

Test Calib

Units Zero

Digital Pressure Gauge

selected units (PSI, bar, etc.)

To select/change display units:

Units

Units

Output signal:

10 V/5 V

PSI

bar

Atm

kg/cm²

in. Hg

in. H2O

Volt

Note: The UNITS button

does not aect the mA

output.

connector

15’ lead

Pin 2

Pin 3

Wide Pin

locking screw

Pin 1

red

black

Pin 2 = 4-20mA output

Pin 3 = +V

supply voltage

7.5 to 32 VDC

control panel

4-20 mA input

Electrical

Select a loop power supply voltage and total loop resistance such that when the loop

current is 20 mA, the gauge will have at least 7.5 VDC at its terminals. Too large a loop

resistance will cause the gauge output to "limit" or saturate before reaching its full

20 mA output.

0 V

Output Signal

zero/low-end

pressure

Pressure Readi ng

Note: For out-of-scale

pressure read ings,

output can go as low

as 3.5mA or as high as

24m A.

full-scale/high-end

pressure

The minimum loop supply voltage is calculated from the formula:

V

= 7.5V + (20mA * total loop resistance).

min

If the loop voltage drops too low, the PDxAM will display the LOW LOOP icon. At this

time, all calibration functions are disabled.

The LCD is loop-powered. If no voltage is applied, or if the connector is removed, the

display will be blank.

ZL0055-0D PAGE 2 ©2012 Veris Industries 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Page 3

TM

Units

Calib

Test

Current

measurement

device

Calib

Units

OR

PD SEriES

inStallation GUiDE

test

To switch the PD into Test Mode, press and hold down the TEST button. The Test Mode

allows setup and testing of the output voltage without altering the system pressure.

To change the test output level, press and hold the TEST button, and press the CALIB

button while holding TEST. Each time the CALIB button is pressed, the test level

output increases by 2 mA.

VERIS INDUSTRIES

http://www.veris.com

1-800-354-8556

Test Calib

Units Zero

Digital Pressure Gauge

1-503-598-4564

®

Press and hold to enter Test Mode.

To change test output level, press

CALIB while holding TEST.

zero Pressure calibration

Press ZERO then CALIB.

VERIS INDUSTRIES

http://www.veris.com

1-800-354-8556

1-503-598-4564

®

Hold both for 3 seconds.

Release when display reads zero

pressure.

sPan Pressure calibration

Units

Calib

Calib

Notes:

Only attempt Span ca libration if the user has access to a pressure reference of known accuracy. Use

calibration equipment swith at least four times the gauge accuracy. Perform Zero calibration

before span calibration.

If the user tries to calibrate the unit beyond ±10% of the factory calibratio n, the display will read

“ERR” indicating an erroneous calibration.

To cancel calibration, press and release the CALIB button.

To restore factory calibration, repeat steps 1 and 2, then h old the ZERO button for 3 seconds, u ntil

the display reads “FAC.”

1. Press to select pressure units.

2. Press and hold for 3 seconds, until display alternately

reads “CAL” and the calibration pressure (e.g. “CAL” and

“500” to calibrate at 500 psi).

3. Connect the gauge port to a pressure reference of known

accuracy. Apply pressure level selected in Step 2.

4. Press and hold the CALIB button for 3 seconds until

display reads “DONE.” Calibration is now complete.

Test Calib

Units Zero

Digital Pressure Gauge

Open gauge por t.

The PD can be re-zeroed without aecting the span calibration. The gauge port must

be open with no pressure or vacuum applied.

Perform this step when pressure uni ts show in the display (not mA). Zero calibration is retained

after unit is turned o .

current outPut calibration

The current output on the PD analog pressure gauge has been set at the factory.

These setting will not normally need adjustment. Perform these steps only if

necessary.

1. Press to select the mA units.

2. Connect the leads to an accurate current measurement

device.

3. Press and hold for 3 seconds, until the display ashes

between “CAL” and “4.00.” Set the loop current to 4.00

mA

4. Press TEST to decrease the output by 0.01 mA. Press UNITS

to increase the output. While the output will change, the

display will not.

5. Press and hold for 3 seconds to accept the calibration at

4.00 mA. The display will change to “CAL” and “20.00.”

6. Repeat steps 3 through 5 to calibrate at 20 mA. Display will now read “DONE.”

Notes:

To cancel calibration changes, briey press and rel ease the CALIB button.

To restore factory calibration, repeat step 3 on ly, then hold the ZERO button for 3 seconds, unti l the

display reads “ FAC.”

ZL0055-0D PAGE 3 ©2012 Veris Industries 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other count ries.

Loading...

Loading...