Page 1

SENSED AMPS

30/60/120 A*

0 V

0 A

5 V

SENSOR OUTPUT

*Factory calibrated ranges selected with the amperage range switch

Minimize Installed Cost

Current Monitoring | Current Transducers with Relay:

4 to 20 mA Analog Output

H931

Load Trending and Control Relay

in One Package

H931

TM

Maximize Reliability

Loop-powered

Loop-powered analog current

transducer with integral start/stop

command relay

Saves time

Reduces the number of installed

components…saves time and

space

Retrofit

Self-gripping, split-core design for

fast retrofit installation…no need

to remove conductor

Reduces

installation

charges

One device to install for

start/stop and status

Fewer wires

Power the current sensor and

receive the 4 to 20 mA signal with

only two wires

Factory

calibrated

Selectable factory calibrated

ranges up to 120 A for increased

flexibility and resolution

The Hawkeye 931 provides accurate load trending information with

a proportional 4 to 20 mA output signal. These devices offer three

amperage ranges for versatility, with easy slide-switch selection. The

command relay is fully integrated in the device, but it is isolated from

the current transducer. This combination makes these products ideal

for start/stop control and status monitoring of motors, using one device

instead of two.

SPECIFICATIONS

Sensor Power 30 mA (max.) @ 12 to 30 Vdc

Insulation Class 600 Vac RMS

Frequency Range 50/60 Hz

Temperature Range -15 to 60 °C (5 to 140 °F)

Humidity Range 10 to 90% RH non-condensing

Accuracy ±2% F.S. from 10% to 100% (selected range)

Response Time 2 sec.

2

Terminal Block Wire Size 24 to 14 AWG (0.2 to 2.1 mm

Terminal Block Torque 3.5 to 4.4 in-lbs (0.4 to 0.5 N-m)

WARRANTY

Limited Warranty 5 years

AGENCY APPROVALS

Agency Approvals

UL 508 open device listing, CAT III, Pollution

Degree 2, basic insulation

)

APPLICATIONS

• Load trending

• Motor control

• Positive proof of flow

EXAMPLE LINEAR OUTPUT

Scale software as shown

Note: Do not use LED status indicators as evidence of applied voltage

TM

HQ0001766.G 0117

Page 2

Current Monitoring | H931

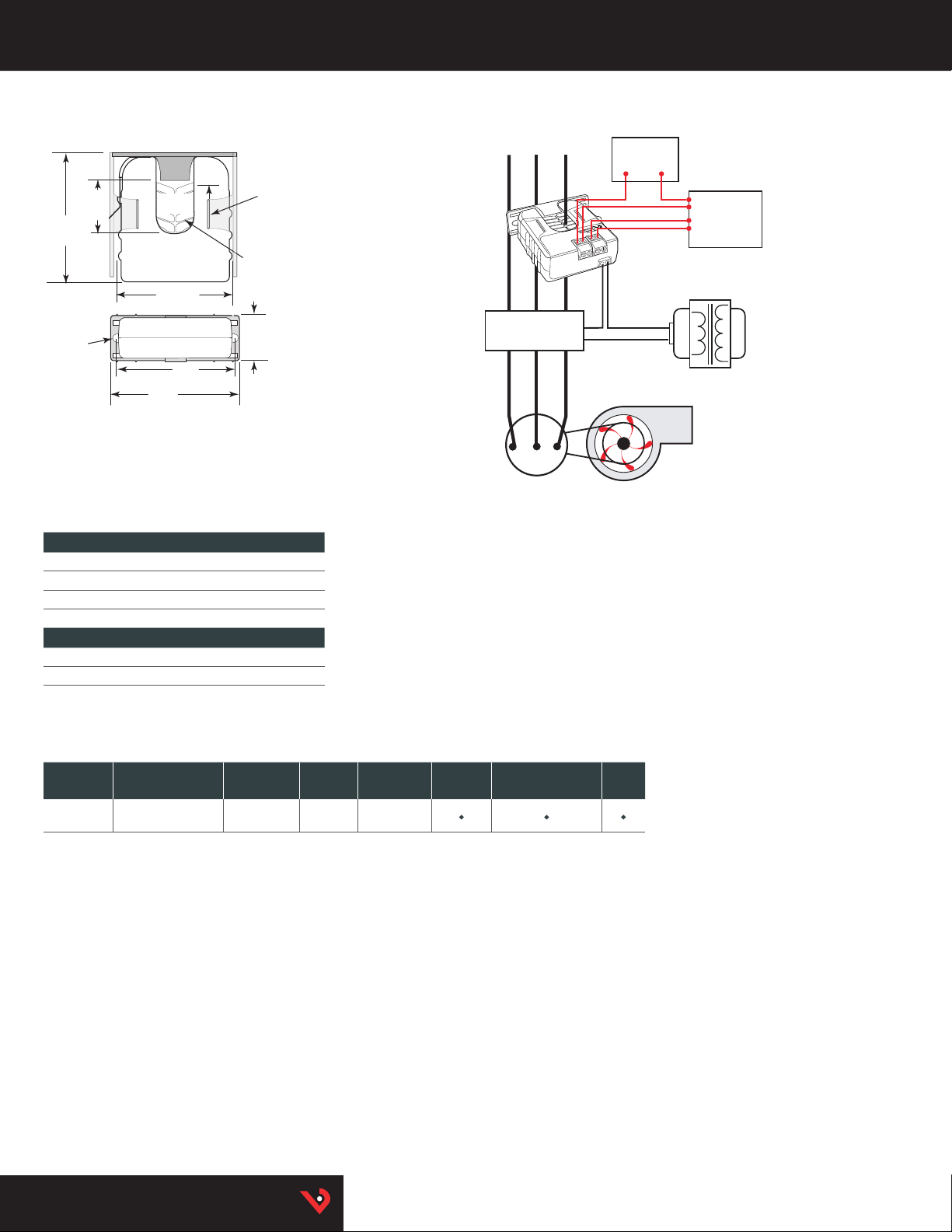

DIMENSIONAL DRAWING TRENDING & CONTROLLING MOTOR LOADS

Wiring Diagram

Removable Mounting Bracket

1.0”

(25 mm)

1.1”

(26 mm)

3.1”**

(79 mm)

Ø 0.3”

(8 mm)

* Terminal block may extend up to 1/8” over the height dimensions shown.

** Slide switch may extend up to 1/4” over the height dimensions shown.

(21 mm)

(70 mm)

3.0”

(76 mm)

0.8”

2.8”

2.5”

(64 mm)

Bracket can

be mounted

on three sides

for added

installation

flexibility.

Self-gripping Iris

1.4”*

(36 mm)

RELAY CONTACT RATINGS (N.O.)

Resistive 5 A @ 250 Vac, 30 Vdc

5 A @ 30 Vac, 30 Vdc

Inductive 2 A @ 250 Vac, 30 Vdc

2 A @ 30 Vac, 30 Vdc

TYPICAL COIL PERFORMANCE

Voltage AC DC

24 15 15

CONTACTOR

Motor

12 to 30 Vdc

Power Source

Fan or Pump

CONTROLLER

Analog Input

(4 to 20 mA)

Digital Output

(Relay Coil)

CONTROL POWER

ORDERING INFORMATION

MODEL

H931 0 to 30/60/120 A 4 to 20 mA

AMPE RAGE

RANGE

SENSOR

OUTPUT

RE LAY

TYPE

SPST,

N.O.

RE LAY

COIL

24 Vac/dc • • •

RE LAY

RELAY POWER

LED

UL

HQ0001766.G 0117

TM

Loading...

Loading...